Toyota 02-8FDF18, 02-8FGF20, 02-8FDF20 User Manual [nl]

Operator’s Manual

en

English

Polish

Latvian

Estonian

Lithuanian

Instrukcja obsługi

Juhi käsiraamat

Vartotojo instrukcija

02-8FGF15,18,20,25,30

02-8FDF15,18,20,25,30

52-8FDF20,25,30

02-8FGKF20

02-8FDKF20

pl

lv

et

lt

007080-O

00_A5028-0EE00_cover.p65 7/13/07, 10:12 AM1

02-8FGJF35

Publication No. A5028-0EE00 PRINTED IN FRANCE

52-8FDJF35

00_A5028-0EE00_frontcover.fm Page 1 Wednesday, July 18, 2007 7:16 PM

Operator’s Manual

Instrukcja obsługi

Ekspluatācijas rokasgrāmata

Juhi käsiraamat

en (English)

pl (Polski)

lv (Latviešu)

et (Eesti)

Vartotojo instrukcija

lt (Lietuviškai)

01_A5028-0E00_En.fm 2 ページ 2007年7月4日 水曜日 午後4時1分

ENGLISH

BEFORE INITIAL OPERATION

CONTENTS

Note to Operators and Supervisors ....................................................................................................... 2

Before Initial Operation ........................................................................................................................ 2

Caution Plates ....................................................................................................................................... 6

Main Components................................................................................................................................. 7

Driving Controls and Instrument Panel ................................................................................................ 7

Instruments............................................................................................................................................ 8

Multifunction Display (Option) .......................................................................................................... 12

Switches and Levers ........................................................................................................................... 18

Body Components............................................................................................................................... 29

Handling the Toyota DPF-II System (Option).................................................................................... 37

Pre-Operation Check........................................................................................................................... 40

Before Garaging the Vehicle............................................................................................................... 45

Weekly Maintenance........................................................................................................................... 45

Self Servicing...................................................................................................................................... 47

Fuel Tank Check ................................................................................................................................. 51

Frame Serial Number.......................................................................................................................... 51

How to Read the Name Plate .............................................................................................................. 51

Lubrication Chart ................................................................................................................................ 52

Periodic Maintenance ......................................................................................................................... 53

Periodic Replacement Table ............................................................................................................... 53

Protect Your Investment with Toyota Genuine Parts.......................................................................... 53

Periodic Maintenance Table................................................................................................................ 54

Service Data........................................................................................................................................ 58

LPG Device (Option).......................................................................................................................... 60

Mast Specifications & Rated Capacities............................................................................................. 68

Wheel & Tire ...................................................................................................................................... 76

Vehicle Dimensions ............................................................................................................................ 77

NOTE TO OPERATORS AND SUPERVISORS

This manual explains the correct operation and maintenance of Toyota Industrial vehicles as well as

daily lubrication and periodic inspection procedures.

Please read this manual thoroughly even though you may already be familiar with other Toyota

Industrial vehicles because it contains information which is exclusive to this series of vehicles. The

manual has been produced based on a standard vehicle. However, if you have questions on other

types, please contact your Toyota Industrial vehicle dealer (Toyota dealer).

In addition to this manual, it is essential that you review the separate publication entitled

“Operator’s Manual for Safety Operation” for forklift vehicle operators. It contains important

information about the safe operation of forklift vehicles. Toyota reserves the right to make any

changes or modifications of specifications in this manual without giving previous notice and without

incurring any obligation.

• Please read this manual thoroughly. This

will give you a complete understanding of

Toyota industrial vehicles and permit you to

operate them correctly and safely.

Correct handling of new vehicles promotes

performance and extends service life. Drive

with special caution while becoming familiar with a new vehicle.

In addition to the standard operating procedures, pay attention to the following safety

items.

• Please acquire thorough knowledge of the

Toyota Industrial vehicle. Read the operator’s manual thoroughly prior to operating

the vehicle. Get to know its operation and

components. Learn about the safety devices

and accessory equipment and their limits and

precautions. Be sure to read the caution plate

attached to the vehicle.

• Please learn safe driving points and safety

management. Understand and maintain

working area traffic rules. Ask the work area

supervisor about any special working precautions.

• Wear neat clothing for operation.

Improper clothing for vehicle operation may

interfere with smooth operation and cause an

unexpected accident. Always wear appropriate clothing for easy operation.

• Please keep away from live electric power

lines. Know the locations of inside and outside power lines and maintain sufficient distance.

• Be sure to perform pre-operation checks

and periodic maintenance. This will prevent sudden malfunctions, improve work

efficiency, save money and insure safe working operation.

• Always warm up the engine before starting operation.

• Be sure to avoid forward tilt when the

forks are elevated with a load. In the worst

case, this will cause overturning due to poor

stability resulting from forward shifting of

the center of gravity.

• Never attempt traveling when the forks

are elevated with a load beyond the specified height. Traveling with a load on the

forks elevated beyond the specified height

may cause overturning due to the upward

shift of the center of gravity. Keep the forks

weight at 10-20cm (6-8in) above the ground

when traveling.

• Please avoid overloading or uneven load-

ing. Overloading or an uneven load is dangerous. If the center of gravity is not evenly

distributed, i.e. nearer to the front side of the

load and the load is below the maximum,

limit the load weight according to the load

rating table.

• If you hear any unusual noise or sense

anything unusual, stop, inspect and repair

immediately.

• Be sure to observe the correct operating

procedures and precautions for the operation of vehicles equipped with power

steering and power brakes.

• If the engine stops during traveling, this

will affect the operation. Stop the vehicle

in a safe place as described below. Steering

operation becomes heavy because the power

steering becomes ineffective. Operate the

steering wheel more firmly than usual.

• Please use only the recommended types of

fuel and lubricants. Low-grade fuel and

lubricants will shorten service life.

Diesel fuel

Recommendation

Use diesel fuel with a cetane index of 46 or

more and a sulfur content of not more than 50

ppm that is based on European diesel fuel standard EN590/99.

CautionCaution

• Don’t use the bio-diesel fuel because of

bad influence on the engine.

• In winter, use winter diesel fuel to prevent

clogging of the fuel filter caused by paraffin precipitation.

en-2

01_A5028-0E00_En.fm 3 ページ 2007年7月4日 水曜日 午後4時1分

• Flammable and/or combustible materials

can be damaged and in some cases ignited

by a hot exhaust system or hot exhaust

gases. To minimize the possibility for such

damage or fire, the operator must obey

the following recommended practices:

• Do not operate the lift vehicle over or near

flammable and/or combustible materials,

including dried grass and paper scraps.

• Park the lift vehicle with rear end at least

30cm (12in) away from lumber, veneer

board, paper products and other similar

materials to avoid discoloration, deformation or combustion of those materials.

• For the vehicles using color tires, a static

strap must be fixed.

• Vehicles equipped with the wet brake

option require a warm up period before

starting load handling operations when

temperature is below -10°C (14°F). The

warm up method consists of driving the

vehicle without load for approximately 200

meters (600 ft).

Precautions to be taken when using

SAS models

(SAS: System of Active Stability)

CautionCaution

• Whenever you get on an SAS models,

please check the caution plate, which will

inform you what functional features are

provided on the vehicle. Do not proceed to

operate the vehicle before making certain

that each of the features is operating correctly.

• For those models fitted with double/dual

wheels, there is no rear tire swing lock

control cylinder/stabilizer.

• While driving the vehicle, be alert about

any warning lamp that may appear.

Should an error code be indicated by a

warning lamp or the hour-meter, park the

vehicle at a safe location and ask a Toyota

dealer for an inspection.

• The SAS, which is electronically controlled, may need to be initialized after

completion of a maintenance operation.

Do not remove or modify any SAS features. Whenever an inspection may be

necessary, make contact with a Toyota

dealer.

• When washing the vehicle, carefully prevent water from spraying directly over

the electronics (controller, sensor and

switches) employed in the SAS.

Description of features available in

SAS models

Active control rear stabilizer:

When the vehicle makes a turn on the spot, a

centrifugal force will be generated in the lateral

direction of the vehicle. In such an event, this

feature will operate so that the rear axle will be

locked from pivoting to support the vehicle on

four wheels. Thus, the vehicular stability will be

enhanced in both right and left directions.

CautionCaution

With the rear axle locked from pivoting, the

stability will be increased. Nevertheless, it

does not signify that the vehicle would never

tipover. Operate the vehicle as outlined in

this manual.

Automatic forks leveling control

• With tilting the mast forward while pressing

the tilt lever knob switch will cause the fork

to automatically stop at its horizontal position (the mast vertically positioned).

• After stopping the forks at its horizontal

position with the tilt lever knob switch

pressed, you may want to tilt the forks further forward. To do this, return the tilt lever

to the neutral position once. Then, after

releasing the tilt lever knob switch, operate

the tilt lever.

When the tilt lever is operated from the backward to forward position with the knob switch

depressed, the mast will perform as follows:

Not load Loaded

High lift

Stops with forks level

height

(mast vertical)

Low lift

Stops with forks level (mast vertical)

height

CautionCaution

• With the mast titled forward with a load

on the forks and elevated, pressing the tilt

lever knob switch will cause the mast to

stop moving. Absolutely avoid such operation because this automatic forks leveling control, if operated while handling a

load, may cause the vehicle to tipover.

• In case of the vehicle with an attachment,

do not allow the forks to be automatically

positioned horizontally, with a load on the

elevated while the engine is running at

high rev. This will lead to a hazard.

• Some specialty models onto which a heavy

attachment is mounted may not be

equipped with the automatic forks leveling control. Confirm with a Toyota dealer

in advance.

No forward tilt

Note:

• The mast will not move if it is tilted forward

by pressing the tilt lever knob switch with a

load at an elevated height (more than 2 m).

• When the mast is tilted forward from its vertical position, it will not be possible to tilt

forward even if the tilt lever knob switch is

pressed.

• While it is tilting backward, the forks will

not stop at the horizontal position (mast vertical) even if the tilt lever knob switch is

pressed. (except vehicles equipped with mini

lever or joy stick)

Active mast front tilt angle control

According to the lift and to the load, the angle at

which the mast can be tilted forward is automatically controllable within a range of angles illustrated below.

Light load

High lift

height

Low lift

height

(no load)

No restriction

for front tilt

angle

No restriction for front tilt angle

CautionCaution

• If a load is tilted forward at a low lift

height, and then the load is elevated there

is a fear that the vehicle may tip forward

when the load stops at a height having a

tilt angle beyond the specified angle

range. Always ensure the mast is vertical

when elevating the load or forks and only

tilt forward when the height required has

been reached.

• With a load at a high lift height, never

match the load (mast angle) by controlling

the mast forward tilt angle, since it

involves the fear that the vehicle may tip

forward.

• Even with a load positioned within the

allowable angle range, never tilt the mast

beyond its vertical position, or the vehicle

may tip over, losing its stability forward

or backward. Never tilt the mast forward,

with an elevated load.

Intermediate

load

Angle restricted

between 1° and

5° forward tilt

angle

Heavy load

Forward tilt

angle

restricted to 1°

en

en-3

01_A5028-0E00_En.fm 4 ページ 2007年7月4日 水曜日 午後4時1分

CautionCaution

• Some specialty models onto which a heavy

attachment is mounted may not be

equipped with the mast forward tilt control. Confirm with a Toyota dealer in

advance.

• Once you have mounted or replaced any

attachment on a forklift, ask a Toyota

dealer for an inspection.

• If you use two or more removable attachments alternately, the heaviest one should

be used to carry out matching (SAS setting). Contact your Toyota dealer to

request compatibility matching.

• When attaching an attachment to a model

without forks, the attachment must be

compatible with the model. Contact your

Toyota a dealer to request compatibility

matching.

Note:

When the forks are elevated to the maximum

height, a high pressure (relief pressure) may

remain in the lift cylinder. This high pressure

causes the vehicle to judge that it has a high load

even if there is no load. As a result, the mast will

be stopped from tilting forward. In this case,

lower the forks slightly (to release the pressure)

and the mast may be tilted forward.

Active mast rear tilt speed control

• At a high lift height, the mast has a backward tilt speed controller (slow down) irrespective of the load. When lowering from a

high lift height to a lower lift height while

tilting the mast backward, the control speed

will not change.

• At a low lift height, the mast can be tilted at

full speed even if there is a load. If the mast

is tilted backward at a low lift height with

the tilt knob switch pressed, the mast has the

backward tilt speed controlled (slowed

down) as long as the tilt lever knob switch is

pressed. (Except mini lever/joy stick models)

• If the low lift height is then changed to a

high lift height while tilting the mast backward, the control speed will not change as

long as the tilt lever knob switch is pressed.

The mast may be tilted backward at the full

speed so long as the tilt lever knob switch is

not pressed.

Key-lift interlock

When the ignition switch is turned to OFF and

lowering the lift lever, the forks will not lower.

However, by sitting on the normal seated position and turning the ignition switch to ON, the

forks will lower even when the engine is off.

(Except mini lever/joy stick models)

Active steering synchronizer

If the steering wheel knob is not angularly

matched with the steer tires, such out-of-position will be automatically corrected while turning the steering wheel. Thus, the knob is kept at

a constant position relative to the steer tires.

If SAS feature should fail:

The SAS models are equipped with a controller,

sensors and various actuators. If any of these are

found not to be operating normally, it will tell

you that:

• Steering wheel knob is out-of-position may

not be corrected.

• Functions such as Automatic forks levelling

control, Active mast front tilt angle control,

Active mast rear tilt speed control may not

be operated.

• Swing lock cylinder may not be unlocked.

If any of the phenomena referred to above

should take place.

• Diagnosis lamp will light up or blink.

• Error code will be displayed in the hour

meter.

Thus, the operator will be informed. In such

an event, move the vehicle to a safe location

and ask a Toyota dealer to inspect and repair.

Action to be taken in emergency

Move the vehicle to a safe location and ask a

Toyota dealer for a repair.

If any phenomenon different from normal operations (failure to run or the like), among others,

should take place, ask a Toyota dealer for an

inspection.

Note:

Once a torque converter model has its control

lever abnormal, it is impossible to manually

operate the vehicle, which need be towed,

accordingly.

