TPG A795 Programming Manual

A795 Two-Color Thermal Receipt Printer

User Guide

Programming Supplement

A795-D100 PS Revision E 05/25/05

Includes TPG, Inc. LogoEZ

Made under one or more of the following U.S. patents:

4886381, 5579043, 5613787, 5651624, 5713678, 5752779, 5789916, 5800080, 5879090, 5887999, 5975776,

6027266, 6085973, 6089450, 6129465, 6155483, 6404452, 6486902, 6504331, 5749277, 6722754, 6739773,

6784909.

®

colorization information

Federal Communications Commission (FCC) Radio Frequency Interference Statement Warning

Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to operate the

equipment.

Note

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Information to the User

This equipment must be installed and used in strict accordance with the manufacturer’s instructions. However, there is no guarantee that interference to

radio communications will not occur in a particular commercial installation. If this equipment does cause interference, which can be determined by turning

the equipment off and on, the user is encouraged to contact TPG, Inc. immediately.

TPG, Inc. is not responsible for any radio or television interference caused by unauthorized modification of this equipment or the substitution or attachment of

connecting cables and equipment other than those specified by TPG, Inc. The correction of interferences caused by such unauthorized modification,

substitution or attachment will be the responsibility of the user.

In order to ensure compliance with the Product Safety, FCC and CE marking requirements, you must use the power supply, power cord, and interface

cable which are sold for use with this product or which meet the following parameters:

Power Supply

UL Listed (QQGQ), Class 2 power supply with SELV (Secondary Extra Low Voltage), non-energy hazard output, limited energy source, input rated 100240 Vac, 1.5/0.8 A, 50/60 Hz, output rated 24 Vdc, 2.3 A for 55 watt unit; 100-240 Vac, 2.0A, 50/60 Hz, output rate 24 Vdc, 3.125 A for 75 watt unit.

Use of this product with a power supply other than the TPG, Inc. power supply will require you to test the power supply and TPG, Inc. printer for FCC and

CE mark certification.

Communication Interface Cable

A shielded (360 degree) interface cable must be used with this product. The shield must be connected to the frame or earth ground connection or earth

ground reference at EACH end of the cable.

Use of a cable other than described here will require that you test the cable with the TPG, Inc. printer and your system for FCC and CE mark certification.

Power Cord

A UL listed, detachable power cord must be used. For applications where the power supply module may be mounted on the floor, a power cord with Type

SJT marking must be used. For applications outside the US, power cords which meet the particular country’s certification and application requirements

should be used.

Use of a power cord other than described here may result in a violation of safety certifications which are in force in the country of use.

Industry Canada (IC) Radio Frequency Interference Statement

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Voluntary Control Council for Interference (VCCI) Radio Frequency Interference Statement

This is a Class A product based on the standard of the Voluntary Control

Council for Interference by Information Technology Equipment (VCCI). If this

equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective actions.

Disclaimer

Information in this document is subject to change without notice. Consult your TPG, Inc. sales representative for information that is applicable and current.

TPG, Inc. reserves the right to improve products as new technology, components, software, and firmware become available.

No part of this document may be reproduced, transmitted, or translated in any form or by any means, electronic or mechanical, for any purpose without the

express written permission of TPG, Inc.

Copyright

Copyright © 2005 by TPG, Inc.

950 Danby Road, Ithaca, New York 14850, USA. All rights reserved. Printed in USA. Confidential, Unpublished. Property of TPG, Inc.

Trademarks

TPG, Inc.™ is a trademark of TPG, Inc. and its subsidiaries.

Microsoft, Windows NT are registered Trademarks of Microsoft Corporation in the U.S.A. and/or other countries.

Inside Out Networks, Inside Out, EPIC, and Edgeport are trademarks of Inside Out Networks.

All other trademarks and registered trademarks are the property of their respective holders.

Patents

Made under one or more of the following U.S. patents: 4886381, 5579043, 5613787, 5651624, 5713678, 5752779, 5789916, 5800080, 5879090, 5887999,

5975776, 6027266, 6085973, 6089450, 6129465, 6155483, 6404452, 6486902, 6504331, 5749277, 6722754, 6739773, 6784909.

Web Site

http://www.TPGprinters.com

Revision E May 2005

Contents

A795 User Guide: Programming Supplement

Chapter 1: About this Supplement ................................................. 9

How to use this supplement ......................................................... 9

Where to find the basics ............................................................... 9

Where to find advanced technical information ............................ 9

Support ........................................................................................ 9

Chapter 2: Diagnostics and Configuration.................................... 11

Start-up Diagnostics .................................................................. 11

Runtime diagnostics .................................................................. 12

Remote diagnostics.................................................................... 12

Indicators ................................................................................... 14

Printer configuration.................................................................. 15

Configuring the printer..................................................................16

Communication interface ..............................................................17

RS-232C serial interface settings ....................................................17

Diagnostic modes .........................................................................18

Enable or disable data scope mode ................................................18

Enable or disable receipt test mode................................................19

Printer emulations.........................................................................19

Printer settings and functions ........................................................20

Select the emulation/software options sub-menu: ......................20

Select the hardware options sub-menu to set: .............................21

3

Contents

Chapter 3: Programming the Printer ............................................ 23

Overview of commands.............................................................. 23

Comparison to A793................................................................... 23

T wo-color commands (comparison A794 to A795) ..................... 24

Character appearance ................................................................ 26

Width specifications ......................................................................26

Standard..................................................................................26

Compressed .............................................................................26

Print zones ................................................................................. 26

Print zones for 80mm paper...........................................................26

Print zones for 82.5mm paper ........................................................27

Rotated printing commands ...................................................... 27

Emulation modes ....................................................................... 28

Print setup in emulation modes .....................................................28

A795 User Guide: Programming Supplement

4

Contents

Chapter 4: Programming Commands ........................................ 29

Commands listed by function ................................................. 29

Printer actions ............................................................................. 29

Print and paper feed .................................................................... 30

Vertical and horizontal positioning ............................................... 30

T ext characteristics....................................................................... 31

Graphics ...................................................................................... 32

Status .......................................................................................... 33

Batch mode ............................................................................ 33

Real time ................................................................................ 33

Unsolicited status mode .......................................................... 33

Bar codes .................................................................................... 34

Page mode.................................................................................. 35

Macros ........................................................................................ 35

User data storage ......................................................................... 36

Flash download ....................................................................... 36

Command conventions............................................................ 37

Command descriptions............................................................ 38

Printer actions ............................................................................. 38

Clear printer............................................................................ 38

Perform full knife cut .............................................................. 38

Perform partial knife cut.......................................................... 39

Generate tone......................................................................... 39

Select peripheral device (for multi-drop) ................................. 39

Initialize printer....................................................................... 39

Select paper sensors to output paper-end signals..................... 40

Select sensors to stop printing ................................................. 40

Enable or disable panel button ................................................ 41

Generate pulse to open cash drawer ....................................... 41

Set current color ..................................................................... 42

Select cut mode and cut paper ................................................ 42

Set paper type (ColorPOS

Set interpretation of “Set current color” command ................... 44

Print test form......................................................................... 44

Print and paper feed .................................................................... 45

Print and feed paper one line .................................................. 45

