Toyota 5, 6, 7 LPG Service Manual

FOREWORD

This repair manual describes the construction, opera tion and repair method of a

Gas

device for Liquefied Petroleum

5F

G

70-30,

6FG

70-30, 6FGF75-30, 6FGU 75-30,

7FGU 75-32, 6FG(E)33-45, 5FG50.60, 5FGC70-30, 6FGCU 75-30,

(LPG) mounted on the Toyota forklift of

7FG

70-J35,

7FGF

75-J35,

7FGCU75-32

series

and

7FG35-45, 7FGU35-80, 7FGCU35-70

series.

This Manual has been compiled to provide you with useful information on the

proper maintenance of

Toyota's forklift to maintain

its

high performance and

excellent durability sufficiently for a long time.

TOYOTA

Material Handling Company

A

Division

of

TOYOTA INDUSlRlES CORPORATION

ENGINE

Note:

Refer to

4P

the

ENGINE

PERFORMANCE

repair manual for

each

model.

CURVES

-

--

--

Gasoline

-

LPG

-

LPG

(combined

10.511 800

with

4P

Engine

Engine

speed (r.p.m.1

Performance

Curves

2

x

10

KA

KM

1

ENGINE SPECIFICATIONS

Note:

Refer to the repair manual

for

each model.

5FG 10

-

30

series,

PS/rpm

Max~mum

horse

power

1

NET

HP/rpm

kg

Maximum

m/rpm

torque

ft-lb/rpm

Maximum fuel

consumption

ldle

speed

No-load maximum

governed speed rPm

I

Ignition timing

BTDC

'Irprn

rpm

5FG

A

38/2800

36,2800

1 1

5/2000

81/2000

2

10

6

50

(0)

750

3050

1

5O/650

33

-

45

series

5

K

5FG10-25

I

1

series

B

36/2800

34/2800

10 8/2000

76/2000

175

-

-

C

38/2800

36'2800

9/2200

10

176/2200

180

750

-

54/2400

52/2400

16 5/1800

115/1800

750

1 - 2.5

3

10°/650 / 10°/750 / 7O/650

Pneurnat~c models

5FG 10--30

A

48/2400

4612400

15/1600

105/1600

195

700

(El

ton

2650

t

2800

1

4Y

B

190

-

+

-

series

C

501'2400

4812400

16/1800

110/1800

185

7 50

-

1

7O/750

3F

5FG33-45

A

72/2 100

69/21 00

26/1200

182/1200

200

-

2350

1

7O/750

(Unt~l August 1994)

series

B

65/2 100

62/2100

24 5/1400

171/1400

200

+

-

1

:g01750

I

:2701750

C

68/2 100

65/2100

25/1200

175/1200

185

850

-

1

18O/850

6FG 10

Maximum

horse power

Max~mum

torque

consumption

Idle speed rpm

No-load

governed speed

Ignition timing

-

kg

SAE

tL

fuel

maxmum

BTDC

30

PSlrpm

rnlrpm

NET

lblrpm

gr1PS

O1rprn

series,

\

11 512000

h

rvm

5k2'1750

6FG10 - 25

A

3812800

3712800

8312000

210

750

3050

..

.

-

6FGFl5

5

K

senes

B

3612800

3812800

3512800

3712800

10 812000

10 912200

7912200

7812000

175

+

+

10k2°1750

.

C

180

t-

+

+

-

30

6FGF15 - 25

A

5412400

5312400

16 511800

1 191 1800

200

750

2600

7&2"750

series,

6FG10 - 25

8

4812400

4712400

15 011600

1081 1600

190

e

fi

+

5FG33

series

series

C

5012400

4912400

16 011800

1 161 1800

185

+

1

ton

2-2

2600

2650

-

-

Pneumatic models

4Y

6FG28, 30

A

5812600

5712600

16 511800

1

191 1800

200

750

2800

5

ton

7kZo1750

45

series

series

6FGF30

0

5212600

5112600

15 011800

1081 1600

190

+-

+

+

C

5412600

5312600

16 011800

1

161 1800

185

+

2600

+

1

FZ

{From September

5FG33 - 45

A

8512100

8112100

3011200

2091 1200

190

750

2350

3*2"750

series

B

7812100

7412100

28 511400

1991 1400

185

+

+

+

19941

C

7812100

7412100

28 511400

19911 400

185

+

+

+

GM

6FGU

20-30

series

B

5512400

54

1811200

130

210

75Ot5;

2600 & 50

12&27750

PERIODIC MAINTENANCE

INSPECTION

METHOD

I : Inspection. Repairor replacement if required.