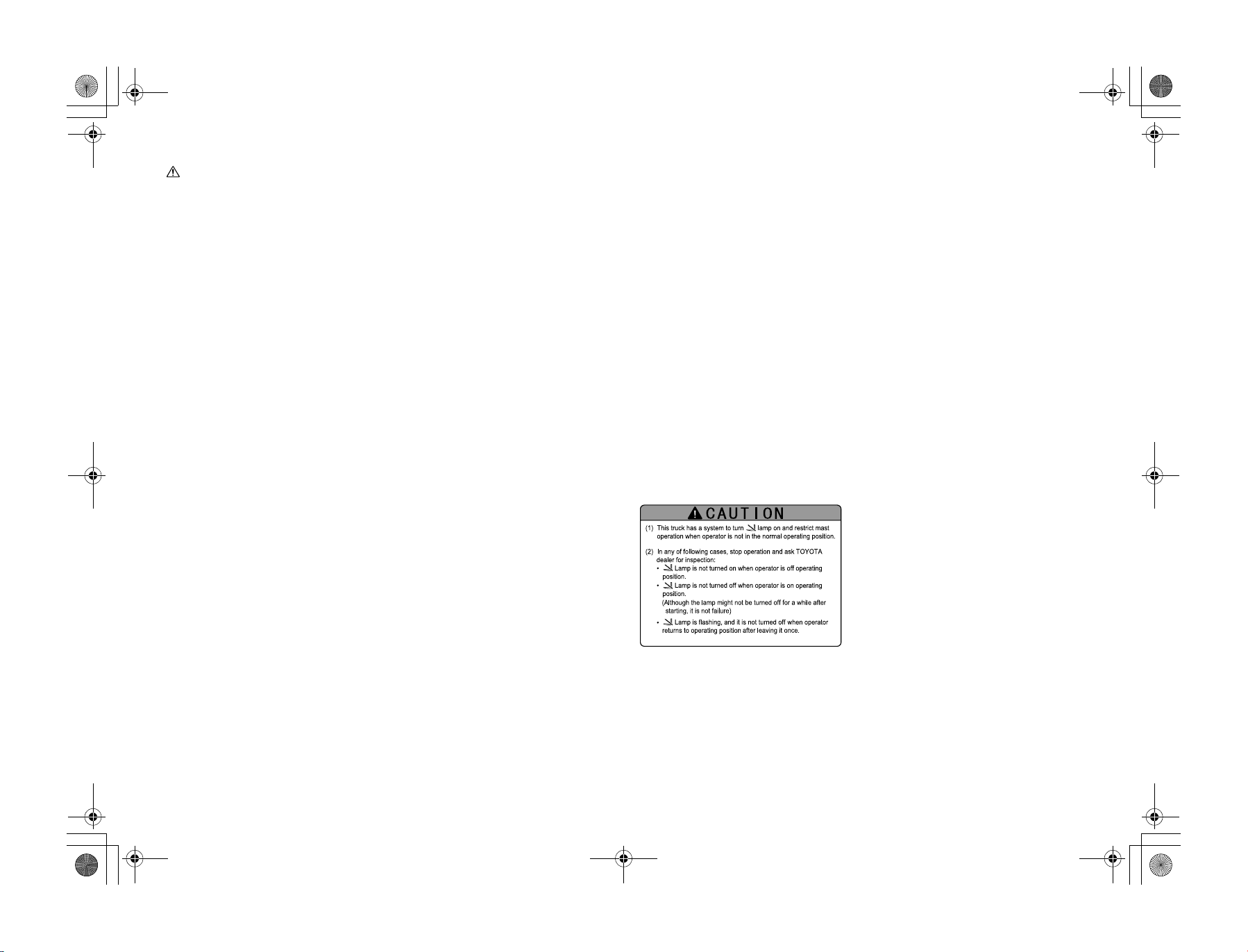

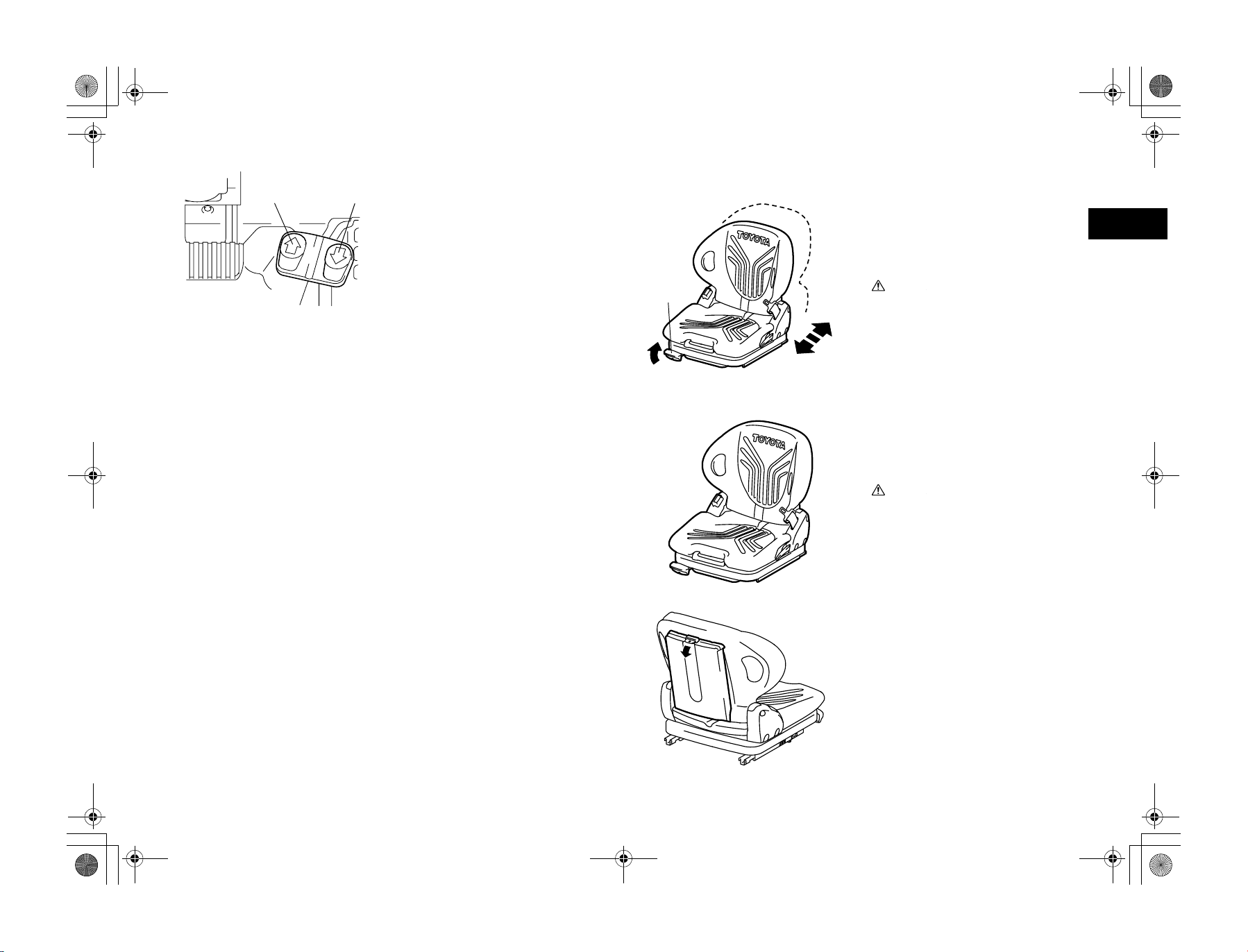

OPS System

The OPS (Operator Presence Sensing) System

prevents traveling and load handling operations

when the operator is not seated in the operator’s

seat.

If the operator leaves the operator’s seat while

the vehicle is operating, the OPS lamp will light

up, and a buzzer will sound for one second to

warn the operator that the OPS System will be

activated. If the operator leaves the operator’s

seat for longer than two seconds, the OPS System will be activated and traveling and load

handling operations will be stopped. However,

if the operator returns to the normal seating

position within two seconds, the OPS System

will not activate and will allow travel and load

handling operations to continue.

Again, if an abnormality occurs to the OPS System, the diagnosis lamp will blink to warn the

operator. In this case, the OPS System may have

malfunctioned. Contact your Toyota dealer to

request an inspection.

This forklift is equipped with an OPS (Operator

Presence Sensing) System. Before operating the

forklift, check that each of the System’s functions is working correctly.

Travel OPS Functions

If the operator leaves the seat while the vehicle

is traveling, the OPS lamp will light up, and two

seconds later, traveling will be stopped. However, this does not apply the brakes to stop

travel. (If the operator returns to the normal

seating position within 2 seconds, traveling can

be continued.)

If the OPS System is activated while driving up

a slope or incline, the drive to the front wheels is

stopped and consequently the vehicle will roll

back down the slope incline. To avoid this problem, make sure to sit on the seat at all times.

If more than 2 seconds has elapsed, apply the

brakes, return the control lever to the neutral

position and sit on the seat again.

Load Handling OPS Function

Forklifts with a standard lever

If the operator leaves the seat during operations,

the OPS lamp will light up, and two seconds

later, load handling operations will be stopped.

(If the operator returns to normal seating position within 2 seconds, loading can be continued.) If the operator leaves the seat while

operating the control lever, loading can be continued for 2-4 seconds.

If load-handling OPS is activated when the lift

lever is in the lowering position, move the lever

to a position other than the lowering position

and return to the normal seated position to deactivate load handling OPS. If load-handling OPS

is activated when the lift lever is in a position

other than the lowering position, load handling

OPS is deactivated 1 second after the operator

returns to the normal seated position.

Forklifts with a mini lever/joy stick lever

(Option)

If the operator leaves the seat during load han-

dling operations, the OPS lamp will light up,

and two seconds later, load handling operations

will be stopped. (If the operator returns to the

seat within 2 seconds, load handling operations

can be continued.)

To resume load handling functions, return to the

seat and return all of the levers to the neutral

position.

OPS Operation Functions

If the operator leaves the seat, a buzzer will

sound for approx. one second (“pii”) and the

OPS lamp will light up and inform the operator

that the OPS System is active. If the operator

returns to the normal seating position, the OPS

lamp will turn off.

en-4

01_A5028-0E00_En.fm 5 ページ 2007年7月4日 水曜日 午後4時1分

Return-to-Neutral Warning

If the OPS System has caused traveling operations to stop, and the operator is re-seated while

the control lever is not returned to the neutral

position, the buzzer will sound (“pi, pi, pi...”)

indicating that the travel OPS functions has not

been deactivated.

Forklifts with a standard lever

If the OPS System has caused load handling

operations to stop, and the operator is re-seated

while the lift lever is still set in the lowering

position, the buzzer will sound (“pi, pi, pi...”)

indicating that suspension of lowering has not

been deactivated.

Forklifts with a mini lever/joy stick lever

(Option)

If the OPS System has caused load handling

operations to stop, and the operator is re-seated

without returning all load handling levers to

neutral position, the buzzer will sound (“pi, pi,

pi...”) indicating that the OPS System has not

been deactivated.

SAS/OPS Controller Abnormality

Warning

If the SAS/OPS System registers an abnormality, the diagnosis lamp will blink to inform the

operator.

If the diagnosis lamp starts blinking, the SAS/

OPS System may have malfunctioned. Park the

vehicle at a safe location and request an inspection by your Toyota dealer.

In the following cases, park the vehicle in a safe

location and have the vehicle inspected by your

Toyota dealer.

• The OPS lamp does not light up even if the

operator leaves the seat.

• The OPS lamp does not turn off even if the

operator is re-seated. (In the case of diesel

engine vehicles, the diagnosis lamp may

light up during engine warm-up after a coldstart, but does not indicate an abnormality.)

CautionCaution

When the ignition switch is turned to OFF,

and the operator has been seated for a long

period, there are the cases where the OPS

lamp blinks when the ignition switch is

turned to ON. In that case, the light will go

out by leaving the seat once and return to the

normal seated position.

The Auto Speed Control Functions

(Option)

CautionCaution

• The optional Auto Speed Control Functions limit maximum travel speed and

high speed acceleration relative to load

height and weight and reduces the

chances of tip-overs. However, this feature

will not prevent all tip-overs in all circumstances.

• According to road surface conditions and

loading operations, temporary changes in

speed limits and sense of acceleration may

be experienced.

• During operation using the inching and

brake pedal, temporary changes in speed

limitations and sense of acceleration may

be experienced.

• There are cases where the idle-up of

engine increases the vehicle speed, when

the lift lever is operated upward on the

idle conditions.

Speed limits after load lifting height

and weight sensing

(Maximum speed limiter)

When the load is in an elevated position, this

function limits the maximum speed in accordance with the weight of the load. This function

reduces instability caused by sudden stopping.

Note:

• Although the maximum speed limiter will be

deactivated when the load is lowered, sudden accelerations will remain limited until

the accelerator pedal is re-engaged.

• If the load height is raised when the speed

limit is exceeded, the speed will be gradually

reduced until the set speed limit is reached.

(Auto speed control indicator)

Auto speed control indicator will be displayed

to inform the operator the speed limit after load

lifting height and weight sensing is in operation.

Load height and weight sensors to

prevent sudden acceleration

(Acceleration limiter)

When the load is in an elevated position, this

function limits sudden acceleration of the vehicle in accordance with the weight of the load.

(Preventing sudden starts)

When the load is in an elevated position at a

high engine rev, this function will suppress the

sudden acceleration of the vehicle and resultant

loss of the load even if the vehicle is operated

erroneously such as by abruptly releasing the

brake pedal or the inching and braking pedal

while the accelerator pedal is engaged, or by

setting the control lever in forward or reverse

direction.

(Loading priority function)

If you depress the clutch and brake pedal when

the load height and weight sensors to prevent

sudden acceleration in operation or when the

control lever in neutral and re-press the accelerator only if below constant speed, this function

will release the Maximum speed limiter and the

Acceleration limiter to reduce the impact of

loading.

(Function on/off indicator)

When the load height and weight sensors to prevent sudden acceleration in operation and the

speed limits after load lifting height and weight

sensing is de-active, the function on/off indicator will be displayed to inform the operator.

Low speed setting

When the low speed setting switch is pressed,

traveling will not be possible at the preset speed

or greater.

Pressing the low speed setting switch again will

deactivate this function.

Maximum speeds can be set between approximately. 8-15 km/h.

Note:

• Depending on the vehicle weight, the set

speeds may not be attained while traveling

uphill. Similarly, the set speed may be

exceeded during downhill travelling, but

will resume at the set speed when it is

reached after going down the hill.

• When a maximum speed limit has also been

set, the lower speed setting will take precedence.

• Depending on road surface changes and the

vehicle conditions, the set speed may be

exceeded temporarily.

• When setting the maximum speed, consult

your supervisor or a Toyota dealer.

en

en-5

01_A5028-0E00_En.fm 6 ページ 2007年7月4日 水曜日 午後4時1分

Maximum speed limit

This function prevents the vehicle from traveling at a faster speed from that speed preset by

your supervisor or company. The maximum

speed can be set between approximately. 815km/h.

Note:

• Depending on the vehicle weight, the set

speed may not be attained while traveling

uphill. Similarly, the set speed may be

exceeded during downhill travelling, but

will resume at the set speed when it is

reached after going down the hill.

• Depending on road surface changes and the

vehicle conditions, the set speed may be

exceeded temporarily.

• When setting the maximum speed, consult

your supervisor or a Toyota dealer.

Increasing the idling lifting speed

When the lift lever is raised, the forks can be

raised at a steady speed without pressing on the

accelerator pedal to increase the engine rev.

Note:

• There are circumstances where the idle-up of

engine increases the vehicle speed when the

lift lever is operated.

• The lifting speed will differ depending on

the vehicle model, specifications, and load

conditions.

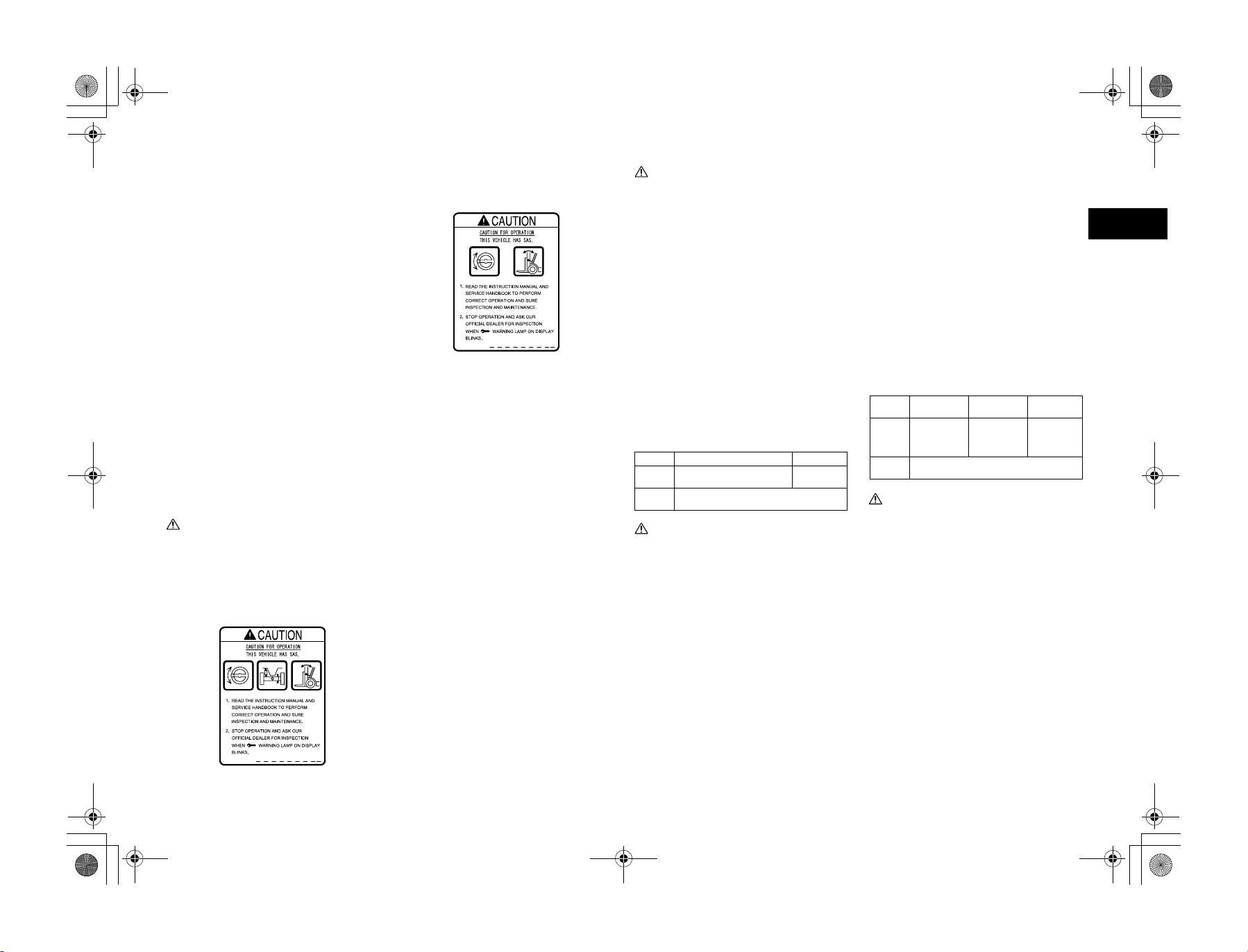

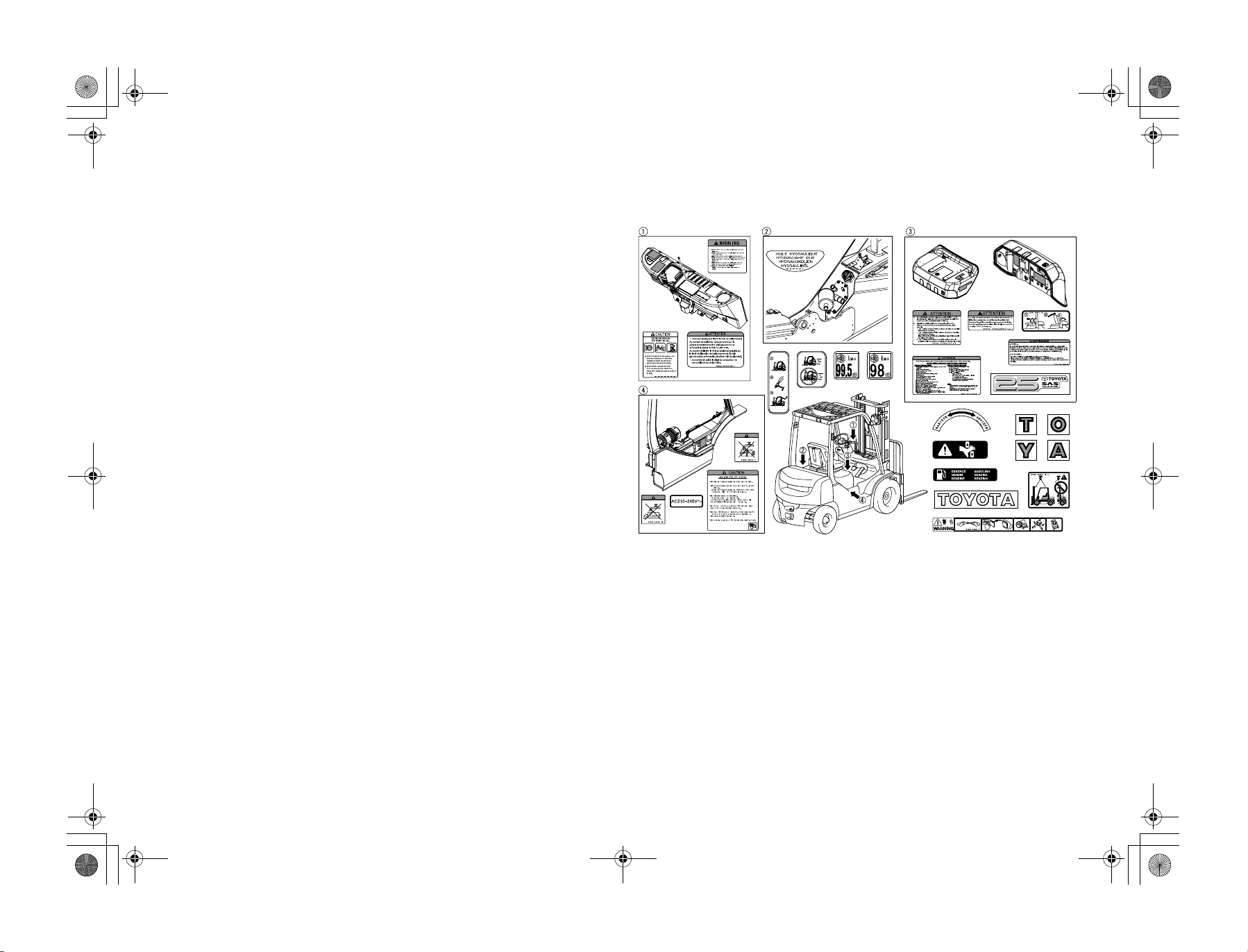

CAUTION PLATES

Caution plates are attached on a vehicle. Before driving it, please be sure to read them thoroughly.

