Page 1

INSTALLATION

CP & RCP Series

INSTRUCTIONS

Radiant Ceiling Panel Heaters

GENERAL INFORMATION:

Wiring: Check voltage on nameplate of heater to make sure it conforms with supply voltage. 277 volt heaters

operated at 240 volt and 240 volt heaters operated at 208 volts will give a capacity of 75% rated wattage.

All wiring must conform to the N.E.C./C.E.C. and existing local code requirements.

Location: Heaters are intended for ceiling mount only. If the situation requires, heating panels may be installed

directly adjacent to walls and to other heating panels.

WARNING: Adhere to all applicable building codes and regulations when installing or using ceiling

heaters. Failure to do so could cause improper activation of re suppression systems leading to property

damage or bodily injury.

AVERTISSEMENT: respecter tous les codes et réglementations applicables lors de l’installation ou de

l’utilisation de radiateurs de plafond. L’omission de le faire pourrait entraîner une mauvaise activation

des systèmes de suppression des incendies entraînant des dommages matériels ou corporels.

Controls: Heaters may be controlled by a wall mounted line voltage or pilot duty thermostat, timer or other

suitable device. (Controls are not supplied with heaters).

Insulation: Insulation is built into the ceiling heaters above the heating element surface to reduce heat loss

through the ceiling and deect the heat downward into the heated space. Additional insulation placed in the

ceiling is highly recommended to further reduce the upward passage of heat.

Handling Panels are factory supplied in a white egg shell textured nish to match surrounding ceiling areas as

closely as possible. Since this nish is more difcult to clean than a high gloss type, it is suggested that the

installer wear clean gloves to prevent unnecessary soiling.

CLEANING/MAINTENANCE

Cleaning should be done with a vacuum cleaner and soft brush attachment. Gently go over the face of the panel

and remove any dust or lint. There is no other maintenance required for the heater.