Print and carriage return .......................................................... 45

Feed n dot rows ...................................................................... 45

Feed n print lines .................................................................... 45

Add n extra dot rows ............................................................... 46

Print........................................................................................ 46

Print and feed paper ............................................................... 47

Print and feed n lines .............................................................. 47

®

)...................................................... 43

Revision E May 2005

Revision E May 2005

A795 User Guide: Programming Supplement

Vertical and horizontal positioning ............................................... 48

Horizontal tab ......................................................................... 48

Set horizontal and vertical minimum motion units ................... 48

Set column ............................................................................. 48

Set absolute starting position................................................... 49

Set vertical line spacing to 1/6 inch.......................................... 49

Set vertical line spacing ........................................................... 50

Set horizontal tab positions...................................................... 50

Set relative print position......................................................... 51

Select justification ................................................................... 52

Set left margin ........................................................................ 52

Set printing area width ............................................................ 53

T ext characteristics commands..................................................... 54

Select double-wide characters ................................................ 54

Select single-wide characters .................................................. 54

Select 90 degree counter-clockwise rotated print .................... 54

Select pitch (column width) .................................................... 55

Set right-side character spacing ............................................... 55

Select print mode ................................................................... 56

Select or cancel user-defined character set .............................. 56

Define user-defined character set ........................................... 57

Select or cancel underline mode ............................................. 57

Copy character set from ROM to RAM ...................................... 58

Cancel user-defined character................................................. 58

Select or cancel emphasized mode ......................................... 58

Select or cancel double-strike.................................................. 59

Select or cancel italic print....................................................... 59

Select international character code.......................................... 60

Select or cancel 90 degree clockwise rotated print .................. 60

Select international character set............................................. 61

Select or cancel upside-down print mode................................ 61

Select character size ............................................................... 62

Select or cancel white/black reverse print mode ...................... 63

Reverse color text mode (ColorPOS

T ext strike-through mode (ColorPOS

®

)....................................... 63

®

) ..................................... 64

Select superscript or subscript modes ...................................... 64

5

Contents

A795 User Guide: Programming Supplement

6

Contents

Graphics ...................................................................................... 65

Download BMP logo .............................................................. 65

Select bit image mode.......................................................... 66

Print advanced raster graphics ............................................. 67

Select single-density graphics ............................................. 67

Select double-density graphics ............................................ 68

Select the current logo (ColorPOS

Define downloaded bit image (ColorPOS

Print downloaded bit image (ColorPOS

Print raster monochrome graphics (ColorPOS

Print raster color graphics (ColorPOS

Download logo image (ColorPOS

Apply shading to logo (ColorPOS

Merge watermark mode (ColorPOS

Monochrome shade mode (ColorPOS

Color shade mode (ColorPOS

Logo print with color plane swap (ColorPOS

Form and merge real time surround graphic (ColorPOS

Save graphics buffer as logo (ColorPOS

Background logo print mode (ColorPOS

Apply margin message mode (ColorPOS

Shade and store logo (ColorPOS

Logo print with knife cut ......................................................... 76

Set temporary max target speed.............................................. 76

Set LogoEZ

Set LogoEZ

Convert 6-dots/mm bitmap to 8-dots/mm bitmap ................ 81

Enable constant speed logos ............................................... 81

Status ........................................................................................ 82

Status command introduction ............................................... 82

Batch mode ........................................................................... 82

Transmit peripheral device status (RS-232C printers only) . 83

Request alternate status (A793 emulation only) .................. 83

Transmit paper sensor status ............................................... 84

Transmit printer ID ................................................................ 85

Transmit printer ID, remote diagnostics extension .............. 86

Transmit status ..................................................................... 88

Send printer software version............................................... 90

Real time commands ................................................................ 90

Preferred implementation ...................................................... 90

Alternate implementation ...................................................... 90

Rules for using real time commands ................................... 91

Moving data through the buffer ............................................. 91

Busy line and fault conditions .............................................. 91

Real time status transmission .............................................. 92

Real time request to printer .................................................. 93

Real time printer status transmission .................................. 93

Real time commands disable ............................................... 94

®

) .................................... 68

®

)........................... 69

®

) ............................. 70

®

) .................. 70

®

) ............................... 71

®

)....................................... 71

®

) .......................................... 72

®

)....................................... 72

®

) ................................... 73

®

) ................................................ 73

®

) .......................... 73

®

) ......... 74

®

) ................................. 74

®

) ................................ 75

®

) ............................... 75

®

) ............................................ 75

®

colorization ...................................................... 77

®

attribute mapping ............................................ 80

Revision E May 2005

Revision E May 2005

A795 User Guide: Programming Supplement

Unsolicited status mode ............................................................ 95

Select or cancel unsolicited status mode (USM) ................ 95

Recognizing data from the printer ......................................... 97

Bar codes .................................................................................. 98

Select printing position of HRI characters............................ 98

Select pitch of HRI characters .............................................. 98

Select bar code height.......................................................... 98

Print bar code........................................................................ 99

Select PDF 417 parameters ............................................... 101

Select bar code width ......................................................... 102

Page mode .............................................................................. 103

Print and return to standard mode...................................... 103

Cancel print data in page mode.......................................... 103

Print data in page mode ...................................................... 103

Select page mode ............................................................... 104

Select standard mode ......................................................... 104

Select print direction in page mode.................................... 105

Set print area in page mode ............................................... 106

Set absolute vertical print position in page mode .............. 107

Set relative vertical print position in page mode................. 107

Macros ..................................................................................... 108

Select or cancel macro definition ....................................... 108

Execute macro .................................................................... 108

User data storage .................................................................... 109

Write to user data storage .................................................. 109

Read from user data storage .............................................. 109

Read from non-volatile memory .......................................... 109

Write to non-volatile memory (NVRAM) ............................. 109

Select memory type (SRAM/flash) ......................................110

Flash memory user sectors allocation ................................110

Erase user flash sector ........................................................ 111

User storage status (ColorPOS

®

) ........................................112

Flash download......................................................................... 113

Switch to flash download mode ...........................................113

Return boot sector firmware part number ............................ 114

Return segment number status of flash memory................114

Select flash memory sector to download ............................ 114

Get firmware CRC ................................................................114

Return microprocessor CRC................................................ 115

Erase all flash contents except boot sector ....................... 115

Return main program flash CRC..........................................115

Erase selected flash sector ................................................. 115

Download to active flash sector ...........................................116

Download paper type description (ColorPOS

Return paper type description (ColorPOS

®

) ...................116

®

) ........................ 117

Reset firmware ..................................................................... 117

7

Contents

A795 User Guide: Programming Supplement

8

Contents

Appendix A:

Commands listed by hexadecimal code ..............................119

By command code .................................................................119

Appendix B:

Resident Character Sets.....................................................125

Character sets .....................................................................125

Code page 437 (US) ................................................................ 125

Code page 737 (Greek) ........................................................... 126

Code page 850 (Multilingual)................................................... 127

Code page 852 (Slavic) ........................................................... 128

Code page 858 (with Eurosymbol) .......................................... 129

Code page 860 (Portuguese) .................................................. 130

Code page 862 (Hebrew) ......................................................... 131

Code page 863 (French Canadian) ......................................... 132

Code page 865 (Nordic)........................................................... 133

Code page 866 (Cyrillic) .......................................................... 134

Code page 1252 (Windows Latin 1) ........................................ 135

Revision E May 2005

Revision E May 2005

A795 User Guide: Programming Supplement

Chapter 1: About this Supplement

Chapter 1: About this Supplement

How to use this supplement

This is a supplemental guide providing programming information on TPG, Inc.’s A795 printer. It is written for techsavvy users who are interested in customizing or adjusting printer functionality and is meant to be used in

conjunction with the A795 ColorPOS

If you experience any difficulties during the programming process or feel unsure of adjustments you have made,

contact your TPG, Inc. representative for further assistance.

