Page 1

TPI 712BT

Flue Gas Analyser

Page 2

Page 3

Contents

1. Introduction

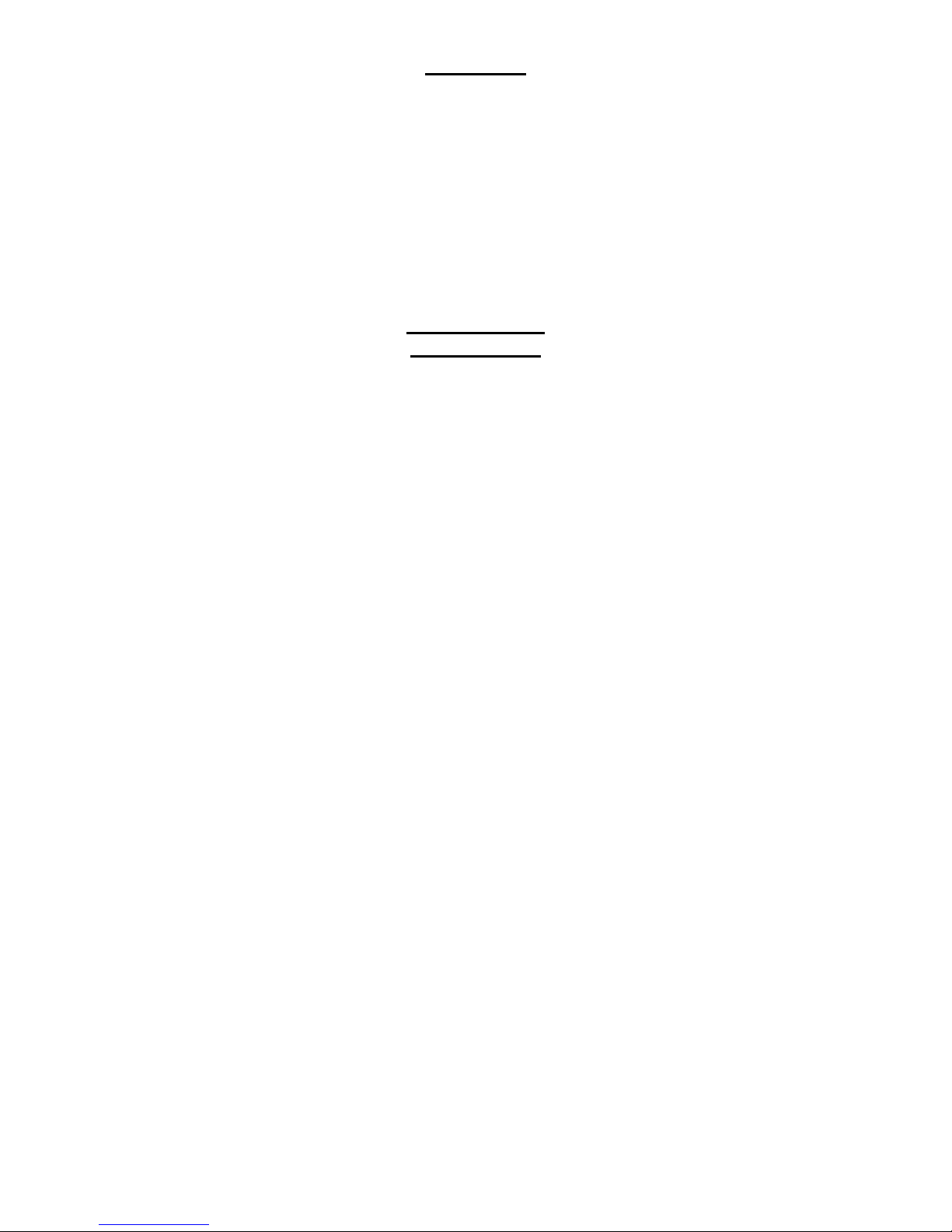

2. Instrument Overview

2.1 Front View

2.2 Back View

2.3 Side Views

2.4 Top View

3. Turning On & Off and Charging

3.1 Turning On

3.2 Turning Off

3.3 Charging

4. The 5 Functions

4.1 Function 1: - Flue Gas Analysis & CO Build Up Test

4.2 Function 2: - Temperature Reading

4.3 Function 3: - Pressure Testing & Tightness Test

4.4 Function 4: - Leak Detection

4.5 Function 5: - Date/Time

5. Saving Data

6. Reviewing Data

7. Printing Data

8. Timed Logging

9. Downloading Data to a PC

10. Turning Off & Charging

Appendix A Specifications

Appendix B Calibration & Service

Appendix C Guarantee

Appendix D Troubleshooting Guide

Appendix E Index

Page 4

1. Introduction

Thank you for purchasing TPI brand products. The TPI 712BT Flue Gas Analyser

is a state of the art, easy to use analyser designed not only to display and

calculate the required readings from a flue but also to cover most of the other

desirable parameters associated with combustion. The instrument is ruggedly

constructed and comes with a limited 3 Year Warranty

This manual will guide you through the functions of the TPI 712, which will give

you many years of reliable service. The TPI 712 software has in-built selfdiagnostics that can easily be interrogated by our fully qualified and professional

engineers should an error occur. Please call the number below before returning

your instrument to your distributor should an error occur. We can rectify over 75%

of proposed faults over the phone.

TPI HELPLINE

01293 530196

Your TPI 712BT Flue Gas Analyser comes complete with the following items as

standard: -

• TPI 712BT Instrument

• Rubber Boot

• Soft Carrying Case

• Sampling Probe (c/w Type “K” Thermocouple)

• In-Line Water Trap Bowl Filter (c/w Spare Particle Filter)

• Battery Charger

• Mini In-Line Pump Protection Filter (c/w 5 spare filters)

• Exhaust Spigot (removable)

• Pressure Tubing (2 x 1 metres)

• GK11M Air Probe

• Instruction Manual

Your TPI 712BT Flue Gas Analyser has the following options available: -

• Infrared Printer (see Appendix )

• Various Temperature Probes (see Appendix B)

Page 5

2. Instrument Overview

2.1 Front View

Rubber Boot

Protects the instrument from accidental damage

Display

Large 3 Parameter Backlit Display

Battery Indicator

Showing battery life

Selected Fuel Type

N Gas, LPG, L Oil, Heavy Oil, OPT (1~6) (See 3.1)

