Page 1

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM0000010EX1UGX

Title: FOREWORD / CAUTION / SECTION: FOREWORD: CAUTION (2013 FR-S)

CAUTION

This contents does not include all the necessary items about repair and service. This manual is

made for the use of persons who have special techniques and certifications. If non-specialized or

uncertified technicians perform repairs or service only using this manual or without proper

equipment or tools, this may cause severe injury to you or other persons nearby and also cause

damage to your customer's vehicle.

In order to prevent dangerous operation and damage to your customer's vehicle, be sure to follow

the instructions shown below.

This contents must be read thoroughly. It is especially important to have a good

understanding of all the contents written in the PRECAUTION of "INTRODUCTION"

section.

The service method written in this manual is very effective to perform repair and service.

When performing the operations following the procedures using this manual, be sure to

use tools specified and recommended. If using non-specified or tools other than

recommended tools and service methods, be sure to confirm the safety of the technicians

and that there is no possibility of causing personal injury or damage to the customer's

vehicle before starting the operation.

If part replacement is necessary, the part must be replaced with the same part number

or equivalent part. Do not replace it with an inferior quality part.

It is important to note that this manual contains various "Cautions" and "Notices" that

must be carefully observed in order to reduce the risk of personal injury during service or

repair, or reduce the possibility that improper service or repair may damage the vehicle

or render it unsafe. It is also important to understand that these "Cautions" and

"Notices" are not exaggerations and are possible hazardous consequences that might

result from failure to follow these instructions.

Page 2

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM0000010EW2RZX

Title: FOREWORD / CAUTION / SECTION: FOREWORD: FOREWORD (2013 FR-S)

FOREWORD

This is Volume 1 of the 2013 SCION FR-S manual. There are three volumes to this manual. The

sections included in each volume are indicated by black type in the Section Index. Use the Section

Index of each volume to find the volume with the section you need.

Applicable models ZN6 series

Please note that the publications below have also been prepared as relevant service manuals for the

components and system in these vehicles.

MANUAL NAME PUB. NO.

2013 SCION FR-S Electrical Wiring Diagram EM20S0U

2013 SCION FR-S New Car Features NM20S0U

All information in this manual is based on the latest product information at the time of publication.

However, specifications and procedures are subject to change without notice. For the most current

information available, refer to the Toyota Technical Information System (TIS) online at dealership

locations or on the Internet at http://techinfo.toyota.com.

If you find any failures in this manual, you are kindly requested to inform us by using the report

form on the next page.

Repair Manual Quality Report

Att.) Service Manager, Your Distributor

Page 3

Page 4

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM000000UYV0BHX

Title: INTRODUCTION: HOW TO USE THIS MANUAL: GENERAL INFORMATION (2013 FR-S)

GENERAL INFORMATION

1. GENERAL DESCRIPTION

(a) This manual is written in accordance with SAE J2008.

(b) Repair operations can be separated mainly into the following 3 processes:

(1) Diagnosis

(2) Removing/Installing, Replacing, Disassembling/Reassembling, Checking and Adjusting

(3) Final Inspection

(c) The following procedure is omitted from this manual. However, this procedure must be performed.

(1) Use a jack or lift to perform operations.

(2) Clean all removed parts.

(3) Perform a visual check before and after performing any work.

2. INDEX

(a) An alphabetical INDEX section is provided at the end of the manual as a reference to help find the

item to be repaired.

3. PREPARATION

(a) Use of Special Service Tools (SST) and Special Service Materials (SSM) may be required, depending

on the repair procedure. Be sure to use SST and SSM when they are required and follow the work

procedure properly. A list of SST and SSM is in the "Preparation" section of this manual.

4. REPAIR PROCEDURES

(a) A component illustration is placed under the title where necessary.

(b) Non-reusable parts, grease application areas, precoated parts and torque specifications are noted

in the component illustrations.

The following illustration is an example.

Page 5

(c) Torque specifications, grease application areas and non-reusable parts are emphasized in the

procedures.

HINT:

There are cases where such information can only be explained by using an illustration. In these cases,

torque, oil and other information are described in the illustration.

(d) Only items with key points are described in the text. What to do and other details are explained

using illustrations next to the text. Both the text and illustrations are accompanied by standard

values and notices.

Illustration What to do and where to do it

Task heading What work will be performed

Explanation

text

(e) Illustrations of similar vehicle models are sometimes used. In these cases, minor details may be

different from the actual vehicle.

(f) Procedures are presented in a step-by-step format.

How to perform the task

Information such as specifications and warnings, which are written in boldface

text

5. SERVICE SPECIFICATIONS

(a) Specifications are presented in boldface text throughout the manual. The specifications are also

found in the "Service Specifications" section for reference.

6. TERM DEFINITIONS

CAUTION Possibility of injury to you or other people.

NOTICE Possibility of damage to components being repaired.

HINT Provides additional information to help you perform repairs.

7. INTERNATIONAL SYSTEM OF UNITS

Page 6

(a) The units used in this manual comply with the International System of Units (SI UNIT) standard.

Other units from the metric system and the English systems are also provided.

Example:

Torque: 30 N·m (310 kgf·cm, 22ft·lbf)

Page 7

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM000000UZB09AX

Title: INTRODUCTION: TERMS: ABBREVIATIONS USED IN MANUAL (2013 FR-S)

ABBREVIATIONS USED IN MANUAL

ABBREVIATION MEANING

ABS Anti-Lock Brake System

A/C Air Conditioner

AC Alternating Current

ACC Accessory

ACIS Acoustic Control Induction System

ACM Active Control Engine Mount

ACSD Automatic Cold Start Device

ACT Actuator

A.D.D Automatic Disconnecting Differential

ADM P.T. Astra Daihatsu Motor

A/F Air-Fuel Ratio

AFS Adaptive Front-Lighting System

AHC Active Height Control Suspension

AID Air Injection Control Driver

ALR Automatic Locking Retractor

ALT Alternator

AMP Amplifier

ANT Antenna

ASG Automated Sequential Gearbox

ASL Automatic Sound Levelizer

ASSB Assembly Services Sdn. Bhd.

A/T, ATM Automatic Transmission (Transaxle)

A-TRAC, A-TRC Active Traction Control

ATDC After Top Dead Center

ATF Automatic Transmission Fluid

AUTO Automatic

AUX Auxiliary

AVG Average

AVS Adaptive Variable Suspension

AWD All Wheel Drive

B+, +B Battery Voltage

Page 8

BA Brake Assist

BACS Boost Altitude Compensation System

BATT Battery

BDC Bottom Dead Center

B/L Bi-Level

B/S Bore-Stroke Ratio

BTDC Before Top Dead Center

BVSV Bimetallic Vacuum Switching Valve

Calif. California

CAN Controller Area Network

CB Circuit Breaker

CCM Carbon Ceramic Material

CCo Catalytic Converter for Oxidation

CCV Canister Closed Valve

CD Compact Disc

CF Cornering Force

CG Center of Gravity

CH Channel

CKD Complete Knock Down

CNG Compressed Natural Gas

COMB. Combination

CPS Combustion Pressure Sensor

CPU Central Processing Unit

CRAWL Crawl Control

CRS Child Restraint System

CTR Center

C/V Check Valve

CV Control Valve

CVT Continuously Variable Transmission (Transaxle)

CW Curb Weight

DC Direct Current

DEF Defogger

DFL Deflector

DIFF. Differential

DIFF. LOCK Differential Lock

D/INJ Direct Injection

DLC Data Link Connector

Page 9

DLI Distributorless Ignition

DOHC Double Overhead Camshaft

DP Dash Pot

DS Dead Soak

DSP Digital Signal Processor

DTC Diagnostic Trouble Code

DVD Digital Versatile Disc

EBD Electric Brake Force Distribution

EC Electrochromic

ECAM Engine Control And Measurement System

ECD Electronically Controlled Diesel

ECDY Eddy Current Dynamometer

ECT Electronic Controlled Automatic Transmission

ECU Electronic Control Unit

ED Electro-Deposited

EDU Electronic Driving Unit

EDIC Electric Diesel Injection Control

EFI Electronic Fuel Injection

E/G Engine

EGR Exhaust Gas Recirculation

ELR Emergency Locking Retractor

EMPS Electric Motor Power Steering

EPS Electric Power Steering

ENG Engine

ES Easy & Smooth

ESA Electronic Spark Advance

EVAP Evaporative Emission Control

E-VRV Electric Vacuum Regulating Valve

EX Exhaust

FE Fuel Economy

FF Front-Engine-Front-Wheel-Drive

F/G Fuel Gauge

FIPG Formed In Place Gasket

FL

F/P Fuel Pump

FR

Fusible Link

Front Left

Front

Page 10

Front Right

F/W Flywheel

FW/D Flywheel Damper

FWD Front Wheel Drive

GAS Gasoline

GND Ground

GPS Global Positioning System

GSA Gear Shift Actuator

GTMC Gac Toyota Motor Co., Ltd.

