Loading...

Loading...C

- Celica Supra 1982

- Celica Supra 1986

- CEV2

- Challenger 2016

- CHASER JZX100

- CHASER JZX90

- CHR2

- Chr 20193

- CLASSIC

- CN-TS0170LA

- CN-TS0171LA

- CN-TS0270A

- CN-TS0272A

- CN-TS0370K

- CN-TS0371A

- CN-TS0372K

- CN-TS0373A

- CN-TS0820

- CN-TS0821

- CN-TS0822

- CN-TS0823

- CN-TS0920

- CN-TS0922

- CN-TS0923

- CN-TS09821

- CN-TS6070LA

- CN-TS6190

- CN-TS6271A

- Coaster 20152

- Coaster 2016

- Coaster 2017

- Coaster 2018

- Comfort 2014

- COMPUTER-CONTROLLED SYSTEM

- Corola

- Corola 2006

- Corolla19

- Corolla 1100

- Corolla 1200

- Corolla 1987

- Corolla 19963

- Corolla 19973

- Corolla 19986

- Corolla 19995

- Corolla 20005

- Corolla 2000-2002

- Corolla 20015

- Corolla 20024

- Corolla 20035

- Corolla 2004739

- Corolla 20055

- Corolla 20064

- Corolla 20076

- COROLLA 20085

- Corolla 200910

- Corolla 20109

- Corolla 20115

- Corolla 20124

- Corolla 20137

- Corolla 20143

- Corolla 201513

- Corolla 201617

- Corolla 201713

- Corolla 20183

- Corolla 20193

- Corolla 20203

- Corolla Axio 2016

- Corolla Axio 2018

- COROLLA - BROCHURE 2011

- Corolla Bulgarian 2016

- Corolla Crossbars 1992

- Corolla E12-A

- Corolla E12-D

- COROLLA Estate

- Corolla FR AE86L Series 1987

- COROLLA Hatchback

- Corolla Hatchback 20193

- Corolla Hatchback 20202

- COROLLA HB

- Corolla HV 2019

- Corolla Hybrid 20203

- Corolla iM 20173

- COROLLA Liftback

- Corolla Matrix3

- Corolla Matrix 20092

- Corolla MN 00505-QRG09-COR

- Corolla Navigointi 2014

- Corolla Roofrack Sedan 1992

- Corolla Roofrack Sedan Liftback 1992

- COROLLA Saloon

- COROLLA SEDAN2

- Corolla Thf 2001

- Corolla TNS600 2004

- COROLLA TS

- Corolla Verso3

- Corolla Verso 20042

- Corolla Verso 2005

- Corolla XI E160 2012 — 2019

- Corolla XI E170 2012 — 2019

- Corolla XII E210 2018

Loading...

Loading... Loading...

Loading...Nothing found

Corolla 2004

DIAGNOSTICS – ABS WITH EBD SYSTEM

3 pgs18.76 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

3 pgs84.94 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

3 pgs51.95 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

2 pgs46.46 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

2 pgs14.87 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

3 pgs52.1 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

2 pgs13.29 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

1 pgs71.89 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

6 pgs62.47 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

1 pgs8.93 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

2 pgs13.66 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

1 pgs30.65 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

2 pgs8.47 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

3 pgs18.14 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

1 pgs6.05 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

4 pgs57.87 Kb0

DIAGNOSTICS – ABS WITH EBD SYSTEM

4 pgs48.34 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs10.55 Kb0

DIAGNOSTICS – AUDIO SYSTEM

1 pgs14.46 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs9.06 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs12.23 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs17.39 Kb0

DIAGNOSTICS – AUDIO SYSTEM

1 pgs5.03 Kb0

DIAGNOSTICS – AUDIO SYSTEM

1 pgs6.19 Kb0

DIAGNOSTICS – AUDIO SYSTEM

3 pgs39.21 Kb0

DIAGNOSTICS – AUDIO SYSTEM

1 pgs43.99 Kb0

DIAGNOSTICS – AUDIO SYSTEM

3 pgs27.63 Kb0

DIAGNOSTICS – AUDIO SYSTEM

1 pgs7.3 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs18.25 Kb0

DIAGNOSTICS – AUDIO SYSTEM

6 pgs45.86 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs19.95 Kb0

DIAGNOSTICS – AUDIO SYSTEM

1 pgs9.82 Kb0

DIAGNOSTICS – AUDIO SYSTEM

1 pgs8.99 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs7.96 Kb0

DIAGNOSTICS – AUDIO SYSTEM

2 pgs12.86 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs14.57 Kb0

DIAGNOSTICS – COMBINATION METER

1 pgs8.89 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs23.61 Kb0

DIAGNOSTICS – COMBINATION METER

5 pgs99.04 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs15.59 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs15.84 Kb0

DIAGNOSTICS – COMBINATION METER

3 pgs17.81 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs14.49 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs14.86 Kb0

DIAGNOSTICS – COMBINATION METER

3 pgs22.51 Kb0

DIAGNOSTICS – COMBINATION METER

1 pgs7.57 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs16.32 Kb0

DIAGNOSTICS – COMBINATION METER

1 pgs5.84 Kb0

DIAGNOSTICS – COMBINATION METER

2 pgs12.29 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

2 pgs15.78 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

3 pgs34.3 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

3 pgs33.55 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

2 pgs13.94 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

2 pgs13.06 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

1 pgs7.92 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

3 pgs20.19 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

3 pgs23.95 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

3 pgs22.29 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

4 pgs26.37 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

2 pgs14.84 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

1 pgs7.46 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

2 pgs13.93 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

1 pgs56.98 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

5 pgs56.24 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

3 pgs19.33 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

1 pgs14.78 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

2 pgs21.59 Kb0

DIAGNOSTICS – CRUISE CONTROL SYSTEM

2 pgs9.17 Kb0

DIAGNOSTICS – POWER DOOR LOCK CONTROL SYSTEM

5 pgs96.52 Kb0

DIAGNOSTICS – POWER DOOR LOCK CONTROL SYSTEM

1 pgs10.48 Kb0

DIAGNOSTICS – POWER DOOR LOCK CONTROL SYSTEM

1 pgs63.01 Kb0

DIAGNOSTICS – POWER DOOR LOCK CONTROL SYSTEM

1 pgs5.47 Kb0

DIAGNOSTICS – POWER DOOR LOCK CONTROL SYSTEM

3 pgs46.44 Kb0

DIAGNOSTICS – POWER DOOR LOCK CONTROL SYSTEM

1 pgs6.37 Kb0

DIAGNOSTICS – POWER DOOR LOCK CONTROL SYSTEM

3 pgs43.37 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs39.79 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs18.39 Kb0

DIAGNOSTICS – SFI SYSTEM

6 pgs66.47 Kb0

DIAGNOSTICS – SFI SYSTEM

8 pgs46.59 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs10.92 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs47.58 Kb0

DIAGNOSTICS – SFI SYSTEM

7 pgs59.86 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs13.19 Kb0

DIAGNOSTICS – SFI SYSTEM

6 pgs50.12 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs43.63 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs13.85 Kb0

DIAGNOSTICS – SFI SYSTEM

7 pgs57.77 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs12.57 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs14.49 Kb0

DIAGNOSTICS – SFI SYSTEM

3 pgs18.54 Kb0

DIAGNOSTICS – SFI SYSTEM

10 pgs81.59 Kb0

DIAGNOSTICS – SFI SYSTEM

8 pgs49.39 Kb0

DIAGNOSTICS – SFI SYSTEM

13 pgs130.21 Kb0

DIAGNOSTICS – SFI SYSTEM

14 pgs89.12 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs47.57 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs37.34 Kb0

