Page 1

CABINET UNIT HEATER

6300/T Series

WARNING

S PRODUCT BEFORE READING ALL

PERSONAL

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 EC0 NO. 1-4635 P/N 00009979 SHT. 01 OF 09

REFER TO MOUNTING CLEARANCES ON PAGE 3.

Electric Cabinet Unit Heaters provide quiet, controlled heat

entrifugal blowers and a variety of air inlet

The cabinet is styled for use in offices, stores, schools,

churches, dormitories, airport terminals, reception rooms,

entrance lobbies, corridors and stairwells. They are easily

on textured

finish which blends with almost any location. Cabinet unit

recessed or

lo fan and heat

operation, dust filter, single/three phase field convertible,

in thermostat and field

convertible for remote thermostat control.

Housing……………………………..Constructed with durable 16ga. steel

Read all instructions before using this heater.

Follow all local and electrical codes, the National Electric

code (NEC) and the Occupational Safety and Health Act

Before attempting any electrical connections or

inspections for any reason to service the heater, make

er controlling the circuit to which

the heater is to be connected has been thrown to the OFF

position, or make sure the fuse for the circuit has been

removed. The circuit panel door, or fuse box door, should

cation of

The heater must be grounded in accordance with

applicable codes to the ground screw provided in the

cable from kinks, sharp objects,

5. Do not install heater behind room or cabinet doors or in a

position where the air discharge or intake louvers can be

blocked in any manner. Do not install behind towel racks,

Check heater voltage on data plate and make sure that it is

he wall/ceiling mounting structure and anchoring

provisions must be of sufficient strength to support the

vicing of this heater should be done by a

Do not locate this heater in an area where combustible

Cabinet Unit Heaters come completely assembled. No

STANDARD AND CUSTO M

! DO NOT ATTEMPT TO INSTALL, OPERATE, OR SERVICE THI

INSTRUCTIONS CAREFULLY. FAILURE TO C OMPLY WITH THESE INSTRUCTIONS COULD RESULT IN FIRE,

INJURY AND/OR PROPERTY DAMAGE! RETAIN INSTRUCTIONS F OR FUTURE REFERENCE.

DESCRIPTION

distribution by c

and discharge arrangements.

installed in new or existing buildings.

These heaters are painted with a beige, baked-

heaters are designed for recessed, semisurface mounting on walls, or ceilings.

Standard models feature a fan switch, hi-

24 volt control circuit, built-

ASSEMBLY

assembly is required.

IMPORTANT SAFETY INFORMATION

1.

(OSHA).

2.

sure that the circuit break

be locked or tagged to prevent unexpected appli

power. Failure to do so could result in electrical shock.

3.

housing. Failure to ground may result in electrical shock.

4. Protect the power supply

oil, grease, hot surfaces and chemicals.

REQUIRED CLEARANCE

SPECIFICATIONS

Housing finish………………...………..Baked-on textured beige enamel

Wiring diagram…………..……Loca ted ins ide cen ter fr ont acce ss panel

Dimensions- Standard Models

W33”, H25”, D9-1/2” – 99lbs…………………………..………5KW Heater

W46”, H25”, D9-1/2” – 130lbs……………………...………..10KW Heater

Dimensions- Custom Models

W33”, H25”, D9-1/2” – 99lbs…………………….…….2 thru 6KW Heater

W46”, H25”, D9-1/2” – 130lbs…..………….…….….4 thru 12KW Heater

W66”, H25”, D9-1/2” – 215lbs…..………….…….….6 thru 18KW Heater

W79”, H25”, D9-1/2” – 248lbs…..………….…….….8 thru 24KW Heater

furniture, drapes or coat racks

6.

the same as the electrical supply.

7. T

weight of the heater.

8. All wiring and ser

qualified electrician.

9.

vapors, gases, liquids, or excessive lint or dust is present.

SAVE THESE INSTRUCTIONS

Page 2

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 ECO NO. 1-4635 P/N 00009979 SHT. 02 OF 09

Safe and dependable operation of the heater depends on

The heater can be mounted in any of the positions shown

in Mounting Configurations, observing proper clearances

and outlets as shown in Mounting

Configurations. In all positions, clearance from the end of

Inlet grille and outlet grilles can easily be field altered. In

essed

Mounting holes are provided in the back of the cabinet,

accessible through the blower compartment, for securing

the heater to the wall. In some cases, it may be necessary

of bolts

are desired. The blower deck may be slipped forward by

loosening two screws at the front to provide access to

NOTE: For ceiling mounted heaters, never use internal

lied external

INSTALLATION

Controls are accessible through the discharge grille, using

a screwdriver. The rocker switch for heat can be adjusted

for high or low, and the rocker for the summer fan (if

ntinuous fan” for

continuous room air circulation. Adjust the thermostat and

let the heater operate a few hours. If more or less heat is

then desired, adjust accordingly. If a remote thermostat is

trol

terminal block. Attach wires from the remote field supplied

thermostat. Adjust the heat/fan rocker switch to either high

phase and 600

desired,

replace factory installed jumper wire on the control terminal

Refer to page 7 for description of control options.