GTS Global TechStream

H/B Hatchback

H-FUSE High Current Fuse

HID High Intensity Discharge (Headlight)

HPU Hydraulic Power Unit

HSG Housing

HT Hard Top

HV Hybrid Vehicle

HWS Heated Windshield System

IC Integrated Circuit

IDI Indirect Diesel Injection

IFS Independent Front Suspension

IG Ignition

IIA Integrated Ignition Assembly

IMC INDUS Motor Company Ltd.

IN Intake (Manifold, Valve)

INT Intermittent

I/P Instrument Panel

IRS Independent Rear Suspension

ISC Idle Speed Control

ISCV Idle Speed Control Valve

KD Kick-Down

KDSS Kinetic Dynamic Suspension System

LAN Local Area Network

LCD Liquid Crystal Display

LED Light Emitting Diode

LEV Low Emission Vehicle

LH Left-Hand

Page 11

LHD Left-Hand Drive

LIN Local Interconnect Network

L/H/W Length, Height, Width

LLC Long-Life Coolant

LNG Liquefied Natural Gas

LPG Liquefied Petroleum Gas

LSD Limited Slip Differential

LSP & BV Load Sensing Proportioning and Bypass Valve

LSPV Load Sensing Proportioning Valve

MAP Manifold Absolute Pressure

MAX. Maximum

MIC Microphone

MIL Malfunction Indicator Lamp

MIN. Minimum

MG1 Motor Generator No. 1

MG2 Motor Generator No. 2

MMT Multi-mode Manual Transmission

MP Multipurpose

MPI Multipoint Electronic Injection

MPX Multiplex Communication System

M/T Manual Transmission (Transaxle)

MT Mount

MTG Mounting

N Neutral

NA Natural Aspiration

NO. Number

O2S Oxygen Sensor

OC Oxidation Catalyst

OCV Oil Control Valve

O/D Overdrive

OEM Original Equipment Manufacturing

OPT Option

ORVR On-board Refilling Vapor Recovery

O/S Oversize

P & BV Proportioning and Bypass Valve

PBD Power Back Door

PCS

Power Control System

Page 12

Pre-crash Safety System/Pre-collision System

PCV Positive Crankcase Ventilation

PKB Parking Brake

PPS Progressive Power Steering

PROM Programmable Read Only Memory

PS Power Steering

PSD Power Slide Door

PTC Positive Temperature Coefficient

PTO Power Take-Off

PZEV Partial Zero Emission Vehicle

P/W Power Window

R & P Rack and Pinion

RAM Random Access Memory

RBS Recirculating Ball Type Steering

REAS Relative Absorber System

R/F Reinforcement

RFS Rigid Front Suspension

RH Right-Hand

RHD Right-Hand Drive

RL Rear Left

ROM Read Only Memory

RR

RRS Rigid Rear Suspension

RSE Rear Seat Entertainment

RWD Rear Wheel Drive

SC Supercharger

SCV

SFTM Sichuan Faw Toyota Motor Co., Ltd.

SIA Subaru of Indiana Automotive, Inc.

Rear

Rear Right

Swirl Control Valve (for gasoline engine)

Suction Control Valve (for diesel engine)

SICS Starting Injection Control System

SLLC Super Long Life Coolant

SOC State Of Charge

SOHC Single Overhead Camshaft

SPEC Specification

SPI Single Point Injection

Page 13

SPV Spill Control Valve

SRS Supplemental Restraint System

SSM Special Service Materials

SST Special Service Tools

STD Standard

STJ Cold-Start Fuel Injection

SULEV Super Ultra Low Emission Vehicle

T/A Transaxle

TACH Tachometer

TASA Toyota Argentina S.A.

TCAP Toyota Caetano Portugal, S.A.

TCM Transmission Control Module

TCV

TDB Toyota do Brasil Ltda.

TDC Top Dead Center

TDV Toyota de Venezuela, C.A.

TEMP. Temperature

TFT TOYOTA Free-Tronic

TFTM Tianjin Faw Toyota Motor Co., Ltd.

THS ll TOYOTA Hybrid System ll

TIS Total Information System for Vehicle Development

T/M Transmission

TMC Toyota Motor Corporation

TMCA Toyota Motor Corporation Australia Ltd.

TMMBC Toyota Motor Manufacturing de Baja California, S. de R.L. de C.V.

TMMC Toyota Motor Manufacturing Canada Inc.

Timing Control Valve (for diesel engine)

Tumble Control Valve (for gasoline engine)

TMMF Toyota Motor Manufacturing France S.A.S.

TMMI Toyota Motor Manufacturing, Indiana, Inc.

TMMIN P.T. Toyota Motor Manufacturing Indonesia

TMMK TOYOTA Motor Manufacturing Kentucky, Inc.

TMMR Toyota Motor Manufacturing Russia

TMMT Toyota Motor Manufacturing Turkey Inc.

TMMTX Toyota Motor Manufacturing, Texas, Inc.

TMUK Toyota Motor Manufacturing (UK) Ltd.

TMP Toyota Motor Philippines Corp.

TMT Toyota Motor Thailand Co. Ltd.

Page 14

TMV Toyota Motor Vietnam Co., Ltd.

TPCA Toyota Peugeot Citroen Automobiles Czech, s.r.o.

TRAC/TRC Traction Control System

TSAM Toyota South Africa Motors (Pty) Ltd.

TVIP TOYOTA Vehicle Intrusion Protection

TWC Three-Way Catalyst

U/D Underdrive

U/S Undersize

VCV Vacuum Control Valve

VDIM Vehicle Dynamics Integrated Management

VENT Ventilator

VGRS Variable Gear Ratio Steering

VIM Vehicle Interface Module

VIN Vehicle Identification Number

VLC Valve Lift Control

VPS Variable Power Steering

VSC Vehicle Stability Control

VSV Vacuum Switching Valve

VTV Vacuum Transmitting Valve

VVT-i Variable Valve Timing-intelligent

W/, w/ With

WGN Wagon

W/H Wire Harness

W/O, w/o Without

X-REAS X-Relative Absorber System

1ST, 1st First

2ND, 2nd Second

2WD Two Wheel Drive Vehicle (4 x 2)

3RD, 3rd Third

4TH, 4th Fourth

4WD Four Wheel Drive Vehicle (4 x 4)

4WS Four Wheel Steering System

5TH, 5th Fifth

6TH, 6th Sixth

7TH, 7th Seventh

8TH, 8th Eighth

Page 15

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM00000286702CX

Title: INTRODUCTION: TERMS: GLOSSARY OF SAE AND SCION TERMS (2013 FR-S)

GLOSSARY OF SAE AND SCION TERMS

This glossary lists all SAE-J1930 terms and abbreviations used in this manual in compliance with SAE

recommendations, as well as their SCION equivalents.

SAE

ABBREVIATION

A/C Air Conditioning Air Conditioner

ACL Air Cleaner Air Cleaner, A/CL

AIR Secondary Air Injection Air Injection (AI)

AP Accelerator Pedal B+ Battery Positive Voltage +B, Battery Voltage

BARO Barometric Pressure CAC Charge Air Cooler Intercooler

CARB Carburetor Carburetor

CFI Continuous Fuel Injection CKP Crankshaft Position Crank Angle

CL Closed Loop Closed Loop

CMP Camshaft Position Cam Angle

CPP Clutch Pedal Position CTOX Continuous Trap Oxidizer -

SAE TERM SCION TERM

( )-ABBREVIATION

CTP Closed Throttle Position LL ON, Idle ON

DFI Direct Fuel Injection Direct Injection (DI./INJ)

DI Distributor Ignition DLC3 Data Link Connector 3 OBD II Diagnostic Connector

DTC Diagnostic Trouble Code Diagnostic Trouble Code

DTM Diagnostic Test Mode ECL Engine Coolant Level ECM Engine Control Module Engine Electronic Control Unit (ECU)

ECT Engine Coolant Temperature

EEPROM

EFE Early Fuel Evaporation

EGR Exhaust Gas Recirculation Exhaust Gas Recirculation (EGR)

Electrically Erasable Programmable Read

Only Memory

Coolant Temperature, Water Temperature

(THW)

Electrically Erasable Programmable Read

Only Memory (EEPROM)

Cold Mixture Heater (CMH), Heat Control

Valve (HCV)

Page 16

EI Electronic Ignition Distributorless Ignition (DLI)

EM Engine Modification Engine Modification (EM)

EPROM

Erasable Programmable Read Only

Memory

Programmable Read Only Memory (PROM)

EVAP Evaporative Emission Evaporative Emission Control (EVAP)

FC Fan Control -

FEEPROM

FEPROM

Flash Electrically Erasable Programmable

Read Only Memory

Flash Erasable Programmable Read Only

Memory

-

-

FF Flexible Fuel FP Fuel Pump Fuel Pump

GEN Generator Alternator

GND Ground Ground (GND)

HO2S Heated Oxygen Sensor

Heated Oxygen Sensor (HO

S)

2

IAC Idle Air Control Idle Speed Control (ISC)