Where to find the basics

®

Two-Color Thermal Receipt Printer: User Guide.

9

If you are looking for information on setup or basic operation, refer to the A795 ColorPOS® User Guide. This

supplemental guide assumes that you have the A795 ColorPOS

familiar with the printer.

®

User Guide handy for reference or are already

Where to find advanced technical information

This guide contains the most complete information available on programming the printer. If you cannot find what you

need here or would like further guidance on how to program the printer, contact an TPG, Inc. representative for

assistance.

®

If you are having problems with the physical operation of the printer, the A795 ColorPOS

in-depth information on diagnostics and service. The A795 ColorPOS

service technicians who have been certified by TPG, Inc. to perform advanced procedures.

®

Service Guide is available to qualified

Service Guide, provides

Support

For more advanced procedures and troubleshooting, you may need to refer to the printer’s service guide or speak to

an TPG, Inc. technical professional. Your representative is able to provide you with necessary information.

For on-line service, refer to the Web site at www.TPGprinters.com or e-mail to: support@TPGprinters.com.

A795 User Guide: Programming Supplement

10

Chapter 1: About this Supplement

Revision E May 2005

This page intentionally lef t blank.

Revision E May 2005

Revision E May 2005

A795 User Guide: Programming Supplement

Chapter 2: Diagnostics and Configuration

Chapter 2: Diagnostics and Configuration

The A795 printer performs a number of diagnostics that provide useful information about the operating status of the

printer. The following diagnostic tests are available. See pages 11 and 12 for more information.

11

• Start-up diagnostics

Performed during the printer’s start-up cycle.

• Runtime diagnostics

Performed during normal printer operation.

• Remote diagnostics

Maintained during normal operation and

reported in the print test.

• The printer can be configured with the following

settings and functions through the configuration menu

that is printed on the receipt. For more information on

configuring the printer, see “Printer configuration” on

page 15.

Communication interfaces

Diagnostic modes

RS-232C settings

Printer emulations/software options

Hardware options

Start-up Diagnostics

When the printer receives power or performs a hardware reset, it automatically performs the startup

diagnostics (also known as level 0 diagnostics) during the start-up cycle. The following diagnostics

are performed:

• Turn off motors

• Perform boot CRC check of the firmware ROM, test

external SRAM, test EEPROM, and test main program

CRC

Failure causes Start-up Diagnostics to stop; the

printer beeps and the LED flashes a set number of

times, indicating the nature of the failure. The

table in the “Indicators” section (page 14)

describes the specific tone and LED sequences.

• Check if paper is present

• Return the knife to the home position

Failure causes a fault condition. The table in

the “Indicators” section (page 14) describes

the specific tone and LED sequences.

• Check if receipt cover is closed

Failure does not interrupt the start-up cycle.

When the start-up diagnostics are complete, the printer

makes a two-tone beep (low then high frequency), the

paper feed button is enabled, and the printer is ready for

normal operation.

If the printer has not been turned on before, or a new

EEPROM has been installed, the default values for the

printer functions will be loaded into the EEPROM

during start-up diagnostics.

A795 User Guide: Programming Supplement

12

Chapter 2: Diagnostics and Configuration

Runtime diagnostics

Runtime diagnostics (sometimes called level 2 diagnostics) run during normal printer operation.

When the following conditions occur, the printer automatically turns off the appropriate motors and

disables printing to prevent damage to the printer:

Revision E May 2005

• Paper out

• Receipt cover open

• Knife unable to home

• Printhead too hot

• Voltages out of range

The LED on the operator panel will signal when these

conditions occur as well as indicate what state or mode the

printer is in.

Remote diagnostics

Remote diagnostics (sometimes called level 3 diagnostics) keeps track of the following tallies and

prints them on the receipt during the print test. See the sample test printout on the next page. These

tallies can be used to determine the printer’s state of health.

• Model number

• Serial number

• CRC number

• Number of lines printed

• Number of knife cuts

• Number of hours the printer has been on

• Number of flash cycles

• Number of cutter jams

• Number of times the cover is opened

• Maximum temperature reached

(See tallies note on the following page.)

Revision E May 2005

A795 User Guide: Programming Supplement

Chapter 2: Diagnostics and Configuration

13

*** A795 – Diagnostics Form ***

Model number : A795-2119

Serial number : A012251287

Boot Firmware

Revision : V1.02

CRC : 76EB

P/N : 189-1076076A

Flash Firmware

Revision : V1.13

CRC : AB62

P/N : 189-7950290A

H/W parameters

Flash Memoriy Size : 2 Mbytes

Flash Logos/Fonts : 1024 kbytes

Flash User Storage : 0 kbytes

SRAM Size : 256 kbytes

Head setting : D

Paper Type setting : Type 5, Version 0

Color Density Adj : 100%

Print Density (Mono) : 100%

Max Speed : 100 mm/sec

Paper Width : 80 mm

Max Power : 55 W

Knife : Enabled

Partial Cut : 135 steps

Paper Low Sensor : Disabled

Comm. Interface

RX Buffer Size : 4096

Interface type : RS232/USB

Parameters

Baud Rate : 115200

Data Bits : 8

Stop Bit : 1

Parity : NONE

Flow Control : DTR/DSR

Reception Errors : Ignore

Alternate DTR/DSR : Disabled

USB Driver Type : RS232 Emulation

Resident Code Pages : 437, 850, 852, 858

860, 863, 865, 866

1252, 862, 737

Available Paper Types : 00.00 01.00 05.00

01.90 01.92 01.93

Logo(s) defined : Yes

User Char(s) defined : NO

**************************************

**************************************

Select a sub-menu :

– EXIT

– Print Current Configuration -> 2 clicks

– Set Communication Interface -> 3 clicks

– Set Diagnostics Modes -> 4 clicks

– Set Emulation/Software Options -> 5 clicks

– Set Hardware Options

– Set Paper Type

Enter code, then hold Button DOWN

at least 1 second to validate

MAIN MENU

-

> 1 click

-

> 6 clicks

-

> 7 clicks

Paper type can be changed in the configuration menu.

Paper types and grades available:

Type 0 - Monochrome grades

Kanzaki P-310

Type 1 - Two-color grades

Kanzaki P-310 RB (Red/Black)

Type 4 - Two-color grades

Kanzaki P-320 BB (Blue/Black)

Type 5 - Two-color grades

Kanzaki P-320 RB (Red/Black)

See “printer configuration” section for more information.

When the printer is configured for USB and the

native USB solution driver is used, this location will

show either: “USB Driver Type: TPG , Inc.” or “USB

Driver Type: Printer Class”.