DIAGNOSTICS – SFI SYSTEM

4 pgs29.17 Kb0

DIAGNOSTICS – SFI SYSTEM

9 pgs62.83 Kb0

DIAGNOSTICS – SFI SYSTEM

7 pgs43.61 Kb0

DIAGNOSTICS – SFI SYSTEM

25 pgs245.17 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs58.87 Kb0

DIAGNOSTICS – SFI SYSTEM

4 pgs33.06 Kb0

DIAGNOSTICS – SFI SYSTEM

9 pgs59.25 Kb0

DIAGNOSTICS – SFI SYSTEM

4 pgs31.41 Kb0

DIAGNOSTICS – SFI SYSTEM

1 pgs9.69 Kb0

DIAGNOSTICS – SFI SYSTEM

8 pgs67.84 Kb0

DIAGNOSTICS – SFI SYSTEM

6 pgs50.83 Kb0

DIAGNOSTICS – SFI SYSTEM

1 pgs5.95 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs8.67 Kb0

DIAGNOSTICS – SFI SYSTEM

1 pgs8.17 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs24.39 Kb0

DIAGNOSTICS – SFI SYSTEM

3 pgs26.6 Kb0

DIAGNOSTICS – SFI SYSTEM

3 pgs11.8 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs17.55 Kb0

DIAGNOSTICS – SFI SYSTEM

5 pgs47.78 Kb0

DIAGNOSTICS – SFI SYSTEM

1 pgs7.05 Kb0

DIAGNOSTICS – SFI SYSTEM

8 pgs81.88 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs18.85 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs561.07 Kb0