(The sample shows those of an English version.)

en-6

01_A5028-0E00_En.fm 7 ページ 2007年7月4日 水曜日 午後4時1分

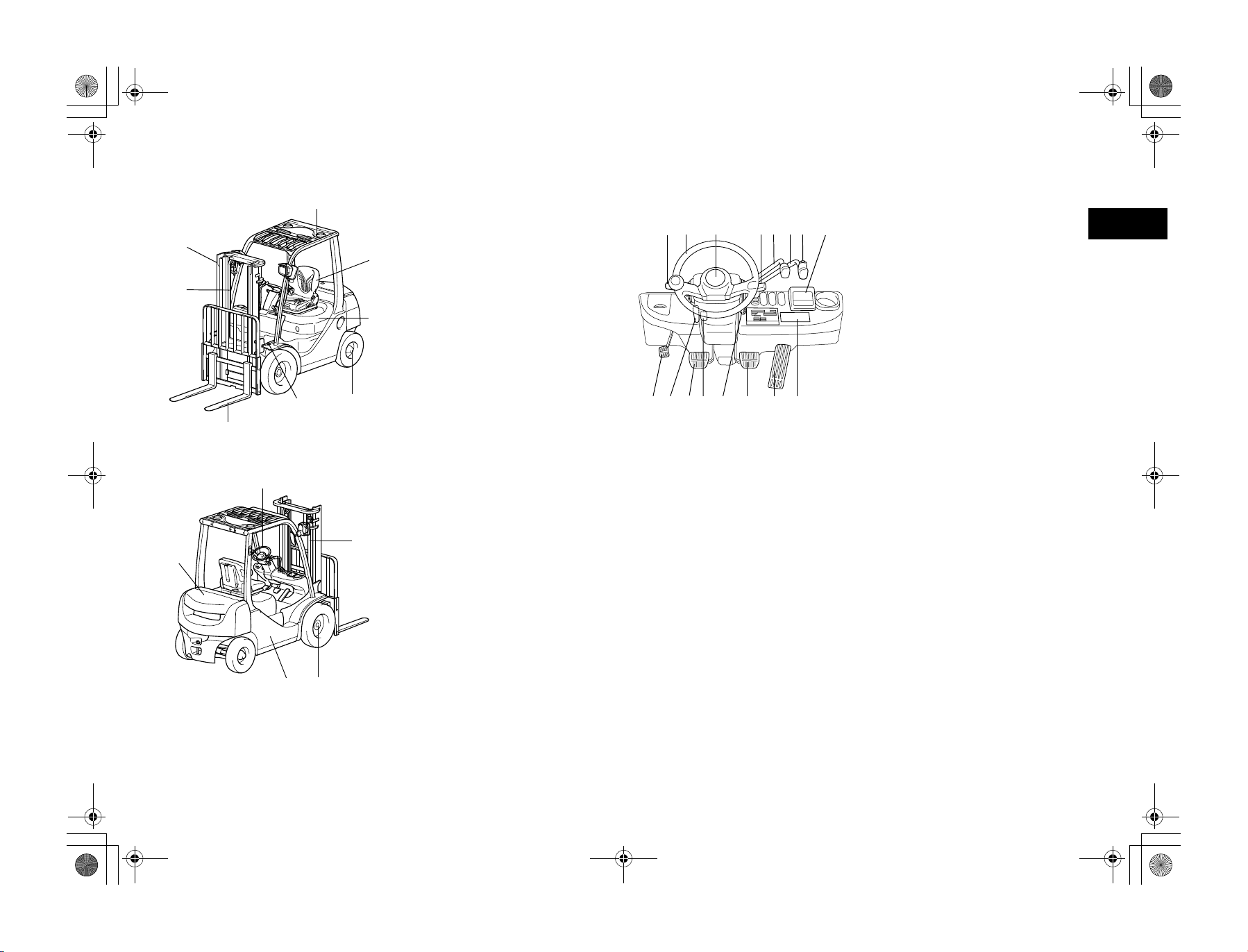

MAIN COMPONENTS

8

1

2

4

3

13

9

5

12

1. Mast

2. Chain

3. Forks

4. Tilt cylinder

7

5. Rear axle

6. Engine hood

7. Operator’s seat

8. Head guard

6

9. Counter weight

10. Frame

11. Front axle

12. Lift cylinder

13. Steering wheel

DRIVING CONTROLS AND INSTRUMENT PANEL

1. Control lever

2. Steering wheel

11623 45678

15 14 13 12 11 10 9

3. Horn button

4. Light control and turn signal switch

5. Lift lever

6. Tilt lever

7. Tilt lever knob switch

8. Multi function display (Option)

9. Combination meter

10. Accelerator pedal

11. Brake pedal

12. Ignition switch

13. Parking brake release lever

14. Inching and brake pedal

15. Tilt steering adjust lever

16. Parking brake pedal

en

10 11

en-7

01_A5028-0E00_En.fm 8 ページ 2007年7月4日 水曜日 午後4時1分

INSTRUMENTS

1

56 8 9

Gasoline engine models

1

457 8 9

Diesel engine models

23

10

23

10

Combination meter

(1)

Meters and warning lamps are arranged as

shown in the left figures.

1. Water temperature gauge

2. Hour meter

3. Brake warning lamp

(OK monitor: Option)

4. Sedimenter warning lamp

(Diesel engine models)

11

12 13

11

12 13

5. Fuel gauge

6. Engine check lamp

(Gasoline engine models)

7. Glow indicator lamp

(Diesel engine models)

8. Engine oil pressure warning lamp

9. Charge warning lamp

10. OPS lamp

11. Diagnosis lamp

12. Air cleaner warning lamp

(OK monitor: Option)

13. Coolant level warning lamp

(OK monitor: Option)

(1) Start

Warning lamp check method

Please check if all warning lamps come on

when the ignition switch is turned to ON.

Note:

Use the light control switch to check the meterlighting lamp.

Caution

Caution

• The glow indicator lamp (Diesel engine

models) is only on for 2 seconds when the

engine coolant temperature exceeds

50°C.

• If a lamp does not light up, contact your

Toyota dealer to request an inspection.

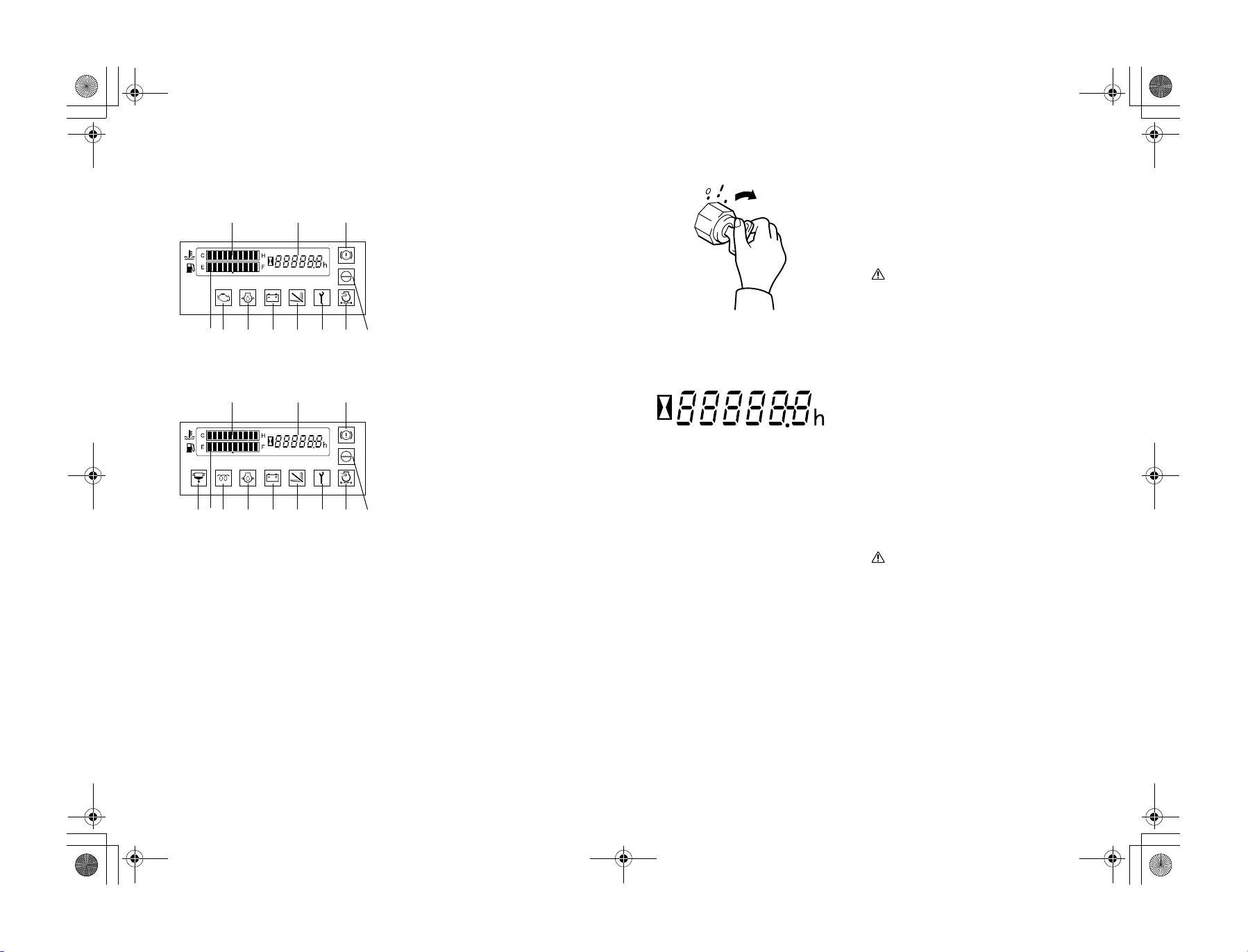

Hour meter also serving as diagnosis indicator

The hour meter operates when the ignition

switch is turned to ON. It indicates the total

number of vehicle operating hours.

The unit of the right most digit is 1/10 hour.

Please use this meter for the timing of periodic

maintenance and recording the operation

hours.

When an abnormality occurs to the vehicle

(diagnosis lamp lights up or blinks) the error

code and hour meter will be alternately displayed.

Caution

Caution

Should an error code be displayed, park the

vehicle in a safe location and contact your

Toyota dealer to request an inspection.

en-8

01_A5028-0E00_En.fm 9 ページ 2007年7月4日 水曜日 午後4時1分

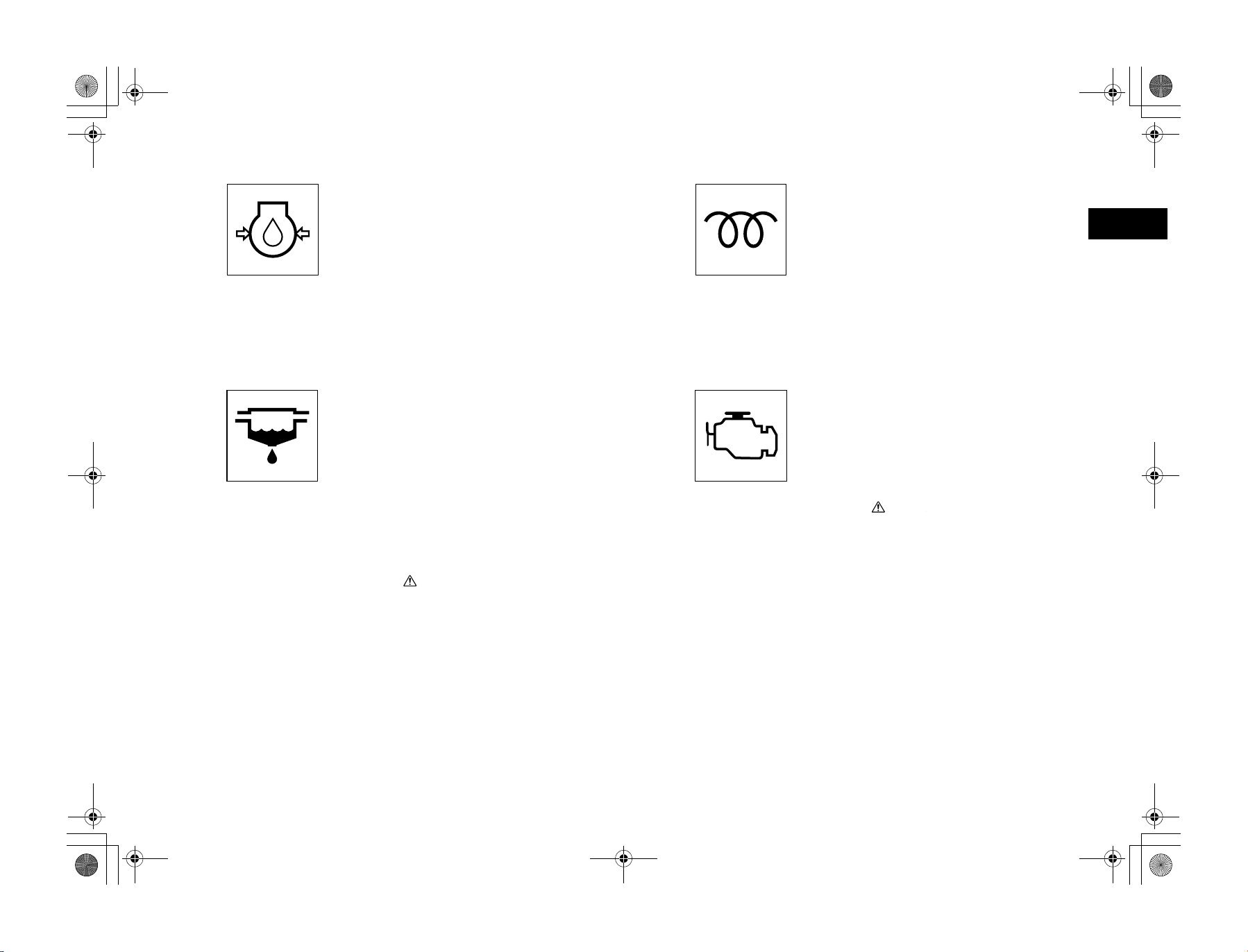

Engine oil pressure warning lamp

Comes on to indicate low engine oil pressure

while the engine is running.

1. If normal, the lamp comes on when the

ignition switch is turned to ON and goes

off when the engine starts.

2. If the lamp comes on while the engine is

running, either the engine oil is low or the

lubrication system is faulty. Stop the

operation immediately and ask a Toyota

dealer for inspection and repair.

Note:

The “engine oil pressure warning lamp” does

not indicate the oil level. Check the oil level

using the oil level gauge before starting work.

Sedimenter warning lamp

(Diesel engine models)

The sedimenter is a device for separating water

from the fuel.

1. The warning lamp comes on to indicate

water in the sedimenter exceeds the predetermined level while the engine is running.

2. If normal, the lamp comes on when the

ignition switch is turned to ON and goes

off when the engine starts.

3. If the lamp comes on while the engine is

running, drain water immediately. (See

the self service section for the draining

instructions.)

Glow indicator lamp

(Diesel engine models)

Indicates heating of glow plugs.

When the ignition switch is turned to ON, the

lamp comes on and glow plug heating begins.

The lamp goes off automatically when glow

plug heating is complete. The engine will start

easily once the glow plugs are heated.

Note:

The glow indicator lamp is on for 2 seconds

when the engine coolant temperature exceeds

50°C.

Engine check lamp

(Gasoline engine models)

1. When an error occurs to the engine controller, the display will light up to inform

the operator.

2. When condition is normal, the lamp will

light up when the ignition switch is

turned to the ON position. The lamp will

turn off when the engine is started.