If the RS-232C, USB emulation solution driver is

used, nothing is printed here. See User Guide,

Appendix A.

To enter Printer Config Menu :

1) Flip DIP switch #1 down

2) Reset the printer, while holding

the Paper Feed button down

Print test and configuration menu samples will vary per model or printer

configuration. (Shown approximately 60% of size.)

For more information about See this section

Accessing the remote diagnostic tallies “Command descriptions” in Chapter 4: Programming commands

(Status commands: Transmit printer ID, remote diagnostics extension,

Hexadecimal 1D 49 40 n)

A795 User Guide: Programming Supplement

14

Chapter 2: Diagnostics and Configuration

Revision E May 2005

Indicators

The printer communicates various conditions both visually, with the green LED or audibly,

with a series of tones or beeps. The following table lists these indicators.

Indicator Sequence Condition

L ED Continuous, flashing quickly Paper out

Cover off

Knife unable to home

L ED Continuous, flashing slowly Paper is low

(if paper low sensor is installed)

Printhead too hot

Voltages out of range

T o ne Two-tone beep Start-up diagnostics completed successfully

(low frequency, high frequency)

L ED Single beep Boot CRC test failure

and T one Single LED flash

L ED Double beep SRAM test failure

and T one Double LED flash

L ED Triple beep EEPROM test failure

and T one Triple LED flash

L E D Four beeps Dynamic memory initialization failure

and T one Four LED flash

L E D Two-T one beep Main program CRC test failure

and T one (high frequency, low frequency) O r

Continuous flashing of LED DIP switch is in on position indicating

flash download mode

The printer is also able to communicate its status to the host application if the application has been programmed to

receive this information.

For more information about See this section

Error conditions and “ Troubleshooting the

correcting them printer” on page 30,

Chapter 4: Using the

Printer, in the A795 User

Guide

For more information about See t his section

Communication of printer “Command descriptions”

status to the host application in Chapter 4: Programming

commands, page 38

Revision E May 2005

A795 User Guide: Programming Supplement

Chapter 2: Diagnostics and Configuration

Printer configuration

Printers are shipped with all the functions and parameters preset at the factory. Settings for

various printer parameters can be changed. This menu is printed on the receipt and scrolls

through instructions for selecting and changing any of the functions or parameters.

Note: When changing the paper type you will either need to send the “Set paper type”

(1D 81 mn) command or make a selection in the configuration menu. See pages 16

and 43.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently

changing other settings that might affect the performance of the printer.

15

The following functions and parameters can be changed

in the scrolling configuration menu (except as noted):

• Communication Interface

RS-232C serial interface (9-pin)

RS-232C serial interface (25-pin)

Universal serial bus (USB)

• RS-232C serial interface settings

Baud rate

Data bits (can not be changed)

Stop bits (can not be changed)

Parity (can not be changed)

Hardware (DTR/DSR) or software (XON/XOFF)

flow control

Data reception errors

Alternate DTR/DSR

• Diagnostic Modes

Normal

Datascope

Receipt test

• Printer Emulations

A795 native mode

A794 emulation

A793 emulation

LEGACY emulation

• Printer settings and functions

Emulation/Software options submenu

Printer ID mode

Default lines per inch

Carriage return usage

Default font

Font size

Hardware options submenu

Color density

Monochrome print density

Power supply wattage (max power)

Knife option

Partial cut distance

Paper low sensor

Paper width

Printhead setting

For more information about Se e t his s ection

Using the configuration menu “Configuring the printer”

to configure the printer on page 16.

A795 User Guide: Programming Supplement

16

Chapter 2: Diagnostics and Configuration

Configuring the printer

The configuration menu allows you to select functions or change various settings for the

printer. Instructions printed on the receipt guide you through the processes.

Caution: Be extremely careful changing any of the printer settings to avoid

changing other settings that might affect the performance of the printer.

Switch 1 & 2 are

shown in the

normal OFF position

Off

On

Connector

Cover Open

121212

DIP Switches

Revision E May 2005

1 Open the connector cover.

2 Set DIP Switch 1 to ON position (down). DIP Switch

2 should be in the OFF position (up).

3 Make sure receipt paper is loaded in the printer

before proceeding. (For loading instructions, see the

A795 User Guide, page 14.)

4 Cycle DIP switch 2 down (reset ON position), then

up (normal OFF position).

- or Press and hold the paper feed button (4) while

closing the receipt cover (5), continually holding the

paper feed button until the configuration printout

begins.

• The printer beeps, prints the diagnostics form and

the configuration main menu.

*********

MAIN MENU

**********

*******************************

Select a sub-menu :

- EXIT -> 1 click

- Print Current Configuration -> 2 clicks

- Set Communication Interface -> 3 clicks

- Set Diagnostics Modes -> 4 clicks

- Set Emulation/Software Options -> 5 clicks

- Set Hardware Options -> 9 clicks

Enter code, than hold Button DOWN

at least 1 second to validate

• The printer pauses and waits for a main menu

selection to be made; short clicks are used, except

when answering “Yes” or validating selection (see

sample printout).

5 To communicate with the printer, you will press the

paper feed button using either short or long clicks.

Use a long click (more than one second) for “yes” and

a short click for a “no.” Follow the printed instructions

to make selections.

6 Continue through your menu selections until you are

asked, “Save New Parameters?”. Select “Yes” or “No.”

a If you wish to save, select “Yes,” then return DIP

switch 1 to the OFF Postion (up).

b. Open the receipt cover.

Press and hold the paper feed button while closing

the receipt cover.

• The diagnostic printout verifies your new

settings.

7 If you would like to continue configuring the printer,

select “No.” The printer then returns to the

configuration menu, where you can set parameters

again.

Revision E May 2005

A795 User Guide: Programming Supplement

Chapter 2: Diagnostics and Configuration

Communication interface

To change the communication interface settings, enter the configuration menu, select “Set

Communication Interface” from the main menu and answer “Yes” to “SET INTERFACE TYPE?”

printed on the receipt.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently

changing other settings that might affect the performance of the printer.

17

Press the paper feed button as instructed to select the

communication interface you want.

Note: For USB installation, see Appendix A, USB Driver Installation, page 39.

• Communication interface

• RS-232C interface: 1 click

• USB: Auto when no

RS-232C activity

RS-232C serial interface settings

To change the RS-232C serial interface settings, enter the configuration menu, select “Set

Communication Interface” from the main menu and answer “No” to “SET INTERFACE TYPE?”

printed on the receipt. This will take you to the instructions for selecting the RS-232C settings.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently

changing other settings that might affect the performance of the printer.

Press the paper feed button as instructed on the configuration menu to select the

RS-232C settings you want to change.

• Baud rate

115200 baud

57600 baud

38400 baud

19200 baud

9600 baud

4800 baud

2400 baud

1200 baud

• Number of data bits (can not be changed)

• Stop bits (can not be changed)

• Parity (can not be changed)

• Hardware flow control

Software (XON/XOFF)

Hardware (DTR/DSR)

• Data reception errors

Ignore errors

Print “?”

• Alternate DTR/DSR

Enabled

Disabled

Note: Press the paper feed button for at least one

second to validate the selection.