DIAGNOSTICS – SFI SYSTEM

1 pgs35.3 Kb0

DIAGNOSTICS – SFI SYSTEM

6 pgs22.71 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs19.77 Kb0

DIAGNOSTICS – SFI SYSTEM

2 pgs25.71 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

2 pgs17.69 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

2 pgs23.01 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

5 pgs60.52 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

5 pgs57.47 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

8 pgs76.18 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

6 pgs70.96 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

6 pgs69.95 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

4 pgs40.38 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

3 pgs25.49 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

4 pgs37.01 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

3 pgs20.02 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

2 pgs18.75 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

3 pgs38.68 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

3 pgs27.33 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

1 pgs6.01 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

1 pgs56.86 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

6 pgs111.43 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

3 pgs23.71 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

1 pgs7.31 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

2 pgs16.56 Kb0

DIAGNOSTICS – SUPPLEMENTAL RESTRAINT SYSTEM

2 pgs8.84 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

2 pgs24.27 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

1 pgs10.48 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

3 pgs47.64 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

2 pgs28.48 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

3 pgs37.72 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

3 pgs37.38 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

3 pgs30.66 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

3 pgs46.44 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

3 pgs43.56 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

2 pgs26.45 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

3 pgs30.59 Kb0

DIAGNOSTICS – TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

4 pgs58.37 Kb0

DIAGNOSTICS – WIRELESS DOOR LOCK CONTROL SYSTEM

1 pgs6.78 Kb0

DIAGNOSTICS – WIRELESS DOOR LOCK CONTROL SYSTEM

1 pgs72.41 Kb0

DIAGNOSTICS – WIRELESS DOOR LOCK CONTROL SYSTEM

8 pgs45.94 Kb0

DIAGNOSTICS – WIRELESS DOOR LOCK CONTROL SYSTEM

1 pgs5.18 Kb0

DIAGNOSTICS – WIRELESS DOOR LOCK CONTROL SYSTEM

1 pgs7.22 Kb0

Electrical Wiring Diagram - ABS

5 pgs46.62 Kb0

Electrical Wiring Diagram - air conditioning

4 pgs40.82 Kb0

Electrical Wiring Diagram - back up light

2 pgs15.44 Kb0

Electrical Wiring Diagram - Back–Up Light

2 pgs19.87 Kb0

Electrical Wiring Diagram - charging

2 pgs27.49 Kb0

Electrical Wiring Diagram - Charging

2 pgs28.45 Kb0

Electrical Wiring Diagram - Cigarette Lighter

2 pgs12.88 Kb0

Electrical Wiring Diagram - cigarette lightger

2 pgs7.87 Kb0

Electrical Wiring Diagram - clock

2 pgs19.7 Kb0

Electrical Wiring Diagram - Clock

2 pgs22.85 Kb0

Electrical Wiring Diagram - combination meter

6 pgs69.85 Kb0

Electrical Wiring Diagram - Combination Meter

6 pgs85.25 Kb0

Electrical Wiring Diagram - connectors

6 pgs166.22 Kb0

Electrical Wiring Diagram - cruise control

6 pgs54.96 Kb0

Electrical Wiring Diagram - Cruise Control for 2ZZ–GE

4 pgs47.77 Kb0

Electrical Wiring Diagram - door lock control

8 pgs49.18 Kb0

Electrical Wiring Diagram - Door Lock Control

6 pgs56.99 Kb0

Electrical Wiring Diagram - ECT

6 pgs64.08 Kb0

Electrical Wiring Diagram - electrochromic mirror

2 pgs8.61 Kb0

Electrical Wiring Diagram - engine control

12 pgs121.29 Kb0

Electrical Wiring Diagram - Engine Control for 1ZZ–FE

12 pgs118.77 Kb0

Electrical Wiring Diagram - Engine Control for 2ZZ–GE

10 pgs111.43 Kb0

Electrical Wiring Diagram - Engine Immobiliser System

2 pgs25.88 Kb0

Electrical Wiring Diagram - F RELAY LOCATIONS

12 pgs189.05 Kb0

Electrical Wiring Diagram - fog light

2 pgs20.97 Kb0

Electrical Wiring Diagram - Fog Light

2 pgs24.22 Kb0

Electrical Wiring Diagram - foreword

1 pgs6.83 Kb0

Electrical Wiring Diagram - G ELECTRICAL WIRING ROUTING

6 pgs205.59 Kb0

Electrical Wiring Diagram - G ELECTRICAL WIRING ROUTING

9 pgs269.03 Kb0

Electrical Wiring Diagram - grounding points

4 pgs60.01 Kb0

Electrical Wiring Diagram - headlight

6 pgs58.32 Kb0

Electrical Wiring Diagram - heater

2 pgs22.03 Kb0

Electrical Wiring Diagram - Heater

2 pgs25.34 Kb0

Electrical Wiring Diagram - horn

2 pgs11.37 Kb0

Electrical Wiring Diagram - Horn

2 pgs18.79 Kb0

Electrical Wiring Diagram - howtouse

9 pgs124.87 Kb0

Electrical Wiring Diagram - illumination

4 pgs34.43 Kb0

Electrical Wiring Diagram - Illumination

4 pgs45.29 Kb0

Electrical Wiring Diagram - index

1 pgs9.46 Kb0

Electrical Wiring Diagram - indexDiagrams

1 pgs5.52 Kb0

Electrical Wiring Diagram - interior light

4 pgs41.2 Kb0

Electrical Wiring Diagram - Interior Light

4 pgs39.58 Kb0

Electrical Wiring Diagram - introduction

1 pgs4.64 Kb0

Electrical Wiring Diagram - J POWER SOURCE

6 pgs54.06 Kb0

Electrical Wiring Diagram - Key Reminder Buzzer

4 pgs26.26 Kb0

Electrical Wiring Diagram - M Overall

47 pgs863.15 Kb0

Electrical Wiring Diagram - M OVERALL ELECTRICAL

71 pgs687.73 Kb0