1 of 7REV 11/15/18 ECO 1-7483 FORM: 9688

Page 2

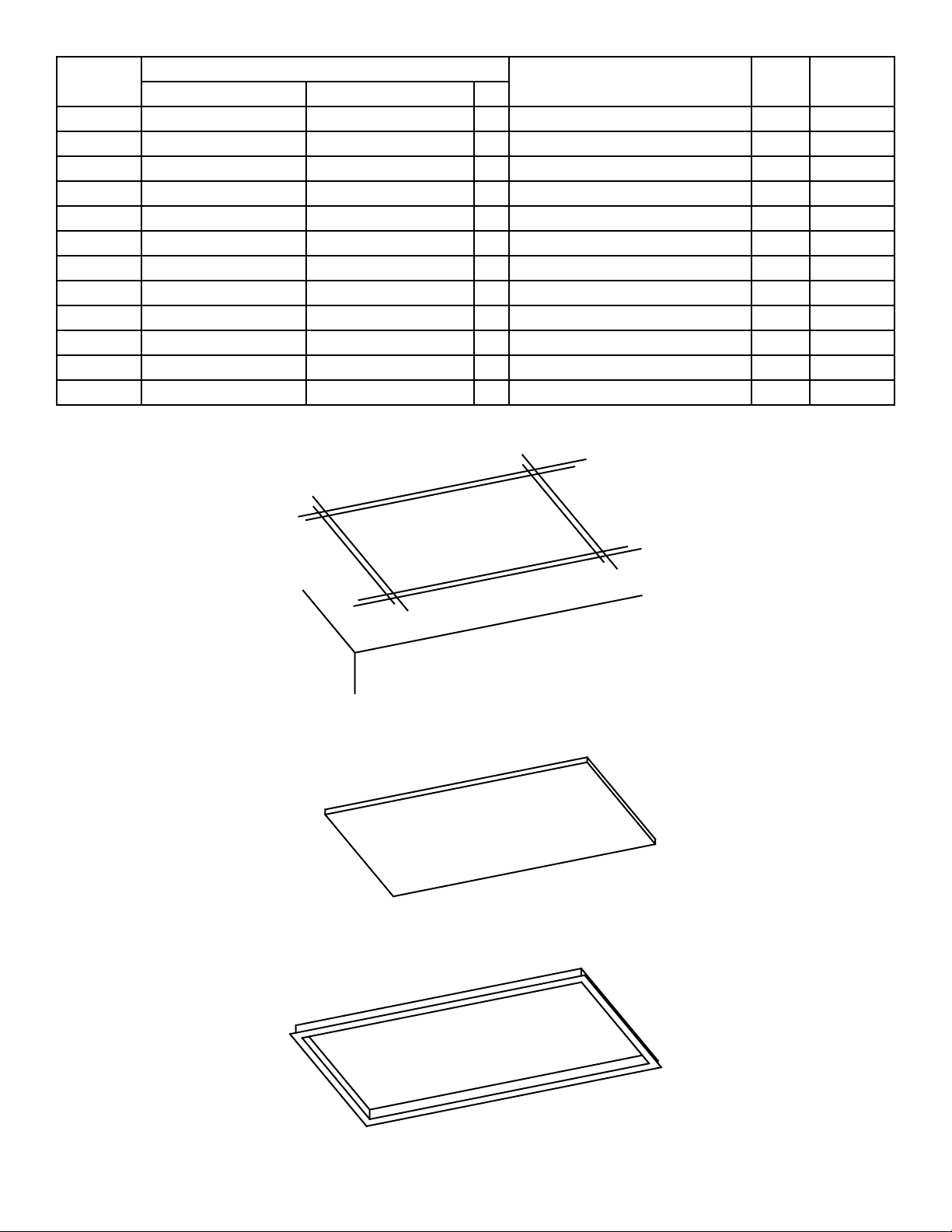

Model

No.

CP805 23 3/4 (603MM) 47 3/4 (1213MM) 1 24 X 48 (610MM X 1219MM) 500 208

CP125 23 3/4 (603MM) 47 3/4 (1213MM) 1 24 X 48 (610MM X 1219MM) 500 120/240

CP705 23 3/4 (603MM) 47 3/4 (1213MM) 1 24 X 48 (610MM X 1219MM) 500 277

CP807 23 3/4 (603MM) 47 3/4 (1213MM) 1 24 X 48 (610MM X 1219MM) 750 208

CP127 23 3/4 (603MM) 47 3/4 (1213MM) 1 24 X 48 (610MM X 1219MM) 750 120/240

CP707 23 3/4 (603MM) 47 3/4 (1213MM) 1 24 X 48 (610MM X 1219MM) 750 277

CP802 23 3/4 (603MM) 23 3/4 (603MM) 1 24 X 24 (610MM X 610MM) 250 208

CP122 23 3/4 (603MM) 23 3/4 (603MM) 1 24 X 24 (610MM X 610MM) 250 120/240

CP702 23 3/4 (603MM) 23 3/4 (603MM) 1 24 X 24 (610MM X 610MM) 250 277

CP803 23 3/4 (603MM) 23 3/4 (603MM) 1 24 X 24 (610MM X 610MM) 375 208

CP123 23 3/4 (603MM) 23 3/4 (603MM) 1 24 X 24 (610MM X 610MM) 375 120/240

CP703 23 3/4 (603MM) 23 3/4 (603MM) 1 24 X 24 (610MM X 610MM) 375 277

A B C

Panel Size

T-Bar Spacing Watts Volts

B

A

RADIANT

PANEL

C= PANEL DEPTH = 1"

