Page 1

717

Combustion Efficiency Analyzer

The Value Leader

TM

www. .com

information@itm.com1.800.561.8187

Page 2

Contents

Introduction.................................................. 1

General Overview............................................... 1, 2

Instrument Overview........................................... 3 ~ 7

Front View............................................. 3

Keypad................................................. 4

Back View............................................. 5

Side Views............................................ 6

Top View............................................... 7

Basic Analyzer Functions...................................... 8, 9

Analyzer Batteries................................... 8

Turning The Analyzer On & Fuel Selection.. 8, 9

Turning The Analyzer Off........................... 9

Activating The Backlight........................... 9

Combustion Analysis Overview.............................. 10

Combustion Analyzer Mode.................................. 11 ~ 19

Combustion Test Procedure....................... 11 ~ 19

Typical Test Locations.............................. 13 ~ 15

Combustion Analysis Displays.................... 17 ~ 18

Typical Test Results................................ 19

Thermometer Mode........................................... 20

Manometer Mode............................................. 21

Let By Pressure Test Mode.................................. 22, 23

Setting Date & Time.......................................... 24

Storing Data................................................... 25

Recalling Data................................................ 26

Printing Data.................................................. 27, 28

Specifications................................................ 29, 30

Calibration & Service....................................... 31

Warranty...................................................... 31

Appendix A General Maintenance & Function Tests........... 32~ 34

Appendix B A773 Sulfur Filter Installation & Maintenance. 35, 36

Appendix C Error Codes and Troubleshooting.................. 37, 38

Appendix D Field Sensor Replacement........................ 39 ~ 42

Appendix E Technical Notes..................................... 43

Appendix F Testing for Carbon Monoxide in Ambient Air.... 44

Appendix G Carbon Monoxide Limits in Ambient Air Chart.. 45

Appendix H Carbon Monoxide Facts............................ 46

Appendix I Battery Replacement................................ 47

www. .com

information@itm.com1.800.561.8187

Page 3

Introduction

Thank you for purchasing TPI brand products. The TPI 717 combustion analyzer is a state of the art, easy to use analyzer designed not

only to display and calculate the required readings from a flue but also

to cover most of the other measurements associated with combustion.

The instrument is ruggedly constructed and comes with a 3 Year unit

and 2 Year sensor Guarantee.

General Overview

The TPI 717 combustion analyzer uses field replaceable state of the art

electrochemical sensors. This sensor technology provides the longest

lasting, most accurate and reliable means for performing combustion

tests. The sensors in your analyzer will need to be replaced periodically

and calibration is recommended once every year.

Electrochemical sensors by nature are always active. Therefore the

time the analyzer is off and not being used must be taken into account

when determining sensor life. The sensors in your analyzer are warranted for two years. This warranty does not cover sensors damaged

through misuse of the analyzer.

You should keep the batteries of your 717 fresh so power is constantly

being supplied to your sensors.

The following guidelines will help prevent damage to your sensors:

Always use the mini pump filter when testing flue gases.

Always periodically check and replace the mini pump filter as needed.

Always make sure the in-line filter / water trap is installed properly.

Always periodically check and replace the in-line filter as needed.

Always remove water or condensation from the inside of the in-line filter / water trap assembly prior to performing tests.

Always use the optional oil filter (p/n A773) when performing tests on

oil burning equipment.

www. .com

1

information@itm.com1.800.561.8187

Page 4

General Overview (Continued)

Never over saturate your sensors by performing tests on equipment

with gas levels beyond the capability of you analyzer.

Always keep the A796 water trap / filter assembly clean and replace the

filter as necessary. Replacement filter part number is A762F.

This manual will guide you through the functions of the TPI 717 which

will give you many years of reliable service.

Your TPI 717 Flue Gas Analyzer comes complete with the following

standard accessories:

•

TPI 717 Instrument

• Rubber Boot (A765)

• Soft Carrying Case (A768)

• Flue Sampling Probe (A770)

• In-Line Filter assembly installed on Flue probe (A796)

• Temperature Probe (GK11M)

• Mini Pump Protection Filter Assembly and spare filters (A763)

• Exhaust Spigot (removable) (A764)

• Instruction Manual

( ) Denotes part number

Your TPI 717 Flue Gas Analyzer has the following options available:

• Infrared printer (A740)

• Spare In-Line Filter (A762F is a package of 5 filters)

• Field replaceable smart CO sensor (A760S)

• Field replaceable smart O2 sensor (A761S)

2

www. .com

information@itm.com1.800.561.8187

Page 5

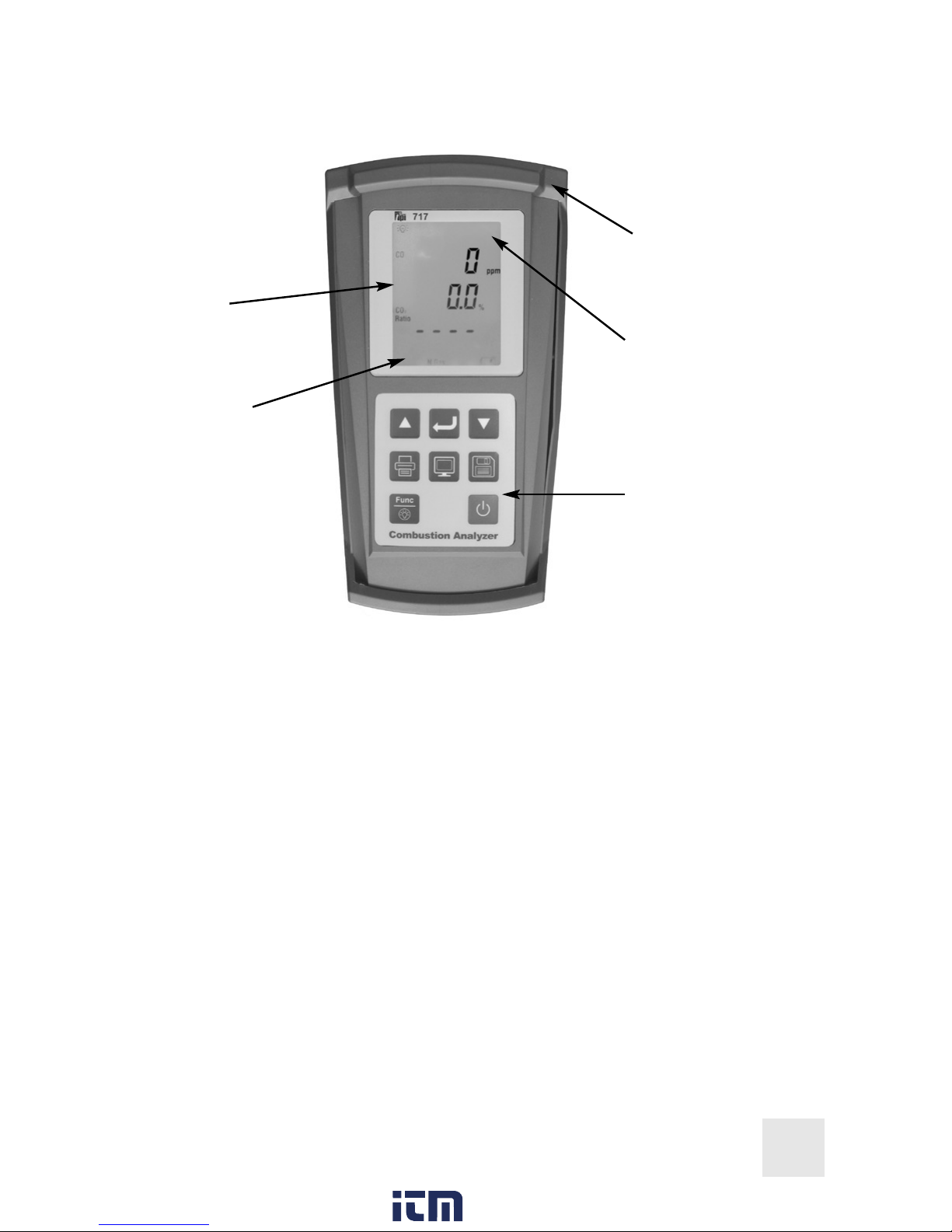

Instrument Overview

Front View

LCD

Rubber

Boot

Display

Battery

Condition

Icon

Selected

Fuel Type

Keypad

Rubber Boot Protects the instrument from accidental damage

Display Large 3 Parameter Backlit LCD Display

Battery Condition Icon Shows condition of batteries.

Keypad Selects all available functions

Selected Fuel Type N GAS, LPG, LIGHT OIL, HEAVY OIL, OPT 1

NOTE: When selecting oil as fuel be sure to use the optional

oil filter (A773) or readings could become erratic. See

Appendix E for installation instructions.

