Toyota 5FGC, 5FDC18-30 Repair Manual

FOREWORD

This manual covers the service procedures of the TOYOTA FORKLIFT

5FGC/5FDC18-30 Series. Please use this manual for providing quick, correct

servicing of the corresponding forklift models.

This manual deals with the above models as of August

that disagreement can take place between the descriptions in the manual and

actual vehicles due to change in design and specifications. Any change or

modifications thereafter will be informed by Toyota

Service News.

For the service procedures of the mounted engine, read the repair manuals listed

below as reference together with this manual.

(Reference)

Repair manuals related to this manual are as follows:

TO YO TA INDUSTRIAL VEHICLE

REPAIR MANUAL (No.

TOY0 TA INDUSTRIAL VEHICLE 2J ENGINE

REPAIR MANUAL (No.

4

Y

CE602)

CE603)

ENGINE

1986.

Please understand

Industrial Vehicles' Parts

&

TOYOTA MOTOR CORPORATION

SECTION

GENERAL

-

-

TORQUE CONVERTER

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE

REAR AXLE

I

STEERING

-

INDEX

BRAKE

BODY

y

'

MAST

CYLINDER

OIL PUMP

OIL CONTROL VALVE

APPENDIX

0

GENERAL

Page

VEHICLE EXTERIOR VIEWS

VEHICLE MODELS

ABBREVIATIONS & TIPS ON OPERATION

STANDARD BOLT & NUT TIGHTENING TORQUE

PRECOAT BOLTS

HIGH PRESSURE HOSE FllTlNG

TIGHTENING TORQUE

FRAME NUMBER

SAFE LOAD BY WIRE ROPE

SUSPENSION ANGLE

WIRE ROPE SUSPENSION ANGLE LIST

CAPACITY AND TYPES OF

SPECIFIED LUBRICANTS

LUBRICATION

...................................

.....................................

....................................

........................................

..........................

..........

.............................

.............................

.............

..........................

0-2

...

PERIODIC MAINTENANCE TABLE

PERIODIC REPLACEMENT PARTS

LUBRICANTS

......................................

...................

