Page 1

DC580

Digital Air Velocity Meter

The Value Leader

TM

www.testproductsintl.com

Page 2

Contents

Introduction ......................................... Page 1

General Overview & Guidelines ................. Page 1

Features and Guidlines ........................... Page 2

LCD Overview ....................................... Page 3

Keypad Overview ................................... Page 4

Probe Overview ..................................... Page 5

Turning the DC580 on & Connecting a probe ..Page 6

Units of Measure Setup Mode ................... Page 7

Duct Type and Size Setup Mode ................ Page 8

Definition of Free Area ........................... Page 9

Taking a Measurement ........................... Page 10

Selecting Between Air Velocity and Volume .. Page 11

Storing a Reading ................................. Page 11

Recalling a Stored Reading ..................... Page 12

Preparing to Traverse a Rectangular Duct .... Page 13

Time Based Traverse of a Horizontal Duct .... Page 14 - 16

Point Based Traverse of a Horizontal Duct .... Page 17 - 19

Preparing to Traverse a Round Duct ............ Page 20

Time Based Traverse of a Round Duct ......... Page 21 -23

Point Based Traverse of a Round Duct ......... Page 24 - 26

Traversing a Grille ................................. Page 27-28

Auto Off, Backlight, Hold and Min, Max, Avg.. Page 29

Bluetooth Activation & App Use.................. Page 30 - 34

Specifications ...................................... Page 35 - 36

Battery Replacement .............................. Page 36

Troubleshooting & Care............................ Page 37

Warranty, Service, Calibration ................... Page 37

Page 3

Introduction

Thank you for purchasing TPI brand products. The TPI DC580 digital air

velocity meter is a state of the art, easy to use air velocity tester designed to

display air velocity, air flow, and temperature. It can be used with the TPI

DC580 app to generate reports and store readings.

The DC580 can be ordered in several configurations:

Part Number

DC580C1 DC580 w/ Hotwire probe & Carry case

DC580C2 DC580 w/ Vane probe & Carry case

DC580C3 DC580 w/ Hotwire & Vane probes & Carry case

This manual covers all features for the DC580 and the use of both

hotwire and vane type probes.

Description

Features & Guidelines

Features:

• Measure air velocity and temperature simultaneously

• Field replaceable smart hot wire and vane probes

• Communicate with Android Smart Phone via Bluetooth LE and TPI App

• Display minimum, maximum & average

• Multiple measuring units: m/s, km/h, ft/min, knots, mile/h

Guidelines:

Always allow the DC580 sufficient time to acclimate to the test environ-

ment especially when moving from location to location.

Always operate the DC580 and probes within the temperature and

humidity limits outlined in the specifications area of this manual.

Never allow any object to enter the sensor area of the hotwire probe or

vane probe.

Never attach the DC580 magnetic boot to a hot surface.

1

Page 4

Instrument Overview

Rubber Boot

Display

Keypad

Probe Input

Jack

2

Magnets

Hanger Strap

Attachment

Point

Hanger Hook

Attachment

Point

DC580 Front

DC580 Back

Probe Input Jack - Connection point for hotwire and vane probes.

Rubber Boot - Protects the instrument from accidental damage

Display - Large 2 two line LCD display w/ backlight

Magnets - Used to attach the DC580 to metal surfaces

Keypad - Selects all available functions

Hanger Hook Attachment Point - Used with optional boot hook (p/n A103)

Hanger Stap Attachment Point - Used with optional magnetic hanger strap

(p/n A124)

