Page 1

C92542

05–297

–DIAGNOSTICS ABS WITH EBD SYSTEM (April, 2003)

057U9–04

PRE–CHECK

1. DIAGNOSIS SYSTEM

(a) Release the parking brake lever.

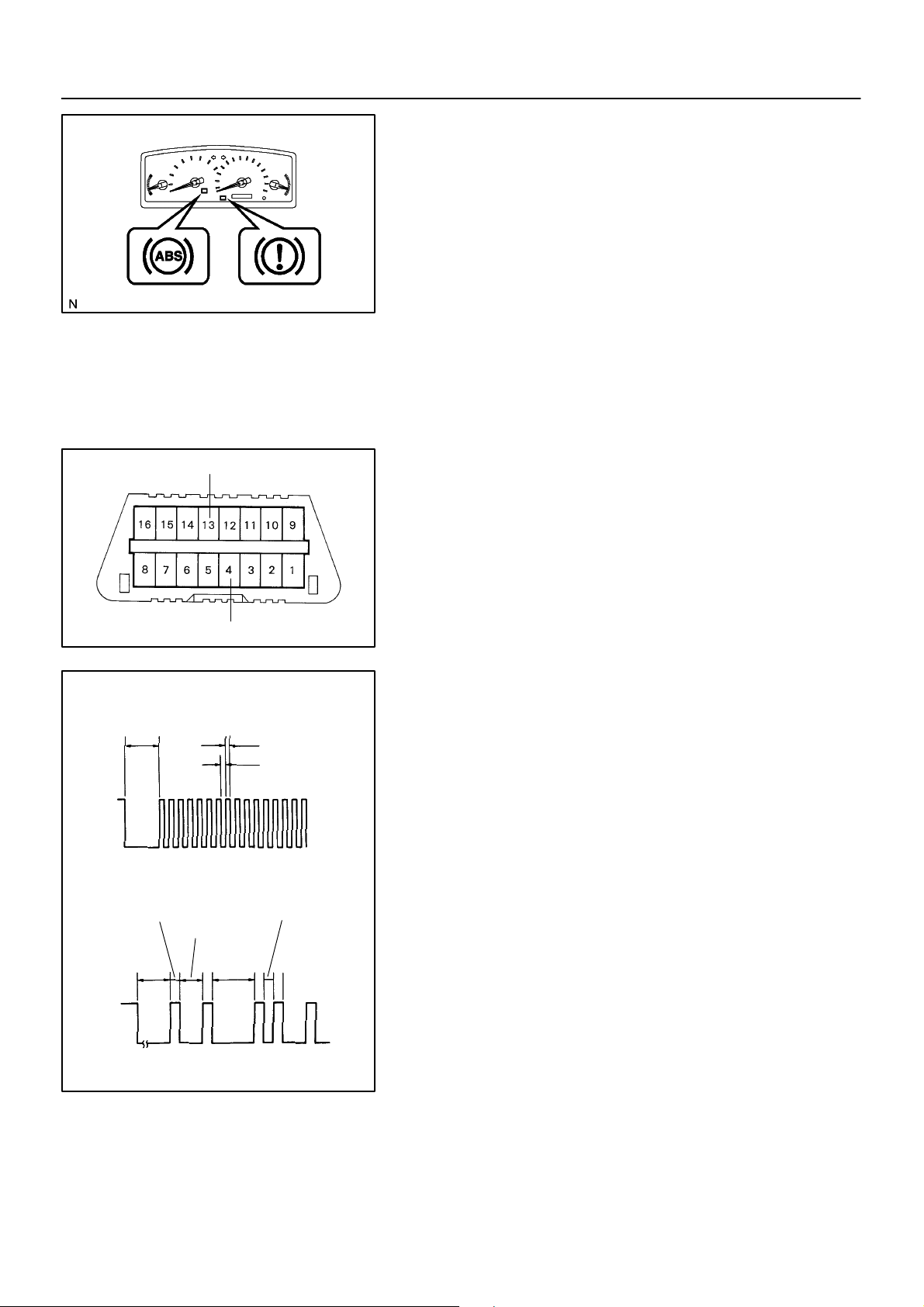

(b) Check the warning lights.

When the ignition switch is turned ON, check that the ABS

warning light and brake warning light goes on for 3 sec.

HINT:

! When the parking brake is applied or the level of the brake

fluid is low, the brake warning light is lit.

! If the indicator check result is not normal, proceed to trou-

bleshooting for the ABS warning light circuit (See page

05–332 or 05–335) or brake warning light circuit (See

page 05–338).

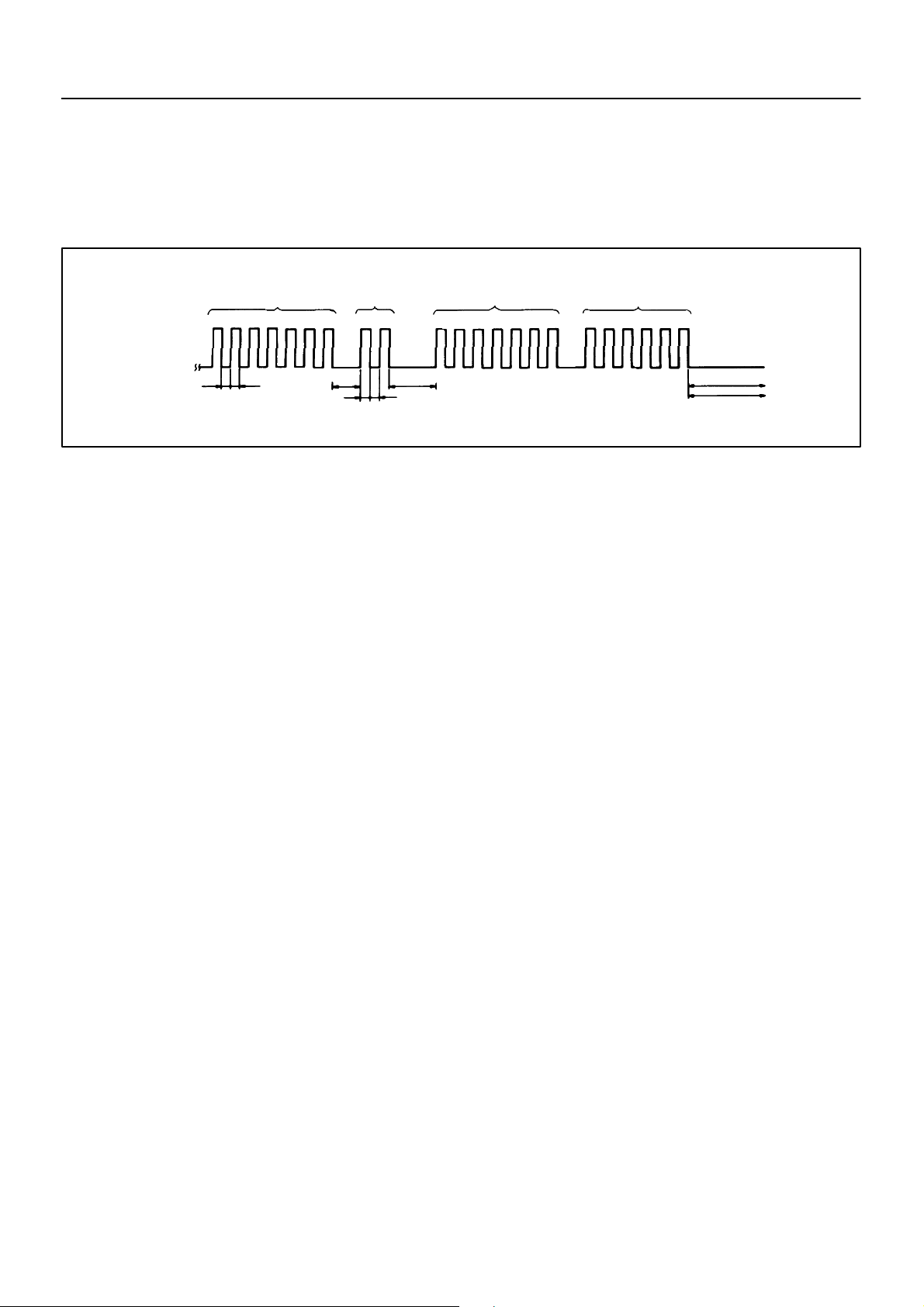

ON

OFF

ON

OFF

Normal Code

2 sec.

Code 11 and 21

0.5 sec.

4 sec.

Code 11

Tc

CG

1.5 sec.

2.5 sec.

0.25 sec.

0.25 sec.

0.5 sec.

Code 21

C52361

R01346

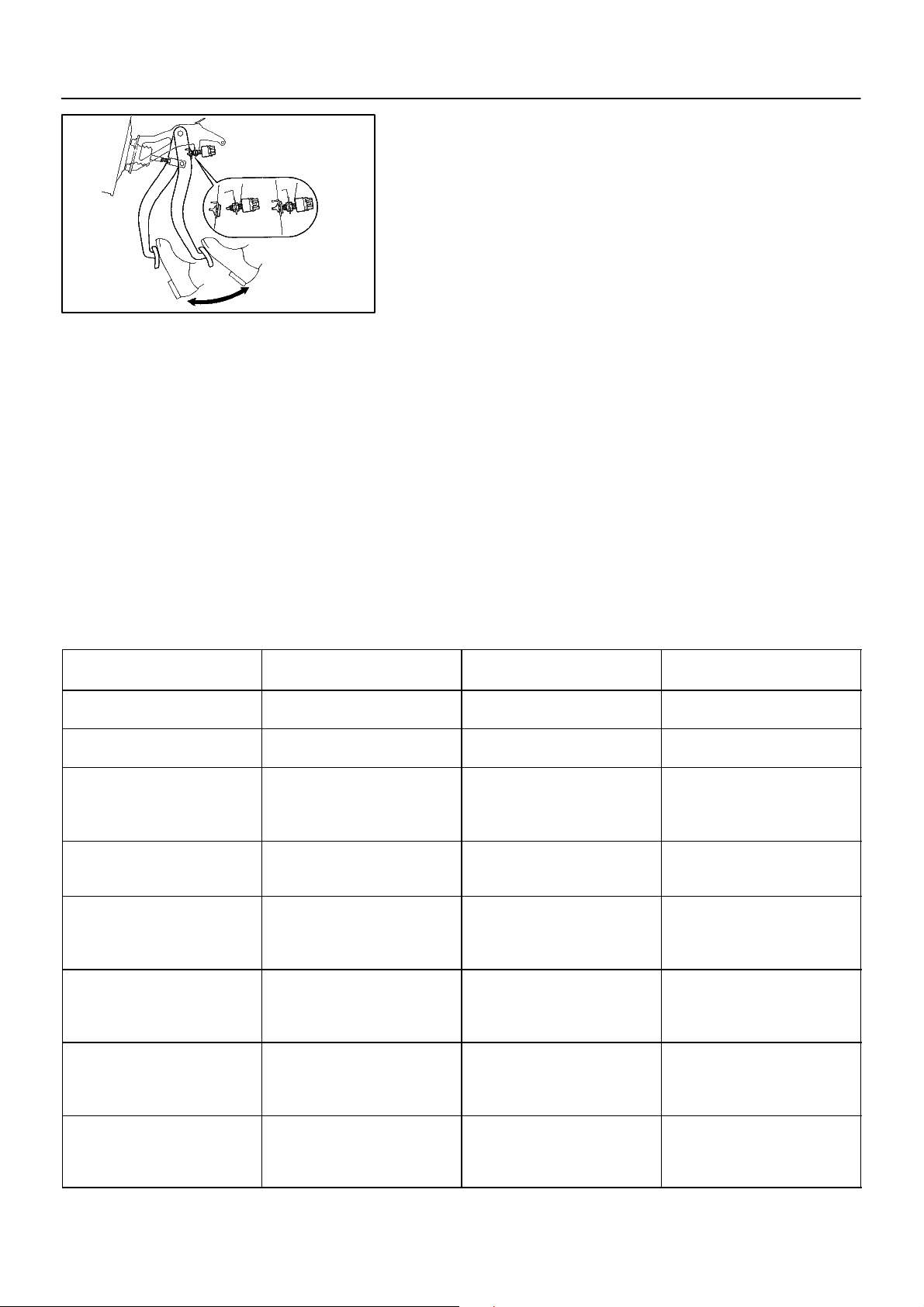

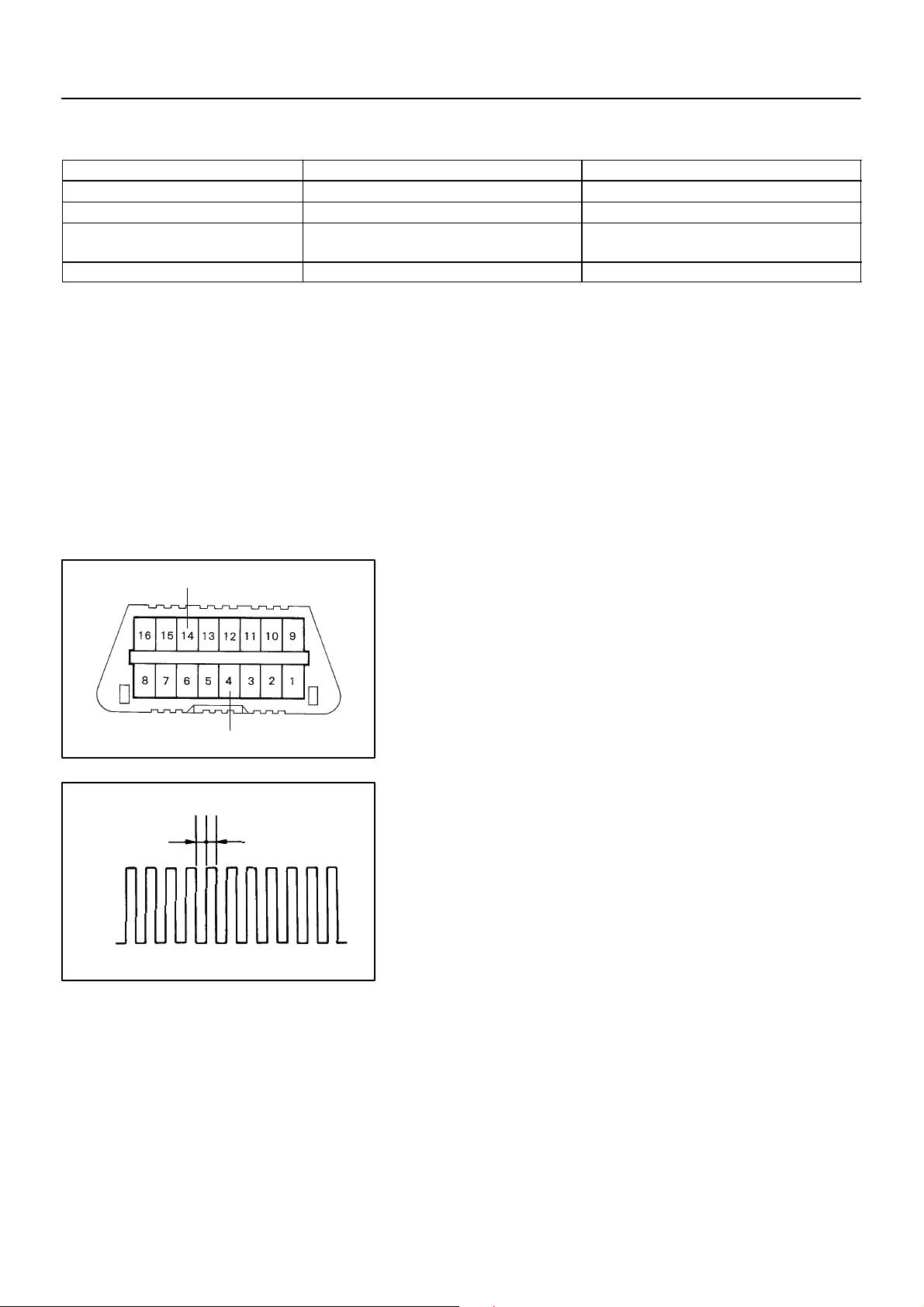

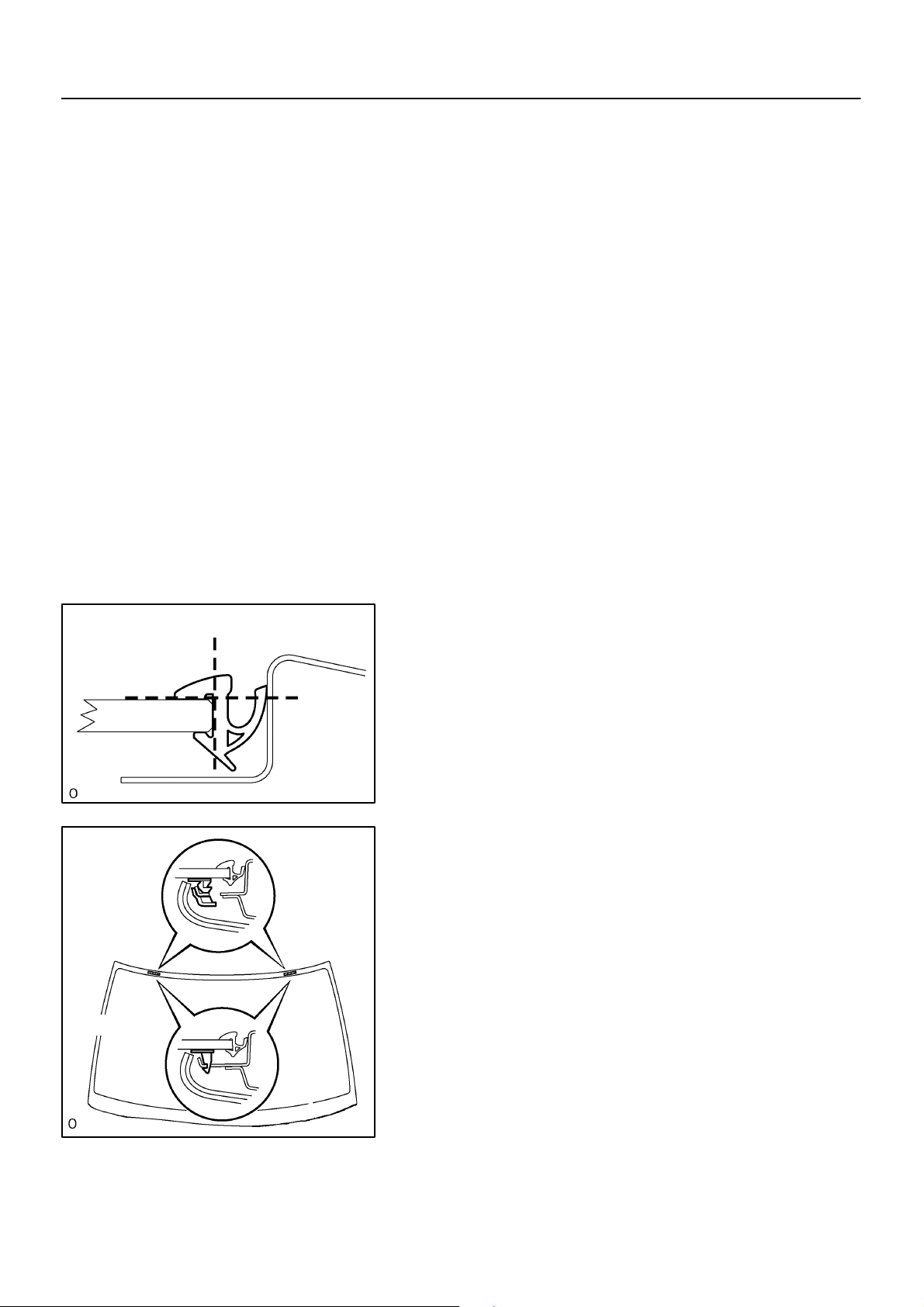

(c) In case of not using hand–held tester:

Check the DTC.

(1) Using SST, it connects terminal Tc and CG of DLC3.

SST 09843–18040

(2) Turn the ignition switch to ON.

(3) Read the DTC from the ABS warning light on the

combination meter.

HINT:

! If not code appears, inspect the diagnostic circuit or ABS

warning light circuit (See page 05–332 or 05–335 ).

! As an example, the blinking patterns for normal code and

codes 11 and 21 are shown on the left.

(4) Codes are explained in the code table on page

05–303.

If 2 or more malfunctions are indicated at the same time, the

lowest numbered DTC will be displayed 1st.

(5) After completing the check, remove the SST from

the DLC3.

SST 09843–18040

(d) In case of using hand–held tester:

Check the DTC.

(1) Read the DTC by following the prompts on the tes-

ter screen.

HINT:

Please refer to the hand–held tester operator’s manual for further details.

