Page 1

TPI Corporation

P.O. Box 4973

Johnson City, 37602

WWW.TPICORP.COM

MTM

Models ‘TH’, ‘THSS’ and ‘THA’

Series 222,223,342,343,462,463

2 and 3 Lamp Units

OVERHEAD ELECTRIC INFRARED HEATER

MODELS TH AND THSS

IMPORTANT SAFETY INFORMATION INSIDE

• Serious injury or death possible

• Read, understand, and follow all safety

information and instructions in this manual

before using or servicing this product.

• Retain these instructions for future reference.

MODEL THA

REFER TO

COMPLETE

INDEX OF

INFORMATION

ON

PAGE 2

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

Page 2

TABLE OF CONTENTS

Warnings Page 3

Important Instructions Page 4

Specications Page 5

Installation Planning & Layout Design Page 6

Application Guide Page 7

Clearances to Combustibles Page 8

Mounting Instructions Page 9

Totally Exposed Outdoor Applications Page 10

Lamp Installation & Replacement Page 10

Electrical Wiring for Models 222, 342, & 462 Page 11

Electrical Wiring for Models 223, 343, & 463 Page 12

Maintenance, Troubleshooting Page 13

Optional Recessed Mounting Frame Installation Page 14

Optional Wire Guard Installation Models ‘TH’ and ‘THSS’ Page 15

Optional Wire Guard Installation Models ‘THA’ Page 16

ATTENTION:

The table to the right provides

denitions of the signal

words that can be found

throughout this manual.

These signal words are used

to express the severity of the

hazard at hand. The signal

words are generally used

in conjunction with safety

symbols that correspond to

the text for that particular

hazard. As you read this

manual, refer back to this

table when you are unsure

of the signal word denition.

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

2

Page 3

SAFETY INFORMATION

READ THIS MANUAL CAREFULLY before

installing or servicing this product. Improper

installation, operation, or maintenance can result

in death, severe injury, or property damage!

NOT FOR INDOOR RESIDENTIAL USE!

FOR INDOOR COMMERCIAL/INDUSTRIAL USE.

FOR PROTECTED AND UNPROTECTED OUTDOOR USE.

NOT FOR USE IN HAZARDOUS OR EXPLOSIVE

ATMOSPHERES!

INSTALLATION AND SERVICE OF THESE

PRODUCTS MUST BE CONDUCTED BY TRAINED

PERSONNEL EXPERIENCED WITH ELECTRICAL

EQUIPMENT.

CLEARANCES TO COMBUSTIBLES A S

DOCUMENTED IN THIS MANUAL AND ON THE

HEATER MUST BE MAINTAINED AT ALL TIMES!

Combustibles: Failure to maintain minimum

clearances to combustible materials can result in

serious re hazard. Locations used for storage of

combustible materials must have signs posted to

specify maximum permissible stacking heights such

that required clearances are maintained. These signs

must be conspicuously located or adjacent to heater

thermostats.

Vehicles: These heaters must be installed such that

the minimum clearances described in this manual are

maintained from vehicles parked below the heater.

Suspension: The use of appropriate mounting

hardware (beam clamps, chains, rods, turnbuckles,

etc.) are a must. The weight of the heater must

be entirely supported from a permanent part

of the building structure having adequate load

characteristics.

Do not attach ductwork to this heater or attempt to

use it as a make-up air heater. Such use voids the

warranty and may create unsafe conditions.

Do not insert ngers or foreign objects into the heater.

Do not block or tamper with the heater while it is in

operation. Do not touch heater while it is in operation

or just after it has been turned off, as some parts may

be hot enough to cause injury.

Make certain that the power source conforms

to the electrical requirements of the heater.

Disconnect power before installing or servicing.

If the power disconnect is out of sight, lock

it in the open position and tag it to prevent

unexpected application of power. Failure to do

so could result in fatal electric shock.

WARNING: DO NOT DEPEND UPON A

THERMOSTAT OR OTHER SWITCH AS THE SOLE

MEANS OF DISCONNECTING POWER WHEN

INSTALLING OR SERVICING THE HEATER. FOR

CE APPLICATIONS AN ALL POLE DISCONNECT

WITH CONTACT SEPARATION OF AT LEAST

3mm MUST BE USED. ALWAYS DISCONNECT

BREAKER AS DESCRIBED ABOVE. FAILURE

TO DO SO COULD RESULT IN FATAL ELECTRIC

SHOCK.

This heater is intended ONLY for permanent

installation in accordance with the National

Electric Code (NEC), all applicable local codes

and ordinances, and all sections of this manual.