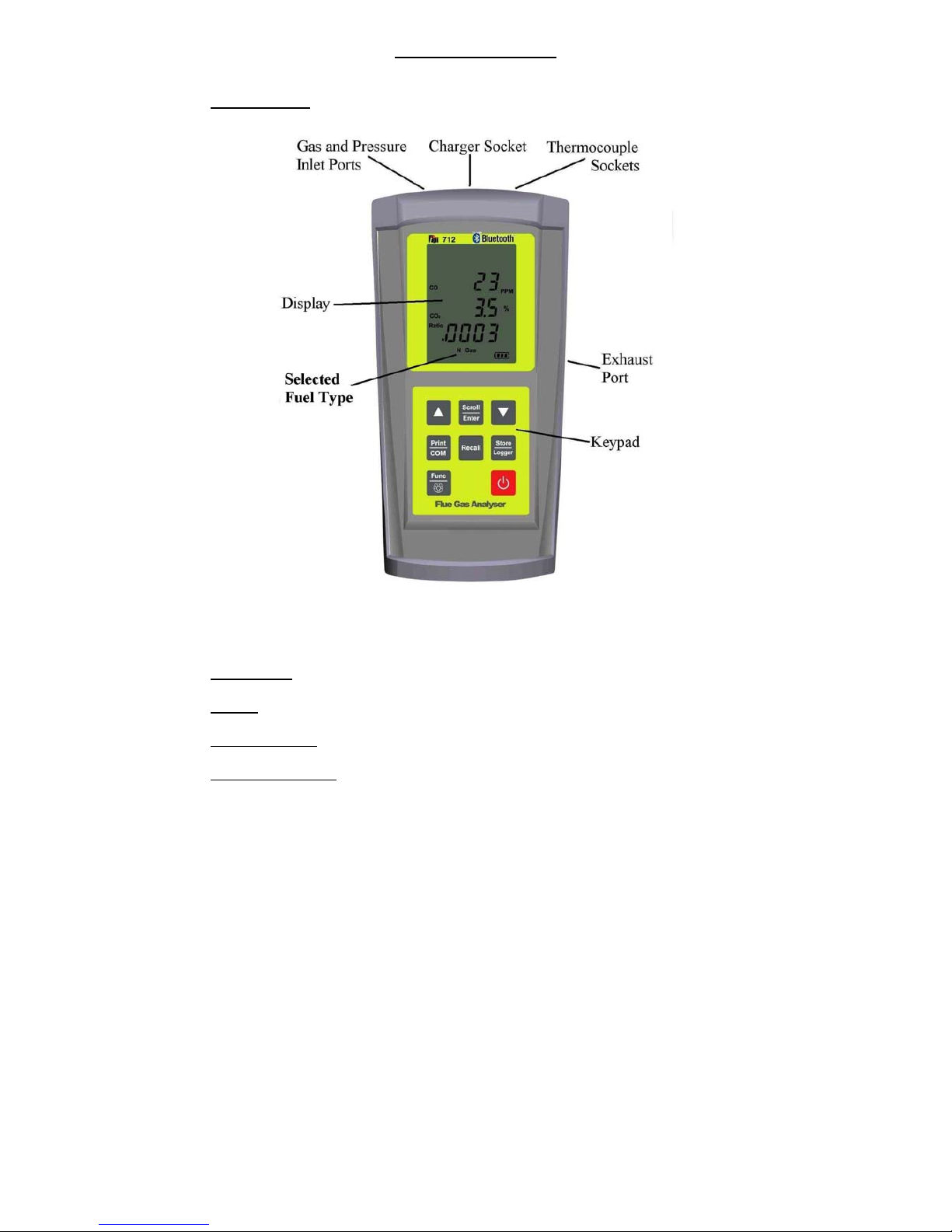

Page 6

Scrolls through selectable fuels (see 3.1 )

Switches between Gross and Nett Efficiency (see 4.1.2)

Switches between ºC and ºF (see 4.2.1)

Scrolls through mbar, kPa and inH

2

O (see 4.3.1)

Moves up through the Stored Data Addresses (see 5, 6 & 7)

Increases data logging time intervals (see 8)

Zeroes pressure reading (see 4.3.1)

Moves down through the Stored Data Addresses (see 5, 6 & 7)

Decreases data logging time intervals (see 8)

Scrolls through Flue Gas Analysis Function Screens (see 4.1)

Turns temperature differential calculation ON/OFF (see 4.2.1)

Turns ch2 temperature ON/OFF (see 4.3.1)

Allows you to change the Date and Time (see 4.5)

Allows you to choose a Stored Data Address (see 5, 6, 7, & 8)

Sends stored data to a separate infrared printer (see 7)

Sends real time, stored or logged data to a PC (see 9)

Allows you to view stored data on the display (see 6)

Stores readings to memory (see 8)

Starts and Stops data logging (see 8)

Moves you through the 5 Functions (see 4)

Turns Backlight ON and OFF (see 4)

Turns the instrument ON and OFF (see 3.1 & 3.2)

Page 7

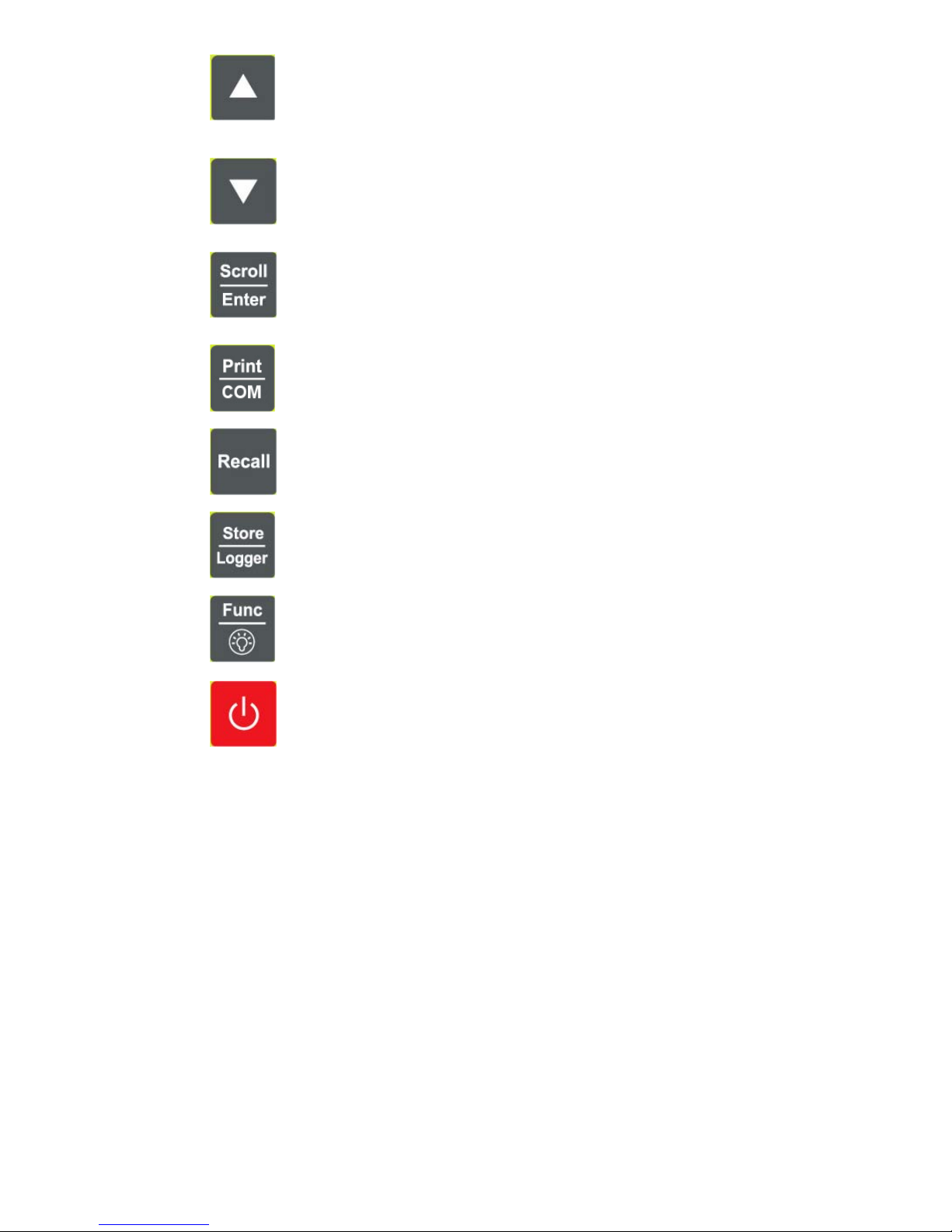

2.2 Back View

Gas and Pressure Inlet Ports

Connection for In-Line Pump Protection Filter

(see 2.4 & 4.4)

Connections for Pressure Tubing (see 2.4 & 4.3)