IAT Intake Air Temperature Intake or Inlet Air Temperature

ICM Ignition Control Module IFI Indirect Fuel Injection Indirect Injection (IDL)

IFS Inertia Fuel-Shutoff ISC Idle Speed Control KS Knock Sensor Knock Sensor

MAF Mass Airflow Air Flow Meter

MAP Manifold Absolute Pressure Manifold Pressure Intake Vacuum

Electric Bleed Air Control Valve (EBCV)

MC Mixture Control

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDP Manifold Differential Pressure MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)

MIL Malfunction Indicator Lamp Check Engine Light

MST Manifold Surface Temperature MVZ Manifold Vacuum Zone NVRAM Non-Volatile Random Access Memory O2S Oxygen Sensor

Oxygen Sensor, O

Sensor (O 2 S)

2

OBD On-Board Diagnostic On-Board Diagnostic System (OBD)

OC Oxidation Catalytic Converter Oxidation Catalytic Convert (OC), CCo

OL Open Loop Open Loop

PAIR Pulsed Secondary Air Injection Air Suction (AS)

PCM Powertrain Control Module -

Page 17

PNP Park/Neutral Position PROM Programmable Read Only Memory PSP Power Steering Pressure -

PTOX Periodic Trap Oxidizer

Diesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAM Random Access Memory Random Access Memory (RAM)

RM Relay Module ROM Read Only Memory Read Only Memory (ROM)

RPM Engine Speed Engine Speed

SC Supercharger Supercharger

SCB Supercharger Bypass E-ABV

SFI Sequential Multiport Fuel Injection

Electronic Fuel Injection (EFI), Sequential

Injection

SPL Smoke Puff Limiter SRI Service Reminder Indicator SRT System Readiness Test ST Scan Tool TB Throttle Body Throttle Body

TBI Throttle Body Fuel Injection

Single Point Injection

Central Fuel Injection (Ci)

TC Turbocharger Turbocharger

TCC Torque Converter Clutch Torque Converter

TCM Transmission Control Module Transmission ECU, ECT ECU

TP Throttle Position Throttle Position

TR Transmission Range -

Bimetallic Vacuum Switching Valve (BVSV)

TVV Thermal Vacuum Valve

Thermostatic Vacuum Switching Valve

(TVSV)

Three-Way Catalytic (TWC)

TWC Three-Way Catalytic Converter

TWC+OC

Three-Way + Oxidation Catalytic

Converter

Manifold Converter

CC

RO

CC

+ CCo

R

VAF Volume Airflow Air Flow Meter

VR Voltage Regulator Voltage Regulator

VSS Vehicle Speed Sensor Vehicle Speed Sensor

WOT Wide Open Throttle Full Throttle

WU-OC Warm Up Oxidation Catalytic Converter WU-TWC Warm Up Three-Way Catalytic Converter -

Page 18

3GR Third Gear -

4GR Fourth Gear -

Page 19

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM000000UYW0DPX

Title: INTRODUCTION: IDENTIFICATION INFORMATION: VEHICLE IDENTIFICATION AND SERIAL

NUMBERS (2013 FR-S)

VEHICLE IDENTIFICATION AND SERIAL NUMBERS

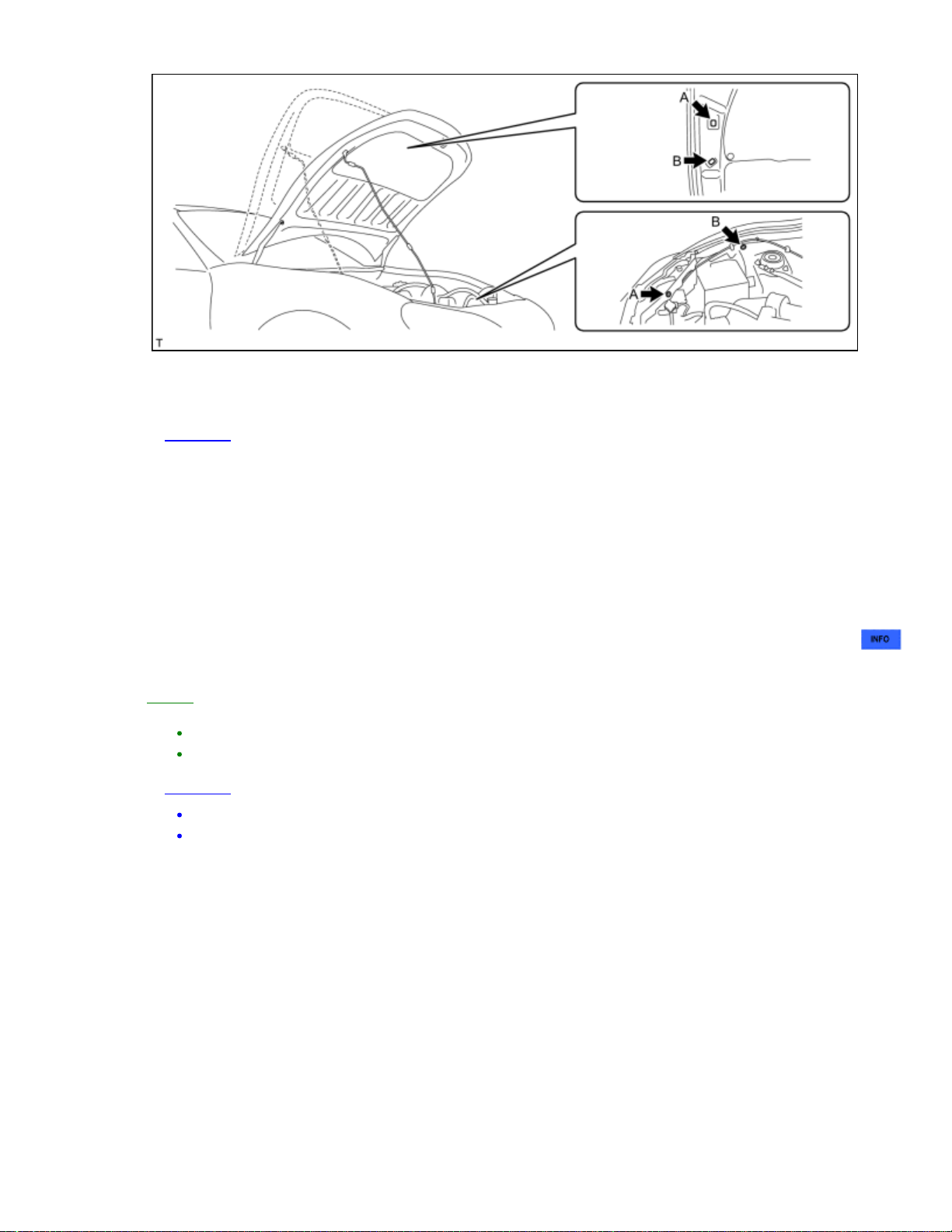

1. VEHICLE IDENTIFICATION NUMBER

(a) The vehicle identification number is stamped on the vehicle body and on the certification label as

shown in the illustration.

Text in Illustration

*A Manual transmission - *1 Vehicle Identification Number *2 Certification Label

2. ENGINE SERIAL NUMBER AND TRANSMISSION SERIAL NUMBER

(a) The engine serial number is stamped on the cylinder

block of the engine as shown in the illustration.

Text in Illustration

*1 FA20 Engine Serial Number

(b) The transmission serial number is printed on the transmission number label.

Page 20

Text in Illustration

*A TL70 *B TX6A

*1 Transmission Number Label - -

Page 21

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM000000UZ30BTX

Title: INTRODUCTION: HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS: ELECTRONIC CIRCUIT

INSPECTION PROCEDURE (2013 FR-S)

ELECTRONIC CIRCUIT INSPECTION PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance measurements are standard values measured at an

ambient temperature of 20°C (68°F). Resistance measurements may be inaccurate if measured

at high temperatures, i.e. immediately after the vehicle has been running. Measurements should

be made after the engine has cooled down.

(b) HANDLING CONNECTORS

Text in Illustration

*a INCORRECT

*b CORRECT

(1) When disconnecting a connector, first squeeze the

mating connector housing halves tightly together to

release the lock, and then press the lock claw and

separate the connector.

(2) When disconnecting a connector, do not pull on the

harnesses. Grasp the connector directly and separate

it.

(3) Before connecting a connector, check that there are

no deformations, damage, looseness or missing

terminals.

(4) When connecting a connector, press firmly until it

locks with a "click" sound.

(5) If checking a connector with a TOYOTA electrical

tester, check the connector from the backside

(harness side) using a mini test lead.

NOTICE:

As a waterproof connector cannot be checked from the

backside, check it by connecting a sub-harness.

Do not damage the terminals by moving the inserted

tester needle.

(c) CHECKING CONNECTORS

Page 22

Text in Illustration

*a Core Wire

*b Looseness of Crimping

*c Terminal Deformation

*d Pull Lightly

(1) Checking when a connector is connected: Squeeze the connectors together to confirm that they

are fully connected and locked.