Any variance voids the warranty and may create

unsafe conditions.

USE COPPER WIRING ONLY

Special attention must be given to any bonding*

(grounding) information pertaining to this

heater. To prevent the risk of electrocution, the

heater must be securely and adequately bonded.

This should be accomplished by connecting a

conductor between the service panel and the

green grounding screw provided on the heater.

To ensure a proper bond, the bonding means

must be tested by a qualied electrician.

Check branch voltage. Heaters should be

operated at voltages no higher than the heating

elements and the heater are designed for. (Lower

voltages, however, pose no problem other than

a loss of wattage). Heaters are not intended for

process heating applications.

In cases where property damage may result from

malfunction of the heater, a back-up system or a

temperature alarm should be used.

*Bonding is the term that describes the completion of the

electrical circuit back to its source, which allows a breaker or

fuse to clear if a short occurs in the line.

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

3

Page 4

IMPORTANT INSTRUCTIONS

1. Read all instructions before installing or using the heater

2. This heater is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. Keep away

from combustible materials at minimum, the following required distances.

CAUTION:

ceiling. Heaters MUST BE SEPARATED by more than 36 inches and 72 inches

from any combustible surface in direct radiation path.

ATTENTION: NE PAS installer à moins de 24 pouces à une surface verticale ou 6 pouces à un

plafond. Chauffe doivent être séparés par plus de 36 pouces et 72 pouces de toute

surface combustible dans le chemin de rayonnement direct

3. Extreme caution is necessary when any heater is used by or near children or invalids and whenever

the heater is left operating and unattended.

4. Do not operate any heater after it malfunctions. Disconnect power at service panel and have heater

inspected by a reputable electrician before reusing.

5. Do not use outdoors.

6. To disconnect heater, turn controls to off, and turn off power to heater circuit at the main disconnect

panel (or operate internal disconnect switch if provided).

7. Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause

an electric shock or re, or damage to the heater.

8. To prevent a possible re, do not block air intakes or exhaust in any manner.

9. A heater has hot and arcing or sparking parts inside. Do not use it in areas where gasoline, paint, or

ammable vapors or liquids are used or stored.

10. Use this heater only as described in this manual. Any other use not recommended by the manufacturer

may cause re, electric shock, or injury to persons.