Electrical Wiring Diagram - M OVERALL ELECTRICAL

3 pgs64.97 Kb0

Electrical Wiring Diagram - Moon Roof

2 pgs24.38 Kb0

Electrical Wiring Diagram - NEW FEATURES

2 pgs14.39 Kb0

Electrical Wiring Diagram - Power Outlet

2 pgs15.16 Kb0

Electrical Wiring Diagram - Power Source

4 pgs58.33 Kb0

Electrical Wiring Diagram - Power Window

4 pgs44.31 Kb0

Electrical Wiring Diagram - Power Window Power Source

4 pgs60.13 Kb0

Electrical Wiring Diagram - Radiator F a n

2 pgs17.69 Kb0

Electrical Wiring Diagram - Radiator Fan

2 pgs23.14 Kb0

Electrical Wiring Diagram - Radio and Player

4 pgs21.48 Kb0

Electrical Wiring Diagram - Rear Window Defogger

2 pgs13.29 Kb0

Electrical Wiring Diagram - Rear Window Defogger

2 pgs22.77 Kb0

Electrical Wiring Diagram - Remote Control Mirror

2 pgs17.65 Kb0

Electrical Wiring Diagram - Remote Control Mirror

2 pgs21.13 Kb0

Electrical Wiring Diagram - Seat Belt Warning

2 pgs23.29 Kb0

Electrical Wiring Diagram - Seat Belt Warning

4 pgs46.39 Kb0

Electrical Wiring Diagram - Shift Lock

2 pgs16.95 Kb0

Electrical Wiring Diagram - SRS

7 pgs60.41 Kb0

Electrical Wiring Diagram - SRS

7 pgs62.13 Kb0

Electrical Wiring Diagram - Starting and Ignition

4 pgs37.08 Kb0

Electrical Wiring Diagram - Starting and Ignition

4 pgs38.72 Kb0

Electrical Wiring Diagram - Stop Light

2 pgs14.24 Kb0

Electrical Wiring Diagram - Stop Light

2 pgs20.04 Kb0

Electrical Wiring Diagram - Taillight

4 pgs29.6 Kb0

Electrical Wiring Diagram - Taillight

4 pgs32.01 Kb0

Electrical Wiring Diagram - TVIP System

6 pgs69.35 Kb0

Electrical Wiring Diagram - TVIP System

6 pgs62.36 Kb0

Electrical Wiring Diagram - Wiper and W asher

2 pgs27.13 Kb0

Electrical Wiring Diagram - Wiper and Washer

4 pgs26.18 Kb0

Electrical Wiring Diagram - Wireless Door Lock Control

8 pgs65.77 Kb0

Electrical Wiring Diagram - Wireless Door Lock Control

6 pgs69.09 Kb0

MAINTENANCE – BODY

1 pgs5.92 Kb0

MAINTENANCE – BRAKE

1 pgs12.97 Kb0

MAINTENANCE – CHASSIS

1 pgs5.89 Kb0

MAINTENANCE – ENGINE

1 pgs13.1 Kb0

MAINTENANCE – INSIDE VEHICLE

2 pgs9.11 Kb0

MAINTENANCE – OUTSIDE VEHICLE

1 pgs6.69 Kb0

MAINTENANCE – UNDER HOOD

1 pgs7.8 Kb0

MAJOR TECHNICAL SPECIFICATIONS

3 pgs18.57 Kb0

OUTLINE OF NEW FEATURES

1 pgs3.56 Kb0

Owner Manual

267 pgs2.81 Mb0

Owner's Manual

23 pgs554.06 Kb0

Owner's Manual

8 pgs285.05 Kb0

Owner's Manual

272 pgs5.99 Mb0

REPAIR INSTRUCTION

12 pgs244.35 Kb0

Repair Manual

1 pgs4.61 Kb0

Repair Manual

2 pgs6.19 Kb0

Repair Manual - ABBREVIATIONS D

1 pgs3.65 Kb0

Repair Manual - AIR BAG FRONT RH SENSOR

1 pgs34.51 Kb0

Repair Manual - AIR BAG FRONT RH SENSOR

1 pgs15.65 Kb0

Repair Manual - AIR BAG SENSOR ASSY CENTER

1 pgs30.39 Kb0

Repair Manual - AIR BAG SENSOR ASSY CENTER

1 pgs24.49 Kb0

Repair Manual - AIR BAG SENSOR FRONT LH

1 pgs4.77 Kb0

Repair Manual - AIR CONDITIONING SYSTEM

3 pgs31.43 Kb0

Repair Manual - AIR CONDITIONING SYSTEM

1 pgs10.41 Kb0

Repair Manual - AIR CONDITIONING SYSTEM

1 pgs23.99 Kb0

Repair Manual - AIR CONDITIONING UNIT ASSY

2 pgs115.95 Kb0

Repair Manual - AIR CONDITIONING UNIT ASSY

16 pgs787.28 Kb0

Repair Manual - AMPLIFIER ANTENNA ASSY

1 pgs19.21 Kb0

Repair Manual - ANTENNA CORD SUB–ASSY

3 pgs58.21 Kb0

Repair Manual - AUDIO VISUAL SYSTEM

2 pgs28.08 Kb0

Repair Manual - AUDIO VISUAL SYSTEM

1 pgs8.21 Kb0

Repair Manual - AUDIO VISUAL SYSTEM

2 pgs117.61 Kb0

Repair Manual - AUTOMATIC TRANSAXLE ASSY

2 pgs78.36 Kb0

Repair Manual - AUTOMATIC TRANSAXLE ASSY

11 pgs334.01 Kb0

Repair Manual - AUTOMATIC TRANSAXLE ASSY

1 pgs6.52 Kb0

Repair Manual - AUTOMATIC TRANSAXLE FLUID

1 pgs10.68 Kb0

Repair Manual - AUTOMATIC TRANSMISSION / TRANS

2 pgs31.44 Kb0

Repair Manual - BACK UP LAMP ASSY LH

1 pgs25.27 Kb0

Repair Manual - BACK WINDOW GLASS

1 pgs30.73 Kb0

Repair Manual - BACK WINDOW GLASS

5 pgs55.49 Kb0

Repair Manual - BODY ROCKER PANEL MOULDING LH

1 pgs16.02 Kb0

Repair Manual - BRAKE

2 pgs21.63 Kb0

Repair Manual - BRAKE ACTUATOR ASSY

1 pgs5.54 Kb0

Repair Manual - BRAKE ACTUATOR ASSY

3 pgs79.56 Kb0

Repair Manual - BRAKE ACTUATOR ASSY

1 pgs54.69 Kb0

Repair Manual - BRAKE BOOSTER ASSY

1 pgs18.36 Kb0

Repair Manual - BRAKE BOOSTER ASSY

4 pgs98.43 Kb0

Repair Manual - BRAKE BOOSTER ASSY

2 pgs57.23 Kb0

Repair Manual - BRAKE FLUID

2 pgs47.95 Kb0

Repair Manual - BRAKE MASTER CYLINDER SUB–ASSY

5 pgs117.65 Kb0

Repair Manual - BRAKE MASTER CYLINDER SUB–ASSY

2 pgs28.11 Kb0

Repair Manual - BRAKE PEDAL SUB–ASSY

1 pgs29.34 Kb0

Repair Manual - BRAKE PEDAL SUB–ASSY

2 pgs39.62 Kb0

Repair Manual - BRAKE SYSTEM

1 pgs5.6 Kb0

Repair Manual - BRAKE SYSTEM

2 pgs17.93 Kb0

Repair Manual - CAMSHAFT

3 pgs126.79 Kb0

Repair Manual - CAMSHAFT

12 pgs417.91 Kb0

Repair Manual - CENTER STOP LAMP ASSY

1 pgs15.84 Kb0

Repair Manual - CHAIN SUB–ASSY

3 pgs131.62 Kb0

Repair Manual - CHAIN SUB–ASSY

11 pgs393.91 Kb0

Repair Manual - CHARGING SYSTEM

3 pgs38.29 Kb0

Repair Manual - CHARGING SYSTEM

1 pgs4.86 Kb0

Repair Manual - CIGARETTE LIGHTER ASSY

1 pgs17.87 Kb0

Repair Manual - CLOCK ASSY

1 pgs15.24 Kb0

Repair Manual - CLUTCH

1 pgs18.25 Kb0

Repair Manual - CLUTCH MASTER CYLINDER ASSY

1 pgs19.94 Kb0

Repair Manual - CLUTCH MASTER CYLINDER ASSY

4 pgs68.26 Kb0

Repair Manual - CLUTCH PEDAL SUB–ASSY

2 pgs21.2 Kb0

Repair Manual - CLUTCH PEDAL SUB–ASSY

1 pgs21.17 Kb0

Repair Manual - CLUTCH PEDAL SUB–ASSY

4 pgs71.57 Kb0

Repair Manual - CLUTCH RELEASE CYLINDER ASSY

1 pgs23.61 Kb0

Repair Manual - CLUTCH RELEASE CYLINDER ASSY

2 pgs49.97 Kb0

Repair Manual - CLUTCH START SWITCH ASSY