Page 5

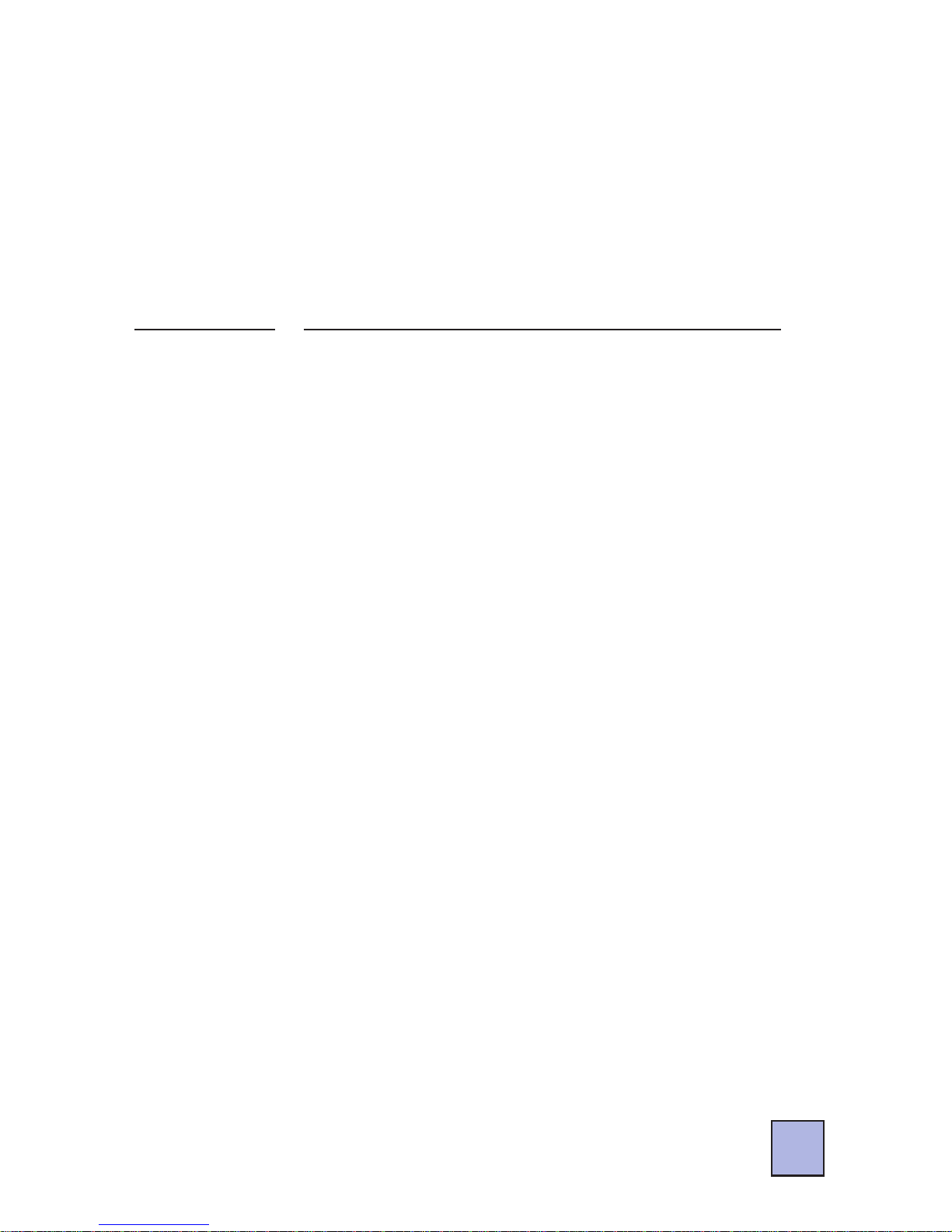

LCD Overview

Air Velocity and Air

Flow Volume Display

Area

Temperature Display

Area

Indicates timed record mode is active.

Indicates the displayed reading is the Maximum, Minimum,

or Average measurement.

Indicates Record mode is active.

Indicates Hold is active. Displayed readings freeze.

Indicates Set up mode is active.

Indicates auto power off is active.

Indicates units of measure for air velocity and volume.

mph = miles per hour, fpm = feet per minute,

m/s = meters per second, km/h = kilometers per hour, knots

CFM = cubic feet per minute,

CMM = cubic meters per minute

C F = Indicates temperature in Celsius or Fahrenheit.

cm2ft2= Duct size in square centimeters or square inches.

HW Vane = Indicates probe connection. Hot Wire or Vane.

= Indicates Bluetooth status.

Free Area = Amount of area blocked by grille, register, etc.

Dia = Diameter of duct if it is round

H = Height of duct if it is square or rectangular

W = Width of duct if it is square or rectangular

= Duct type, round or square. Also spot record indica-

tor.

= Low battery indicator. Replace batteries

when displayed.