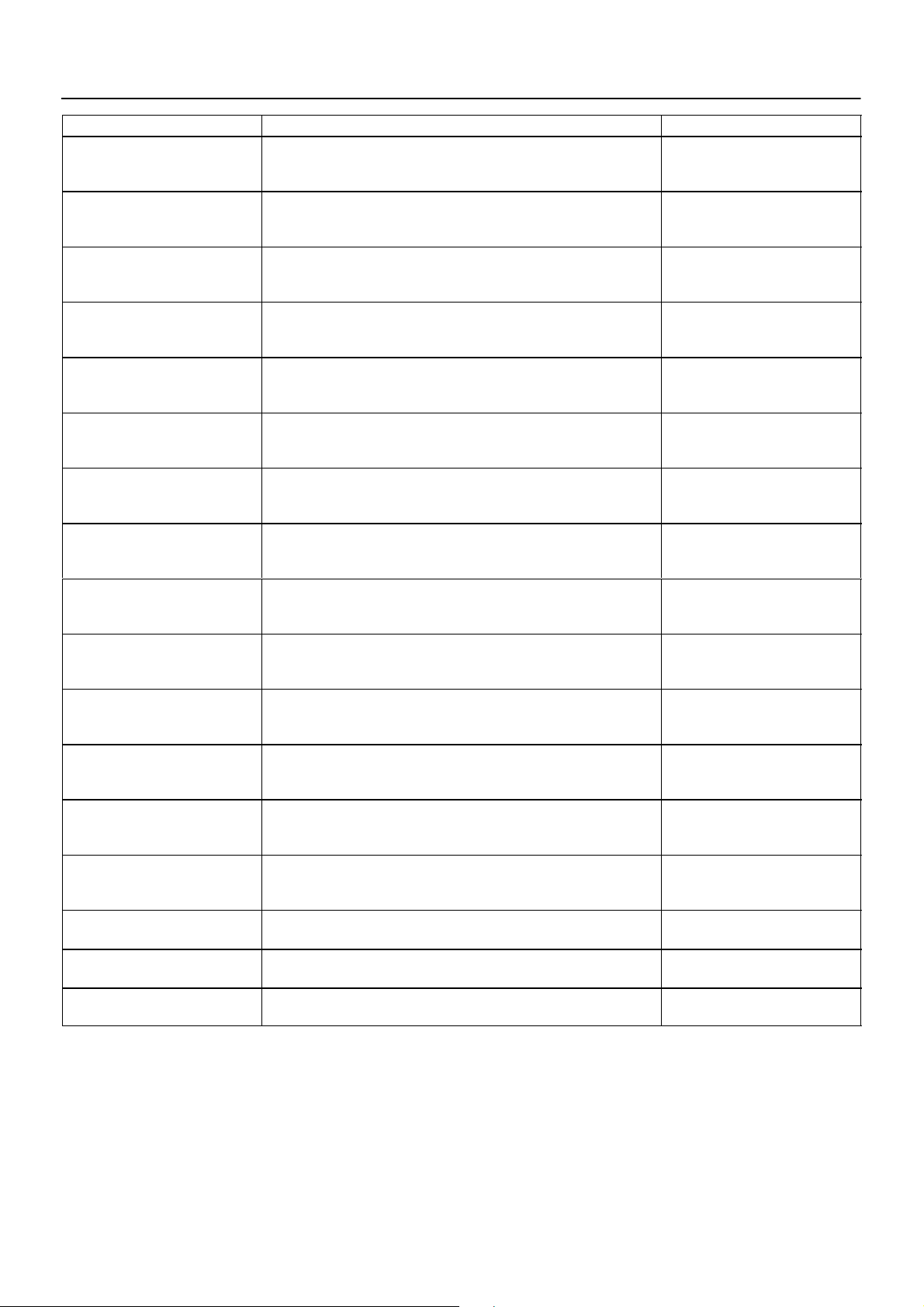

(e) In case of not using hand–held tester:

Clear DTC.

(1) Using SST, it connects the terminal Tc and CG of the

DLC3.

SST 09843–18040

(2) Turn the ignition switch to ON.

2004 COROLLA (RM1037U)

462Author!: Date!:

Page 2

05–298

–DIAGNOSTICS ABS WITH EBD SYSTEM (April, 2003)

(3) Clear DTC stored in ECU by depressing the brake

pedal 8 or more times whitin 5 sec.

(4) Check that the ABS warning light shows the normal

code.

(5) Remove the SST from the DLC3.

SST 09843–18040

HINT:

Disconnect the battey cable during repairs will not erase the

BR3890

DTC in the ECU.

(f) In case of using hand–held tester:

Clear the DTC.

(1) Turn the ignition switch to ON.

(2) Operate the hand–held tester to erase the codes.

HINT:

Please refer to the hand–held tester operator’s manual for further details.

2. DATA LIST

HINT:

According to the DATA LIST displayed by the Hand–held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as a first step of troubleshooting is one

of the method to shorten the labor time.

(a) Connect the Hand–held tester to the DLC3.

(b) Turn the ignition switch to ON.

(c) According to the display on tester, read the ”DATA LIST”.

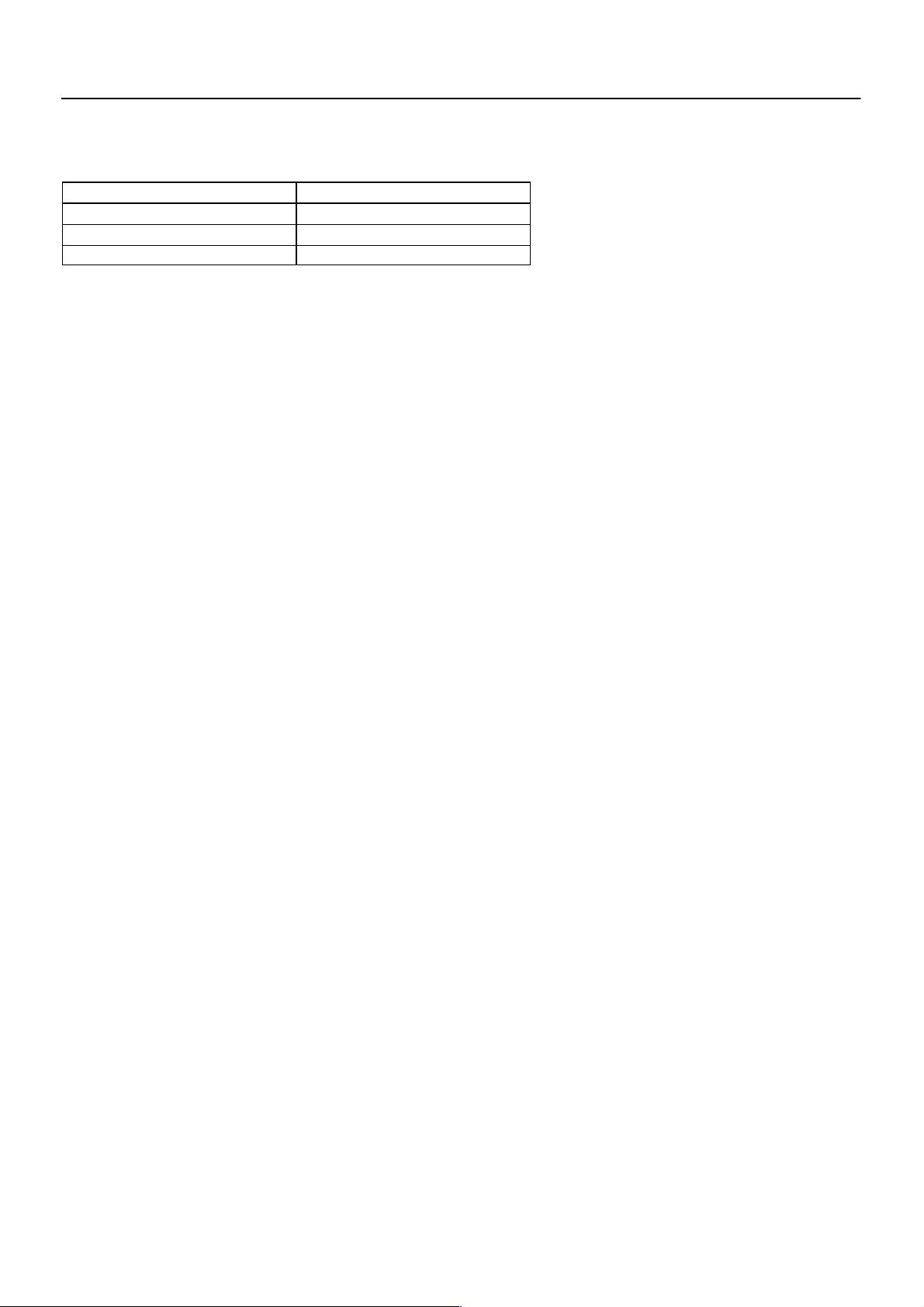

Item

ABS MOT RELAY

SOL RELAY

STOP LIGHT SW

PKB SW

ABS OPERT FR

ABS OPERT FL

ABS OPERT RR

ABS OPERT RL

Measurement Item /

Range (Display)

ABS motor relay / ON or

OFF

Solenoid relay / ON or

OFF

Stop light switch / ON or

OFF

Parking brake switch / ON

or OFF

ABS operation (FR) / BEFORE or OPERATE

ABS operation (FL) / BEFORE or OPERATE

ABS operation (RR) / BEFORE or OPERATE

ABS operation (RL) / BEFORE or OPERATE

Normal Condition Diagnostic Note

ON : Brake pedal depressed

OFF : Brake pedal released

ON : Parking brake applied

OFF : Parking brake released

BEFORE : No ABS operation (FR)

OPERATE : During ABS

operation (FR)

BEFORE : No ABS operation (FL)

OPERATE : During ABS

operation (FL)

BEFORE : No ABS operation (RR)

OPERATE : During ABS

operation (RR)

BEFORE : No ABS operation (RL)

OPERATE : During ABS

operation (RL)

2004 COROLLA (RM1037U)

463Author!: Date!:

Page 3

–DIAGNOSTICS ABS WITH EBD SYSTEM (April, 2003)

05–299

Item Diagnostic NoteNormal Condition

WHEEL SPD FR

WHEEL SPD FL

WHEEL SPD RR

WHEEL SPD RL

IG VOLTAGE

SFRR

SFRH

SFLR

SFLH

SRRR

SRRH

SRLR

SRLH

AIR BLD SUPPORT

TEST MODE

#CODES

Measurement Item /

Range (Display)

Wheel speed sensor (FR)

reading / min.: 0 km/h (0

MPH, max.: 326 km/h (202

MPH)

Wheel speed sensor (FL)

reading / min.: 0 km/h (0

MPH, max.: 326 km/h (202

MPH)

Wheel speed sensor (RR)

reading / min.: 0 km/h (0

MPH, max.: 326 km/h (202

MPH)

Wheel speed sensor (RL)

reading / min.: 0 km/h (0

MPH, max.: 326 km/h (202

MPH)

ECU power supply voltage

/ NORMAL or TOO LOW

ABS solenoid (SFRR) ON /

OFF

ABS solenoid (SFRH) ON /

OFF

ABS solenoid (SFLR) ON /

OFF

ABS solenoid (SFLH) ON /

OFF

ABS solenoid (SRRR) ON /

OFF

ABS solenoid (SRRH) ON

/ OFF

ABS solenoid (SRLR) ON /

OFF

ABS solenoid (SRLH) ON /

OFF

Air bleed support /

SUPPORT or NOT SUP

Test mode / NORMAL or

TEST

Number of DTC recorded /

min.: 0, max.: 255

Actual wheel speed

Actual wheel speed

Actual wheel speed

Actual wheel speed

NORMAL : 9.5 V or over

TOO LOW : Below 9.5 V

Supported

NORMAL : Normal mode

TEST : During test mode

Min.: 0, max.: 19

Speed indicated on

speedometer

Speed indicated on

speedometer

Speed indicated on

speedometer

Speed indicated on

speedometer

3. ACTIVE TEST

HINT:

Performing the ACTIVE TEST using the Hand–held tester allows the relay, actuator and so on to operate

without parts removal. Performing the ACTIVE TEST as a first step of troubleshooting is one of the methods

to shorten the labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

(a) Connect the Hand–held tester to the DLC3.

(b) Turn the ignition switch to ON.

(c) According to the display on tester, perform the ”ACTIVE TEST”.

2004 COROLLA (RM1037U)

464Author!: Date!:

Page 4

05–300

–DIAGNOSTICS ABS WITH EBD SYSTEM (April, 2003)

Item Vehicle Condition / Test Details Diagnostic Note

SFRR Turns ABS solenoid (SFRR) ON / OFF

SFRH Turns ABS solenoid (SFRH) ON / OFF

SFLR Turns ABS solenoid (SFLR) ON / OFF

SFLH Turns ABS solenoid (SFLH) ON / OFF

SRRR Turns ABS solenoid (SRRR) ON / OFF

SRRH Turns ABS solenoid (SRRH) ON / OFF

SRLR Turns ABS solenoid (SRLR) ON / OFF

SRLH Turns ABS solenoid (SRLH) ON / OFF

SFRR & SFRH Turns ABS solenoid SFRR & SFRH ON / OFF

SFLR & SFLH Turns ABS solenoid SFLR & SFLH ON / OFF

SRRH & SRRR Turns ABS solenoid SRH & SRR ON / OFF

SRLR & SRLH Turns ABS solenoid SRLR & SRLH ON / OFF

SFRH & SFLH Turns ABS solenoid SFRH & SFLH ON / OFF

SOL RELAY Turns ABS solenoid relay ON / OFF

ABS MOT RELAY Turns ABS motor relay ON / OFF

ABS WARN LIGHT Turns ABS warning light ON / OFF

BRAKE WRN LIGHT Turns BRAKE warning light ON / OFF

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of solenoid

(clicking sound) can be

heard

Operation of motor can be

heard

Observe combination meter

Observe combination meter

4. FREEZE FRAME DATA

(a) The vehicle (sensor) status memorized during ABS operation or at the time of error code detection can

be displayed using the hand–held tester.

(b) Only one record of freeze frame data is stored and the freeze frame data generated during ABS opera-

tion are constantly updated. Also, the number of the ignition switch’s ”ON” after the freeze frame data

is stored can be memorized up to 31 and it can be displayed.

HINT:

If the ignition switch ”ON” operation exceeds 31 times, ”31” appears on the display.

2004 COROLLA (RM1037U)

465Author!: Date!:

Page 5

05–301

–DIAGNOSTICS ABS WITH EBD SYSTEM (April, 2003)

(c) If the diagnosis code abnormality occurs, the freeze frame data at the occurrence of the abnormality

is stored but the ABS actuation data is deleted.

Hand–held tester display Measurement Item Reference Value*

VEHICLE SPD Vehicle speed Speed indication of a meter

STOP LIGHT SW Stop light switch signal Stop light switch ON: ON, OFF: OFF

# IG ON

SYSTEM Operate system ABS operate: ABS

Numbers of operations of ignition switch ON after

memorizing freeze frame data

0 – 31

*: If no conditions are specifically stated for ”Idling”, it means the shift lever is at N or P position, the A/C switch

is OFF and all accessory switches are OFF.

5. SPEED SENSOR SIGNAL CHECK

HINT:

If the ignition switch is turned from ON to ACC or LOCK during

test mode, DTC will be erased.

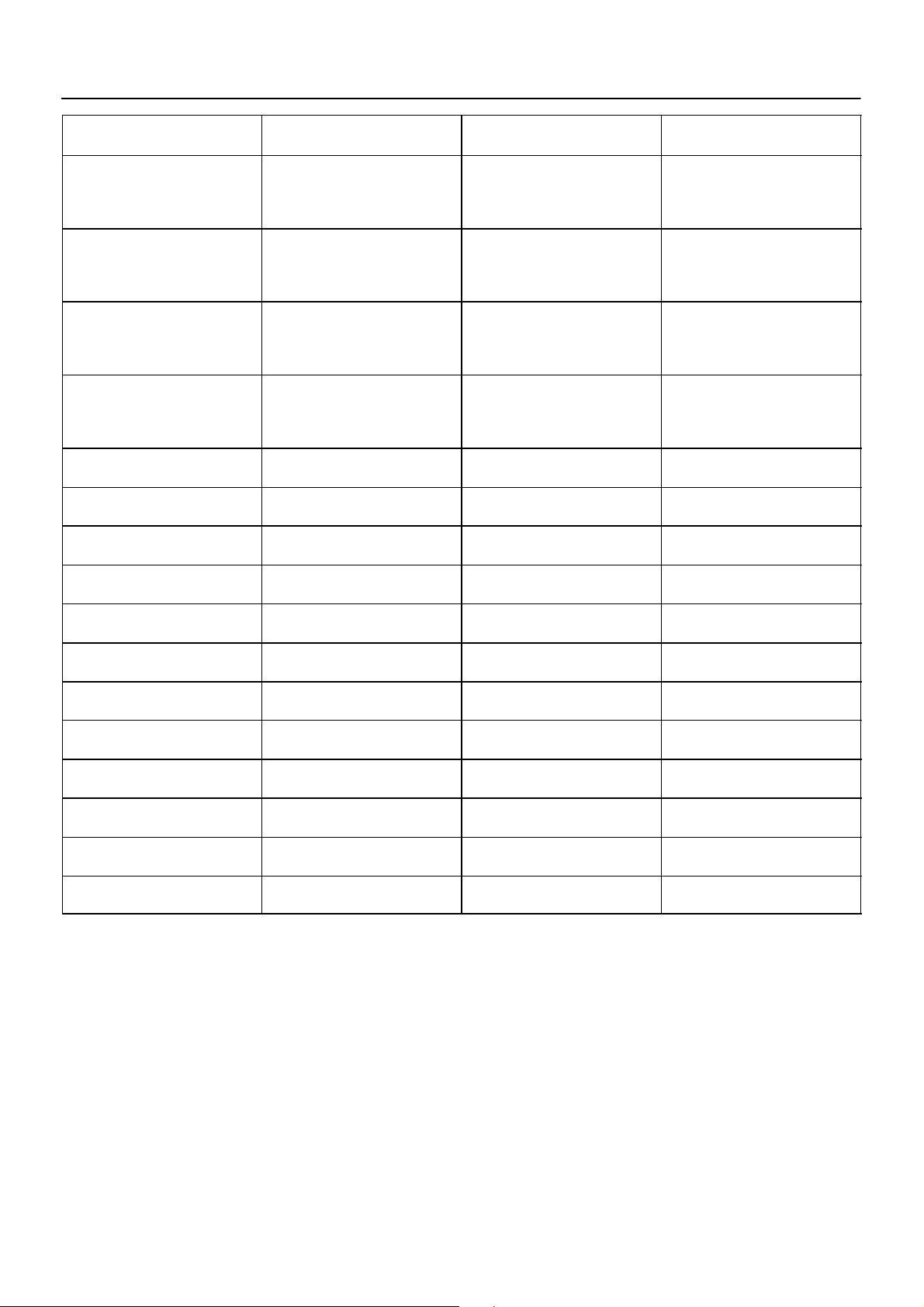

(a) In case of not using hand–held tester:

Check the speed sensor signal.

(1) Turn the ignition switch to ON.

ON

OFF

0.13 sec.

Ts

CG

0.13 sec.

C52361

BR3904

(2) Using SST, it connects the terminal Ts and CG of

DLC3.

SST 09843–18040

(3) Start the engine.

(4) Check that the ABS warning light blinks.

HINT:

If the ABS warning light does not blink, inspect the ABS warning

light circuit and Ts circuit (See page 05–332 or 05–335).

(5) Drive the vehicle straight forward at the speed of 45

km/h (28 mph) or over for several seconds and

check that the ABS warning light comes off.

HINT:

The sensor check may not be completed if the wheels spin or

the steering wheels steered during check.

(6) Stop the vehicle.

(7) Using SST, it connects the terminal Tc and CG of the

DLC3.

SST 09843–18040

(8) Read the number of blinks of the ABS warning light.

2004 COROLLA (RM1037U)

466Author!: Date!:

Page 6

05–302

–DIAGNOSTICS ABS WITH EBD SYSTEM (April, 2003)

HINT:

! See the list of DTC shown on the 05–303.

! If every sensor is normal, a normal code is output (A cycle

of 0.25 sec. ON and 0.25 sec. OFF is repeated).

! If 2 or more malfunctions are indicated at the same time,

the lowest numbered code will be displayed.

Malfunction Code (Example Code 72, 76)

72 7 6

ON

OFF

0.5 sec.

0.5 sec.

1.5 sec.

0.5 sec. 0.5 sec.

2.5 sec.

(b) In case of using hand–held tester:

HINT:

Please refer to the hand–held tester operator’s manual for further details.

4 sec.

Repeat

BR3893

(9) After performing the check, turn the ignition switch

to OFF, and remove the SST from the DLC3.