1 pgs8.28 Kb0

Repair Manual - CLUTCH START SWITCH ASSY

1 pgs9.58 Kb0

Repair Manual - CLUTCH START SWITCH ASSY

1 pgs8.42 Kb0

Repair Manual - CLUTCH SWITCH ASSY

1 pgs4.62 Kb0

Repair Manual - CLUTCH SYSTEM

1 pgs10.64 Kb0

Repair Manual - CLUTCH UNIT

1 pgs30.45 Kb0

Repair Manual - CLUTCH UNIT

4 pgs105.93 Kb0

Repair Manual - COMBINATION METER

5 pgs27.27 Kb0

Repair Manual - COMBINATION METER

1 pgs9.15 Kb0

Repair Manual - COMBINATION METER ASSY

1 pgs33.64 Kb0

Repair Manual - COMMUNICATION SYSTEM

1 pgs7.79 Kb0

Repair Manual - COOLANT

1 pgs14.94 Kb0

Repair Manual - COOLER COMPRESSOR ASSY

1 pgs31.39 Kb0

Repair Manual - COOLER COMPRESSOR ASSY

5 pgs156.83 Kb0

Repair Manual - COOLING

1 pgs10.45 Kb0

Repair Manual - COOLING FAN SYSTEM

1 pgs11.34 Kb0

Repair Manual - COOLING FAN SYSTEM

1 pgs6.15 Kb0

Repair Manual - COOLING FAN SYSTEM

2 pgs25.48 Kb0

Repair Manual - COOLING FAN SYSTEM

2 pgs20.96 Kb0

Repair Manual - CRUISE CONTROL

1 pgs20.25 Kb0

Repair Manual - CRUISE CONTROL ECU ASSY

1 pgs13.29 Kb0

Repair Manual - CRUISE CONTROL SYSTEM

1 pgs55.9 Kb0

Repair Manual - CYLINDER BLOCK ASSY

1 pgs37.19 Kb0

Repair Manual - CYLINDER BLOCK ASSY

23 pgs599.93 Kb0

Repair Manual - CYLINDER HEAD ASSY

1 pgs28.47 Kb0

Repair Manual - CYLINDER HEAD ASSY

12 pgs304.4 Kb0

Repair Manual - CYLINDER HEAD GASKET

4 pgs181.01 Kb0

Repair Manual - CYLINDER HEAD GASKET

16 pgs552.62 Kb0

Repair Manual - DIAGNOSTICS

1 pgs14.46 Kb0

Repair Manual - DIFFERENTIAL CASE ASSY

5 pgs163.71 Kb0

Repair Manual - DIFFERENTIAL CASE ASSY

1 pgs28.14 Kb0

Repair Manual - DOOR CONTROL TRANSMITTER

3 pgs12.62 Kb0

Repair Manual - DRIVE SHAFT / PROPELLER SHAFT

4 pgs73.75 Kb0

Repair Manual - DRIVE SHAFT, PROPELLER SHAFT, AXLE

2 pgs59.58 Kb0

Repair Manual - DRIVE SHAFT, PROPELLER SHAFT, AXLE

1 pgs8.33 Kb0

Repair Manual - ECM

3 pgs99.56 Kb0

Repair Manual - EMISSION CONTROL

1 pgs7.1 Kb0

Repair Manual - EMISSION CONTROL SYSTEM

5 pgs114.06 Kb0

Repair Manual - EMISSION CONTROL SYSTEM

5 pgs108.91 Kb0

Repair Manual - ENGINE ASSEMBLY

3 pgs36.11 Kb0

Repair Manual - ENGINE CONTROL SYSTEM

1 pgs4.7 Kb0

Repair Manual - ENGINE HOOD/DOOR

1 pgs11.53 Kb0

Repair Manual - ENGINE HOOD/DOOR REAR DOO

7 pgs144.06 Kb0

Repair Manual - ENGINE MECHANICAL

4 pgs59.7 Kb0

Repair Manual - ENGINE REAR OIL SEAL

3 pgs74.51 Kb0

Repair Manual - EXHAUST

1 pgs4.63 Kb0

Repair Manual - EXHAUST PIPE ASSY

1 pgs19.17 Kb0

Repair Manual - EXHAUST PIPE ASSY

2 pgs36.06 Kb0

Repair Manual - EXTERIOR/INTERIOR TRIM

1 pgs6.99 Kb0

Repair Manual - F RELAY LOCATIONS

12 pgs200.2 Kb0

Repair Manual - FAN AND GENERATOR V BELT

1 pgs9.6 Kb0

Repair Manual - FLOOR SHIFT ASSY

1 pgs27.7 Kb0

Repair Manual - FLOOR SHIFT ASSY

2 pgs66.15 Kb0

Repair Manual - FLOOR SHIFT ASSY

10 pgs285.67 Kb0

Repair Manual - FLOOR SHIFT PARKING LOCK CABLE ASSY

3 pgs72.67 Kb0

Repair Manual - FLOOR SHIFT SHIFT LEVER ASSY

1 pgs36.61 Kb0

Repair Manual - FLOOR SHIFT SHIFT LEVER ASSY

3 pgs99.51 Kb0

Repair Manual - FOG LAMP ASSY LH

1 pgs8.07 Kb0

Repair Manual - FOG LAMP ASSY LH

1 pgs11.74 Kb0

Repair Manual - FRONT AXLE HUB SUB–ASSY LH

1 pgs51.47 Kb0

Repair Manual - FRONT AXLE HUB SUB–ASSY LH

5 pgs121.95 Kb0

Repair Manual - FRONT AXLE LH HUB BOLT

1 pgs27.76 Kb0

Repair Manual - FRONT BRAKE

1 pgs29.88 Kb0

Repair Manual - FRONT BRAKE

5 pgs108.6 Kb0

Repair Manual - FRONT BUMPER

1 pgs64.6 Kb0

Repair Manual - FRONT BUMPER

2 pgs58.24 Kb0

Repair Manual - FRONT DIFFERENTIAL OIL SEAL

2 pgs33.56 Kb0

Repair Manual - FRONT DIFFERENTIAL OIL SEAL

2 pgs31.89 Kb0

Repair Manual - FRONT DOOR

2 pgs36.73 Kb0

Repair Manual - FRONT DOOR

2 pgs72.53 Kb0

Repair Manual - FRONT DOOR

9 pgs230.2 Kb0

Repair Manual - FRONT DOOR BELT MOULDING ASSY LH

1 pgs19.56 Kb0

Repair Manual - FRONT DRIVE SHAFT

2 pgs68.11 Kb0

Repair Manual - FRONT DRIVE SHAFT

10 pgs252.3 Kb0

Repair Manual - FRONT NO.1 SPEAKER ASSY

2 pgs43.99 Kb0

Repair Manual - FRONT NO.2 SPEAKER ASSY

1 pgs16.48 Kb0

Repair Manual - FRONT SEAT

1 pgs38.29 Kb0

Repair Manual - FRONT SEAT

3 pgs48.96 Kb0

Repair Manual - FRONT SEAT AIRBAG ASSY RH

5 pgs74.48 Kb0

Repair Manual - FRONT SEAT BELT

1 pgs37.67 Kb0

Repair Manual - FRONT SEAT BELT

5 pgs70.82 Kb0

Repair Manual - FRONT SEAT BELT

1 pgs11.82 Kb0

Repair Manual - FRONT SEAT BELT

2 pgs30.38 Kb0

Repair Manual - FRONT SHOCK ABSORBER WITH COIL SPRING

4 pgs184.19 Kb0

Repair Manual - FRONT SUSPENSION

1 pgs18.91 Kb0

Repair Manual - FRONT SUSPENSION

2 pgs95.39 Kb0

Repair Manual - FRONT SUSPENSION ARM SUB–ASSY LOWER NO.1 LH

4 pgs125.09 Kb0

Repair Manual - FRONT SUSPENSION SYSTEM

1 pgs9.43 Kb0

Repair Manual - FRONT SUSPENSION SYSTEM

1 pgs8.69 Kb0

Repair Manual - FRONT WHEEL ALIGNMENT

3 pgs63.94 Kb0

Repair Manual - FUEL

1 pgs18.85 Kb0

Repair Manual - FUEL INJECTOR ASSY

1 pgs30.4 Kb0

Repair Manual - FUEL INJECTOR ASSY

4 pgs111.4 Kb0

Repair Manual - FUEL PUMP ASSY

2 pgs50.21 Kb0

Repair Manual - FUEL PUMP ASSY

6 pgs146.15 Kb0

Repair Manual - FUEL SYSTEM

2 pgs28.25 Kb0

Repair Manual - FUEL SYSTEM

2 pgs31.11 Kb0

Repair Manual - FUEL SYSTEM

4 pgs81.99 Kb0

Repair Manual - FUEL TANK ASSY

3 pgs69.39 Kb0

Repair Manual - FUEL TANK ASSY

9 pgs188.66 Kb0

Repair Manual - GENERATOR ASSY

1 pgs37 Kb0

Repair Manual - GENERATOR ASSY

5 pgs125.28 Kb0

Repair Manual - GENERATOR ASSY

1 pgs51.95 Kb0

Repair Manual - HEADLAMP DIMMER SWITCH ASSY

1 pgs17.72 Kb0

Repair Manual - HEATER AIR CONDITIONER

3 pgs54.03 Kb0