&

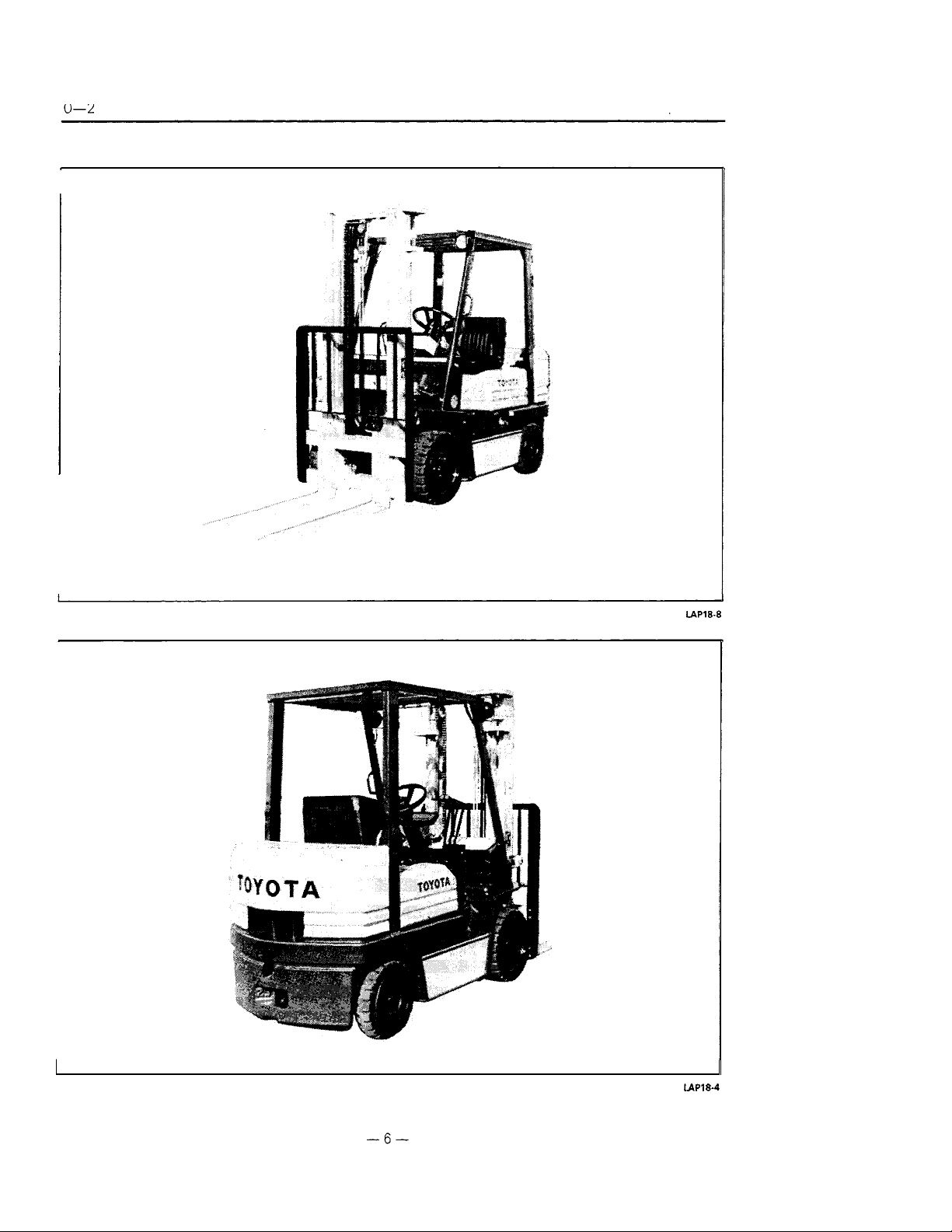

VEHICLE EXTERIOR VIEWS

Vehicle Front View

LAPI

8-8

Vehicle Rear View

LAPI

8-4

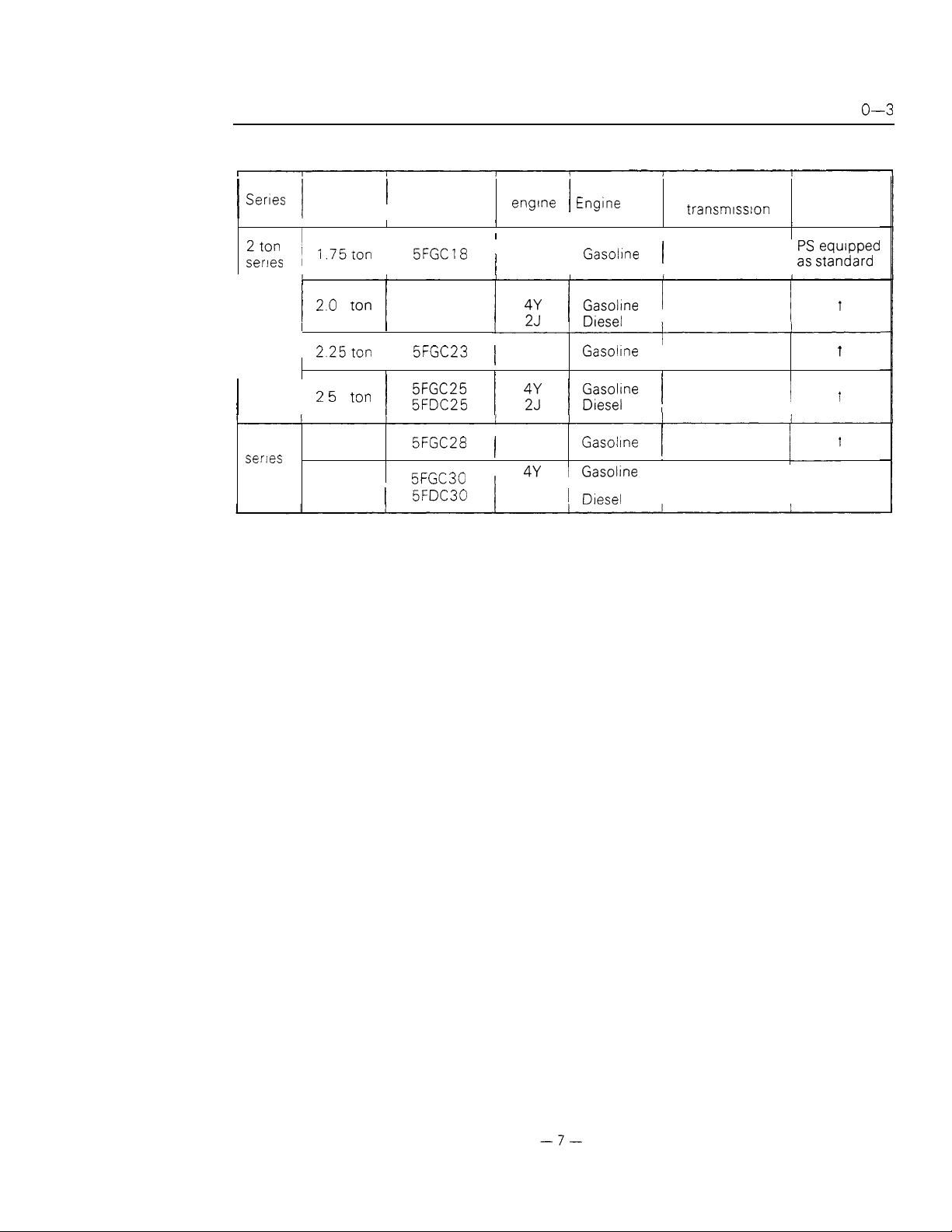

VEHICLE

MODELS

I

Ser~es Payload

I

2ton

serles

I175ion 5FGC18

,

I

1

2.0 ton

I

i

225ton I 5FGC23

1

3 ton

serles

2 75 ton

0

3

1

I

I

I

I

I I

5FGC25

1

5FDC25

5FGC28

1

5FGC30

5FDC30

ton

Model

4Y

I

Gasollne 1 Torque converter

Mounted

englne 1 Eng~ne type

I I I

I

I

I

I

1

I

1

42:

4Y

42:

4Y

4Y

2J

g:::;ine

Gasollne I Torque converter

E:::iine

Gasolne Torque converter

'

GasOilne

Diesel

Power

transmlsslon

I

I

i

Torque converter

I

I

Torque converter

I

Torque converter

Remarks

I

as

standard

PS

equ'pped

1

It

i

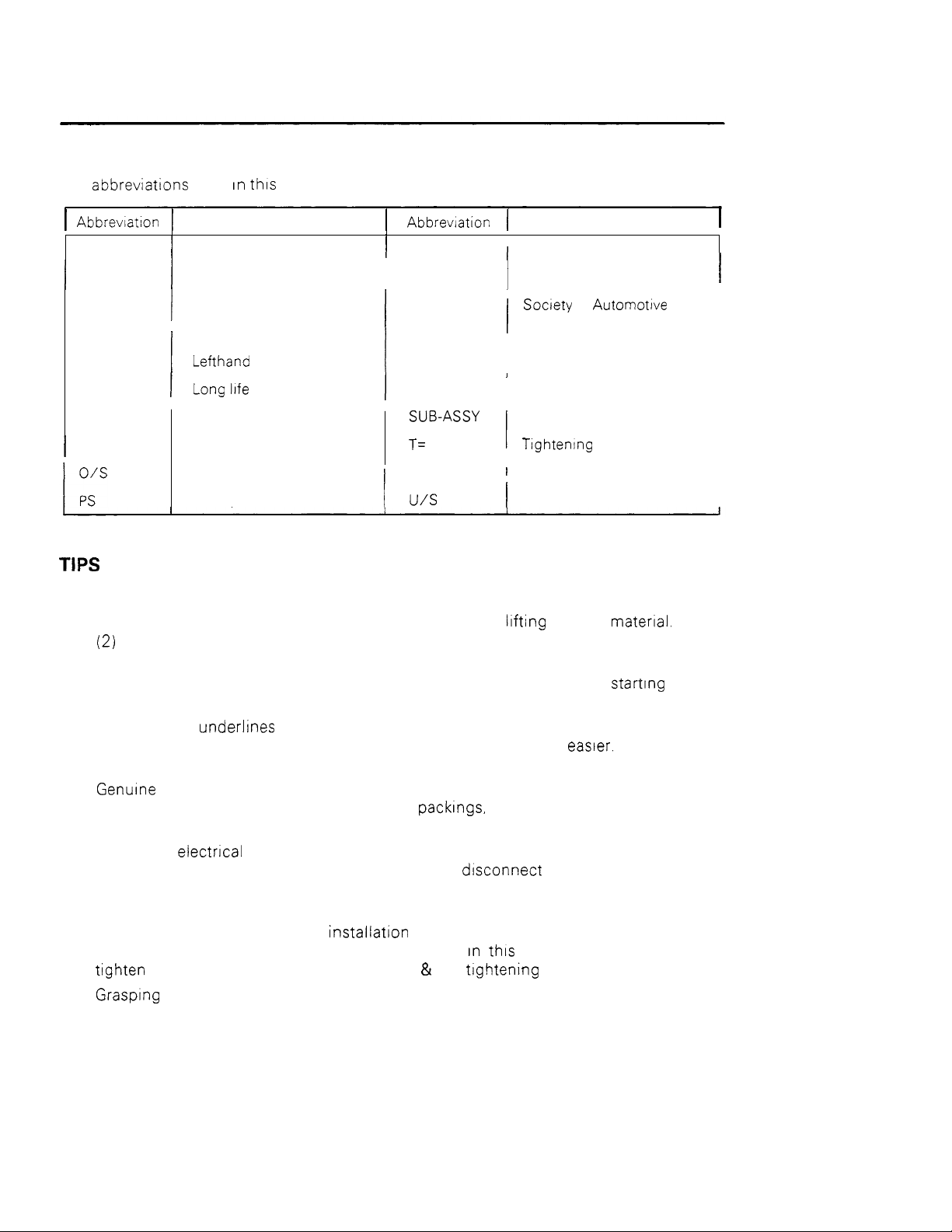

ABBREVIATIONS

The abbrev~at~ons used In thls manual are as follows:

I

Abbreviat~on

ABDC

I

ASSY Assembly

ATDC

BBDC

I

1

1

After bottom dead center

1

After drop dead center

Before bottom dead center

Meaning

/

Abbrev~ation

1

1

P/S

,

RH

1

SAE

1

I

1

Power steering

/

Righthand

I

Soc~ety of Automot~ve

Engineers

Meaning

I

I

LH

LLC

OHV

I

OPT

TIPS ON OPERATION

1.