SAVE THESE INSTRUCTIONS

DO NOT install closer than 24 inches to a vertical surface or 6 inches to a

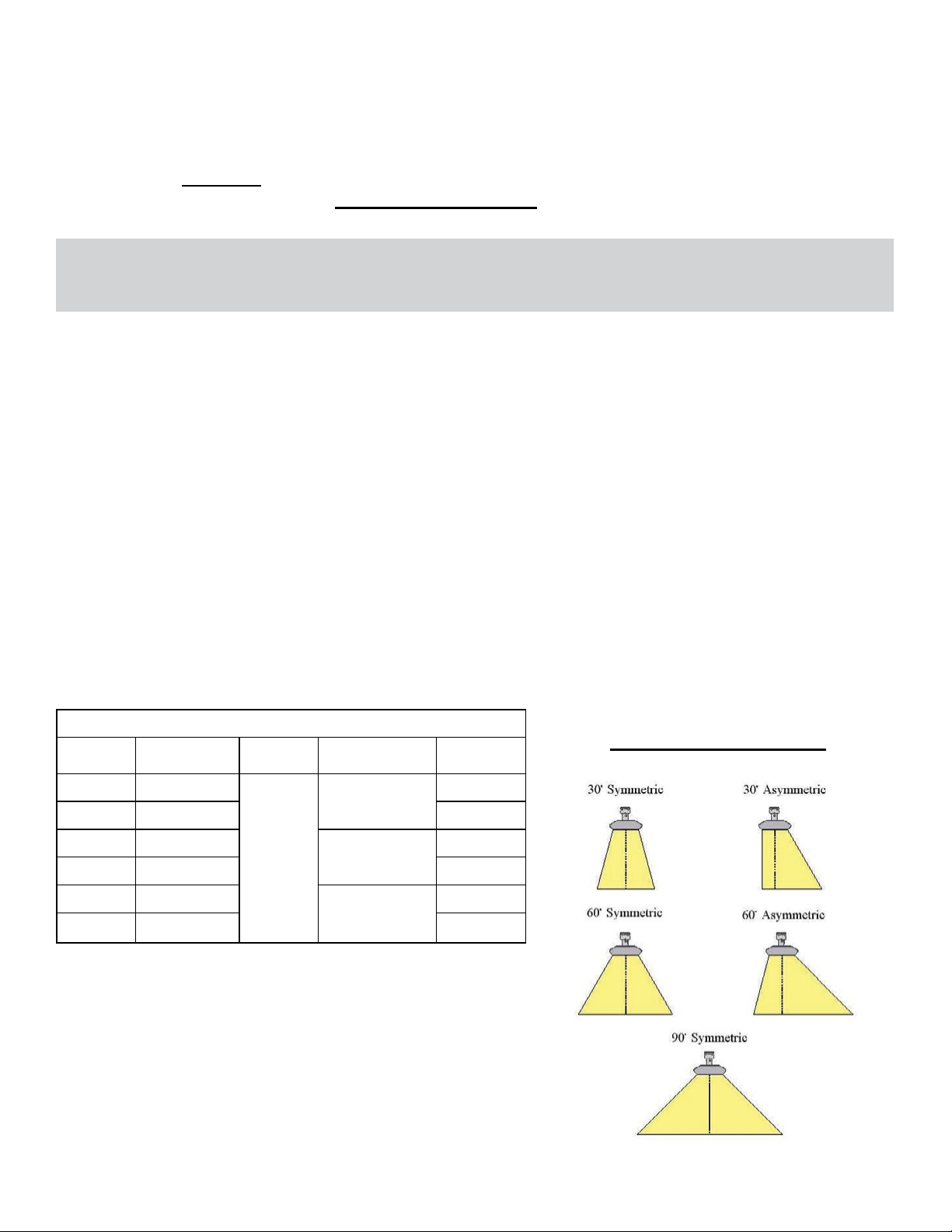

MODEL NUMBER DESIGNATION CHART

SERIES

222 30

223 60 220V

342 90

343 A30 277V

462 A60

463 480V

REFLECTOR

PATTERNS

TAB

HINGE

TH

HOUSING

MATERIAL

BLANK =

BROWN

SS=

STAINLESS

STEEL

A=

ARCHITECTURAL

ALUMINUM

EXTRUSION

VOLTAGES

208V

240V

380V

MODEL CONFIGURATION EXAMPLES:

222-30-TH-240V; 222 SERIES, 30

PAINTED HOUSING

O

PATTERN, BROWN

342-60-THSS-277V; 342 SERIES, 60O PATTERN

STAINLESS STEEL HOUSING

463-90-THA-480V; 463 SERIES, 90O PATTERN

PAINTED ALUMINUM

EXTRUSION HOUSING

REFLECTOR PATTERNS

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

4

Page 5

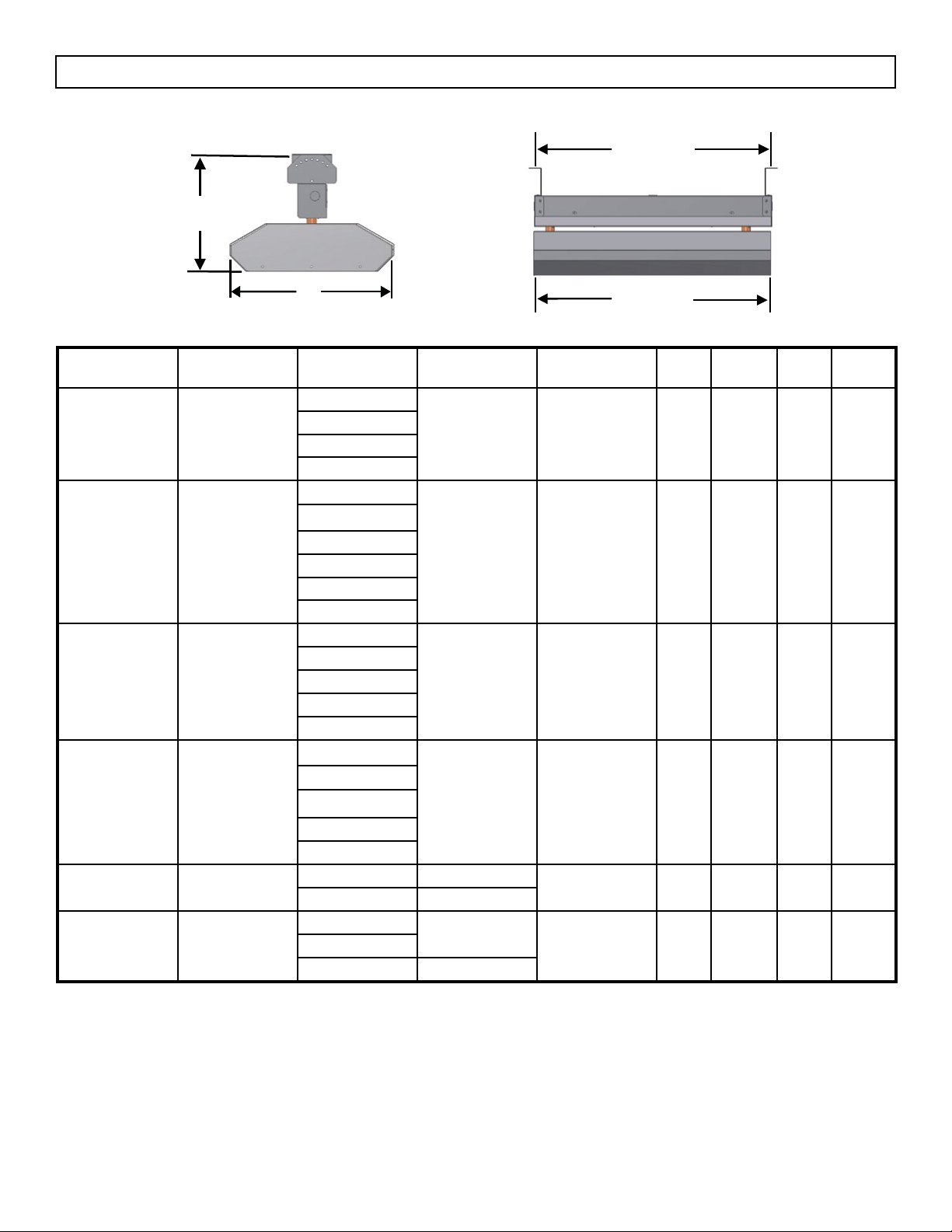

SPECIFICATIONS

MOUNTING CENTERS

D

c

HEATER

SERIES

222 2

223 3

342 2

343 3

462 2

463 3

NUMBER

OF LAMPS

B

VOLTAGE

and PHASE

208; 1ph

240; 1ph

277; 1ph

480; 1ph

208; 1 or 3ph

220; 1 or 3ph

240; 1 or 3ph

277; 1 or 3ph

380; 1 or 3ph

480; 1 or 3ph

208; 1ph

240; 1ph

277; 1ph

480; 1ph

600; 1ph

208; 1 or 3ph

240; 1 or 3ph

277; 1 or 3ph

480; 1 or 3ph

600; 1 or 3ph

480; 1ph 7300

600; 1ph 7600

380; 1 or 3ph

600; 1 or 3ph 11400

WATTAGE BTU’S A B C D

A

3200 10,992 24” 15” 11” 23-1/2”

4800 16,382 24” 21-1/2” 11” 23-1/2”

5000 17,065 33” 15” 11” 32-1/2”

7500 25,298 33” 21-1/2” 11” 32-1/2”

24,915 46” 15” 11” 45-1/2”

10950

37,372 46” 21-1/2” 11” 45-1/2”480; 1 or 3ph

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

5

Page 6

INSTALLATION PLANNING

The Fostoria Mul-T-Mount Series offers the highest watt density and heating efciency in an

electric infrared heater. All models are listed for spot-heat or total building heat indoors

(excluding residential), or for totally unprotected outdoor applications. Fixtures are also

listed for recessed applications, such as in ceilings or canopies.

2 and 3-Lamp models are available in either Stainless Steel , a Hi-Temp Brown Powder

Coated or an Architectural extruded aluminum housing with powder coat nish.

The specially designed “T” Tab wire channel allows for one-man installation.

No asbestos or mercury is used in the manufacture of these heaters.

CHECKING YOUR SHIPMENT

Upon receipt of your shipment, check the carton(s)

for damage.

Any accessory items ordered for heater will be

shipped in their own carton.

Claims for damaged material or shortages that

were not evident upon receipt of shipment must be

reported to carrier and Fostoria customer service

immediately.

Before starting to install the heater, make sure

that all components and accessories ordered are

available.

INSTALLER QUALIFICATIONS

Only rms or individuals qualied to perform work

in accordance with the applicable specications for

electrical equipment should be engaged to install

Fostoria MTM systems. Consult local building

inspectors, re marshals, your local Fostoria

representative or the factory for guidance.