3

Page 6

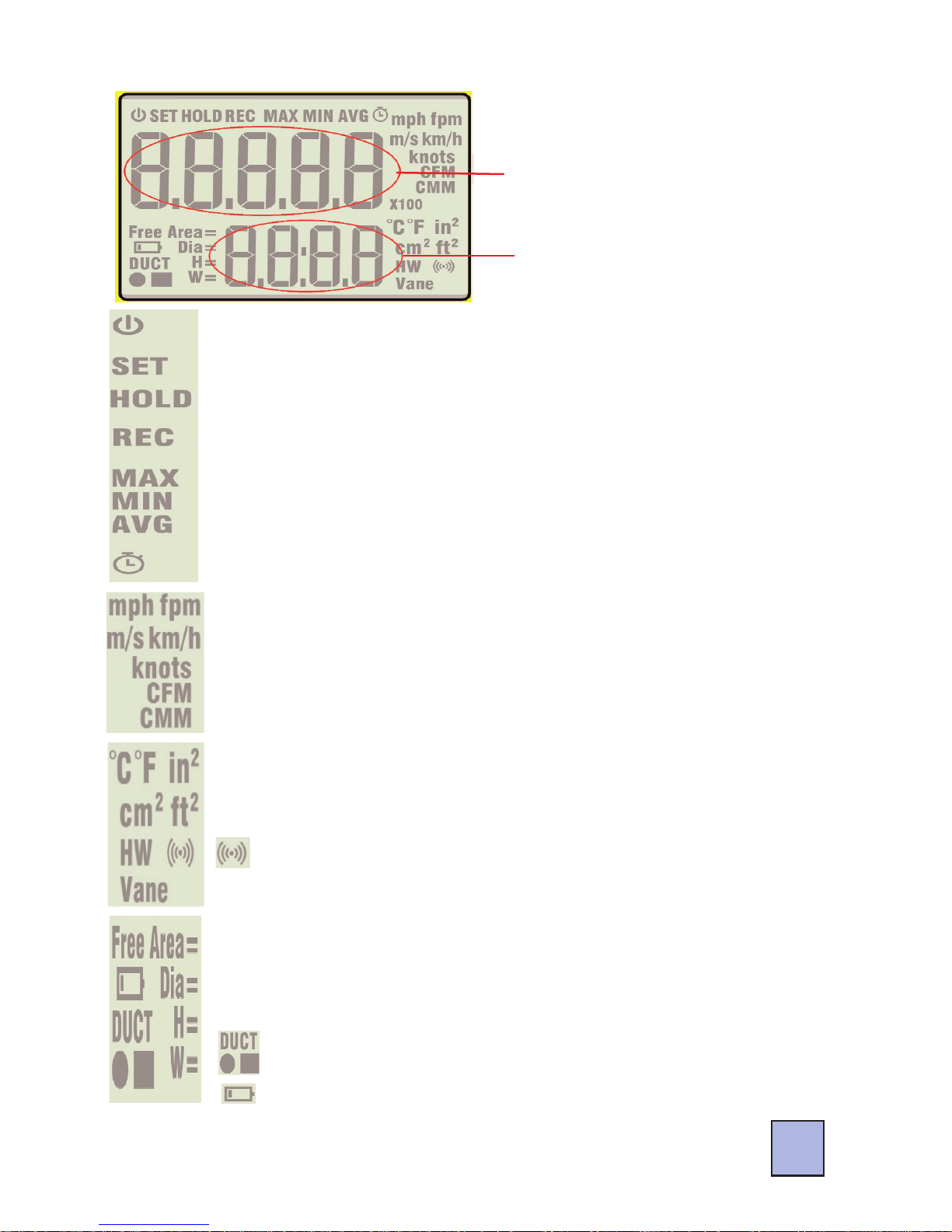

Keypad Overview

Use to navigate up in setup mode menus.

Use to freeze the current reading on the LCD when performing a

measurement.

Use to confirm entry when in setup mode menus.

Use to switch between air velocity and air flow when taking measurements.

Use to activate memory mode and store readings.

Use to decrease the parameter in setup mode menus.

Use to activate and deactivate auto power off.

Use to turn the DC580 on and off. (Press and hold)

Use to setup duct type and size.

Use to navigate left in menu mode.

Use to activate time and point record modes and to cycle

through min, max, and average readings.

Use to setup units of measurement for air velocity, air volume, temperature, and duct size.

Use to return to normal operation from recall mode.

Use to navigate right in setup mode menus.

Use to recall and display recorded measurements.

Use to turn the backlight on and off.

Use to activate Bluetooth communication mode.