B

RECESSED HEATING

PANEL WITH INVERTED

"T" STYLE FRAME

FRAME FOR RECESSED

HEATING PANEL

A

REV 11/15/18 ECO 1-7483 FORM: 9688 2 of 7

Page 3

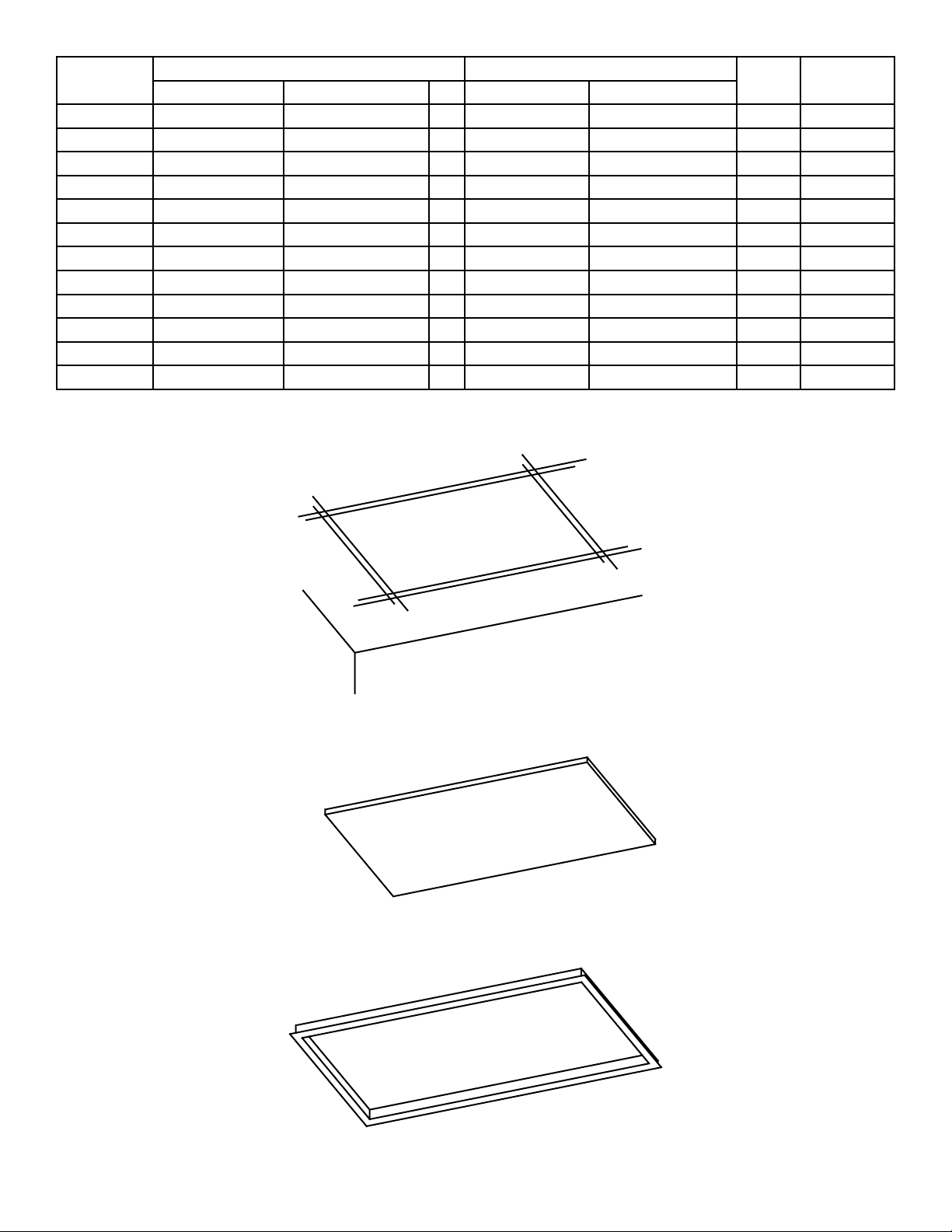

Model

No.

RCP805 21 3/4 (552MM) 47 3/4 (1213MM) 1 22 1/2 (571MM) 48 12 (1232MM) 500 208

RCP125 21 3/4 (552MM) 47 3/4 (1213MM) 1 22 1/2 (571MM) 48 12 (1232MM) 500 120/240

RCP705 21 3/4 (552MM) 47 3/4 (1213MM) 1 22 1/2 (571MM) 48 12 (1232MM) 500 277

RCP807 21 3/4 (552MM) 47 3/4 (1213MM) 1 22 1/2 (571MM) 48 12 (1232MM) 750 208

RCP127 21 3/4 (552MM) 47 3/4 (1213MM) 1 22 1/2 (571MM) 48 12 (1232MM) 750 120/240

RCP707 21 3/4 (552MM) 47 3/4 (1213MM) 1 22 1/2 (571MM) 48 12 (1232MM) 750 277

RCP802 21 3/4 (552MM) 21 3/4 (552MM) 1 22 1/2 (571MM) 22 1/2 (571MM) 250 208

RCP122 21 3/4 (552MM) 21 3/4 (552MM) 1 22 1/2 (571MM) 22 1/2 (571MM) 250 120/240

RCP702 21 3/4 (552MM) 21 3/4 (552MM) 1 22 1/2 (571MM) 22 1/2 (571MM) 250 277

RCP803 21 3/4 (552MM) 21 3/4 (552MM) 1 22 1/2 (571MM) 22 1/2 (571MM) 375 208

RCP123 21 3/4 (552MM) 21 3/4 (552MM) 1 22 1/2 (571MM) 22 1/2 (571MM) 375 120/240

RCP703 21 3/4 (552MM) 21 3/4 (522MM) 1 22 1/2 (571MM) 22 1/2 (571MM) 375 277

A B C D E

Panel Size FRAME OUT SIZE

Watts Volts

B

A

RADIANT

PANEL

C= PANEL DEPTH = 1"

B

RECESSED HEATING

PANEL WITH INVERTED

"T" STYLE FRAME

FRAME FOR RECESSED

HEATING PANEL

A

3 of 7REV 11/15/18 ECO 1-7483 FORM: 9688

Page 4

IMPORTANT INSTRUCTIONS

1. When using electrical appliances, basic precautions should always be followed to reduce the risk of re, electrical

shock, and injury to persons, including the following:

2. Read all instructions before using this heater.

3. CAUTION: High temperature, risk of re, keep electrical cords, drapery, furnishings and other combustibles at

least 3 feet (0.9m) from the front of the heater. Zero clearance on sides and rear.