CautionCaution

If the engine check lamp lights up during

operation, stop operations and park the

vehicle in a safe location, ask your Toyota

dealer to perform an inspection.

en

CautionCaution

Continued operation with the lamp on may

cause seizure of the injection pump and

pump damage. If the warning lamp lights

up, always make sure to drain the water.

en-9

01_A5028-0E00_En.fm 10 ページ 2007年7月4日 水曜日 午後4時1分

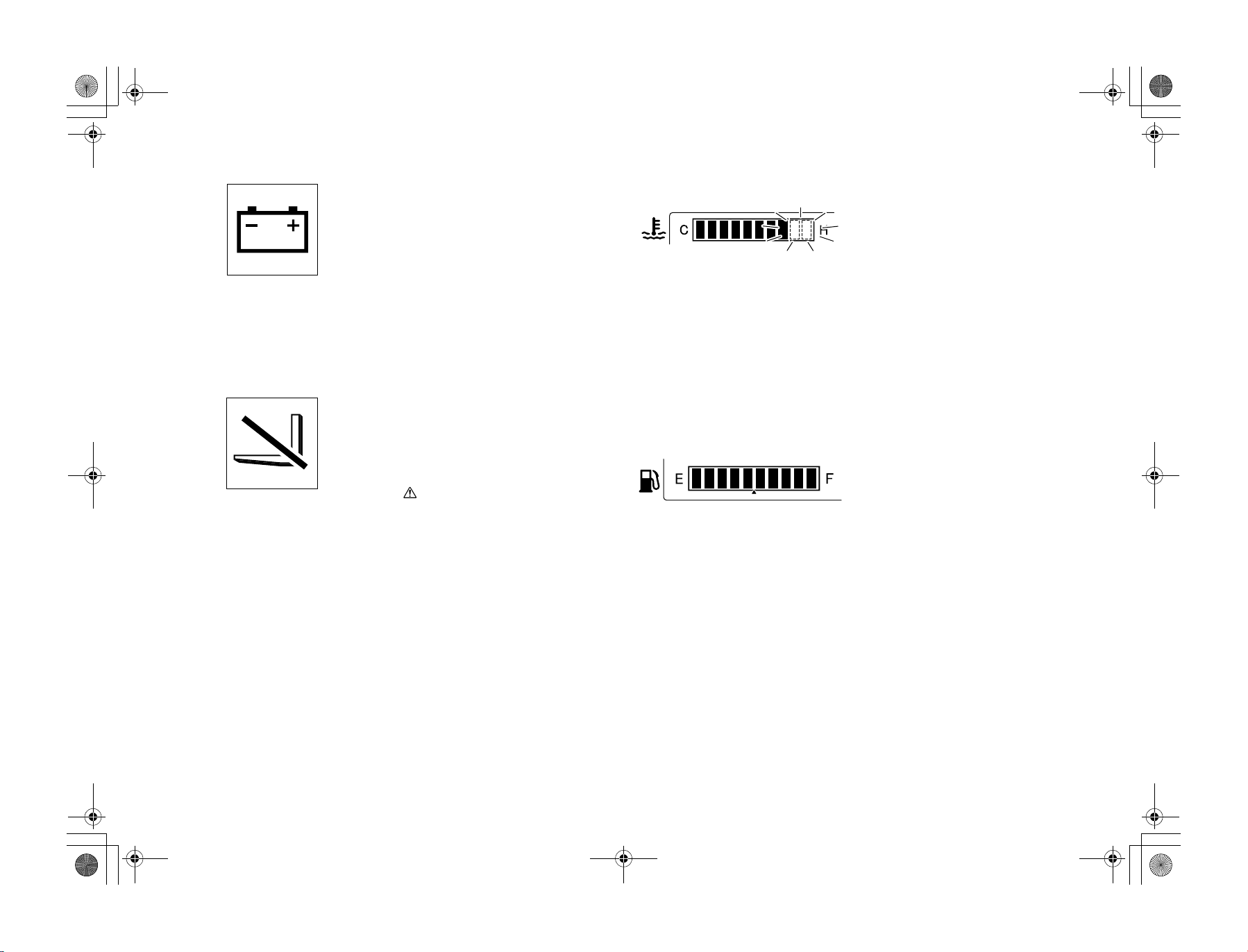

Charge warning lamp

1. This lamp comes on to indicate an abnormality in the charging system while the

engine is running.

2. If normal, the lamp comes on when the

ignition switch is turned to ON and goes

off when the engine starts.

3. If the lamp comes on while the engine is

running, stop immediately, park the vehicle in a safe location, stop the engine and

after the engine has cooled down inspect

the fan belt for cuts or looseness, adjust it,

and restart the engine.

If lamp does not go off, the electrical system may be faulty.

Please ask a Toyota dealer immediately

for inspection and repair.

OPS lamp

If the operator leaves the seat, the OPS lamp

will light up, indicating that the OPS System is

operating. (If the operator returns to normal

seating position within 2 seconds, loading can

be continued.) In such a situation, return the

control lever and lift lever to the neutral position, then sit on the seat again.

CautionCaution

In the following cases, a malfunction may

have occurred to the OPS System. Park the

vehicle in a safe location and contact your

Toyota dealer to request an inspection.

• If the operator leaves the seat, the OPS

lamp does not light up.

• Even when the operator re-seats, the OPS

lamp does not turn off.

Water temperature gauge

Indicates the temperature of the engine coolant.

1. This gauge functions with the ignition

switch ON, and displays the coolant

water temperature from left to right in a

10-stage gradation scale.

2. The operator will be notified when the

water temperature is 115ºC or over

(above 8th stage), as the final two stages

at far right begin blinking. Again, when

the engine protection function activates

(for vehicles with Multifunction display:

Option), the entire gauge will start blinking to inform the operator.

3. Temporary overheating may be caused by

coolant leakage, low engine coolant level,

loosened fan belt, or other problem in the

cooling system. Contact your Toyota

dealer to request an inspection.

Fuel gauge

(Excluding LPG models)

Indicates the amount of remaining fuel in the

fuel tank in terms of a 10-stage gradation scale.

The operator will be notified that remaining

fuel level is low when the two stages at far left

start blinking.

It takes some time for the indication to be stabilized after refuelling and the ignition switch

is turned to ON.

Note:

• If the operating area is not level, atten-

tion must be paid because the correct

level may not be indicated.

• When the gauge begins blinking, refuel

as soon as possible.

• In case of diesel engine, be sure to refuel

it before it runs out because when this

occurs it becomes necessary to bleed air

from the fuel supply system.

en-10

01_A5028-0E00_En.fm 11 ページ 2007年7月4日 水曜日 午後4時1分

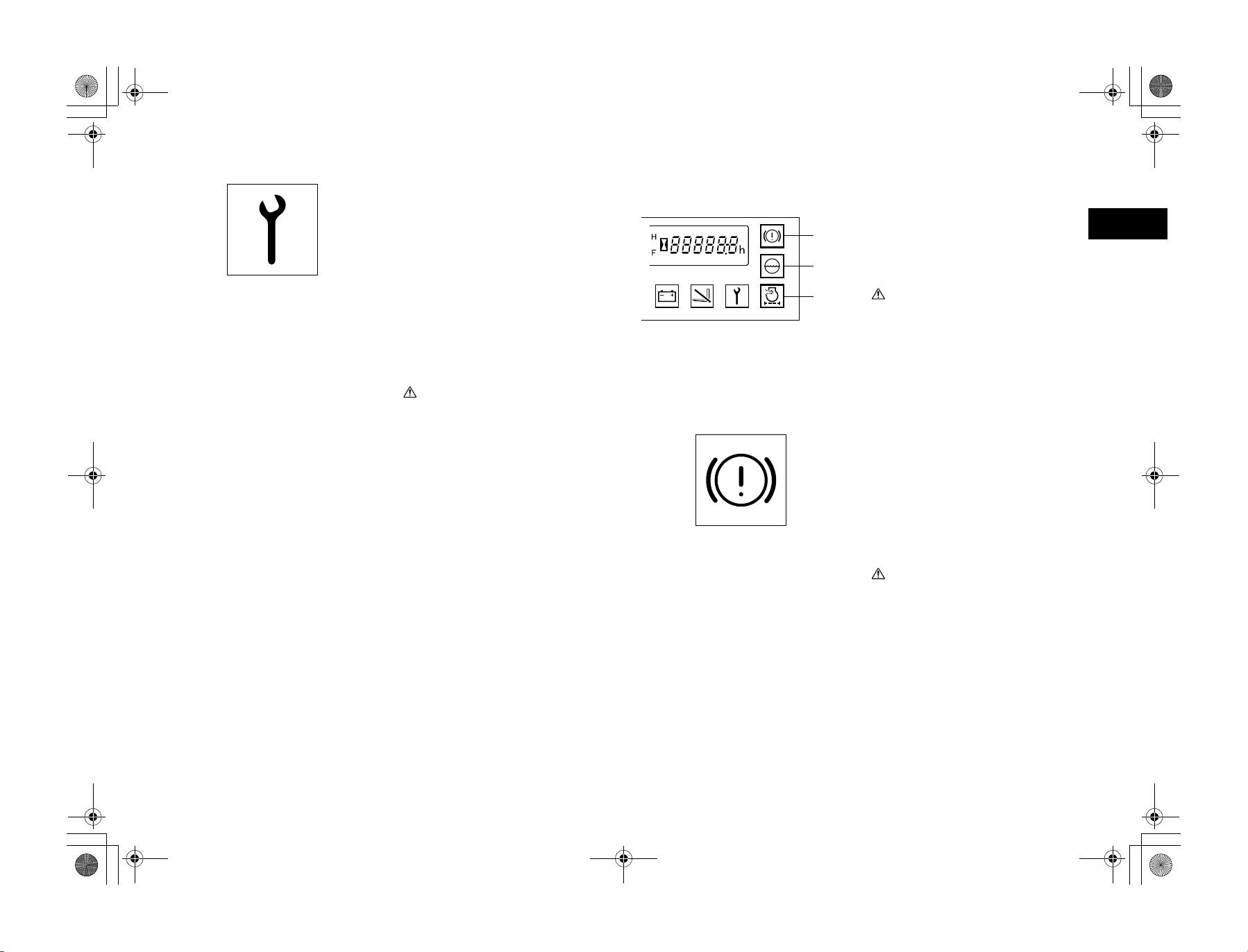

Diagnosis lamp

If an abnormality is registered by the SAS,

OPS, mini lever, or Auto speed control, the

respective lamps will light up or blink to

inform the operator and the diagnosis error

code will be displayed in the hour meter display area.

If the following conditions occur to the lamp,

there may be a system abnormality. Contact

your Toyota dealer to request an inspection.

• The lamp does not light up when the ignition switch is turned ON.

• The lamp lights up when ignition switch is

turned ON and stays ON.

• The lamp blinks during ignition switch is

turned ON.

CautionCaution

• Continuing to use the vehicle while the

diagnosis lamp is lighted or blinking

may lead to a breakdown. When the

lamp lights up or blinks, halt all operations and park the vehicle in a safe location. Contact your Toyota dealer to

request an inspection. (In the case of diesel engine vehicles, the diagnosis lamp

may light up during engine warm-up

after a cold-start, but does not indicate

an abnormality.)

• If the operator remains seated for a long

period with the ignition switch turned to

OFF, the next time the ignition switch is

turned to ON, the diagnosis lamp may

start blinking. If this occurs, leave the

seat. The diagnosis lamp will then turn

off.

(1) Brake warning lamp

(2) Coolant level warning lamp

(3) Air cleaner warning lamp

(1)

(2)

(3)

OK monitor (Option)

Senses the engine coolant level, brake fluid

level, clogged air cleaner element and parking

brake status. The lamp comes on to indicate a

problem. If the lamp comes on when the ignition switch is on (irrespective of the engine

speed), the corresponding part may be abnormal. Contact your Toyota dealer to request an

inspection.

CautionCaution

Always perform pre-operation checks. Do

not rely on the OK monitor, even if it is not

lit.

Brake warning lamp

When the parking brake is engaged or brake

liquid is low, the warning lamp will light up to

notify the operator.

1. The warning lamp will light up when the

parking brake is engaged. After disengaging the brake to operate the vehicle,

check to make sure the warning lamp has

turned off.

2. The lamp will light up to notify the operator when the brake oil is low.

CautionCaution

• If the warning lamp does not turn off

when the parking brake is disengaged,

the brake fluid may be low. Inspect the

brake fluid level and replenish it if necessary.

• If the warning lamp remains a lighted

even if the brake fluid level is sufficient,

contact your Toyota dealer to request an

inspection.

en

en-11

01_A5028-0E00_En.fm 12 ページ 2007年7月4日 水曜日 午後4時1分

(1)

Coolant level warning lamp

1. When the coolant level of the radiator

reserve tank becomes low, the indicator

lamp will light up to notify the operator.

2. If the lamp lights up while the engine is

running, this may indicate a deficiency in

coolant. Stop the engine and inspect the

coolant level in the radiator reserve tank

and the radiator. Before checking coolant

level in the radiator wait for it to cool as it

maybe under pressure when hot.

Note:

Even if the coolant level warning lamp is not

lighted, always inspect the coolant level before

starting operations.

Air cleaner warning lamp

1. This lamp comes on when the air cleaner

element gets clogged while engine is running.

2. If normal, the lamp comes on when the

ignition switch is turned to ON and goes

off when the engine starts.

3. If the lamp comes on while the engine is

running, stop operations and park the

vehicle in a safe location, stop the engine

and clean the element and dust cup. For

the cleaning method, refer to the Weekly

Inspection Section in this manual.

Brake warning lamp

(Wet brake models)

If the wet brake function is abnormal, the

warning lamp will light and warning buzzer

will sound to inform operator. When the warning lamp lights and buzzer sounds, cease work

operation and stop the vehicle in a safe place.

Securely set the parking brake and fully

depress the brake pedal until buzzer stops with

the engine still running. After confirming that

buzzer is turned off and warning lamp goes off,

restart the work operation.

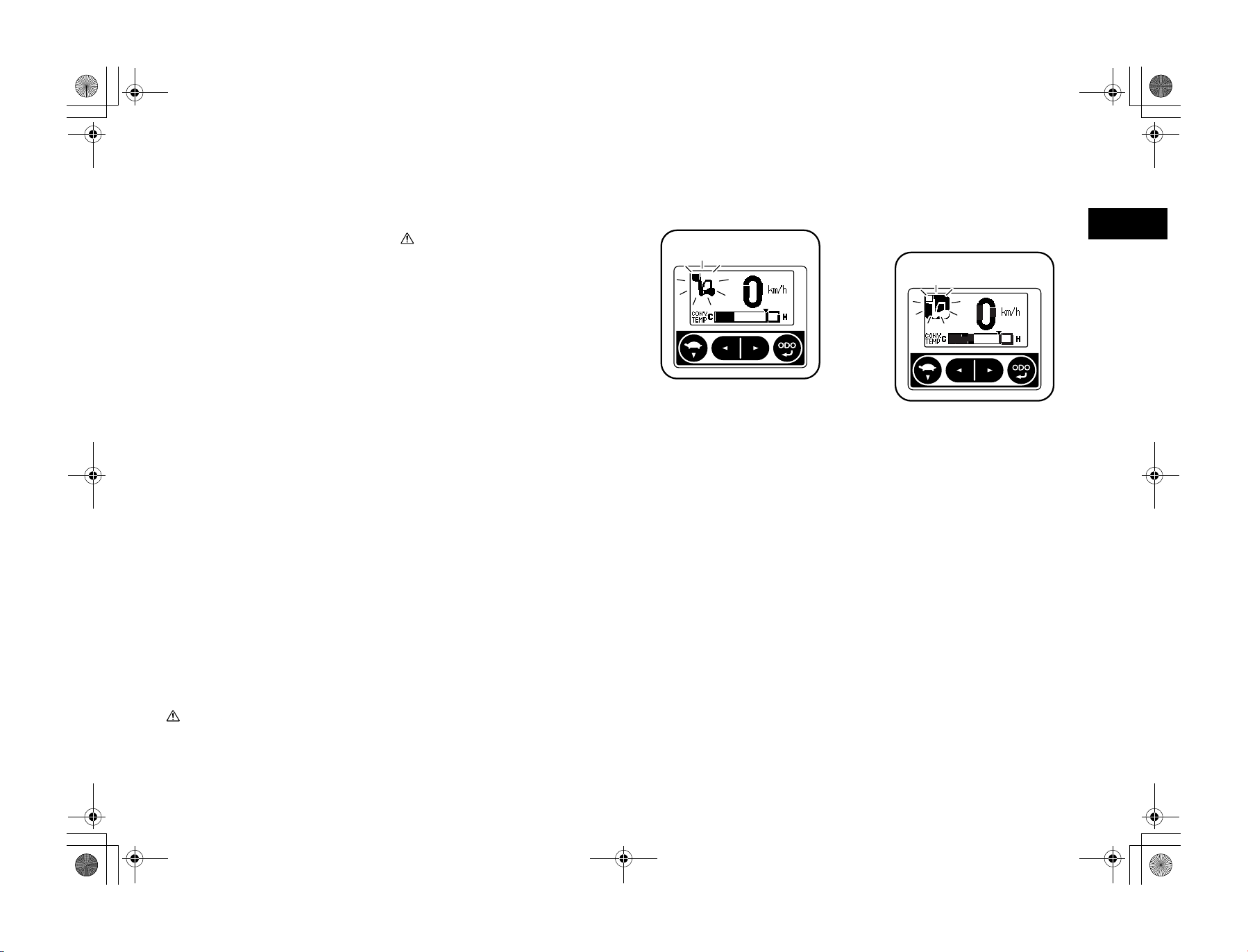

MULTIFUNCTION DISPLAY (OPTION)

1. Multifunction display area

(Multifunction display)

(Multifunction display DX)

1

2 3 4 5

(Multifunction display DX:

Vehicles with Auto speed control)

6 3 4 5

2. Down switch

3. Left switch

4. Right switch

5. Meter display switch

6. Low speed setting switch (Only for DX

models with Auto speed control)

(1) Brake warning lamp

en-12

CautionCaution

If the warning lamp does not go off or

buzzer does not stop even when the brake

pedal is depressed, ask a Toyota dealer for

an inspection.