(Bituminous Coal), OPT 2 (Anthracite Coal),

OPT 3 (Coke), OPT 4 (Butane), OPT 5 (Wood),

OPT 6 (Bagasse)

www. .com

3

information@itm.com1.800.561.8187

Page 6

Keypad

Func

4

Scrolls through selectable fuels (see page 8 )

Switches between ºC and ºF (see pages 18 & 21)

Scrolls through selectable pressure units

Moves up through the Stored Data Addresses

Zeroes pressure reading (See page 21)

Moves down through the Stored Data Addresses

Scrolls through Combustion Analysis Displays (See 17& 18)

Turns ch2 temperature ON/OFF (see page 20)

Allows you to choose a Stored Data Address

Sends stored data to a separate infrared printer (see pg 25)

Allows you to view stored data on the display (see pg 24)

Stores readings to memory (see pg 23)

Scrolls through and selects analyzer functions (see 20~22)

Turns Backlight ON and OFF (see 9)

Turns the instrument ON and OFF (see pages 8 & 9)

www. .com

information@itm.com1.800.561.8187

Page 7

Back View

Sample and Pressure Inlet Ports: Connection for Flue Probe

(see pages 7 & 11)

Connection for Mini Pump Protection

Filter (see pages 7 & 11)

Connection for pressure tubing

(see pages 7 & 21)

Calibration and Information Label: Displays calibration information and

serial number

Battery Compartment: Holds 3 AA Alkaline Batteries

Rubber Boot: Protects the instrument

Smart Sensor Access: For field replaceable sensors

(See appendix L)

Calibration and

Information

Label

Battery

Compartment

Rubber

Boot

Connection for

Mini Pump

Protection Filter

Connections for

Pressure Tubing

Sample and

Pressure Inlet

Ports

5

Access area to

smart sensors

www. .com

information@itm.com1.800.561.8187

Page 8

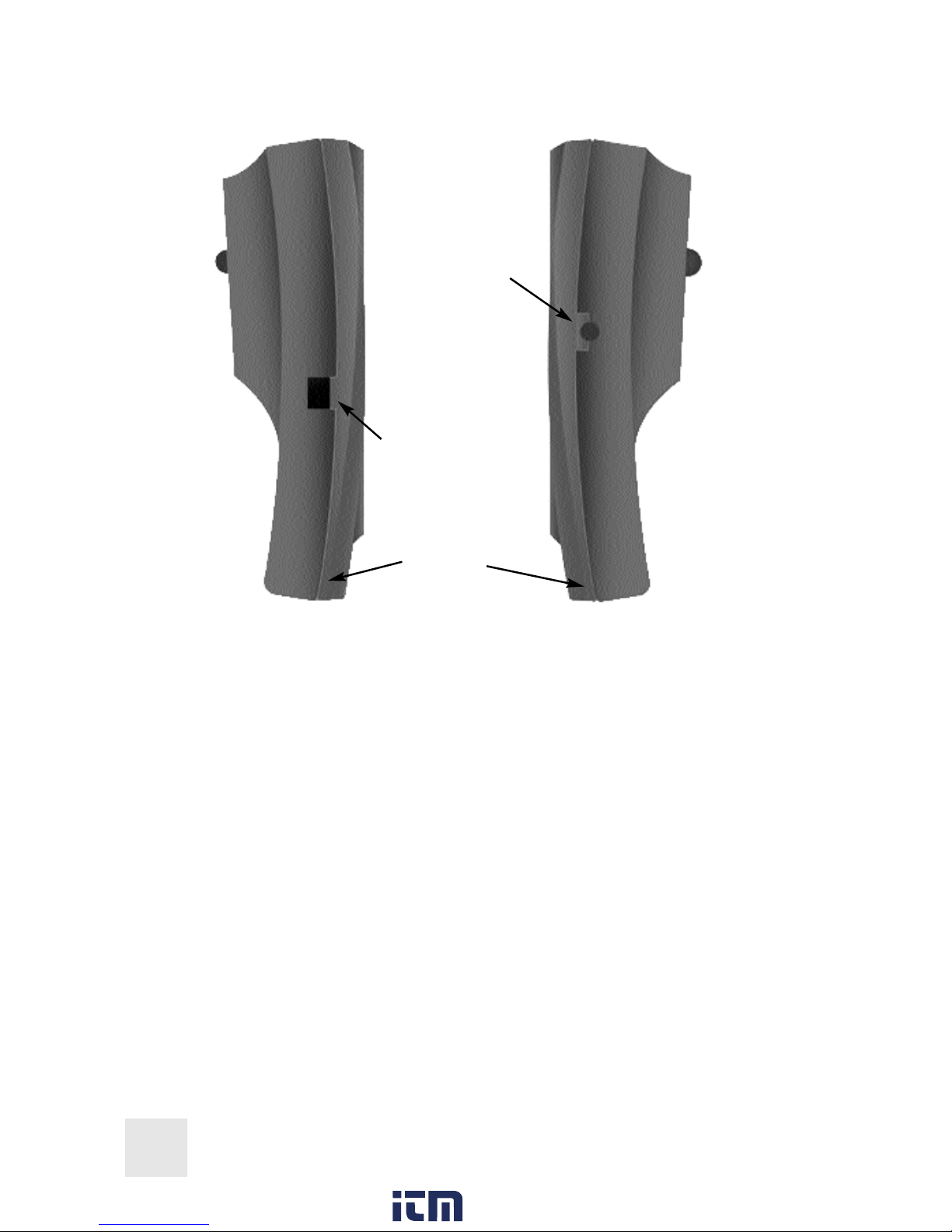

Side Views

Exhaust

Port

Infrared

Window

Rubber

Boot

6

Exhaust Port Port for connection of Exhaust Adapter

Infrared Window Window for sending stored data to IR Printer

(see page 25 )

Rubber Boot Protects the instrument from accidental damage

www. .com

information@itm.com1.800.561.8187

Page 9

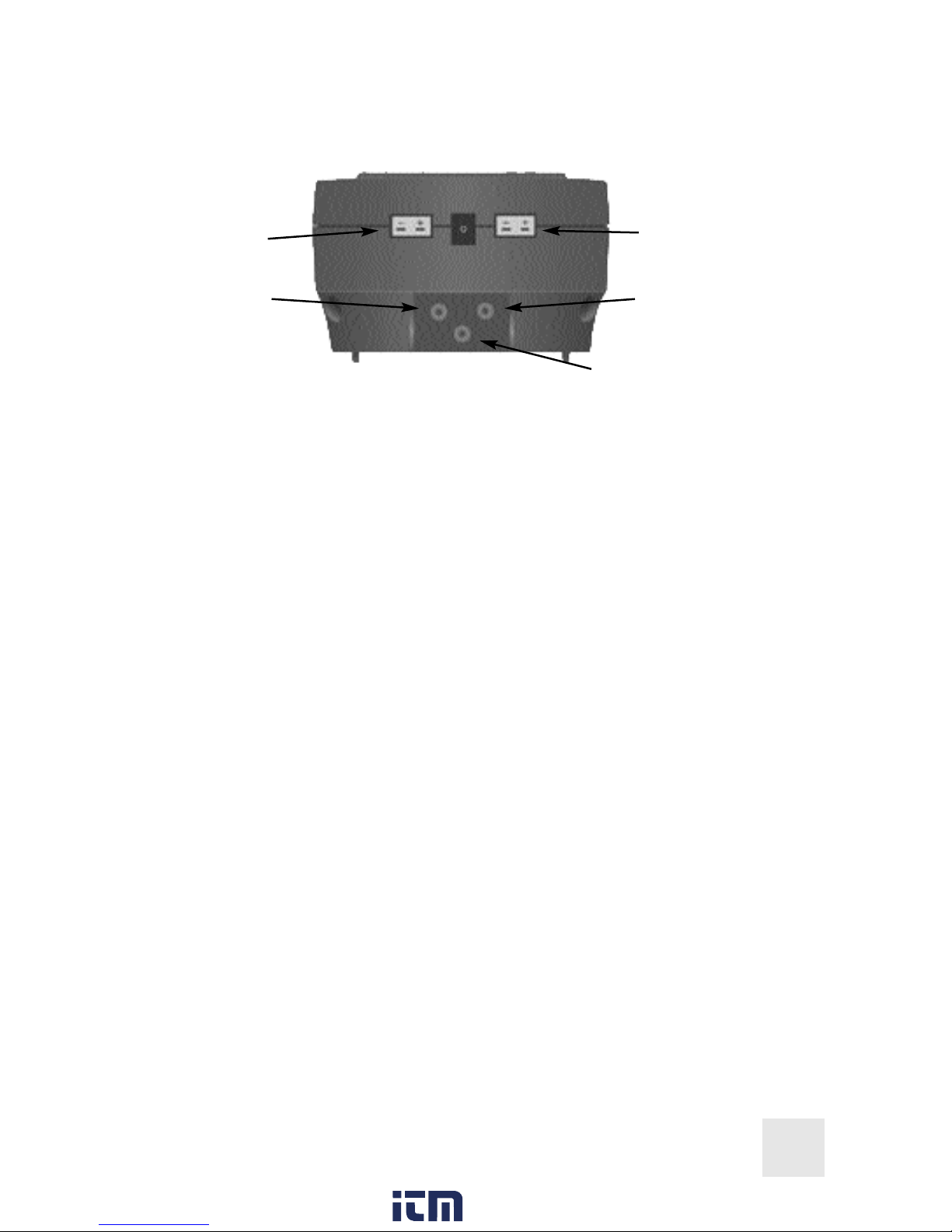

Top View

T1

T2

P (+) P (-)

Gas Sampling Port

T1 Socket Connection for thermocouple plug on flue probe

(see page 11)

Connection for any 'K' type thermocouple probe

(see page 20)

T2 Socket Connection for ambient 'K' type thermocouple probe

(see page 11 )