4

Page 7

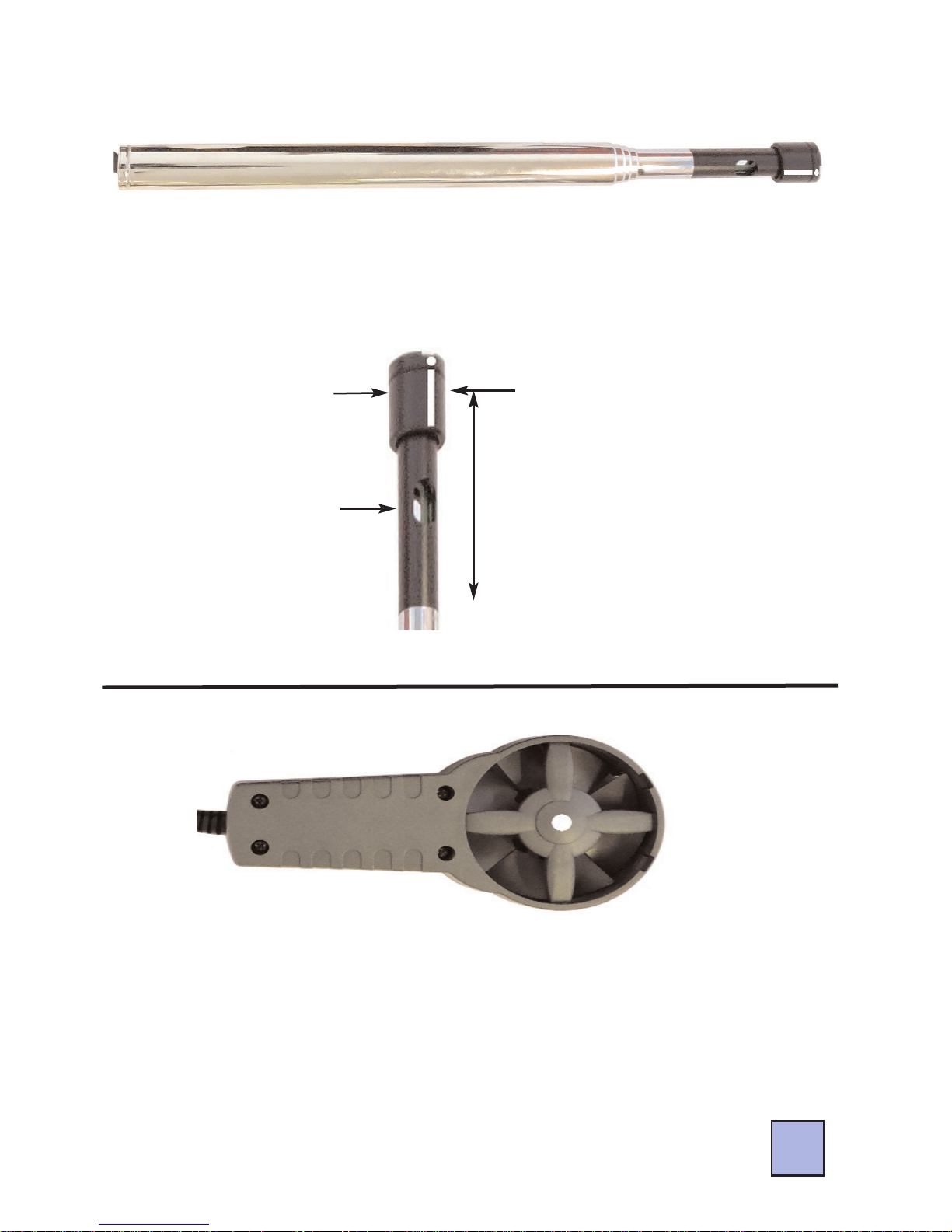

Probe Overview

Hot wire probe for the DC580. This probe can be used to measure

air velocity and flow inside ducts. The white dot should face into

the air stream. The probe can be expanded by pulling out the sensor shaft enabling the probe to extend like an antenna.

Temperature

Sensor

Air velocity sensor

underneath protective

hood.

Slide the sensor protective

hood all the way down to

perform air velocity measurements. Make sure the

temperature sensor is not

covered.

Replace the cover when

not in use.

Hot Wire Probe Sensors

Hot Wire Probe (Part number A581)

Vane Probe (Part number A582)

Vane probe for the DC580. This probe can be used to measure air

velocity and flow at registers, hoods, and other openings. The

white line/dot should face into the air stream.

Note: The DC580 can be purchased to include one or both of

these probes. These probes are also available for purchase separately. Please see page 36 for information on kits and probes.

5

Page 8

Turning the DC580 on and Connecting a Probe

6

To turn the DC580 on press and hold the key for more than two

seconds.

If a probe is not connected the display will read ‘oPEn’. When this

is displayed only the and keys operate.

When a probe is connected the DC580 will auto detect which probe

has been connected and will act accordingly.

Hot wire probe - Make sure the hotwire probe cover has been put

into the closed position before connecting the probe. When the hot

wire probe is connected a 5 second warm up period will begin and

the display will read ‘H---d’ and display the countdown. After the

countdown the DC580 is ready to take measurements. Slide the

cover down to the open position and perform tests.

Vane Probe - Connect the vane probe and the DC580 is ready to

take measurements.

After power is turned on and a probe is connected the DC580 is

ready to take measurements. Use the setup modes as needed to

adjust units of measure and duct size.

Page 9

Units of Measure Setup Mode

7

Setup the units of measure to be used. The meter will default to

these settings upon start up. These can be changed as necessary.

1. Connect a probe to the DC580. Turn the DC580 on by pressing

and holding the key for more than 2 seconds.

2. Press the key to enter the units of measure setup mode. The

air velocity annunciator will begin flashing.

3.Use the key to cycle through the air velocity units until the

required unit is shown. Press the key to move to the air flow

units.

4. Use the key to cycle through air flow units. CFM and CMM are

available. When the desired unit is displayed press the key to

move to temperature units.

5. Press the key to cycle between temperature units. ºF and ºC

are available. When the desired unit is displayed press the key

to move to duct dimension units.

6. Press the key to cycle through the duct dimension units.

Inches (in), centimeters (cm), meters (m), and feet (ft) are available.

When the desired unit of measure is displayed press the key.

7. The DC580 exits the units setup menu and returns to normal operation.

Note: At any time in the above procedure the key can be

pressed to return to normal operation. Units of measure that were

not adjusted will remain unchanged.

Page 10

Duct Type and Size Setup Mode

8

When measuring air velocity, the volume of air or airflow can be displayed. This is a calculation based on the duct type and size. For air

flow to be accurate the duct size needs to be entered into the

DC580.

The units of measure used in the duct size can be set by following

the steps outlined in section page 7.

1. Connect a probe to the DC580 and turn it on as outlined earlier.

2. Press the key to activate duct size entry mode.

3.Use the key to cycle through the duct type. The types are

round, rectangular, and free area. Select free area if measuring at a

supply or return with an obstruction like a grille. NOTE: The free area

of the duct must be known. This is published by the grille manufacturer.

4. Once the duct type is displayed, =round, =rectangular, or free

area press the key to confirm the selection.