MISE EN GARDE: Température élevée, risque d’incendie, maintenez les cordons électriques, les draperies,

les meubles et autres matériaux combustibles à au moins 0,9 m de l’avant de l’appareil. Zéro dégagement sur

les côtés et à l’arrière.

4. Extreme caution is necessary when any heater is used by or near children or invalids and whenever the heater is left

operating and unattended.

5. Do not operate any heater after it malfunctions, has been dropped or damaged in any manner. Return heater to

authorized service facility for examination, electrical or mechanical adjustment, or repair.

6. Do not use outdoors.

7. To disconnect heater, turn controls to off, and turn off power to heater circuit at main disconnect panel (or operate

internal disconnect switch if provided).

8. Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause an electric shock or

re, or damage the heater.

9. To prevent a possible re, do not block air intakes or exhaust in any manner.

10. A heater has hot and arcing or sparking parts inside. WARNING: Do not use it in area where gasoline, paint, or

ammable liquids are used or stored.

AVERTISSEMENT: Ne l’utilisez pas dans un endroit où de l’essence, de la peinture ou des liquides inammables sont

utilisés ou stockés.

11. Use this heater only as described in this manual. Any other use not recommended by the manufacturer may cause re,

electric shock, or injury to persons.

12. This heater may include an audible or visual alarm to warn that parts of the heater are getting excessively, hot. If the

alarm sounds (or illuminates), immediately turn the heater off and inspect for any objects on or adjacent to the heater

that may have blocked the airow or otherwise caused high temperatures to have occurred. DO NOT OPERATE THE

HEATER WITH THE ALARM SOUNDING (OR ILLUMINATING).

13. SAVE THESE INSTRUCTIONS

REV 11/15/18 ECO 1-7483 FORM: 9688 4 of 7

Page 5

HEA

TING

SUR

FRAME

RECESSED

ON

PAN

FOR

LY

EATING

H

ELS

PAN

FACE

FRAME

EL

MOUN

WI

TH

T

UNTING

SUR

FRAME

HEA

FOR

CP

TING

FRAME DEPTH = 3"

MO

FACE

"T"

PANE

BA

R

L

RECESSED PANEL FRAME ACCESSORY

FOR USE WITH RECESSED PANELS ONLY

NOMINAL SIZE

22” X 22” (559MM X 559MM)

22” X 48” (550MM X 1219MM)

FACE

SUR

FRAME

SURFACE MOUNTED FRAME ACCESSORY

FOR SURFACE MOUNTED PANELS

CATALOG NUMBERS NOMINAL SIZE

SF200 24” X 24” (610MM X 610MM)

SF400 24” X 48” (610MM X 1219MM)

M

OUN

TING

Frame is constructed of extruded aluminum.

INSTALLATION INSTRUCTIONS

T-BAR CEILING PANELS

All wiring must be in accordance with the latest edition of the N.E.C./C.E.C. and local codes. Install the junction

box above and away from the panel above any ceiling insulation. Reference Fig. 1.

WARNING: Adhere to all applicable building codes and regulations when installing or using ceiling

heaters. Failure to do so could cause improper activation of re suppression systems leading to property

damage or bodily injury.

AVERTISSEMENT: respecter tous les codes et réglementations applicables lors de l’installation ou de

l’utilisation de radiateurs de plafond. L’omission de le faire pourrait entraîner une mauvaise activation

des systèmes de suppression des incendies entraînant des dommages matériels ou corporels.

Use supply conductors suitable for 75OC.

Heater junction box and thermostat outlet box must be grounded through the grounding conductor. Install

heating panels in “T” Bar ceiling maintaining a minimum clearance between overhead ceiling or roof and at back

of panel.for wiring.

CLIP

FIG. 1

JUNCTION BOX

"T" BAR

POWER SOURCE

CLIP

BEND OVER

"T" BAR

THERMOSTAT

HEATING

PANEL

"T" BAR

5 of 7REV 11/15/18 ECO 1-7483 FORM: 9688

Page 6

WIRING INFORMATION

IMPORTANT INFORMATION: READ BEFORE CONNECTING TO POWER SUPPLY

1. Disconnect branch circuit or power supply before connecting or servicing.

2. All wiring must be done in accordance with the N.E.C./C.E.C., or local code having jurisdiction.

3. Do not cover face of heater at any time with an object, other construction or furnishing as over heating could result and

combustion of objects.