Calibration and Info Label

Displays calibration information

Displays serial number

Battery Compartment

Holds rechargeable battery

Rubber Boot

Protects the instrument from accidental damage

Page 8

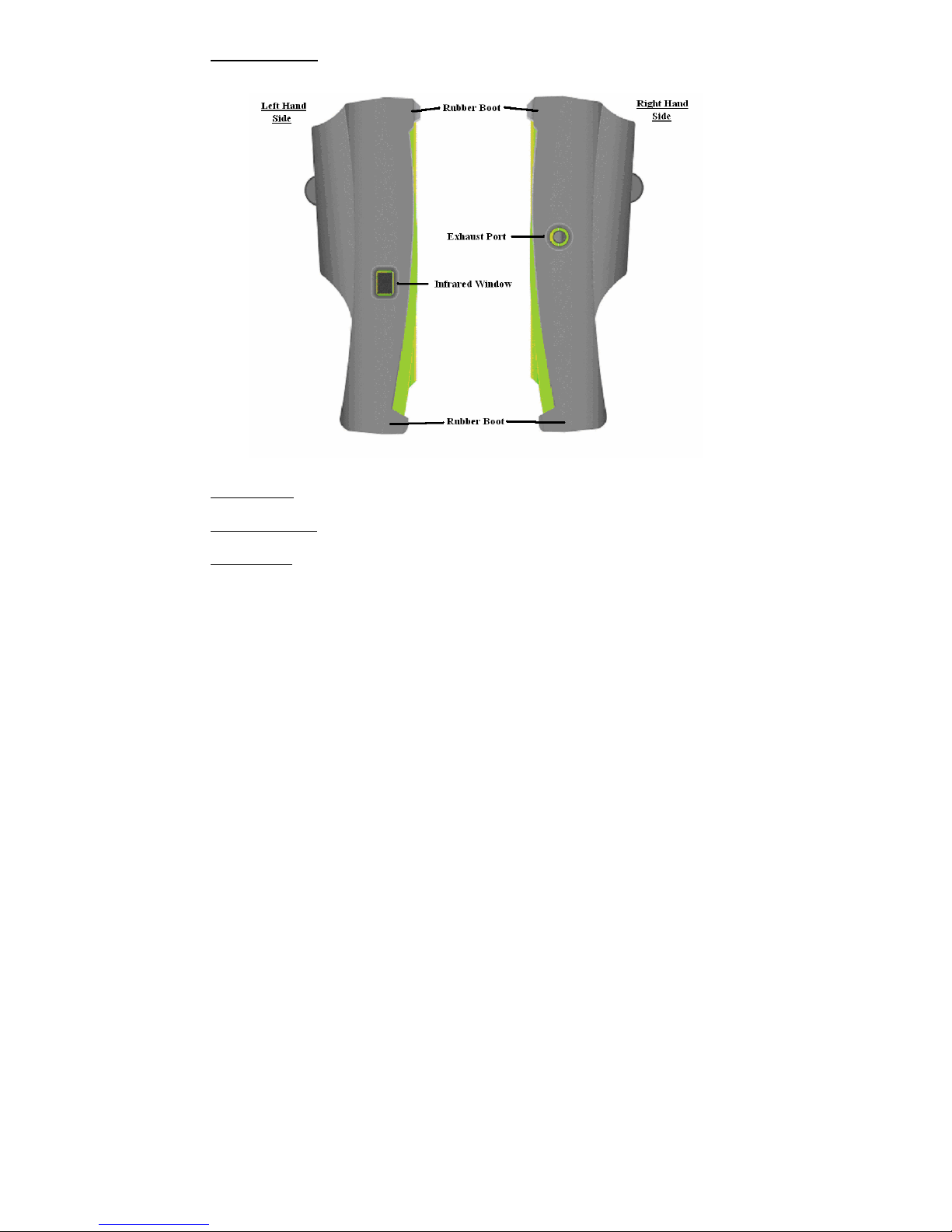

2.3 Side Views

Exhaust Port

Port for connection of Exhaust Adaptor

Infrared Window

Window for sending stored data to IR Printer (see 7)

Rubber Boot

Protects the instrument from accidental damage

Page 9

2.4 Top View

Charger Socket

Connection for 220V/115V charger (see 3.3)

Thermocouple (ch1) T1 Socket

Connection for thermocouple plug on probe

(see 4.1)

Connection for any ‘K’ type thermocouple probe

(see 4.2)

Thermocouple (ch2) T2 Socket

Connection for any ‘K’ type thermocouple probe

(see 4.2)

Gas Inlet Port

Connection for In-Line Pump Protection Filter for

(see 4.4)

Pressure (+) Port

Connections for Pressure Tubing (see 4.3)

Pressure (-) Port

Connections for Pressure Tubing (see 4.3)

Page 10

3. Turning On & Fuel Selection

3.1 Turning On

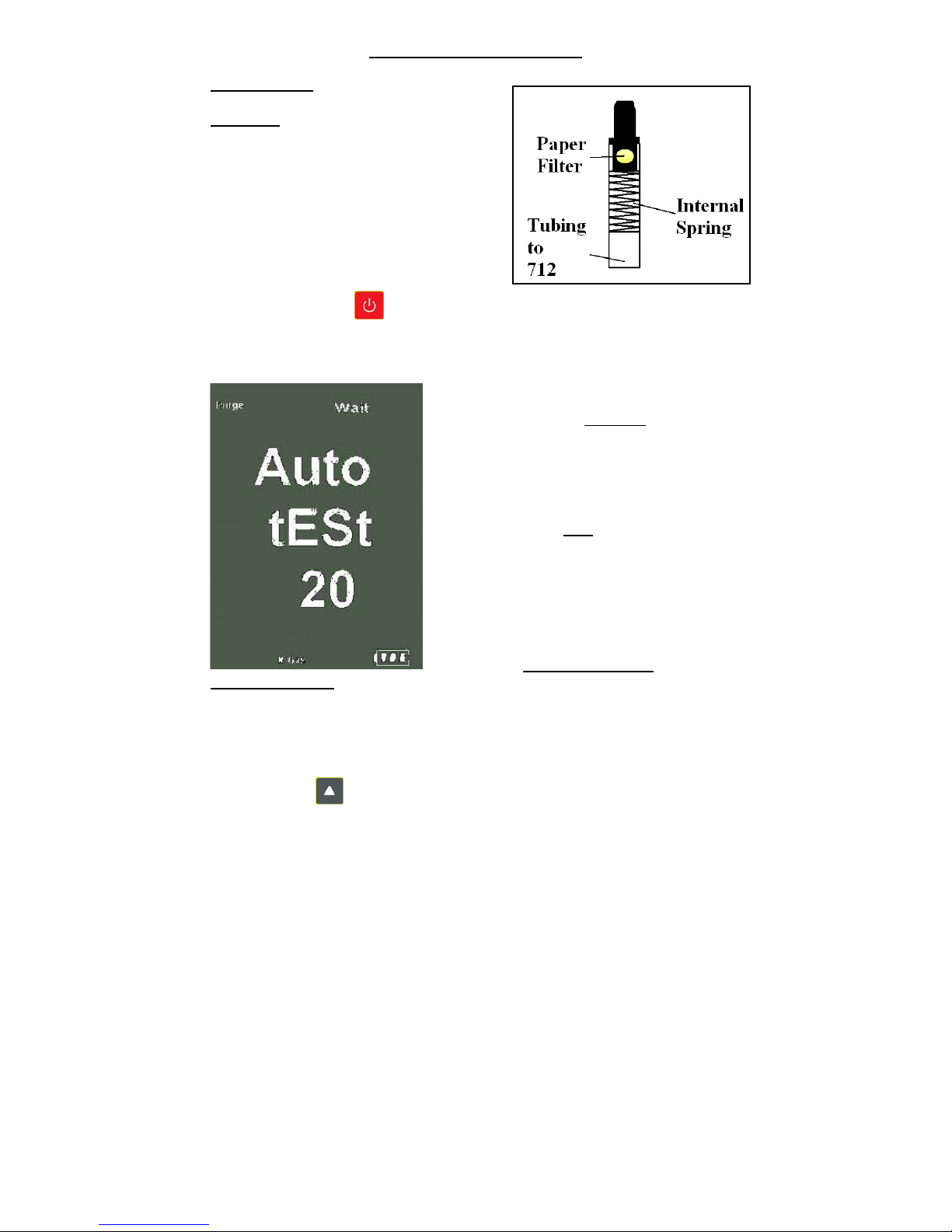

Always: - Before turning on please ensure

that the

In-Line Pump Protection Filter

(shown across) is connected to the Gas

Sample Port (see 2.2 or 2.4).

**THIS MUST REMAIN ON THE UNIT

AT ALL TIMES.**

Failure to do so may result in pump failure

and will invalidate the warranty.

Press the Power Key for approximately 2 seconds and the TPI 712 will start

up and display ALL Segments on the display for approx. 1 second. The 712 will

then enter its 30-second purge period countdown with the following screen being

displayed.