Repair Manual - HEATER CONTROL ACCESSORY ASSY

2 pgs62.84 Kb0

Repair Manual - HOOD

2 pgs42.61 Kb0

Repair Manual - HORN BUTTON ASSY

1 pgs31.38 Kb0

Repair Manual - HORN BUTTON ASSY

7 pgs132.98 Kb0

Repair Manual - HORN BUTTON ASSY

1 pgs40.23 Kb0

Repair Manual - HORN SYSTEM

1 pgs15.93 Kb0

Repair Manual - HORN SYSTEM

1 pgs27 Kb0

Repair Manual - HORN SYSTEM

1 pgs5.25 Kb0

Repair Manual - HOW TO PROCEED WITH TROUBLESHOOTING

10 pgs174.02 Kb0

Repair Manual - HOW TO USE THIS MANUAL

3 pgs43.32 Kb0

Repair Manual - IDENTIFICATION INFORMATION

1 pgs14.1 Kb0

Repair Manual - IGNITION

1 pgs5.67 Kb0

Repair Manual - IGNITION SYSTEM

2 pgs23.82 Kb0

Repair Manual - IGNITION SYSTEM

1 pgs9.74 Kb0

Repair Manual - INNER REAR VIEW MIRROR ASSY

1 pgs16.59 Kb0

Repair Manual - INNER REAR VIEW MIRROR ASSY

2 pgs32.88 Kb0

Repair Manual - INNER REAR VIEW MIRROR ASSY

1 pgs8.97 Kb0

Repair Manual - INPUT SHAFT ASSY

1 pgs23.07 Kb0

Repair Manual - INPUT SHAFT ASSY

10 pgs283.23 Kb0

Repair Manual - INSTRUMENT PANEL PASSENGER AIR BAG ASSY

1 pgs32.45 Kb0

Repair Manual - INSTRUMENT PANEL SUB–ASSY LOWER

1 pgs4.78 Kb0

Repair Manual - INSTRUMENT PANEL SUB–ASSY LOWER

7 pgs266.03 Kb0

Repair Manual - INSTRUMENT PANEL/METER

1 pgs19.66 Kb0

Repair Manual - INSTRUMENT PANEL/METER

2 pgs83.08 Kb0

Repair Manual - L PART NUMBER OF CONNECTORS

4 pgs21.91 Kb0

Repair Manual - LH HEADLAMP ASSY

2 pgs38.13 Kb0

Repair Manual - LH HEADLAMP ASSY

1 pgs21.11 Kb0

Repair Manual - LH HEADLAMP ASSY

2 pgs41.4 Kb0

Repair Manual - LICENSE PLATE LAMP ASSY

1 pgs9.18 Kb0

Repair Manual - LIGHTING

1 pgs8.63 Kb0

Repair Manual - LIGHTING SYSTEM

5 pgs41.13 Kb0

Repair Manual - LIGHTING SYSTEM

3 pgs18.76 Kb0

Repair Manual - LIGHTING SYSTEM

1 pgs5.17 Kb0

Repair Manual - LIGHTING SYSTEM

2 pgs13.89 Kb0

Repair Manual - LOWER BALL JOINT ASSY FRONT LH

2 pgs38.53 Kb0

Repair Manual - LUBRICATION

1 pgs6.71 Kb0

Repair Manual - LUBRICATION SYSTEM

2 pgs32.4 Kb0

Repair Manual - LUGGAGE COMPAR TMENT DOOR

2 pgs30.78 Kb0

Repair Manual - LUGGAGE COMPARTMENT DOOR GARNISH OUTSIDE

1 pgs12.41 Kb0

Repair Manual - LUGGAGE DOOR HINGE TORSION BAR RH

1 pgs30.22 Kb0

Repair Manual - MANUAL TRANSAXLE ASSY

2 pgs104.67 Kb0

Repair Manual - MANUAL TRANSAXLE ASSY

3 pgs141.72 Kb0

Repair Manual - MANUAL TRANSAXLE ASSY

34 pgs1.66 Mb0

Repair Manual - MANUAL TRANSAXLE ASSY

8 pgs250.18 Kb0

Repair Manual - MANUAL TRANSAXLE OIL

1 pgs12.01 Kb0

Repair Manual - MANUAL TRANSAXLE SYSTEM

1 pgs9.79 Kb0

Repair Manual - MANUAL TRANSMISSION/TRANSAXLE

7 pgs126.09 Kb0

Repair Manual - NAME PLATE

1 pgs46.97 Kb0

Repair Manual - NEW FEATURES

2 pgs41.04 Kb0

Repair Manual - OIL FILTER SUB–ASSY

2 pgs26.26 Kb0

Repair Manual - OIL PUMP ASSY

4 pgs150.06 Kb0

Repair Manual - OIL PUMP ASSY

2 pgs60.85 Kb0

Repair Manual - OIL PUMP ASSY

1 pgs29.54 Kb0

Repair Manual - OUTER REAR VIEW MIRROR ASSY LH

1 pgs10.5 Kb0

Repair Manual - OUTPUT SHAFT ASSY

1 pgs30.45 Kb0

Repair Manual - OUTPUT SHAFT ASSY

11 pgs442.84 Kb0

Repair Manual - OUTSIDE MOULDING

2 pgs26.81 Kb0

Repair Manual - PARK/NEUTRAL POSITION SWITCH ASSY

1 pgs15.78 Kb0

Repair Manual - PARK/NEUTRAL POSITION SWITCH ASSY

3 pgs93.2 Kb0

Repair Manual - PARKING BRAKE

1 pgs6.26 Kb0

Repair Manual - PARKING BRAKE CABLE ASSY NO.1

1 pgs52.09 Kb0

Repair Manual - PARKING BRAKE CABLE ASSY NO.1

2 pgs39.93 Kb0

Repair Manual - PARKING BRAKE CABLE ASSY NO.3

1 pgs34.76 Kb0

Repair Manual - PARKING BRAKE CABLE ASSY NO.3

3 pgs91.56 Kb0

Repair Manual - PARKING BRAKE LEVER SUB–ASSY

1 pgs38.18 Kb0

Repair Manual - PARKING BRAKE LEVER SUB–ASSY

2 pgs59.39 Kb0

Repair Manual - PARKING BRAKE SYSTEM

1 pgs14.42 Kb0

Repair Manual - PARKING BRAKE SYSTEM

1 pgs6.34 Kb0

Repair Manual - PARTIAL ENGINE ASSY

11 pgs449.49 Kb0

Repair Manual - PARTIAL ENGINE ASSY

34 pgs1.4 Mb0

Repair Manual - PARTIAL ENGINE ASSY

18 pgs610.72 Kb0

Repair Manual - POWER DOOR LOCK CONTROL SYSTEM

4 pgs73.26 Kb0

Repair Manual - POWER DOOR LOCK CONTROL SYSTEM

2 pgs8.22 Kb0

Repair Manual - POWER MIRROR CONTROL SYSTEM

2 pgs29.44 Kb0

Repair Manual - POWER MIRROR CONTROL SYSTEM

1 pgs14.99 Kb0

Repair Manual - POWER POINT SOCKET ASSY

1 pgs11.22 Kb0

Repair Manual - POWER POINT SOCKET ASSY RR

1 pgs11.92 Kb0

Repair Manual - POWER SOURCE

4 pgs112.36 Kb0

Repair Manual - POWER STEERING

4 pgs79.44 Kb0

Repair Manual - POWER STEERING SYSTEM

4 pgs95 Kb0

Repair Manual - POWER STEERING SYSTEM

1 pgs5.17 Kb0

Repair Manual - POWER WINDOW CONTROL SYSTEM

5 pgs88.72 Kb0

Repair Manual - POWER WINDOW CONTROL SYSTEM

1 pgs5.22 Kb0

Repair Manual - POWER WINDOW CONTROL SYSTEM

1 pgs66.65 Kb0

Repair Manual - POWER WINDOW CONTROL SYSTEM

1 pgs7.21 Kb0

Repair Manual - PROPORTIONING VALVE ASSY

1 pgs29.87 Kb0

Repair Manual - PROPORTIONING VALVE ASSY

1 pgs41.04 Kb0

Repair Manual - RACK PINION POWER STEERING GEAR ASSY

3 pgs104.04 Kb0

Repair Manual - RACK PINION POWER STEERING GEAR ASSY

18 pgs407.83 Kb0

Repair Manual - RADIATOR ASSY

1 pgs5.51 Kb0

Repair Manual - RADIO RECEIVER ASSY

2 pgs75.14 Kb0

Repair Manual - REAR AXLE BEAM ASSY

5 pgs130.77 Kb0

Repair Manual - REAR AXLE HUB BEARING ASSY LH

1 pgs29.4 Kb0

Repair Manual - REAR AXLE HUB BEARING ASSY LH

2 pgs49.53 Kb0

Repair Manual - REAR AXLE LH HUB BOLT

1 pgs34.17 Kb0

Repair Manual - REAR BRAKE

1 pgs47.9 Kb0

Repair Manual - REAR BRAKE

7 pgs244.47 Kb0

Repair Manual - REAR BUMPER

1 pgs60.06 Kb0

Repair Manual - REAR BUMPER

2 pgs44.74 Kb0

Repair Manual - REAR COMBINATION LAMP ASSY LH

1 pgs19.94 Kb0