Connection for any 'K' type thermocouple probe

(see page 20)

Gas Sample Port Connection for Mini Pump Protection Filter and Flue

Probe (see pages 7 & 11)

P (+) Port Connections for Pressure Tubing (see page 21)

P (-) Port

7

www. .com

information@itm.com1.800.561.8187

Page 10

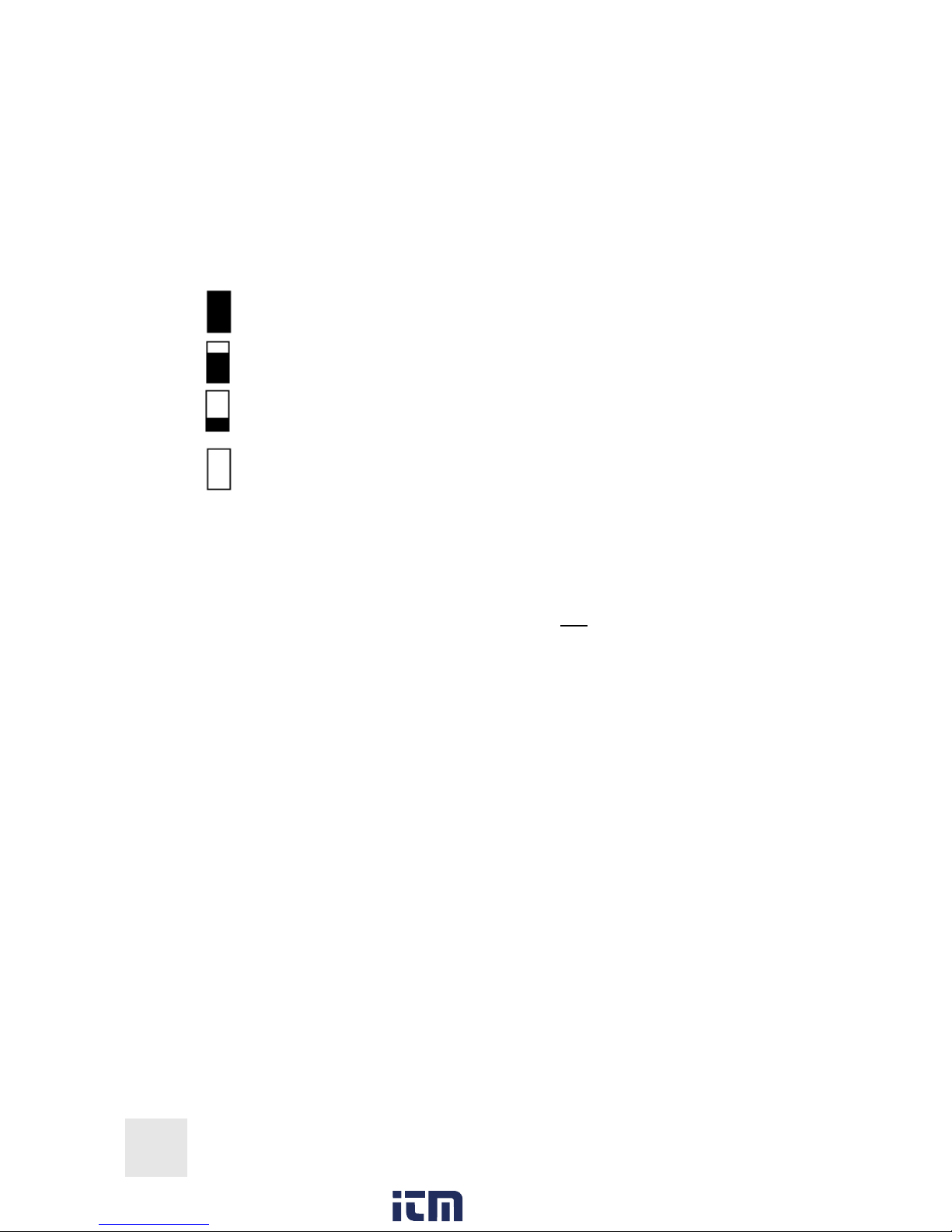

BASIC ANALYZER FUNCTIONS

Analyzer Batteries

Your combustion analyzer is fitted with three AA size 1.5V alkaline batteries.

It is important to keep battery power to the sensors in your analyzer even

when it is not in use.

Your analyzer has a battery status indicator in the lower right corner of the

display. Battery status is determined as follows:

Indicates batteries are at full capacity.

Indicates batteries are at 2/3 capacity.

Indicates batteries are at 1/3 capacity. Replacement of batteries

should be considered soon.

Indicates batteries are very low and in need of replacement

immediately. See Appendix J for battery replacement instructions.

Turning The Analyzer On & Fuel Type Selection

Always: - Before turning on please ensure that the Mini Pump Protection

Filter assembly and the Temperature Sampling Probe complete with InLine Filter or the Tubing & In-Line Filter fare not

Sample Port (see page 7)

The instrument MUST be turned on in a clean air environment as the initial

purge will set the Carbon Monoxide level to Zero and the Oxygen to 20.9%.

Press and hold down the Power Key and the TPI 717 will start its 30 second

countdown 'Purging...' will be displayed.

After the 717 has completed purging the fuel type can be selected by pressing the Up Arrow key. The selected fuel type is displayed in the lower left corner of the display. Selectable fuels are Natural Gas, LIGHT OIL, HEAVY OIL,

LPG, Bituminous Coal, Anthracite Coal, Coke, Butane, Wood (Dry), Bagasse,

and Wood Pellet.

After start up, several tests can be performed to ensure proper function of

the analyzer and flue probe. Please refer to Appendix A.

connected to the Gas

*NOTE: When selecting oil as fuel be sure to use the optional

oil filter (A773) or readings could become erratic. See

Appendix E for installation instructions.

8

www. .com

information@itm.com1.800.561.8187

Page 11

After the 30 second countdown the instrument is ready to take Flue,

Temperature, and Pressure readings and the default combustion display will

be displayed.

The 717 will auto power off if no keys have been pressed for 10 minutes and

the CO level is below 15ppm. Auto off can be disabled (see Appendix D). The

auto power off feature is always enabled upon power up.

The Scroll/Enter Key allows you to scroll through the combustion displays as

outlined on pages 17&18. The Func Key is used to select the 717 function

mode and allows you to set it to be a combustion analyzer, manometer, or

thermometer. In addition, the Func Key is used to access the date and time

display. See pages 20 through 24 for more information on the Func Key.

Turning The Analyzer Off

Always: - Before turning off return the instrument to a clean air environment

and allow the Carbon Monoxide level to return to below 15ppm and the

Oxygen level to return to 20.9% (± 0.3%) Press the Power Key to turn the

instrument off:- NOTE Should you attempt to turn the instrument Off and the

CO reading is above 15ppm then the instrument will remain On and a short

Beep will be heard. The Instrument can only be switched off if the CO is

below 15ppm

The instrument has an auto shut off after 10 minutes should no keys have

been pressed for this period and as mentioned above that the CO is below

15ppm. Should the CO be above 15ppm then the 10 minute auto shut off

countdown will not begin till the CO has gone below 15ppm. The auto power

off feature can be disabled. Please see Appendix D. The auto power off feature is always enabled upon power up.

Activating the Backlight

The display backlight can be activated at any time by pressing and holding

down the Func Key for approximately 2 seconds. The backlight will automatically shut off after approximately 20 seconds to preserve battery life.

9

www. .com

information@itm.com1.800.561.8187

Page 12

COMBUSTION ANALYSIS OVERVIEW

Performing combustion analysis is very important to the overall safety and

efficiency of heating equipment. The following guidelines and descriptions are

generic and meant to provide you with a basic understanding of combustion

testing. TPI always recommends you contact the manufacturer of the device

under test, obtain information specific to the device, and follow the procedures and safety guidelines for performing tests and affecting repairs.

In general, for most applications, flue gas samples should be taken prior to

the draft diverter or any other opening that allows room air to enter the system. This prevents room air from mixing with gases in the flue and diluting

the test sample. To ensure accurate and consistent combustion tests, it is

important gas and temperature samples be taken at the same location. This is

easy with the TPI flue probe because the temperature sensor is an integral

part of the probe.

Prior to taking a sample, the device under test should be on and operating.

Putting the flue probe in the sample area prior to starting the device may

cause saturation of the sensors due to the higher initial concentration of carbon monoxide that may be encountered upon start up. If this happens, allow

your analyzer to purge in fresh air until the carbon monoxide level returns to

0 ppm and the oxygen level returns to 20.9%. This may take more than an

hour depending on how saturated the sensors are.

The figures on pages 13 through 15 show locations for performing tests on

commonly encountered equipment. Remember to consult with the manufac-

turer of the device under test for specific test information.

Pressing the Func Key enables access to the different functions available on

the 717. The default function is Combustion Analyzer. Other available functions are: Thermometer, Manometer/Tightness Test, and Date / Time display.

Refer to the Appendix G “Technical Notes” for additional information.

10

www. .com

information@itm.com1.800.561.8187

Page 13

Combustion Analyzer (Default Start Up Mode)

Mini Pump

Protection Filter

Assembly

Ambient Air

Connection (T2)

GK11M Probe

Flue Probe

Connection (T1)

In-line Filter

Assembly

Flue Probe

Tubing

11

COMBUSTION TEST PROCEDURE

Note: It is recommended you perform routine general maintenance on your

analyzer to ensure proper function. Please refer to Appendix A for general

maintenance schedule and function tests.