The instrument should ALWAYS be turned on

in a clean air environment as the 30 second

purge will attempt to set the Carbon Monoxide

level to 0 ppm and the Oxygen to 20.9%.

If there is insufficient clean air in the sensor

chamber after the 30 second purge period an

error indicating this may

be displayed, please

see troubleshooting guide (appendix D) for

appropriate remedy. If the error is still present

after attempting the suggested remedy please

call the

TPI HELPLINE

01293 530196

3.2 Fuel Selection

During the last 20 seconds of the 30 second purge time (i.e. as the 712 counts

down from 19 to 0) the user can scroll through the following Fuels: - Natural Gas,

LPG, Light Oil, Heavy Oil & OPT 1-6 (1=Bituminous Coal, 2=Anthracite Coal,

3=Coke, 4=Butane, 5=Wood(Dry) & 6=Bagasse) by repeatedly pressing the

Up Arrow Key to select the Fuel they are working with.

Page 11

4. THE 5 FUNCTIONS

After the 30-second countdown the instrument is ready to take Flue Gas,

Temperature, Pressure or Leak Detection readings and will Display the

following Screen.

You are now ready to take Flue Gas Analysis

Readings. Please continue on with the manual from

Section 4.1 (below) which will guide you through the

various Analysis Screens.

However, if you do not wish to perform a Flue Test at

this moment Press the Func/Backlight Key

and move onto Section 4.2 of the manual.

At any time you can activate the Backlight by holding down

the

Func/Backlight Key for 2 seconds.

4.1 Function 1: - Flue Gas Analysis

Ensure you have connected the Temperature Sampling Probe complete with

In-Line Water Trap Bowl Filter to the In-Line Pump Protection Filter (See 3.1)

which should ALWAYS be connected to the Gas Sample Port (see 2.2 or 2.4)

and that the ‘K’ Type Thermocouple Plug is in Thermocouple Socket (ch1)

(see 2.4). Also ensure that a ‘K’ Type Air Probe is connected to

Thermocouple Socket (ch2) (see 2.4) in order to calculate efficiency.

Page 12

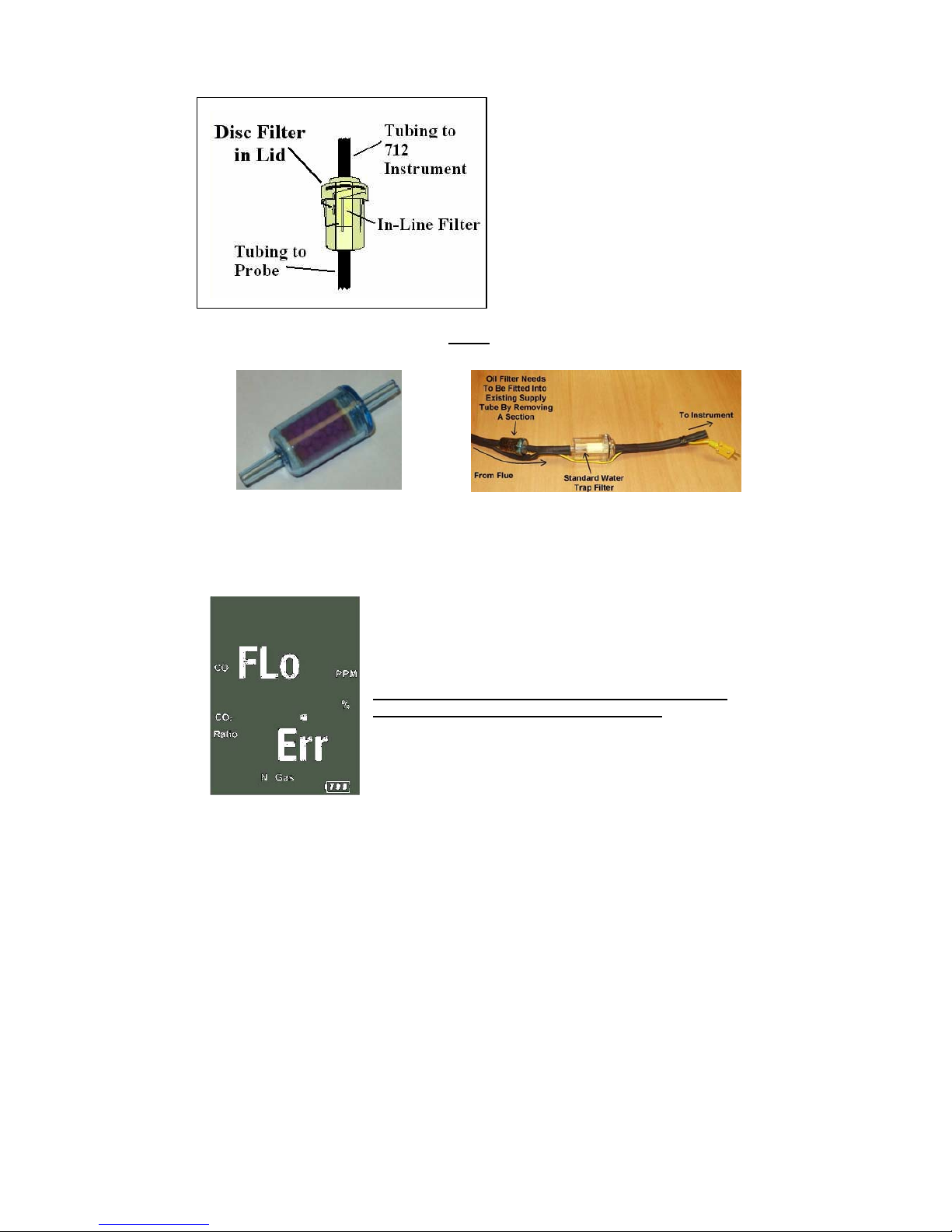

Your temperature-sampling probe comes complete with an In-Line Water Trap

Bowl Filter as standard.

This consists of a Particle Filter in the

Bowl Compartment and a Disc Filter

in the Lid (as shown in the diagram

across). The Disc Filter in Lid will

prevent any excessive water from

entering the 712 Flue Gas Analyser if

used correctly.

If you are working with OIL then you MUST

ensure that you also use the optional

Oil Filter as shown below. Failure to do so will result in erroneous readings.

If any of the filters

become excessively dirty or blocked then the

following screen will be displayed as a warning and no further

readings will be able to be taken until either the dirty filters are

replaced or the blockage removed:-

The 712 will also give off an audible Beeping Alarm

to warn that a “FLo Err” is being detected

Page 13

WARNING: - Ensure that the In-Line Water Trap Bowl Filter hangs in a vertical

position whilst readings are being taken, particularly if water is visible (see below).

Failure to comply may result in damage to the instrument and will invalidate

the warranty.

WARNING: -

There is ONLY one correct way to connect the

‘K’ type thermocouple plug into the socket (see 2.4). The

thermocouple plug is designed with one thick (negative) and

one thinner (positive) prong. Forcing the plug into the socket

the wrong way round may result in damage to the instrument.

Failure to comply may result in damage to the instrument

and will invalidate the warranty.

Pressing the Scroll/Enter Key will take you through the following Flue Gas

Analysis Screens

4.1.1 Screen 1

Displays Carbon Monoxide (CO) reading in parts per

million (ppm)

Displays calculated Carbon Dioxide (CO

2

) figure in

percentage (%)

Displays calculated CO/CO

2

(Ratio) figure

Page 14

4.1.2 HIGH CO ALARM

Should the CO reading rise above 2,000ppm a continuous series of Alarm Beeps

will be heard. If this occurs then the Probe should immediately be disconnected

from the instrument and the instrument returned to a clean air environment. This

Alarm alerts the user that there is a high concentration of CO, and this procedure

will protect the sensors within the instrument.

Failure to comply may result in damage to the instrument and will invalidate

the warranty.