Safe operation

(1)

(2)

2.

Preparation of SSTs and measuring Instruments

(1)

3.

Neatness and

(1

)

(2)

4.

Genulne Toyota parts

Always use genuine Toyota parts even for

-

replaced after each disassembly work.

5.

Repairs on electrrcal system

Before doing any repair on the electrical system,

terminals.

Always disconnect the negative

Tightening torque at the time of installatron

6.

Be sure to observe the tightening torque given In thls mannual. If not specified,

tlghten to the torque listed in "Standard Bolt & Nut t~ghtening Torques.

7.

Grasplng the defect status

When a defect is found, do not immediately start disassembly and replacement. First

check if the defect needs disassembly and replacement for repair. For example, do

not disassemble the torque converter for a defect of vehicle starting failure but check

such factors as the oil status, hydraulic pressure and rotation which directly cause the

defect.

1

Lefthand

1

~ong l~ie coolant

Overhead valve

Option

Oversize

Horsepower

Make sure that correct size wire rope is used when

After jacking up, always support with a rigid rack or stand.

Prepare necessary SSTs and measuring instruments before startlng repair

operation.

underlines

Keep the working place neat and orderly to make operation easler.

Hydraulic equipment should be disassembled with clean tools in clean places.

(-)

1

SST

1

STD

SUB-ASSY

T= T~ghten~ng torque

OOT

packlngs, gaskets and o-rings which are

terminal first.

disconnect

Special service tool

1

Standard

Subassembly

I

I

I

Number of teeth

1

Undersire

lifting

a heavy

the cables from battery

material.

"

(00)