1. Defective thermostat

1. Replace thermos tat

WARNING: Disconnect heater from power supply before servicing

and/or inspecting the heat source. Failure to do so may result in

Periodically check the condition of the filter.

The filter can be removed by opening the front access panel with a

screwdriver. Lift the filter up and out. (Contact Fostoria Industries

lacement filters. Please provide the

model number of the heater and whether the filter is disposable or

*

1/2” – 3/4” Conduit

1/2” – 3/4” Conduit

Mounting

2-3/4”

3-3/8”

knockouts

6-7/8”

MAINTENANCE

proper installation by qualified per sonnel.

electrical shock.

1. Fan and motor are permanently lubricated. No oiling is necessary.

form the inlet

2. Make sure all wire connections are tight.

3. Be sure to keep the blower wheel tight on the motor shaft.

the heater to a side wall is zero inches.

4. For optional filters—

no case can inlet and outlet grilles be partially rec

or your local distributor for rep

into the walls or ceilings.

permanent).

to remove the blower deck if more mounting screws

TROUBLESHOOTING CHART

mounting holes located behind the blowers.

thermostat. Always use a field supp

thermostat.

OPERATING INSTRUCTIONS

supplied) can be set for automatic or “co

desired, remove factory installed jumper wire on the con

or low.

Cabinet Size Nominal Low CF Nominal High CFM

33” 230 250

46” 460 500

66” 690 750

79” 920 1000

The 480 volt, 3-phase, 3-wire; 600 volt 1-

volt 3-phase units are all single speed only.

If external load management control of the unit is

block with leads from the external management control.

1/4" Dia Mounting Holes

4"4"

12"/24"

7/8", 1-3/32"

1-23/64", 1-23/32

7/8",1-3/32"

11-11/16"

4-1/16"

Dimensions

25"

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Heater does not

energize

No power to

heater

Not enough

heat

2. Defective Hi/Lo switch

3. Defective transformer

4. Defective li near limit

5. Tripped manual limit(s)

1. Defective fuse or

breaker

1. Element may be

Defective.

2. Defective contactor

3. Defective Hi/Lo

switch

4. Air filter may be

dirty

5. Defective fan motor

6. Defective fan ti m e

delay relay.

1” – 1-1/4” Conduit

2-3/8”

2. Replace Hi/Lo sw itch

3. Replace transformer

4. Replace linear l imit

5. Determine cause

before resetting*

1. Check fuse/circuit

breaker

1. Replace defective

2. Replace contactor

3. Replace Hi/Lo

4. Replace/clean filter

5. Replace fan motor

6. Replace fan time

If unit is installed in/on ceiling,

check for temperature stratification

Knockout only on back

element(s)

switch

delay relay

9”

25”

3”

1-9/16”

Page 3

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 ECO NO. 1-4635 P/N 00009979 SHT. 03 OF 09