4.1.3 Screen 2

Displays Oxygen (O

2

) reading in percentage (%)

Displays calculated Excess Air (X Air) figure in

percentage (%)

Displays calculated Efficiency (Eff.) figure in percentage

(%)

Pressing the Up Arrow Key will toggle between

Gross & Nett Efficiency

4.1.4 Screen 3

Displays Carbon Monoxide (CO) reading in parts per

million (ppm)

Displays Oxygen (O

2

) reading in percentage (%)

Page 15

4.1.5 CO Build Up Feature

Whilst on Screen 3 of the Combustion Screens (see 4.1.3) press and HOLD the

Store/Logger Key until the 712 beeps and the following screen is

displayed:-

“S-L9” will be flashing. Press the Scroll/Enter Key

and choose an address location by pressing the

Up & Down Arrow Keys.

When an address location (0-4) has been

chosen press the

Scroll/Enter Key to start the CO

logging session.

The 712 will return to the previous screen and “Logger” will be flashing at the top

of the display. The instrument will now log the CO level every minute for the next

30 minutes and store the results in the chosen address location.

You can end the CO logging at any point by pressing and holding down the

Store/Logger Key.

Both the Maximum and Average CO readings will be stored during this test.

These readings can then be either Printed to a compatible IR Printer (see 7) or

Downloaded to a compatible PC (see 9)

4.1.6 Screen 4

Displays CO air free calculated reading

Page 16

4.1.7 Screen 5

Displays Temperature reading of Channel 1 (ch1) in

degrees Centigrade (ºC)

Displays Temperature reading of Channel 2 (ch2) in

degrees Centigrade (ºC)

Displays the Differential Temperature (Diff.) between ch1

and ch2 in ºC

‘oPEn’ will be displayed if no ‘K’ type probe is

connected to the thermocouple socket

4.1.8 CO above 15ppm (Failsafe) Protection Beep

The 712 will not allow the user to either Turn the instrument OFF or to move to

another Function whilst the CO level is above 15ppm. A short beep will be heard

should the user attempt either of the above with the CO above 15ppm.

This is a Failsafe Feature of the 712 to protect the instrument from giving false

readings when next turned on. The 712 should be run in a clean air environment

with just the In-Line Pump Protection Filter attached until the CO level drops

below 15ppm. The 712 will then be able to be moved to a different function

screen or be turned OFF.

4.2 Function 2: - Temperature Reading

The pump will stop running when in this function

Remember:-

It was the Function Key that got you here!!!

Ensure you have a ‘K’ type probe connected to one or both of the

thermocouple sockets ch1 or ch2 (see 4.2)

Page 17

WARNING: -

There is ONLY one correct way to connect the

‘K’ type thermocouple plug into the socket (see 2.4). The

thermocouple plug is designed with one thick (negative) and one

thinner (positive) prong. Forcing the plug into the socket the

wrong way round may result in damage to the instrument.

Failure to comply may result in damage to the instrument

and will invalidate the warranty.

4.2.1 Screen 1

Displays Temperature reading of Channel 1 (ch1) in

degrees Centigrade (ºC) or degrees Fahrenheit (ºF)

Displays Temperature reading of Channel 2 (ch2) in

degrees Centigrade (ºC) or degrees Fahrenheit (ºF)

Displays the Differential Temperature (Diff.) between ch1

and ch2 in ºC or ºF

Pressing the Up Arrow Key will toggle between

ºC and ºF

‘oPEn’ will be displayed if no ‘K’ type probe is

connected to the thermocouple socket

4.3 Function 3: - Pressure Testing

The pump will stop running when in this function

Remember:-

It was the Function Key that got you here!!!

Ensure you have Pressure Sampling Tube connected to one or both of the

Pressure Ports (see 2.2 or 2.4)

Page 18

4.3.1 Screen 1

Displays Pressure reading in either millibars (mbar),

kiloPascals (kPa), or inches of Water (inH

2

O)

Pressing the Up Arrow Key will scroll through

mbar, kPa and inH

2

O

Pressing the Down Arrow Key will Zero the

Pressure reading

Pressing the Scroll/Enter Key will toggle the ch2

temperature reading ON and OFF

Pressure Resolution

The pressure resolution can be toggled between 0.01mbar & 0.1mbar by pressing

and holding down both the Up & Down Arrow Keys simultaneously.

4.3.2 Tightness Test Feature

Whilst on Screen 1 of the Pressure Screen (see 4.3.1) press the

Store/Logger Key and the following screen will be displayed:-

“Stor” will be flashing. Press the Up Arrow Key

and “tItn” will be flashing.

Choose the Tightness Test Feature

by pressing the Scroll/Enter Key.

Choose an address location (0-49) by

pressing the

Up & Down Arrow Keys.

When an address location (0-49) has

been chosen press the

Scroll/Enter Key to start the

Tightness Test.

Page 19

When the Tightness Test starts the

Live Pressure Reading is displayed on the top line,

tItn on the middle line

and the Timer on the bottom line.

Once the timer reaches 1 minute it will start to flash.

After the correct stabilisation period has elapsed press

the Scroll/Enter Key

The Start Pressure will be stored and displayed on the

middle line.

The Timer will continue to count up with the

Live Pressure Reading still being displayed on the top

line.

Once the required test period has elapsed press the

Scroll/Enter Key

The Stop Pressure Reading will be stored and

displayed on the bottom line.

The Start Pressure Reading will be displayed on the

middle line and both will be flashing.

The timer will stop with the Live Pressure Reading

being displayed on the top line.

Page 20

Press the Scroll/Enter Key and “End YES” with

“YES” flashing will be displayed.

To end the Tightness Test Feature press the

Scroll/Enter Key and you will be returned to

Screen 1 of the Pressure Screen (see 4.3.1).

However if you wish to continue and perform another

Tightness Test then press the Up Arrow Key so

that “no” is flashing and press the

Scroll/Enter Key.

The information stored during the Tightness Test Feature can be either Reviewed

on the screen (see 6), Printed to a compatible IR Printer (see 7) or Downloaded to

a compatible PC (see 9)

4.4 Function 4: - Leak Detection

The pump will start running in this function with a 25 second countdown

Remember:-

It was the Function Key that got you here!!!

Ensure you have the In-Line Pump Protection Filter connected to the Gas

Sample Port (see 2.2 or 2.4) and that the instrument is in a clean air

environment.

PLEASE ENSURE THAT THE MINI IN-LINE PUMP PROTECTION FILTER IS IN

PLACE AT ALL TIMES WHILST IN ALL

FUNCTIONS.

Page 21

4.4.1 Screen 1

During 25 second purge period “LEAK” is displayed on

the screen.

It is not uncommon for the 25 second purge period to be

repeated. This may happen to give the sensor sufficient

time to warm up before readings can be taken.

Displays and Sounds an indication to the level of

Flammable Gas detected as follows: -

Value on Screen Value of Flammable Gas Tone Sounded

0 < 100ppm No Tone

1 > 100ppm but < 1,000ppm Long Pitched Tone

2 > 1,000ppm but < 5,000ppm Medium Pitched Tone

3 > 5,000ppm Short Pitched Tone

4.5 Function 5: - Date/Time

The Time, Date and Year can be changed whilst in this function as below:-

4.5.1 Screen 1

1. Press the Scroll/Enter Key once to allow

you to change the Time, Date and Year

2. Press the Up Arrow Key to Increase the

Minutes

3. Press the Down Arrow Key to Decrease

the Minutes

4. Press the Scroll/Enter Key to confirm the

desired Minute and move onto the Hours

5. Repeat steps 2 to 4 to change the Hour, the

Day, the Month and the Year

6. The unit will return to normal after the desired

Year has been confirmed

Page 22

5. SAVING DATA

In addition to the CO Build Up Test & the Tightness Test it is also possible to save

complete combustion readings, temperature and single pressure readings as

follows:-

1. Have the 712 analyser set to the relevant screen for the readings that you

wish to save (i.e. Any of the combustion screens (see 4.1) for combustion

readings or pressure screen (see 4.3.1) for single pressure reading)

2. Press the Store/Logger Key once and ‘Stor’ will be displayed on

the screen.

3. Press the Scroll/Enter Key once. ‘Addr’ will be

displayed and a location number (0 to 49) will be

flashing on the screen.