1. Turn the 717 on in fresh air as outlined on page 8. After the initial purge

cycle the 717 will default to combustion analyzer mode and combustion display 1 will be seen.

• Combustion Display 1 (Default Start Up Display)

• Displays Oxygen (O2) reading in percent (%)

• Displays Carbon Monoxide (CO) in parts per million (ppm)

2. Connect the Mini Pump Protection Filter assembly and Flue Probe Tubing

complete with In-Line Filter to the Gas Sample Port and the 'K' Type

Thermocouple Plug from the Flue Probe into Thermocouple (T1) Socket. The

GK11M ambient air temperature probe is connected to the (T2) socket. (See

below & page 7)

WARNING: - Ensure the 'K' type thermocouple probes are inserted into the

sockets correctly (see page 7). The plugs are polarity marked and forcing the

plug into the socket the wrong way may result in damage to the

instrument.

www. .com

information@itm.com1.800.561.8187

Page 14

IMPORTANT: Prior to taking a sample, the device under test should be on and

12

at operating temperature. Putting the flue probe in the sample area prior to

starting the device may cause saturation of the sensors due to the higher

initial concentration of carbon monoxide that may be encountered upon

start up. If this happens, allow your analyzer to purge in fresh air until the

carbon monoxide level returns to 0 ppm and the oxygen level returns to

20.9%. This may take more than an hour depending on how saturated the

sensors are.

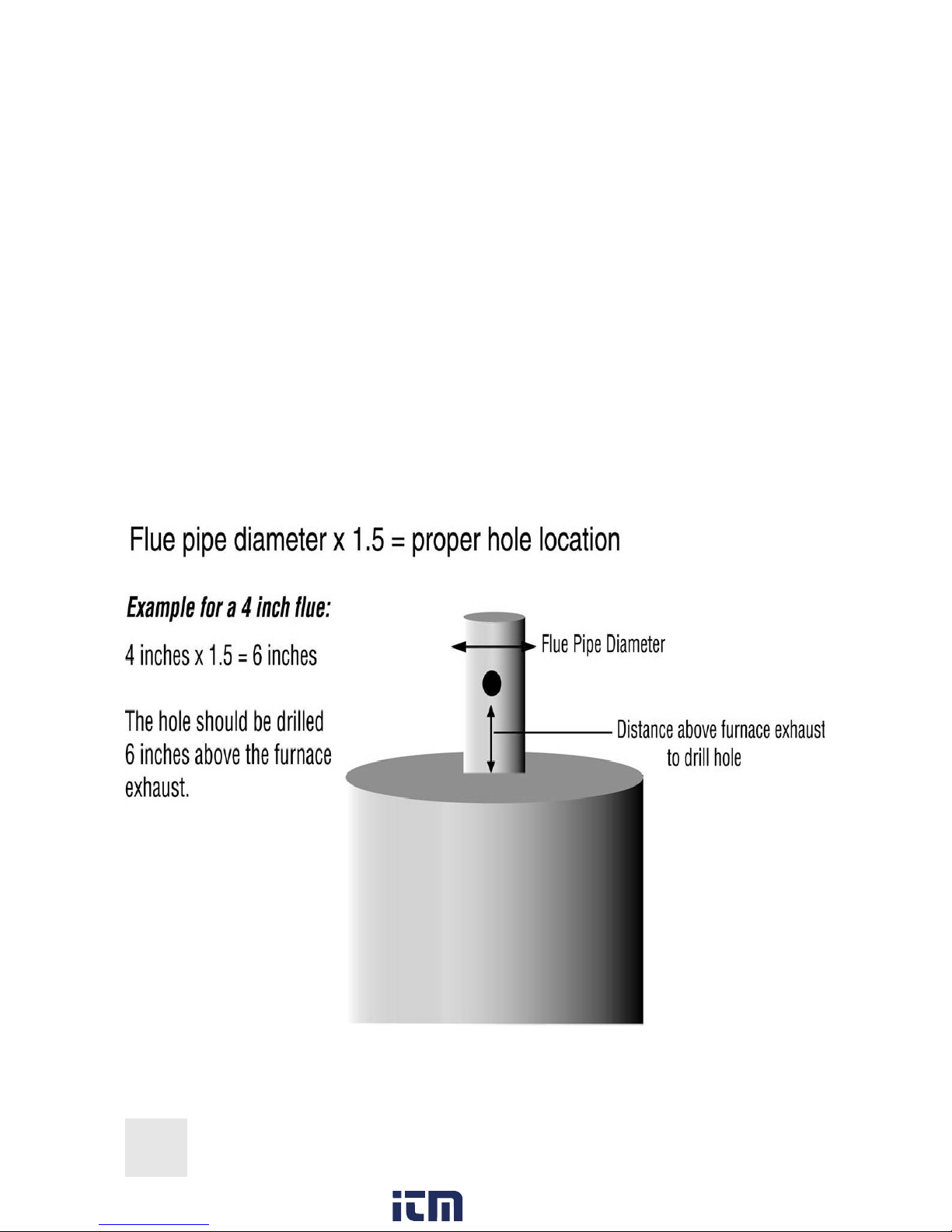

3. Drill a 1/4 inch hole into the flue of the device under test. For most applications, flue gas samples should be taken prior to the draft diverter or any

other opening that allows room air to enter the system. This prevents room

air from mixing with gases in the flue and diluting the test sample.

It is important to use manufacturers recommended test locations whenever

possible.

Refer to the figure below for calculating the sample hole location.

The figures on the following pages show typical test locations on commonly

encountered equipment.

www. .com

information@itm.com1.800.561.8187

Page 15

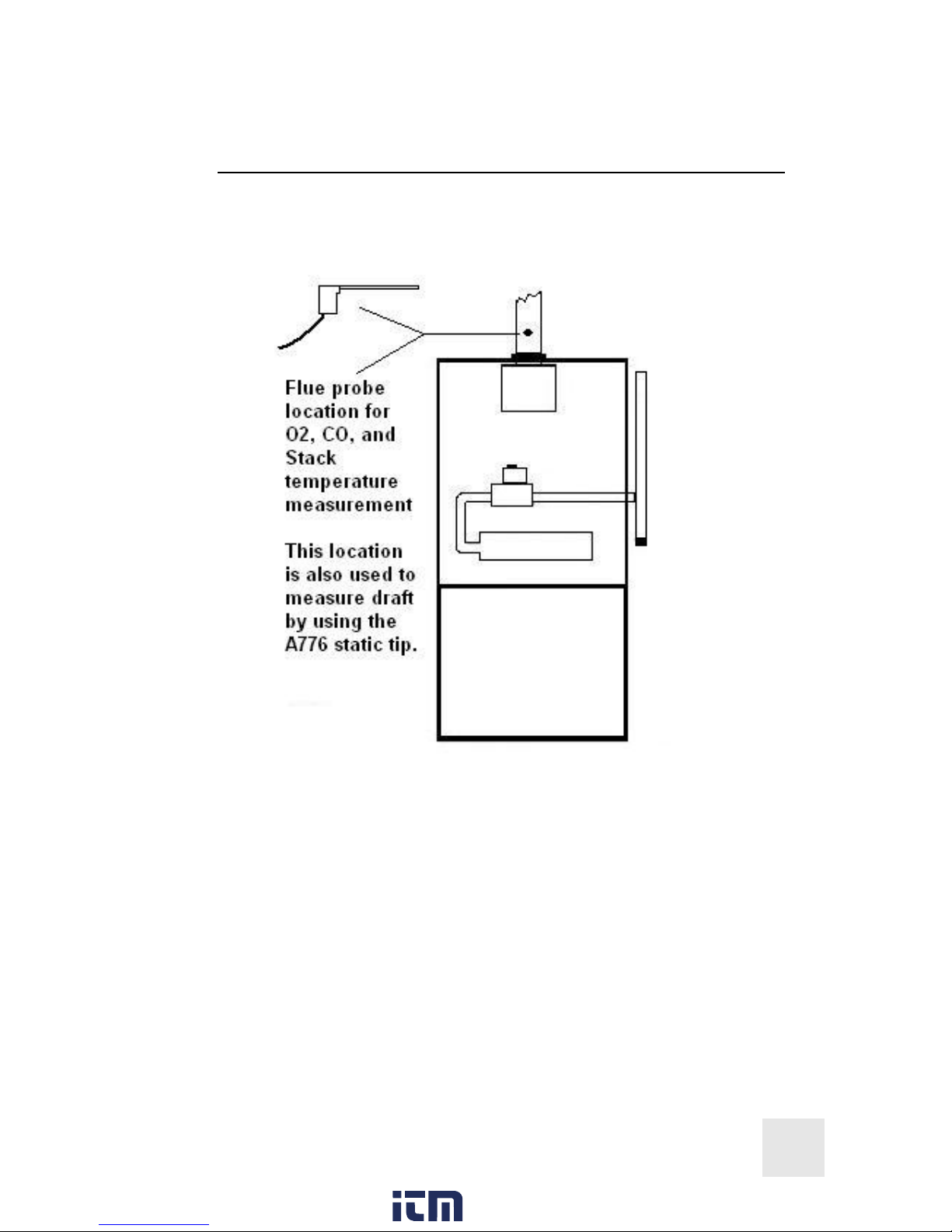

TYPICAL TEST LOCATIONS

Atmospheric Gas Fired Fan

Assist Boiler / Furnace

Typical Test Locations

Figure 1

It is important to use manufacturers recommended test locations

whenever possible.