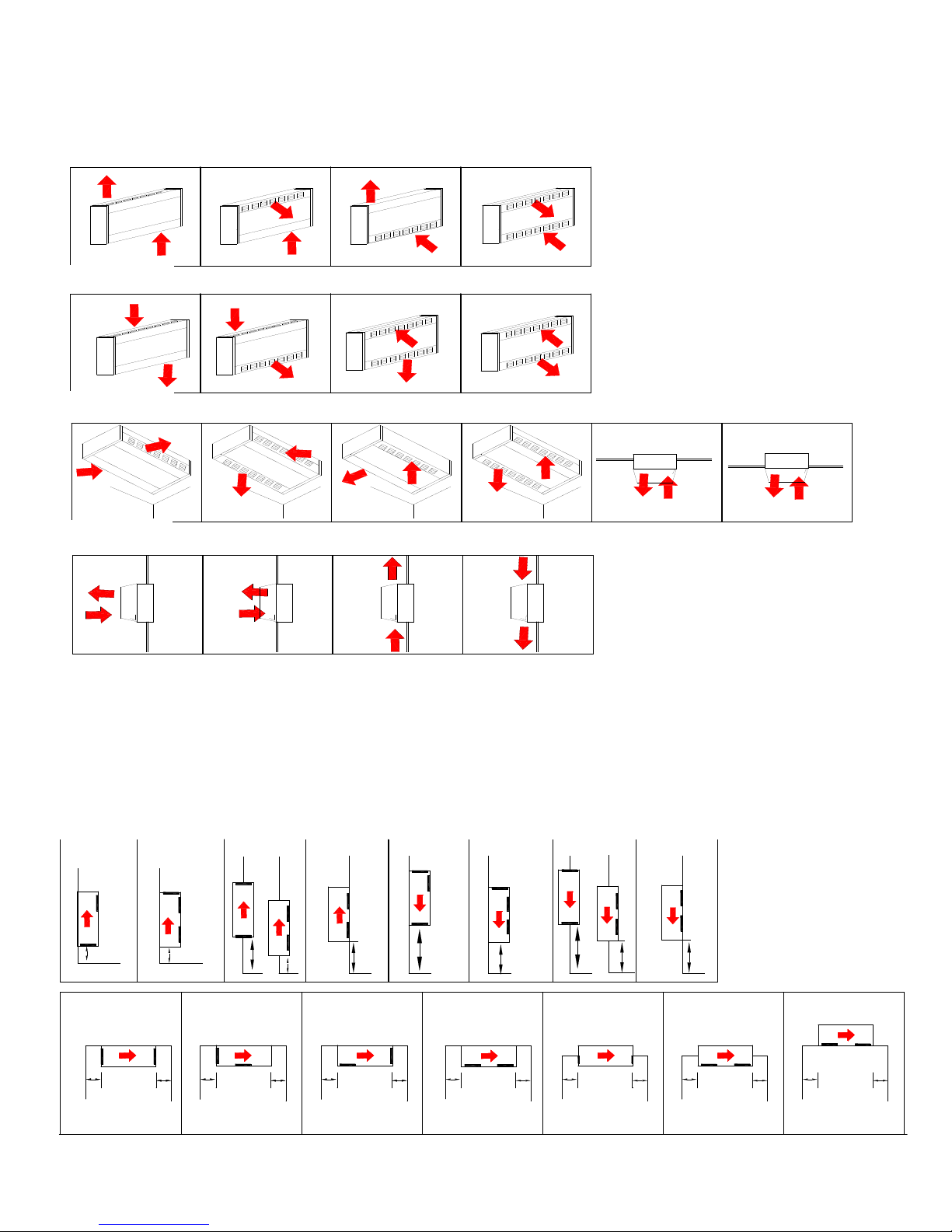

MOUNTING CONFIGURATIONS

All Angle Heater Series offers a selection of air inlet and discharge arrangements.

Inlet and outlet grille arrangements are easily altered by opening front panel of unit

Heaters Cannot be

NOTE: Semi reces sed to be recessed

MOUNTING CLEARANCES

Mounting holes are provided in the back of the cabinet, accessible through the blower

UP FLOW

DOWN FLOW

Unit may be mounted upside down to

A

B

W

C

D

Y

A

D

W

Y

D

Y

A

C

Z

B

D

X

A

Z

X

D

D

X

A

W

V

W

B

V

C

Y V

Y

V

D

W

A

V

D

Y

V

D

Y

V

A

B C D

A

B

C

D

A

B

C

D

D

D

D

D

A

A

UP FLOW

WALL

CEILING

DOWN FLOW

and removing (2) screws.

mounted on the

END!

reverse direction of air flow.

3 ½ “ maximum unless both

inlet and outlet grilles are to the

front.

SEMI RECESSED

FULLY RECESSED SEMI RECESSED SEMI RECESSED

Proper clearances are indicated for each mounting configuration. In all positions,

clearance from end of heater to a side wall is zero inches.

compartment. If necessary, remove blower deck if additional mounting screws or

bolts are desired. Blower deck may be slipped forward by loosening four screws at

the front to provide access to mounting holes.

KEY

W 6” minimum

X 12”minimum

Y 0 or greater

Z 24”minimum

V 48”minimum

Page 4

CAUTION

ll amp load

This heater must be grounded before operating, as required by the National Electric Code and by applicable local