Repair Manual - REAR DOOR

2 pgs43.25 Kb0

Repair Manual - REAR DOOR BELT MOULDING ASSY LH

1 pgs20.34 Kb0

Repair Manual - REAR SEAT ASSY

1 pgs23.74 Kb0

Repair Manual - REAR SEAT ASSY

1 pgs16.76 Kb0

Repair Manual - REAR SEAT ASSY

1 pgs47.3 Kb0

Repair Manual - REAR SEAT ASSY

1 pgs16.02 Kb0

Repair Manual - REAR SEAT BELT

1 pgs50.02 Kb0

Repair Manual - REAR SEAT BELT

3 pgs44.65 Kb0

Repair Manual - REAR SHOCK ABSORBER WITH COIL SPRING

1 pgs7.77 Kb0

Repair Manual - REAR SHOCK ABSORBER WITH COIL SPRING

3 pgs115.09 Kb0

Repair Manual - REAR SPEAKER ASSY

1 pgs19.69 Kb0

Repair Manual - REAR SPOILER

2 pgs26.18 Kb0

Repair Manual - REAR SUSPENSION

2 pgs34.31 Kb0

Repair Manual - REAR SUSPENSION

1 pgs39.39 Kb0

Repair Manual - REAR WHEEL ALIGNMENT

1 pgs10.44 Kb0

Repair Manual - REFRIGERANT

5 pgs101.89 Kb0

Repair Manual - REFRIGERANT

1 pgs6.01 Kb0

Repair Manual - REFRIGERANT LINE

1 pgs49.56 Kb0

Repair Manual - ROOF ANTENNA POLE SUB–ASSY

1 pgs8.54 Kb0

Repair Manual - ROOF DRIP SIDE FINISH MOULDING CENTER LH

1 pgs19.86 Kb0

Repair Manual - ROOF HEADLINING ASSY

3 pgs83.41 Kb0

Repair Manual - ROOF HEADLINING ASSY

6 pgs140.83 Kb0

Repair Manual - SEAT

1 pgs4.74 Kb0

Repair Manual - SEAT BELT

1 pgs9.61 Kb0

Repair Manual - SEAT BELT WARNING SYSTEM

2 pgs43.33 Kb0

Repair Manual - SEAT BELT WARNING SYSTEM

1 pgs39.83 Kb0

Repair Manual - SEAT BELT WARNING SYSTEM

1 pgs6.65 Kb0

Repair Manual - SEAT POSITION AIR BAG SENSOR

1 pgs19.32 Kb0

Repair Manual - SEAT POSITION AIR BAG SENSOR

1 pgs18.27 Kb0

Repair Manual - SFI SYSTEM

1 pgs14.53 Kb0

Repair Manual - SFI SYSTEM

3 pgs53.38 Kb0

Repair Manual - SHIFT LOCK SYSTEM

2 pgs10.71 Kb0

Repair Manual - SHIFT SELECT LEVER SHAFT ASSY

2 pgs35.72 Kb0

Repair Manual - SHIFT SELECT LEVER SHAFT ASSY

5 pgs137.38 Kb0

Repair Manual - SIDE AIR BAG SENSOR ASSY RH

1 pgs27.37 Kb0

Repair Manual - SIDE AIR BAG SENSOR ASSY RH

1 pgs21.57 Kb0

Repair Manual - SIDE MUDGUARD SUB–ASSY LH

1 pgs17.06 Kb0

Repair Manual - SKID CONTROL SENSOR

2 pgs53.17 Kb0

Repair Manual - SLIDING ROOF SYSTEM

2 pgs35.32 Kb0

Repair Manual - SLIDING ROOF SYSTEM

1 pgs11.88 Kb0

Repair Manual - SLIDING ROOF SYSTEM

1 pgs35.08 Kb0

Repair Manual - SLIDING ROOF SYSTEM

1 pgs61.43 Kb0

Repair Manual - SLIDING ROOF SYSTEM

6 pgs182.42 Kb0

Repair Manual - SLIDING ROOF SYSTEM

1 pgs5.86 Kb0

Repair Manual - SLIDING ROOF/CONVERTIBLE

1 pgs9.97 Kb0

Repair Manual - SPEED SENSOR FRONT LH

2 pgs63.21 Kb0

Repair Manual - SPEEDOMETER SENSOR

1 pgs12.74 Kb0

Repair Manual - SPIRAL CABLE SUB–ASSY

1 pgs4.77 Kb0

Repair Manual - SPIRAL CABLE SUB–ASSY

2 pgs39.86 Kb0

Repair Manual - STABILIZER BAR FRONT

2 pgs59.64 Kb0

Repair Manual - STABILIZER BAR REAR

1 pgs16.96 Kb0

Repair Manual - STARTER ASSY

1 pgs54.52 Kb0

Repair Manual - STARTER ASSY

7 pgs209.61 Kb0

Repair Manual - STARTER ASSY

1 pgs17.02 Kb0

Repair Manual - STARTING CHARGING

1 pgs16.92 Kb0

Repair Manual - STARTING SYSTEM

2 pgs52.83 Kb0

Repair Manual - STEERING

1 pgs8.16 Kb0

Repair Manual - STEERING

1 pgs5.3 Kb0

Repair Manual - STEERING

2 pgs43.53 Kb0

Repair Manual - STEERING

1 pgs8.53 Kb0

Repair Manual - STEERING COLUMN

1 pgs18 Kb0

Repair Manual - STEERING COLUMN ASSY

2 pgs48.46 Kb0

Repair Manual - STEERING COLUMN ASSY

7 pgs190.25 Kb0

Repair Manual - SUPPLEMENTAL RESTRAINT SYSTEM

2 pgs33.7 Kb0

Repair Manual - SUPPLEMENTAL RESTRAINT SYSTEM

4 pgs84.64 Kb0

Repair Manual - SUPPLEMENTAL RESTRAINT SYSTEM

7 pgs181.13 Kb0

Repair Manual - TERMS

5 pgs19.4 Kb0

Repair Manual - TERMS

3 pgs13.33 Kb0

Repair Manual - THEFT DETERRENT DOOR LOCK

1 pgs7.73 Kb0

Repair Manual - THERMOSTAT

2 pgs36.99 Kb0

Repair Manual - THROTTLE BODY ASSY

1 pgs51.88 Kb0

Repair Manual - THROTTLE BODY ASSY

5 pgs142.61 Kb0

Repair Manual - TIMING CHAIN OR BELT COVER OIL SEAL

2 pgs65.71 Kb0

Repair Manual - TIRE WHEEL

1 pgs4.71 Kb0

Repair Manual - TORQUE CONVERTER CLUTCH AND DRIVE PLATE

2 pgs63.92 Kb0

Repair Manual - TRANSMISSION VALVE BODY ASSY

4 pgs204.4 Kb0

Repair Manual - TRANSMISSION WIRE

1 pgs31.83 Kb0

Repair Manual - TRANSMITTER BATTERY

1 pgs16.76 Kb0

Repair Manual - VALVE CLEARANCE

11 pgs371.09 Kb0

Repair Manual - VANE PUMP ASSY

1 pgs38.38 Kb0

Repair Manual - VANE PUMP ASSY

7 pgs161.59 Kb0

Repair Manual - VEHICLE CONTROL SYSTEM

1 pgs7.74 Kb0

Repair Manual - VEHICLE INTRUSION PROTECTION SYSTEM

9 pgs30.3 Kb0

Repair Manual - W/RECEIVER CONDENSER ASSY

1 pgs89.53 Kb0

Repair Manual - W/RECEIVER CONDENSER ASSY

1 pgs4.93 Kb0

Repair Manual - W/RECEIVER CONDENSER ASSY

4 pgs138.1 Kb0

Repair Manual - WASHER NOZZLE

1 pgs51.81 Kb0

Repair Manual - WATER PUMP ASSY

1 pgs10.75 Kb0

Repair Manual - WATER PUMP ASSY

2 pgs44.32 Kb0

Repair Manual - WHEEL AND TIRE SYSTEM

1 pgs20.38 Kb0

Repair Manual - WINDOW DEFOGGER SYSTE

1 pgs11.89 Kb0

Repair Manual - WINDOW DEFOGGER SYSTE

1 pgs46.63 Kb0

Repair Manual - WINDOW DEFOGGER SYSTE

1 pgs6.11 Kb0

Repair Manual - WINDSHIELD GLASS

1 pgs51.4 Kb0

Repair Manual - WINDSHIELD WIPER MOTOR ASSY

4 pgs98.35 Kb0

Repair Manual - WINDSHIELD WIPER SWITCH ASSY

1 pgs16.71 Kb0

Repair Manual - WINDSHIELD/WINDOWGLASS/MIRROR

1 pgs12.58 Kb0

Repair Manual - WIPER AND WASHER SYSTEM

3 pgs28.73 Kb0

Repair Manual - WIPER AND WASHER SYSTEM

1 pgs9.4 Kb0

Repair Manual - WIPER AND WASHER SYSTEM

1 pgs8.16 Kb0

Repair Manual - WIPER RUBBER LH

1 pgs16.09 Kb0

Repair Manual - WIPER WASHER

1 pgs13.31 Kb0

Repair Manual - WIRELESS DOOR LOCK CONTROL SYSTEM

2 pgs13.93 Kb0

Repair Manual - WIRELESS DOOR LOCK CONTROL SYSTEM