13

www. .com

information@itm.com1.800.561.8187

Page 16

Condensing Boiler / Furnace

Typical Test Locations

Figure 2

TYPICAL TEST LOCATIONS

It is important to use manufacturers recommended test locations

whenever possible.

14

www. .com

information@itm.com1.800.561.8187

Page 17

Test all exhaust ports at the

top of the heat exchanger.

Atmospheric Forced Air Furnace

Typical Test Locations

Figure 3

TYPICAL TEST LOCATIONS

It is important to use manufacturers recommended test locations

whenever possible.

15

www. .com

information@itm.com1.800.561.8187

Page 18

4. Insert the flue probe into the sample hole of the device under test. The

16

probe tip should be in the middle of the flue pipe or exhaust stream.

Ensure the In-Line Filter / Water Trap hangs below the analyzer in the proper

vertical position when readings are being taken. Failure to comply reduces

the effectiveness of the water trap and may result in damage to the instrument. Refer to the pictures below for correct and incorrect use.

WARNING: - Should the CO reading rise above 2,000ppm a continuous series

of Alarm Beeps will be heard. The Probe should immediately be disconnected

from the instrument and the instrument returned to a clean air environment.

This Alarm alerts the user that there is a high concentration of CO, and this

procedure will protect the sensors within the instrument. The alarm level can

be changed. Please see Appendix D

Make sure to check the water trap periodically during testing to ensure it

does not fill with condensate and empty it as necessary. If the filter begins to

fill during a test, open the lid and empty out the condensate. After closing the

lid, allow readings to stabilize again.

IMPORTANT: The water trap is fitted with a water block filter (p/n A794W) in

the lid to prevent water from flowing down into the pump. If the water trap

fills the water block filter will stop the flow to the analyzer and FLO ERR will

display. The water trap should be emptied immediately if this happens. The

water block filter may need to be dried out or replaced before testing can

resume.

www. .com

information@itm.com1.800.561.8187

Page 19

5. Allow the readings to stabilize. Multiple combustion analysis displays are

17

available to provide the various test results. Use the Scroll/Enter Key to move

through the various combustion displays.

• Combustion Display 1 (Default Start Up Display)

• Displays Oxygen (O2) reading in percent (%)

• Displays Carbon Monoxide (CO) reading in parts per million

(ppm)

• Pressing the Down Arrow Key will toggle between Gross &

Net Efficiency (Note: Gross Efficiency is used in the USA.

Refer to Appendix G, Note 4 for additional information)

• Pressing the UP Arrow Key will toggle between available fuels

(see page 8)

Pressing the Scroll Enter key changes the display:

• Combustion Display 2

• Displays Oxygen (O2) reading in percentage (%)

• Displays Carbon Dioxide (CO2) calculation in percentage

(%)

• Displays calculated CO/CO2 (Ratio) figure. The 717 calculates this number by first converting the CO2 measurement

from percentage to ppm. The formula for this conversion is:

CO2ppm=(CO2%*10,000). This ratio is not used in any other

calculations. 10,000ppm = 1%

Pressing the Scroll Enter key changes the display:

• Combustion Display 3

• Displays Temperature reading on input T1

• Displays Carbon Monoxide (CO) reading in parts per million

(ppm)

• Displays Combustion Efficiency (Eff.) in percentage (%)

• Pressing the Down Arrow Key will toggle between Gross &

Net Efficiency (Note: Gross Efficiency is used in the USA.

Refer to Appendix G, Note 4 for additional information)

Pressing the Scroll Enter key changes the display: (Next Page)

www. .com

information@itm.com1.800.561.8187

Page 20

• Combustion Display 4

• Displays Oxygen (O2) reading in percent (%)

• Displays Carbon Monoxide (CO) reading in parts per million (ppm)

• Displaye Excess Air (XAir) in percentage (%)

The formula for CO air free is: COairfree = (20.9/20.9 - O2 meas.) x CO meas.

Pressing the Scroll Enter key changes the display:

• Combustion Display 5

• • Displays CO air free (-CF-)

CO air free takes into account excess air (make up air) and

factors this out of the displayed reading. Some systems inject

extra air to ensure complete combustion. This can dilute the

CO sample resulting in a low CO reading when the standard

CO display is being read.

This display should be used if the manufacturer specifications are stated

as CO air free. If it is used on a system that is not specified in CO air free

the displayed reading may appear abnormally high as compared to the

manufacturer specification.

Pressing the Scroll Enter key again will make the display return to combustion display 1 (Default display)

6. During a combustion test you can save, print, and send data to a computer. See pages 25 through 31. Allow readings to stabilize before saving or

printing the data. Refer to page 19 for typical test results.

7. Pressure measurements can be made during a combustion test if required.

Refer to page21.

8. After the test is complete, remove the flue probe from the test location and

allow the analyzer to purge in a fresh air environment with the probe

attached. Make sure the analyzer purges to below 15ppm. Never remove the

battery to turn the analyzer off before the purge is complete. Refer to page 9

for complete instructions.

18

www. .com

information@itm.com1.800.561.8187

Page 21

Typical Test Results

Actual test results vary depending on the equipment under

test. TPI recommends you check with the manufacturer of the

equipment being tested to determine specific acceptable

results.

Power Burners (Gas Fired)

Oxygen 3% to 6%

Carbon Monoxide Less than 100ppm (air free)

Stack Temperature 300

°F to 500°F

Draft -0.15 inH2O

Power Burners (Oil Fired)

Oxygen 4% to 7%

Carbon Monoxide Less than 100ppm (air free)

Stack Temperature 325

°F to 625°F

Draft -0.15 inH2O

Gas Fired Burners (Atmospheric / Fan Assist)

Oxygen 7% to 9%

Carbon Monoxide Less than 100ppm (air free)

Stack Temperature 325°F to 500°F

Draft -0.15 inH2O to -0.4 inH2O

www. .com

19

information@itm.com1.800.561.8187

Page 22

Thermometer Mode

With the analyzer running, press the Func Key to access the thermometer

function. In this mode the 717 functions like a K-Type thermocouple thermometer. The pump will stop running when in this function.

The thermometer function allows you to perform temperature tests.

1. Ensure you have a 'K' type probe connected to one or both of the thermocouple sockets T1 or T2 (refer to figure below)

Function Display 1 (Temperature)

T1 Temperature

T2 Temperature

Differential Temperature

WARNING: - There is ONLY one correct way to connect the 'K' type thermocouple plug into the socket (see page 7). Forcing the plug into the socket the

wrong way may result in damage to the instrument.

2. Touch the temperature probe to the item under test and read the displayed

temperature.

Other Features:

• Pressing the Up Arrow Key will toggle between ºC and ºF

• 'oPEn' will be displayed if no 'K' type probe is connected to the thermocouple socket

NOTE: Analyzer shown in picture above with optional second GK11M

probe. Analyzer ships with one GK11M as standard.

20

www. .com

information@itm.com1.800.561.8187

Page 23

Manometer Mode

Function 2 Display (Pressure)

Temperature reading (T1)

Pressure reading

21

With the analyzer running, press the Func Key repeatedly to access the

manometer function. In this mode the 717 functions like a differential

manometer. The pump will stop running when in this function.

The pressure function

allows you to perform draft

and pressure tests.

1. Ensure you have Pressure Sampling Tube connected to one or both of the

Pressure Ports and there are no restriction in the tubing (see figure below)

2. Zero the display by pressing the Down Arrow Key.

3. Connect the tube(s) to the device under test and read the pressure on the

display.

Other Features:

• Pressing the Up Arrow Key will scroll through mbar, kPa and inH2O

• Pressing the Down Arrow Key will Zero the Pressure reading

The 717 incorporates a differential manometer. This means when a single

hose is connected to the (+) port and pressure is applied, the 717 will read

positive pressure. If a single hose is connected to the (-) port and pressure is

applied, the 717 will read a negative pressure. If both ports are connected to

a pressure, the 717 will read the difference (P1 - P2) between the two.

www. .com

information@itm.com1.800.561.8187

Page 24

Let By Pressure Test Mode

22

With the analyzer running, press the Func Key repeatedly to access the Let By

pressure test function (Tightness test). In this mode the 717 can perform a

standing pressure test. (This feature is used predominately in the U.K.)

“Let By” will be shown at the top of the display and the

pump will stop running when in this function.

1. Ensure you have Pressure Sampling Tube connected to the (+) Pressure

Port and there are no restriction in the tubing.

2. Zero the display by pressing the Down Arrow Key.

3. Connect the tube to the device under test and press Go (Enter Key).

4. Once “GO” is pressed the analyzer will begin a 60 second countdown and

Wait will display in the lower left corner of the display.

5. After the countdown is displayed “Pass” and “Fail” will be displayed. If the

pressure bled down out of specficiation for the device under test then “Fail”

should be pressed (Down Arrow Key) and the test is over. The results can be

printed by pressing the print key or stored by pressing the save key.