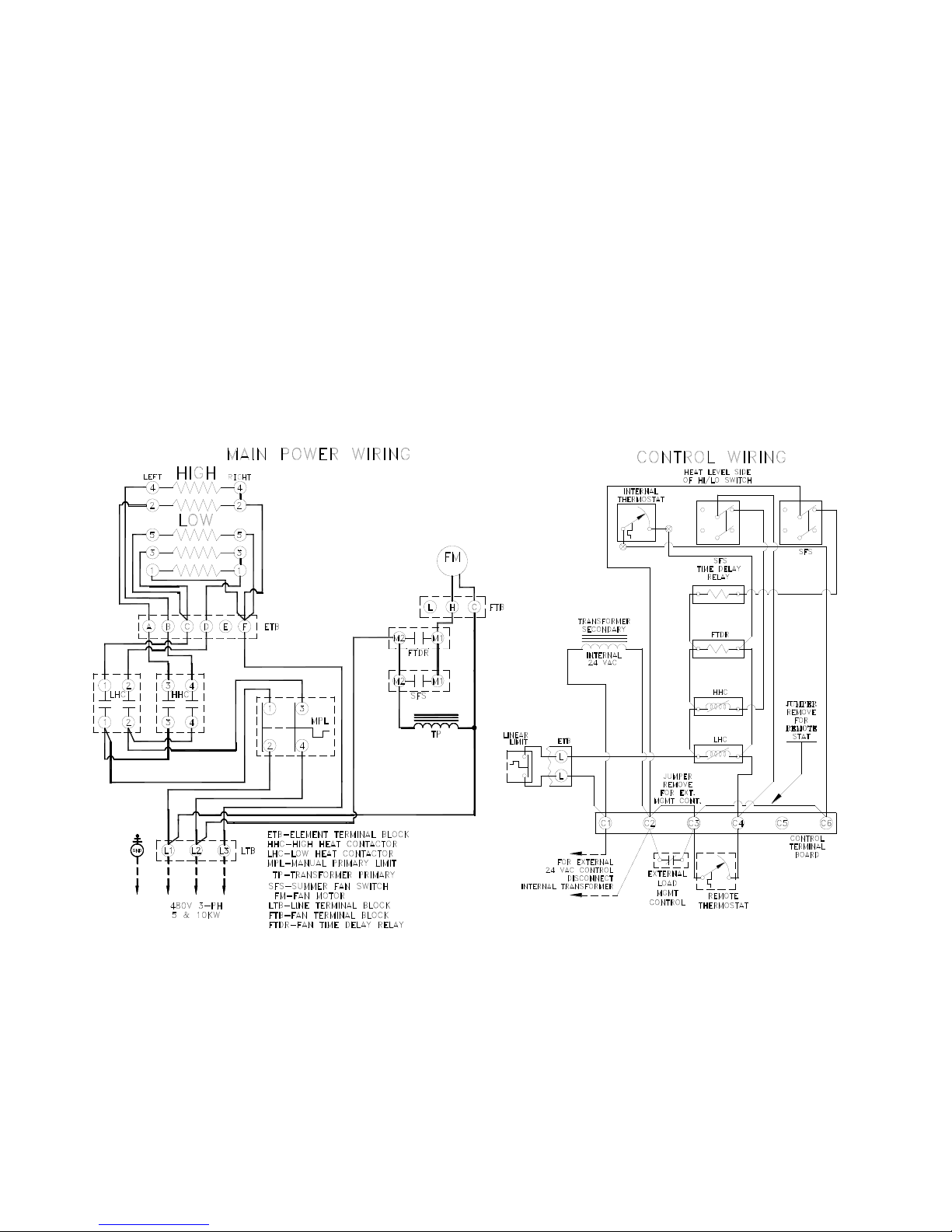

Typical Wiring

For actual wiring of your unit(s) refer to

The NEC requires that over current protection and supply wire for electric heating equipment be rated at least 125% of the fu

of the circuit. A field supplied disconnect switch should be used to control the input voltage to the unit.

All supply wiring shall conform to the latest edition of the NEC and to all local codes having jurisdiction. Conduit knockouts are

provided in the back of the wiring compartment. Make sure all field wiring connections are properly made and are tight.

Electrical Ground---

codes. Use a conductor, of the appropriate size, secured to the ground lug in the heater and to a grounded connection in the service

panel.

the diagram located inside the front

access panel.

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 EC0 NO. 1-4635 P/N 00009979 SHT. 04 OF 09

Page 5

PARTS VIEW AND PARTS LIST ..Directional Air Heater Final Assembly

Unit

Length

1

3

4

7

4

1

2

3

5

4

5 & 6

3

2

1

1

*Field adjustable for various configurations

**See page 6 for individual parts

Switch av ai lable on all units except 480V, 3-phase,

Item Part No. Description Qty

33”

46”

66”

79”

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

**

**

52293001

62273001

58337001

**

**

52293002

62273002

58337002

**

**

**

**

52293001

52293002

62273003

58337003

**

**

52293002

62273004

Heat deck assbly-SNG

Blower deck assembly-SNG

Disposable filter-SNG

Intake/discharge grille*

Front Panel

Heat deck assbly-DBL

Blower deck assembly-DBL

Disposable filter-DBL

Intake/discharge grille*

Front Panel

Heat deck assbly-SNG

Heat deck assbly-DBL

Blower deck assembly-SNG

Blower deck assembly-DBL

Disposable filter-SNG

Disposable filter-DBL

Intake/discharge grille*

Front Panel

Heat deck assbly-DBL

Blower deck assembly-DBL

Disposable filter-DBL

Intake/discharge grille*

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

2

1

2

2

2

2

High/Low

Thermostat

Summer Fan

(optional)

Fan Relay

2

ΠΠΠContactor

Contractor

3-wire and 600V, 3-phase and single phase units.

Required for optional summer fan in 480V, 3-

phase, 3-wire, and 600V, 3-phase and single units.

For 415/240 and 480/277 ST Option Contact

Factory for part number.