Round Duct - Use the keys to enter the diameter

of the duct. Press the key to confirm the selection.

Rectangular Duct - Use the keys to enter the

height (H) of the duct. Press the key to confirm the selection.

Use the same keys to enter the width (W) of the duct. Press the

key to confirm the selection.

Free Area - Use the keys to enter the free area of

the duct. Press the key to confirm the selection.

For more information on free area please see the next page.

Page 11

Definition of Free Area

Free Area is the total area in which air flows through a supply outlet or a return grille. Free area is the effective area of the outlet or

grille and takes into account any restrictions.

If a grille is not used and there is no restriction on the area in

which air flows then the free area is equal to the actual area. This

is the case when measuring air flow at the middle of a duct, or if

the grille is removed from the return or supply duct.

When measuring airflow with a grille in place or restriction present,

the free area is the total area minus the area covered by the

restriction (grille fins).

Grille manufacturers publish free area specifications and this is the

most accurate information to use when setting up your DC580 to

measure air flow (volume).

Whenever possible it is best to use free area when entering duct

size. This will ensure the most accurate air flow reading.

9

Page 12

Taking a Measurement

10

1. Insert the hot wire or vane air velocity probe into the DC580. If

the hotwire probe is used make sure the sliding cover is over the

air sensor. (See page 5)

2. Press and hold the key until the DC580 turns on.

3. If the hotwire probe is used the DC580 will countdown from 5.

During this time the hotwire sensor is being warmed up. If the

vane probe is used there will be no countdown.

4, If necessary, set the units of measure and duct size as outlined

on page 7 and 8.

5. Insert the air velocity probe into the air stream with the white dot

facing into the air. If the hotwire probe is being used make sure the

sliding cover is in the down position and the sensor is exposed.

6. The air velocity will be displayed in the upper display and the

temperature will be displayed in the lower display.

The most accurate way to take a reading of a duct or grille is to

traverse it and take the average reading. The DC580 can do this

without the need of manual calculations.

The following pages include instructions for traversing ducts and

grilles along with various features and functions available on the

DC580.

Page 13

Selecting Between Air Velocity and Volume (Air Flow)

Display shows air velocity

in fpm and temperature

Press the Enter

key to toggle

the display.

Display shows air flow

(volume) in CFM and

temperature

11

When an air velocity is displayed on the DC580 the key can be

pressed to toggle the top display between air velocity and air flow.

Note: The duct size must be entered correctly for the air flow reading to be accurate. Air flow is a calculation based on the duct size

and the measured air velocity.

Storing a Reading

The displayed reading can be stored in memory. This will store the

air velocity, air volume, and temperature.

1. When taking a measurement, once the

reading is on the display press the key.

2. The display will prompt you for a memory

location to store the reading. To cancel

press the key or use the keys to select the

memory location to store the reading then press the key.

Clearing Memory: Saving data to the same memory location will

write over the data already saved. All locations can be cleared by

pressing the key to enter memory mode then pressing and

holding the key for approximately 3 seconds.

Page 14

Recalling a Stored Reading

Stored readings can be recalled and displayed on the DC580.

1. With the DC580 in normal operation press the key.

2. The display will prompt

you to select a memory

location to display the

stored reading.

3. Use the keys to select the memory location to

display.

4. The stored reading will

be displayed.

Press the key to toggle

between the stored

air velocity and air volume.

5. Press the key to exit recall and return to normal operation.

Stored information can also be sent to the DC580 App. The app

will display the duct size and also provides the ability to export the

data to a CSV file or send a report via email. Please see page 30

for more information on the app.

Stored air

velocity and

temperature

displayed.

Press the

enter key to

toggle the

display.

Stored air

volume is

displayed.

12

Page 15

Preparing to Traverse a Rectangular Duct

To do a proper airflow measurement (CFM) you should do traverse

readings to obtain the true average airflow through the duct. It is recommended to do at least 12 points of measurement. There are two

ways to perform this test using the DC580, Time Based Traverse and

Spot Based Traverse. Time based is typically easier but both are

explained in the next sections.

1. You will need to determine the easiest access to take your readings. Normally it is best to enter from the side (Height) of the duct

since you will have to drill less holes, but you may have to drill from

the bottom (Width) of the duct. See below.

Not the ideal side to enter

the duct but may be necessary

Choose one

side to enter

the duct.

Ideal side to

enter the duct.

13

Page 16

Time Based Traverse of a Horizontal Duct

Press the Up Arrow key repeatedly

until the timer symbol is seen.

14

1. Insert the hotwire probe into the DC580 and turn the meter on.

2. Enter the duct type and size and prepare the duct for transverse

measurements as outlined on page 13.

3. Press the key. The display will prompt for time or point based

traverse. Use the key to select time based traverse record.

4. Press the key to confirm the selection.

5. Insert the hotwire probe all the way into the duct at the first hole.

Make sure the white dot is facing the air flow. HINT: If you turn the

probe you will see the readings change up or down, when the

reading is at the highest you are in the proper position.