6. If the device did not leak down then “Pass” is pressed (Up Arrow Key) and

the screen changes to “Stabilize”. Press Go (Enter Key).

7. Once “GO” is pressed the analyzer will begin a 60 second countdown and

Wait will display in the lower left corner of the display.

www. .com

information@itm.com1.800.561.8187

Page 25

Let By Pressure Test Mode (continued)

23

8. After the countdown is displayed “Pass” and “Fail” will be displayed. If the

pressure bled down out of specficiation for the device under test then “Fail”

should be pressed (Down Arrow Key) and the test is over. The results can be

printed by pressing the print key or stored by pressing the save key.

9. If the device did not leak down then “Pass” is pressed (Up Arrow Key) and

the screen changes to “Tightness”. Press Go (Enter Key).

10. Once “GO” is pressed the analyzer will begin a 120 second countdown

and Wait will display in the lower left corner of the display.

11. After the countdown is displayed “Pass” and “Fail” will be displayed. If

the pressure bled down out of specficiation for the device under test then

“Fail” should be pressed (Down Arrow Key) and the test is over. The results

can be printed by pressing the print key or stored by pressing the save key.

12. If the device did not leak down then “Pass” is pressed (Up Arrow Key)

and the screen changes to “Finish...”. The test results can be printed by

pressing the print key or stored by pressing the save key.

CO Room Test

In this mode the 717 will log a Carbon Monoxide reading once per minute.

This can be used to monitor CO levels in a room over a period of time.

1. With the analyzer running, press the Func Key repeatedly to access the CO

room test function.

2. Press Start (Enter Key).

3. The 717 will begin saving CO readings once per minute for up to 50 readings.

4. Press Stop (Enter Key) or wait until 50 readings have been saved.

5. Test results can be saved by pressing the Save Key or printed by

pressing the Print Key.

www. .com

information@itm.com1.800.561.8187

Page 26

SETTING DATE AND TIME

24

The 717 uses a 24 hour clock.

The first lin is the time in HH.MM format.

The second line is the date in MM.DD format.

The third line is the year.

With the analyzer running, press the Func Key repeatedly to access the

date/time screen. From this function Time, Date and Year can be changed.

If the Date and Time do not need to be changed, press the Func Key to

bypass this function and return the 712 to combustion analyzer mode

(Function 1).

1. Once the Time, Date, and Year screen is displayed, press and hold the

Print and Down Arrow Keys until “Clock Set” is displayed.

2. Use the Print Key and Recall Key to change the cursor location.

3. Use the Up Arrow and Down Arrow Keys to change the value.

4. Once the time and date has been entered press the Enter Key to store the

time and date.

www. .com

information@itm.com1.800.561.8187

Page 27

STORING DATA

During testing data can be stored for later retrieval.

When data is saved, all data previously in the address will be overwritten.When saving pressure/draft readings, select an address different from

the one used to save combustion readings.

1. Press the Store Key.

2. “Addr” and an address location from 0 to 99 will flash on the display. Use

the Up/Down Arrow Keys to select the desired location to store the data

and press the Scroll/Enter Key.

Function Key.

3. The data is stored and the analyzer returns to normal operation.

You have just successfully stored a set of readings which can be reviewed

on screen (see pg 26) or sent to the IR printer (see pg 27)

To cancel storing information press the

www. .com

25

information@itm.com1.800.561.8187

Page 28

RECALLING DATA

The recall feature allows you to display stored data or retrieve the last date of

calibration.

Recalling Saved Data or Calibration Date

Recalling Flue gas, Temperature, or Pressure data -

1. Press the Recall button once.

2. The display will show “FluE”. Use the Arrow Keys

to select the desired data to recall. (“FLue” for flue gas test

data, “tE P” for temperature data, “PrSu” for pressure data,

“CAL” for last calibration date.function.To cancel recalling infor

mation press the Function Key.

3. Press the Enter Key.

4. “Addr” will be displayed and a number from 0 to 99 will

flash. Note: If CAL was selected the calibration date will be dis

played. Proceed to step 6.

3. Using the up and down arrows, select the memory location of

the readings you want to display.

4. Press the Scroll/Enter key once. The 717 will display a page of

the data that was stored and RECALL will be displayed.

5. Use the Enter Key to scroll through the data that was saved.

6. Press the Function Key to return to normal operation.

26

www. .com

information@itm.com1.800.561.8187

Page 29

PRINTING DATA

WARNING: - To operate correctly there must be a clear line of sight between

the Infrared Window on the instrument (see 3.3) and the Infrared Window on

the IR Printer (see Printer instructions). Place the printer so it is no closer

than approximately 6 inches from the analyzer.

1. Press the Print Key once 'rEAL', “Stor’, and “Cal” will be displayed and

‘rEAL’ will be flashing. To cancel printing press the Function Key.

Selecting ‘rEAL’ will cause the 717 to prin

display (real time data). Selecting ‘Stor’ will cause the 717 to print data

stored in memory. Selecting “Cal” will cause the 717 to print the last date

of calibration. Use the Up and Down Arrow Keys to select the desired print

mode and press the Scroll/Enter Key.

REAL Print Mode - If rEAL print mode is selected, the analyzer will display ‘Wait’ ‘out’ and bars will change position on the LCD until printing is

complete.

STOR Print Mode - If Stor mode is selected, 'Addr' will be displayed on

the top line along with 'SA ' and a location number from 0 to 49 will be

flashing on the screen. Select the required address location that you wish

to print data from by pressing the Up and Down Arrow Keys and press

the ‘Scroll/Enter’ Key. The analyzer will display ‘Wait’, ‘out’ and bars will

change position on the LCD until printing is complete.

CAL Print Mode - If Cal print mode is selected, the analyzer will display

‘Wait’ ‘out’ and bars will change position on the LCD until printing is complete.

t the test data currently on the

After printing is complete, ‘End’ will be d

blink. Selecting ‘YES’ will return the 717 to normal operation, selecting

‘no’ will return the 717 to the print selection screen so you can print

again. Use the Up and Down Arrow Keys to make the selection and press

the Scroll/Enter Key.

Combustion and pressure/draft printouts must be performed separately.

Perform a combustion test and save the data. Perform a pressure/draft

test and save the data in a different address. Print each address separately.

www. .com

isplayed and ‘YES’ (or ‘no’) will

27

information@itm.com1.800.561.8187

Page 30

PRINTING DATA (Continued)

Printout Interpretation

Data from combustion

test is printed here.

Smoke Test Result.

For use on oil fired

equipment.

(Circle one to indicate

the result of a smoke

test performed using

the optional A788

smoke test pump.)

Date and time of

combustion test.

Fuel type selected

during test.

Customer information

and signed confirmation of test.

(Fill in this data and

have the customer

sign for confirmation.)

28

www. .com

information@itm.com1.800.561.8187

Page 31

SPECIFICATIONS

Instrument

Operating Temperature Range 32°F to +122°F (-10°C to +50°C)

Battery 1.5V AA size (3)

Battery Life > 6 Hours

Fuels Natural Gas, LPG, Light Oil, Heavy Oil

OPT 1 (Bituminous Coal), OPT 2

(Anthracite Coal), OPT 3 (Coke), OPT 4

(Butane), OPT 5 (Wood), OPT 6

(Bagasse)

Display Backlit LCD

Data Storage 50 sets of readings

Time & Date 24 Hour Real Time Clock

Dimensions 200mm x 90mm x 60mm

Weight 500g

Casing Rubber Boot as Standard

Switch Off Failsafe

Exhaust Safety Spigot

Conforms to BS7927 (and the draft BS7967)

Flue Temperature Probe

Construction Pistol Grip with Stainless Steel Shaft

Hose Length 2500mm

Insertion Length 200mm

'K' Type Thermocouple Accuracy +/- 0.3%, +/- 1°C

Maximum Temperature 1472°F (800°C)

Gases

Range Resolution Accuracy

Oxygen 0-25% 0.1% +/- 0.3%

Carbon Monoxide 0-10,000 ppm 1 ppm +/- 5 ppm or 5%

Whichever is greater

Carbon Dioxide 0-25% 0.1% Calculated

CO/CO2 Ratio 0-0.999 0.001 Calculated

Combustion Efficiency 0-100% 0.1% Calculated

www. .com

29

information@itm.com1.800.561.8187

Page 32

SPECIFICATIONS (Continued)

Pressure Measurement

Selectable Ranges mbar, kPa and inH2O

Range - 150 mbar to + 150 mbar

-15 kPa to + 15 kPa

-60 inH2O to 60 inH2O

Resolution 0.01 mbar, 0.001 kPa, 0.001 inH2O

Accuracy +/- 0.5% fsd

Temperature Measurement

Input Type K-Type thermocouple

Range -58°F to 1832°F (-50°C to 1000°C)*

Resolution 1°F (1°C)

Accuracy +/- (0.3% of rdg + 2°F) or +/- (0.3% of rdg +

1°C)

* The thermocouple supplied (GK11M) has the ability to measure temperatures in the -50°F to 950°F range. The 712 accepts industry standard K-type

thermocouple probes with sub-mini connectors.

30

www. .com

information@itm.com1.800.561.8187

Page 33

CALIBRATION & SERVICE

It is recommended that your analyzer be calibrated every 12 months. Please

consult Test Products International for further details or send your analyzer

to the address below for service.