SST 09843–18040

Check the speed sensor signal.

(1) Do step (3) to (6) on the previous page.

(2) Read the DTC by following the prompts on the tes-

ter screen.

2004 COROLLA (RM1037U)

467Author!: Date!:

Page 7

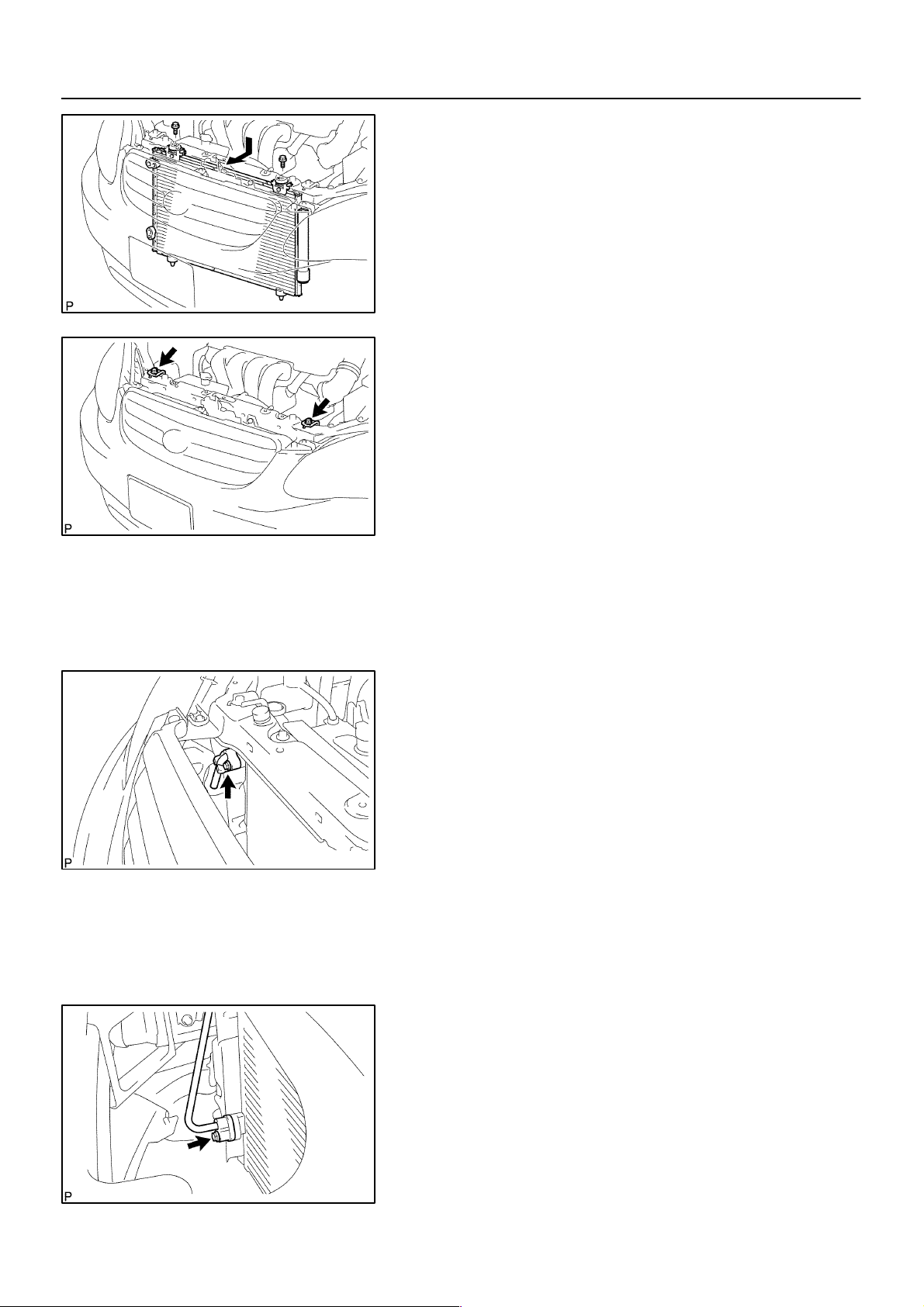

–HEATER & AIR CONDITIONER W/RECEIVER CONDENSER ASSY

OVERHAUL

HINT:

COMPONENTS: See page 55–40

1. DISCHARGE REFRIGERANT FROM REFRIGERATION SYSTEM (See page 55–11)

SST 07110–58060 (07117–58080, 07117–58090, 07117–78050, 07117–88060, 07117–88070,

07117–88080)

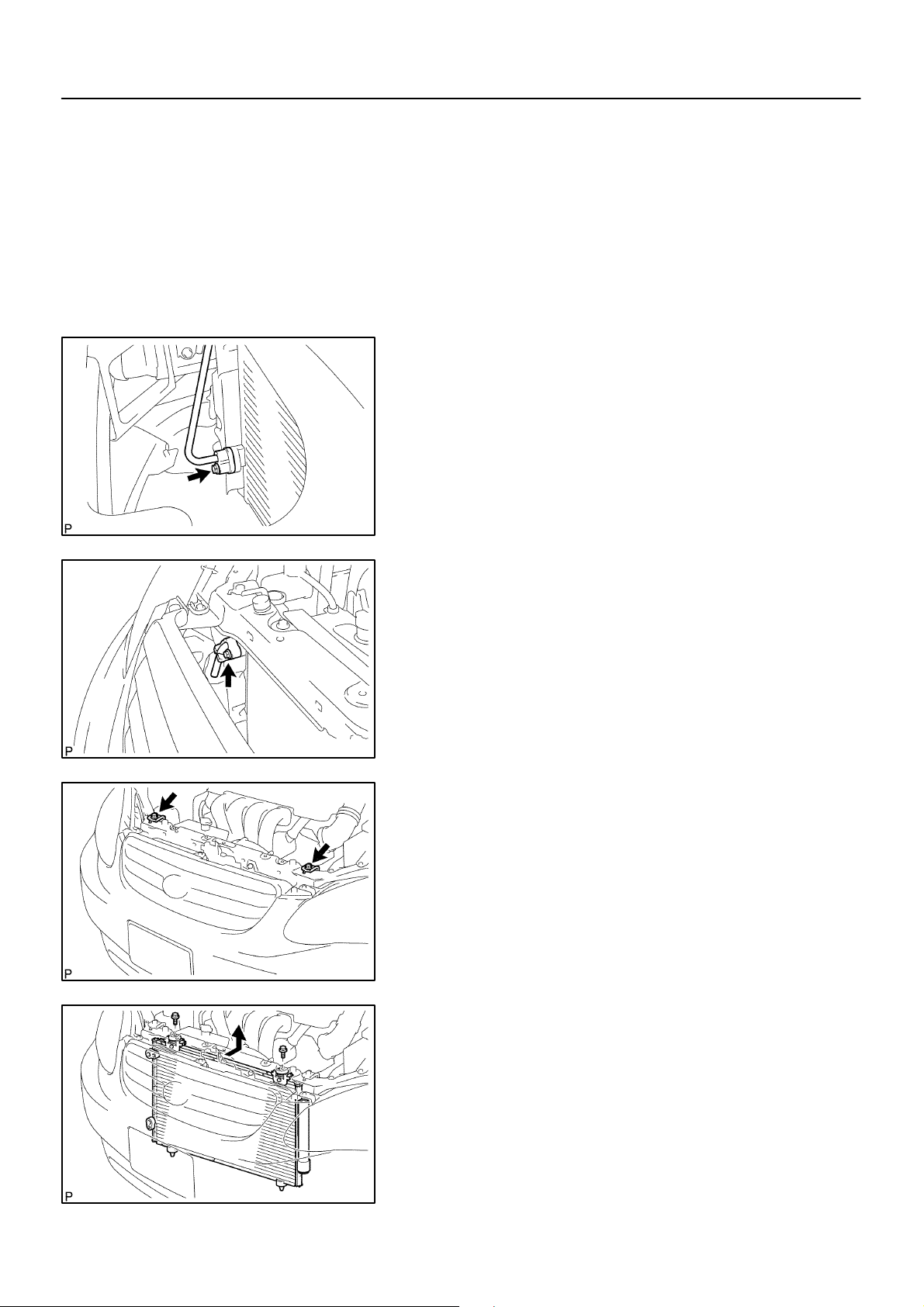

2. DISCONNECT COOLER REFRIGERANT LIQUID PIPE

A

(a) Remove the bolt and disconnect the cooler refrigerant liq-

uid pipe A from the w/receiver condenser assy.

(b) Remove the O–ring from the cooler refrigerant liquid pipe

A.

NOTICE:

Seal the opening of the disconnected parts using vinyl tape

I31967

to prevent moisture and foreign matter from entering.

55–41

550IY–01

I32450

I32451

3. DISCONNECT DISCHARGE HOSE SUB–ASSY

(a) Remove the bolt and discharge hose sub–assy from the

w/receiver condenser assy.

(b) Remove the O–ring from the discharge hose sub–assy.

NOTICE:

Seal the opening of the disconnected parts using vinyl tape

to prevent moisture and foreign matter from entering.

4. REMOVE W/RECEIVER CONDENSER ASSY

(a) Remove the 2 bolts and 2 radiator upper supports.

(b) Remove the 2 bolts.

(c) Slide the upper part of the radiator assy rearward to re-

move the w/receiver condenser assy.

2004 COROLLA (RM1037U)

I32452

1611Author!: Date!:

Page 8

55–42

14 mm

(0.55 in.)

Hexagon

Wrench

–HEATER & AIR CONDITIONER W/RECEIVER CONDENSER ASSY

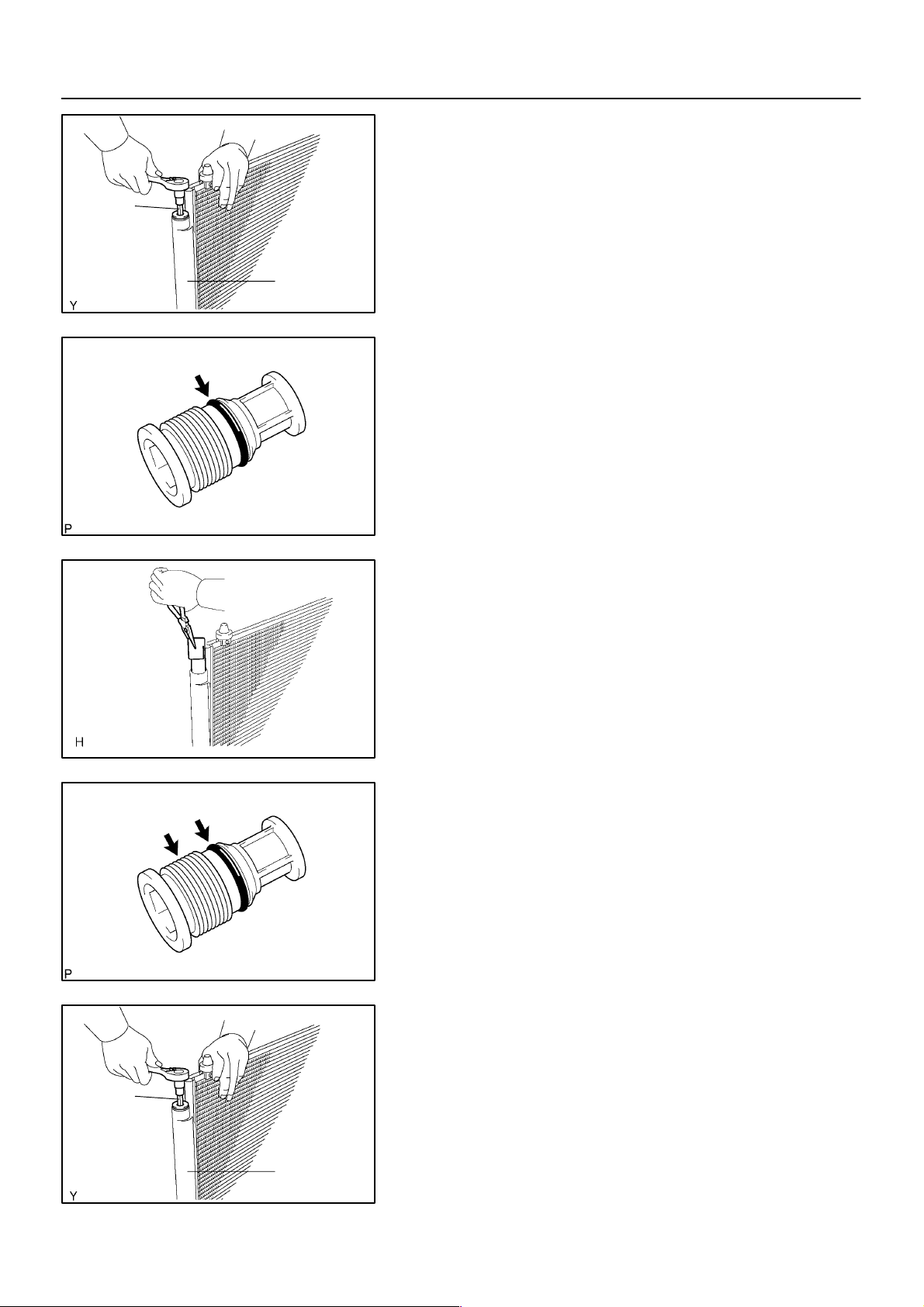

5. REMOVE COOLER DRYER

(a) Using a socket hexagon wrench 14 mm (0.55 in.), remove

the cap from the modulator.

Modulator

I30086

(b) Remove the O–ring from the cap.

E55408

I32475

(c) Using pliers, remove the cooler dryer.

6. INSTALL COOLER DRYER

(a) Using pliers, install the cooler dryer.

E50386

(b) Install the new O–ring to the cap.

(c) Sufficiently apply compressor oil to the fit surfaces of the

O–ring and the cap.

Compressor oil: ND–OIL 8 or equivalent

E55408

14 mm

(0.55 in.)

Hexagon

Wrench

2004 COROLLA (RM1037U)

(d) Using a socket hexagon wrench 14 mm (0.55 in.), install

the cap to the modulator.

Torque: 2.9 N⋅m (29 kgf⋅cm, 25 in.⋅lbf)

Modulator

I30086

1612Author!: Date!:

Page 9

I32453

I32451

55–43

–HEATER & AIR CONDITIONER W/RECEIVER CONDENSER ASSY

7. INSTALL W/RECEIVER CONDENSER ASSY

(a) Install the w/receiver condenser assy with the 2 bolts.

Torque: 9.8 N⋅m (100 kgf⋅cm, 87 in.⋅lbf)

(b) Install the 2 radiator upper supports with the 2 bolts.

8. INSTALL DISCHARGE HOSE SUB–ASSY

(a) Remove the attached vinyl tape from the hose and con-

necting part of the w/receiver condenser assy.

(b) Sufficiently apple compressor oil to the new O–ring and

hose joint.

Compressor oil: ND–OIL 8 or equivalent

(c) Install a O–ring to the discharge hose sub–assy.

I32450

(d) Install the discharge hose sub–assy to the w/receiver

condenser assy with the bolt.

Torque: 5.4 N⋅m (54 kgf⋅cm, 48 in.⋅lbf)

9. INSTALL COOLER REFRIGERANT LIQUID PIPE A

(a) Remove the attached vinyl tape from the pipe and w/re-

ceiver condenser assy.

(b) Sufficiently apple compressor oil to the new O–ring and

pipe joint.

Compressor oil: ND–OIL 8 or equivalent

(c) Install a O–rings to the cooler refrigerant liquid pipe A.

(d) Install the cooler refrigerant liquid pipe A to the w/receiver

condenser assy with the bolt.

Torque: 5.4 N⋅m (54 kgf⋅cm, 48 in.⋅lbf)

2004 COROLLA (RM1037U)

I31967

1613Author!: Date!:

Page 10

55–44

–HEATER & AIR CONDITIONER W/RECEIVER CONDENSER ASSY

10. CHARGE REFRIGERANT (See page 55–11)

SST 07110–58060 (07117–58060, 07117–58070, 07117–58080, 07117–58090, 07117–78050,

07117–88060, 07117–88070, 07117–88080), 07117–48130, 07117–48140

Specified amount: 490 ! 30 g (17.28 ! 1.06 oz.)

11. WARM UP ENGINE

12. INSPECT LEAKAGE OF REFRIGERANT (See page 55–11)

2004 COROLLA (RM1037U)

1614Author!: Date!:

Page 11

55–39

–HEATER & AIR CONDITIONER W/RECEIVER CONDENSER ASSY

W/RECEIVER CONDENSER ASSY

550IW–01

ON–VEHICLE INSPECTION

1. INSPECT W/RECEIVER CONDENSER ASSY

(a) If a fin of the w/receiver condenser assy is dirty, clean it with water and dry it with compressor air.

NOTICE:

Do not damage the fin of the w/receiver condenser assy.

(b) If a fin of the w/receiver condenser assy is bent, make it straight using a screwdriver or pliers.

2. INSPECT W/RECEIVER CONDENSER ASSY FOR LEAKAGE OF REFRIGERANT

(a) Using a halogen leak detector, check pipe joints for gas leakage.

(b) If gas leakage is detected in a joint, check the torque of the joint.

2004 COROLLA (RM1037U)

1609Author!: Date!:

Page 12

55–40

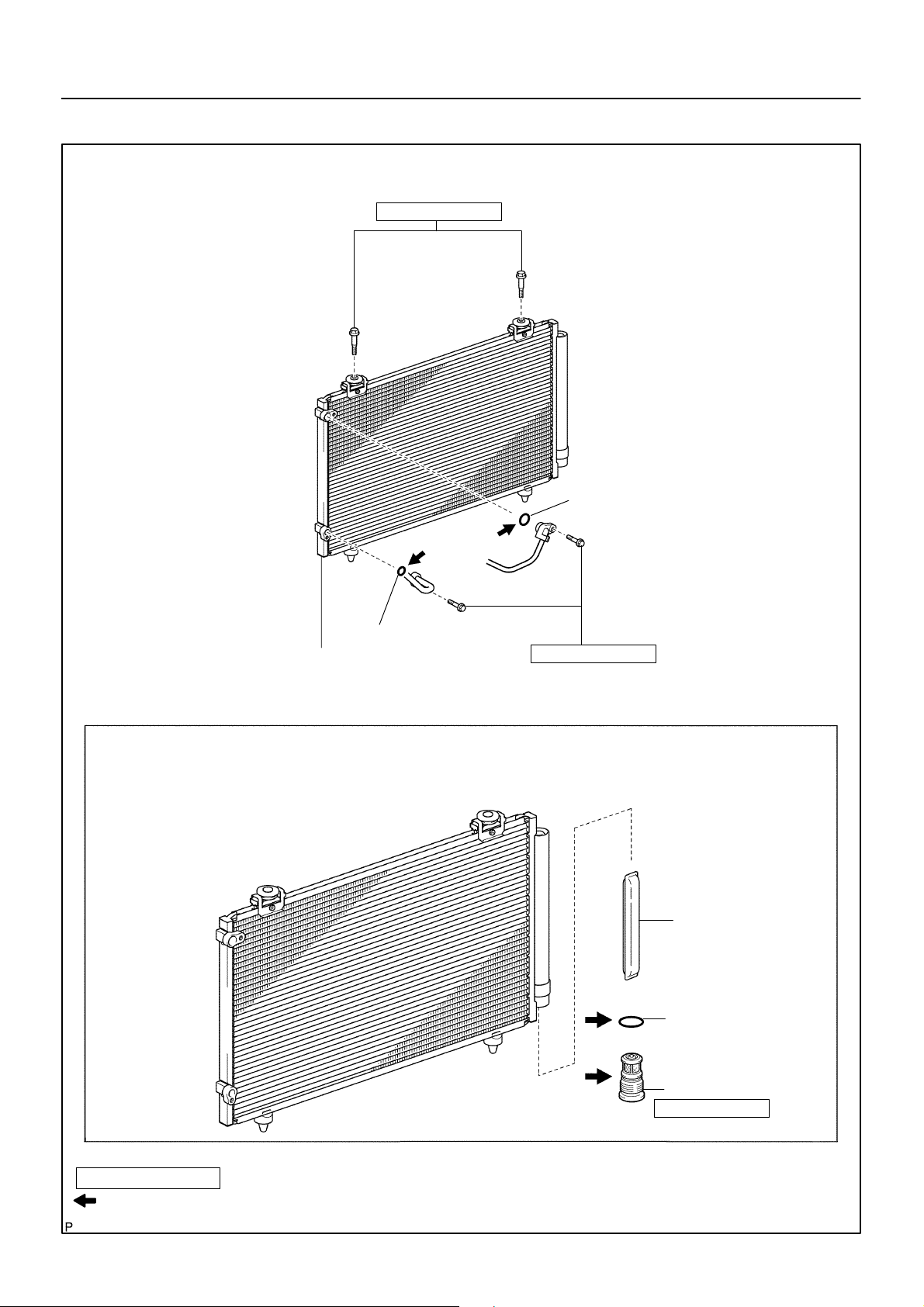

COMPONENTS

–HEATER & AIR CONDITIONER W/RECEIVER CONDENSER ASSY

550IX–01

9.8 (100, 87 in.⋅lbf)

! O–Ring

! O–Ring

W/receiver Condenser Assy

5.4 (54, 48 in.⋅lbf)

Cooler Dryer

! O–Ring

N⋅m (kgf⋅cm, ft⋅lbf) : Specified torque

Compressor Oil ND–OIL 8 or equivalent

! Non–reusable part

2004 COROLLA (RM1037U)

Cap

2.9 (29, 25 in.⋅lbf)

I32505

1610Author!: Date!:

Page 13

73–7

–THEFT DETERRENT & DOOR LOCK WIRELESS DOOR LOCK CONTROL SYSTEM

WIRELESS DOOR LOCK CONTROL SYSTEM

730B0–02

PRECAUTION

1. NOTICES WHEN CHECKING

(a) Power door LOCK/UNLOCK function:

The wireless remote control function operates only when the following 3 conditions are met.