4. Select the required address location that you wish to

save the data to by pressing the Up and

Down Arrow Keys

**Please Note:- Choosing the same Address Location on which previously

Stored Data is being held will OVERWRITE

the previous readings with the

New Stored Data. This will be the case regardless of the particular readings

you are attempting to save (i.e. should you have Combustion Readings stored

at Address 1 and you Save Temperature Readings to Address 1 then the

Previous Combustion Readings will be overwritten with the New Temperature

Readings) and the previously Stored Readings will not be retrievable.

5. Press the Scroll/Enter Key once and the readings

will be stored to the location that was chosen in step 3

and “End yES” with “yES” flashing will be displayed

6. If you do not wish to save any further readings at this

moment press the Scroll/Enter Key and you will

be returned to the screen you were originally on.

7. However if you wish to continue and save another set of readings then

press the Up Arrow Key so that “no” is flashing and press the

Scroll/Enter Key.

The information that you just stored can be either be Reviewed on the screen

(see 6), Printed to a compatible IR Printer (see 7) or Downloaded to a compatible

PC (see 9)

Page 23

6. REVIEWING DATA

1. Press the Recall Key once and the following screen will be

displayed.

‘Stor’ will be flashing on the display. If you wish to review

the Tightness Test Readings or the Last Time Calibrated

Date then press the Down Arrow Key to have ‘tItn’

or ‘CAL’ flashing rather than ‘Stor’

2. Press the Scroll/Enter Key once and if you have chosen to view

the Last Time Calibrated (CAL) then the Date that the Last Time the 712

was calibrated will be displayed flashing on the screen. (Go To Step 6)

3. However if you have chosen to view either Stored (Stor)

or Tightness Test (tItn) Readings then ‘Addr’ will be

displayed and a location number will be flashing.

Select the required address location that you wish to

review by pressing the Up and Down Arrow

Keys.

4. Press the Scroll/Enter Key once and the Time & Date of the

Saved Data from the selected address location will be displayed flashing

on the screen.

**If there is no data present at that location then ‘nULL dAtA’ will be

displayed flashing**

5. The rest of the Saved Data at this address location can be reviewed

by pressing the Up and Down Arrow Keys

6. Press the Scroll/Enter Key once and “End YES”

with “YES” flashing will be displayed. Should you not

wish to view any further stored data then press the

Scroll/Enter Key once to Exit and be returned to

the screen you were originally on.

7. However if you wish to continue and review another set

of readings then press the Up Arrow Key so that “no” is flashing.

8. Press the Scroll/Enter Key once and repeat from Step 2

Page 24

7. PRINTING DATA

WARNING: -

To operate correctly there must be a clear line of sight between the

Infrared Window on the instrument (see 2.3) and the Infrared Window on the IR

Printer (see Printer instructions)

1. Press the Print/COM Key once and the following screen will be

displayed.

‘rEAL’ will be flashing.

If you wish to Print Out previously Stored (Stor) or

Tightness Test (tItn) or CO Build Up Test (S-L9)

Readings then press the Down Arrow Key to have

‘Stor’, ‘tItn’ or ‘S-L9’ flashing rather than ‘rEAL’

2. Press the Scroll/Enter Key once and if you have chosen to print out

Real Time (rEAL) readings then the ‘Print Out’ screen (below left) will be

displayed and the Real Time (rEAL) readings will be sent to the printer.

However if you have chosen to print either

Stored (Stor) or Tightness Test (tItn) or CO

Build Up Test (S-L9) Readings then ‘Addr’

will be displayed and a location number will

be flashing.

Select the required address location that

you wish to review the saved data from

by pressing the Up and Down

Arrow Keys

3. Press the Scroll/Enter Key . The ‘Print Out’ screen (above left) is

displayed and the selected readings will be sent to the printer.

4. Once the selected data has been sent to the IR printer

“End YES” with “YES” flashing will be displayed. Should

you not wish to print any further stored data then press the

Scroll/Enter Key once to Exit and be returned to the

screen you were originally on.

5. However if you wish to continue and review another set of readings then

press the Up Arrow Key so that “no” is flashing.

6. Press the Scroll/Enter Key once and repeat.

Page 25

8. TIMED LOGGING

Press and hold down the Store/Logger Key for approximately 2 seconds

until the instrument beeps an the following screen is displayed:-

‘S-L9’ will be flashing.

Press the Down Arrow Key so that ‘Lo99’ is

flashing then press the Scroll/Enter Key and follow

the steps below:-

1. ‘S-t’ will be displayed with ’05 S’ flashing indicating that the instrument

will log a set of 100 readings every 5 seconds.

You can choose from the following logging times

‘05 S’ (100 readings every 5 seconds)

‘10 S’ (100 readings every 10 seconds)

‘20 S’ (100 readings every 20 seconds)

‘30 S’ (100 readings every 30 seconds)

‘01 M’ (100 readings every 1 minute)

‘02 M’ (100 readings every 2 minutes)

‘03 M’ (100 readings every 3 minutes)

by pressing either the Up or Down Arrow Keys

2. Once you have chosen your required logging period press

the Scroll/Enter Key once and ‘PA9E’ will be

displayed.

A page number from 0 to 3 will be flashing.

Select the required page location that you wish to log

the data to by pressing the Up or Down Arrow

Keys

3. Press the Scroll/Enter Key once and the instrument will return to

the previous screen/function with ‘Logger’ flashing on the top line.

The instrument will continue logging until all 100 sets of readings

have been saved or you press and hold down the

Store/Logger Key.

The data logged during this process can ONLY be downloaded to a compatible

PC.WARNING: -

The instrument will NOT turn off if data logging is commencing.

A beep will be heard to warn you of this fact if you try to turn the instrument off.

Page 26

.

9. Connecting to a Compatible Bluetooth Device

1. Press and hold down the Print/COM Key to instruct the 712BT to search

for other Bluetooth devices. “Comm” will be displayed solid & “Wait” will

be flashing on the 712BT LCD.

2. Initiate communication with the 712BT via the relevant means on your

Bluetooth enabled PC, Laptop, XDA etc….

3. If this is the first time you have tried to connect the 712BT to your device

then you must first pair the 2 devices. On your device you will be

prompted to enter a Pairing Pin No. (Please enter the 5 digit Serial No. on

the back of the 712BT). Once the devices have been paired then there is

no need to repeat this step in the future.

4. Upon a successful connection between the 712BT and your device the

“Wait” will disappear and the “COMM” will be flashing on the 712BT

LCD. You are now ready to download the data from the 712BT to your

device.

5. Open up an appropriate program on your device such as Hyper Terminal

on a PC etc… You may need to use the following settings:-

i. Bits per second = 9600

ii. Data Bits = 8

iii. Parity = None

iv. Stop Bits = 1

v. Flow Control = None

6. You may also need to select the relevant Com Port number that was

assigned to your Bluetooth connection.

7. Press and hold down the Recall Key for approx 2 seconds. “rEAL”,

“Stor” & “tItn” will be displayed with “rEAL” flashing. The “rEAL”

flashing indicates that Real Time Data will be sent to your Device.

8. However should you wish to send either a Stored Set of Readings,

Tightness Test, CO Build Up Test or Logged Data then press the Down &

Up Arrow Keys until the desired ‘Stor’, ‘tItn’, ‘S-L9’ or ‘Lo99’ are

flashing.

9. Once you have selected the mode of data that you wish to send to

your device press the Scroll/Enter Key once.

Page 27

10. Upon a successful transfer of data the 712BT will return to the original

screen.

11. “Comm” will remain flashing on the 712BT LCD. Should you wish to

transfer more data to your device repeat from step 7.

12. Should the connection between the 712BT and your device be lost then

go back to step 2.

Page 28

10. Turning Off & Charging

Always: -

Before turning off the TPI 712 return to a clean air environment and

allow the Carbon Monoxide level to return to below 15ppm and the Oxygen level

to return to 20.9% (± 0.3%).

Press the Power Key to turn the instrument off.

NOTE:

Should you attempt to turn the instrument Off and the CO reading is

above 15ppm then the instrument will remain On and a short Beep will be heard.