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 ECO NO. 1-4635 P/N 00009979 SHT. 05 OF 09

4” Π

Summer Fan

(optional)

Fuse/Holder

Transformer

Voltage Item

208-3/1

240-3/1

&415-3

277-1&

480-3

4-wire

480-1&

480-3

3-wire

600-3/1

All

2

1

2Π

3

1

2

3

1

2

3

1

2

3

4

5

6

7

Π Excludes 208/240V 3-phase 66” and 79” units, 18 and 24 KW.

Consult factory. See page 7 for description of control options

Control Options

B1/B8 B2/B7 B3/B5 B4/B6

51135001

58027001

60719037

51135001

58027001

60719037

51135001

58027001

60719011

51135001

58027001

60719012

51135001

58027001

60719040

42438001

Optional

Optional

51135006

58027006

N/R

51135006

58027002

N/R

51135006

58027002

N/R

51135006

58027002

N/R

51135006

58027002

N/R

42438001

Optional

Optional

51135001

58027001

N/R

51135001

58027001

N/R

51135001

58027001

N/R

51135001

58027001

N/R

51135001

58027001

N/R

42438001

Optional

Optional

B1 thru B4 – 93854088

B5 thru B8 – 93854112

51135006

58027002

41043001

51135006

58027002

41017001

51135006

58027002

41017009

51135006

58027002

41017001

51135006

58027002

58342002

42438001

44066001

40062001

Page 6

208

3/1 1 52275001

208V 1KW Heating Element

240

3/1

52275002

240V 1KW Heating Element

277

1

52275003

277V 1KW Heating Element

415

3

52275002

240V 1KW Heating Element

480/277

3/1

52275003

277V 1KW Heating Element

52275013

2,4&6KW-300V 1KW Heating Element

52275013

2&4KW-300V 1KW Heating Element

52275014

3,5&6KW-347V 1KW Heating Element

3

44067001

Manual Reset Limit

PARTS VIEW AND PARTS LIST (CONTINUED)

415

3-4wire

52289001

208/240V Motor single shaft

277

1

52289003

277V Motor single shaft

480

3-4wire

52289003

277V Motor single shaft

600

3/1

52289005

575V Motor single shaft

All

3/1

2

62441001

Blower wheel

1

208/240

3/1

52290001

208/240V Motor Double shaft

415

3-4wire

52290001

208/240V Motor Double shaft

277

1

52290003

277V Motor Double shaft

480

3-4wire

52290003

277V Motor Double shaft

600

3/1

52290005

575V Motor Double shaft

All

3/1

2

62441001

Blower wheel

2

208/240

3/1

52289001

208/240V Motor single shaft

415

3-4wire

52290001

208/240V Motor double shaft

52289003

277V Motor single shaft

52289004

480V Motor single shaft

52290004

480V Motor double shaft

52290003

277V Motor double shaft

52289005

575V Motor single shaft

52290005

575V Motor double shaft

All

3/1

2

62441001

Blower wheel

3

208/240

3/1

52290001

208/240V Motor double shaft

415

3-4wire

52290001

208/240V Motor double shaft

277

1

52290003

277V Motor double shaft

480

3-3wire/1

52290004

480V Motor double shaft

480

3-4wire

52290003

277V Motor double shaft

All

3/1

2

62441001

Blower wheel

4

1

1

3

2

Heat Deck Assembly

Blower Deck Assembly

Unit

Length

Volts Phase Item Part No. Description Qty

208/240 3/1

52289001 208/240V Motor single shaft

2

66 and 79 inch units are Custom

Specified Cabinets Unit Heaters

33”

46”

66”

79”

480 3-3wire/1 52289004 480V Motor single shaft

480 3-3wire/1 52290004 480V Motor Double shaft

277 1

480 3-3wire/1

480 3-4wire

600 3/1

600 3/1 52290005 575V Motor double shaft

1

1

52290003 277V Motor double shaft

1

52289003 277V Motor single shaft

1

1

1

1

2

NOTE: 1. 66” Units use the following sizes of Heat/Blower deck assemblies.

2. 79” Units have (2) 46” Heat/Blower deck assemblies.

Length

ΠQuantity varies with KW

ΠΠAll except for the following 66” and 79” 3-phase units: which have Qty. 2

208V – 16KW thru 24KW

240V – 20KW thru 24KW

ΠΠΠBoth 2-Wire, 3 -Wire and 4-Wire syst ems.