(1) No key is inserted into the ignition key cylinder.

(2) All the doors are closed. However, doors can be unlocked even when any of the doors is opened.

(3) The power door lock system operates normally.

HINT:

! The UNLOCK function operates even when a door is open.

! The UNLOCK function operates even when the key is inserted into the ignition key cylinder, however

it must be in the OFF position.

(b) Remote panic function:

The wireless remote control function operates only when the following condition is met.

(1) The ignition switch is OFF.

HINT:

The key can be inserted, however it must be in the OFF position.

(c) The wireless door lock remote control operational area differs depending on the situation.

(1) The operational area differs depending on the operators and the ways the transmitter is held.

(2) In certain areas, the remote control function will only operate partially for the operational area

will be reduced due to the vehicle body shape and the influence of the surrounding environment.

(3) Since the transmitter uses faint electric waves, strong electric waves or noise in the frequency

used may reduce the operational area or the remote control may not function.

(4) When the battery weakens, the operational area is reduced or the remote control may not func-

tion.

HINT:

If the door control transmitter has been left in a place that is exposed to direct sunlight, such as on the instrument panel, it may cause the battery to weaken or cause other such problems.

2004 COROLLA (RM1037U)

1799Author!: Date!:

Page 14

73–8

–THEFT DETERRENT & DOOR LOCK WIRELESS DOOR LOCK CONTROL SYSTEM

730B1–02

ON–VEHICLE INSPECTION

1. INSPECT WIRELESS DOOR LOCK CONTROL FUNCTIONS

HINT:

! The switch described in this text is a switch for transmitting signals (LOCK switch, UNLOCK switch

and PANIC switch) which is built into the door control transmitter.

! All the functions listed below must be checked in the remote control operational area.

(a) Put the vehicle under the conditions that allow the wireless control function to be operated (See PRE-

CAUTION on page 73–7).

(b) Check the basic function.

(1) Check that all the doors lock when the LOCK switch is pressed.

(2) Check that only the driver side door unlocks when the UNLOCK switch is pressed once and the

other doors unlock when the UNLOCK switch is pressed again within 3 seconds.

(c) Check the chattering prevention function.

(1) Check that the corresponding operation occurs only once and is not repeated continuously while

the switch is held. However, when the switch is operated repeatedly at 1 second intervals, check

that the corresponding operation is carried out.

(d) Check the automatic lock function.

(1) Check that all the doors lock automatically as long as none of them have been opened or all the

doors have not been locked within approx. 30 seconds after they are unlocked by pressing the

UNLOCK switch.

(2) Check that the automatic locking function does not operate when any door has been opened or

all of them have been locked within approx. 30 seconds after they are unlocked by pressing the

UNLOCK switch.

(e) Check the switch operation fail–safe function.

(1) Check that the doors can not be locked using the switch while the key is in the ignition key cylin-

der. However, this does not apply when the system is in the recognition code registration mode.

(f) Check the operation stop function when a door is open or not completely closed.

(1) Check that the doors are not locked by the switch while any door is open or not completely closed.

However, the glass hatch open operation is possible in this situation.

(g) Check the repeat function.

(1) Check that all the doors attempt to automatically lock once again 1 second after the LOCK switch

has been pressed while the movement of the driver side door control knob is being restricted

while in the unlocked position.

(h) Check the hazard warning lamps flashing functions (answer–back).

(1) When the LOCK switch is pressed, check that the lamps flash once with the locking of all the

doors.

(2) When the UNLOCK switch is pressed once, check that the lamps flash twice with the unlocking

of the driver side door.

(3) When the UNLOCK switch is pressed again within 3 seconds, check that the lamps flash twice

with the unlocking of all the doors.

(i) Check the remote panic alarm function.

(1) Check that the horn sounds, and the headlamps, the taillamps and the hazard warning lamps

flash for 60 seconds by the theft alarm function when the PANIC switch is pressed. Also, check

that the horn stops sounding and the lamps stop flashing when either switch of the transmitter

is pressed once again.

(j) Check the illuminated entry function.

(1) When all the doors are locked, pressing the UNLOCK switch causes the room lamp (when the

lamp switch is in the DOOR position) to illuminate simultaneously with the unlock operation.

(2) Check that the room lamp goes off in approx. 15 seconds if doors have not been opened.

2004 COROLLA (RM1037U)

1800Author!: Date!:

Page 15

–THEFT DETERRENT & DOOR LOCK WIRELESS DOOR LOCK CONTROL SYSTEM

73–9

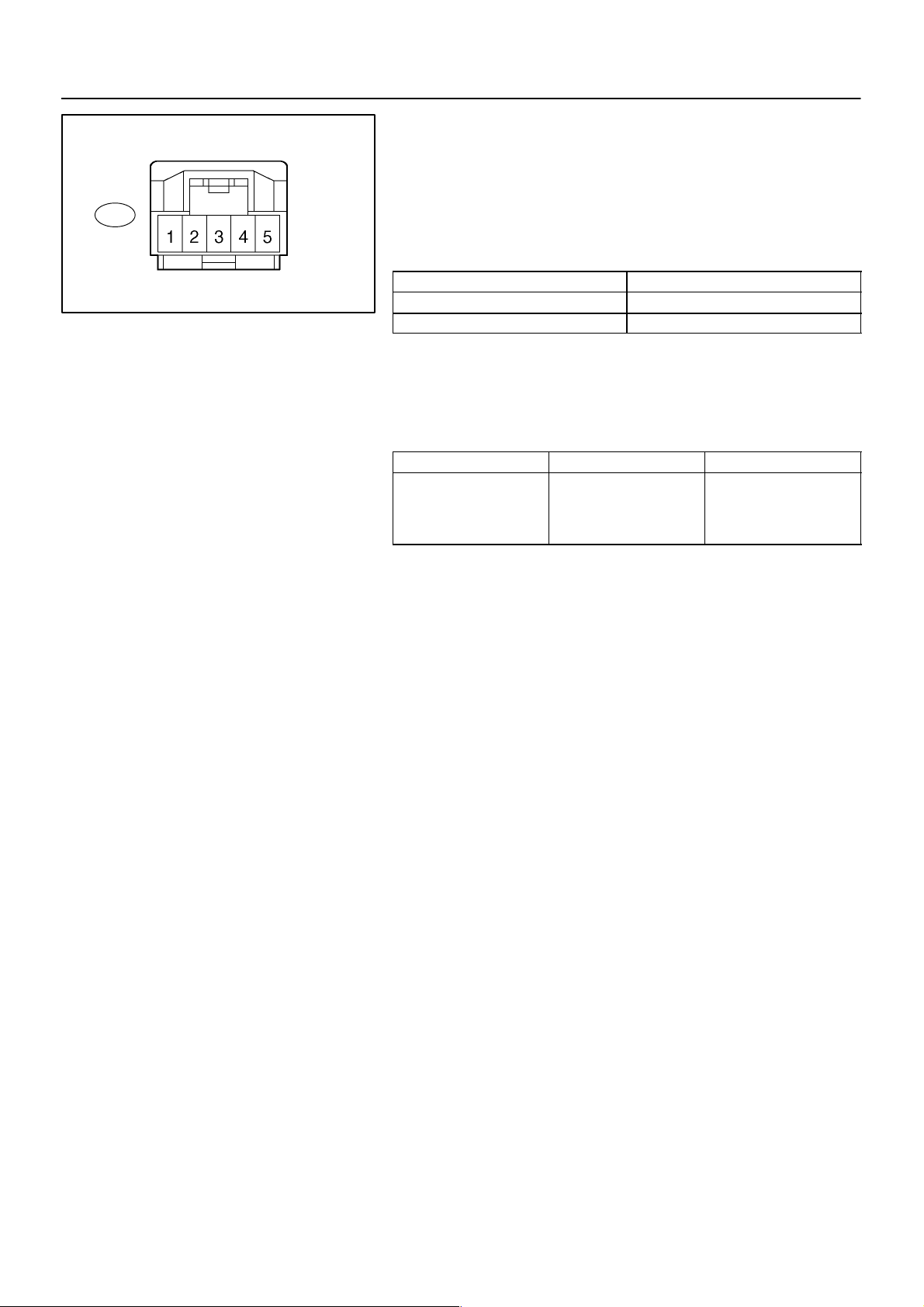

Door Control Receiver

(Wire Harness Side)

D3

B59092

2. CHECK DOOR CONTROL RECEIVER

(a) Disconnect the D3 connector from the door control receiv-

er.

(b) Check the continuity and voltage between the terminals

of the door control receiver connector and the body

ground, as shown in the illustration and table.

Standard:

Symbols (Terminal No.) Specified condition

+B (D3– 5) – Body ground 10 – 14 V

GND (D3–1) – Body ground Continuity

If the result is not as specified, there may be a malfunction on

the wire harness side.

(c) Reconnect the connector and check the voltage between

the terminal and body ground.

Standard:

Symbols (Terminal No.) Condition Specified Condition

RDA (D3–2) –

Body ground

No key in ignition key

cylinder, all doors closed

and each transmitter

switch OFF → ON

1 V or less →

Approx. 6 – 7 V →

1 V or less

If the result is not as specified, the receiver may have a malfunction.

2004 COROLLA (RM1037U)

1801Author!: Date!:

Page 16

66–10

–WIPER & WASHER WIPER RUBBER LH

WIPER RUBBER LH

REPLACEMENT

1. REMOVE FR WIPER BLADE LH

(a) Remove the front wiper blade LH from the front wiper arm LH.

NOTICE:

Do not fold down the front wiper arm with the front wiper blade being removed from it.

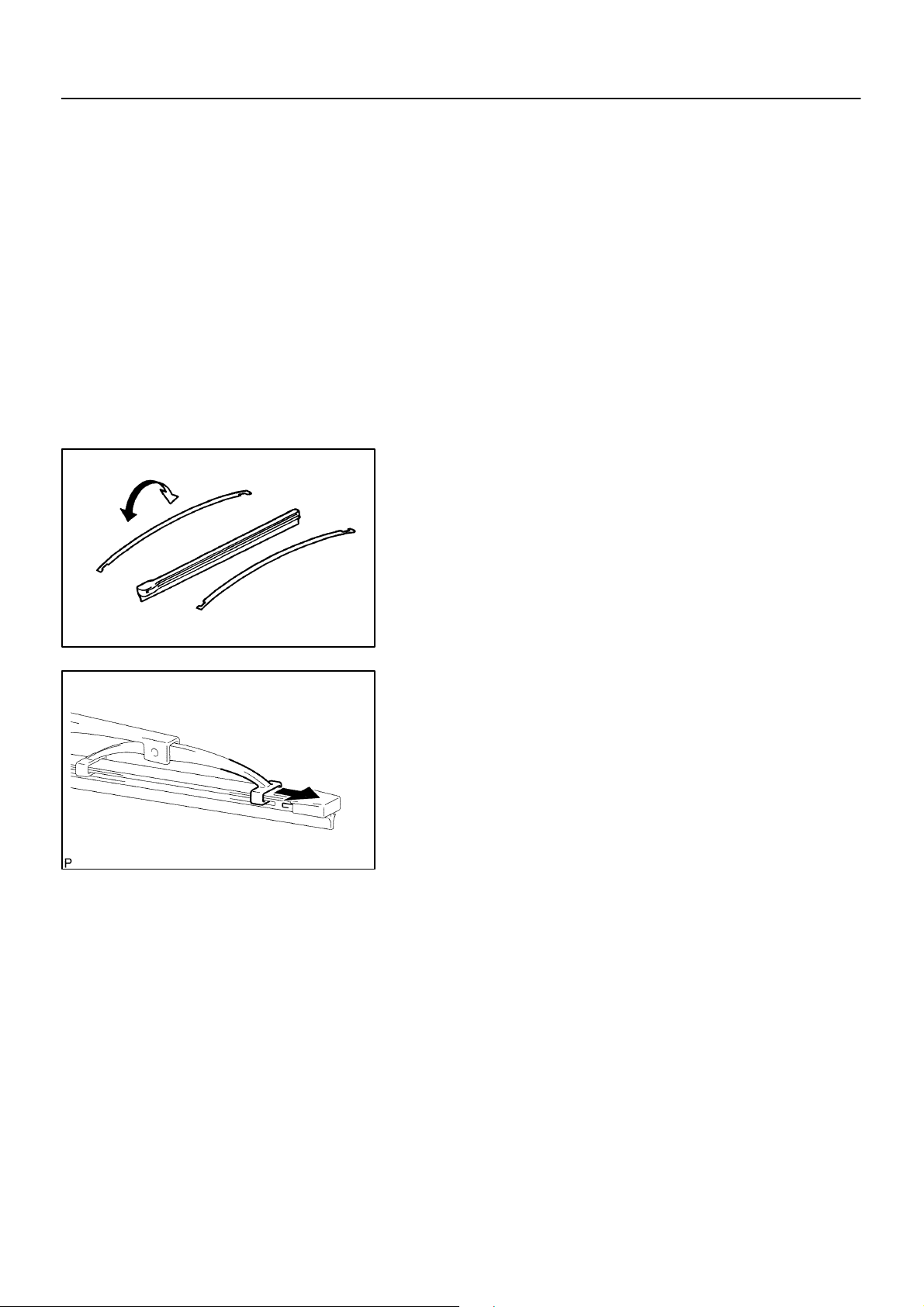

2. REMOVE WIPER RUBBER LH

(a) Remove the front wiper rubber LH from the front wiper blade.

(b) Remove the 2 wiper rubber backing plates from the wiper rubber LH.

3. INSTALL WIPER RUBBER LH

Curve

(a) Install the 2 wiper rubber backing plates to the wiper rub-

ber LH.

NOTICE:

Be careful to observe and keep direction of curvature for

correct replacement.

66072–01

E59361

E57398

(b) Install the wiper rubber LH so that the head part (Larger

side) of the wiper rubber faces the arm axie side.

NOTICE:

Push the front wiper blade into the grooves of the wiper

rubber to engage them completely.

2004 COROLLA (RM1037U)

1710Author!: Date!:

Page 17

66–6

–WIPER & WASHER WINDSHIELD WIPER MOTOR ASSY

WINDSHIELD WIPER MOTOR ASSY

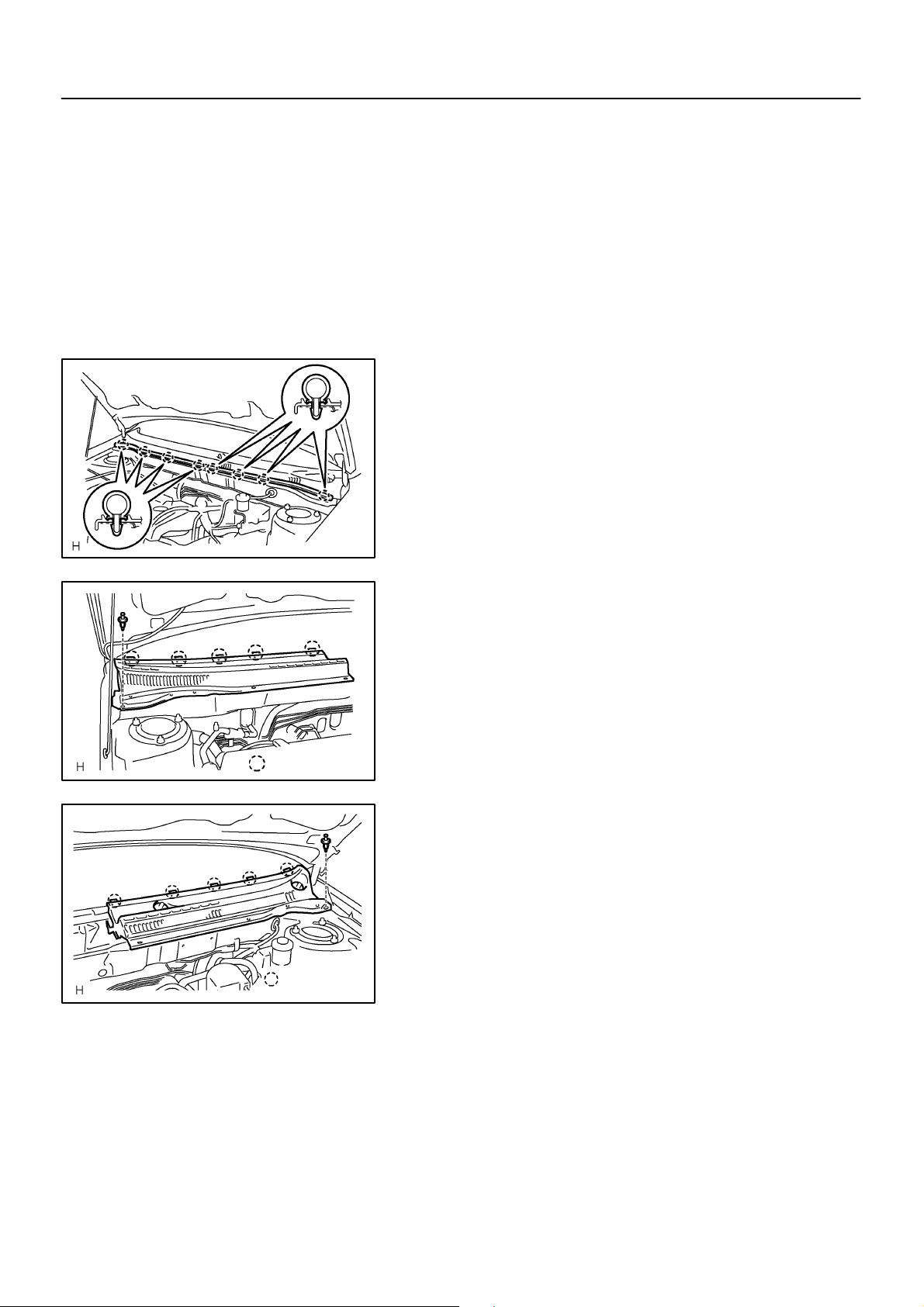

REPLACEMENT

1. REMOVE WINDSHIELD WIPER ARM COVER

2. REMOVE FR WIPER ARM RH

(a) Operate the wiper and stop the windshield wiper motor assy at the automatic stop position.

(b) Remove a nut and FR wiper arm RH.

3. REMOVE FR WIPER ARM LH

(a) Remove a nut and FR wiper arm LH.

4. REMOVE HOOD TO COWL TOP SEAL

(a) Using a clipremover, disengage the meshing of 8 clips

and remove the hood to cowl top seal.

66071–01

Claws

Claws

E60623

5. REMOVE COWL TOP VENTILATOR LOUVER RH

(a) Remove a clip and release the 5 claws, and remove the

cowl top ventilator louver RH.

E60624

6. REMOVE COWL TOP VENTILATOR LOUVER LH

(a) Remove a clip and release the 5 claws, and remove the

cowl top ventilator louver LH.