C:

Cleaning

*

1

:

Soapy water "2 : Detector

1

nspect i on Period

l tern

Gas

leak

from

pip~ng

and

joint

Damage of piping and joint

Tar removal from regulator

Regulator adjustment status

Regulator function

Carburetor and adapter

Filter clogging

Loosened installation and functioning of solenoid valve

Gas cylinder

Hours

I*'

I

*2

C

I

I

I

C

I

I

Every

6

weeks

250

0

Every

3

months

500

-

OC

OC

O+

Every

6

months

1000

t-

+

C

+--

0-

0-

0-

0-

0

+

+

Every

12months

2000

+

+

t

+

+

+

t

+

+--

Looseness and damage of gas cylinder mounting

PERIODIC

REPLACEMENT PARTS

Item

O-ring for

LPG

LPG

LPG

cylinder valve

high and low-pressure rubber hoses

regulator diaphragm and O-ring

Fuel filter

I

O+

i

Replacement timing

Every 24 months

Every 24 months

Every 24 months or

Every 24 months or

STD,conditions are the same as those of the STD and high performance filters.

t

3000

3000

t-

I

hours

hours

OPERATION DESCRIPTION

(From September

BASIC CONSTRUCTION AND

OPERATION OF LPG DEVICE 1A-2

..........................

1989)

Page

FUEL FILTER FOR LPG 1A-3

SOLENOID VALVE 1A-4

CARBURETOR FOR LPG 1A-5

ADAPTER

REGULATOR IA-8

Note

:

See the "IB" section for models manufactured

Vehicle Models

6FG10-30 Series

6FGUf6FGCU15-30 Series

6FGF15-30 Series

7FG10-J35 Series

7FGU/7FGCU15-32 Series

7FGF15-J35 Series

7FG35-45 Series

7FG(C)U35-80 Series

..............................................

..........................................

..................................

......................................

................................

in

and

(4Y

Engine Model)

LPG Only Model

(

LPG and Gasoline Model

WfTWC System

1

A-6

after October 1997.

OPERATION DESCRIPTION

(From

BASIC CONSTRUCTION AND

OPERATION OF LPG DEVICE

October

1997)

..........................

Page

1

B-2

CARBURETOR FOR LPG

ADAPTER

REGULATOR

REGULATOR SYSTEM COMPONENTS

Note

:

Vehicle Models

6FG10-30

6FGUf6FGCU15-30

6FGF15-30

7FG10-J35 Series

7FGU17FGCU 15-32 Series

7FGF15-J35

7FG35-45

7FG(C)U35-80

..............................................

..........................................

Series

Series

Series

Series

Series

Series

LPG

(

LPG

................................

..................

(4Y

Engine Model)

Only Model

and Gasoline Model

W/TWC

System

1 B-

3

1B-5

1

B-6

18-10

BASIC

CONSTRUCTION

AND

OPERATION OF

LPG

DEVICE

The liquid

built

gas which is sucked into the engine through the carburetor. The engine cooling water is led to the regula

tor as the heat source for

LPG

from the

in filter. The filtered

LPG

cylinder is taken into the regulator for filtration of foreign matters by the

LPG

is then sent to the pressure reduction chamber, where it is vaporized into

LPG

vaporization.