A) Qty.1 ea.-33

B) Qty. 1 ea.-46”

Unit

33”

46”

Volts PH. Item Part No. Description Qty

480

600

208 3/1

240 3/1 52275006 240V 2KW Heating Element

277 1 52275007 277V 2KW Heating Element

415 3 52275006 240V 2KW Heating Element

480/277 3/1 52275007 277V 2KW Heating Element

480

600 3/1 52275012 600V 2KW Heating Element

All Units

ΠΠ

ΠΠ

Π

Π

1

3

52275004 480V 1KW Heating Element

52275014 3&5KW-347V 1KW Heating Element

52275005 208V 2KW Heating Element

1

52275008 480V 2KW Heating Element

2 60149051 Linear Safety Limit 1

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 EC0 NO. 1-4635 P/N 00009979 SHT. 06 OF 09

Π

Π

1Π

Page 7

Description of control opti ons f or “Custom Specified” Cabinet Unit Heaters

Note: All units are field convertible to the following:

Load management control with an external dry switch. When closed, unit operates under control of the internal or external

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 ECO NO. 1-4635 P/N 00009979 SHT.07 OF 09

1. For control by a field supplied remote thermostat.

2.

thermostat. When open, unit turns off.

B1--- Built-in single stage thermostat and relays which are operated by a field supplied 120 volt sourc.

Night set back can be accomplished by interrupting the 120 volt source to the unit. The unit is field convertible to the

following:

1. With a program controller provided by the installer; when the controller supplies the 120 volt source to the unit, it will heat

until the internal thermostat is satisfied. At night, the program controller will switch to a zone thermostat

which will control the 120 volt source to all of the heaters.

B2--- Built-in single stage thermostat and relays which are operated by a field supplied 24 volt source.

Night set back can be accomplished by interrupting the 24 volt source to the unit. The unit is field convertible to the

following:

1. With a program controller provided by the installer; when the controller supplies the 24 volt source to the unit, it will heat

until the internal thermostat is satisfied. At night, the program controller will switch to a zone thermostat

which will control the 24 volt source to all of the heaters.

B3--- Built-in single stage thermostat and relays which are operated by and internal 24 volt source.

B4--- Built-in single stage thermostat and relays which are operated by an internal 120 volt source.

(also includes fusing in the fan circuit and the transformer primary.)

B5--- Built-in two stage thermostat and relays which are operated by and internal 24 volt source.

B6--- Built-in two stage thermostat and relays which are operated by an internal 120 volt source.

(also includes fusing in the fan circuit and the transformer primary.)

B7--- Built-in two stage thermostat and relays which are operated by a field supplied 24 volt source.

Night set back can be accomplished by interrupting the 24 volt source to the unit. The unit is field convertible to the

following:

1. With a program controller provided by the installer; when the controller supplies the 24 volt source to the unit, it will heat

until the internal thermostat is satisfied. At night, the program controller will switch to a zone thermostat

which will control the 24 volt source to all of the heaters.

B8--- Built-in two stage thermostat and relays which are operated by a field supplied 120 volt source.

Night set back can be accomplished by interrupting the 120 volt source to the unit. The unit is field convertible to the

following:

1. With a program controller provided by the installer; when the controller supplies the 120 volt source to the unit, it will heat

until the internal thermostat is satisfied. At night, the program controller will switch to a zone thermostat

which will control the 120 volt source to all of the heaters.

Note: Standard Units are equipped with B3 Control Option

Page 8

Model

Heat

STANDARD CABINET UNIT HEATER SPECIFICATIONS

Standard Unit Heaters are 33” and 46” wide.

Output

Kw

HI LO HI LO HI LO 1PH 3PH

Norm. CFM

Output

Fan Speed

RPM

BTUH

(1,000’s)

Volts/HZ

50/60

Amps

Copper Wire

Size 75°C

AWG

Maximum

Fuse Size

6333D052033B300F 5 3 250 230 1550 1400 171/10.2 208/60

6333D052433B300F 5 3 250 230 1550 1400 17.1/10.2 240/60

6333D054834B300F 5 3 250 230 1550 1400 17.1/10.2 277-480/60

6333D054833B300F 5 3 250 - 1550 - 17.1/10.2 480/60 - 7.76 14 15

6333D055733B300F 5 3 250 - 1550 - 17.1/10.2 600/60 - 5.48 14 15

6346D102033B300F 10 6 500 460 1550 1400 34.1/20.5 208/60

6346D102433B300F 10 6 500 460 1550 1400 34.1/20.5 240/60

6346D104834B300F 10 6 500 460 1550 1400 34.1/20.5 277-480/60

6346D104833B300F 10 6 500 - 1550 - 34.1/20.5 480/60 - 15.35 12 20

6346D105733B300F 10 6 500 - 1550 - 34.1/20.5 600/60 - 12.28 12 20

ΠComes factory wired as a 3-phase unit, can be field converted to single phase ΠΠcomes factory wired as 480V/3-phase/4-wire unit, can be field converted to 277V/single phase

25.04Π

21.83Π

18.95ΠΠ

49.98ΠΠ

43.57Π

37.70ΠΠ

17.57 8/10 35/25

15.38 10/12 30/20

8.02 10/14 25/15

35.06 6/8 70/45

30.68 6/8 60/40

15.87 6/12 50/20

“CUSTOM-BUILT” CABINET UNIT HEATER

MODEL NUMBER BREAKDOWN

A) Series designation –T

B) Cabi net si ze – 33 = 33 in., 46 = 46 in., 66 = 66 in., or 79 = 79 in.