E60625

2004 COROLLA (RM1037U)

1706Author!: Date!:

Page 18

E60708

66–7

–WIPER & WASHER WINDSHIELD WIPER MOTOR ASSY

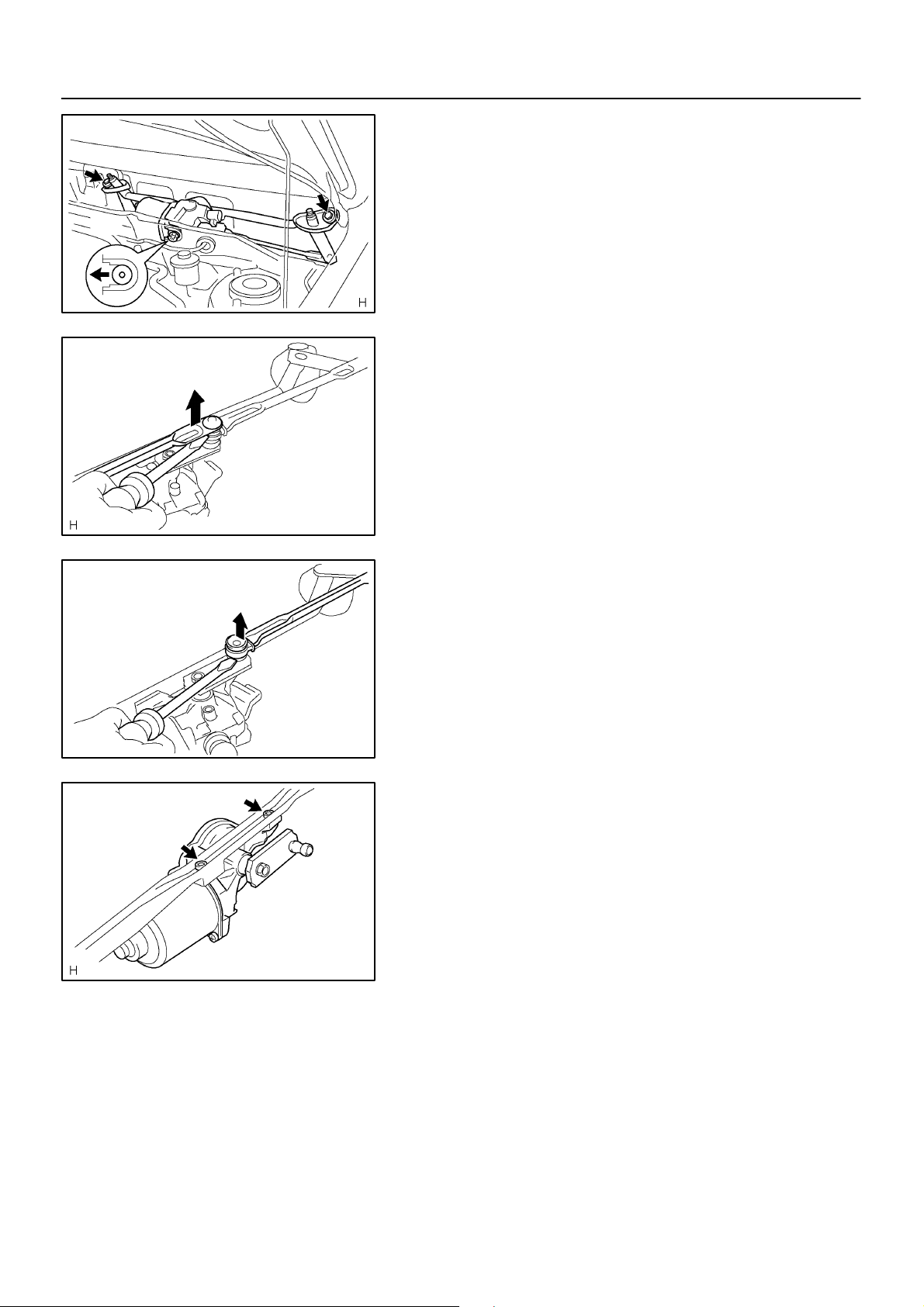

7. REMOVE WIPER LINK ASSY

(a) Disconnect the connector.

(b) Remove the 2 bolts.

(c) Slide the wiper link assy to vehicle’s passengers side. Dis-

engage the meshing of the rubber pin and remove the

wiper link assy.

8. REMOVE WINDSHIELD WIPER MOTOR ASSY

(a) Using a screwdriver and disengage the meshing of 2 rods

at the clank arm pivot of the windshield wiper motor assy.

HINT:

Tape the screwdriver tip before use.

E50396

E50397

E50398

(b) Remove 2 torx bolts and windshield wiper motor assy.

2004 COROLLA (RM1037U)

1707Author!: Date!:

Page 19

66–8

–WIPER & WASHER WINDSHIELD WIPER MOTOR ASSY

9. INSTALL WINDSHIELD WIPER MOTOR ASSY

(a) Apply MP grease to the clank arm pivot of the windshield wiper motor assy.

(b) Using 2 torx bolts, install the windshield wiper motor assy to the windshield wiper link assy.

Torque: 7.5 N⋅m (76 kgf⋅cm, 66 in.⋅lbf)

10. INSTALL WIPER LINK ASSY

(a) Install the meshing of the rubber pin.

(b) Install the windshield wiper link assy.with the 2 bolts.

Torque: 5.5 N⋅m (56 kgf⋅cm, 49 in.⋅lbf)

(c) Connect the connecter.

E60709

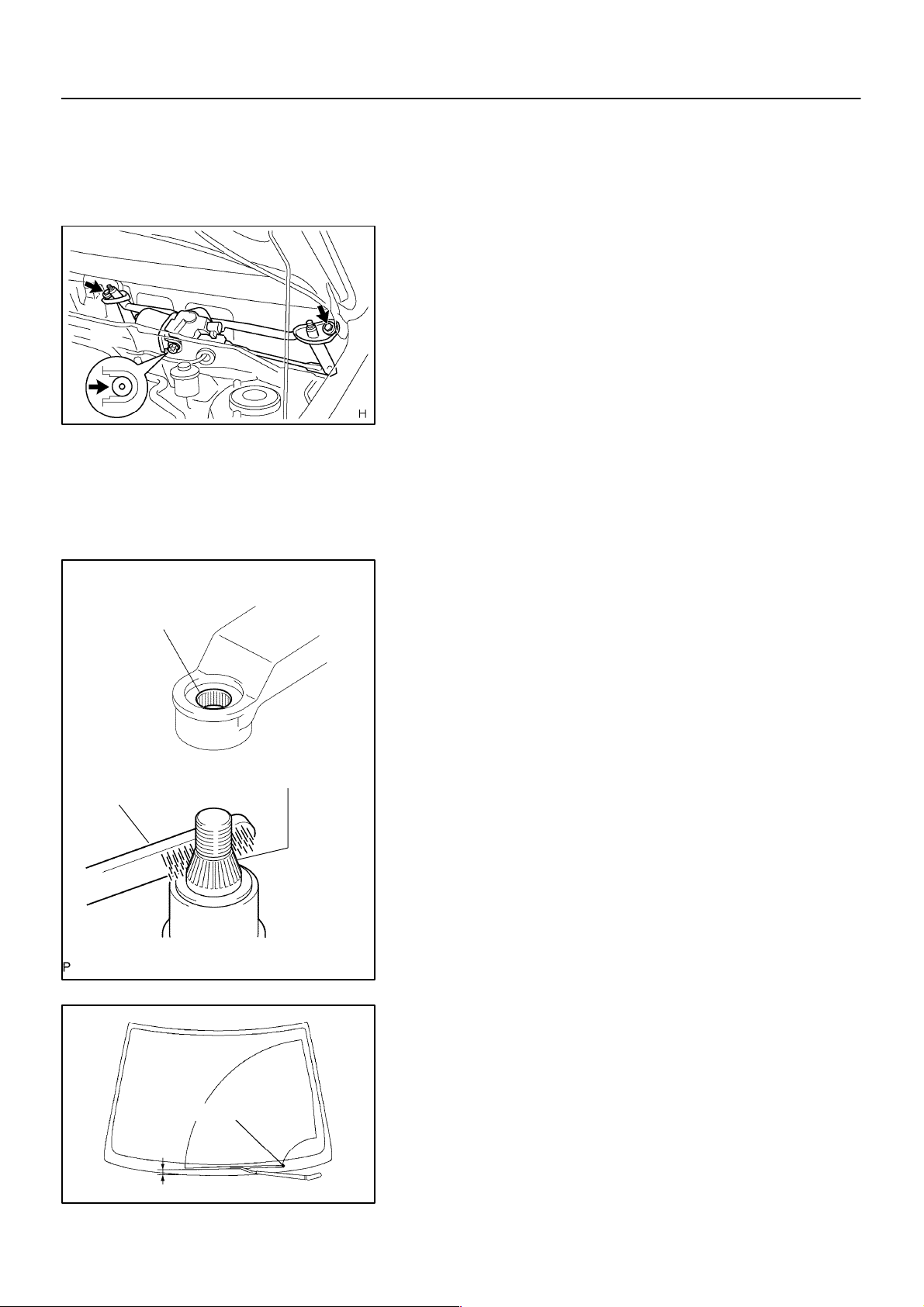

11. INSTALL FR WIPER ARM LH

(a) Operate the wiper, and stop the windshield wiper motor

assy at the automatic stop position.

Wiper Arm Serration

Wire Brush

Installation Position Mark

(b) Scrape off the serration part of the wiper arm with a round

file or equivalent.

(c) Clean the wiper pivot serration with the wire brush.

Wiper Pivot Serration

E58837

(d) Install the front wiper arm LH with a nut at the position as

shown in the illustration.

Torque: 20.5 N⋅m (209 kgf⋅cm, 15 ft⋅lbf)

HINT:

Hold down the arm hinge with hand to fasten a nut.

25 + 15.0mm (0.98 + 0.59in.)

2004 COROLLA (RM1037U)

E60710

1708Author!: Date!:

Page 20

Installation Position Mark

25 + 15.0mm (0.98 + 0.59in.)

66–9

–WIPER & WASHER WINDSHIELD WIPER MOTOR ASSY

12. INSTALL FR WIPER ARM RH

(a) Scrape off the serration part of the wiper arm with a round

file or equivalent.

(b) Clean the wiper pivot serration with the wire brush.

(c) Install the front wiper arm RH with a nut to the position

shown in the illustration.

Torque: 20.5 N⋅m (209 kgf⋅cm, 15 ft⋅lbf)

HINT:

Hold down the arm hinge with hand to fasten a nut.

(d) Operate the wiper while running the water or the washer

fluid over the window, and check the wiping condition and

that the rear wiper does not hit against the vehicle body.

E60711

2004 COROLLA (RM1037U)

1709Author!: Date!:

Page 21

03–52

–SERVICE SPECIFICATIONS WIPER & WASHER

WIPER & WASHER

TORQUE SPECIFICATION

Part Tightened N⋅m kgf⋅cm ft⋅lbf

Wind shield wiper motor assy × Wiper link assy 7.5 76 66 in.⋅lbf

Wiper link assy × Body 5.5 56 49 in.⋅lbf

FR Wiper arm RH × Wiper link 20.5 209 15

FR Wiper arm LH × Wiper link 20.5 209 15

030PT–01

2004 COROLLA (RM1037U)

156Author!: Date!:

Page 22

WIPER & WASHER

PREPARATION

SST

02–47

–PREPARATION WIPER & WASHER

021C7–01

Recomended Tools

Equipment

To r qu e w r en c h

09843–18040

09042–00010

09082–00040

(09083–00150)

Diagnosis Check Wire No.2 WIPER AND WASHER SYSTEM

Torx Socket T30 WINDSHIELD WIPER MOTOR ASSY

TOYOTA Electrical Tester WIPER AND WASHER SYSTEM

Test Lead Set WIPER AND WASHER SYSTEM

2004 COROLLA (RM1037U)

92Author!: Date!:

Page 23

–WIPER & WASHER WINDSHIELD WIPER SWITCH ASSY

WINDSHIELD WIPER SWITCH ASSY

REPLACEMENT

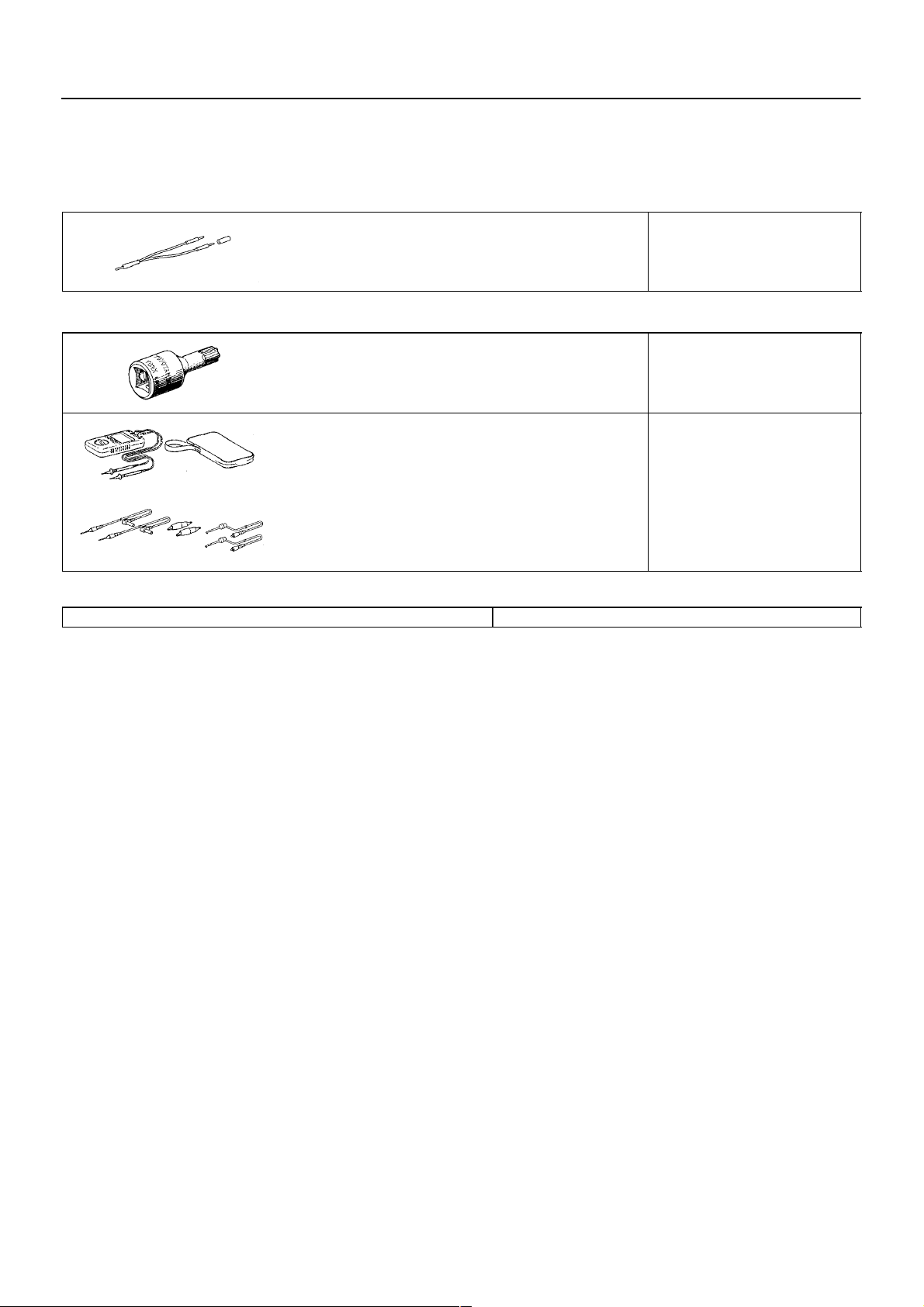

1. REMOVE STEERING COLUMN COVER LWR

(a) Remove 3 screws and steering column cover LWR.

E60462

2. REMOVE WINDSHIELD WIPER SWITCH ASSY

(a) Disconnect the connecter of the windshield wiper switch.

(b) Release the claw and pull out the windshield wiper switch

assy as shown in the illustration.

NOTICE:

Pressing the claw hard breaks the claw.

66–11

66073–01

Claw

E60688

2004 COROLLA (RM1037U)

1711Author!: Date!:

Page 24

–PREPARATION WINDSHIELD/WINDOWGLASS/MIRROR

WINDSHIELD/WINDOWGLASS/MIRROR

PREPARATION

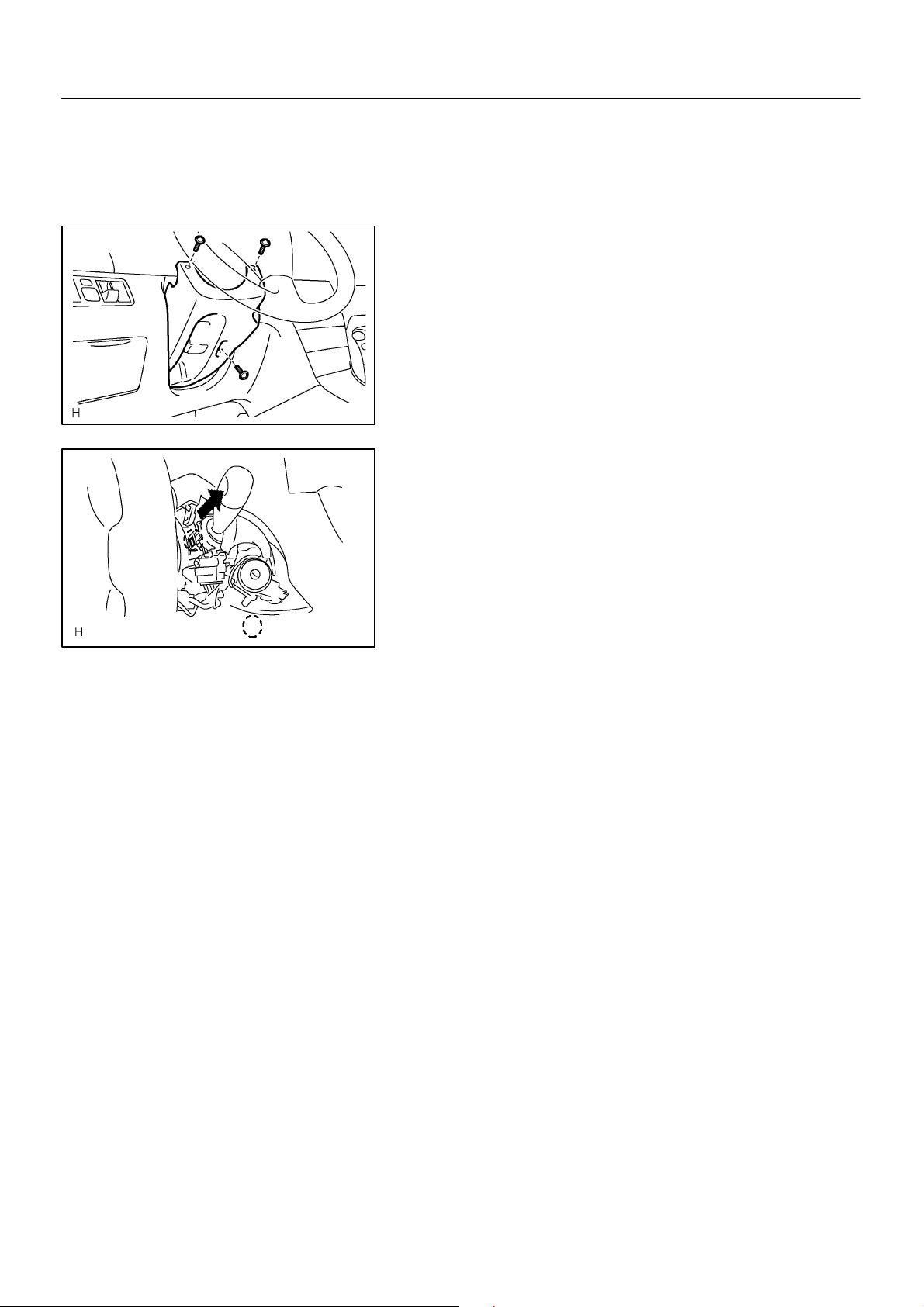

Recomended Tools

02–51

021CG–01

09070–20010

09082–00040

(09083–00150)

Moulding Remover WINDSHIELD GLASS

TOYOTA Electrical Tester WINDOW DEFOGGER SYSTEM

Test Lead Set POWER WINDOW CONTROL

Equipment

Adhesive

Knife

Piano wire Windshield

Plastic sheet To av o i d su r f a ce d a m ag e .

Sealer gun

To r qu e w r en c h

Tape To av o i d su r f a ce d a m ag e .

Wooden block or similar object For tying both piano wire ends

SSM

POWER MIRROR CONTROL

SYSTEM

POWER WINDOW CONTROL

SYSTEM

SYSTEM

08833–00030

08850–00801

Three cement black or equivalent WINDSHIELD GLASS

BACK WINDOW GLASS

Windshield Glass Adhesive Set

or equivalent

WINDSHIELD GLASS

BACK WINDOW GLASS

2004 COROLLA (RM1037U)

96Author!: Date!:

Page 25

70–10

–WINDSHIELD/WINDOWGLASS/MIRROR WINDSHIELD GLASS

REPLACEMENT

HINT:

Installation is according to the reverse order of the removal.