(2) Checking when a connector is disconnected: Check by pulling the wire harness lightly from the

backside of the connector. Look for unlatched terminals, missing terminals, loose crimps or

broken conductor wires. Visually check for corrosion, metallic or foreign matter and water, and

bent, rusted, overheated, contaminated or deformed terminals.

(3) Checking the contact pressure of the terminal:

Prepare a spare male terminal. Insert it into a female

terminal, and check for ample tension when inserting

and after full engagement.

NOTICE:

When testing a gold-plated female terminal, always use

a gold -plated male terminal.

(d) CONNECTOR TERMINAL REPAIR METHOD

Text in Illustration

*a CORRECT

*b INCORRECT

(1) If there is any foreign matter on the terminal, clean

the contact point with compressed air or a cloth.

Never rub the contact point using sandpaper as the

plating may come off.

(2) If there is abnormal contact pressure, replace the

female terminal. If the male terminal is gold-plated

(gold color), use a gold-plated female terminal; if it is

silver-plated (silver color), use a silver-plated female

terminal.

Page 23

(3) Damaged, deformed or corroded terminals should be

replaced. If the terminal does not lock into the

(e) WIRE HARNESS HANDLING

Text in Illustration

housing, the housing may have to be replaced.

*a INCORRECT

(1) If removing a wire harness, check the wiring and

clamps before proceeding so that it can be restored in

the same way.

(2) Never twist, pull or slacken the wire harness more

than necessary.

(3) The wire harness should never come into contact with

any high temperature part, rotating, moving, vibrating

or sharp-edged parts. Avoid contact with panel edges,

screw tips and other sharp items.

(4) When installing parts, never pinch the wire harness.

(5) Never cut or break the cover of the wire harness. If it

is cut or broken, repair it with insulating tape or

replace the wire harness.

2. CHECK FOR OPEN CIRCUIT

(b) Check the resistance.

(a) For an open circuit in the wire harness in Fig. 1, measure

the resistance and voltage as follows:

(1) Disconnect connectors A and C and measure the resistance between the terminals of the

connectors.

Page 24

Standard Resistance (Fig. 2):

Connector A terminal 1 - Connector C terminal 1 10 kΩ or higher

Connector A terminal 2 - Connector C terminal 2 Below 1 Ω

HINT:

Measure the resistance while lightly shaking the wire harness vertically and horizontally.

If the results match the values specified above, an open circuit exists between terminal 1 of

TESTER CONNECTION SPECIFIED CONDITION

connector A and terminal 1 of connector C.

(2) Disconnect connector B and measure the resistance

between the terminals of the connectors.

Standard Resistance (Fig. 3):

TESTER CONNECTION SPECIFIED

CONDITION

Connector A terminal 1 - Connector B1

terminal 1

Connector B2 terminal 1 - Connector C

terminal 1

Below 1 Ω

10 kΩ or higher

If the results match the values specified above, an

open circuit exists between terminal 1 of

connector B2 and terminal 1 of connector C.

(c) Check the voltage.

(1) In a circuit in which voltage is applied to the ECU

connector terminal, an open circuit can be checked by

conducting a voltage check.

With each connector still connected, measure the

voltage between body ground and the following

terminals (in this order): 1) terminal 1 of connector

A, 2) terminal 1 of connector B, and 3) terminal 1 of

connector C.

Standard Voltage (Fig. 4):

TESTER CONNECTION SPECIFIED CONDITION

Connector A terminal 1 - Body ground 5 V

Connector B terminal 1 - Body ground 5 V

Connector C terminal 1 - Body ground Below 1 V

If the results match the values specified above, an

open circuit exists in the wire harness between

terminal 1 of connector B and terminal 1 of

connector C.

Page 25

3. CHECK FOR SHORT CIRCUIT

(b) Check the resistance to body ground.

(a) If a wire in the harness is shorted to ground (Fig. 5),

locate the shorted section by measuring the resistance as

follows:

(1) Disconnect connectors A and C and measure the resistance.

Standard Resistance (Fig. 6):

TESTER CONNECTION SPECIFIED CONDITION

Connector A terminal 1 - Body ground Below 1 Ω

Connector A terminal 2 - Body ground 10 kΩ or higher

HINT:

Measure the resistance while lightly shaking the wire harness vertically and horizontally.

If the results match the values specified above, a short circuit exists between terminal 1 of

connector A and terminal 1 of connector C.

(2) Disconnect connector B and measure the resistance.

Standard Resistance (Fig. 7):

TESTER CONNECTION SPECIFIED

CONDITION

Connector A terminal 1 - Body ground 10 kΩ or higher

Connector B2 terminal 1 - Body

ground

If the results match the values specified above, a

Below 1 Ω

Page 26

short circuit exists between terminal 1 of

connector B2 and terminal 1 of connector C.

4. CHECK AND REPLACE ECU

NOTICE:

The connector should not be disconnected from the ECU. Perform the inspection from the backside

of the connector on the wire harness side.

When no measuring condition is specified, perform the inspection with the engine stopped and the

ignition switch ON.

Check that the connectors are fully seated. Check for loose, corroded or broken wires.

(a) First, check the ECU ground circuit. If it is faulty, repair it. If it is normal, the ECU could be faulty.

Temporarily replace the ECU with a normally functioning one and check if the symptoms occur. If

the trouble symptoms disappear, replace the original ECU.

(1) Measure the resistance between the ECU ground

terminal and body ground.

Text in Illustration

*a Ground

Standard resistance:

Below 1 Ω

(2) Disconnect the ECU connector. Check the ground

terminals on the ECU side and wire harness side for

bent terminals, corrosion or foreign matter. Lastly,

check the contact pressure of the female terminals.

Text in Illustration

Component without harness connected

*a

(ECU)

*b Ground

Front view of wire harness connector

*c

(to ECU)

*d Ground

Page 27

Last Modified: 3-27-2012 6.4 F From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM000000UZ20BWX

Title: INTRODUCTION: HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS: GENERAL INFORMATION

(2013 FR-S)

GENERAL INFORMATION

A large number of ECU controlled systems are used in this vehicle. In general, ECU controlled

systems are considered to be very intricate, requiring a high level of technical knowledge to

troubleshoot. However, most problem checking procedures only involve inspecting the ECU

controlled system circuits one by one. An adequate understanding of the system and a basic

knowledge of electricity is enough to perform effective troubleshooting, accurate diagnosis and

necessary repairs.

(For using the Techstream*)

HINT:

*: The Techstream is the name for the diagnostic tester in North America.

Before using the Techstream, read the operator's manual thoroughly.

If the Techstream cannot communicate with the ECU controlled systems when connected

to the DLC3 with the ignition switch ON and the Techstream turned on, there is a

problem on the vehicle side or the Techstream side.

i. If communication is possible when the Techstream is connected to another

vehicle, inspect the diagnosis data link line (bus (+) line), CANH and CANL

lines, and the power circuits for the vehicle ECUs.

ii. If communication is still not possible when the Techstream is connected to

another vehicle, the problem is probably in the Techstream itself. Perform the

Self Test procedure outlined in the Techstream operator's manual.

1. TROUBLESHOOTING PROCEDURES

The troubleshooting procedures consist of diagnosis procedures for when a DTC is stored and

diagnosis procedures for when no DTC is stored. The basic idea is explained in the following

table.

PROCEDURE

TYPE

DTC Based

Diagnosis

Symptom

Based

Diagnosis

(No DTCs

stored)

The diagnosis procedure is

based on the DTC that is

stored.

The diagnosis procedure is

based on problem

symptoms.

DETAILS TROUBLESHOOTING METHOD

The malfunctioning part is identified based on the

DTC detection conditions using a process of

elimination.

The possible trouble areas are eliminated one-by-

one by use of the Techstream and inspection of

related parts.

The malfunctioning part is identified based on the

problem symptoms using a process of elimination.

The possible trouble areas are eliminated one-by-

one by use of the Techstream and inspection of

related parts.

Vehicle systems are complex and use many ECUs that are difficult to inspect independently.

Therefore, a process of elimination is used, where components that can be inspected

Page 28

individually are inspected, and if no problems are found in these components, the related ECU is

identified as the problem and replaced.

It is extremely important to ask the customer about the environment and the conditions

present when the problem occurred (Customer Problem Analysis). This makes it possible to

simulate the conditions and confirm the symptom. If the symptom cannot be confirmed or the

DTC does not recur, the malfunctioning part may not be identified using the troubleshooting

procedure, and the ECU for the related system may be replaced even though it is not defective.

If this happens, the original problem will not be solved.

In order to prevent endless expansion of troubleshooting procedures, the troubleshooting

procedures are written with the assumption that multiple malfunctions do not occur

simultaneously for a single problem symptom.

To identify the malfunctioning part, troubleshooting procedures narrow down the target by

separating components, ECUs and wire harnesses during the inspection. If the wire harness is

identified as the cause of the problem, it is necessary to inspect not only the connections to

components and ECUs but also all of the wire harness connectors between the component and

the ECU.