INSTALLER RESPONSIBILITY

National and local codes and ordinances together

with specications provided by Fostoria Industries

comprise the information needed for proper

installation. The installer must furnish all materials

that have not been purchased from Fostoria

Industries or its representatives. It is the installer’s

responsibility that the materials and methods of

installation result in a job that is workmanlike and

in keeping with all applicable codes.

In storage areas where stacking of materials

may occur, the installer must provide signs which

specify the maximum stacking height so as to

maintain the required clearances to combustibles.

ELECTRICAL BONDING (GROUNDING)

A protective non-corrosive conductor terminal

must be rmly attached to a protective bonding

conductor (both supplied by customer). This must

then be secured to the heater with the supplied

green screw and lock washer in the heater wireway to ensure a proper bond (ground).

LAYOUT DESIGN

When positioning heaters, keep in mind the clearance to combustible materials, lights, sprinkler heads,

overhead doors, storage areas with stacked materials, gas and electrical lines, parked vehicles, cranes,

etc. Refer to page eight (8) for minimum clearance to verify that a safe installation condition exists.

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

6

Page 7

APPLICATION GUIDE

OUTDOOR COMFORT HEATING

Two (2) watts per square foot is equal to One (1) degree temperature rise. Heater installation

shall comply with all OIPM, NEC, and local restrictions.

SPOT HEATING (OUTDOOR) APPLICATION CHART

MODEL

SERIES

222-60 8-10 10.5 X 9.5 32 15”

223-60 8-10 10.5 X 9.5 48 24”

342-60 10-12 14 X 12 30 15”

343-60 10-12 14 X 12 45 23”

462-60 10-12 15 X 12 41 20”

463-60 10-12 15 X 12 61 30”

RECOMMENDED

MOUNTING HEIGHT (FT.)

COVERAGE OF HEATHER

LENGTH X WIDTH (FT.)

WATT PER

SQUARE

FOOT

TEMPERATURE

RISE EXPECTED

INDOOR SPOT HEATING

One (1) watt per square foot is equal to One (1) degree temperature rise. When comfort spot heating

people, two heaters should be used to heat both sides of the individual. Heater installation shall comply

with all OIPM, NEC, and local restrictions.

SPOT HEATING (INDOOR) APPLICATION CHART

MODEL

SERIES

222-60 8-10 13 X 12 21 20”

223-60 10-12 15 X 14 23 23”

222-30 12-14 8.5 X 7.5 50 50”

342-60 8-10 14 X 12 30 30”

343-60 10-12 16 X 14 24 34”

462-60 12-14 19 X 16 24 24”

463-60 12-14 19 X 16 36 36”

RECOMMENDED

MOUNTING HEIGHT (FT.)

A*

COVERAGE OF HEATER

LENGTH X WIDTH (FT.)

WATT PER

SQUARE

FOOT

TEMPERATURE

RISE EXPECTED

*Clearances to combustibles must be maintained regardless of recommended mounting height. See

page 8 for clearance distances.

6’ 8”

A

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

7

Page 8

MINIMUM CLEARANCES TO COMBUSTIBLES

EXPLOSION HAZARD

FIRE HAZARD

BURN HAZARD

•

Serious injury or death may

occur.

• Do not use in locations containing

hazardous atmospheres.

• Do not touch any part of heater

while in operation or directly

thereafter. It is very HOT.

END VIEW – 0 DEGREE TILT

6”

• Dimensions are listed in inches

•

Dimension “B” indicates the

required clearance to combustibles;

it DOES NOT indicate the required

mounting height.

TOP VIEW - 2 UNITS SHOWN

Multiple Heaters may be butted

together on end surfaces

C”

C”

B”

C”

END VIEW – 0-45 DEGREE TILT

6”

24” FROM A

VERTICAL OR

COMBUSTIBLE

SURFACE

OR

B”

36” FROM

ANOTHER

HEATER

B”

B”

WARNING!

B” Dimension

2-Lamp units:

-72” for a single unit

-72” for (2) or more

heaters being

mounted end-to-end.

3-Lamp units:

-72” for a single unit

-96” for (2) or more

heaters being

mounted end-to-end.

C” Dimension

TYP. BOTH SIDES AND

ENDS

24” FROM A VERTICAL

OR COMBUSTIBLE

SURFACE

36” FROM ANOTHER

HEATER

Heaters should be installed so that the minimum clearance to vehicles, as marked on the

heater, will be maintained. If vehicle lifts are present, ensure that the minimum clearance

to combustibles will be maintained from the highest raised vehicle

.