1. REMOVE FR WIPER ARM RH (See page 66–6)

2. REMOVE FR WIPER ARM LH (See page 66–6)

3. REMOVE HOOD TO COWL TOP SEAL (See page 66–6)

4. REMOVE COWL TOP VENTILATOR LOUVER LH (See page 66–6)

5. REMOVE COWL TOP VENTILATOR LOUVER RH (See page 66–6)

6. REMOVE FRONT DOOR WEATHERSTRIP RH (See page 76–21)

7. REMOVE FRONT DOOR WEATHERSTRIP LH (See page 76–21)

8. REMOVE FRONT PILLAR GARNISH RH (See page 76–21)

9. REMOVE FRONT PILLAR GARNISH LH (See page 76–21)

10. REMOVE INNER REAR VIEW MIRROR ASSY (See page 70–27)

11. REMOVE RH VISOR ASSY (See page 76–21)

12. REMOVE LH VISOR ASSY (See page 76–21)

13. REMOVE GLOVE BOX LAMP ASSY (See page 76–21)

14. REMOVE ASSIST GRIP SUB–ASSY (See page 76–21)

15. REMOVE VISOR HOLDER (See page 76–21)

16. REMOVE ROOF HEADLINING ASSY (See page 76–21)

17. REMOVE ROOF DRIP SIDE FINISH MOULDING CENTER RH (See page 76–17)

18. REMOVE ROOF DRIP SIDE FINISH MOULDING CENTER LH (See page 76–17)

700GO–01

2–Piece Type

1–Piece Type

Cut

Cut

19. REMOVE WINDSHIELD MOULDING OUTSIDE

(a) Using a knife, cut off the moulding as shown in the illustra-

tion.

NOTICE:

Do not damage the body with the knife.

(b) Remove the remaining moulding.

HINT:

When removing, make a cut partly, pull and remove it by hand.

B50448

20. REMOVE WINDSHIELD GLASS

HINT:

Depending on a vehicle type, either a 1–piece type or a 2–piece

type of stopper is installed.

(a) Push a piano wire through between the body and glass

from the interior.

HINT:

Apply protective tape to the outer surface to keep the surface

from being scratched.

2004 COROLLA (RM1037U)

B58592

1745Author!: Date!:

Page 26

–WINDSHIELD/WINDOWGLASS/MIRROR WINDSHIELD GLASS

70–11

Stopper

(b) Tie both wire ends to wooden blocks or similar objects.

NOTICE:

! When separating the glass, take care not to damage

the paint and interior/exterior ornaments.

Piano Wire

! To prevent the piano wire to be cut, do not cross it.

(c) Cut the adhesive by pulling the piano wire around it.

(d) Using a suction rubber, remove the glass.

NOTICE:

B50449

Leave as much adhesive on the body as possible when cutting off the glass.

21. CLEAN WINDSHIELD GLASS

(a) Using a scraper, remove the damaged stoppers, dam and

adhesive sticking to the glass.

(b) Clean the outer circumference of the glass with white gas-

oline.

NOTICE:

! Do not touch the glass after cleaning it.

! Be careful not to damage the body.

BO3986

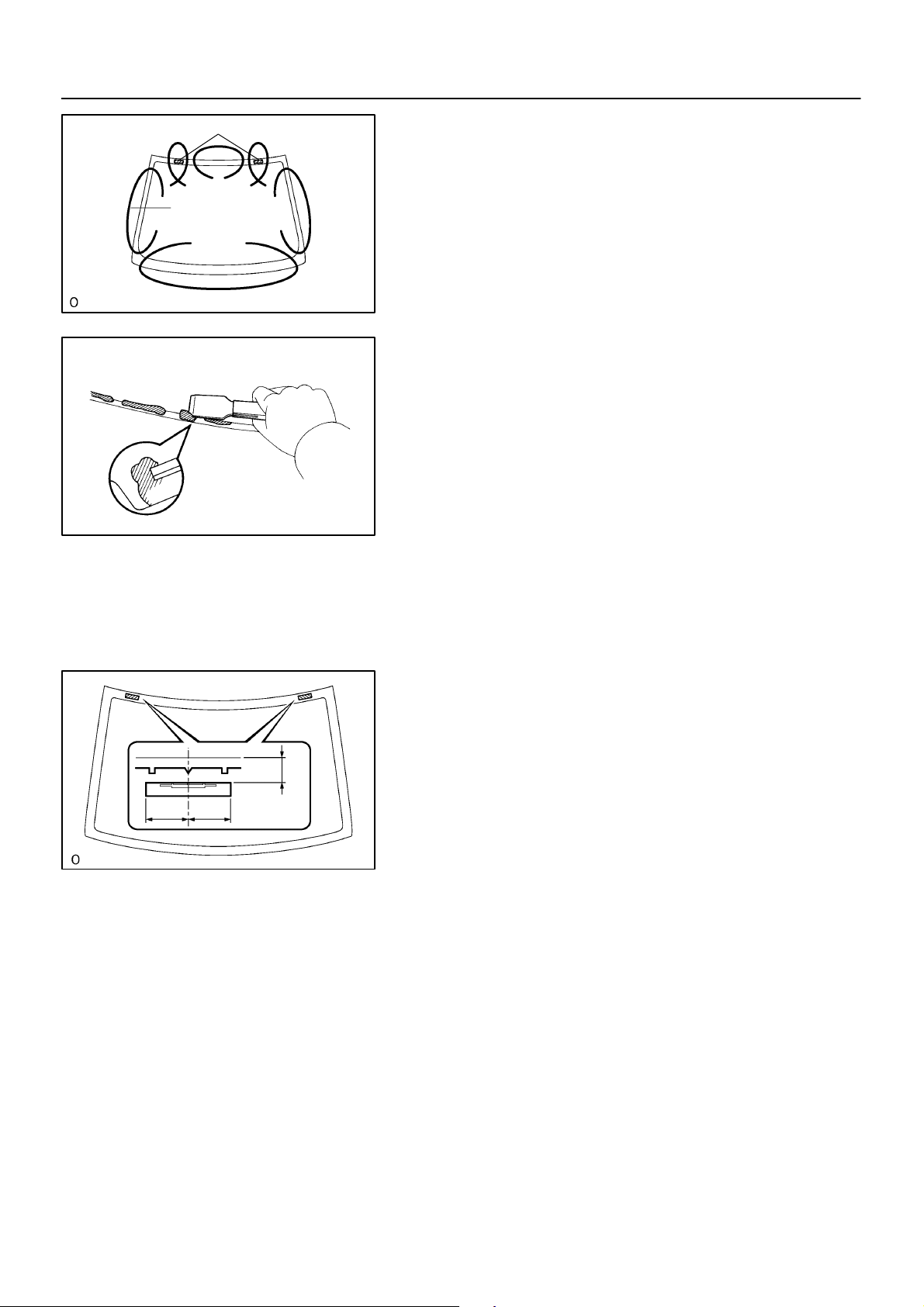

22. INSTALL WINDSHIELD GLASS STOPPER NO.1

(a) Install 2 new windshield glass stoppers No.1 to the body.

23. INSTALL WINDSHIELD GLASS STOPPER NO.2

(a) Coat the installation part of the stopper with Primer G.

NOTICE:

! Dry the primer coating for 3 minutes or more.

B

! Do not apply too much primer.

(b) Install 2 new windshield glass stoppers No.2 onto the

A

A

glass as shown in the illustration.

A: 40.0 mm (1.575 in.)

B59836

B: 7.7 mm (0.303 in.)

2004 COROLLA (RM1037U)

1746Author!: Date!:

Page 27

70–12

–WINDSHIELD/WINDOWGLASS/MIRROR WINDSHIELD GLASS

24. INSTALL FRONT PILLAR OUTER DAM

(a) Coat the installation part of the front pillar outer dam with Primer G.

NOTICE:

! Dry the primer coating for 3 minutes or more.

! Do not apply too much primer.

(b) Install 2 new front pillar outer dams with double–stick tape as shown in the illustration.

NOTICE:

Do not touch the glass face after cleaning it.

A: 7 mm (0.28 in.)

B: 22.5 mm (0.886 in.)

C: 45 mm (1.77 in.)

D: 5 mm (0.20 in.)

a – a

b – b

d

Adhesive

Adhesive

2004 COROLLA (RM1037U)

BO4420

c – c

Dam

Dam

B59167

25. INSTALL WINDSHIELD GLASS

(a) Clean and shape the contact surface of the vehicle’s

body.

(1) Using a knife, cut away any rough areas on the

body.

HINT:

Leave as much adhesive on the body as possible.

(2) Clean the cut surface of the adhesive with a piece

of shop rag saturated in cleaner.

(b) Position the glass.

(1) Using a suction rubber, place the glass in the correct

position.

(2) Check that all the contacting parts of the glass rim

are perfectly even.

(3) Place reference marks between the glass and body.

NOTICE:

Check that the stoppers are attached to the body correctly.

HINT:

When reusing the glass, check and correct the reference mark’s

positions.

1747Author!: Date!:

Page 28

–WINDSHIELD/WINDOWGLASS/MIRROR WINDSHIELD GLASS

(4) Remove the glass.

(c) Coat the contact surface of the body panel with Primer M.

(d) Using a brush, coat the exposed part of the contact sur-

face on the vehicle side with Primer M.

NOTICE:

! Dry the primer coating for 3 minutes or more.

! Do not coat the adhesive with Primer M.

! Do not apply too much primer.

(e) Coat the contact surface of the glass with Primer G.

(1) Using a brush or sponge, coat the edge of the glass

and the contact surface with Primer G.

NOTICE:

! Dry the primer coating for 3 minutes or more.

! Do not apply too much primer.

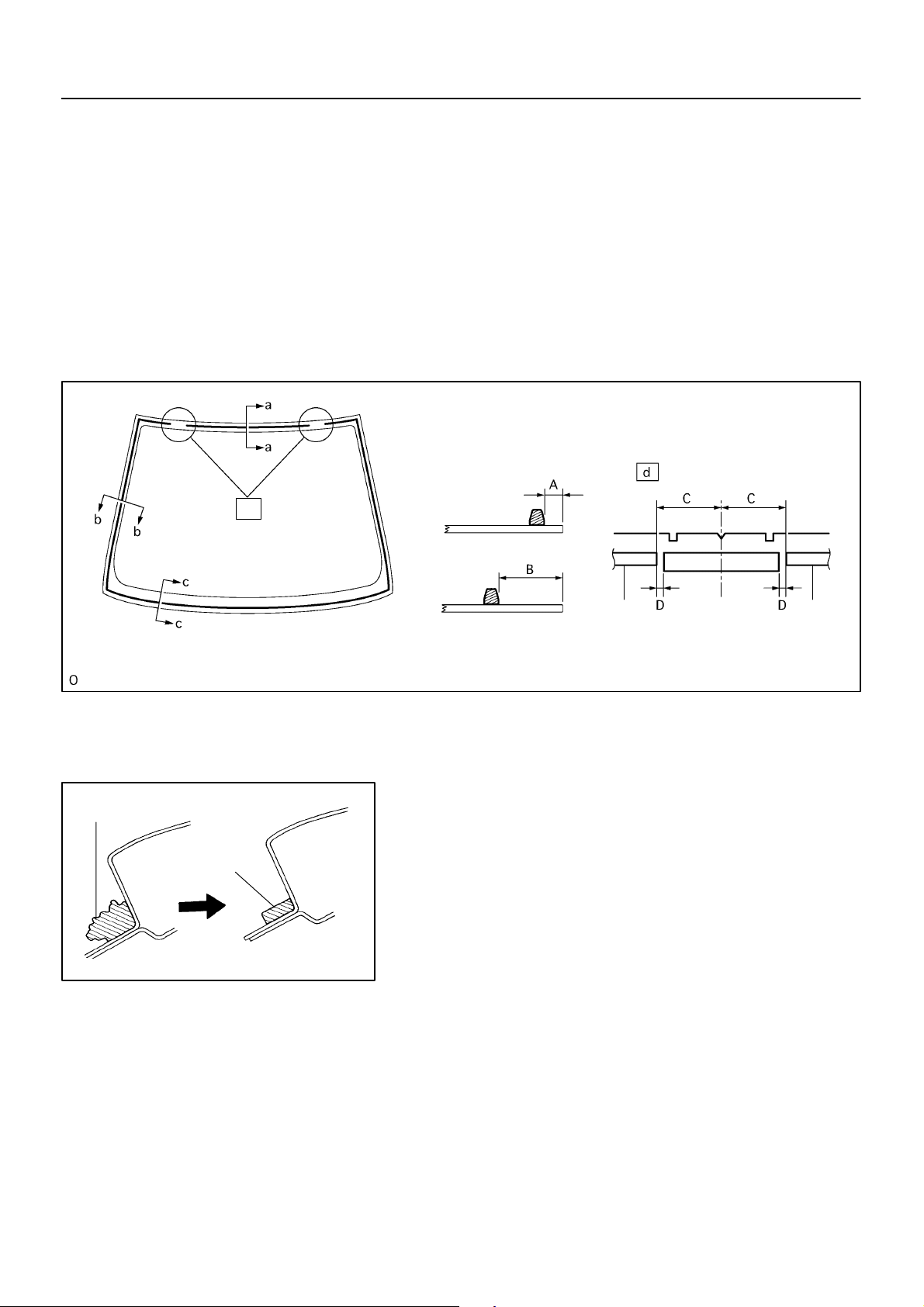

(f) Apply adhesive.

a

(1) Cut off the tip of the cartridge nozzle as shown in the

illustration.

a

Part No. 08850–00801 or equivalent

HINT:

b

b

c

c

a – a

b – b

B

After cutting off the tip, use all adhesive within the time described in the table below.

Temperature Tackfree time

35"C (95"F) 15 minutes

20"C (68"F) 100 minutes

5"C (41"F) 8 hours

(2) Load the sealer gun with the cartridge.

c – c

A

(3) Coat the glass with adhesive, as shown in the il-

lustration.

A: 8.0 mm (0.315 in.) or more

B

A

B

B: 12.5 mm (0.492 in.) or more

(g) Install the glass.

A

B59952

(1) Using a suction rubber, position the glass so that the

reference marks are aligned, and press it in gently

along the rim.

NOTICE:

! Dry the primer coating for 3 minutes or more.

! Check that the stoppers are attached to the body cor-

rectly.

! Check the clearance between the body and glass.

(2) Lightly press the glass front surface for close con-

tact.

(3) Using a scraper, remove any excess or protruding

adhesive.

HINT:

Apply adhesive on the glass rim.

26. INSTALL WINDSHIELD MOULDING OUTSIDE

(a) Install a new windshield moulding to the windshield glass before the adhesive has hardened.

(b) Hold the

windshield glass in place securely with protective tape or equivalent until the adhesive has

completely hardened.

70–13

2004 COROLLA (RM1037U)

1748Author!: Date!:

Page 29

70–14

–WINDSHIELD/WINDOWGLASS/MIRROR WINDSHIELD GLASS

(c) Using a scraper, remove any excess or protruding adhesive before the adhesive has hardened.

NOTICE:

Take care not to drive the vehicle during the time described in the table below.

Temperature Tackfree time

35"C (95"F) 1.5 hours

20"C (68"F) 5 hours

5"C (41"F) 24 hours

27. INSPECT FOR LEAK AND REPAIR

(a) Conduct a leak test after the adhesive has completely hardened.

(b) Seal any leak with sealant.

2004 COROLLA (RM1037U)

1749Author!: Date!:

Page 30

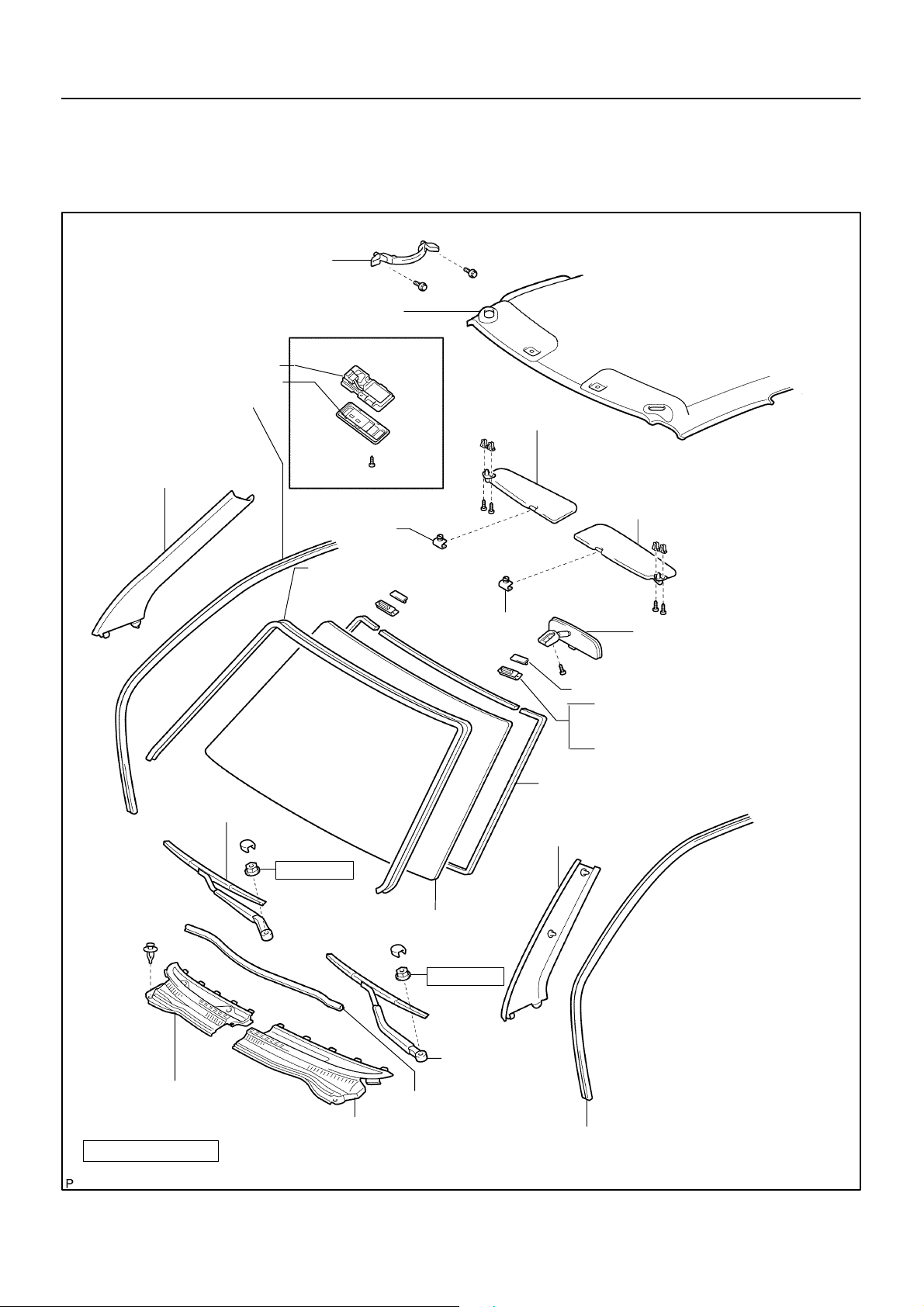

WINDSHIELD GLASS

COMPONENTS

Assist Grip Sub–assy

Roof Headlining Assy (Partial)

70–9

–WINDSHIELD/WINDOWGLASS/MIRROR WINDSHIELD GLASS

700GN–01

Glove Box Lamp Assy

Map Lamp Cover

Front Door Opening Trim

Weatherstrip RH

Front Pillar Garnish RH

w/ Sliding Roof

RH Visor Assy

Visor Holder

! Windshield Moulding Outside

Visor Holder

LH Visor Assy

Inner Rear View Mirror Assy

! Windshield Glass Stopper*

! Windshield Glass Stopper No.1*

! Windshield Glass Stopper No.2*

! Front Pillar Outer Dam

1

2

2

FR Wiper Arm RH

Cowl Top Ventilator Louver RH

N⋅m (kgf⋅cm ft⋅lbf)

: Specified torque

! Non–reusable part

2004 COROLLA (RM1037U)

20 (205, 15)

Windshield Glass

20 (205, 15)

FR Wiper Arm LH

Hood to Cowl Top Seal

Cowl Top Ventilator Louver LH

Front Pillar Garnish LH

*1:

1–piece type

*2:

2–piece type

Front Door Opening Trim Weatherstrip LH

B59170

1744Author!: Date!:

Page 31

70–22

PROBLEM SYMPTOMS TABLE

Symptom Suspected Area See page

Rear window defogger does not operate

(Indicator lamp on)

Rear window defogger does not operate

(Indicator lamp off)

–WINDSHIELD/WINDOWGLASS/MIRROR WINDOW DEFOGGER SYSTEM

1. M–HTR/DEF IUP fuse

2. DEF fuse

3. DEF relay

4. Rear window defogger wire

5. Wire harness

1. GAUGE fuse

2. Defogger switch (A/C panel switch)

3. Air control assembly

4. Wire harness

700GS–01

–

68–1

–

70–23

–

2004 COROLLA (RM1037U)

1757Author!: Date!:

Page 32

–WINDSHIELD/WINDOWGLASS/MIRROR WINDOW DEFOGGER SYSTEM

WINDOW DEFOGGER SYSTEM

LOCATION

Instrument Panel J/B

Defogger Relay

70–21

700GR–01

Defogger Wire

Instrument Panel J/B

GAUGE Fuse

2004 COROLLA (RM1037U)

M–HTR/DEF IUP Fuse

Defogger Fuse

B59159

1756Author!: Date!:

Page 33

INSPECTION

B16200

70–23

–WINDSHIELD/WINDOWGLASS/MIRROR WINDOW DEFOGGER SYSTEM

700GT–01

1. INSPECT DEFOGGER RELAY (Marking: DEF)

(a) Remove the defogger relay from the instrument panel

J/B.