1 pgs6.35 Kb0

Repair Manual -SPEED CONTROL MAIN SWITCH ASSY

1 pgs15.35 Kb0

Repair Manual -VEHICLE LIFT AND SUPPORT LOCATIONS

2 pgs45.84 Kb0

Repair Manual – CRUISE CONTROL ACTUATOR ASSY

1 pgs61.41 Kb0

Repair Manual – IGNITION OR STARTER SWITCH ASSY

1 pgs14.98 Kb0

Repair Manual – IGNITION OR STARTER SWITCH ASSY

1 pgs13.06 Kb0

SERVICE SPECIFICATIONS - BRAKE

1 pgs5.46 Kb0

SERVICE SPECIFICATIONS - BRAKE

1 pgs9.75 Kb0

SERVICE SPECIFICATIONS - CLUTCH

1 pgs5.32 Kb0

SERVICE SPECIFICATIONS - CLUTCH

1 pgs9.07 Kb0

SERVICE SPECIFICATIONS - ENGINE CONTROL SYSTEM

1 pgs9.97 Kb0

SERVICE SPECIFICATIONS - ENGINE CONTROL SYSTEM

1 pgs9.07 Kb0

SERVICE SPECIFICATIONS - ENGINE MECHANICAL

3 pgs16.9 Kb0

SERVICE SPECIFICATIONS - ENGINE MECHANICAL

2 pgs18.83 Kb0

SERVICE SPECIFICATIONS - FRONT SUSPENSION

1 pgs9.29 Kb0

SERVICE SPECIFICATIONS - MANUAL TRANSMISSION / TRANSAXLE

3 pgs11.95 Kb0

SERVICE SPECIFICATIONS - MANUAL TRANSMISSION / TRANSAXLE

2 pgs13.72 Kb0

SERVICE SPECIFICATIONS – COOLING

1 pgs6.14 Kb0

SERVICE SPECIFICATIONS – COOLING

1 pgs8.93 Kb0

SERVICE SPECIFICATIONS – CRUISE CONTROL

1 pgs4.67 Kb0

SERVICE SPECIFICATIONS – CRUISE CONTROL

1 pgs8.19 Kb0

SERVICE SPECIFICATIONS – EMISSION CONTROL

1 pgs5.95 Kb0

SERVICE SPECIFICATIONS – ENGINE HOOD/DOOR

1 pgs10.37 Kb0

SERVICE SPECIFICATIONS – EXHAUST

1 pgs4.91 Kb0

SERVICE SPECIFICATIONS – EXHAUST

1 pgs8.41 Kb0

SERVICE SPECIFICATIONS – EXTERIOR/INTERIOR TRIM

1 pgs8.77 Kb0

SERVICE SPECIFICATIONS – FRONT SUSPENSION

1 pgs9.85 Kb0

SERVICE SPECIFICATIONS – FUEL

1 pgs6.21 Kb0

SERVICE SPECIFICATIONS – FUEL

1 pgs9.14 Kb0

SERVICE SPECIFICATIONS – HEATER AND AIR CONDITIONING

1 pgs5.55 Kb0

SERVICE SPECIFICATIONS – HEATER AND AIR CONDITIONING

1 pgs9.13 Kb0

SERVICE SPECIFICATIONS – IGNITION

1 pgs5.31 Kb0

SERVICE SPECIFICATIONS – IGNITION

1 pgs8.26 Kb0

SERVICE SPECIFICATIONS – INSTRUMENT PANEL/METER

1 pgs8.22 Kb0

SERVICE SPECIFICATIONS – LUBRICATION

1 pgs8.33 Kb0

SERVICE SPECIFICATIONS – LUBRICATION

1 pgs8.68 Kb0

SERVICE SPECIFICATIONS – PARKING BRAKE

1 pgs4.68 Kb0

SERVICE SPECIFICATIONS – PARKING BRAKE

1 pgs8.89 Kb0

SERVICE SPECIFICATIONS – POWER STEERING

1 pgs5.92 Kb0

SERVICE SPECIFICATIONS – POWER STEERING

1 pgs10.67 Kb0

SERVICE SPECIFICATIONS – REAR SUSPENSION

1 pgs7.45 Kb0

SERVICE SPECIFICATIONS – REAR SUSPENSION

1 pgs9.04 Kb0

SERVICE SPECIFICATIONS – SEAT

1 pgs8.63 Kb0

SERVICE SPECIFICATIONS – SEAT BELT

1 pgs9.12 Kb0

SERVICE SPECIFICATIONS – SLIDING ROOF/CONVERTIBLE

1 pgs5.61 Kb0

SERVICE SPECIFICATIONS – SLIDING ROOF/CONVERTIBLE

1 pgs8.52 Kb0

SERVICE SPECIFICATIONS – STANDARD BOLT

1 pgs14.42 Kb0

SERVICE SPECIFICATIONS – STANDARD BOLT

1 pgs11.96 Kb0

SERVICE SPECIFICATIONS – STANDARD BOLT

1 pgs6.58 Kb0

SERVICE SPECIFICATIONS – STARTING CHARGING

1 pgs6.17 Kb0

SERVICE SPECIFICATIONS – STARTING CHARGING

1 pgs9.64 Kb0

SERVICE SPECIFICATIONS – STEERING COLUMN

1 pgs4.7 Kb0

SERVICE SPECIFICATIONS – STEERING COLUMN

1 pgs8.5 Kb0

SERVICE SPECIFICATIONS – TIRE WHEEL

1 pgs4.74 Kb0

SERVICE SPECIFICATIONS – WIPER WASHER

1 pgs8.47 Kb0

Troubleshooting Manual - С

5 pgs179.48 Kb0

User Manual

786 pgs40.77 Mb1

User Manual

805 pgs39.26 Mb1

User Manual

543 pgs23.55 Mb0

User Manual

455 pgs23.31 Mb0

Electrical Wiring Diagram

251 pgs3.73 Mb0

Table of contents

Loading...

Loading...Toyota Corolla 2004 Repair Manual - LUBRICATION SYSTEM

...Toyota Repair Manual - LUBRICATION SYSTEM

Specifications and Main Features

Frequently Asked Questions

User Manual

17–1

–LUBRICATION LUBRICATION SYSTEM (April, 2003)

LUBRICATION SYSTEM (April, 2003)

1707J–03

ON–VEHICLE INSPECTION

1. CHECK ENGINE OIL LEVEL

(a) After warming up the engine and then 5 minutes after the engine stops, oil level should be between

the ”L” and ”F” marks on the oil level gage.

If low, check for leakage and add oil up to the ”F” mark.

NOTICE:

Do not fill with engine oil above the ”F” mark.

2. CHECK ENGINE OIL QUALITY

(a) Check the oil for deterioration, entry of water, discoloring

Recommended Viscosity (SAE)

5W–30

C –29 –18 –7 4 16 27 38

F –20 0 20 40 60 80 100

A66623

or thinning.

If the quality is visibly poor, replace the oil.

Oil grade:

Use API grade SL ”Energy–Conserving”, or ILSAC

multigrade engine oil.

SAE 5W–30 is the best choice for good fuel economy,

and good starting in cold weather.

If SAE 5W–30 is not available, SAE 10W–30 may be

used.

However, it should be replaced with SAE 5W–30 at the

next oil replacement.

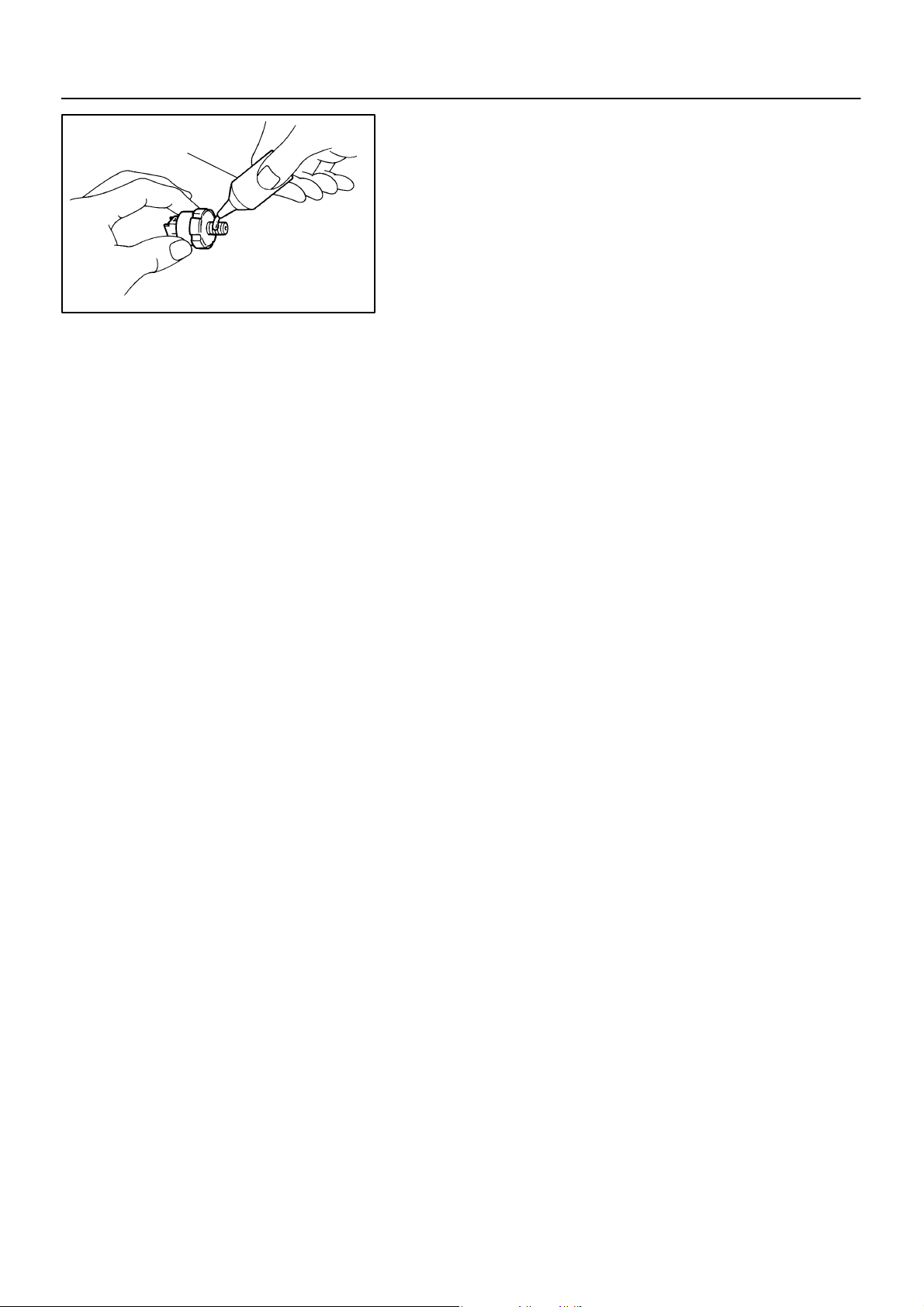

3. INSPECT OIL PRESSURE

(a) Disconnect the oil pressure switch connector.

Oil Pressure

Switch

Oil Pressure Gauge

2004 COROLLA (RM1037U)

(b) Using a 24 mm deep socket wrench, remove the oil pres-

sure switch.

A63370

(c) Install the oil pressure gauge.

(d) Warm up the engine.

(e) Inspect the oil pressure.

Oil pressure:

At idle 29 kPa (0.3 kgf/cm2, 4.2 psi) or more

At 3,000 rpm 294 to 539 kPa (3.0 to 5.5 kgf/cm2, 43 to 78 psi)

A63373

1196Author: Date:

17–2

Adhesive

A50082

–LUBRICATION LUBRICATION SYSTEM (April, 2003)

(f) Apply adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Part No. 08833–00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(g) Using a 24 mm deep socket wrench, install the oil pres-

sure switch.

Torque: 15 N⋅m (153 kgf⋅cm, 11 ft⋅lbf)

(h) Connect the oil pressure switch connector.

(i) Check for the engine oil leaks.

2004 COROLLA (RM1037U)

1197Author: Date:

Loading...

Loading...+ hidden pages