01_A5028-0E00_En.fm 13 ページ 2007年7月4日 水曜日 午後4時1分

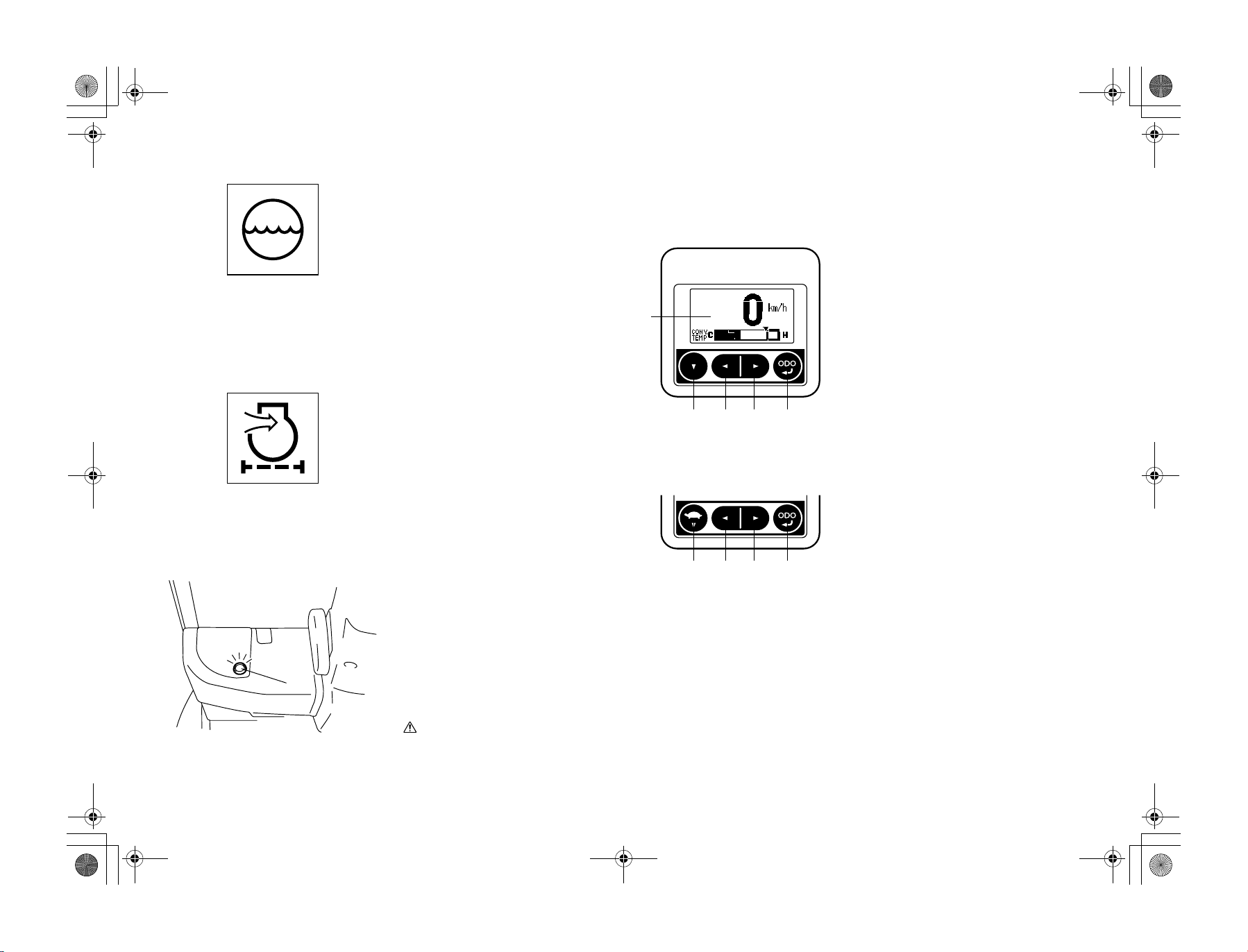

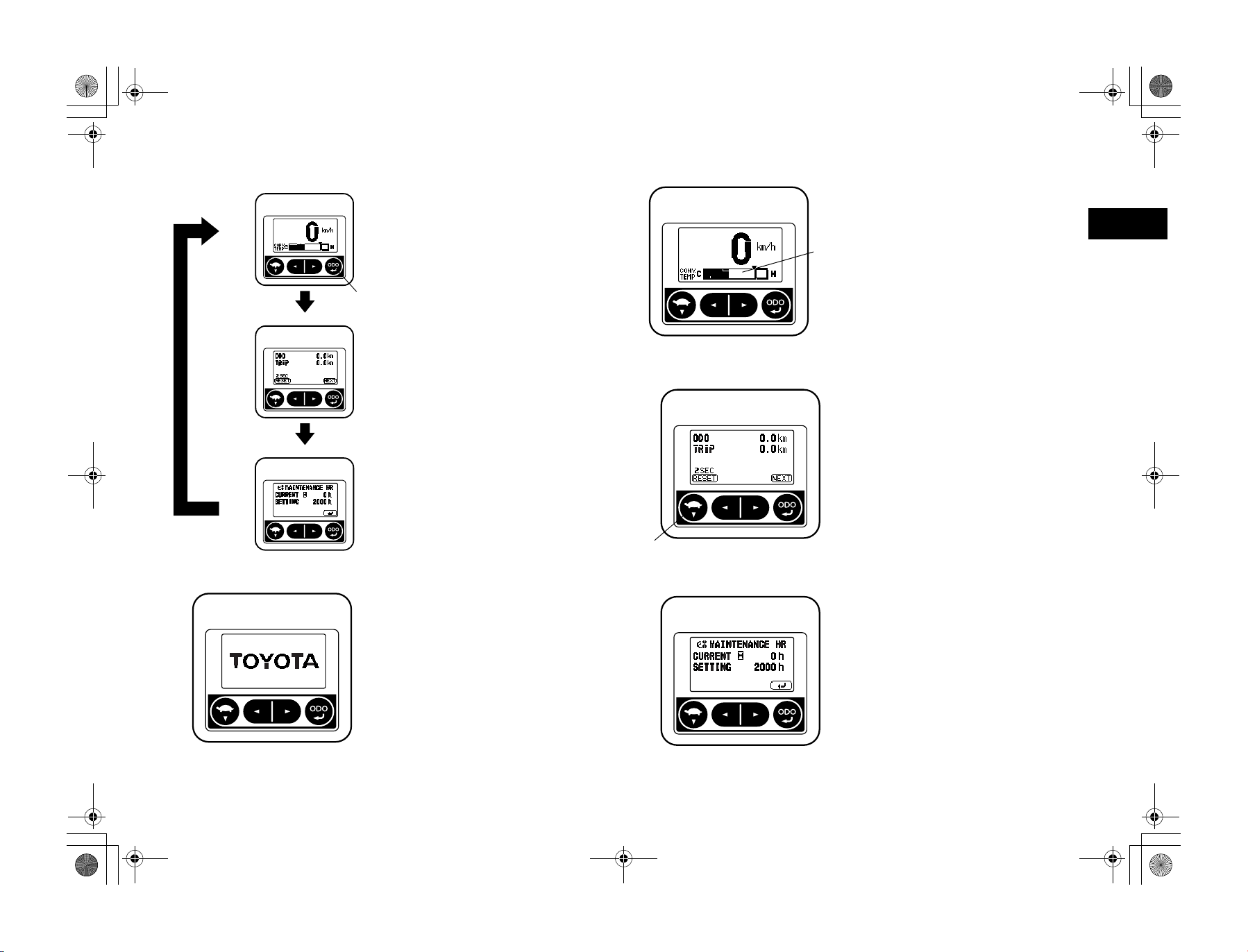

Digital speed meter display

ODO • TRIP Meter display

Maintenance display

(1) Meter display switch

(1)

DISPLAY SCREEN TABLE

From the standard screen display, pressing the

meter display switch will change the display

between ODO, TRIP, and Maintenance Hour

Meter display screens.

Note:

Always operate the switch panel with your finger tips and when the vehicle is stopped.

Start screen

When the ignition switch is turned to ON, the

start screen will appear for 1 second.

Note:

BT Specification (Option) will not display

anything for 1 second when the ignition switch

is turned to ON.

(1)

(1) Torque converter oil temperature gauge

(1)

(1) Low speed setting switch or down switch

Standard screen

Vehicle speed is digitally indicated in km/h at

the top of the screen. At the bottom of the

screen, torque converter oil temperature is

indicated in a 10-stage level.

ODO • TRIP meter

ODO......... Displays the total distance traveled.

TRIP......... After resetting this function, dis-

Note:

• Pressing the low speed setting switch (DX

• Always operate the switch panel with your

plays the total distance traveled

until now.

models with Auto speed control) or the

down switch for more than 2 seconds will

reset the total travel distance.

finger tips and when the vehicle is stopped.

Maintenance hour meter

Displays the set value and current value of the

maintenance hour meter.

CURRENT...............Displays the current time.

SETTING.................Displays the maintenance

The maintenance hour meter time setting can

be set between 10-2000 hours. 10-200 hours

setting can be set in 10 hour intervals, and 2002000 hours setting can be set in 50 hour intervals.

Note:

To change the time setting, consult your supervisor or Toyota dealer.

hour time setting.

en

en-13

01_A5028-0E00_En.fm 14 ページ 2007年7月4日 水曜日 午後4時1分

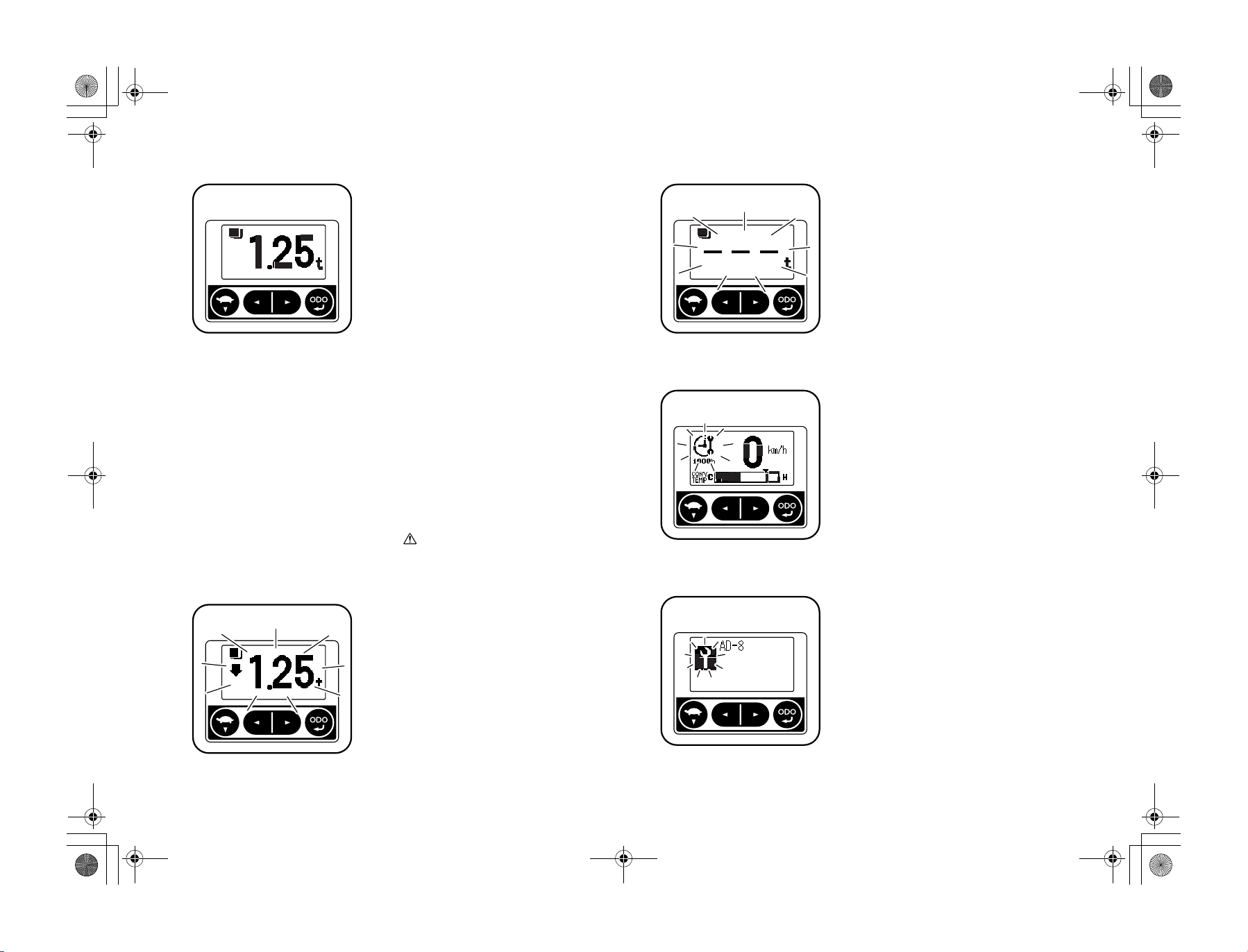

Load meter

(Only with DX models)

Pressing the lift lever knob switch or the load

meter switch (mini lever models) will allow

the operator to confirm the weight of the load

being handled.

Note:

In the case of joy stick models (Option), the

load meter switch and fork automatic leveling

control switch functions are combined.

1. Adjust the load to a height of 500mm

above ground level and set the mast vertical.

2. In the standard screen, press the lift lever

knob switch or the load meter switch

(mini lever models).

Note:

• For each operation, the meter reading will

display for 3 seconds. (the display will

remain indicated while the switch is held

down).

• Pressing the lift lever knob switch or the

load meter switch (mini lever models)

while the vehicle is traveling will not display the load display screen.

• If the load is less than 100kg, the meter will

indicate 0.00t.

CautionCaution

This function should be used as reference

when conducting handling operations, and

not used in business dealings or as proof.

Load meter error display

When the load meter is operated while the load

is in an elevated position, an arrow will appear

at screen left and the measured weight indication will blink to notify the operator that the

reading is inaccurate.

To measure the load, always set the load to a

height of approximately 500mm above ground

and set the mast vertical.

Note:

If 0 is slightly deviated toward the minus side,

the display will indicate -0.00 t.

Load meter sensor error display

When the load meter sensor malfunctions, the

display will blink as indicated in the diagram at

left.

Note:

When the load meter sensor blinks to indicate

an error, contact your Toyota dealer to request

an inspection.

Maintenance indicator

When the reset maintenance time occurs, the

operator will be notified through the display

and a warning sound. Conduct necessary maintenance.

Note:

The maintenance time setting should be determined by the supervisor. For information on

setting the maintenance time, contact your

supervisor or Toyota dealer.

Diagnosis indicator

If an abnormality is registered within the Multifunction display, the operator is notified

through a warning sound together with diagnosis error content display.

Note:

• The error code display will be different

depending on the abnormal area and nature

of the abnormality. There are also occasions when the error is not indicated

depending on the area of abnormality.

• When the diagnosis indicator is displayed,

contact your Toyota dealer to request an

inspection.

en-14

01_A5028-0E00_En.fm 15 ページ 2007年7月4日 水曜日 午後4時1分

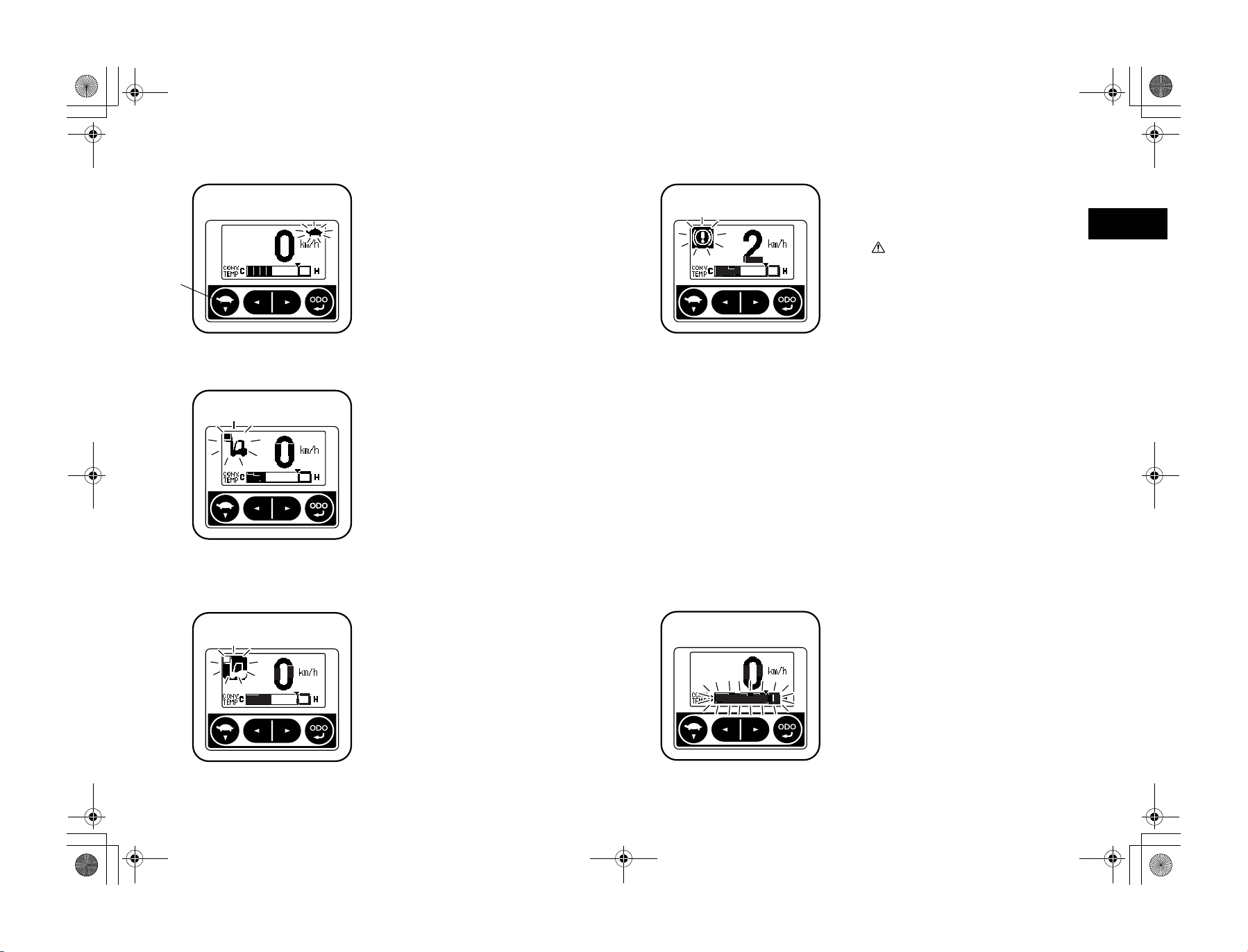

(1)

(1) Low speed setting switch

Low speed setting indicator

(Only for DX models with Auto

speed control)

When low speed settings have been set, the

turtle mark is displayed.