For more information about See this section

Setting the RS-232C Serial “Configuring the printer”

interface settings on page 16.

A795 User Guide: Programming Supplement

18

Chapter 2: Diagnostics and Configuration

Diagnostic modes

To change the diagnostic modes enter the configuration

menu, select “Set Diagnostic Modes” from the main menu

and select one of the following modes:

• Normal: normal operating mode of the printer.

• Datascope: the receipt printer prints incoming

commands and data in hexadecimal format to help

troubleshoot communication problems.

• Receipt test: the receipt printer prints two code

pages to verify proper printing of the receipt.

Caution: Be extremely careful changing any of the

printer settings to avoid inadvertently changing other

settings that might affect the performance of the printer.

See Configuring the printer,” page 16 for instructions on

how to enter the configuration menu.

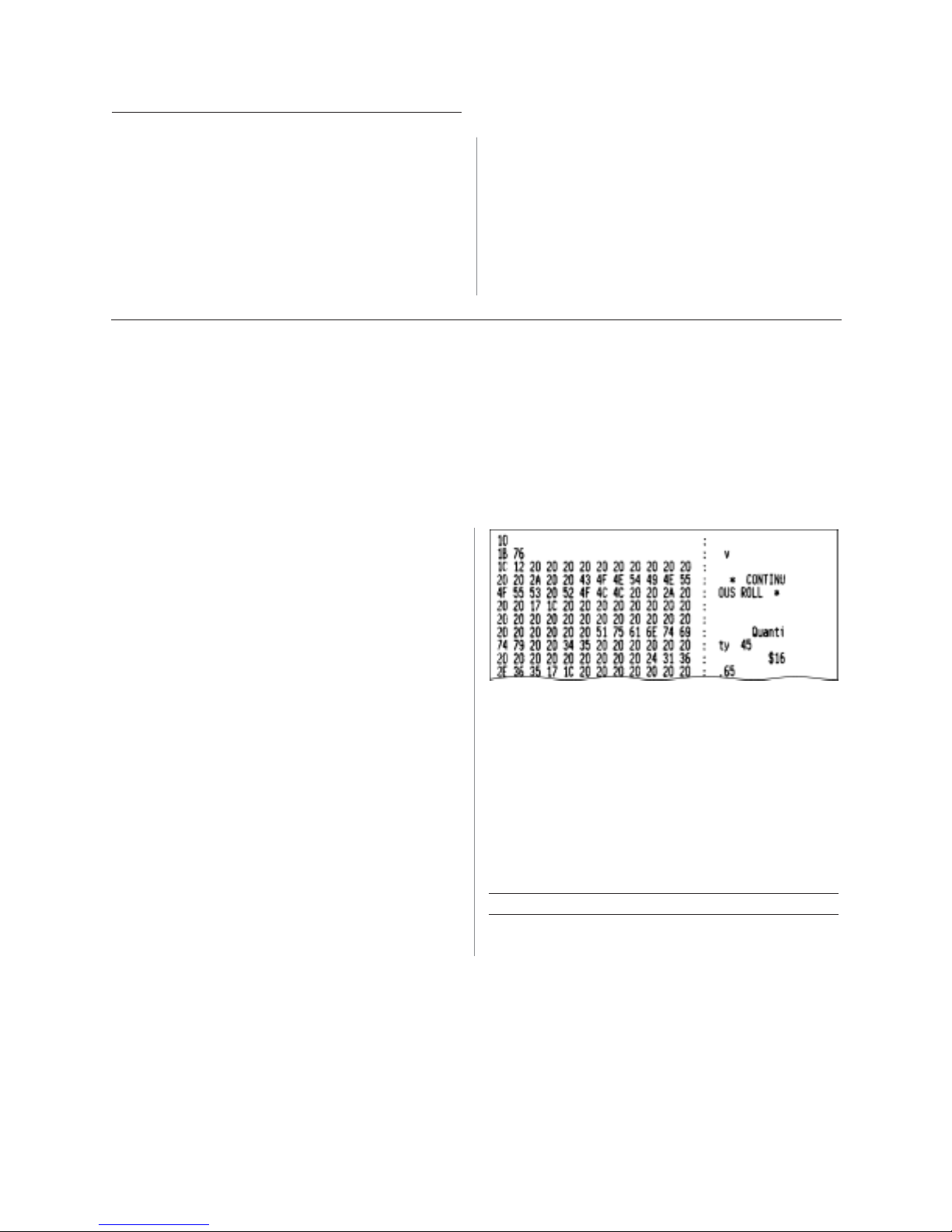

Enable or disable data scope mode

The data scope mode test prints a hexadecimal dump of all data sent to the printer: “1” prints

as hexadecimal 31, “A” as hexadecimal 41 and so on. This helps troubleshoot communication

problems and runs during a normal application (after being enabled through printer configuration).

Note: Data scope mode is usually considered a level 1 diagnostic test.

Data scope mode is enabled and disabled by selecting the “Diagnostic Modes” sub-menu of the

configuration menu.

Revision E May 2005

Press the paper feed button as instructed on the

“Diagnostic Modes Menu” to enable or disable the data

scope mode test.

• Off, normal mode (Data scope mode disabled)

• Data scope mode (enabled)

Note: Press the paper feed button for at least one second

to validate the selection.

T o run the data scope mode:

1 After you have enabled the data scope mode, exit the

configuration menu.

2 Run a transaction from the host computer.

All commands and data sent from the host computer

will be printed as hexadecimal characters as shown in

the illustration.

T o exit the data scope mode:

1 Enter the configuration menu again.

See “Configuring the printer,” page 16.

2 Disable the data scope mode.

3 Exit the configuration menu.

The printer is on-line and can communicate normally

with the host computer.

For more information about See this section

Enabling the data scope “Configuring the printer”

mode on page 16.

Revision E May 2005

A795 User Guide: Programming Supplement

Chapter 2: Diagnostics and Configuration

Enable or disable receipt test mode

The receipt test mode verifies proper receipt printing. Receipt test is enabled and disabled by

selecting the “Diagnostic Modes” sub-menu of the configuration menu. See “Configuring the

printer”, page 16 for instructions on how to enter the configuration menu.

19

T o run the Receipt test mode:

1 Enable the receipt test mode in the configuration

menu.

2 Exit the configuration menu.

3 Push the paper feed button. The receipt station

prints two code pages and cuts the receipt.

4 To repeat this test, push the paper feed button again.

T o exit the receipt test mode:

1 Enter the configuration menu again. (See

“Configuring the printer”, page 16.)

2 Disable the receipt test mode.

3 Exit the configuration menu.

The printer is on-line and can again communicate

normally with the host computer.

Printer emulations

To change the printer emulations settings, enter the configuration menu, select “Emulation/

Software Options” from the main menu and answer “Yes” to “Set the printer emulations?” printed

on the receipt. This will take you to the instructions for setting the printer emulation.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently changing

other settings that might affect the performance of the printer.

Press the paper feed button as instructed to select the

printer emulation you want.

• A795 native mode

• A794 emulation

• A793 emulation

• LEGACY emulation

Note: The A793, A794 and Application Compatible

Escape Command emulations do not recognize the

ColorPOS ® commands.

Note: Press the paper feed button for at least one

second to validate the selection.