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

8

Page 9

MOUNTING INSTRUCTIONS

CLEARANCES TO COMBUSTIBLES AS ON PAGE 8 OF THIS MANUAL AND ON THE HEATER MUST BE

MAINTAINED AT ALL TIMES!

NOTE: If asymmetrical reectors are used, be sure to mount the wireway with the “T” slots facing

away from the wall or obstruction, and toward the area to be heated.

CAUTION: Install heater so that the quartz lamps are horizontal. Failure to do this may cause the

heating element within the tube to sag and cause premature burnout.

Mounting Centers

Heater Series “A” dimension

222 & 223 23-1/2

342 & 343 32-1/2

462 & 463 45-1/2

Top channel assembly

1. Attach the adjustment hanging brackets to the top wire

channel. On each end, place (1) 10-32 x ½ screw

through the bottom hole of the adjustment hanging

bracket and through the bottom hole of the top wire

channel. Place (1) 10-32 lock nut on the screw. Don’t

tighten completely. NOTE: The adjustment hanging

brackets are NOT required for chain suspension.

2. Adjust bracket to desired mounting angle (see gure B).

3. Place (1) 10-32 x ½” screw through the slot in the

adjustment hanging bracket and the hole in the top wire

channel. Place (1) 10-32 lock nut on the screw and

tighten.

4. Tighten 10-32 lock nuts from step #1.

5. Hook heater body into mounted wire channel cover.

Unit will hang freely by the “T” tabs, leaving both hands

free to wire unit (see gure C).

6. Close wire channel using the (4 or 6) 8-32 x 3/8 screws

provided in hardware pack. NOTE: Quantity will vary

depending on heater length.

Figure B

Figure A

WIRE CHANNEL COVER CONTAINS

KNOCKOUTS ON BOTH ENDS AND

TOP CENTER

screws (provided) to secure

Use blunt tip #8-32 X 3/8

top channel to wiring

channel

Figure C

MOUNTING OPTIONS

CHAIN SUSPENSION: Use 14 gauge jack chain and “S”

hooks (not supplied). “S” hooks must be crimped shut so

the heater cannot be inadvertently lifted off of its mounting.

*NOTE – 462 & 463 Series heaters are not designed for

chain suspension. One of the three mounting options

to the right should be used for these heaters.

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

STEM SUSPENSION: Use solid rods (1/4” diameter min.)

or suitable tubing. Drill holes in top wire channel 4” from

each end for mounting.

VMB-41-SS: Wall Mounting Bracket.

RECESSED MOUNTING: Refer to page 14 of this

manual.

9

Page 10

TOTALLY EXPOSED OUTDOOR APPLICATIONS

For totally exposed outdoor applications (not

ceiling protected) the connections must be made

as illustrated at right.

Red sleeves used for visible light reduction are

not recommended for applications near coastal

waters. Purchase lamps with integral light lter

from factory for these applications.

LAMP INSTALLATION & REPLACEMENT

CAUTION: Disconnect power before installing

or replacing supplied quartz lamps or quartz

tubes. These elements can and should be

installed prior to mounting heater.

1. Remove the housing end caps and open

positioning clips.

Note: All conduit, conduit ttings and junction

boxes are supplied by the customer.

2. Position heating elements in “L” slots at ends of

reector. Avoid handling quartz glass as much

as practical. Quartz glass should be wiped off

with a clean cloth before energizing heater.

3. Close positioning clips to secure the heating

element in the slot (see gure A).

4. Carefully wrap heating element pigtail clockwise

around terminal screws (see gure B).

5. Tighten terminal screws (see gure B).

CAUTION: Do not draw pigtail so tight

that pressure is put on heating element.

Maintain a partial loop (or looseness) in the

pigtail 1/2” max. see FIGURE B.

NOTE: Cut excess pigtail off at terminal to

prevent lead from touching metal parts.

6. Install end caps using sheet metal screws

supplied in parts kit.

Note: The Mul-T-Mount heaters are designed for

use with Fostoria quartz lamp infrared heating

elements only. They are NOT intended to be

used with straight metal rod heating elements.

POSSIBLE LAMP FAILURE

The heating elements used in this product can be damaged

by contamination (salt deposits from perspiration or

coastal air) on the surface of the quartz sleeve. At high

temperatures, these salts will cause the quartz to become

porous and leak, allowing air to come in contact with the

tungsten element. When this occurs, the element will burn

out quickly and the outer quartz sleeve can break. The

instructions below must be followed.

• Always wear cotton or latex gloves when installing or

replacing elements.