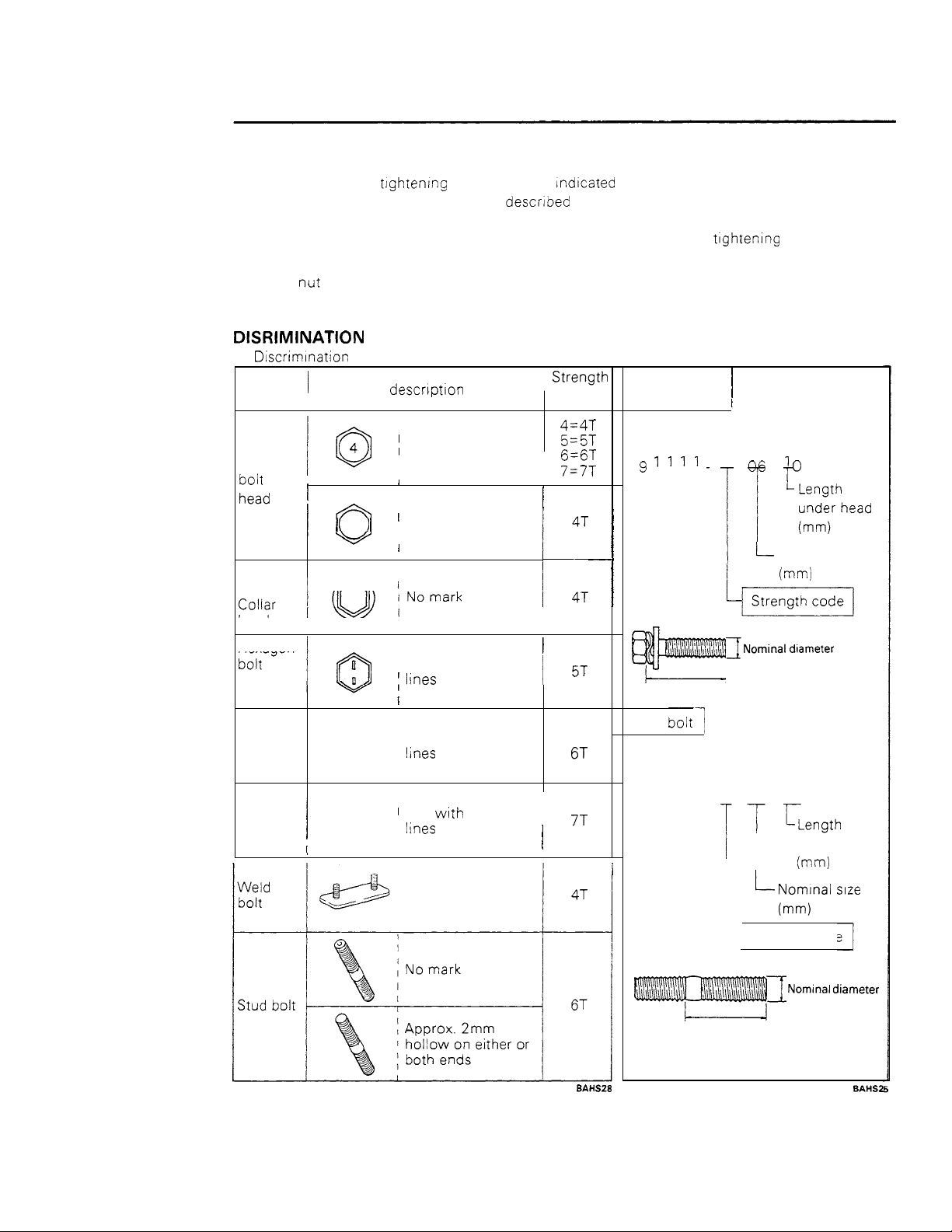

STANDARD BOLT & NUT TIGHTENING TORQUE

Standard bolt and nut ttghtening torques are not ~ndicated

Therefore, judge the tightening torque as descr~bed below

1

Find out the type of bolt from the list below Then, judge the bolt tightenrng torque from the

tightening torque table

2

The nut tightening torque can be judged in the same way according to the type of the mating

bolt

DlSRlMlNATlON OF BOLT STRENGTH

1

Discriminat~on by actual bolt

2

Discrimination by part number

Hexagon

bolt

Standard

head

Hexagon

bolt

head

Hexagon

Standard

bolt

Hexagon

bolt

Collar

head

Hexagon

bolt

1

Shape and

I

I

;

I

1

1

I

description

1

Number in relief or 5=5T

I

hallmark on head 6=6T

I

I

I

I

No mark

1

I

I

I

I

Bolt with two relief

I

llnes on head

I

I

I

I

Bolt with two relief

I

nes on head

I

I

1

Boit w~th three relief

llnes on head

I

Strength

I

I

1

I

!

code

4=4T

7=7T

6T

7T

Hexagon bolt

Part number example

3

Length

to

bottom surface of head

Stud bolt1

Part number example

92132

/

I

-

4 06 0

l~om~nal dlameter

-

4 06 14

L-

Nominal size

(mm)

under head

imm)

BAHS28

Length

L

;;;nai siz;