For more information about See this section

Setting the printer emulation “Configuring the Printer”,

page 16

A795 User Guide: Programming Supplement

20

Chapter 2: Diagnostics and Configuration

Printer settings and functions

To change the printer settings and functions, enter the configuration menu, select the submenu from the main menu and answer the questions printed on the receipt until you come to

the instructions for selecting the printer settings.

Caution: Be extremely careful changing any of the printer settings to avoid inadvertently

changing other settings that might affect the performance of the printer.

Press the paper feed button as instructed to select the printer settings you want.

Select the emulation/software options sub-menu to set:

Revision E May 2005

• Printer ID mode

This function is used to determine what printer ID

value is returned in response to a Transmit printer ID

command (1D 49 n) when the printer is in A794

emulation mode. The printer can be configured to send

back the ID of the A795, A794, A793 or Application

Compatible Escape Command systems.

• Default lines per inch

This function allows you to set the default for lines per

inch to:

• 8.13 lines per inch

• 7.52 lines per inch

• 6.77 lines per inch

• 6.00 lines per inch

• Carriage return usage

This function allows the printer to ignore or use the

carriage return (hexadecimal 0D) command depending

on the application. Some applications expect the

command to be ignored while others use the command

as a print command.

• Default font

Sets the default for monochrome, two-color, and

LEGACY emulations.

• Font size

Allows user to set font size for the emulation being

used.

Revision E May 2005

Select the hardware options sub-menu to set:

• Printhead setting

This setting is the printhead energy rating and

must match the rating marked on the front right of

the thermal mechanism in the printer. Whenever a

new thermal mechanism is installed, this setting

must match the indicated energy rating on the

mechanism. (See A795 Service manual for

replacing the thermal mechanism.)

• Paper Type Name

Sets the printer to optimum performance for paper

being used. This can also be done through the

command 1D81 m n. See the following chapter for

command usage.

A vailable paper types may vary. Currently there are

4 types:

0 = monochrome, Kanzaki P310

1 = two-color, Kanzaki P310RB

4 = two-color, Kanzaki P320BB

5 = two-color, Kanzaki P320RB

(See page 36 in User Guide for available paper

manufacturers.)

• Color density

Adjusts printhead energy level to darken color

printing or adjust for paper variations. When printer

prints high-density color print lines (text or

graphics), it automatically slows down. Factory

setting is 100%.

CAUTION: Choose a color density setting no higher

than necessary to achieve acceptable color print

density. Failure to observe this rule may result in a

printer service call and may void the printer warranty.

Running at a higher energy level will reduce the

printhead life. Consult your TPG, Inc. technical

support specialist if you have questions.

A795 User Guide: Programming Supplement

Chapter 2: Diagnostics and Configuration

• Print density (monochrome papers only)

Adjusts printhead energy level to darken printout

or adjust for paper variations. When printer prints

high-density print lines (text or graphics), it

automatically slows down. Factory setting is

100%.

CAUTION: Choose a print density setting no higher

than necessary to achieve acceptable print density.

Failure to observe this rule may result in a printer

service call and may void the printer warranty.

Running at a higher energy level will reduce the

printhead life. Consult your TPG, Inc. technical

support specialist if you have questions.

• Power supply wattage (Max power)

You can choose between a 55-watt or 75-watt power

supply. This matches the wattage of the printer to the

power supply.

55-watt power supply (standard)

75-watt power supply (Enables printer to optimize

speed at higher dot coverage.)

• Knife option

This should only be changed if the knife is removed or

you do not want to cut the paper.

• Partial cut distance

Allows the user to set the distance that the knife will

cut across a receipt in 5 step increments between 110-

160.

• Paper low sensor

Senses when the paper roll is getting low on paper.

See troubleshooting section: “Receipt paper is low” in

the A795 User Guide.

• Paper width

Allows the user to set the printer for 58mm, 80mm or

82.5mm paper width.

21

For more information about See this section

Setting the printer functions “Configuring the printer”

and settings (See page 16.)

A795 User Guide: Programming Supplement

22

Chapter 2: Diagnostics and Configuration

Revision E May 2005

This page intentionally lef t blank.

Revision E May 2005

A795 User Guide: Programming Supplement

Chapter 3: Programming the Printer

Chapter 3: Programming the Printer

Overview of commands

Commands control all operations and functions of the printer. This includes selecting the size

and placement of characters and graphics on the receipt to feeding and cutting the paper. The

programming commands have been organized, in order of hexadecimal code within functional

groups. For this reason, “related” commands may not be listed adjacent to one another.

23

The operation of various printers may be emulated by

the commands, including the following:

• A793

• A794

• A795 native mode

• LEGACY

Any of the commands may be used in any combination

to program a host computer to communicate with the

printer (unless otherwise noted).

Some commands listed and described here may not be

implemented and are identified as “not implemented.” If

received, they are ignored and not sent to the print buffer

as data.

Any nonlegal commands have their parameter sent to the

print buffer as data.

Comparison to A793

The following table details the list of commands whose behavior differs between the

A793, A794, and A795 because of the physical differences of a 6 dots/mm head (A793) versus

an 8 dots/mm head (A794 and A795).

Command Description Difference between previous product

and new product emulation mode.

15 n Feed n dot rows This command will move the paper on the receipt in

n/203 inch steps instead of n/152 inch steps.

16 n Add n extra dot rows The dot rows will be measured in n/203 inches versus

n/152 inches.

1B 20 n Set right-side character spacing This command sets the right side spacing to “n” horizontal

1B 24 n1 n2 Set absolute starting position For graphics commands, the position is scaled to best

1B 26 s c1 c2 n1 d1...nn dn] Define user-defined character set Since the dots on the A795 printhead are smaller , user

1B 2A m n1 n2 d1...dn Select bit image mode In A793 emulation mode, graphics are scaled to best

1B 33 n Set line spacing This command uses n in terms of n/360 inches. Since the

continued...

motion units. By default, these units are in terms of 1/203

inches versus 1/152 inches.

match A793. In text mode, the equivalent character

position is calculated.

defined characters that were used on the previous printers

will appear smaller on the A794 printer .

match the size of the graphic in the A793 printer .

A793 had a fundamental step of 1/152 inch and the A795

has a fundamental step of 1/203 inch, the actual line

spacing will not exactly match the requested spacing.

A795 User Guide: Programming Supplement

24

Chapter 3: Programming the Printer

Command Description Difference between previous product

and new product emulation mode.

1B 4A n Print and feed paper This command uses n in terms of n/360 inches. Since the

A793 had a fundamental step of 1/152 inch and the A795

has a fundamental step of 1/203 inch, the actual line

spacing will not exactly match the requested spacing.

1B 59 n1 n2 d1...dn Select double-density graphics In A793 emulation mode, the printer scales the graphics

to provide the best match.

1B 5C n1 n2 Set relative print position The parameter to this command is in units of dots.

However, the command moves and aligns to character

positions. In A793 emulation mode, this command

calculates how many character positions to move

based on the A793 character width in dot s (10)

versus the A795 (13).

1B 61 n Select justification This command does true dot resolution alignment for

centering versus character-aligned centering.

1D 2A n1 n2 d1...dn] Define downloaded bit image In A793 emulation mode, this command scales the

incoming data to provide a best match to the size of

the image as it printed on A793.