Page 17

Time Based Traverse of a Horizontal Duct (Continued)

Start with the probe all

the way into the duct.

Press the key.

Slowly pull the probe

to the entrance hole.

Before removing the

probe see step 8.

15

6. With the probe in place press the key and the DC580 will

begin recording.

7. Slowly pull the probe towards the entrance point of the duct.

8. Stop at the last measurement point prior to pulling the probe out of

the duct. Press the key to pause the recording.

Page 18

Time Based Traverse of a Horizontal Duct (Continued)

16

9. Pull the probe out and insert it into the next test hole all the way

into the duct.

10. Press the key to begin recording. Repeat these steps for

all test holes.

11. When the duct has been completely traversed and prior to

pulling the probe out of the last test hole, press the key to

pause the recording.

12. Press the key to store the readings. See section page 11

on storing readings. This will store the average air velocity, air

volume, and temperature readings.

13. If another traverse needs to be made press the key to

clear the timer and begin traversing a duct.

If finished, press and hold the key to exit record and return

to normal operation. The stored readings can be recalled and

displayed (see page 12) or sent to the DC580 app (see page

30).

Note: At any time during the traverse process when REC is displayed the key can be pressed to cycle through the minimum (MIN), maximum (MAX), and average (AVG) readings.

Page 19

Point Based Traverse of a Horizontal Duct

1. Insert the hotwire probe into the DC580 and turn the meter on.

2. Enter the duct size and prepare the duct for transverse measurements as outlined on the previous page.

3. Press the key. The display will prompt for time or point based

traverse. Use the key to select point based traverse record.

4. Press the key to confirm the selection.

5. Divide the duct into at least 12 equal boxes, you will need to take

the reading in the center of each box. Be sure that the sample

points are no more than 4 inches apart from center to center. If

needed you can add more sample points (boxes) to cover larger

duct sizes. Insert the hotwire probe all the way into the duct at the

first hole. Make sure the white dot is facing the air flow.

Press the Up Arrow

key repeatedly until

the timer symbol is

seen.

17

Page 20

Point Based Traverse of a Horizontal Duct (Continued)

Start with the probe all

the way into the duct.

Press the Enter key.

Slowly pull the probe

to the entrance hole.

Stop at each point and

press the Enter key.

18

6. With the probe in place press the key to record the reading.

7. Slowly pull the probe towards the entrance point of the duct. Stop

at each point and press the key to record reading.

8. Pull the probe out and insert it into the next test hole all the way

into the duct.

Page 21

Point Based Traverse of a Horizontal Duct (Continued)

19

9. Press the key to record the reading. Repeat these steps for

all test holes.

10. When the duct has been completely traversed press the

key to store the readings. See section page 11 on storing readings. This will store the average air velocity, air volume, and

temperature readings.

11. If another traverse needs to be made press the key to clear

the counter and begin traversing a duct.

If finished, press and hold the key to exit record and return

to normal operation.

Note: At any time during the traverse process when REC is displayed the key can be repeatedly pressed to cycle through

the minimum (MIN), maximum (MAX), and average (AVG) readings.

Page 22

Preparing to Traverse a Round Duct

20

Preparing the Duct

To do a proper airflow measurement (CFM) you should do traverse

readings to obtain the true average airflow through the duct. You will

need to drill 2 holes at 90 degrees to each other, similar to the drawing below.

1. Take your measurements by inserting the hotwire probe into the

drilled hole. and use the insertion depth chart to determine how far in

the duct you will go for each point. Then you will repeat for the other

hole.

2. Be sure you have the tip of the hotwire pointed into the flow of air,

there is a white dot on the tip, this should be inline with the flow.

HINT: If you turn the probe you will see the readings change up or

down, when the reading is at the highest you are in the proper position.

Page 23

Time Based Traverse of a Round Duct

Press the Up Arrow key repeatedly

until the timer symbol is seen.

21

Using Time Based Traverse Record Function

1. Insert the hotwire probe into the DC580 and turn the meter on.

2. Enter the duct type and size. Prepare the duct for transverse

measurements as outlined on the previous page.

3. Press the key. The display will prompt for time or point based

traverse. Use the key to select time based traverse record.

4. Press the key to confirm the selection.

5. Insert the hotwire probe all the way into the duct at the first hole.

Make sure the white dot is facing the air flow.

Page 24

Time Based Traverse of a Round Duct (Continued)

Start with the probe all

the way into the duct.

Press the key.

Slowly pull the probe

to the entrance hole.

Before removing the

probe see step 8.

22

6. With the probe in place press the key and the DC580 will

begin recording.

7. Slowly pull the probe towards the entrance point of the duct.

8. Stop at the last measurement point prior to pulling the probe out of

the duct. Press the key to pause the recording.

Page 25

Time Based Traverse of a Round Duct (Continued)

23

9. Pull the probe out and insert it into the other test hole all the way

into the duct.

10. Press the key to begin recording. Repeat these steps for

all test holes.

11. When the duct has been completely traversed and prior to

pulling the probe out of the last test hole, press the key to

pause the recording.