C) Inlet-outl et arrangement – A , B, C, or D

D) Rating in KW – 02 through 24

E) Voltage rating – 20 = 208V, 24 = 240V, 27 = 277V, 48 = 480V, or 57 = 600V

F) Phase – 1 = 1phase or 3 = 3phase

G) Number of wires in electric service – 2 = 2wires, 3 = 3wires, or 4 = 4wires

H) Control option – B1 through B8, or ST

I) Summer Fan Switch Option – S = Switch included or 0 = No switch

J) Over current Protection Option – C = Circuit breaker included or 0 = No protection

K) Motor Fusing Option – M = Motoring fuse included or 0 = No protection

L) Filter Option – F = Filter included or 0 = No filter

M) Disconnect Switch Option – D = Switch included or 0 = No sw i tch

N) Special Paint Color Option – P = Special color or Blank = Standard

T 46 D 08 24 1 2 B3 S C M F D P

A B C D E F G H I J K L M N

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 ECO NO. 1-4635 P/N 00009979 SHT.08 OF 09

Page 9

“CUSTOM-BUILT” CABINET UNIT HEATER SPECIFICATIONS

Custom Specified Heaters are 33”, 46”, 66”, 79” wide.

# of Heat

Fan

600V 1-phase unit has (4) elements

ISSUE DATE 06/15/01 REV. DATE REV. NO. 00 ECO NO. 1-4635 P/N 00009979 SHT. 09 OF 09

Heater

Length

33”

46”

66”

79”

Π

Elements per

Deck

KW

LT RT Hi Lo Hi/Lo

2 - 2 2 1

3 - Π3 3 2

4 - 4 4 2

5 - ΠΠ5 5 3

6 - 6 6 3

4 - 2 4 2

6 - 3 6 4

8 - 4 8 4

10 - 5 10 6

12 - 6 12 6

6 2 2 6 3

Π3

9

12 4 4 12 6

ΠΠ

15

5

18 6 6 18 9

8 2 2 8 4

12 3 3 12 8

16 4 4 16 8

20 5 5 20 12

24 6 6 24 12

Heat KW

3 9 6

5 15 9

ΠΠ600V 1-phase unit has (6) elements

Speed

RPM

1550/

1400

1550/

1400

1550/

1400

1550/

1400

Total Heater Amps/Supply Wire 75 degrees C copper

Single Phase Three Phase

208V 240V 277V 480V 600V 208V 240V

10.62/14 9.33/14 8.12/14 4.67/14 3.83/14 9.22/14 8.13/14 4.80-14 4.14/14 4.40/14 3.33/14

15.42/12 13.50/12 11.73/14 6.75/14 5.50/14 9.22/14 8.13/14 5.17/14 4.14/14 4.40/14 3.38/14

20.23/10 17/67/10 15.34/12 8.84/14 7.16/14 13.40/12 11.75/14 8.34/14 5.95/14 6.21/14 6.22/14

25.04/8 21.83/10 18.95/10 10.92/14 8.00/14 17.57/10 15.38/12 8.34/14 7.76/14 8.02/14 5.48/14

29.85/8 26.00/8 22.56/10 13.00/12 10.49/14 17.57/10 15.28/12 9.34/14 7.76/14 8.02/14 6.26/14

21.13/10 18.57/10 16.00/12 9.29/14 7.46/14 18.36/10 16.16/10 9.59/14 8.11/14 9.92/14 6.49/14

30.75/8 26.90/8 23.26/10 13.45/12 10.79/14 18.36/10 16.16/10 10.23/14 8.11/14 9.92/14 6.49/14

40.36/6 35.23/8 30.48/8 17.62/10 14.12/12 26.71/8 23.42/10 16.66/10 11.73/14 12.25/12 9.39/14

49.98/6 43.57/6 37.70/6 21.79/10 17.45/10 35.06/8 30.68/8 16.66/10 15.35/12 15.87/12 12.28/12

59.59/4 51.90/6 44.92/6 25.95/8 20.78/10 35.06/8 30.68/8 18.56/10 15.35/12 15.87/12 12.28/12

31.75/8 27.90/8 24.12/8 13.95/12 11.29/14 27.58/8 24.29/8 - 12.25/12 14.32/12 9.82/14

46.17/6 40.40/8 34.99/8 20.20/10 16.29/12 27.58/8 24.29/8 - 12.25/12 14.32/12 8.87/14

60.59/4 52.90/4 45.82/6 26.45/8 21.28/10 40.11/6 35.17/8 - 17.68/10 18.46/10 15.61/12

75.02/3 65.40/4 56.65/4 32.70/8 25.45/8 52.63/4 46.06/6 - 23.11/10 23.89/10 15.66/12