Revision E May 2005

1D 2F m Print downloaded bit image In A793 emulation mode, this command scales the

incoming data to provide a best match to the size of

the image as it printed on A793.

Two-color commands (comparison A794 to A795)

The following table details the list of commands that have been added for two-color ColorPOS

functionality (ColorPOS® commands, 1D 81 through 1D 97 are in bold) or existing commands

that have been altered by the addition of two-color capacity.

TPG, Inc. ColorPOS® two-color and color interpreted commands

Hexadecimal ASCII Description

1B 72 m ESC r m Set current color

1D A0 nl nh 1 D GS Set temporary maximum target speed

1D 23 n GS # n Select current logo

1D 42 n GS B n Select or cancel white/black reverse print mode

1D 2A n1 n2 d1 – dm GS * n1 n2 d1 – dm Define downloaded bit image

1D 2F m GS / m Print downloaded bit image

®

1D 81 m n GS 0x81 m n Set paper type

1D 82 n1– n72/n80 GS 0x82 n1– n72/n80 Print raster monochrome graphics

1D 83 n1– n144/n160 GS 0x83 n1– n144/n160 Print raster color graphics

Revision E May 2005

TPG, Inc. ColorPOS® two-color and color interpreted commands continued

Hexadecimal ASCII Description

1D 84 n m n1 n2 d1 dx GS 0x84 n m n1 n2 d1 dx Download logo image

1D 85 m n GS 0x85 m n Reverse color text mode (two-color)

1D 86 m GS 0x86 m Monochrome shade mode

1D 87 m GS 0x87 m Color shade mode

1D 89 n m GS 0x89 n m Logo print with color plane swap

1D 8B n m o GS 0x8B n m o Apply shading to logo

1D 8C n m GS 0x8C n m Merge watermark mode

1D 8D n m GS 0x8D n m Text strike through mode

1D 8E m nL nH d1...dn GS 0x8E m nL nH d1...dn Download paper type description

A795 User Guide: Programming Supplement

Chapter 3: Programming the Printer

25

1D8F m GS 0x8F m Return paper type description

1D 90 m x y o p q GS 0x8A m x y o p q Form and print real time surround graphic

1D 91 n GS 0x91 n Save graphics buffer as logo

1D 92 n GS 0x92 n Background logo print mode

1D 97 m n GS 0x87 m n User storage status

1D 99 l m n o U S Apply margin message mode

1D 9A n m o GS 0x9A n m o Shade and store logo

1D 9B m n G S Logo print with knife cut

1F 03 16 05 n U S Set interpretation of “Set current color” command

TPG, Inc. LogoEZ® colorization commands

Hexadecimal ASCII Description

1F 03 16 f m n o p q US ETX SYN Set LogoEZ® surround graphics

1F 03 16 f s p/r t US ETX SYN f s p/r t Set colorization

1F 03 17 a m s US ETX ETB a m s Set attribute mapping

Note: The new TPG, Inc. LogoEZ ® colorization utility provides you a fast and easy way to get basic two-color and

logos onto your receipt without having to enter commands. Check out the TPG, Inc. Website at:

www.TPGprinters.com.

A795 User Guide: Programming Supplement

26

Chapter 3: Programming the Printer

Character appearance

The appearance of text can be changed using the following print modes:

Revision E May 2005

• Standard

• Compressed

• Double-high

• Double-wide

• Upside-down

• Rotated

• Underlined

Width specifications

Standard

• Characters per inch: 15.6

• Characters per line: 44

• Cell size: 13 X 24 dots

Print zones

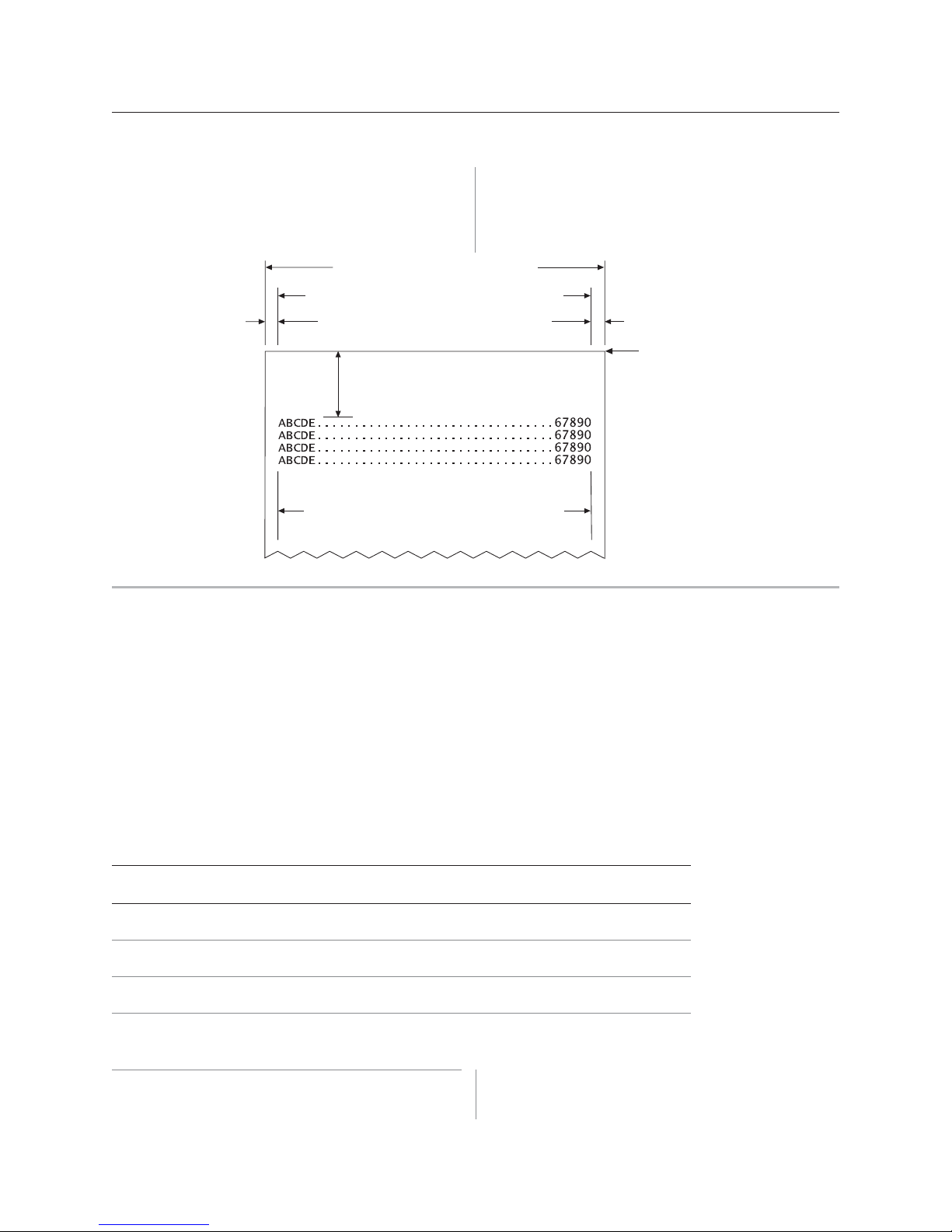

Print zones for 80mm paper

Specifications of print zone for 80mm paper:

• 576 dots (addressable) @ 8 dots/mm,

centered on 80mm

• Standard mode: minimum margins:

2.0mm (.079 inches)

• Bold

• Reverse

• Italic

• Strike-through

• Scaled

• Shading

Compressed

• Characters per inch: 20.3

• Characters per line: 56

• Cell size: 10 X 24 dots

• Top margin to manual tear-off:

17.8mm (0.70 inches)

• Top mar gin to knife cut:

19.0mm (0.75 inches)

Paper width = 80 mm (3.15)

Printable zone, 576 dots = 72 mm (2.835)

Nominal margins, 4 mm (0.157)

Cut edge

Top margin, 17.8 mm (.70) minimum

44 standard columns = 71.5 mm (2.815)

56 compressed columns = 70 mm (2.756)

Note: The application centers 44 standard character cells (13 X 24 dots), or

56 compressed character cells (10 X 24 dots), or 576 addressable bits of

graphics across an 80mm wide receipt. Minimum print line height is 24 dots

for text or graphics. Standard print line spacing is 27 dots

(i.e., 3 extra row dots).

The A795 adds a 27 dot high font, so standard print spacing is 30 dots.

Cut edge

Revision E May 2005

Print zones for 82.5mm paper

Specifications of print zone for 82.5 mm paper:

• 640 dots (addressable) @ 8 dots/mm,

centered on 82.5mm

• Standard mode: minimum margins:

1.0mm (0.040 inches)

Paper width = 82.5 mm (3.25)

Printable zone, 640 dots = 80 mm (3.15)

Nominal margins (2) = 1.25 mm (0.05)

Top margin, 17.8 mm (0.70) Minimum

Cut edge

A795 User Guide: Programming Supplement

Chapter 3: Programming the Printer

• Top margin to manual tear-off:

17.8mm (0.70 inches)

• Top mar gin to knife cut:

19.0mm (0.75 inches)

Cut edge

27

48 standard columns = 78.0 mm (3.07)

62 compressed columns = 77.5 mm (3.05)

Rotated printing commands

Three commands control the rotation of printing. The table shows the combinations of set/

cancel upside down print, set/cancel rotated print (clockwise), and rotated print

(counterclockwise).

Rotated clockwise and rotated counterclockwise print commands are mutually exclusive: the

setting of the last received command is effective. Unintended consequences may result when

rotated clockwise is mixed with other commands.

The samples of the print show only the normal-size characters. Double-wide and double-high

characters are printed in the same orientation. They may also be mixed

on the same line.

Upside down Rotated CW Rotated CCW Resulting output

(1B 7B n) (1B 56 n) (1B 12)

Canceled Canceled Cleared A B C

Canceled Set X

Set Canceled X

Set Set X

ABC

B

C

B

A

A B C

A

C

X X Set

Note: The following print modes cannot be mixed on

the same line:

A795 User Guide: Programming Supplement

28

Chapter 3: Programming the Printer

Revision E May 2005

• Standard and compressed pitch

• Vertical (normal) and rotated

• Right-side up and upside-down

• Single-high (normal) and double-high

Emulation modes

The TPG, Inc. A795 printer may be operated in a number of different emulation modes.

However, printing characteristics and defaults may differ, depending on the desired mode. For

instance, two-color paper and ColorPOS

native mode.

Print setup in emulation modes

Refer to the chart below for defaults and allowed printing options in each emulation mode.

Emulation LP I Font(s) Font Default Default Comments

mode options options size LPI ED R

A795 native 6.00, 6.77, 7.52, 8.13 Standard 13X24 7.52 3 Default setup for monochrome paper

®

commands and features are available only in A795

T all 13X27 6.77 3

ColorPOS

®

13X27 6.77 3 Default setup for two-color paper

A794, A793 6.00, 7.52, 8.13 Standard 13X24

7.52 3

emulations

LEGACY* 6.00 Tall 13X27

6.00 7 Default setup for

LEGACY emulation

emulation Standard 13X24

6.00 10

*LEGACY

The following list clarifies how the A795 printer will

behave in each emulation mode:

Two-color paper and ColorPOS

®

commands and features

are supported only in A795 native mode.

• If the paper type is changed using the 0x1D 0x81

command, the font and default lines per inch (LPI) will

be setup as in the table above.

• If only the font is changed, the default LPI will

automatically be changed as in the table above.

• If emulation is switched to LEGACY, A794 or A793

emulation(s), the paper type will automatically be

changed to monochrome paper, and the font and LPI

will be changed as in the table above.

• If emulation is switched from any emulation to A795

native, the font and LPI will remain unchanged because

the A795 native mode supports all font and LPI options

offered in the emulation modes.

• The “Set Default LPI” option in the configuration menu

is not offered in LEGACY emulation made. The LPI is

set at 6.00.

Revision E May 2005

Chapter 4: Programming commands

29A795 User Guide: Programming Supplement

Chapter 4: Programming Commands

Commands listed by function

Commands in bold are ColorPOS® commands.

Printer actions

Code (hexadecimal) Command Page

1 0 Clear printer 38

1 9 Perform full knife cut (or code 1B 69) 3 8

1 A Perform partial knife cut (or code 1B 6D) 3 9

1B 07 Generate tone 39

1B 3D n Select peripheral device (for multi-drop) 3 9

1B 40 Initialize printer 39

1B 63 33 n Select paper sensors to output paper end signals (parallel only) 4 0

1B 63 34 n Select sensors to stop printing 4 0

1B 63 35 n Enable or disable panel button 4 1

1B 69 Perform full knife cut (or code 19) 3 8

1B 6 D Perform partial knife cut (or code 1A) 3 9

1B 70 n p1 p2 Generate pulse to open cash drawer 41

1B 72 m Set current color 4 2

1D 56 m Select cut mode and cut paper (or code 1D 56 m n)42

1D 56 m n Select cut mode and cut paper (or code 1D 56 m)42

1D 81 m n Set paper type (for two-color printing) 43

1F 03 16 05 n Set interpretation of “Set current color” command 44

1F 74 Print test form 44

A795 User Guide: Programming Supplement

30

Chapter 4: Programming commands

Revision E May 2005

Print and paper feed

Code (hexadecimal) Command Page

0A Print and feed paper one line 4 5

0 D Print and carriage return 4 5

15 n Feed n dot rows 45

16 n Add n extra dot rows 46

17 Print 46

1B 4A n Print and feed paper 4 7

1B 64 n Print and feed n lines 4 7

Vertical and horizont al positioning

Code (hexadecimal) Command Page

09 Horizontal tab 48

1B 14 n Set column 48

1B 24 nL nH Set absolute starting position 49

1B 32 Set vertical line spacing to 1/6 inch 4 9

1B 33 n Set vertical line spacing 5 0

1B 44 [n] k 00 Set horizontal tab positions 50

1B 5C n1 n2 Set relative print position 51

1B 61 n Select justification 5 2

1D 4C nL nH Set left margin 52

1D 50 x y Set horizontal and vertical minimum motion units 48

1D 57 nL nH Set printing area width 53

Loading...

Loading...