12. Press the key to store the readings. See section page 11

on storing readings. This will store the average air velocity, air

volume, and temperature readings.

13. If another traverse needs to be made press the key to

clear the timer and begin traversing a duct.

If finished, press and hold the key to exit record and return

to normal operation.

Note: At any time during the traverse process when REC is displayed the key can be repeatedly pressed to cycle through

the minimum (MIN), maximum (MAX), and average (AVG) readings.

Page 26

Point Based Traverse of a Round Duct

1. Insert the hotwire probe into the DC580 and turn the meter on.

2. Enter the duct type and size. Prepare the duct for transverse

measurements as outlined on the previous page.

3. Press the key. The display will prompt for time or point based

traverse. Use the key to select point based traverse record.

4. Press the key to confirm the selection.

5. Divide the duct into at least 10 equal boxes, you will need to take

the reading in the center of each box. Be sure that the sample

points are no more than 4 inches apart from center to center. If

needed you can add more sample points (boxes) to cover larger

duct sizes. Insert the hotwire probe all the way into the duct at the

first hole. Make sure the white dot is facing the air flow.

Press the Up Arrow

key repeatedly until

the timer symbol is

seen.

24

Page 27

Point Based Traverse of a Round Duct (Continued)

Start with the probe all

the way into the duct.

Press the key.

Slowly pull the probe to the

entrance hole. Stop at each

point and press the key.

Stop at each point and

press the Enter key.

25

6. With the probe in place press the key to record the reading.

7. Slowly pull the probe towards the entrance point of the duct. Stop

at each point and press the key to record reading.

8. Pull the probe out and insert it into the other test hole all the way

into the duct.

Page 28

Point Based Traverse of a Round Duct (Continued)

26

9. Press the key to record the reading. Repeat these steps for

all the other test hole.

10. When the duct has been completely traversed press the

key to store the readings. See page 11 on storing readings. This

will store the average air velocity, air volume, and temperature

readings.

11. If another traverse needs to be made press the key to clear

the counter and begin traversing a duct.

If finished, press and hold the key to exit record and return

to normal operation.

Note: At any time during the traverse process when REC is displayed the key can be repeatedly pressed to cycle through

the minimum (MIN), maximum (MAX), and average (AVG) readings.

Page 29

3. Traversing a Grille

Press the Up Arrow key repeatedly

until the timer symbol is seen.

27

Using Time Based Traverse Record Function

1. Insert the vane probe into the DC580 and turn the meter on.

2. Enter the duct type and size. Remove the grille if possible or use

the free area specification from the manufacturer.

3. Press the key. The display will prompt for time or point based

traverse. Use the key to select time based traverse record.

4. Press the key to confirm the selection.

5. Put the vane probe so the white dot is facing the air flow. Press

the key to begin recording.

Page 30

3. Traversing a Grille (Continued)

28

6. Slowly move the vane across the grilled towards the other end.

Start

End

7. Stop at the last measurement point prior to removing the vane.

Press the key to pause the recording.

8. Press the key to store the readings. See page 11 on storing

readings. This will store the average air velocity, air volume, and

temperature readings.

9. If another traverse needs to be made press the key to clear

the timer and begin traversing a duct.

If finished, press and hold the key to exit record and return to

normal operation.

Note: At any time during the traverse process when REC is displayed the key can be pressed to cycle through the minimum

(MIN), maximum (MAX), and average (AVG) readings.

Page 31

Activate / Deactivate Auto Power Off

29

The DC580 always defaults to auto power off mode. When auto

power off is activated the annunciator will show in the upper left

corner of the display.

To deactivate auto power off from normal operation mode press

and hold the key until the annunciator turns off. Press and

hold the key again or turn the meter off and on to activate auto

power off.

Turning the Backlight On/Off

The backlight can be turned on to make it easier to see the display

in dim areas.

From normal operation mode press the key to turn the back

light on. Press the key again to turn the backlight off.

NOTE: The backlight will automatically turn off after approximately

one minute. This is not adjustable and is done to maximize battery

life.

Turning Display Hold On/Off

The displayed reading can be held on the display if needed.

From normal operation mode during a measurement press the

key to hold the displayed reading. Press the key to unhold the

reading and return to normal operation.

Minimum, Maximum, Average

The minimum, maximum, and average reading can be displayed

using the Record function.

At any time when REC is active like while performing a traverse

measurement the key can be repeatedly pressed to cycle

through the minimum (MIN), maximum (MAX), and average (AVG)

readings.

Page 32

Activate / Deactivate Bluetooth

Bluetooth can be activated in order to communicate with the

DC580 app.

1. Activate Bluetooth by pressing and holding the key until the

annunciator shows in the lower right corner of the display. The

annunciator will blink until connected to a phone.

2. Deactivate Bluetooth by pressing and holding the key until

the annunciator turns off. Turning the DC580 off will also deactivate Bluetooth.

Using the DC580 App

Connecting to a DC580

Download the DC580 app from the app store.

1. Insert a probe in the DC580 and turn it on. Activate Bluetooth as

outlined above.