(b) Inspect the defogger relay.

Standard:

Terminal No. Condition Specified condition

1 ⇔ 2 Constant Continuity

3 ⇔ 5

Apply B+ between

terminals 1 and 2

Continuity

If the result is not as specified, replace the relay.

2004 COROLLA (RM1037U)

1758Author!: Date!:

Page 34

16–8

WATER PUMP ASSY

REPLACEMENT

1. REMOVE ENGINE UNDER COVER RH

2. DRAIN COOLANT (See page 16–7)

3. REMOVE FAN AND GENERATOR V BELT

–COOLING WATER PUMP ASSY

160C9–01

(See page 14–4)

B00145

B00143

B00147

4. REMOVE GENERATOR ASSY

(a) Disconnect the wire clamp from the wire clip on the recti-

fire end frame.

(b) Remove the rubber cap and nut, and disconnect the alter-

nator wire.

(c) Disconnect the alternator connector.

(d) Remove the 2 bolts and alternator.

2004 COROLLA (RM1037U)

5. REMOVE WATER PUMP ASSY

(a) Remove the 6 bolts, water pump and O–ring.

B00150

1190Author!: Date!:

Page 35

16–9

–COOLING WATER PUMP ASSY

6. INSTALL WATER PUMP ASSY

B

(a) Place a new O–ring on the timing chain cover.

(b) Install the water pump with the 6 bolts.

B

A

B

Torque:

Bolt A 9.0 N⋅m (92 kgf⋅cm, 80 in⋅lbf)

Bolt B 11 N⋅m (113 kgf⋅cm, 8 ft⋅lbf)

B

A

A32555

7. INSTALL GENERATOR ASSY

Torque:

12 mm head 25 N⋅m (250 kgf⋅cm, 18 ft⋅lbf)

14 mm head

54 N⋅m (550 kgf⋅cm, 39 ft⋅lbf)

8. ADD COOLANT (See page 16–7)

9. CHECK ENGINE COOLANT LEAK (See page 16–7)

2004 COROLLA (RM1037U)

1191Author!: Date!:

Page 36

16–10

INSPECTION

–COOLING WATER PUMP ASSY

160CA–01

1. INSPECT WATER PUMP ASSY

(a) Visually check the drain hole for coolant leakage.

Hole

B10233

2004 COROLLA (RM1037U)

1192Author!: Date!:

Page 37

66–12

–WIPER & WASHER WASHER NOZZLE

WASHER NOZZLE

66074–01

ADJUSTMENT

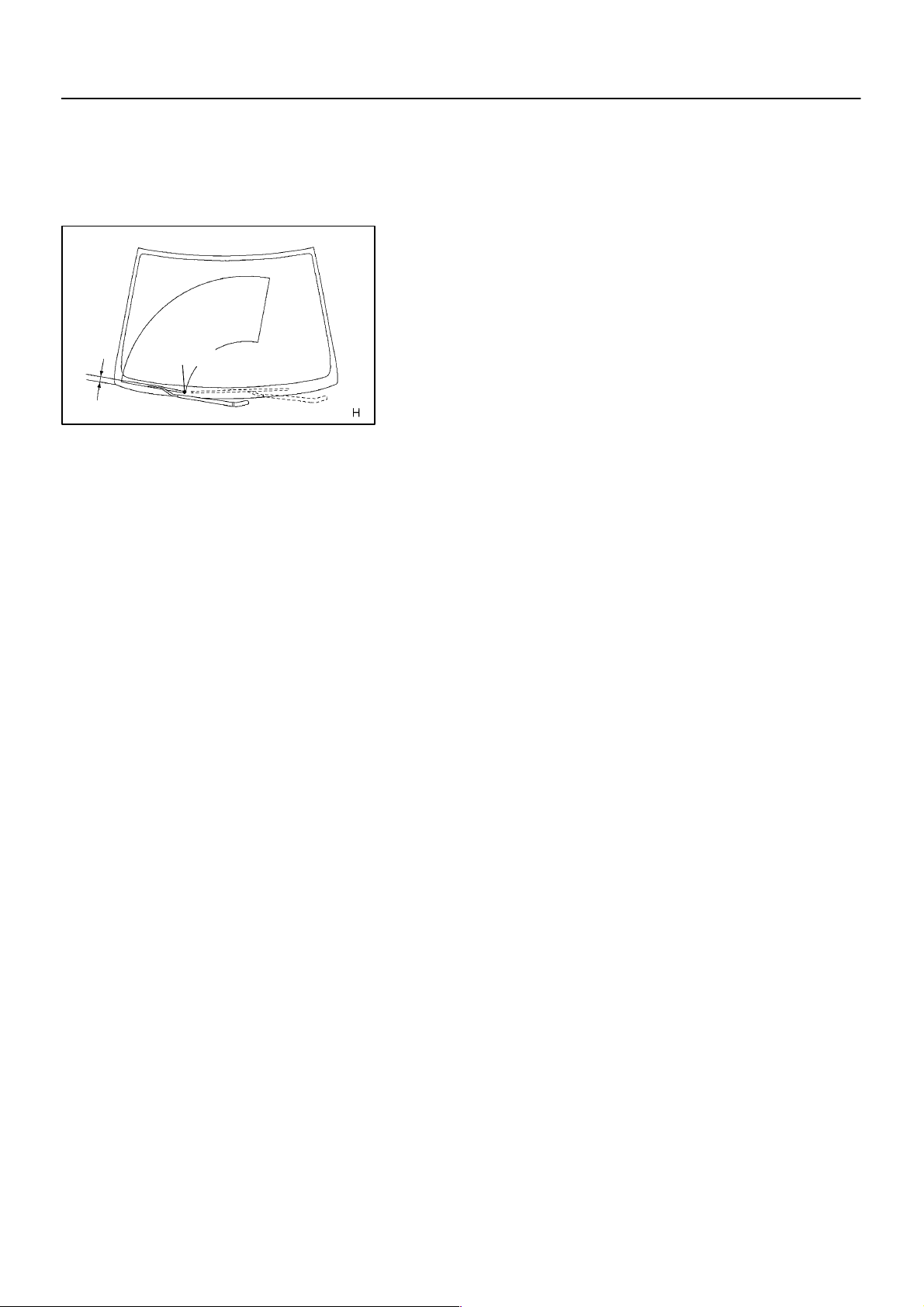

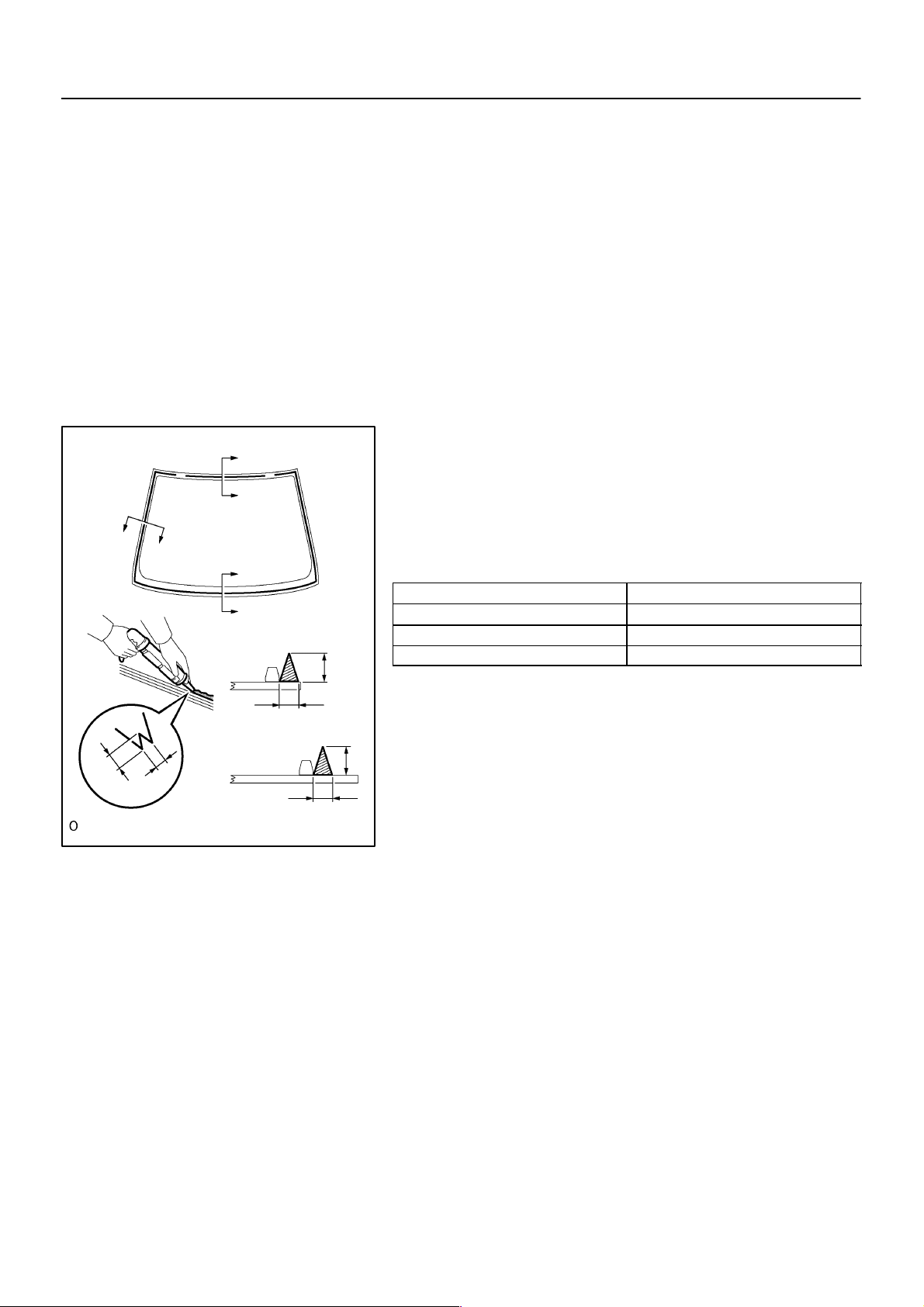

1. INSPECT WASHER NOZZLE

(a) With the engine running, check that the point where the washer fluid hits the windshield and the rear

window is within the range indicated by the hatched line.

Ceramic Line

A

A

I

A:150mm(5.91in.)

B:440mm(17.32in.)

C:180mm(7.09in.)

D:260mm(10.24in.)

A

A

B

C

H

D

F

A

A

B

C

G

D

E

J

E:455mm(17.91in.)

F:465mm(18.31in.)

G:65mm(2.56in.)

H:70mm(2.76in.)

I:200mm(7.87in.)

J:155mm(6.10in.)

2004 COROLLA (RM1037U)

E60687

1712Author!: Date!:

Page 38

–DIAGNOSTICS COMBINATION METER

WARNING BUZZER DOES NOT SOUND (KEY REMINDER

WARNING, LIGHT REMINDER WARNING)

WIRING DIAGRAM

Combination Meter

RH J/B

U1

Unlock Warning SW

W–B

1

L–B(*1)

2

Instrument Panel J/B

15

4A

14

4A

L–B(*1)

L–B(*2)

16

C9

05–659

057T3–02

KEY SW

IE

Integration Relay

DCTY

A

J6

J/C

*1: w/ Door Lock Control

*2: w/o Door Lock Control

5

IL

ID

3

R–W

1

R–W

D4

Door Courtesy SW

(Driver’s Side)

1

17

C9

D–DOOR

I32381

INSPECTION PROCEDERE

1 CHECK BUZZER

(a) Check that all of the warning buzzers sound.

A B

Some buzzers sound No buzzer sounds

B CHECK AND REPLACE COMBINATION METER

A

2004 COROLLA (RM1037U)

ASSY

824Author!: Date!:

Page 39

05–660

–DIAGNOSTICS COMBINATION METER

2 INSPECT FRONT DOOR COURTESY LAMP SWITCH ASSY(See Page 65–7)

NG REPLACE FRONT DOOR COURTESY LAMP

SWITCH ASSY

OK

3INSPECT UN–LOCK WARNING SWITCH ASSY(See Page 05–682)

NG REPLACE UN–LOCK WARNING SWITCH ASSY

OK

4CHECK HARNESS AND CONNECTOR(BETWEEN UN–LOCK WARNING SWITCH

AND COMBINATION METER ASSY)

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

5CHECK HARNESS AND CONNECTOR(BETWEEN COURTESY LAMP SWITCH AND

COMBINATION METER ASSY)

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE COMBINATION METER ASSY

2004 COROLLA (RM1037U)

825Author!: Date!:

Page 40

05–617

–DIAGNOSTICS AUDIO SYSTEM (April, 2003)

057P4–02

SOUND QUALITY IS BAD IN ALL MODES (VOLUME IS TOO LOW)

WIRING DIAGRAM

See page 05–614

INSPECTION PROCEDURE

1ADJUST SOUND QUALITY

(a) Adjust the sound quality.

(1) Operate the radio receiver assy to adjust the sound quality.

Standard: malfunction disappear.

OK BAD SOUND QUALITY

NG

2 COMPARE IT WITH ANOTHER CAR OF SAME MODEL

(a) Compare it with another vehicle of the same model.

(1) Compare with the vehicle of the same type which does not have a trouble to see if there is any

difference in the condition of trouble occurrence.

Standard: No difference found.

OK SETTING

NG

3CHECK HARNESS AND CONNECTOR(BETWEEN RADIO RECEIVER ASSY AND

SPEAKER)

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

4INSPECT FRONT NO.1 SPEAKER ASSY

(a) Preparation for Check

(1) Disconnect the connector of the speaker.

(b) Resistance Check

(1) Check the resistance between the terminals of the speaker.

NOTICE:

The speaker should not be removed for checking.

Standard value: 4 Ω

OK

2004 COROLLA (RM1037U)

NG REPLACE FRONT NO.1 SPEAKER ASSY

782Author!: Date!:

Page 41

05–618

–DIAGNOSTICS AUDIO SYSTEM (April, 2003)

5INSPECT FRONT NO.2 SPEAKER ASSY

(a) Check that malfunction disappear when a known good speaker is installed.

Standard: malfunction disappear.

HINT:

Connect the all connectors of speakers.

NG REPLACE FRONT NO.2 SPEAKER ASSY

OK

6INSPECT REAR SPEAKER ASSY

(a) Preparation for Check

(1) Disconnect the connector of the speaker.

(b) Resistance Check

(1) Check the resistance between the terminals of the speaker.

NOTICE:

The speaker should not be removed for checking.

Standard value: 6 Ω

NG REPLACE REAR SPEAKER ASSY

OK

7INSPECT RADIO RECEIVER ASSY(+B, ACC, GND)

+B

ACC

GND

I32244

(a) Check that the continuity between terminals at each

condition, as shown in the chart.

Standard:

Te s te r c o nn e c t i on Condition Specified condition

GND – Body ground Constant Continuity

(b) Check that the voltage between terminals at each condi-

tion, as shown in the chart.

Standard:

Te s te r c o nn e c t i on Condition Specified condition

+B – GND Constant 10 – 14 V

ACC – GND Ignition switch ACC or ON 10 – 14 V

OK CHECK AND REPLACE RADIO RECEIVER

ASSY

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

2004 COROLLA (RM1037U)

783Author!: Date!:

Page 42

73–14

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

730AV–01

ON–VEHICLE INSPECTION

1. OUTLINE OF TOYOTA VEHICLE INTRUSION PROTECTION (TVIP) SYSTEM

HINT:

The theft deterrent system has 2 modes; one is the active mode that is an initially set mode and another is

the passive mode that can be switched ON/OFF by the specified method (See step 4).

(a) When the theft deterrent system detects any theft, the system will sound the horns and flash the lights

to alert the people around the vehicle to the theft.

HINT:

Each mode (active and passive) has 4 states; disarmed state, arming preparation state, armed state, alarm

sounding state.

(1) Disarmed state:

! The user is near the vehicle.

! The alarming function does not operate.

! The theft deterrent function does not operate.

(2) Arming preparation state:

! Time from the user locks a door to leave the vehicle.

! Time for transferring to the armed state.

! The theft deterrent function does not operate.

(3) Armed state:

! The user leaves the vehicle completely.

! The theft deterrent function operates.

(4) Alarm sounding state:

Once a theft is detected in the armed state, the system will sound the horns and flash the lights

to alert the people around the vehicle to the theft.

Refer to the table for the alarming method and time.

Alarming method

Alarming time

Room Light

Headlight

Hazard Warning Light

Vehicle Horn

Illuminating (turn on)

Flashing at a cycle of approx. 0.4 sec.

Flashing at a cycle of flasher relay

Sounding at a cycle of approx. 0.4 sec.

Approx. 60 sec.

HINT:

In the alarm sounding state, when either of the front doors is unlocked and no key is inserted in the ignition

key cylinder, forced door lock signal is output.

2004 COROLLA (RM1037U)

1806Author!: Date!:

Page 43

2. ACTIVE ARMING MODE

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

73–15

Disarmed State

(No key inserted in ignition key cylinder)

Perform any of the followings and the system will go to ”Arming preparation state”:

" With all doors and luggage compartment door closed, lock all doors with key.

" With all doors and luggage compartment door closed, lock all doors by the wireless door

lock operation.

" With all doors and luggage compartment door closed, open and close either of doors or

luggage compartment door, and then close and lock all doors and luggage compartment

door.

Perform any of the followings and the system

will return to ”Disarmed state”:

" Open either of the closed doors or luggage

compartment door.

" Unlock either of the locked front doors.

" Insert the key in the ignition key cylinder.

" Disconnect the battery once, and then

reconnect it.

Continued from next page

Arming Preparation State

Perform the following and the system will

go to ”Armed state”:

" Allow 30 seconds to elapse with all doors

and luggage compartment door closed and

locked.

Continued to next page

2004 COROLLA (RM1037U)

1807Author!: Date!:

Page 44

73–16

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

Continued to previous page

Perform any of the followings and the system

will return to ”Disarmed state”:

" Unlock the locked doors by the wireless door

lock operation.

" Unlock the locked doors with key (except the

luggage compartment door).

" Insert the key into the ignition key cylinder

and turn the ignition ON.

Continued from previous page

Armed State

Perform any of the followings and the system

will go to ”Alarm sounding state”:

" Open either of the closed doors.

" Unlock either of the locked front doors in any

way other than the key and the wireless door

lock operations.

" Open the closed luggage compartment

door.

" Reconnect the battery terminal.

" Turn the ignition switch ON without using the

key.

" Theft is detected by the glass breakage

sensor.

Alarm Sounding State

Perform any of the followings and the system will return to ”Disarmed state”:

" Unlock the locked doors by the wireless

door lock operation.

" Unlock the locked doors with key (except

the luggage compartment door).

" Insert the key into the ignition key cylinder

and turn the ignition ON.

Once a theft is detected, lights will flash and

horns will sound to alert people around the

vehicle to the theft.

After the above specified alarming time (60

sec.) has elapsed, the system will return to

”Armed state”.

2004 COROLLA (RM1037U)

1808Author!: Date!:

Page 45

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

Indicator light output:

Condition Indicator light

Disarmed state OFF

Arming preparation state ON

Armed state BLINK

Alarm sounding state ON

HINT:

Blinking frequency:

0.2 seconds (ON)

1.8 seconds (OFF)

73–17

2004 COROLLA (RM1037U)

1809Author!: Date!:

Page 46

73–18

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

3. PASSIVE ARMING MODE

! This mode can be switched according to the specified method (See step 4).

! Initially set mode (when shipped from factory) is the active mode (No passive mode).

Disarmed State (A)

Perform the following and the system will go to ”Disarmed state (B)”:

" Insert and remove the key from the ignition key cylinder, and then open and close the driver’s door.

Disarmed State (B)

Perform any of the followings and the system

will return to ”Disarmed state (A)”:

" Push the unlock switch on the transmitter.