Strength code

Nomlnal d~ameter

BAHS2

-

-

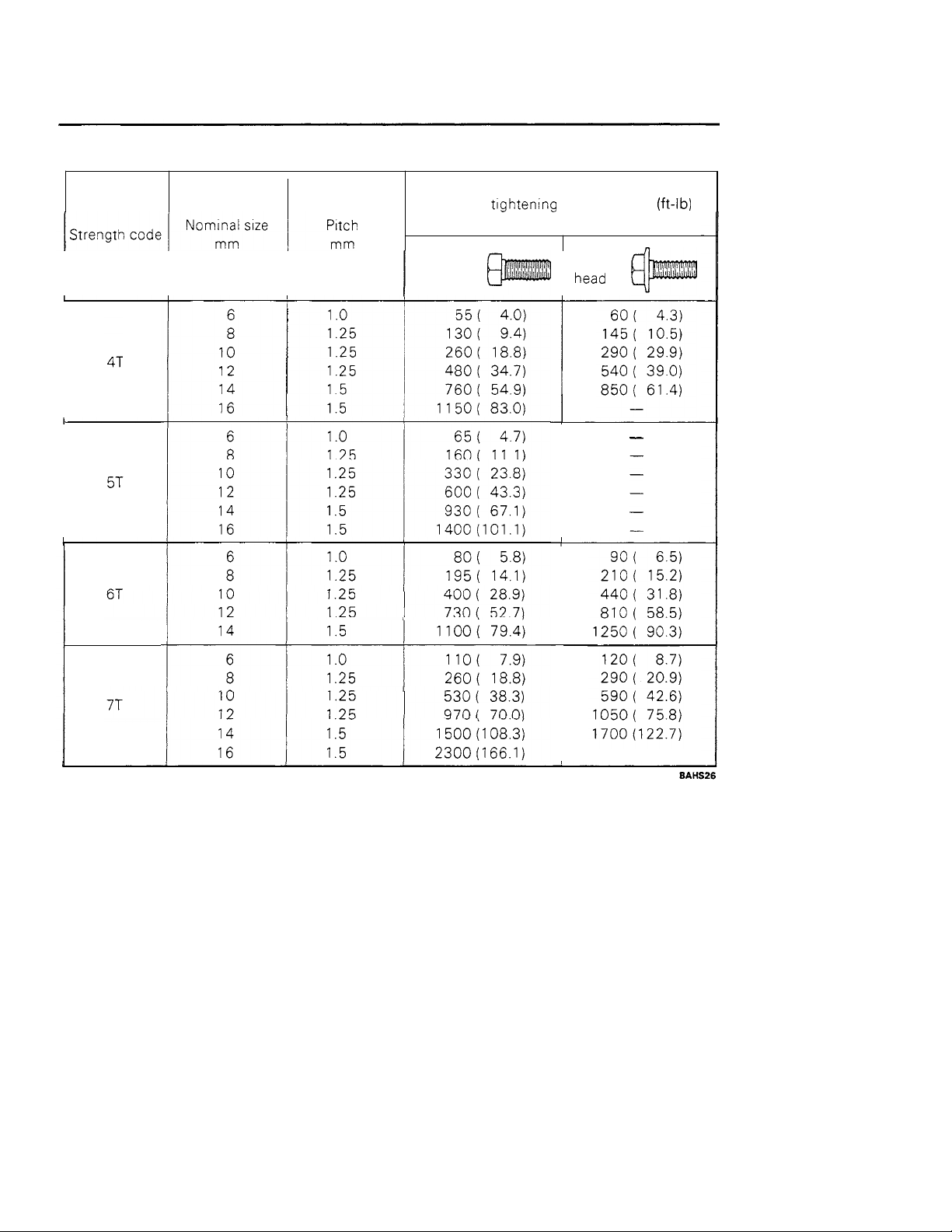

TIGHTENING

TORQUE

TABLE

~

Standard t~ghten~ng torque kg-cm

Standard Collar

1

head head

(ft-lb)

- -

-

---

PRECOAT BOLTS

(Bolts coated wrth seal lock agent on threads)

1

Do not use the precoat bolt as it

any of the follow~ng cases

When the precoat bolt

(1

)

(2)

When the precoat bolt 1s moved

(loosened or tightened) rn

rng check etc

Reference

The tightening torque must be checked

with the lower limit of the allowable

tightening toque range. If the bolt moves,

retighten it according to the following

procedure:

2.

Reusing the precoat bolt

(1)

:

Clean the bolt and threaded hole.

(Clean the threaded hole even

when the precoat bolt

replaced.

j

IS

IS

removed

tighten-

IS

to be

In

I

I

I

I

Precoat

601ts

(2)

Dry the precoat bolt sufficiently by

alr blowing, etc

(3)

Coat the specifred seal lock agent

on the theaded hole for the bolt.

HIGH PRESSURE HOSE FllTlNG TIGHTENING TORQUE

84460

I

1

I

I

I

1.

Before connecting a h~gh pressure hose, wipe the high pressure hose fitting and mating n~pple

contact surfaces with clean cloth to remove foreign matters and dirt. Check that there

dent or other surface defect on the contact surface.

2.

Al~gn the high pressure hose f~tting and nrpple and hold the hose In that the state during

tightening.

3.

The maximum t~ghten~ng torque must not exceed twice the standard t~ghtening torque.

I

,

Hose

diameter

mm

12

25

12

N~~~~~~

of screw

Standard t~ghtenrng torque

Standard

7/16 -20UNF 251 181)

9/16

-18UNF

-16UNF

3/4

7/8 -14UNF

11/16-12UNF

15/16-12UNF

PFI /4

PF3/8

1

50( 362)

I

6 0 ( 43 3)

60( 433)

120( 866) 11 4-1261823- 91 0) 19

150(lOl 1)

501 362) 48- 531347- 383)

'

50( 362) 48- 533347- 383)

PF1/2

PF3/4

PF

1

120( 866) 11 4-126(823- 91 0) 19

140(101

I

1)

kg

-

cm (ft-l

Tighten~ng range

b)

24- 261173 188) 6

48

-

531347- 383) 9

63141 2- 455) 12

-

57

1

57- 63141 2- 455)

1

133-,471960-1061)

57- 63141 2- 455)