2. DESCRIPTION

(a) The data of each system and Diagnostic Trouble Codes (DTCs) can be read from the Data Link

Connector 3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the

Techstream to check for malfunctions and perform repairs.

3. CHECK DLC3

(a) The vehicle ECUs use ISO 15765-4 communication

protocol. The terminal arrangement of the DLC3 complies

with SAE J1962 and matches the ISO 15765-4 format.

TERMINAL NO.

(SYMBOL)

4 (CG) - Body

ground

5 (SG) - Body

ground

16 (BAT) Body ground

6 (CANH) - 14

(CANL)

6 (CANH) - 4

(CG)

14 (CANL) - 4

(CG)

6 (CANH) - 16

(BAT)

TERMINAL

DESCRIPTION

CONDITION SPECIFIED

CONDITION

Chassis ground Always Below 1 Ω

Signal ground Always Below 1 Ω

Battery positive Always 11 to 14 V

CAN bus line

HIGH-level CAN

bus line

LOW-level CAN

bus line

HIGH-level CAN

bus line

Ignition

switch off*

Ignition

switch off*

Ignition

switch off*

Ignition

switch off*

57 to 63 Ω

200 Ω or

higher

200 Ω or

higher

6 kΩ or higher

14 (CANL) - 16

(BAT)

LOW-level CAN

bus line

Ignition

switch off*

6 kΩ or higher

NOTICE:

*: Before measuring the resistance, leave the vehicle as

is for at least 1 minute and do not operate the ignition

switch, any other switches or the doors.

Page 29

If the result is not as specified, the DLC3 may have a

malfunction. Repair or replace the harness or connector.

Page 30

Last Modified: 3-27-2012 6.4 D From: 201203

(b) Warm up the engine to the normal operating temperature.

Model Year: 2013 Model: FR-S Doc ID: RM000000UZ1088X

Title: INTRODUCTION: HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS: HOW TO PROCEED WITH

TROUBLESHOOTING (2013 FR-S)

HOW TO PROCEED WITH TROUBLESHOOTING

1. OPERATION FLOW

HINT:

Perform troubleshooting in accordance with the procedure below. The following is an outline of basic

troubleshooting procedure. Confirm the troubleshooting procedure for the circuit you are working on

before beginning troubleshooting.

1. VEHICLE BROUGHT TO WORKSHOP

NEXT

2. CUSTOMER PROBLEM ANALYSIS

(a) Ask the customer about the conditions and environment when the problem occurred.

NEXT

3. INSPECT BATTERY VOLTAGE

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery before proceeding to the next step.

NEXT

4. SYMPTOM CONFIRMATION AND DTC (AND FREEZE FRAME DATA) CHECK

(a) Visually check the wire harnesses, connectors and fuses for open and short circuits.

Page 31

(c) Confirm the problem symptoms and conditions, and check for DTCs.

Result:

RESULT PROCEED TO

DTC is output A

DTC is not output B

GO TO STEP 6

B

A

5. DTC CHART

(a) Find the output DTC in the DTC chart. Look at the Trouble Area column for a list of

potentially malfunctioning circuits and/or parts.

NEXT

6. PROBLEM SYMPTOMS CHART

(a) Find the problem symptoms in the problem symptoms table. Look at the Suspected Area

column for a list of potentially malfunctioning circuits and/or parts.

GO TO STEP 7

NEXT

7. CIRCUIT INSPECTION OR PARTS INSPECTION

(a) Identify the malfunctioning circuit or part.

NEXT

8. ADJUST, REPAIR OR REPLACE

(a) Adjust, repair or replace the malfunctioning circuit or parts.

Page 32

NEXT

CHECK

CHECK

(INPUT SIGNAL CHECK)

LIST

TEST

9. CONFIRMATION TEST

(a) After the adjustment, repairs or replacement of components, confirm that the malfunction no

longer exists. If the malfunction does not recur, perform a confirmation test under the same

conditions and in the same environment as when the malfunction first occurred.

2. CUSTOMER PROBLEM ANALYSIS

HINT:

When troubleshooting, confirm that the problem symptoms have been accurately identified.

Preconceptions should be discarded in order to make an accurate judgment. To clearly understand

what the problem symptoms are, it is extremely important to ask the customer about the problem

and the conditions at the time the malfunction occurred.

Gather as much information as possible for reference. Past problems that seem unrelated may also

help in some cases.

The following 5 items are important points for problem analysis:

What Vehicle model, system name

When Date, time, occurrence frequency

Where Road conditions

Under what conditions? Driving conditions, weather conditions

How did it happen? Problem symptoms

NEXT

END

3. SYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

HINT:

The diagnostic system in this vehicle has various functions.

The first function is the Diagnostic Trouble Code (DTC) check. A DTC is a code stored in the ECU

memory whenever a malfunction in the signal circuits to the ECU occurs. In a DTC check, a previous

malfunction's DTC can be checked by a technician during troubleshooting.

Another function is the Input Signal Check, which checks if the signals from various switches are

sent to the ECU correctly.

By using these functions, the problem areas can be narrowed down and troubleshooting can

be more effective. Diagnostic functions are incorporated in the following systems of this

vehicle.

SYSTEM SYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC

DTC

SENSOR CHECK/TEST MODE

DATA

ACTIVE

Page 33

(NORMAL

MODE)

SFI System (FA20) ○ ○ - ○ ○

Ignition System (FA20) - - - - Fuel System (FA20) - - - - -

(CHECK

MODE)

Emission Control System

(FA20)

Intake System (FA20) - - - - Cooling Fan System

(FA20)

Starting System (FA20) - - - - Key Inter Lock System

(FA20)

Cruise Control System ○ - - ○ ○

Automatic Transmission

System (TX6A)

Tire Pressure Warning

System

Vehicle Stability Control

System

Power Steering System ○ - - ○ -

Audio and Visual System - - - - -

- - - - -

- - - - -

- - - - -

○ ○

○

○

-

-

-

○ ○ ○

○ ○ ○

○ ○

Charging System (FA20) ○ ○ - ○ ○

Electric Power Control

System

LIN Communication

System

CAN Communication

System

Power Door Lock Control

System

Wireless Door Lock

Control System

Key Reminder Warning

System

Engine Immobiliser

System

Lighting System (INT) - - - ○ ○

Meter / Gauge System ○ - - ○ ○

○

○

○

- - -

○

- - -

○

- -

- - - -

- - - -

- -

- -

○

○ ○

○ ○

○

○ ○

-

-

Clock System - - - - Airbag System ○ ○ - ○ -

Page 34

Occupant Classification

System

○

- -

○

-

Seat Heater System - - - - Seat Belt Warning System - - - ○ ○

Air Conditioning System - - - ○ ○

Power Window Control

System

Window Defogger System - - - ○ ○

Luggage Compartment

Door Opener System

Power Mirror Control

System

Wiper and Washer System - - - - Lighting System (EXT) ○ - - ○ ○

Horn System - - - - -

In the DTC check, it is very important to determine whether the problem indicated by the DTC

either: 1) still occurs, or 2) occurred in the past but has returned to normal. In addition, the DTC

should be compared to the problem symptom to see if they are related. For this reason, DTCs

should be checked before and after confirmation of symptoms (i.e., whether or not problem

symptoms exist) to determine current system conditions, as shown in the flowchart below.

○

- - -

- - - - -

- -

○ ○

○ ○

Never skip the DTC check. Failing to check for DTCs, depending on the case, may result in

unnecessary troubleshooting for systems operating normally or lead to repairs not related to the

problem. Follow the procedure listed in the flowchart in the correct order.

The following flowchart shows how to proceed with troubleshooting using the DTC check. Directions

from the flowchart will indicate how to proceed either to DTC troubleshooting or to the

troubleshooting of each problem symptom.

1. DTC CHECK

NEXT

2. MAKE A NOTE OF DTC DISPLAYED AND THEN CLEAR DTCs

NEXT

3. SYMPTOM CONFIRMATION

Page 35

Result:

RESULT PROCEED TO

No symptoms exist A

Symptoms exist B

GO TO STEP 5

B

A

4. SIMULATION TEST USING SYMPTOM SIMULATION METHODS

NEXT

5. DTC CHECK

Result:

RESULT PROCEED TO

DTC is not output A

DTC is output B

A

6. SYMPTOM CONFIRMATION

TROUBLESHOOT FOR PROBLEM INDICATED BY

B

DTC

Result:

RESULT PROCEED TO

Symptoms exist A

Page 36

No symptoms exist B

If a DTC was displayed in the initial DTC check, the problem may have occurred in a wire harness or

connector in that circuit in the past. Check the wire harness and connectors.

END

B

TROUBLESHOOT FOR EACH PROBLEM

A

SYMPTOM

If problem symptoms are present, but no DTCs were stored again after they were cleared, then the

problem causing the symptom may be occurring for something that does not store DTCs (the DTC that

was displayed in the initial DTC check may have been from a past problem or a secondary problem).