2. Open the app. The main

screen will be displayed.

3. Tap on “Connect” to search

for available DC580 devices.

30

Page 33

Using the DC580 App (Continued)

4. Available DC580’s will be displayed.

5. Tap on an available DC580 and the

app will return to the main display.

From the main display many functions can be accessed.

The real time Air Volume, Air Velocity,

and Temperature can be displayed.

Readings stored in the DC580 memory

can be downloaded and seen.

Your company information can be

entered into the app. This information will

show up on email reports.

The customer information can be entered

into the app, This information will show

up on email reports.

Settings like if a grille is present or what

type of duct is being tested can be

entered.

All of these can also be

accessed from the drop

down menu tab.

31

Page 34

Using the DC580 App (Continued)

Tap on “Volume, Temp, Velocity” to see

the real time readings.

From this screen the auto power off,

units of measure, and duct type / size

can be changed by tapping on the icons

and entering the data.

This information will be transmitted to the

DC580.

Tap on “Reading Mem Data” to download

all saved readings from the memory of the

DC580.

Tap on “Update All” to begin the download.

The memory locations being downloaded

will be displayed. Only locations with data

will download.

Tap on a memory location to see the information contained in it. (See next page)

NOTE: Downloading information from the

DC580 does not delete the data on the

DC580. To do this either store over older

data or perform a memory clear as outlined

on page 11.

32

Page 35

Using the DC580 App (Continued)

After tapping on “Reading Mem Data”

and tapping “Update All” the data stored

in the DC580 will download.

Tapping on a memory location will display the information stored there.

From here a CSV file can be created

and stored on the phone by tapping CSV

or the CSV file can be created and

emailed by tapping email.

Tap on “Company Information” to open the

Company Info input screen. This is where

your company name, address, and email

should be entered.

This information will be part of the CSV

report generated that you can email your

customer.

33

Page 36

Using the DC580 App (Continued)

Tap on “Customer Information” to open

the Customer Info input screen. This is

where your customer’s name, address,

and email should be entered.

The building information can also be

entered as necessary.

This information will be part of the CSV

report generated that you can email your

customer.

Tap on “Settings” to open the Settings input

screen. This is where you select whether

there was a grille in place and what type of

duct was being measured.

This information will be part of the CSV

report generated that you can email your

customer.

34

Page 37

Specifications

35

Page 38

Specifications (Continued)

Optional Accessories

Part Number Description

A103 Boot hook for hanging the DC580

A124 Magnetic hanger strap for hanging the DC580

Replacement Parts

Part Number

Description

DC580 Meter only

A580 Carrying case for DC580

A581 Hotwire probe for DC580

A582 Vane probe for DC580

A583 Protective boot with magnets

Battery Replacement

1. Remove the DC580 from the protective boot by prying the boot

off from the bottom of the meter first.

2. Locate and loosen the battery cover screw.

3. Remove the battery cover and replace the batteries (AA x 3).

4. Install the battery cover and tighten the cover screw. Install the

protective boot at starting by inserting the top of the meter into

the boot first.

36

DC580 battery compartment.

DC580 battery

cover screw.

DC580 battery

cover removed.

DC580 with the

boot removed.

Page 39

Troubleshooting

Problem Possible Solution

DC580 will not turn on Change the battery.

Press and hold the key.

Display reads OPEN Connect a probe to the input.

Probe may be bad; Return for service.

Cannot connect Bluetooth Turn Bluetooth on, see page 30.

Make sure phone Bluetooth is on.

Readings seem to be high or low Change batteries.

Ensure white dot is facing into the air

stream.

Care & Cleaning

Clean the DC580 with a soft lint free cloth. Do not attempt to clean the sensor. Use a mild detergent on the base unit if necessary.

Do not submerse the DC580 or probes.

Warranty, Service, and Calibration

The TPI DC580 air velocity meter is guaranteed free from defects in mate-

rials and workmanship for 3 Years from the date of purchase. This guarantee

does not affect your statuary rights. For additional information please refer to

the included warranty card or contact TPI at 800-368-5719.

optimum performance, calibration is recommended once every year.

To obtain warranty performance, service or calibration of your meter: Include with the product your name, address, phone number, written description of the problem and proof of purchase date. Carefully package and return

to:

. To maintain

TPI / Attn. Service

9615 SW Allen Blvd. Suite 104

Beaverton, OR 97005

37

Page 40

Test Products International, Inc.

9615 SW Allen Blvd., Ste. 104

Beaverton, OR 97005

Tel: 503-520-9197 Fax: 503-520-1225

www.testproductsintl.com

Test Products International, Ltd.

342 Bronte Road South, Unit #6

Milton Ontario Canada L9T5B7

Tel: 905-693-8558 Fax: 905-693-0888

www.tpicanada.com

Test Products International Europe Ltd.

Longley House International Drive

Southgate Crawley

West Sussex RH10 6AQ

Tel: +44 (0) 1293 530196 Fax: +44 (0) 1293 531870

www.tpieurope.com

Loading...

Loading...