Each time the low speed setting switch is

pressed, the turtle indicator will light up. When

the indicator is lighted, the low speed setting

control is active.

Note:

Always operate the switch panel with your finger tips.

Auto speed control indicator

(Only for DX models with Auto

speed control)

When the load height and weight sensors to

prevent sudden acceleration or the speed limits

after load lifting height and weight sensing are

in operation, the auto speed control indicator is

displayed to inform the operator.

Function on/off indicator

(Only for DX models with Auto

speed control)

Even when the speed limits after load lifting

height and weight sensing is deactivated, the

operator is notified via display indication that

the preventing sudden starts function is active.

Parking brake on warning

When the parking brake is engaged while the

lift vehicle is traveling, the warning indicator

will blink and a warning will sound to notify

the operator.

CautionCaution

• If the vehicle is operated without disengaging the parking brake, the brake will

lose effectiveness. Contact your Toyota

dealer to request an inspection.

• If the indicator lamp does not turn off

even when the parking brake is disengaged, stop operations and contact your

Toyota dealer to request inspection.

Parking brake off warning

When the ignition switch is turned to OFF or

the operator leaves the seat while the parking

brake is disengaged, a warning sound will

warn the operator to apply the parking brake.

The warning will also be sounded if the operator returns to the normal seated position and

turns the ignition switch to ON while the parking brake is disengaged.

Note:

• When the parking brake is applied, the

warning sound will stop.

• When leaving the driver's seat, always shift

to NEUTRAL, set the parking brake, lower

the forks, and tilt forward so the tips will

not trip pedestrians, and turn off the ignition switch.

Torque converter oil temperature

overheating warning

When the torque converter oil temperature

reaches level 9 on the indicator (120ºC or

over), the indicator will blink to notify the

operator. When the indicator reaches level 10

(140ºC or over), the entire indicator will blink

to notify the operator.

Note:

When the warning lamp blinks, park the vehicle in a safe location, engage the parking

brake, open the engine hood with the motor

idling, to assist in the cooling of the torque

converter oil.

en

en-15

01_A5028-0E00_En.fm 16 ページ 2007年7月4日 水曜日 午後4時1分

Over-speed alarm

(Only for DX models)

When the set traveling speed is exceeded, the

speed meter will blink and a warning will

sound to notify the operator.

Note:

This function does not limit traveling speed

and is an indication only. Pay attention to your

speed when operating the vehicle.

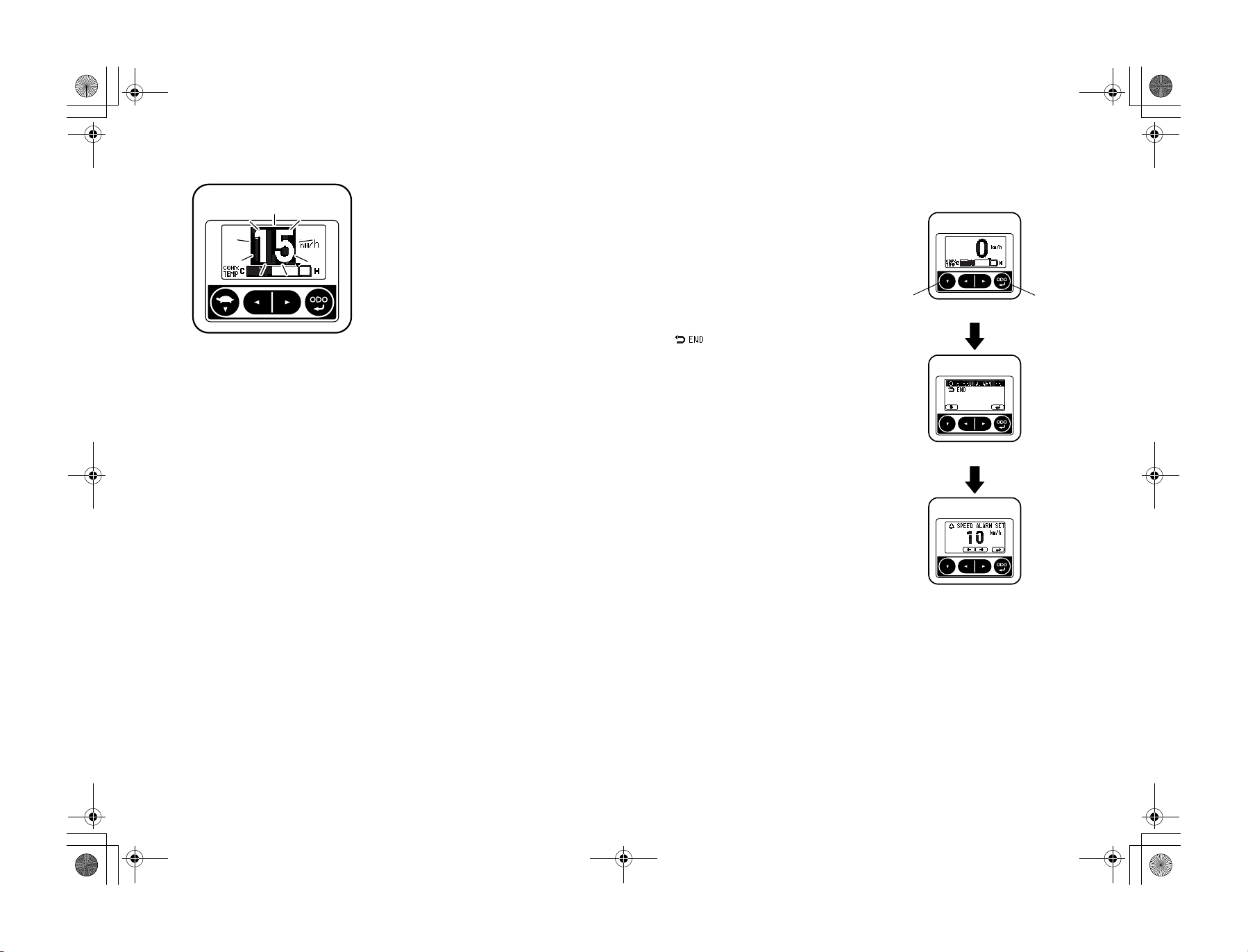

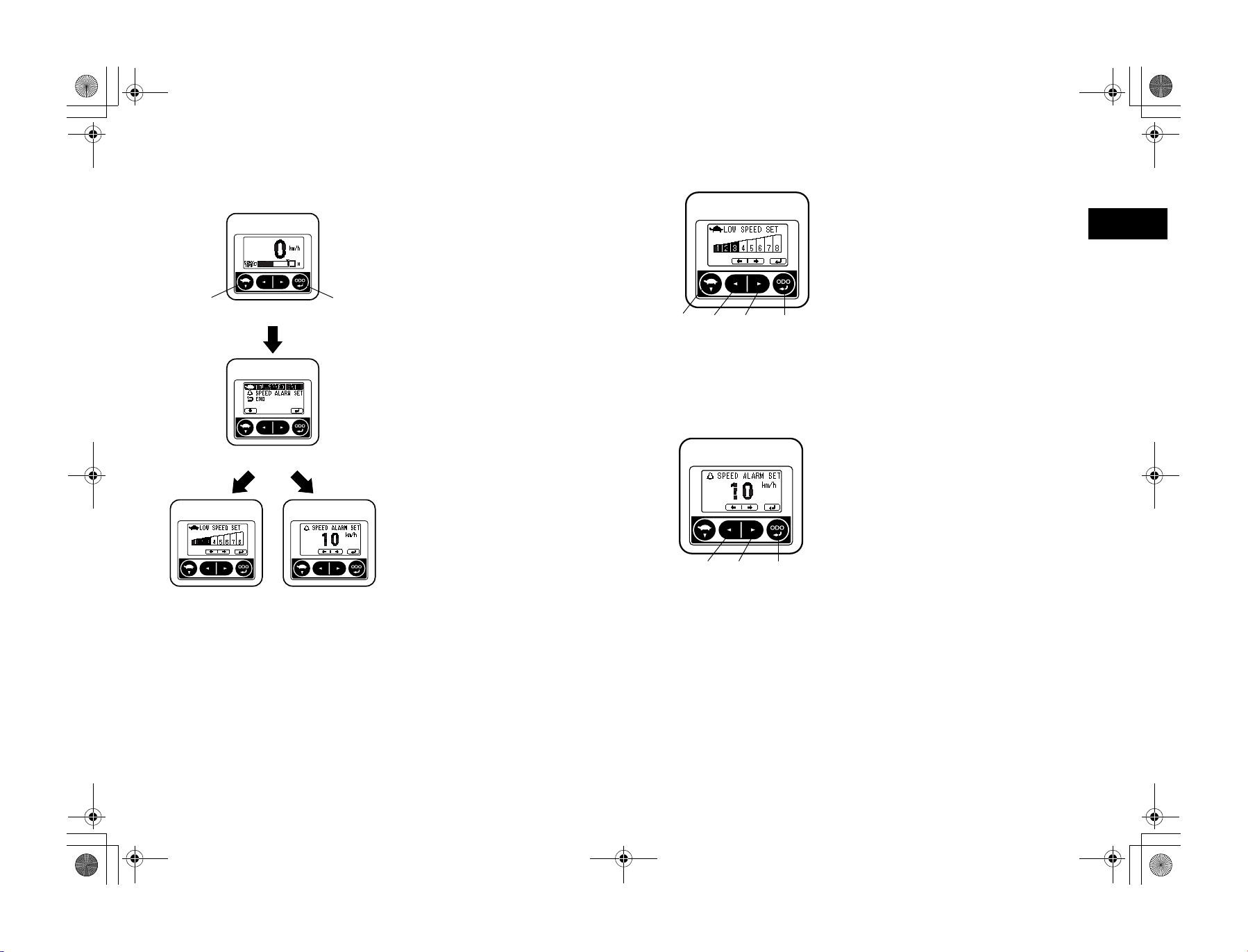

Setting menu screen

With the Multifunction display, pressing the

low speed setting switch or the down switch in

the standard screen for more than 2 seconds

will display the setting menu screen.

Note:

When the supervisor locks the menu, these

screen settings can not be displayed.

Selecting the options using the low speed setting switch or the down switch and then pressing the meter display switch will display each

screen setting.

Select [ ] in the setting menu screen,

and then pressing the meter display switch will

return to the standard screen.

Note:

Always operate the switch panel using your

finger tips.

Vehicles having Multifunction display DX

(1) (2)

<Standard screen>

<Setting menu screen>

en-16

<Over-speed alarm setting screen>

(1) Down switch

(2) Meter display switch

01_A5028-0E00_En.fm 17 ページ 2007年7月4日 水曜日 午後4時1分

Vehicles with Auto speed control and

Multifunction display DX

(1) (2)

<Standard screen>

<Setting menu screen>

(1) (2) (4)(3)

(1) Low speed setting switch

(2) Left switch

(3) Right switch

(4) Meter display switch

(2) (3) (4)

Low speed setting screen

When the low speed settings are activated, a

range of 8 maximum speed settings can be

established.

Selecting the level 8 setting will turn off the

function.

Left switch ............. Decreases the setting level

Right switch .............Increases the setting level

Meter display switch...... Switches to the menu

screen

Note:

• If level 8 is selected, the setting cannot be

changed by pressing the low speed setting

switch or the down switch in the standard

screen.

• Always operate the switch panel using your

finger tips.

Over-speed alarm setting screen

This function allows you to set the traveling

speed which will set off the alarm.

Left switch ...................... Reduces travel speed

Right switch ...................Increases travel speed

Meter display switch...... Switches to the menu

Note:

Always operate the switch panel using your

finger tips.

screen

en

<Low speed setting

screen>

<Over-speed alarm setting screen>

(1) Low speed setting switch

(2) Meter display switch

(2) Left switch

(3) Right switch

(4) Meter display switch

en-17

01_A5028-0E00_En.fm 18 ページ 2007年7月4日 水曜日 午後4時1分

SWITCHES AND LEVERS

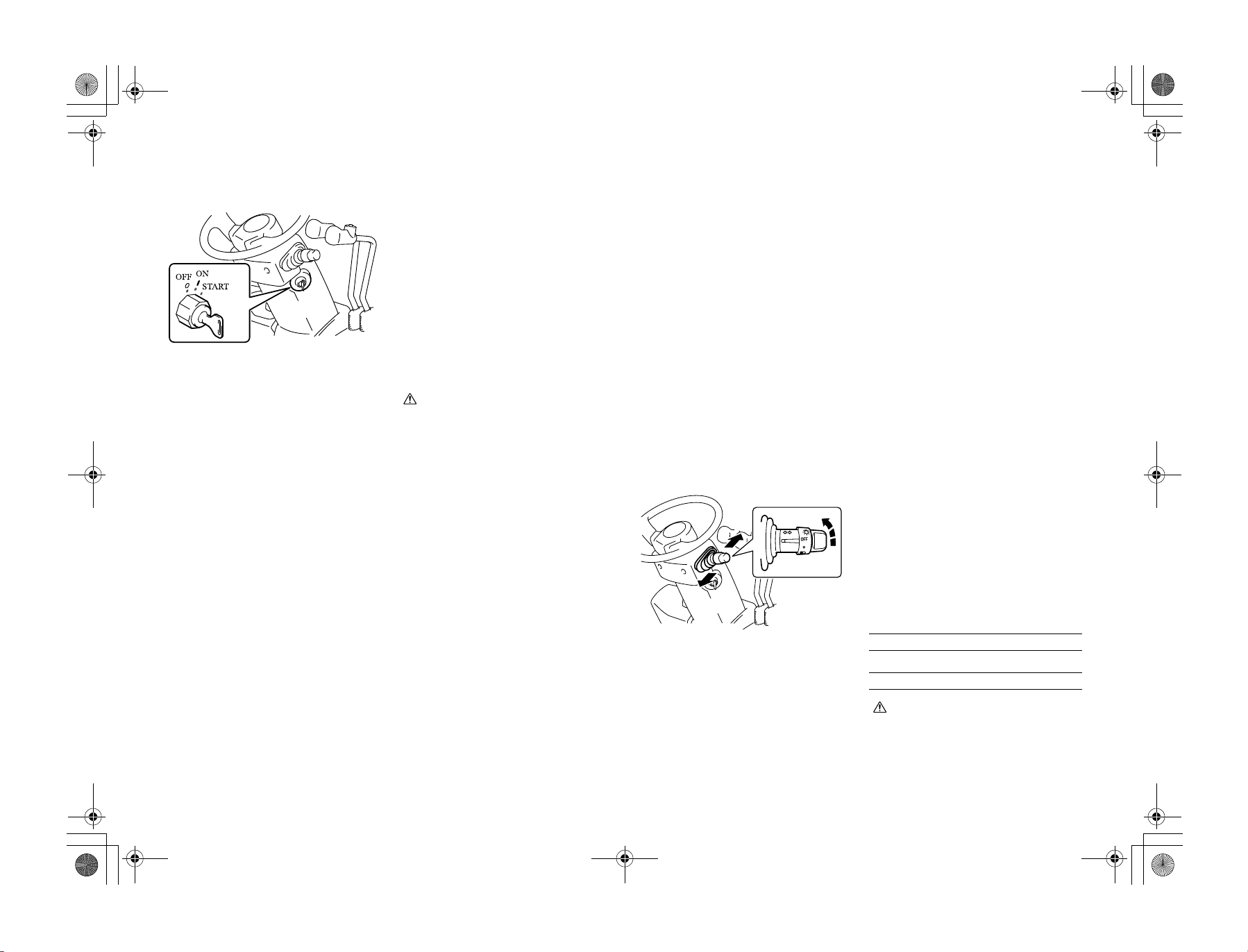

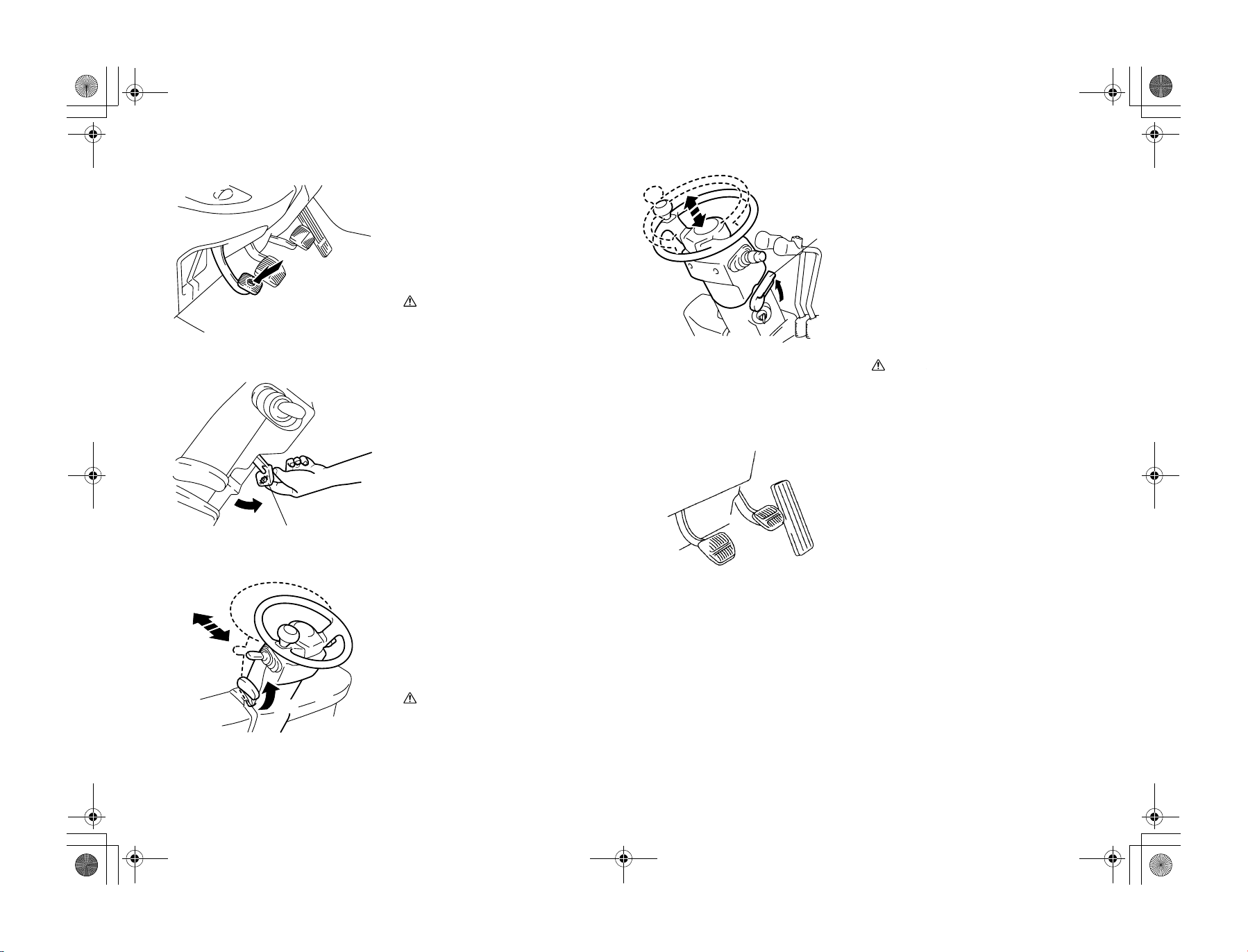

Ignition switch

{ [OFF] ....... Engine stop position.