4. SYMPTOM SIMULATION

HINT:

The most difficult case in troubleshooting is when no problem symptoms occur. In such a case, a

thorough problem analysis must be carried out. A simulation of the same or similar conditions and

environment in which the problem occurred in the customer's vehicle should be carried out. No matter

how much skill or experience a technician has, troubleshooting without confirming the problem

symptoms will lead to important repairs being overlooked and mistakes or delays.

For example:

With a problem that only occurs when the engine is cold or as a result of vibration caused by the

road during driving, the problem can never be determined if the symptoms are being checked on a

stationary vehicle or a vehicle with a warmed-up engine. Vibration, heat or water penetration

(moisture) is difficult to reproduce. The following symptom simulation tests are effective substitutes

for the conditions and can be applied to a stationary vehicle. Important points in the symptom

simulation test:

In the symptom simulation test, the problem symptoms as well as the problem area or parts must

be confirmed. First, narrow down the possible problem circuits according to the symptoms. Then,

connect the tester and carry out the symptom simulation test, judging whether the circuit being

tested is defective or normal. Also, confirm the problem symptoms at the same time. Refer to

Problem Symptoms Table for each system to narrow down the possible causes.

To reproduce DTCs, it is necessary to satisfy the respective DTC detection conditions.

(a) VIBRATION METHOD: When a malfunction seems to

occur as a result of vibration.

Text in Illustration

*a Vibrate Slightly

*b Shake Slightly

(1) PARTS OR SENSORS

Apply slight vibration with a finger to the part or

sensor suspected to be the cause of the problem, and

check whether the malfunction occurs.

NOTICE:

Applying strong vibration to relays may open the relays.

(2) CONNECTORS

Page 37

Slightly shake the connector vertically and

horizontally.

(3) WIRE HARNESS

Slightly shake the wire harness vertically and

horizontally.

HINT:

The connector joint and fulcrum of the vibration are the major

areas that should be checked thoroughly.

(b) HEAT METHOD: When a malfunction seems to occur when the area in question is heated.

(1) Heat the component that is the possible cause of the malfunction with a hair dryer or similar

device. Check if the malfunction occurs.

NOTICE:

Do not heat components to more than 60°C (140°F). Exceeding this temperature may damage the

components.

Do not apply heat directly to parts in an ECU.

(c) WATER SPRINKLING METHOD: When a malfunction

seems to occur on a rainy day or in high-humidity.

(1) Sprinkle water onto the vehicle and check if the

malfunction occurs.

NOTICE:

Never sprinkle water directly into the engine

compartment. Indirectly change the temperature and

humidity by spraying water onto the front of the radiator.

Never apply water directly onto the electronic

components.

HINT:

If the vehicle has or had a water leak problem, the leak may

have damaged the ECU or connections. Look for evidence of

corrosion or short circuits. Proceed with caution during water

tests.

Page 38

(d) HIGH ELECTRICAL LOAD METHOD: When a malfunction

DTC No., DTC

seems to occur when the electrical load is high.

(1) Turn on the heater blower, headlights, rear window

defogger and all other electrical loads. Check if the

malfunction recurs.

5. DIAGNOSTIC TROUBLE CODE CHART

Look for output Diagnostic Trouble Codes (DTCs) (from the DTC checks) in the appropriate section's

Diagnostic Trouble Code chart. Use the chart to determine the trouble area and the proper inspection

procedure. A description of each of the chart's columns is shown in the table below.

ITEM DESCRIPTION

DTC No. Indicates the diagnostic trouble code.

Detection

Item

Trouble

Area

See page

Indicates the system or details of the problem.

Indicates the suspected areas of the problem.

Indicates the page where the inspection procedure for each circuit is to be found, or gives

instruction for checking and repairs.

6. PROBLEM SYMPTOMS TABLE

When no DTC is output but the problem still occurs, use the Problem Symptoms Table. The suspected

areas (circuits or parts) for each problem symptom are shown in the table. The suspected areas are listed

in order of probability. A description of each of the table columns is shown in the following table.

HINT:

In some cases, the problem is not detected by the diagnostic system even though a problem symptom

occurs. It is possible that the problem occurs outside the detection range of the diagnostic system, or

that the problem occurs in a completely different system.

ITEM DESCRIPTION

Symptom Suspected Area Indicates the circuit or part which needs to be checked.

See page Indicates the page where the inspection procedure is located.

7. INSPECTION

A description of the main points for inspection of suspected areas is shown in the following table.

ITEM DESCRIPTION

Description

The major role and operation of the circuit or system and its component parts are

explained.

Page 39

Detection Condition

Indicates the diagnostic trouble codes, DTC detection conditions and suspected

and Trouble Area

Wiring Diagram

areas for a problem.

This is a wiring diagram for the circuit or system.

This diagram can be used together with the Electrical Wiring Diagram to

thoroughly understand the circuit.

Wire colors are indicated by alphabetical codes. B = Black, L = Blue, R = Red, BR

= Brown, LG = Light Green, V = Violet, G = Green, O = Orange, W = White, GR =

Gray, P = Pink, Y = Yellow, SB = Sky Blue

The first letter indicates the basic wire color and the second letter indicates the

color of the stripe.

Inspection

Procedure

Illustration of the

ECU connector

during the check

This shows the procedure not only to determine whether the circuit is normal or

abnormal, but also to determine whether the problem is located in the sensors,

actuators, wire harness or ECU.

The illustration shows whether the connector being checked is connected or

disconnected.

The connections for an electrical tester are indicated by (+) or (-) after the

terminal name.

For inspections between a connector and body ground, information about the

ground is not shown in the illustration.

Page 40

Last Modified: 3-27-2012 6.4 A From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM000004PFL00QX

Title: INTRODUCTION: REPAIR INSTRUCTION: CUSTOMIZE PARAMETERS (2013 FR-S)

CUSTOMIZE PARAMETERS

1. CUSTOMIZE WIRELESS DOOR LOCK CONTROL SYSTEM

2. CUSTOMIZE KEY REMINDER WARNING SYSTEM

3. CUSTOMIZE LIGHTING SYSTEM (INT)

4. CUSTOMIZE METER / GAUGE SYSTEM

5. CUSTOMIZE SEAT BELT WARNING SYSTEM

6. CUSTOMIZE WINDOW DEFOGGER SYSTEM

7. CUSTOMIZE LIGHTING SYSTEM (EXT)

Page 41

Last Modified: 3-27-2012 6.4 D From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM00000315Z04XX

Title: INTRODUCTION: REPAIR INSTRUCTION: INITIALIZATION (2013 FR-S)

INITIALIZATION

1. PROCEDURES NECESSARY WHEN ECU OR OTHER PARTS ARE REPLACED

REPLACEMENT PART NECESSARY

PROCEDURE

Vehicle Identification

Number (VIN)

ECM

TCM

Automatic

transmission

assembly

Valve body

assembly

Transmission

wire

Shift solenoid

valve S1, S2,

S3, S4, SL1,

SL2, SLT,

SLU, and/or

SR

Engine

assembly

registration

ECU communication ID

registration (Engine

immobiliser system)

Reset memory

EFFECT/INOPERATIVE FUNCTION WHEN

NECESSARY PROCEDURES ARE NOT

PERFORMED

MIL comes on

Engine start

Large shift shock

The deterioration of fuel efficiency

SEE

PAGE

Brake actuator

assembly

(Skid control

ECU)

Steering

sensor

Steering

column

assembly

Rack and

pinion power

steering gear

assembly

Adjust front

wheel

alignment

VSC sensor neutral

memorization

VSC system does not operate normally

(warning indicator light comes on).

Page 42

Power steering ECU

assembly

Steering column

assembly

Rotation angle sensor

initialization and torque

sensor zero point

calibration

Rotation angle sensor

initialization and torque

sensor zero point

calibration

P/S warning light comes on

EPS control

Steering effort is different between turning

steering wheel to left and right

Door control

receiver

Tire pressure

warning valve

and

transmitter

Key

Main body

ECU (network

gateway ECU)

Combination

meter

assembly

Door control

transmitter

assembly

Door control

receiver

Transmitter

ID

registration

Initialization

Code registration

(Engine immobiliser

system)

Code registration

(Wireless door lock

system)

When DTC detection conditions of

"transmitter ID not received" DTC

are met, TPWS indicator blinks for

1 minute, and then illuminates.

Tire pressure warning function

Engine start

Wireless door lock control system

Power window

regulator

motor

assembly

Door window

regulator sub-

assembly

Door glass

Front door

frame sub-

assembly rear

lower

Front door

sush

Front door

opening trim

weatherstrip

Initialize power window

control system

Auto up/down function

Jam protection function

Operation function after ignition

switch is turned off

Page 43

Last Modified: 3-27-2012 6.4 L From: 201203

Model Year: 2013 Model: FR-S Doc ID: RM000000UYX0E9X

Title: INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION (2013 FR-S)

PRECAUTION

1. BASIC REPAIR HINT

(a) HINTS ON OPERATIONS

1 Attire

2 Vehicle protection

3 Safety procedures

Preparation of

Always wear a clean uniform.