4. Check to determine that branch circuit voltage is the same as voltage shown on panel data label. Do not connect to

a circuit having a higher voltage as a hazard can result. Connecting to a lower voltage will result in a lower operating

wattage.

NOTE:

1. The 120 and 240 volt panels are furnished as dual rated 120/240 volt units. The operating volts determines which leads

are to be connected. See Fig. 3

A. For 240 volt connection the two black leads are connected to the eld power supply. The white lead is not used and is

to be insulated by wrapping tape over the open conductor.

B. For 120 volt connection the two black leads are to be spliced together and connected to the black eld power supply

conductor. The white lead is to be connected to the white eld power supply conductor.

C.. Grounding: Connect the eld supply grounding conductor to the panel ground conductor (green).

2. The 208 Volt panels are furnished as single rated units and have two black leads to be connected to the eld supply

power leads in the junction box. Reference Fig. 1 for grounding connection.

3. The 277 volt panels are furnished as single rated units and have one black and one white lead to be connected to the

eld supply power. The black lead must be connected to the black eld power supply lead and the white panel lead

must be connected to the white power supply lead. The single pole thermostat must be connected to the black power

supply lead. Reference Fig. 2 for grounding connection.

208 Volt Model Wiring Connection

Panel Conduit & Leads

B

Field Splice

Remote Junction Box

B

OPERATION

1. Turn on the power supply to heater.

2. Rotate thermostat knob fully clockwise.

3. Allow the room to reach desired temperature, then rotate thermostat

knobcounter clockwise until the heater de-energizes.

Field Conductors

208 Volt

GND

Supply

277 Volt Model Wiring Connection

BW

Field Conductors

DOUBLE POLE

THERMOSTAT

FIG. 1

Panel Conduit & Leads

Field Splice

Remote Junction Box

4. For remote thermostat operation, thermostat wiring must be the same size

as power supply wiring.

120/240 Volt Models Wiring Connection

Panel Conduit & Leads

Field Splice

W

Field Conductors

Remote Junction Box

B W

Panel Conduit & Leads

Tape & Insulate White Wire

Field Splice

Remote Junction Box

Field Conductors

B

B

SINGLE POLE

THERMOSTAT

GND

277 Volt

Supply

SINGLE POLE

THERMOSTAT

FIG. 2 FIG. 3

GND

240 Volt

Supply

DOUBLE POLE

THERMOSTAT

GND

120 Volt

Supply

REV 11/15/18 ECO 1-7483 FORM: 9688 6 of 7

Page 7

RECESSED CEILING PANELS

The recessed ceiling panels are designed to be used with a recessed frame (included with recessed panels)

designed to t the cutout in the ceiling. Ref. Fig. 2. The cutout dimensions are as given in the specication table

for the specic panel model in column D and E. Ref. Fig. 3. The frame must be secured to the framing members

as shown in Fig. 4 using wood screws or nails.

The panel is to be placed through the frame opening and lowered into the frame and wired in accordance with

the N.E.C./C.E.C. and local codes.

WARNING: Adhere to all applicable building codes and requlations when installing or using ceiling

heaters. Failure to do so could cause improper activation of re suppression systems leading to property

damage or bodily injury.

If the junction box is mounted in the ceiling or allowed to be mounted above the upper surface of the ceiling and

below the insulation, 75o C conductors must be used. If the junction box is mounted above the ceiling insulation,

the supply conductors may be rated for 60o C.

"T" BAR

FIG. 2

MOUNTING FRAME

THERMOSTAT

RECESS

JUNCTION BOX

POWER

SOURCE

E

D

FIG. 3

FIG. 4

CEILING JOIST

RADIANT-PANEL

FRAME

Assemble surface mounting frame as shown below using the screws provided. Ref. Fig. 5. Secure the frame

to the ceiling with appropriate hardware. Locate the frame so that the junction box will be covered when the

ceiling panel is installed. Ref. Fig. 6. Remove one end of the frame, insert the ceiling panel and make electrical

connections. Install the end of the frame.

If the junction box is mounted in the ceiling or allowed to be mounted above the upper surface of the ceiling and

below the insulation, 75o C conductors must be used.

If the junction box is mounted above the ceiling insulation, the supply conductors may be rated for 60oC.

JUNCTION

BOX

FIG. 5 FIG. 6

7 of 7REV 11/15/18 ECO 1-7483 FORM: 9688

Loading...

Loading...