-

GFGU/GFGCU/7FG(C)U15-32

High

pressure

hose

series

Engine

CARBURETOR

FOR

LPG

GENERAL

This carburetor functions to mix the

priate ratio and lead the mixture into the cylinder. A negative pressure type power valve is built in to

improve the performance in

for structural simplification

a

and

LPG

after pressure reduction

in

the regulator with the air at an appro

heavily loaded state. The carburetor body is integrated with a venturi tube

the number

of

springs is increased from 2 to 3 for reliability improvement.

-

SPECIFICATION

Item

Power valve operating pressure kPa(kgf/cm2)[psi]

Bore diameter mm(in)

Venturi diameter mm(in)

Power jet diameter mm(in)

6FG/6FGF/7FGIO-30/7FGF series

Vehicle

W/TWC

Standard vehicle

5K

I

4Y

-

1

2.0- -

35(1.38)

24(0.94)

2.8(0.110)

+

3.0(0.118)

5K

22.0 (-0.1 22--

t

+

2.4(0.094)

system

I~Y

+

+-

3.0(0.118)

6FGU/GFGCU/

7FG(C)U15-32

0.224)

[-I

series

4Y

.74- -3.1

+-

t

t

7FG35-451

7FG(C)U35-80

series

G M 6-262

91

+

--

28(1

.I

0)