TPI / Attn. Repair

9615 SW Allen Blvd. Suite 104

Beaverton, OR 97005

The following are consumable parts for the instrument:

In-Line Filter Element (pkg of 5) User Replaceable A762F

Water Block Filter User Replaceable A794W

Mini Pump Protection Filter Assem. User Replaceable A763

**Oxygen Sensor User / Factory Replaceable A761

**Carbon Monoxide Sensor User / Factory Replaceable A760

**Sensor replacement requires calibration gas.

Sensors for the 717 can be replaced in the field. Please see appendix #

for the replacement procedure.

WARRANTY

Your TPI 717 Flue Gas Analyzer is guaranteed free from defec

and workmanship for 3 Years from the date of purchase. This guarantee does

not affect your statuary rights. For additional information please refer to the

included warranty card or contact TPI at 800-368-5719.

To obtain warranty performance or maintenance on your analyzer: - Include

with the product your name, address, phone number, written description of

the problem and proof of purchase date. Carefully package and return to:

TPI / Attn. Repair

9615 SW Allen Blvd. Suite 104

Beaverton, OR 97005

ts in materials

www. .com

31

information@itm.com1.800.561.8187

Page 34

Appendix A: General Maintenance

32

All combustion analyzers use consumable items such filters and probes. These

items are user serviceable and can be taken care of by the operator.

The consumable items that will require operator attention are the water trap / filter assembly, flue probe, pump protection filter, and ambient temperature probe.

The recommended maintenance schedule for your analyzer is as follows:

Maintenance Performed

Water trap Check Once per week (Once per day for analyzers

Filter Check that see heavy use or are used in oil fired

Pump Operation Check Once per month (More often for analyzers

Flue Probe Integrity Check that see heavy use or are used in oil fired

Thermocouple Probe Check applications)

Water Trap Check

Visually check the water trap for:

1. Cracks in the bowl.

2. Broken ears on the bowl where the lid locks on.

3. Broken ears on the lid.

4. Worn out o-ring on the lid.

5. Loose connection to the flue probe tubing.

Filter Check

Signs of dirty or water saturated filters are a slow pump, flow error displayed

when the flue probe is connected, and measurements that take longer than normal.

Frequency

applications)

TPI analyzers use three filters to protect the pump and sensors. The first filter to

check is the A763 mini pump protection filter. (see picture below)

Strain Relief Spring Inspection Window

A763 Pump Protection Filter

Look in the inspection window to check the filter. When the filter material

becomes dark, pull the black nose cone out of the tubing and replace the ball filter inside.

www. .com

information@itm.com1.800.561.8187

Page 35

Appendix A: General Maintenance (continued)

Water trap bowl.

A762F

Particle Filter

A794W

Water

Block Filter

Water trap lid. O-ring is

located in the lid recess

Exploded View of A796 Water Trap

33

Filter Check Continued

The other two filters are located in the water trap (p/n A796). The main filter is

the A762F particle filter. This filter stops debris and dust from traveling down to

the analyzer. The secondary filter is the A794W water block filter. This filter

stops flow in the event the water trap fills with condensate. Refer to the picture

below.

Visually inspect the A762F particle filter. If the filter is discolored on the inside

or outside a replacement filter should be installed.

If the A762F is clean but saturated with water a replacement should be installed

to ensure proper flow. The saturated filter can be left to dry and reused later.

Pump Operation Check

1. Turn the analyzer on as outlined on page 8. Do not connect anything to the

inlet. Wait until the analyzer has completed the initial purge and sensor check

and is operating normally prior to proceeding to step 2.

2. Cover the analyzer inlet with your finger. The analyzer should display “FLO

ERR” and a rapid beeping should be heard.

If the analyzer does not beep and display “FLO ERR” this may be an indication

the flow sensor requires calibration, the pump is faulty, or there is an internal

leak. The analyzer should be returned for factory service.

www. .com

information@itm.com1.800.561.8187

Page 36

Appendix A: General Maintenance (continued)

Flue Probe Integrity Check

NOTE: Perform this check after performing the Pump Operation Check outlined

on the previous page.

1. Turn the analyzer on as outlined on page 8. Do not connect anything to the

inlet. Wait until the analyzer has completed the initial purge and sensor check

and is operating normally prior to proceeding to step 2.

2. Connect the A763 mini pump protection filter and flue probe assembly to the

inlet of the analyzer and the yellow thermocouple connector to input T1.

3. Repeatedly press the Scroll/Enter key until temperature is displayed. If the

displayed temperature is approximately the ambient temperature the thermocouple is operating properly and you may proceed to the next step to continue

the test. If the displayed temperature is “OL” the thermocouple is open and the

probe is in need of factory service.

4. Cover the end of the flue probe with a small piece of tube and pinch the end

close. After a short period of time the analyzer should display “FLO ERR” and a

rapid beeping should be heard. If this happens the flue probe his operating

properly and the integrity test is complete. If the analyzer does not display “FLO

ERR” this is an indication of a possible leak somewhere in the flue probe and

you may proceed to the next step for further tests.

5. Pinch the hose below the handle of the flue probe. If the analyzer displays

“FLO ERR” there is a leak in the handle assembly and the probe needs to be factory serviced. If the analyzer does not display “FLO ERR” proceed to the next

step for further tests.

6. Pinch the hose between the analyzer and the water trap. If “FLO ERR” still

does not display there may be an internal leak, pump problem, or other issue

and the analyzer needs to be factory serviced. If “FLO ERR” is displayed there is

a leak in the water trap assembly and the water trap assembly should be

checked as outlined on page 39 & 40.

34

www. .com

information@itm.com1.800.561.8187

Page 37

Appendix B: A773 SULFUR FILTER INSTALLATION & MAINTENANCE

35

When performing combustion tests on oil fired equipment it is important to

use the optional A773 sulfur filter. Failure to do so can result in incorrect and

readings. This filter also protects the sensors from the affects of sulfur. The

A773 does not have to be removed when working with other types of fuels.

PROCEDURE

1. Begin with the water trap section of the flue probe oriented as shown in the

picture below.

2. Remove the water trap from the flue probe hose. (See picture below)

3. Insert the A773 sulfur filter flue probe tube where the water trap was

removed..

www. .com

information@itm.com1.800.561.8187

Page 38

Appendix B: A773 SULFUR FILTER INSTALLATION & MAINTENANCE

36

4. Beginning on the “Flue Probe” side of the A773 sulfur filter, pull the yellow

thermocouple cord out of the channel of the flue probe tube. Pull out approximately the length of the water trap that was removed.

5. Being careful not to cut the yellow cord, cut out a section of the flue probe

tubing the length of the water trap on the “Flue Probe” side of the A773 sulfur filter. (See picture below)

6. Install the water trap in the flue probe hose where the piece was cut out. Make

sure the water trap is positioned correctly. The water trap lid should face the

“Hose End” side of the hose.

A773 SULFUR FILTER MAINTENANCE:

The A773 should be replaced when most of the pellets become discolored, usually white or black.

If the A773 begins to trap condensate and fill with water but the pellets are not

discolored to the point replacement is required, it should be removed and allowed

to dry. Once it is dry it can be reused.

www. .com

information@itm.com1.800.561.8187

Page 39

Appendix C: ERROR CODES & TROUBLESHOOTING

The 717 analyzer will display certain codes to let you know of a malfunction.

Code

Displayed

E01

E02

Flo

Err

Purg

Err

Code Definition Possible Causes Corrective Action

Sensor not responding

properly.

Sensor is faultiy.

Pump not drawing sample at

correct rate.

There is 15ppm or more carbon monoxide remaining in

the internal manifold.

Something wrong in sensor

circuit.

Sensor is at the end of it’s

life.

Water trap full.

Blockage in flue probe or

hose is kiniked.

Water trap particle filter saturated..

Low battery.

When switching between

functions the pump will shut

off. This can trap CO in the

internal manifold. When

returning to analyzer mode

this error will display if the

trapped CO is 15ppm or

more.

Return to TPI for service.

Replace sensors (see

Appendix D for field replacing the sensors or return

instrument to TPI for sensor

replacement.

Empty water trap.

Check for kinks and blockage in flue probe hose.

Replace particle filter in

water trap.

Replace batteries.

Allow the analyzer to run

until the error is cleared.

Lo

Low battery.

bat

oFL

oFL

oPEn

Overflow indication. The

pressure being measured is

outside the maximum measurement capability.

Overflow indication. The temperature being measured is

outside the maximum measurement capability.

Unable to read thermocouple

(temperature).

*Sensor replacement requires calibration gas.

Batteries needs to be

changed.

Pressure being measured is

too high or low.

Pressure sensor damaged or

defective.

Temperature being measured

is too high or low.

Temperature probe not connected to input.

Worn temperature sensor.

www. .com

Charge batteries. (See

Appendix J.

Remove pressure source.

Return to TPI for service.

Remove pressure source.

Connect temperature probe

to analyzer.

Replace temperature probe

or flue probe.

37

information@itm.com1.800.561.8187

Page 40

Appendix C: ERROR CODES & TROUBLESHOOTING (Continued)

Problem Possible Cause Corrective Action

Efficiency reading incorrect NET efficiency selected.

Ambient temperature probe

not plugged in to T2.

Incorrect fuel selected.

Readings are erratic when

working on oil fired equipment.