• Always clean the quartz sleeve with an alcohol

moistened soft cloth before using the heater

• Whenever contamination (milky white appearance

on quartz sleeve) is observed, the element must be

immediately replaced

.

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

10

Page 11

WIRING FOR UNITS WITH (2) LAMPS

ELECTRICAL SHOCK HAZARD

• Serious injury or death may

occur.

TWO-STAGE WIRING

Two-stage operation allows one or both lamps in the heater(s)

to be energized, depending on the signal from an appropriate

two-stage control device (e.g. two-stage thermostat). This will

allow the heater(s) to operate at 50% on, 100% on, or 100% off;

instead of limiting the operation to 100% on or 100% off.

Two circuits are required for two-stage wiring.

• Disconnect from electrical

supply before installing or

servicing this heater.

• This appliance must be

connected to a properly

bonded (grounded)

electrical source.

This xture is equipped with 4 high-temperature silicone

lead wires to accommodate either single phase or three

phase electrical service. They are shipped wire-tied

together. Remove the wire-tie before making electrical

connections.

Wiring connections should always be made through

one of the knockouts in the top wire channel. Consult

the factory, or a qualied electrician for details on

staging.

For two-stage operation connect L1 & L2 of circuit #1 to lamp #1

and connect L1 & L2 of circuit #2 to lamp #2 as illustrated below.

CIRCUIT #1

L1 L2

L1 L2

LAMPNO.1

LAMPNO.2

CIRCUIT #2

Common component layout for controlling

Fostoria Mul-T-Mount heaters

(2 Stage wiring shown)

This is NOT a wiring schematic

Wires in wiring channel are identied with wire markers.

Markers indicate lamp number.

Supply wires must be copper and rated for at least 90º

C. Wire connectors should also have a minimum rating

of 90º C.

For use in TOTALLY EXPOSED OUTDOOR

APPLICATIONS refer to page 10.

SINGLE-STAGE WIRING Connect both wires from

one end of heater to L1 and the remaining wires from

the other end to L2 in the control panel.

LAMPNO.1

L1 L2

LAMPNO.2

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

11

Page 12

WIRING FOR UNITS WITH (3) LAMPS

ELECTRICAL SHOCK HAZARD

• Serious injury or death may

occur.

• Disconnect from electrical

supply before installing or

servicing this heater.

• This appliance must be

connected to a properly

bonded (grounded)

electrical source.

This xture is equipped with 6 high-temperature silicone

lead wires to accommodate either single phase or three

phase electrical service. They are shipped wire-tied

together. Remove the wire-tie before making electrical

connections.

Wiring connections should always be made through

one of the knockouts in the top wire channel. Consult

the factory, or a qualied electrician for details on

staging. Refer to Figure A on page 9.

Supply wires must be copper and rated for at least

90º C. Wire connectors should also have a minimum

rating of 90º C.

For use in TOTALLY EXPOSED OUTDOOR

APPLICATIONS refer to page 10.

SINGLE PHASE, SINGLE STAGE WIRING

Connect all three wires from one end of heater to L1

and the remaining three wires from the other end to

L2; refer to diagram below.

LAMPNO.1

LAMPNO.2

LAMPNO.3

L1 L2

THREE PHASE, SINGLE STAGE WIRING

Balance each leg throughout the three elements in

each heater, as shown below.

LAMPNO.1

LAMPNO.2

LAMPNO.3

L3

L2

L1

Control Panel

TYPICAL SINGLE PHASE WIRING

Wire markers on lead wires indicate lamp number

TYPICAL THREE PHASE WIRING

Wire markers on lead wires indicate lamp number

Control Panel

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

12

Page 13

MAINTENANCE

Pre-Season Maintenance and Annual Inspection

To ensure your safety and for years of trouble-free operation of the heating system, annual service

and inspections must be done by a qualied contractor.

To obtain maximum performance from your heater(s) each year, we recommend the following be

performed at the start of the heating season:

1.Clean reector surface with a damp cloth.

2. Clean quartz lamp with alcohol moistened soft cloth.

3. Make sure heater is secure on all hanging points.

4.Maintain the Clearance to Combustibles. Immediately remove objects in violation of the

clearance to combustibles.

If additional service to the heater is required, contact the factory or your local representative.

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Element does not energize

Not enough heat.

Too much heat.