I [ON]......... Engine operation position.

The intake heater is preheated before starting

in the diesel models.

START ............ Engine, start position. Located

After the engine starts, release the key and it

will return to the I [ON] position automatically.

In the torque converter model, the engine does

not start unless the control lever is set in the

neutral position.

CautionCaution

• Never operate the ignition switch without first sitting on the seat. Otherwise,

the forklift could start to move uncontrolled, causing an accident.

• When the OPS lamp is on, return each

lever to the neutral position and sit on

the seat.

Then confirm that the lamp has gone off.

• Do not leave the switch in the [ON] position when the engine is stopped. It may

cause over discharge of the battery.

• Do not turn the switch to the START

position while the engine is running.

• For the sake of safety it is recommended

to always start the engine of a vehicle

with the transmission gear shift lever

shifted in the neutral position.

• Do not operate the starter motor for

more than 30 seconds continuously.

Return the switch to the [OFF] position

and wait at least 30 seconds prior to

attempting restart.

• In case of the anti-restart ignition switch

(optionally available), be sure to shift the

switch to the [OFF] position before

attempting to start the engine again.

Key insertion and withdrawal

are performed in this position.

Located one position clockwise from { [OFF] position.

one position clockwise from

the I [ON] position.

(2)

(1) Left turn

(2) Right turn

(1)

• With the ignition switch OFF (engine

off), the forks will not lower even if the

lift lever is operated. However, if you sit

in the seat and turn on the ignition

switch, you can lower the forks. (Except

mini lever models) Do not operate the lift

lever before getting on the vehicle and

starting up the engine. (key-off, lift

locked)

• If the diagnosis lamp does not go off even

when the operator sits on the seat, the

battery power may be low. In such a

case, do not drive the vehicle until the

lamp goes off, otherwise the vehicle may

not operate correctly. If you are obliged

to drive the vehicle, do so with the

utmost care. Also, stop driving and ask a

Toyota dealer for inspection if the lamp

does not go off 1-2 minutes after the

engine starts, or when you race the

engine for a while. (For diesel vehicles,

the diagnosis lamp may be on for a while

to warm up the engine after cold starting. This is, however, not an engine malfunction or failure.)

Integrated light and turn signal

switch

This two-position switch serves as both a light

switch and turn signal switch.

Light control switch

Irrespective of a ignition switch position, this

switch allows you to turn on and off the lights.

This switch has two positions. With the switch

at each position, the light comes on as shown

below.

Lamp name Step 1 Step 2

Head lamps

Side clearance lamps, tail lamps

(Option)

Meter illumination lamp

Caution

Caution

Do not keep lights such as head lights on for

a long period when the engine is stopped. It

may cause over discharge of the battery and

make engine starting impossible.

−

{{

{{

{

en-18

01_A5028-0E00_En.fm 19 ページ 2007年7月4日 水曜日 午後4時1分

(1) Forward

(2) Reverse

(1)

(2)

Turn signal switch

Makes the turn signal lamps blink

Left turn ................................... Push forward

Right turn ................................ Pull backward

The signal switch will operate when the ignition switch is ON.

The turn signal lever returns automatically to

the original position after making a direction

change.

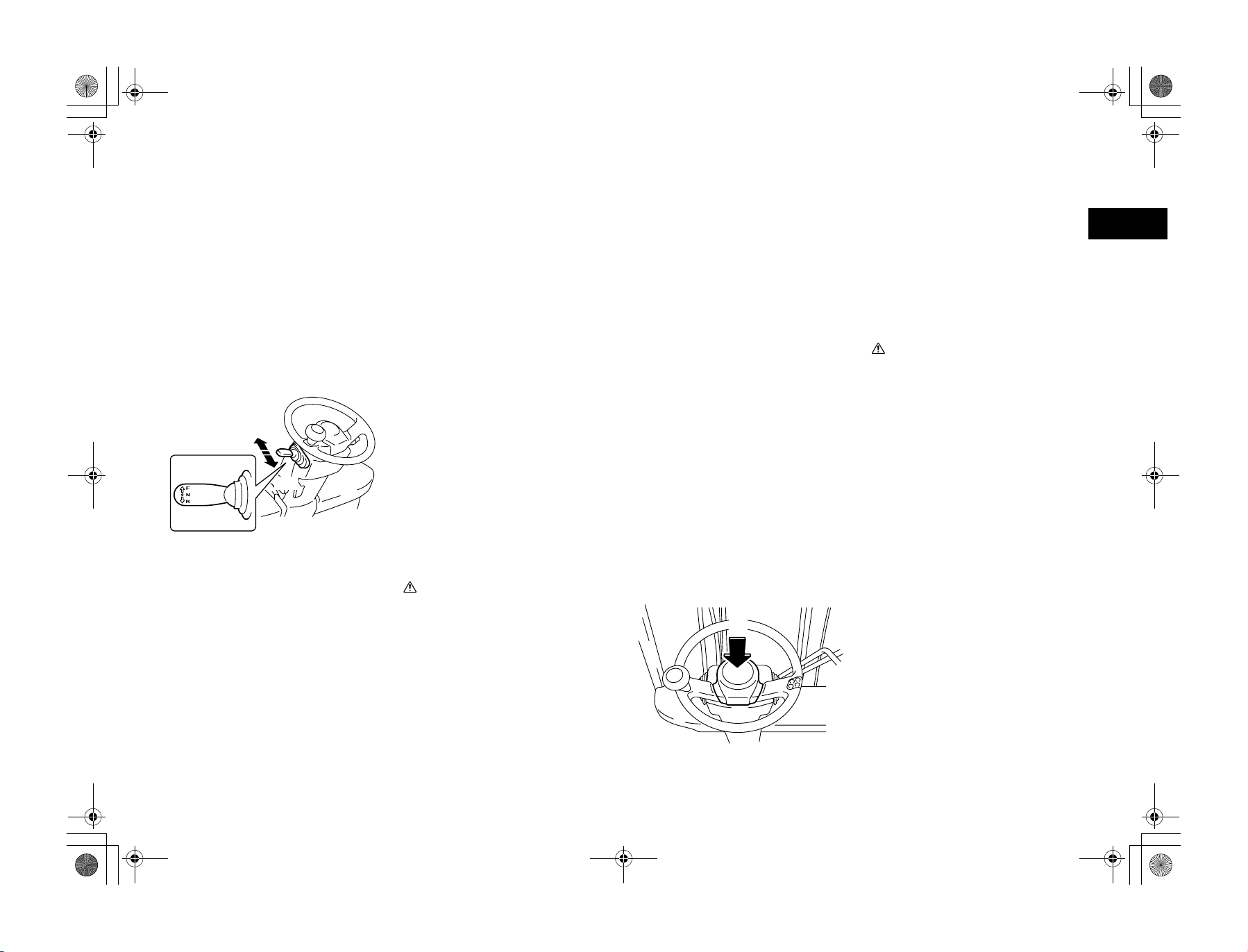

Control lever

Lever for shifting between forward and

reverse.

Forward.................................... Push forward

Reverse..................................... Pull backward

The neutral position is halfway between the forward

and reverse position.

Note:

After the OPS System operates, return the

accelerator pedal to its fully released position

and set the control lever to the neutral position,

and sit on the seat to restart driving. (Even

though the operator sits on the seat, driving is

impossible unless the control lever is in the

neutral position.)

CautionCaution

The engine cannot be started unless the control lever is in the neutral position.

Stop the vehicle before shifting between forward and reverse direction.

(1)

Torque converter interlock function

(Option)

If you switch the control lever direction to

something other than the current travel direction while moving at high speed, this function

electrically disengages the drive and sets the

torque converter to neutral. Once the speed

drops below the set speed while running in

neutral, the travel direction is automatically

switched.

To change travel direction, operate the control

lever after travel speed is reduced sufficiently.

Ask your Toyota dealer for changing speed setting.

CautionCaution

• When the interlock has engaged, release

the accelerator pedal and use the brake

pedal to reduce speed. After the vehicle

has stopped moving, slowly press the

accelerator pedal down to start moving

again. Disengaging the interlock while

the accelerator pedal is pressed down

could result in wheel spin.

• Do not perform Forward or Backward

operation on slopes. If control lever is

operated on a down slope, torque converter interlock function may not operate correctly.

Horn button

Press the button in the center of the steering

wheel to sound the horn.

The horn will sound even when the ignition

switch is OFF.

en

(1) Push

en-19

01_A5028-0E00_En.fm 20 ページ 2007年7月4日 水曜日 午後4時1分

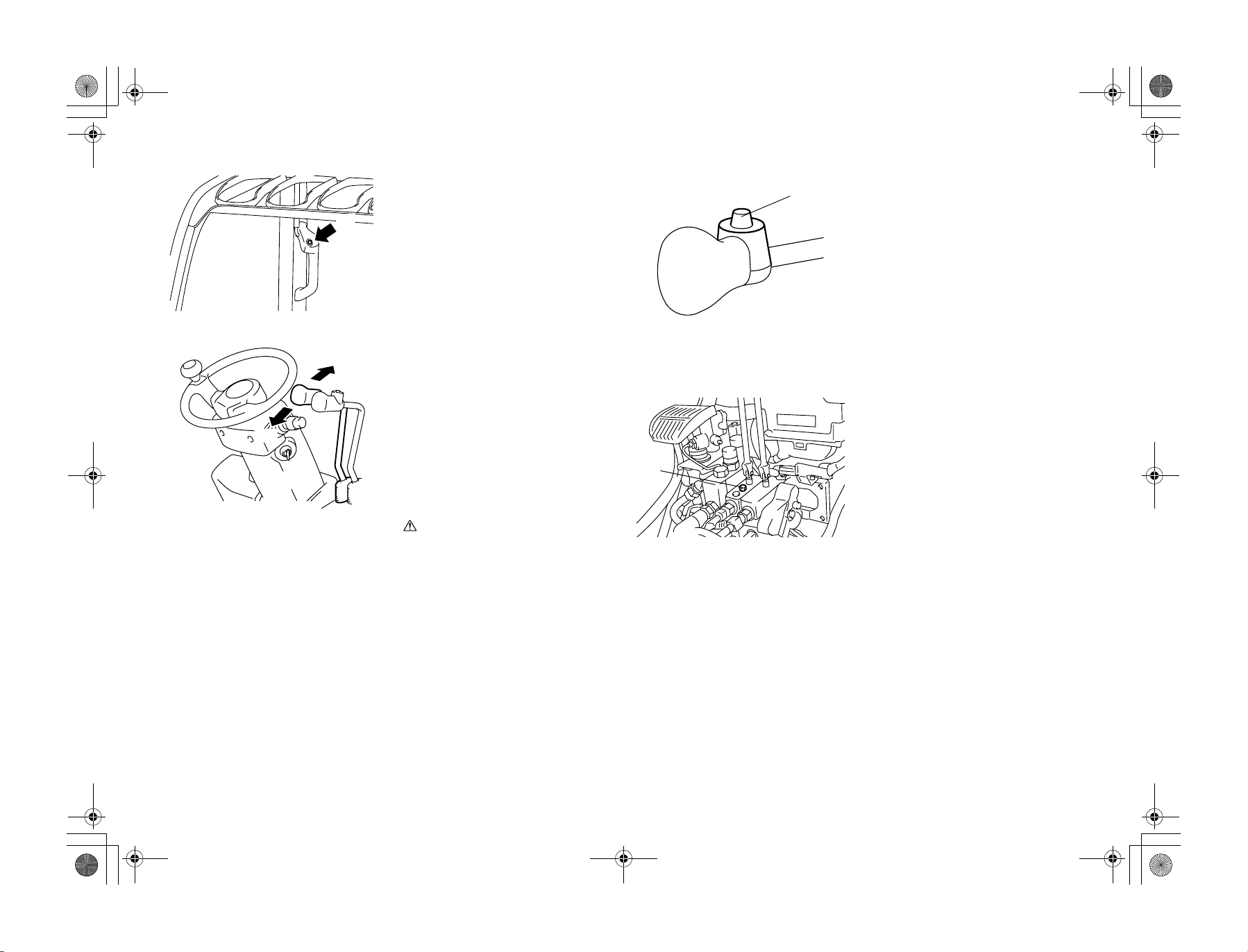

(1) Push

(1) Lower

(2) Raise

(2)

(1)

(1)

Horn button (Option)

The horn will sound when the button at the top

of the rear pillar assist grip is pressed. Use this

horn when backing up.

The horn will sound even when the ignition

switch is OFF.

Lift lever

Raises and lowers the forks.

Raise.......................................... Pull backward

Lower ......................................... Push forward

The lifting speed can be adjusted by how far

the accelerator pedal is depressed and how far

the lever is pull back.

The lowering speed can be adjusted only by

how far the lever is pushed forward.

Note:

The idling lifting speed increase function

(Option) automatically increases lifting speed

by engaging the lift lever.

CautionCaution

• After the OPS System operates, return

the accelerator pedal to its fully released

position and set the lift lever to the neutral position, and sit on the seat to restart

the operation. (If you sit on the seat

while raising the lift lever, the forks will

start to move 1 second later.)

• If you sit on the seat while lowering the

lift lever, the forks will not lower due to

the return to neutral function.

• Always operate the lift lever while correctly seated.

• When the ignition switch is turned to

OFF and lowering the lift lever, the forks

will not lower. However, if the operator

sits in the normal seated position then

the ignition switch is turned to ON, the

forks will be lower even if the engine is

off. (Except mini-lever/joy stick models)

(1) Lift lever knob switch

(1)

(1) Lift lock release bolt

(1)

Lift lever knob switch

(Option)

For vehicles with Multifunction display DX

(Option), pressing the lift lever knob switch

will display the weight of load.

Note:

• Operate this function when you are not performing loading operations.

• When weighing the load, always remember

to position the load at a height of about

500mm above the ground and make the

mast perpendicular.

Key-lift interlock

When the ignition switch is OFF, the lift will

not descend even if the lift lever is lowered.

However, if the operator sits properly in the

seat and turns the ignition switch ON, the forks

can be lowered even if the engine is off

(Except mini lever/joy stick models).

If the ignition switch cannot be turned ON for

whatever reason, loosen the manual lowering

valve located on the oil control valve beneath

the toe board, and operate the lift lever in the

downward direction.