One or all of the following

parameters; Ratio, CO air

free, excess air, and efficiency read and print dashes.

A773 oil filter not installed or

installed incorrectly.

Measured values are such

that the calculated values of

these parameters are out of

range.

Select GROSS efficiency.

See page 17.

Plug ambient probe into T2.

See page 11.

Select the proper fuel for the

equipment being tested. See

page 8.

Make sure the optional oil filter (A773) is installed. See

Appendix B.

Redo combustion test. Since

these are calculated values,

the measure values must be

within certain levels for these

to display. If the measured

oxygen level is above 19.9%

these parameters won’t

read.

Analyzer won’t turn off

Oxygen and/or carbon

monoxide levels outside limits.

These parameters might not

display or be applicable in

some tests.

Allow the analyzer to purge

longer.

38

www. .com

information@itm.com1.800.561.8187

Page 41

Appendix D: Field Sensor Replacement

Sensor access

panel screw.

Battery access

screw.

The 717 uses field replaceable smart sensors. When you receive a sensor it

will come pre-calibrated. Factory calibration once per year is still important to

ensure your analyzer is functioning properly on all functions and ranges.

Contact your TPI distributor to purchase replacement sensors.

Note: You must wait 24 hours after sensor replacement before using your

analzyer.

Follow these steps to replace the sensors:

1. Remove the protective rubber boot by using your hands to pry the boot from

the bottom of the analyzer first. Once the bottom is free the boot can be

removed.

2. Locate the screw that secures the sensor access panel to the back of the analyzer. The screw is located just above the battery access screw. (see picture

below)

3. Loosen the screw and remove the access panel by lifting the end by the

screw up first.

39

www. .com

information@itm.com1.800.561.8187

Page 42

Appendix D: Field Sensor Replacement (continued)

Oxygen (O2)

sensor.

Sensor color is

white.

Carbon Monoxide

(CO) sensor

Sensor color is

red.

Hoses removed from smart sensor.

4. Once the access panel is removed you will have full access to the CO and O2

sensors. (see picture below)

5. To remove a sensor, pull the rubber hose off each side of the sensor. (see

below)

40

www. .com

information@itm.com1.800.561.8187

Page 43

Appendix D: Field Sensor Replacement (continued)

Smart Sensor

Sensor connector after removal

Flat corner of the

sensor holder.

Pins on main

board.

Flat corner on

sensor.

6. Once the hoses are off the sensor, pull the sensor straight out of the holder

(see below).

7. Install the new sensor into the holder by orienting the flat corner of the sensor with the flat corner of the sensor holder. Align the socket of the sensor

with the pins on the main board and press the sensor down onto the pins

and into the holder.

www. .com

41

information@itm.com1.800.561.8187

Page 44

Appendix D: Field Sensor Replacement (continued)

42

Hoses connected to smart sensor.

8. Connect the hoses to the sensor. (see picture below)

9. Repeat steps 5 through 8 for the remaining sensor.

10. Install the sensor back panel and re-install the analyzer into the boot.

10. Wait 24 hours prior to starting the analyzer. Make sure batteries are installed

so the sensors are under power. During this time the 717 sensor calibration

data will be transferred and the sensor will have power applied to enable it to

acclimate.

NOTE: YOU MUST WAIT 24 HOURS AFTER SENSOR INSTALLATION BEFORE

TURNING YOUR ANALYZER ON AND USING IT FOR THE FIRST TIME.

FAILURE TO DO SO WILL RESULT IN AN ERROR CODE DISPLAYED AND

THE ANALYZER WILL NOT FUNCTION PROPERLY.

NOTE: FACTORY CALIBRATION ONCE PER YEAR IS STILL RECOMMENDED TO

ENSURE PROPER OPERATION AND ACCURACY OF ALL FUNCTIONS

AND RANGES.

www. .com

information@itm.com1.800.561.8187

Page 45

Appendix E: Technical Notes

Note 1: When performing a pressure or draft test during a combustion test, the

pump can be turned on to provide a continuous sample to the sensors. This

enables pressure adjustments to be made and the affect to the combustion

process can be seen by returning to combustion analyzer mode. Use the FUNC

Key to activate manometer mode. Press and hold the Up Arrow Key until the

pump reactivates. Perform a pressure test and then use the FUNC key to activate combustion analyzer mode. Repeat this process until pressure adjustments

are complete.

Note 2: Several factors affect combustion efficiency. Dirty or clogged air filters

reduce the amount of air available for combustion therefore reducing efficiency.

Obstructions in the flue block exhaust gases and alter the air mixture in the

combustion chamber which reduces efficiency. Air leaks in the combustion

chamber also alter the mixture causing decreased efficiency.

Note 3: The primary way to affect change in combustion efficiency when working with modern gas fired equipment is through gas manifold pressure adjustment. Confirm manifold pressures are within maufacturers specifications prior

to performing a combustion test. Once manifold pressures are within limits a

combustion test can be performed to provide information regarding any adjustments that may be needed.

Note 4: Gross efficiency calculation takes into account wet losses (latent heat)

and is the unit of measure used in the USA. Net efficiency only takes into

account dry losses (latent heat is not figured in) and is used in Europe.

43

www. .com

information@itm.com1.800.561.8187

Page 46

Appendix F: Testing for Carbon Monoxide in Ambient Air

44

The 717 can be used to test for carbon monoxide in ambient air. For example

tests can be performed in work spaces and living areas like offices and houses

to ensure safety.

1. Following the steps outlined on page 8, turn the analyzer on in a clean air

environment away from the area to be tested,

2. After the purge cycle is complete combustion display 1 will be seen. This is

the default start up display and is the display to use when performing this test.

Please see below.

The middle display shows the carbon monoxide level.

For this test, ignore the top display (oxygen).

3. Connect the Mini Pump Protection filter to the analyzer. See picture below.

4. Begin testing for carbon monoxide. Move from space to space to detect any

CO that may be present. The CO reading will be seen in the top part of the display.

5. If necessary, the flue probe can be attached to test in ducts and plenums.

6. Refer to the chart on page 45 for a list of exposure times and levels of carbon

monoxide in ambient test applications

7. When testing is complete, turn the analyzer off as outlined on page 8.

www. .com

information@itm.com1.800.561.8187

Page 47

Appendix G: Carbon Monoxide in Ambient Air Chart

This chart contains maximum exposure levels and times for carbon monoxide.

This is a general guidline only. It is recommended you check with your local

government for guidelines in your area.

Concentration of

CO in the air

9ppm

35ppm

200ppm

400ppm

800ppm

Toxic Symptoms

The maximium allowable concentration for

short time exposure in a living area according

to ASHRAE.

The maximum allowable concentration for continuous exposure in an 8 hour period according to OSHA.

Maximum allowable concentration at any time

according to OSHA. Slight headache, fatigue,

dizziness and nausea after 2 to 3 hours exposure.

Frontal headaches and other symptoms intensify after 1 to 2 hours exposure. Life threatening after 3 hours. Maximum allowable limit in

flue gas according to EPA and AGA.

Headache, dizziness, nausea, and convulsions within 45 minutes of exposure.

Unconscious within 2 hours. Death within 2 to

3 hours.

1,600ppm

3,200ppm

6,400ppm

12,800ppm

Headache, dizziness, and nausea within 20

minutes of exposure. Death within 1 hour.

Headache, dizziness, and nausea within 5 to

10 minutes of exposure.

Death within 30 minutes to 1 hour.

Headache, dizziness, and nausea within 1 to 2

minutes of exposure.

Death within 10 to 30 minutes.

Death within 1 to 3 minutes.

45

www. .com

information@itm.com1.800.561.8187

Page 48

Appendix H: CARBON MONOXIDE FACTS

Carbon Monoxide (CO) is invisible, odorless, and tasteless. It is the byproduct of

combustion and levels are elevated when there is incomplete combustion.

Sources of CO include:

Unvented kerosene and gas space heaters

Leaking chimneys & furnaces

Gas water heaters

Back drafting from furnaces

Wood stoves& fireplaces

Gas Stoves

Automobile exhaust

Tobacco smoke

Carbon Monoxide is picked up quickly in the body by red blood cells. At high levels of CO the body replaces oxygen with carbon monoxide.

The most common symptoms of CO poisoning are headache, dizziness, weakness, nausea, vomiting, chest pain, and confusion. High levels of CO inhalation

can cause loss of consciousness and death. Unless suspected, CO poisoning can

be difficult to diagnose because the symptoms mimic other illnesses.

People who are sleeping or intoxicated can die from CO poisoning before ever

experiencing symptoms.

Please see the next page for a list of exposure times and symptoms.

46

www. .com

information@itm.com1.800.561.8187

Page 49

Appendix I: Battery Replacement

Battery Cover

Battery Cover Screw

47

When the battery status indicator is empty the batteries should be changed

immediately. For optimum performance replace the batteries with 3 AA size

alkaline batteries. The procedure for replacing batteries is as follows:

1. Turn the analyzer over and locate the phillips head battery cover screw. See

picture below.

2. Loosen the screw. Pull out on the screw to remove the battery cover.

3. Remove the old batteries and observing the polartiy markings in the battery

compartment, install the new batteries.

4. Re-install the battery cover by fitting the bottom part in first.

5. Tighten the battery cover screw.

www. .com

information@itm.com1.800.561.8187

Loading...

Loading...