A hat and safety shoes must be worn.

Prepare a grille cover, fender cover, seat cover and floor mat before starting

work.

When working with 2 or more persons, be sure to check the safety of

one another.

When working with the engine running, make sure to provide

ventilation for exhaust fumes in the workshop.

If working on high temperature, high pressure, rotating, moving or

vibrating parts, wear appropriate safety equipment and take extra

care not to injure yourself or others.

When jacking up the vehicle, be sure to support the specified locations

with safety stands.

When lifting up the vehicle, use appropriate safety equipment.

Page 44

tools and

Before starting work, prepare a tool stand, SST, measuring equipment, oil, and

4

measuring

any replacement parts required.

equipment

Diagnose with a thorough understanding of proper procedures and of

the reported problem.

Removal and

installation,

5

disassembly and

assembly

operations

Before removing any parts, check the general condition of the

assembly and for deformation and damage.

If the procedure is complicated, take notes. For example, note the

total number of electrical connections, bolts or hoses removed. Add

matchmarks to ensure reassembly of components in the original

positions. Temporarily mark hoses and their fittings if needed.

Clean and wash the removed parts if necessary and assemble them

after a thorough check.

Place the removed parts in a separate box to avoid mixing them up

with new parts or contaminating the new parts.

6 Removed parts

For non-reusable parts such as gaskets, O-rings and self-locking nuts,

replace them with new ones as instructed in this manual.

Retain the removed parts for customer inspection, if requested.

Make sure that removed and installed parts (oil filler cap, level

Checks to

7*

perform after

work is finished

dipstick, floor mat, etc.) are properly installed/tightened.

Make sure that none of the cloths or tools that were used have been

left in the engine compartment or within the vehicle.

Check that there are no oil leaks.

CAUTION:

*: Be sure to perform these checks properly, Not performing these checks properly after finishing

work can lead to serious accident or injury.

(b) JACKING UP AND SUPPORTING THE VEHICLE

(1) Care must be taken when jacking up and supporting the vehicle. Be sure to lift and support the

vehicle at the proper locations.

(c) PRECOATED PARTS

Text in Illustration

*a Seal Lock Adhesive

(1) Precoated parts are bolts and nuts that are coated

with seal lock adhesive at the factory.

(2) If a precoated part is retightened, loosened or moved

in any way, it must be recoated with the specified

adhesive.

(3) When reusing a precoated part, clean off the old

adhesive and dry the part with compressed air. Then

apply new seal lock adhesive appropriately to that

part.

(4) Some seal lock agents harden slowly. You may have

to wait for the seal lock adhesive to harden.

Page 45

(d) GASKETS

(1) When necessary, use a sealer on gaskets to prevent leaks.

(e) BOLTS, NUTS AND SCREWS

(1) Carefully follow all the specifications for tightening torque. Always use a torque wrench.

(2) Make sure that no foreign matter (burrs, paint, etc.) gets trapped under the heads of the bolts

and nuts when tightening them.

(f) FUSES

Text in Illustration

*a INCORRECT

*b CORRECT

(1) When inspecting a fuse, check that the wire of the fuse is not broken.

(2) If the wire of a fuse is broken, confirm that there are no shorts in its circuit.

(3) When a fuse is replaced, a fuse with the same amperage rating must be used.

ILLUSTRATION SYMBOL PART NAME ABBREVIATION

FUSE FUSE

MEDIUM CURRENT FUSE M-FUSE

HIGH CURRENT FUSE H-FUSE

Page 46

FUSIBLE LINK FL

CIRCUIT BREAKER CB

(g) CLIPS

(1) The removal and installation methods of typical clips used for vehicle body parts are shown in

the table below.

HINT:

If clips are damaged during a procedure, always replace the damaged clips with new ones.

SHAPE (EXAMPLE) REMOVAL/INSTALLATION

Remove the clips with a clip remover or pliers.

Remove the clips with a clip remover or screwdriver.

Page 47

Remove the clips with a wide scraper to prevent panel damage.

Remove the clips by pushing the center pin through and prying out the

shell.

Remove the clips by unscrewing the center pin and prying out the shell.

Remove the clips by prying out the pin and then prying out the shell.

(h) CLAWS

(1) The removal and installation methods of typical claws used for vehicle body parts are shown in

the table below.

HINT:

If claws are damaged during a procedure, always replace the cap or cover that has damaged claws

Page 48

with a new one.

SHAPE (EXAMPLE) ILLUSTRATION PROCEDURE

Using a screwdriver, disengage the

claws and remove the cap or cover.

Using a screwdriver, disengage the

claws and remove the cap or cover.

Using a screwdriver, disengage the

claws and remove the cap or cover.

(i) HINGES, GUIDES, CLAMPS, PINS, ETC.

(1) The removal and installation methods of typical hinges, guides, clamps and pins used for vehicle

body parts are shown in the table below.

HINT:

If clamps are damaged during a procedure, always replace the cap or cover that has damaged clamps

with a new one.

SHAPE (EXAMPLE) REMOVAL/INSTALLATION

Page 49

(j) REMOVAL AND INSTALLATION OF VACUUM HOSES

(1) To disconnect a vacuum hose, pull and twist it from

the end of the hose. Do not pull it from the middle of

the hose as this may damage the hose.

Text in Illustration

*a INCORRECT

*b CORRECT

Page 50

(2) When disconnecting vacuum hoses, use tags to

identify where they should be reconnected.

(3) After completing any hose related repairs, double-check that the vacuum hoses are properly

connected. The label under the hood shows the proper layout.

(4) When using a vacuum gauge, never force the hose onto a connector that is too large. If a hose

has been stretched, air may leak. Use a step-down adapter if necessary.

(k) TORQUE WHEN USING TORQUE WRENCH WITH EXTENSION TOOL

NOTICE:

(1) Use the formula below to calculate special torque

values for situations where SST or an extension tool is

combined with a torque wrench.

Formula

T' = (L2/(L1 + L2))*T

Reading of torque wrench {N*m (kgf*cm,

T'

ft.*lbf)}

TTorque {N*m (kgf*cm, ft.*lbf)}

L1Length of SST or extension tool {cm (in.)}

L2Length of torque wrench {cm (in.)}

If an extension tool or SST is combined with a torque

wrench and used to tighten to a torque specification in

this manual, the actual torque will be excessive and

parts will be damaged.

2. FOR VEHICLES EQUIPPED WITH SRS AIRBAG AND SEAT BELT PRETENSIONER

This vehicle is equipped with a Supplemental Restraint System (SRS).

Page 51

CAUTION:

Before performing pre-disposal deployment of any SRS component, review and closely follow all

applicable environmental and hazardous material regulations. Pre-disposal deployment may be

considered hazardous material treatment.

Failure to carry out the service operations in the correct sequence could cause the SRS to

unexpectedly deploy during servicing and lead to serious injury. Furthermore, if a mistake is made

when servicing the SRS, it is possible that the SRS may fail to operate properly. Before servicing

(including removal or installation of parts, inspection or replacement), be sure to read the following

section carefully.

(a) GENERAL NOTICE

(1) The power window system utilizes a mechanism in which the door glass moves down slightly

when the door is opened, and in which the glass moves up when the door closed in order to

prevent the door molding from being damaged. When the negative (-) battery terminal needs to

be disconnected for servicing, fully open the driver and passenger door glasses in advance.

(2) As malfunctions of the SRS are difficult to confirm, the Diagnostic Trouble Codes (DTCs) become

the most important source of information when troubleshooting. When troubleshooting the SRS,

always check for DTCs before disconnecting the battery.

(3) Work must be started at least 90 seconds after the ignition switch is turned off and after the

cable is disconnected from the negative (-) battery terminal.

The SRS is equipped with a back-up power source. If work is started within 90 seconds after

turning the ignition switch off and disconnecting the cable from the negative (-) battery

terminal, the SRS may deploy.

When the cable is disconnected from the negative (-) battery terminal, the clock and audio

system memory will be cleared. Before starting work, make a note of the settings of each

memory system. When work is finished, reset the clock and audio system as before.

CAUTION:

Never use a back- up power source (battery or other) to avoid clearing the system memory. The

back-up power source may inadvertently power the SRS and cause it to deploy.

(4) If the vehicle has been involved in a minor collision where the SRS does not deploy, the steering

pad, front passenger airbag assembly, knee airbag assembly, front seat side airbag assembly,

curtain shield airbag assembly and front seat outer belt assembly should be inspected before

further use of the vehicle.

(5) Never use SRS parts from another vehicle. When replacing parts, use new ones.

(6) Before repairs, remove the airbag sensor assemblies if impacts are likely to be applied to the

sensor during repairs.

(7) Never disassemble and attempt to repair any airbag sensor assemblies or airbag assemblies.

1. Steering pad

2. Front passenger airbag assembly

3. Front seat side airbag assembly

4. Curtain shield airbag assembly

5. Front seat outer belt assembly

(8) Replace the airbag sensor assemblies and the airbag assemblies if: 1) damage has occurred

from being dropped, or 2) cracks, dents or other defects in the case, bracket or connector are

present.