" Put the key in the lock cylinder on the driver’s

or passenger’s door and turn it towards unlock.

" Insert the key in the ignition key cylinder.

" Reconnect the battery terminal.

Arming Preparation State

Perform the following and the system will return to ”Disarmed state (B)”:

" Open either of the closed doors or luggage

compartment door.

Perform the following and the system will go to

”Arming preparation state”:

" Close all doors and luggage compartment

door.

Perform the following and the system will go to

”Armed state”:

" Allow 30 seconds to elapse with all doors and

luggage compartment door closed.

2004 COROLLA (RM1037U)

Continued from next page

Continued to next page

1810Author!: Date!:

Page 47

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

Continued from previous pageContinued to previous page

Armed State

73–19

Perform any of the followings and the system

will return to ”Disarmed state (A)”:

" Push the unlock switch on the transmitter.

" Put the key in the lock cylinder on the driver’s

or passenger’s door and turn it towards

unlock.

" Insert the key into the ignition key cylinder

and turn the ignition ON.

Alarm Sounding State

Perform any of the followings and the system will

go to ”Alarm sounding state”:

" Open either of the closed doors and allow the

entry delay time*1 to pass.

" Open the closed luggage compartment door.

" Reconnect the battery terminal.

" Turn the ignition ON without using the key.

*1: See the ”Entry delay function”

on the next page

Perform any of the followings and the system

will return to ”Disarmed state (A)”:

" Push the unlock switch on the transmitter.

" Put the key in the lock cylinder on the driver’s

or passenger’s door and turn it towards

unlock.

" Insert the key into the ignition key cylinder

and turn the ignition ON.

Perform the following and the system will return

to ”Armed state”:

" The alarm sounding time (60 sec.) has

elapsed.

2004 COROLLA (RM1037U)

1811Author!: Date!:

Page 48

73–20

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

Entry delay function:

HINT:

In the armed state, if either closed door is opened, entry delay time will start.

If the transferring condition (Armed state → Disarmed state) is satisfied during this entry delay time, the system will transfer to the disarmed state. However if the condition is not satisfied, the system will judge it to

be a theft, and then the system will transfer to the alarm sounding state.

Door

Close

Open

Indicator

ON

OFF

Alarming output

ON

OFF

Entry delay time

System condition

(0, 14, 30 sec.)

Armed state Alarm sounding

state

HINT:

The entry delay time can be selected among 0, 14, 30 seconds by the customizing function.

Indicator light output:

Condition Indicator light

Disarmed state OFF

Arming preparation state ON

Armed state (Entry delay time) BLINK (ON)

Alarm sounding state ON

HINT:

Blinking frequency:

0.2 seconds (ON)

1.8 seconds (OFF)

Transfer to the active mode:

HINT:

In each state of the passive mode, when the transferring condition to the active mode (disarmed state of

active mode → arming preparation state of active mode) is satisfied, the system will transfer to each state

of the active mode. In this case, the active mode will continue until the system transfers to the disarmed state.

State of Passive Mode Before Transfer State of Active Mode After Transfer

Disarmed state Arming preparation state

Arming preparation state Arming preparation state (continuing for 30 sec.)

Armed state

Armed state (During entry delay time)

Alarm sounding state

(After alarming time has elapsed, the system will transfer to the

armed state)

After alarming time has elapsed, the system will transfer to the

armed state

2004 COROLLA (RM1037U)

1812Author!: Date!:

Page 49

4. CHANGING METHOD OF PASSIVE MODE

(ON or OFF)

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

73–21

Within

5 sec.

Within

40 sec.

2 sec.

" No key in the ignition key cylinder

" Driver’s door opened

" All doors unlocked

Insert and remove the key from the ignition

key cylinder 3 times.

Close the driver’s door.

Lock and unlock all doors 3 times by the key

or remote control.

Open and close the driver’s door.

Lock and unlock the driver’s door lock knob

3 times.

Open the driver’s door.

( = Vehicle initial condition)

Input to the vehicle

Output from the vehicle

Within

20 sec.

2 sec.

The system starts forced door lock once

(answer back).

Unlock the driver’s door lock knob.

Close and open the driver’s door 3 to 5

Close and open the driver’s door 2 times

times

Lock and unlock the driver’s door lock

Lock and unlock the driver’s door lock knob.

knob.

* 0 sec.

The system starts forced door lock once

(answer back).

PASSIVE MODE OFF

The system starts forced door lock once

(answer back).

PASSIVE MODE ON

HINT:

" Initial mode is PASSIVE MODE OFF.

" If there is a different signal in the middle of changing, it is invalid.

*: Entry delay time

4 times 5 times3 times

* 14 sec. * 30 sec.

2004 COROLLA (RM1037U)

1813Author!: Date!:

Page 50

73–22

–THEFT DETERRENT & DOOR LOCK TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

5. FORCED DOOR LOCK CONTROL

(a) Forced door lock is a control that prevents intrusion into vehicles. When a door is unlocked (when an

alarm starts), instantaneously forced door lock will be executed.

(1) Condition to execute forced door lock:

Detecting any or all of the following conditions activates forced door lock.

! Theft deterrent system is in the alarm sounding state of the active mode.

! No key is in the ignition key cylinder.

! Any of the front doors is unlocked.

! Since the previous forced door lock, 0.38 seconds or more have elapsed.

(2) Conditions to stop forced door lock:

Detecting any of the following conditions stops forced door lock.

! All doors are locked.

! The alarm has finished.

! The key is inserted into the key cylinder.

Glass Breakage Sensor ECU

Volume

B59188

6. OPERATE GLASS BREAKAGE SENSOR

(a) If the glass breakage sensor detects the glass is broken

(at 1st time), the sensor will issue an alarm for 20 seconds

(pre–alarming). If the glass breakage sensor detects the

glass is broken further more (at 2nd time), the sensor will

issue an alarm for 60 seconds.

(b) The sensitivity of the glass breakage sensor can be ad-

justed by the volume switch in the glass breakage sensor

ECU.

HINT:

Because the glass breakage sensor has a high sensitivity, it

might issue a wrong alarm if it is adjusted in the volume of high

sensitive.

2004 COROLLA (RM1037U)

1814Author!: Date!:

Page 51

01–4

–INTRODUCTION IDENTIFICATION INFORMATION

IDENTIFICATION INFORMATION

VEHICLE IDENTIFICATION AND SERIAL NUMBERS

1. VEHICLE IDENTIFICATION NUMBER

A

B

D27356

A

C

B

D27359

(a) The vehicle identification number is stamped on the ve-

hicle identification number plate and certification label, as

shown in the illustration.

A: Vehicle Identification Number Plate

B: Certification Label

2. ENGINE SERIAL NUMBER AND TRANSAXLE SERIAL

NUMBER

(a) The engine serial number is stamped on the cylinder

block of the engine, and the transaxle serial number is

stamped on the housing, as shown in the illustration.

A: 1ZZ–FE

B: C59

C: A245E

01031–06

2004 COROLLA (RM1037U)

7Author!: Date!:

Page 52

02–58

VEHICLE CONTROL SYSTEM

PREPARATION

Recomended Tools

–PREPARATION VEHICLE CONTROL SYSTEM

021CP–01

09082–00040

TOYOTA Electrical Tester IGNITION OR STARTER SWITCH

ASSY

2004 COROLLA (RM1037U)

103Author!: Date!:

Page 53

51–8

–POWER STEERING VANE PUMP ASSY

OVERHAUL

NOTICE:

! When using a vise, do not over tighten.

! When installing, coat the parts indicated by the arrows with power steering fluid

(See page 51–7).

1. REMOVE FRONT WHEEL RH

2. DRAIN POWER STEERING FLUID

3. REMOVE ENGINE UNDER COVER RH

4. REMOVE FAN AND GENERATOR V BELT

5. DISCONNECT OIL RESERVOIR TO PUMP HOSE NO.1

(a) Remove the clip and disconnect the oil reservoir to pump hose No.1.

6. DISCONNECT PRESSURE FEED TUBE ASSY

SST

(a) Using SST, disconnect the pressure feed tube assy.

SST 09023–38400

(b) Remove the bolt and disconnect the pressure feed tube

clamp.

5107W–01

F42474

7. REMOVE VANE PUMP ASSY

(a) Disconnect the oil pressure switch connector.

(b) Remove the 2 bolts, nuts and vane pump assy.

C80321

8. REMOVE VANE PUMP BRACKET REAR

(a) Remove the bolt and vane pump bracket rear.

9. FIX VANE PUMP ASSY

(a) Using SST, hold the vane pump assy in a vise.

SST 09630–00014 (09631–00132)

2004 COROLLA (RM1037U)

SST

F42477

1543Author!: Date!:

Page 54

51–9

–POWER STEERING VAN E PUM P ASS Y

10. REMOVE POWER STEERING SUCTION PORT UNION

(a) Remove the bolt and power steering suction port union.

(b) Remove the O–ring from the power steering suction port union.

11. REMOVE FLOW CONTROL VALVE

(a) Remove the pressure port union.

(b) Remove the O–ring from the pressure port union.

(c) Remove the flow control valve and flow control valve compression spring.

12. REMOVE POWER STEERING OIL PRESSURE SWITCH

NOTICE:

Be careful so that oil pressure switch is not dropped or strongly damaged, however if it is damaged

replace it with a new one.

13. REMOVE VANE PUMP HOUSING REAR

(a) Remove the 4 bolts and vane pump housing rear from the vane pump housing front.

(b) Remove the O–ring from the vane pump housing front.

14. REMOVE W/PULLEY SHAFT SUB–ASSY

(a) Using a screwdriver, remove the snap ring from the w/ pulley shaft sub–assy.

(b) Remove the w/ pulley shaft sub–assy.

15. REMOVE VANE PUMP ROTOR

(a) Remove the 10 vane plates.

(b) Remove the vane pump rotor.

16. REMOVE VANE PUMP CAM RING

C65368

C65369

17. REMOVE VANE PUMP SIDE PLATE FRONT

(a) Remove the side plate from the pump housing front.

(b) Remove the O–ring from the side plate front.

(c) Remove the O–ring from the pump housing front.

2004 COROLLA (RM1037U)

1544Author!: Date!:

Page 55

51–10

Vane Pump Shaft

SST

Bushing

Front Housing

–POWER STEERING VAN E PUM P ASS Y

18. REMOVE VANE PUMP HOUSING OIL SEAL

(a) Using SST and a hammer, remove the vane pump hous-

ing oil seal.

SST 09631–10030

NOTICE:

Be careful not to damage the pump housing.

F42143

19. INSPECT OIL CLEARANCE

(a) Using a micrometer and a caliper gauge, measure the oil

seal clearance.

Standard clearance:

0.021 – 0.043 mm (0.0008 – 0.0017 in.)

Maximum clearance: 0.07 mm (0.0028 in.)

If it is more than the maximum, replace the vane pump assy.

F09875

Height

Length

Thickness

Feeler Gauge

20. INSPECT VANE PUMP ROTOR AND VANE PLATES

(a) Using a micrometer, measure the height, thickness and

length of the vane plates.

Minimum height: 7.6 mm (0.299 in.)

Minimum thickness: 1.405 mm (0.0553 in.)

Minimum length: 11.993 mm (0.4722 in.)

N00372

(b) Using a feeler gauge, measure the clearance between a

side face of the vane pump rotor groove and vane plate.

Maximum clearance: 0.03 mm (0.0012 in.)

If it is more than the maximum, replace the vane pump assy.

R10282

21. INSPECT FLOW CONTROL VALVE

(a) Coat the flow control valve with power steering fluid and

check that it falls smoothly into the flow control valve hole

by its own weight.

2004 COROLLA (RM1037U)

F41493

1545Author!: Date!:

Page 56

Compressed Air

F41491 F41622

Vernier Calipers

51–11

–POWER STEERING VAN E PUM P ASS Y

(b) Check the flow control valve for leakage. Close one of the

holes and apply compressed air of 392 – 490 kPa (4 – 5

2

kgf⋅cm

, 57 – 71 psi) into the opposite side hole, and con-

firm that air does not come out from the end holes.

If necessary, replace the vane pump assy.

22. INSPECT FLOW CONTROL VALVE COMPRESSION

SPRING

(a) Using vernier calipers, measure the free length of the

spring.

Minimum free length: 36.9 mm (1.453 in.)

If it is not within the specification, replace the vane pump assy.

R08702

23. INSPECT PRESSURE PORT UNION

(a) If the union seat in the pressure port union is remarkably damaged and it may cause fluid leakage,

replace the vane pump assy.

24. INSTALL VANE PUMP HOUSING OIL SEAL

(a) Coat a new vane pump housing oil seal lip with power

SST

steering fluid.

(b) Using SST and a press, install a new vane pump housing

oil seal.

SST 09950–60010 (09951–00280), 09950–70010

(09951–07100)

NOTICE:

Oil Seal

F08480

Make sure that the vane pump housing oil seal is installed

facing in the correct direction.

25. INSTALL W/PULLEY SHAFT SUB–ASSY

Power Steering Fluid

(a) Coat inside bushing surface of the vane pump housing

front with power steering fluid.

(b) Gradually insert the vane pump shaft.

NOTICE:

Do not damage the vane pump housing oil seal lip in the

vane pump housing front.

2004 COROLLA (RM1037U)

F40339

1546Author!: Date!:

Page 57

51–12

–POWER STEERING VAN E PUM P ASS Y

26. INSTALL VANE PUMP SIDE PLATE FRONT

(a) Coat a new O–ring with power steering fluid and install

it to the vane pump housing front.

C65369

(b) Coat a new O–ring with power steering fluid and install it

to the side plate front.

Inscribed Mark

C65368

(c) Align the dent of the vane pump side plate front with that

of the vane pump housing front, and install the vane pump

side plate front.

NOTICE:

Make sure that the side plate front is installed facing in the

correct direction.

F08482

27. INSTALL VANE PUMP CAM RING

(a) Align the dent of the cam ring with that of the side plate

front, and install the cam ring with the inscribed mark fac-

ing outward.

F08483

Inscribed Mark

2004 COROLLA (RM1037U)

Round End

F08484

28. INSTALL VANE PUMP ROTOR

(a) Install the vane pump rotor with the inscribed mark facing

outward.

(b) Coat 10 vane plates with power steering fluid.

(c) Install the vane plates with the round end facing outward.

1547Author!: Date!:

Page 58

51–13

–POWER STEERING VANE PUMP ASSY

(d) Using a snap ring expander, install a new snap ring to the

w/ pulley shaft sub–assy.

F40343

29. INSTALL VANE PUMP HOUSING REAR

(a) Coat a new O–ring with power steering fluid and install it to the pump housing rear.

(b) Align the straight pin of the vane pump housing rear with the dents of the vane pump cam ring, vane

pump side plate front and vane pump housing front, and install the vane pump housing rear with the

4 bolts.

Torque: 22 N⋅m (220 kgf⋅cm, 16 ft⋅lbf)

30. INSPECT PRELOAD

(a) Check that the pump rotates smoothly without abnormal

noise.

(b) Temporarily install the service bolt.

Recommended service bolt:

Thread diameter: 10 mm (0.3937 in.)

Thread pitch: 1.25 mm (0.0492 in.)

Bolt length: 50 mm (1.9685 in.)

C53369

(c) Using a torque wrench, check the pump rotating torque.

Rotating torque:

0.27 N⋅m (2.8 kgf⋅cm, 2.4 ft⋅lbf) or less

31. INSTALL POWER STEERING OIL PRESSURE SWITCH

(a) Coat a new O–ring with power steering fluid and install it to the power steering oil pressure switch.

(b) Install the power steering oil pressure switch to the vane pump assy.

Torque: 21 N⋅m (210 kgf⋅cm, 15 ft⋅lbf)

32. INSTALL FLOW CONTROL VALVE

(a) Coat the flow control valve compression spring and flow

control valve with power steering fluid.

(b) Install the flow control valve compression spring and flow

control valve.

(c) Coat a new O–ring with power steering fluid and install it

to the pressure port union.

(d) Install the pressure port union.

F42475

Torque: 69 N⋅m (700 kgf⋅cm, 51 ft⋅lbf)

2004 COROLLA (RM1037U)

1548Author!: Date!:

Page 59

51–14

–POWER STEERING VAN E PUM P ASS Y

33. INSTALL POWER STEERING SUCTION PORT UNION

(a) Coat a new O–ring with power steering fluid, and install it to the power steering suction port union.

(b) Install the power steering suction port union with the bolt.

Torque: 12 N⋅m (120 kgf⋅cm, 9 ft⋅lbf)

34. INSTALL VANE PUMP ASSY

(a) Install the vane pump assy with the 2 bolts and nuts.

Torque: 37 N⋅m (380 kgf⋅cm, 27 ft⋅lbf)

(b) Connect the oil pressure switch connector.

NOTICE:

Be careful that the oil does not adhere to the connector.

C80321

35. INSTALL VANE PUMP BRACKET REAR

(a) Install the vane pimp bracket rear with the bolt.

Torque: 37 N⋅m (380 kgf⋅cm, 27 ft⋅lbf)

SST

36. CONNECT PRESSURE FEED TUBE ASSY

(a) Using SST, connect the pressure feed tube assy.

Fulcrum

Length

SST 09023–38400

Torque: 41 N⋅m (420 kgf⋅cm, 30 ft⋅lbf)

HINT:

! Use a torque wrench with a fulcrum length of 345 mm

(13.58 in.).

! This torque value is effective when SST is parallel to a

F13579

torque wrench.

(b) Connect the pressure feed tube clamp with the bolt.

Torque: 7.8 N⋅m (80 kgf⋅cm, 69 ft⋅lbf)

37. CONNECT OIL RESERVOIR TO PUMP HOSE NO.1

(a) Connect the oil reservoir to pump hose No.1 with the clip.

38. INSTALL FAN AND GENERATOR V BELT

39. INSTALL FRONT WHEEL RH

Torque: 103 N⋅m (1,050 kgf⋅cm, 76 ft⋅lbf)

40. ADD POWER STEERING FLUID

41. BLEED POWER STEERING FLUID(See page 51–3)

42. INSPECT FLUID LEAK

43. INSTALL ENGINE UNDER COVER RH

2004 COROLLA (RM1037U)

1549Author!: Date!:

Page 60

VANE PUMP ASSY

COMPONENTS

51–7

–POWER STEERING VAN E PUM P ASS Y

5107V–01

Pressure Port Union

69 (700, 51)

O–Ring!

Flow Control Valve

Suction Port Union

37 (380, 27)

Vane Pump Shaft with

Vane Pump Pulley

12 (120, 9)

O–Ring!

Front Housing

Oil Seal!

Rear Housing

Snap Ring!

Vane Pump Rotor

Spring

22 (220, 16)

Oil Pressure Switch

21 (210, 15)

Vane Pump Bracket Rear

O–Ring!

N⋅m (kgf⋅cm, ft⋅lbf) : Specified torque

Non–reusable part!

Power steering fluid

2004 COROLLA (RM1037U)

Side Plate

O–Ring!

× 10

22 (220, 16)

Vane P l ate

Cam Ring

F42473

1542Author!: Date!:

Page 61

VALVE CLEARANCE

ADJUSTMENT

14–5

–ENGINE MECHANICAL VALVE CLEARANCE

140OE–01

1. REMOVE CYLINDER HEAD COVER NO.2

(a) Remove the 2 nuts, 2 clips and cylinder head cover.

A65077

2. DISCONNECT ENGINE WIRE

(a) Remove the 5 clamps from the 5 clamp brackets.

A64021

A64022

(b) Disconnect the 4 ignition coil connectors.

(c) Remove the bolt and nut installing the engine wire.

3. REMOVE IGNITION COIL ASSY

(a) Remove the 4 bolts and 4 ignition coils.

2004 COROLLA (RM1037U)

A64023

1015Author!: Date!:

Page 62

14–6

–ENGINE MECHANICAL VALVE CLEARANCE

4. DISCONNECT VENTILATION HOSE

(a) Disconnect the ventilation hose from the cylinder head

cover.

A65078

5. DISCONNECT VENTILATION HOSE NO.2

(a) Disconnect the ventilation hose from the cylinder head

cover.

A64058

6. REMOVE CYLINDER HEAD COVER SUB–ASSY

(a) Remove the 9 bolts, 2 seal washers, 2 nuts, 3 clamp

A64856

7. REMOVE ENGINE UNDER COVER RH

brackets and cylinder head cover.

2004 COROLLA (RM1037U)

1016Author!: Date!:

Page 63

Mark

Mark

Mark

Timing Chain

Cover Surface

14–7

–ENGINE MECHANICAL VALVE CLEARANCE

8. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley, and align its groove with timing

mark ”0” of the timing chain cover.

(b) Check that the point marks of the camshaft timing sprock-

et and VVT timing sprocket are in straight line on the tim-