The instrument can only be switched off if the CO is below 15ppm.

The instrument has an auto shut off after 10mins should no keys have been

pressed for this period and, as mentioned above, that the CO is below 15ppm.

Should the CO be above 15ppm then the 10-minute auto shut off countdown will

not begin till the CO has gone below 15ppm.

10.1 Charging

Plug the Charger supplied into the charger socket on the instrument (see 2.4). If

the instrument is turned on then a charging symbol will be displayed. Should the

instrument then be turned off or turn off automatically with the charger plugged in

then the charging symbol will not be displayed BUT the instrument will still be

charging.

The instrument should be charged overnight for a period of 10 to 12 hours and

will give over 6 hours Operating Time.

Alternatively the instrument can be used whilst plugged into the mains

Page 29

Appendix A : SPECIFICATIONS

Instrument

Operating Temperature Range -10˚C to +50˚C

Battery Rechargeable Ni-MH

Battery Life > 6 Hours

Charger Input Voltage 115V or 230V : 50/60 Hz AC

Fuels Natural Gas, LPG, Light Oil, Heavy Oil &

OPT 1 = Bituminous Coal

OPT 2 = Anthrachite Coal

OPT 3 = Coke

OPT 4 = Butane

OPT 5 = Wood (Dry)

OPT 6 = Bagasse

Pressure Ranges mbar, kPa & inH

2

O

Display Backlit LCD

Data Storage 50 sets of readings

Data Logging 4 sets of 100 readings on Timed Interval

Logging

CO Logging 4 sets of 30 minutes of CO readings

Time & Date 24 Hour Real Time Clock

Dimensions 200mm x 90mm x 60mm

Weight 500g

Casing Rubber Boot as Standard

Switch Off Failsafe

Exhaust Safety Spigot

Conforms to BS7927 (and the draft BS7967)

Flue Temperature Probe

Construction Pistol Grip with Stainless Steel Shaft

Hose Length 2500mm

Insertion Length 200mm

‘K’ Type Thermocouple Accuracy +/- 0.3%, +/- 1˚C

Maximum Temperature 800˚C

Page 30

Gases

Range

Resolution Accuracy

Oxygen 0-25% 0.1% +/- 0.3%

Carbon Monoxide 0-10,000 ppm 1 ppm <20 ppm : +/- 3

ppm

>100 ppm : +/- 5 %

Carbon Dioxide

(calculated)

0-25% 0.1% +/- 0.3%

CO/CO

2

Ratio

(calculated)

0-0.999

Combustion Efficiency 0-100% 0.1%

Gas Leak Sensor 100-10,000

ppm

Pressure Measurement

Selectable Ranges mbar, kPa and inH

2

O

Range - 150 mbar to + 150 mbar

Resolution 0.01 mbar

Accuracy +/- 0.5% fsd

Page 31

Appendix B : CALIBRATION & SERVICE

It is recommended that the instrument be calibrated every 12 months. Please

consult your instrument supplier for further details.

The following are consumable parts for the instrument: In-Line Filter Element (pack of 10) User Replaceable Part No. A794/F

Leak Detector Mini Filter Complete User Replaceable Part No. A763

Oxygen Sensor Factory Replaceable

Carbon Monoxide Sensor Factory Replaceable

The following are accessories for the instrument: Flue Temperature Probe Standard Part No. A770

Various ‘K’ Type Probes Optional See TPI Brochure

In-Line Filter Complete Standard Part No. A794

Battery Charger Standard Part No. A766

Rubber Boot Standard Part No. A765

Infrared Printer Standard Part No. A740

Soft Carrying Case Standard Part No. A768

Exhaust Spigot Standard Part No. TBC

PC Software Optional Part No. A769

IRDA-RS232C Adaptor Optional Part No. A767

Oil Filter Complete Optional Part No. A773

Air Probe Standard Part No. GK11M

Appendix C : GUARANTEE

Your TPI 712 Flue Gas Analyser is guaranteed free from defects in materials and

workmanship for 6 Years from the date of purchase. (Subject to annual service

carried out by TPI Europe Ltd).

Covered by TPI: - Repair parts and labour; or replacement of the product at the

option of TPI. Normal transportation charges to the purchaser are also covered.

Not covered by TPI: - Damage to the product which are the result of abuse,

improper use or maintenance are not covered. Any other expenses,

consequential damages, incidental expenses including damages to property are

not covered. Transportation expenses to the customer are not covered.

To obtain warranty performance: - Include with the product your name,

address, phone number, fax number, written description of the problem and

proof of purchase date. Carefully package and return to TPI.

This guarantee does not affect your statuary rights.

Page 32

Appendix D : TROUBLESHOOTING GUIDE

Problem Probable Cause Possible Remedy

Unit does not turn on Batteries are flat Recharge batteries or run

on mains.

Unit does not turn on Dislodged battery Disconnect and Re-

connect battery

Continuous alarm

Sounds

Excessive levels of

CO are being

detected

Remove probe from flue

and run in clean air for

5/10 minutes

Negative pressure

readings on Display

Pressure tubing

connected to wrong

pressure port

Reconnect pressure tubing

to positive pressure port

rather than negative

pressure port

Negative pressure

readings on display

Either there is suction

or pressure was not

zeroed in

atmospheric air

Re-zero in atmospheric

air.

Negative temperature

readings on display

Thermocouple plug

has been plugged in

the wrong way round

Remove thermocouple

plug and plug in the

correct way round

“Flo Err” is displayed Blockage in sampling

probe or

kink/blockage in

sample tube

Check and rectify as

necessary

“Flo Err” is displayed Dirty/blocked filters Remove and replace in-

line filters

Battery life shorter

than usual

Excessive use of

backlight or leak

detector

Turn off backlight when

not needed

“InIt O2 Err” is

displayed

Instrument turned on

in contaminated air.

Turn instrument off and

then turn instrument on

again in clean air.

“InIt CO Err” is

displayed

Instrument has

turned off with Gas

Sample still present

Run instrument in clean air

until after turning the

instrument on/off the error

disappears. Depending on

the level of CO present

this may take up to 1 hr.

Page 33

Appendix E : INDEX

Subject

Section

Alarm (CO) 4.1.2

Alarm (Failsafe) 4.1.8

Auto-Shut Off 10

Backlight 4

Back View 2.2

Battery Charger 1 & 10.1

Battery Indicator 2.1

Calibration Appendix B

Charger Socket 2.4

Charging 10.1

Clock 4.5

CO 4.1.1 & Appendix A

CO Build Up Test 4.1.5

CO

2

4.1.1 & Appendix A

Data (Downloading) 9

Data (Printing) 7

Data (Reviewing) 6

Data (Saving) 5

Data (Timed Logging) 8

Dimensions Appendix A

Display 2.1 & Appendix A

Efficiency (Nett & Gross) 4.1.3

Excess Air 4.1.3

Exhaust Port 2.3

Filters Appendix B

Front View 2.1

Fuel Selection 3.2

Fuels 3.2 & Appendix B

Func/Backlight Key 2.1 & 4

Guarantee Appendix C

Infrared Printer 1, 7 & Appendix B

Infrared Window 2.3 & 7

Inlet Ports 2.2 ; 2.4 ; 3.1 ; 4.1 ; 4.3 & 4.4

In-Line Filter 1 ; 3.1 ; 4.1 & Appendix B

Leak Detection 4.4

Mini In-Line Filter 1 ; 3.1 ; 4.4 & Appendix B

O

2

4.1.2 ; 4.1.3 & Appendix A

Off 10

On 3.1

‘oPEn’ 4.1.4

Operating Temperature Appendix A

Page 34

Power Key 2.1 ; 3.1 & 3.2

Pressure Selections 4.3.1 & Appendix A

Print/COM Key 2.1 & 7

Probes 1 ; 4.1 ; 4.2 ; Appendix A & Appendix B

Pump 3.1

Purging 3.1

Ratio 4.1.1

Reading (Flue Gases) 4.1

Reading (Pressure) 4.3

Reading (Temperature) 4.2

Recall Key 2.1 & 6

Rubber Boot 1 ; 2.1 ; 2.2 ; 2.3 ; 2.4, Appendix A &

Appendix B

Scroll/Enter Key 2.1 ; 4.1 ; 4.2.1 ; 4.3.1 ; 4.5.1 ; 5 ; 6 ; 7 &

8

Service Appendix B

Side Views 2.3

Specifications Appendix A

Store/Logger Key 2.1 & 8

Temperature Selections 4.2

Thermocouple 2.4 ; 4.1 ; 4.2 ; Appendix A & Appendix B

Tightness Test 4.3.2

Top View 2.4

Troubleshooting Appendix D

Up Arrow Key 2.1 ; 3.1 ; 4.1.2 ; 4.2.1 ; 4.3.1 ; 4.5.1 ; 5 ;

6 ; 7 & 8

Warranty Appendix B

Weight Appendix

TPI Helpline

01293 530196

Page 35

Page 36

Test products International, Ltd.