(9) Do not directly expose the airbag sensor assemblies or airbag assemblies to hot air or flames.

(10) Use a voltmeter/ohmmeter with high impedance (minimum = 10 kΩ) for troubleshooting

electrical circuits.

Page 52

(11) Information labels are attached to the SRS components. Follow the instructions on the labels.

(12) After work on the SRS is completed, check the SRS warning light.

(b) SPIRAL CABLE

(1) The steering wheel must be fitted correctly to the steering column with the spiral cable at the

neutral position. Otherwise, cable damage and other problems may occur. Refer to the

information about correct installation of the steering wheel

(c) STEERING PAD

(1) Always place a removed or new steering pad with the surface facing upward. Placing the

steering pad with the pad surface facing downward could cause a serious accident if the airbag

deploys. Also, do not place anything on top of the steering pad.

(2) Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which

could cause serious injury.

(3) Grease or detergents of any kind should not be applied to the steering pad.

(4) Store the steering pad in an area where the ambient temperature is below 93°C (199°F), the

humidity is not high and there is no electrical noise.

(5) Before using an electric welder anywhere on the vehicle, disconnect the airbag ECU assembly

connectors. These connectors contain shorting springs. This feature reduces the possibility of the

airbag deploying due to current entering the squib wiring.

(6) When disposing of the vehicle or the steering pad by itself, the airbag should be deployed using

SST before disposal

(d) FRONT PASSENGER AIRBAG ASSEMBLY

. Deploy the airbag in a safe place away from electrical noise.

.

(1) Always place a removed or new front passenger airbag assembly with the pad surface facing

upward. Placing the airbag assembly with the airbag deployment direction facing downward

could cause a serious accident if the airbag deploys.

(2) Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which

could cause serious injury.

(3) Grease or detergents of any kind should not be applied to the front passenger airbag assembly.

(4) Store the airbag assembly in an area where the ambient temperature is below 93°C (199°F),

the humidity is not high and there is no electrical noise.

(5) Before using an electric welder anywhere on the vehicle, disconnect the airbag ECU assembly

connectors. These connectors contain shorting springs. This feature reduces the possibility of the

airbag deploying due to current entering the squib wiring.

(6) When disposing of the vehicle or the airbag assembly unit by itself, the airbag should be

deployed using SST before disposal

electrical noise.

(e) FRONT SEAT SIDE AIRBAG ASSEMBLY

(1) Always place a removed or new front seat side airbag assembly with the airbag deployment

direction facing upward.

(2) Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which

could cause serious injury.

. Deploy the airbag in a safe place away from

(3) Grease or detergents of any kind should not be applied to the front seat side airbag assembly.

(4) Store the airbag assembly in an area where the ambient temperature is below 93°C (199°F),

the humidity is not high and there is no electrical noise.

(5) Before using an electric welder anywhere on the vehicle, disconnect the airbag ECU assembly

connectors. These connectors contain shorting springs. This feature reduces the possibility of the

airbag deploying due to current entering the squib wiring.

Page 53

(6) When disposing of a vehicle or the airbag assembly unit by itself, the airbag should be deployed

using SST before disposal

. Deploy the airbag in a safe place away from electrical noise.

(f) CURTAIN SHIELD AIRBAG ASSEMBLY

(1) Always place a removed or new curtain shield airbag assembly in a clear plastic bag, and keep it

in a safe place.

CAUTION:

The plastic bag should be disposed of after use.

NOTICE:

Never disassemble the curtain shield airbag assembly.

(2) Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which

could cause serious injury.

(3) Grease or detergents of any kind should not be applied to the curtain shield airbag assembly.

(4) Store the airbag assembly in an area where the ambient temperature is below 93°C (199°F),

the humidity is not high and there is no electrical noise.

(5) Before using an electric welder anywhere on the vehicle, disconnect the airbag ECU assembly

connectors. These connectors contain shorting springs. This feature reduces the possibility of the

airbag deploying due to current entering the squib wiring.

(6) When disposing of a vehicle or the airbag assembly unit by itself, the airbag should be deployed

using SST before disposal

. Deploy the airbag in a safe place away from electrical noise.

(g) FRONT SEAT OUTER BELT ASSEMBLY (SEAT BELT PRETENSIONER)

(1) Never measure the resistance of the front seat outer belt assembly. This may cause the

pretensioner of the front seat outer belt assembly to activate, which could cause serious injury.

(2) Never disassemble the front seat outer belt assembly.

(3) Never install the front seat outer belt assembly on another vehicle.

(4) Store the seat outer belt assembly in an area where the ambient temperature is below 80°C

(176°F), the humidity is not high and there is no electrical noise.

(5) Before using an electric welder anywhere on the vehicle, disconnect the airbag ECU assembly

connectors. These connectors contain shorting springs. This feature reduces the possibility of the

airbag deploying due to current entering the squib wiring.

(6) When disposing of a vehicle or the front seat outer belt assembly unit by itself, the front seat

outer belt assembly should be activated before disposal

. Activate the front seat outer belt

assembly in a safe place away from electrical noise.

(7) As the front seat outer belt assembly is hot after being activated, allow some time for it to cool

down sufficiently before disposal. Never apply water to cool down the front seat outer belt

assembly.

(8) Grease, detergents, oil or water should not be applied to the front seat outer belt assembly.

(h) AIRBAG ECU ASSEMBLY

(1) Never reuse a airbag ECU assembly that has been involved in a collision where the SRS has

deployed.

(2) The connectors to the airbag ECU assembly should be connected or disconnected with the airbag

ECU assembly installed to the vehicle. If the connectors are connected or disconnected while the

airbag ECU assembly is not installed, the SRS may activate.

(3) Work must be started at least 90 seconds after the ignition switch is turned off and the cable is

disconnected from the negative (-) battery terminal, even if only loosening the bolts of the

airbag ECU assembly.

Page 54

(i) WIRE HARNESS AND CONNECTOR

(1) All the connectors in the system are a standard yellow color. If an SRS wire harness has an

open circuit or a connector is broken, replace it.

3. ELECTRONIC CONTROL

Text in Illustration

*1 Cable

*2 Negative (-) Battery Terminal

NOTICE:

The power window system utilizes a mechanism in which the door glass moves down slightly when

the door is opened, and in which the glass moves up when the door closed in order to prevent the

door molding from being damaged. When the negative (-) battery terminal needs to be

disconnected for servicing, fully open the driver and passenger door glasses in advance.

Certain systems need to be initialized after disconnecting and reconnecting the cable from the

negative (-) battery terminal.

After the ignition switch is turned off, the navigation receiver assembly (for Navigation Receiver

Type) or radio and display receiver assembly (for Radio and Display Type with Intuitive Parking

Assist System) records various types of memory and settings. As a result, after turning the ignition

switch off, make sure to wait at least 60 seconds before disconnecting the cable from the negative

(-) battery terminal.

(a) DISCONNECTING AND RECONNECTING NEGATIVE BATTERY CABLE

(1) Before performing work on electronic components, disconnect the cable from the negative (-)

battery terminal to prevent damage to the electrical system or components.

(2) When disconnecting the cable, turn the ignition switch and headlight switch off and loosen the

cable nut completely. Perform these operations without twisting or prying the cable. Then

disconnect the cable.

(3) Clock settings, radio settings, audio system memory, DTCs and other data will be cleared when

the cable is disconnected from the negative (-) battery terminal. Write down any necessary data

before disconnecting the cable.

(b) HANDLING OF ELECTRONIC PARTS

Text in Illustration

*a INCORRECT

(1) Do not open the cover or case of the ECU unless

absolutely necessary. If the IC terminals are touched,

the IC may be rendered inoperative by static

Page 55

electricity.

(2) Do not pull on the wires when disconnecting electronic

connectors. Pull on the connector itself.

(3) Do not drop electronic components, such as sensors or

relays. If they are dropped on a hard surface, they

should be replaced.

(4) When cleaning the engine components with steam,

protect the electronic components, air filter and

emission-related components from water.

(5) Never use an impact wrench to remove or install

temperature switches or temperature sensors.

(6) When measuring the resistance between terminals of

a wire connector, insert the tester probe carefully to

prevent the terminals from bending.

4. REMOVAL AND INSTALLATION OF FUEL CONTROL PARTS

(a) PLACE FOR REMOVING AND INSTALLING FUEL SYSTEM PARTS

(1) Work in a location with good air ventilation that does not have welders, grinders, drills, electric

motors, stoves, or any other ignition sources nearby.

(2) Never work in a pit or near a pit as fuel vapors will collect there.

(b) REMOVING AND INSTALLING FUEL SYSTEM PARTS

(1) Prepare a fire extinguisher before starting work.

(2) To prevent static electricity, install a ground wire between the fuel changer and vehicle, and do

not spray the surrounding area with water. Be careful when performing work in this area, as the

floor surface will become slippery. Do not clean up gasoline spills with water, as this may cause

the gasoline to spread, and possibly create a fire hazard.