1. Defective element.

2. Improper connection.

3. Pigtail loose from socket connection.

1. Heater too small for application.

2. Heater mounted too high or too far.

1. Heater too large for application.

2. Heater mounted too low or too close.

1. Replace element.

2. Check connection to power source.

3. Rewind or re-insert pigtail into socket.

1. Add more heaters.

2. Decrease mounting height or distance.

1. Replace with smaller heater.

2. Increase mounting height or distance.

WARNING: WHEN ADJUSTING MOUNTING HEIGHT FOR MORE OR LESS HEAT, STAY WITHIN

RECOMMENDED MOUNTING HEIGHTS ON PAGE 7.

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

13

Page 14

OPTIONAL RECESSED MOUNTING FRAME INSTALLATION

MOUNTING INSTRUCTIONS

‘TH’ AND ‘THSS’ MODELS ONLY

1. Mount frame to heater with #8 x 1/2" long sheet metal screws supplied by customer. Four screws are

required on the RMF-222-A, six required on the RMF-342-A and eight on the RMF-462-A and RMF-223-SS

units; ten screws are required on the RMF-343-SS and twelve on the RMF-463-SS models. Use the frame

as a template for laying out the holes.

2. Mount the frame to the ceiling, using the outside slots only, with 1/4" lag screws provided by the customer.

Four lag screws are required on the RMF-222-A and RMF-223-SS units, six on the RMF-342-A and RMF343-SS, and eight on the RMF-462-A and RMF-463-SS units. Tabs will center frame in opening. CAUTION:

To maintain required clearance above heater, refer to minimum clearances to combustible on page 8.

FIELD WIRING CONNECTIONS

A. Select the appropriate knockout on the top wiring channel, and install a 12" conduit nipple and

splice box (customer supplied).

B. Route the leads from the wiring channel through the conduit and connect with the supply wiring

inside the splice box.

C. Follow local and national electric codes.

NOTE: Hold dimensions A

and B to + 1/8” for rough

opening in the ceiling.

Heater Series Model Part No. D DIM. A (IN.) DIM B (IN.)

222 Painted RMF-222-A 04494402 27 1/4

Stainless RMF-222-SS-A 04419902

342 Painted RMF-342-A 04418702 36 1/4

Stainless RMF-342-SS-A 04420702

462 Painted RMF-462-A 04494502 49 1/4

Stainless RMF-462-SS-A 04421002

223 RMF-223-SS 08811039 32 1/4

463 RMF-463-SS 08811139 54 1/4

18

29 5/8343 RMF-343-SS 08811339 41 1/4

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

14

Page 15

OPTIONAL WIRE GUARD INSTALLATION MODELS TH AND THSS

Heater Series Wire Guard Part Number

222 CHWG-222 08511500

223 CHWG-223 08543600

342 CHWG-342 08511400

343 CHWG-343 08543500

462 CHWG-462 08516200

463 CHWG-463 08543400

CAUTION: DISCONNECT POWER BEFORE

INSTALLING OR SERVICING. IF THE POWER

DISCONNECT IS OUT OF SIGHT, LOCK IT IN

THE OPEN POSITION AND TAG IT TO PREVENT

UNEXPECTED APPLICATION OF POWER.

FAILURE TO DO SO COULD RESULT IN FATAL

ELECTRICAL SHOCK.

Mounting holes for attaching the lamp guard are provided in

heater housing. NOTE: Mounting holes are not provided on

older models. Using the drill starts provided in the heater

housing, drill a 1/8” diameter hole at each location. (See

dimensional details.)

1. Place mounting clips provided, on the loops of the lamp

guard (see Detail A below).

2. Attach the lamp guard to the heater using the #8 sheet

metal screws provided.

MAINTENANCE

CAUTION: Disconnect power before installing or

servicing. If the power disconnect is out of sight, lock

it in the open position and tag it to prevent unexpected

application of power. Failure to do so could result in

fatal electrical shock.

To service the heater in the overhead position, it will be

necessary to remove the screws from only one side of the

lamp guard. The lamp guard will then swing clear of the

heater.

Detail A

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

15

Page 16

OPTIONAL WIRE GUARD INSTALLATION ‘THA’ MODELS

1. Slide wire guard into track on the bottom of the extrusion.

2. Secure wire guard with the provided screw(s) into the end cap of the heater, being

carefull not to strip screws.

Optional Wire Guards For ‘THA’ Series

Heater Series Wire Guard Part Number

222 THA-222 04898602

223 THA-223 04898702

342 THA-342 04898802

343 THA-343 04898902

462 THA-462 04899002

463 THA-463 04899102

ISSUE DATE 10-09-03 REV. DATE 12/17 REV. LEVEL: 17 ECO 1-7383 OIPM P/N 8329

16

Loading...

Loading...