89.44/2 77.90/3 67.48/4 38.95/6 31.27/8 52.63/4 46.06/6 - 23.11/10 23.89/10 18.54/10

42.26/6 37.14/6 32.00/8 18.57/10 14.92/12 36/72/6 32.32/8 - 16.22/10 19.84/10 12.98/12

61.50/4 53.80/4 46.52/6 26.90/8 21.58/10 36/72/6 32.32/8 - 16.22/10 19.84/10 12.98/12

80.72/2 70.46/3 60.96/4 32.23/8 28.24/8 53.42/4 46.84/6 - 23.46/10 24.50/8 18.78/10

NA 87.14/2 75.40/3 43.57/6 34.90/8 70.12/3 61.36/4 - 30.70/8 31.74/8 24.56/8

NA NA 89.84/2 51.90/6 41.56/6 70.12/3 61.36/4 - 30.70/8 31.74/8 24.56/8

415V

4-Wire

480V

3-Wire

480V

4-Wire

600V

Page 10

)

TERSTERS

TERSTERS

TERS

ABINET UNIT HEAABINET UNIT HEA

ABINET UNIT HEAABINET UNIT HEA

ABINET UNIT HEA

Field Supplied

P/N: 9966

ter.ter.

ter.ter.

ter.

y, they arey, they are

y, they arey, they are

y, they are

tive use onltive use onl

tive use onltive use onl

tive use onl

aa

aa

a

INSTALLATION INSTRUCTIONS

AMES FOR CAMES FOR C

AMES FOR CAMES FOR C

AMES FOR C

TRIM FRTRIM FR

TRIM FRTRIM FR

TRIM FR

maximum, unless both inlet and outlet with screws or rivets

NOTE: Semi-recessed to be recessed 3-1/2” Attach Trim Frame to Cabinet

grilles are to the front. (

NOTE:

ames are for decorames are for decor

ames are for decorames are for decor

ames are for decor

trim fr trim fr

trim fr trim fr

trim fr

caution:caution:

caution:caution:

caution:

Semi-recessed Fully recessed front view

Side View Side View

* Trim Frame extends 1” beyond outer dimensions of heater.

made for supporting the cabinet unit hea made for supporting the cabinet unit hea

made for supporting the cabinet unit hea made for supporting the cabinet unit hea

made for supporting the cabinet unit hea

notnot

notnot

not

Page 11

HEATING PRODUCTS WARRANTY COVERAGE

Heating Products Elements in Baseboard s

Thermostats and Controls

10 Years

2 Years

VENTILATION PRODUCTS WARRANTY COVERAGE

All other Ventilation Products

1 Year

LIMITED WARRANTY

Products manufactured by TPI Corporation are warranted to the original consumer to be free from defects in material and

workmanship for twelve (12) months from the original purchase date.

The TPI limited warranty does not cover products that have been modified outside of our factory, damage or failure caused by acts

of God, abuse, misuse, connected to or placed on other than rated voltage, abnormal usage, fault, installation, failure to follow

suggested maintenance procedures enclosed with the product, improper maintenance or any repairs other than those provided by

an authorized TPI service center.

There are no obligations or liabilities on the part of the Corporation for consequential damages arising out of or in

connection with the use or performance of the product or other indirect damages with respect to loss of property,

revenues, profit, costs of removal installation, or reinstallation.

All implied warranties with respect to TPI products, including implied warranties for merchantability and implied

warranties for fitness, are limited in duration to twelve (12) months from original date of purchase, except those products

or parts of products which are warranted for long periods thereon.

Some states do not allow the exclusions or limitation of incidental or consequential damages and some states do not allow

limitations on how long an implied warranty lasts. The above exclusions or limitations may not apply to you.

During the warranty period, TPI Corporation will, at its sole option, repair or replace any defective parts or products returned, freight

prepaid, to the TPI Corporation factory or such other locations as TPI Corporation may designate. Returned products must be

packaged carefully and TPI Corporation shall not be responsible for damage in transit.

When ret urning parts, the owner must provide the model number of the product and nature of difficulty being experienced. This

warranty does not obligate TPI Corporation to bear the cost of labor in replacing any assembly, unit or component part thereof, nor

does the company assume any liability for secondary charges, expenses for installing or removal, freight or damages. There will

be charges rendered for product repairs made after the warranty period has expired. Proof of purchase, including date, must

accompany request for in-warranty service. In any event, TPI Corporation’s maximum liability shall not in any case exceed the list

price for the product claimed to be defective. This warranty gives to you specific legal rights and you may have other rights, which

may vary from state to state. For the name of your nearest authorized TPI Corporation service center, please write to TPI

Corporation, P.O. Box 4973, Johnson City, TN 37602.

All other Heating Products

Series HD or HDH Fans

Series UHP or IHP Fans

1 Year

5 Years

3 Years

Loading...

Loading...