t

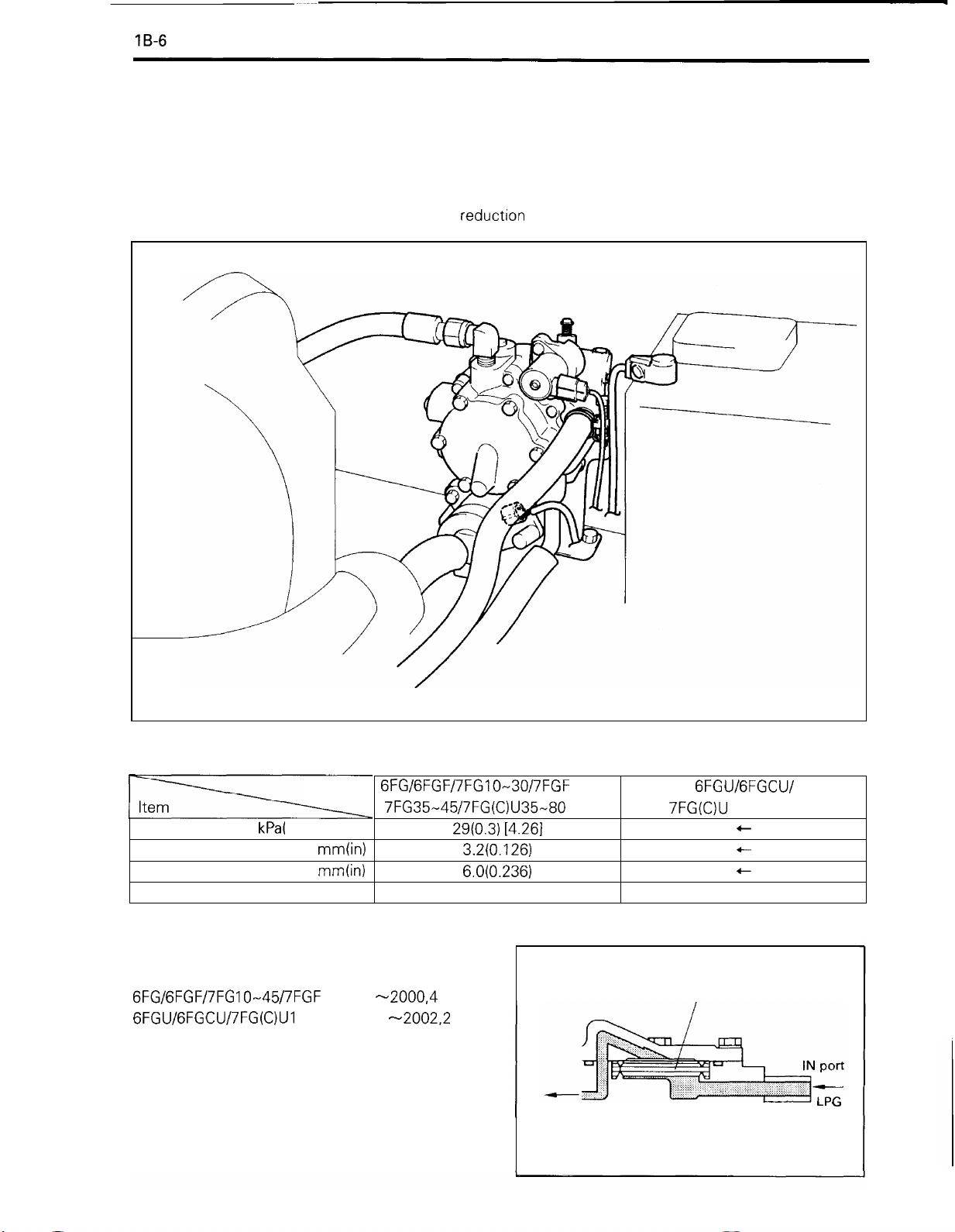

REGULATOR

GENERAL

The regulator for the gasoline engine corresponds

the

the engine while maintaining

vaporized LPG after pressure reduction

new regulator is made very compact since the filter and solenoid separated in the past are integrated with

the regulator. The serviceability is improved

by

to

a part of the carburetor. It supplies the LPG fuel to

reduct~on

at

a constant pressure level. The

of

the

portions requiring adjustment.

SPECIFICATIONS

Primary pressure

Primary

seat

inside diameter mm(in)

Secondary seat inside

Slow lock

Model

kPa(

kgf/cm2)[psi]

diameter mrn(in)

GFG/GFGF/7FGl0-30/7FGF series

7FG35-45/7FG(C)U35-80 series

29(0.3) [4.26]

3.2(0.126)

6.0(0.236)

Solenoid valve type

EXPLANATION ON OPERATION

LPG

Filter

6FG/6FGF/7FG 10-45/7FGF series: --2000,4

GFGU/6FGCU/7FG(C)UI

The filter is built

stances in the

LPG

the regulator are filtered by the filter element, and

LPG

the filtered

is sent to the solenoid valve.

5-32

series: --2002,2

in

the regulator. Insoluble sub

entering from the IN

port

of

6FGU16FGCUI

7FG(C)U 15-

32

series

+

4-

+

Diaphragm type

Filter

-

LI

To solenoid

valve

U

6FG/6FGF/7FG10-45/7FGF/7FG(C)U35-80

GFGU/GFGCU/7FG(C)U 1 5-32

Two types of materials are used in the filter with

rubber packing for sealing in

-

between.

series:

series:

2000,4--

2002,2--

Gasket

+

-

Solenoid

A

solenoid valve integrated with the regulator is

installed between the filter element and the pri

mary pressure reduction chamber. The

switch installed on the instrument panel starts and

stops the

inside the solenoid coil. The current flowing in the

coil generates

valve toward the solenoid against the spring force,

opening a path between the filter and primary

pressure reduction chamber. When no current

flows, the spring forces the valve seat to close the

path.

Regulator

The

The regulator consists of chamber

sure of the vaporized

tion chamber) where the pressure is further educed to near the atmospheric pressure to supply the fuel

according to the negative pressure at the venturi in the carburetor, and chamber

fuel at the time of engine starting or idling.

Valve

LPG

LPG

supply. A slide valve is located

a

magnetic force to attract the slide

LPG

in the liquid phase is vaporized by taking the heat

A

where the

LPG

(primary pressure reduction cham bed, chamber C (secondary pressure reduc

-

To

of

vaporization from the engine cooling water.

LPG

starts to vaporize, chamber B for reducing the pres

Filter

From filter

-

LPG

Valve seat

primary pressure reduction chamber

I

D

that forcibly supplies

-

-

6FG/GFGF/7FG 10-45/7FGF/7FG(C) U35-80

series

GFGU/GFGCU/7FG(C)U

1 5-

32

series

Loading...

Loading...