9615 SW Allen Blvd.

Beaverton, OR 97005

USA

Tel: +1 503 520 9197

Fax : +1 503 520 1225

info@tpi-thevalueleader.com

www.tpi-thevalueleader.com

Test products International, Ltd.

342 Bronte St. South Unit #9

Milton, Ontario L9T 5B7

Canada

Tel: +1 905 693 8558

Fax: +1 905 693 0888

info@tpicanada.com

Test Products International Europe Ltd

Longley House, International Drive

Southgate, Crawley, W.Sussex

RH10 6AQ

England

Tel: +44 (0) 1293 561212

Fax: +44 (0) 1293 813465

contactus@tpieurope.com

www.tpieurope.com

This symbol indicates that at the end of its life this product must not be

disposed of in household waste. This equipment should be environme ntally

disposed of. Please contact your supplier or manufacturer who will be able to

advise you on the correct method of disposal

Page 37

The

Value

Leader

™

II mm pp rr oovv eedd FFee aa tt uu rr ee ss

TPI offers a

complete line

of…

Handheld

Oscilloscopes

Digital Mulimeters

Digital Clamp-On

Meters

Carbon Monoxide

Analysers

Combustion

Efficiency Analysers

Combustible Gas

Detectors

Digital Manometers

Refrigerant Leak

Detectors

Temperature

Instruments

Electrical Testers

Humidity Testers

Airflow Testers

Service &

Calibration

Accessories

TPI 712

“5-in-1” Combustion Analyser

NEW

Improved

3 Year Life

O2 Sensor

* Warranty Subject to Annual Servicing by TPI Europe Ltd.

NEW!!

3 Year O2& CO Sensors.

Longer Life O2 Sensor means only 1 major service during a 6 year period from new.

Saving time and money.

Water Trap & Disc Filter as standard on the thermocouple gas sampling probe.

Complete protection from water ingress into 709R.

In-line Pump Protection Filter as standard. Stopping dust/dirt ingress into pump (the

main cause of pump/analyser failure)

Why choose the TPI 712?

The “5-in-1” TPI 712 is the professional’s choice for flue gas analysis

and is available in a number of kit formats to meet all requirements.

The feature packed TPI 712 has all the measurments required by the

modern heating engineer to commission and service domestic &

industrial heating systems.

Features include:

z Six Year Warranty*

z Least Expensive Published Service Costs

z 10,000 ppm CO Cell for longer life and reliability

z Various Kit Options Available including IR Printer & Pipe Clamps

z Remote Diagnostics to reduce unneccesary instrument return

z CO Build Up Test Software

z Tightness Test Software

z Robust Design complete with Protective Rubber Boot as Standard

z Free Software Upgrades During Annual Service

z Conforms to BS7927 (and the draft BS7967)

z Either IRDA or Data Transfer to PC

The TPI 712 “5-in-1”

Flue Gas Analyser

Allows:

1) Combustion Analysis

Check Net/Gross Efficiency

Adjust CO,CO2& Ratio Values

Check CO2,O2Values in Flues

2) Differential Pressure

Adjust Gas/Air MIxture

Test Air Pressure Switch

Use for Tightness Testing

3) Differential Temperature

Flow & Return Adjustments

Balance Radiators

Check Thermostat & Water

Temperatures

4) CO Detection & Logging

Records Levels for BS7967

Highlights CO Spillage

Indicates areas of High CO

Production in Fires, Ovens etc..

5) Combustible Gas Detector

Check Tightness of Valve &

Pipe connections

Audible & Visual Alarms change

with concentration levels

Starts working at 30ppm

Use with

optional

A740

Printer!

Page 38

Test Products

International, Inc.

Headquarters:

9615 SW Allen Blvd.

Beaverton,

OR 97005

USA

Tel: +1 503-502-9197

Fax: +1 503-520-1225

info@tpi-thevalueleader.com

Test Products

International, Ltd.

342 Bronte St. South

Unit 9

Milton,

Ontario L9T 5B7

Canada

Tel: +1 905-693-8558

Fax: +1 905-693-0888

info@tpicanada.com

Test Products

International UK Ltd.

Longley House,

International Drive

Crawley,

West Sussex

RH10 6AQ

England

Tel: +44 1293 561212

Fax: +44 1293 813465

contactus@tpieurope.com

TECHNICAL

SPECIFICATIONS

AND

ACCESSORIES

712 Tech 14.11.06 Copyright © 2005 Test Products International Europe Ltd.

To learn about the entire line of TPI products visit:

www.tpieurope.com

Instrument Specifications

Operating Temperature Range -10° to 50°C (14° to 122°F)

Battery Rechargeable Ni-MH, >6 Hour Life

Charger Input Voltage 115V or 230V : 50/60 Hz AC

Fuels Natural Gas, LPG, Light Oil, Heavy Oil

OPT 1 = Bituminous Coal

OPT 2 = Anthrachite Coal

OPT 3 = Coke

OPT 4 = Butane

OPT 5 = Wood (Dry)

OPT 6 = Bagasse

Display Backlit LCD

Data Storage 50 sets of readings

Data Logging 400 sets of readings on

‘Timed Interval Logging’

Time & Date 24 Hour Real Time Clock

Dimensions 200mm x 90mm x 60mm

Weight 500g

Exhaust Safety Spigot

Conforms To: BS7927 (and the draft BS7967)

Standard Accessories

Flue Temperature Probe A770

‘K’-Type Temperature Air Probe GK11M

In-Line Water Trap Bowl Filter Complete A794

Mini Pump Protection Filter Assembly A763

Battery Charger A766

Protective Boot A765

Soft Carrying Case A768

Exhaust Spigot A764

Temperature Measurement

Range -40° to 800° C (-40° to 1472° F)

Resolution 1°C or F

Accuracy (K-type) ±0.3%, ±1°C or ±2°F

Draft/Pressure Measurement

Selectable Ranges mBar,kPa, and inH2O

Ranges -150 mBar to +150 mBar

-15 kPa to +15 kPa

-60 inH2O to +60 in H20

Resolution 0.01mBar

Accuracy ±0/5% fsd

Gross/Net Efficiency

Range 0 to 100%

Resolution 0.1%

Oxygen (02) Measurement

Range 0 to 25%

Resolution 0.1%

Accuracy ±0.3%

Carbon Monoxide (CO) Measurement

Range 0 to 10,000 ppm

Resolution 1 ppm

Accuracy ±5 ppm or 5%, whichever is greater

Carbon Dioxide (CO2)

Range 0 to 25%

Resolution 0.1%

Accuracy Calculated

Ratio (CO/CO2)

Range 0 to 0.999

Resolution 0.001

Accuracy Calculated

TPI 712

“5-in-1” Combustion Analyser

Optional Accessories:-

A773 - Oil Filter

A788 - Smoke Test Pump

CK21M - Temperature Pipe Clamps

A767 - IRDA to RS232 Adaptor for PC

A772 - PC Software

A746 - 10 Spare Paper Rolls for IR Printer

Plus Various ‘K’ Type Thermocouple Probe

A740

Infra Red Printer

NOTE:

When selecting

OIL as a fuel be

sure to use the

optional (A773)

oil filter or

readings could

become erratic

Loading...

Loading...