1

133-1471960-1061) 2 5

IS

no

~ns~de

9

9

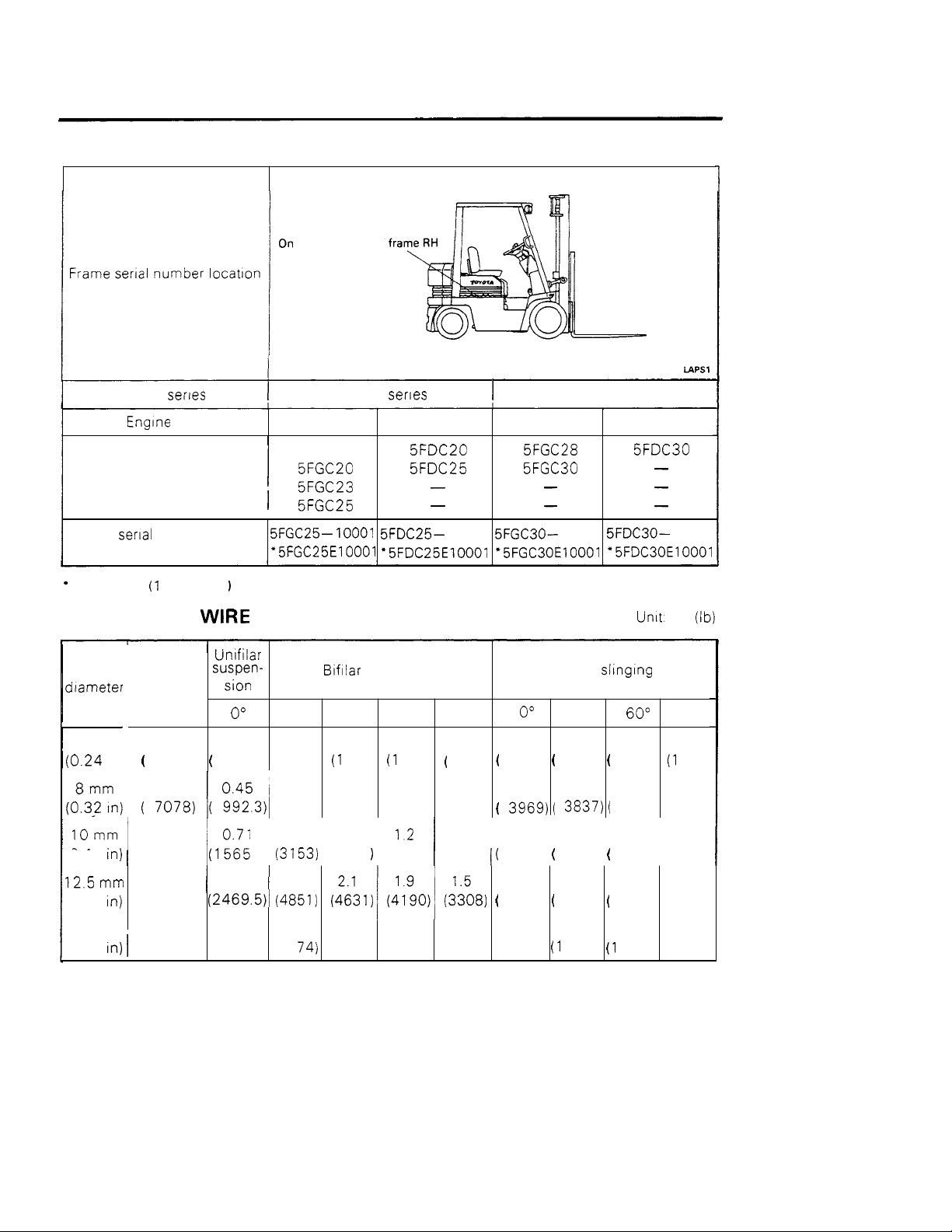

FRAME NUMBER

top

of

rear

pan

1

of

Model serles

Eng~ne type

Model

Frame ser~al number format

.

EEC

spec.

(1

992.

1 1

-

SAFE LOAD

BY

WIRE ROPE SUSPENSION ANGLE

'

Rope

d~ameter

6 rnm

(0.24 in)

Breakdown

load

2.18

(

4807)

3.2

SusPen-

(

1

)

Un~filar

sion

0"

0.31

683.6)

I

1

,

I

1

I

5FGC25-10001

'5FGC25E10001

0.62

(1

367)

0.9

(1985)

2.0 ton serles

4Y

5FGC 18

5FGC20

5FGC23

5FGC25

B~f~lar suspension

30

0

"

"

0.6

(1

323)

0.87

(1918)

2J

5FDC20

5FDC25

-

-

5FDC25- 10001

"5FDC25E10001

90

0.44

(

970)

0.64

(141

"

1)

"

60

0.53

(1

169)

0.78

(1720)

I

3.0 ton series

4Y

5FGC28

5FGC30

-

-

5FGC30- 10001

'5FGC30E10001

Cross

0"

1.24

(

2734)

1.8

(

3969)(

30

1.2

(

2646)

1.74

3837)(

"

2J

5FDC30

-

-

-

5FDC30- 10001

'5FDC30E10001

Un~t. ton (Ib)

sling~ng

60"

1.06

(

2337)

1.56

3440)

90

0.88

(1

940)

1.28

(2822)

"

Omm 502 071 143 137 12

(0 4 in)

12.5 mrn

(0.5 ~n)

14 mrn

(0.56

1

(1

1069)

7.84 1.12

(1

7287)

.

9.83

In) 1 (21 675)

(1

565 6) (31 53) (3021 1 (2646) (2205)

(

2.2

(2469.5)l (4851)

1.4

(30870)

2.8

(61 74) (41 90)

(5954)

2.4

(5292)

1

0 28 27 24 20

11

61 74) ( 5954) ( 5292) (4410)

4.4

(

9702)

1.9 2.7

5.6

(1

2348)

4.2

(

9261)

5.4

(1

1907)

3.8

(

8379)

4.8

(1

0584)

3.0

(6615)

3.8

(8379)

1

-

-

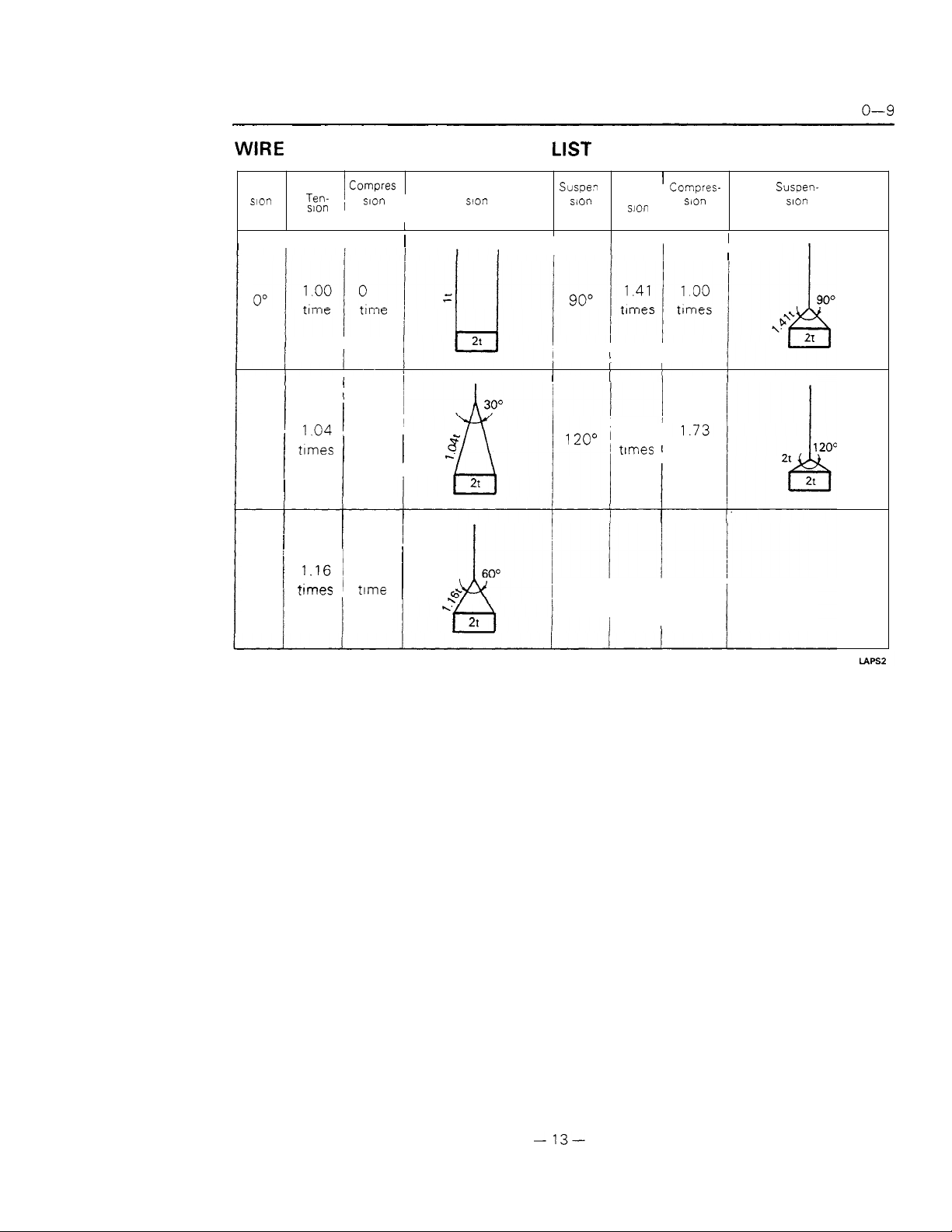

WIRE ROPE SUSPENSION ANGLE LIST

Suspen

s~on

angle

30

"

60

"

-

,

I

CO~P~~S

Ten-

"On

I

strength method

I

I

I

I

I

1

toe tme

I

I

1161

'

tmes , tme

slon

027

058

,

1

I

I

/

1

Suspen

ston

Suspei

SIO~

angle

I

I

1

1

1

I

i

slon

times

I

~ompres-

sion

strength

I

I

I

1

times

I

I

I

Suspen-

,

I

I

slon

method

Loading...

Loading...