Note:

Once the forks have been lowered with the lift

lock release bolt, close and lock the valve.

en-20

01_A5028-0E00_En.fm 21 ページ 2007年7月4日 水曜日 午後4時1分

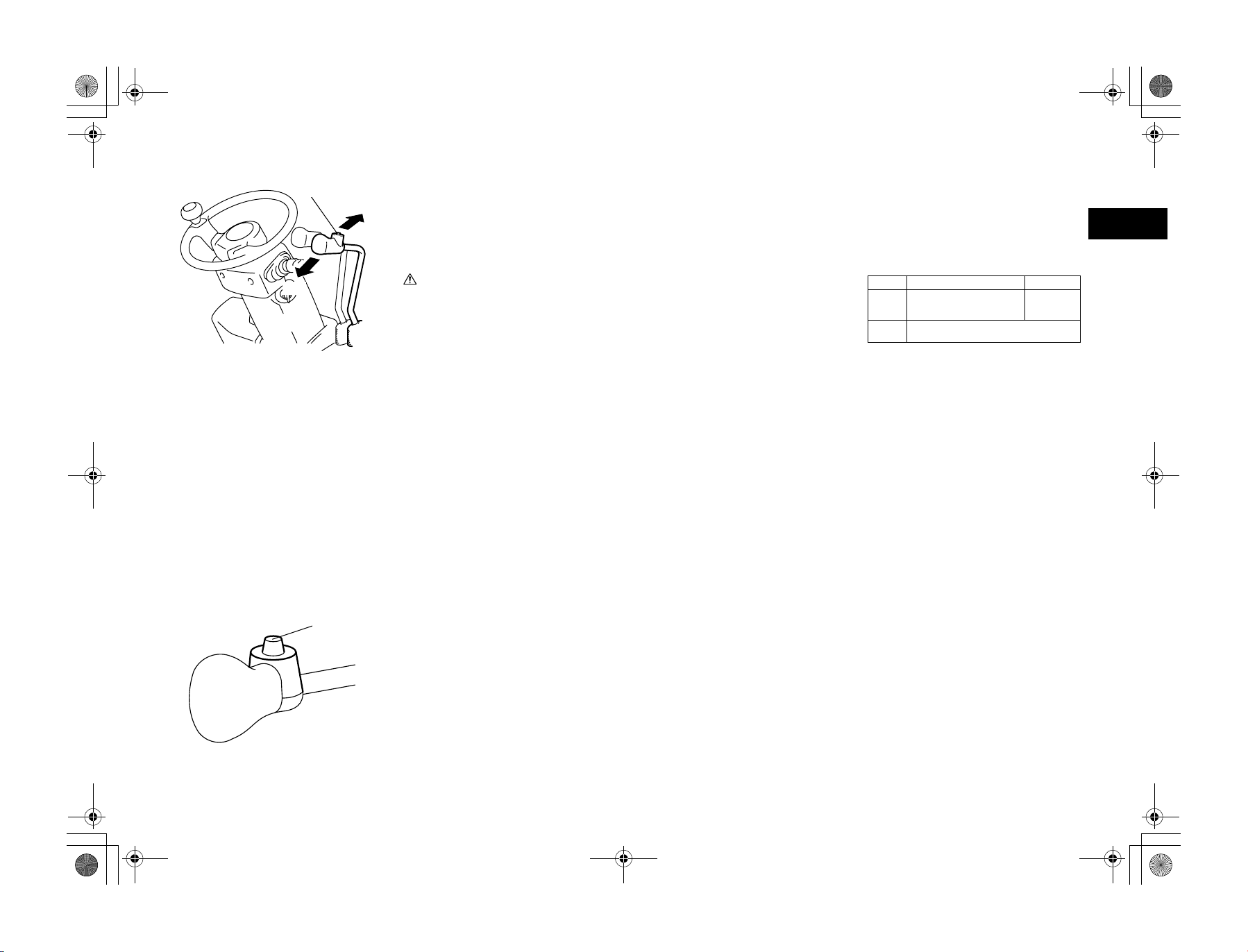

(1) Forward tilting

(2) Backward tilting

(3) Tilt lever knob switch

(2)

(3)

(1)

Tilt lever

Tilts the mast forward and backward.

Forward.................................... Push forward

Backward................................. Pull backward

The forward or backward tilting speed can be

adjusted by the degrees of accelerator pedal

depression and lever operating stroke.

CautionCaution

• Insure the load-handling control levers

are in their neutral positions before

returning to the operator's seat, if not

load-handling functions will start movement 1 second after operator returns to

the seat.

• Always operate the tilt lever from a

seated position.

• After the OPS System operates, return

the accelerator pedal to its fully released

position and the tilt lever to the neutral

position, and sit on the seat to restart the

operation. (If the operator sits on the

seat without returning the load-handling

control levers to their neutral positions,

load-handling functions will start movement 1 second after.)

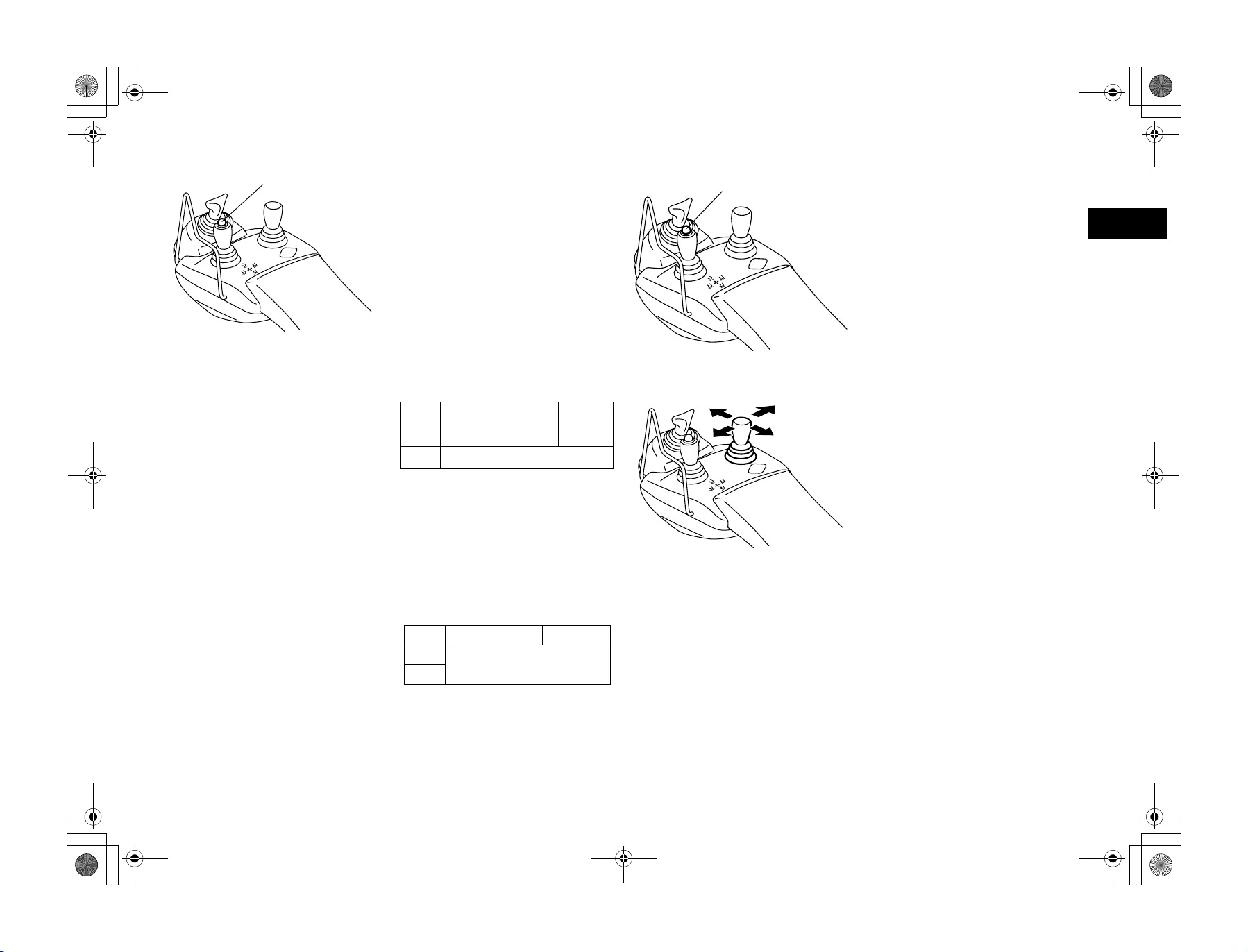

Automatic forks leveling control

With the forks positioned at backward tilt, use

the lever to tilt the forks forward while

depressing the tilt lever knob. Then, the mast

will be automatically stopped with the forks

horizontally positioned.

Motion upon change of tilt from backward to

forward, with tilt lever knob switch pressed:

High lift Forks stopped at its horizontal

Low lift Forks stopped at its horizontal position (with mast

Not loaded Loaded

position (with mast vertically

positioned)

vertically positioned)

No forward tilt

Active mast rear tilt speed control

At a high lift height, the mast has a backward

tilt speed controller (slow down) irrespective

of the load. When lowering from a high lift

height to a lower lift height while tilting the

mast backward, the control speed will not

change.

At a low lift height, the mast can be tilted at

full speed even if there is a load. If the mast is

tilted backward at a low lift height with the tilt

knob switch pressed, the mast has the backward tilt speed controlled (slowed down) as

long as the tilt lever knob switch is pressed.

When the fork enters the upper lift height stage

from the lower one, the rear tilt speed will be

restrained as long as the automatic fork leveling control switch is depressed. If the switch is

not depressed, the fully open speed will be

applied.

en

(1) Tilt lever knob switch

(1)

Tilt lever knob switch

Depressing the tilt lever knob switch while

changing from backward to forward tilt will

automatically stop forks at their horizontal

position.

It is also possible to slow down the backward

tilt speed at a low lift height by depressing

knob switch.

en-21

01_A5028-0E00_En.fm 22 ページ 2007年7月4日 水曜日 午後4時1分

(1)

(1) Forward

(2) Backward

(1)

(1) Lower

(2) Raise

(2)

(2)

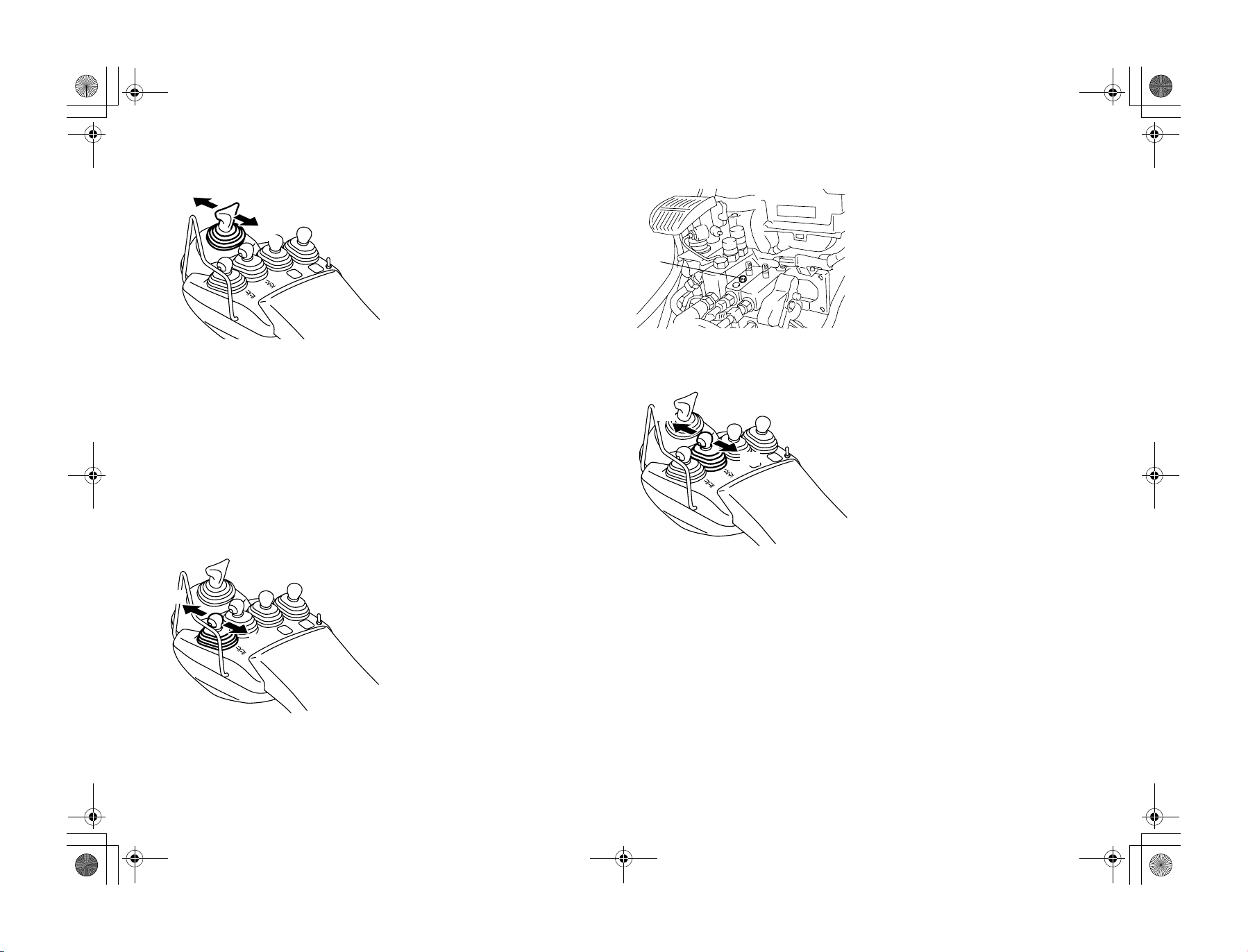

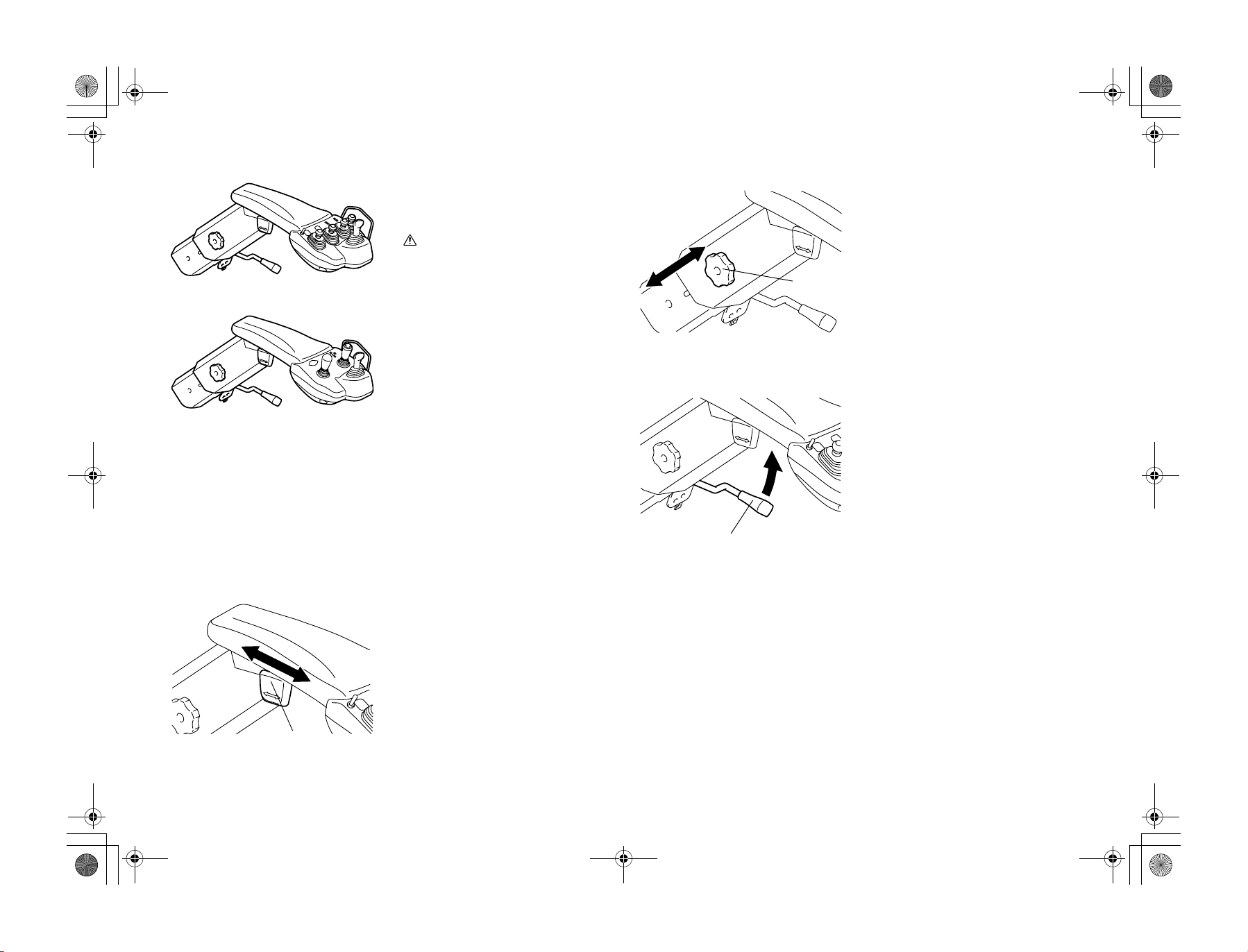

Mini lever (Option)

Control lever

Lever for shifting between forward and

reverse.

Forward.................................... Push forward

Reverse..................................... Pull backward

The speed of forward and backward traveling

can be adjusted by the extent of pressing the

accelerator pedal.

Note:

• Stop the vehicle before shifting between

forward and backward traveling.

• After the OPS System has been activated,

return the accelerator pedal and control

lever to their neutral positions and return to

the seat before recommencing operations.

• Always operate the control lever from a

properly seated position.

• Depending on the vehicle specifications,

the position of the control lever may vary.

Lift lever

Raise and lower the forks for loading.

Raise.......................................... Pull backward

Lower ......................................... Push forward

Raising speed can be adjusted by the extent of

pressing the accelerator pedal and pulling the

lift lever.

Lowering speed can be adjusted by the extent

of pushing the lift lever.

Note:

• After the OPS System has been activated,

return the accelerator pedal and all of the

levers to their neutral positions and return

to the seat before recommencing operations.

• If you return to the seat while lowering the

lift lever, the forks will not descend due to

the return to neutral function.

• Always operate the lift lever from a properly seated position.

(1)

(1) Lift lock release bolt

(1)

(1) Forward

(2) Backward

(2)

Note:

• If you use the idling lifting speed increase

function (Option), pulling the lift lever will

automatically increase the engine speed

and raise the forks at a constant speed without having to step on the accelerator pedal.

• When the ignition switch is turned to OFF,

the forks will not descend even if the lift

lever is lowered. (Key-lift interlock)

• When the forks will not lower due to system malfunction or other reasons, they can

be lowered by opening the lift lock release

bolt.

• If you lower the forks by opening the lift

lock release bolt, close and lock the bolt.

Tilt lever

Tilt the mast forward and backward.

Forward ..................................... Push forward

Backward..................................Pull backward

Forward or backward tilting speed can be

adjusted by the extent of pressing the accelerator pedal and operating the lever.

Note:

• After the OPS System has been activated,

return the accelerator pedal and all of the

levers to their neutral positions and return

to the seat before recommencing operations.

• Always operate the tilt lever from a properly seated position.

en-22

01_A5028-0E00_En.fm 23 ページ 2007年7月4日 水曜日 午後4時1分

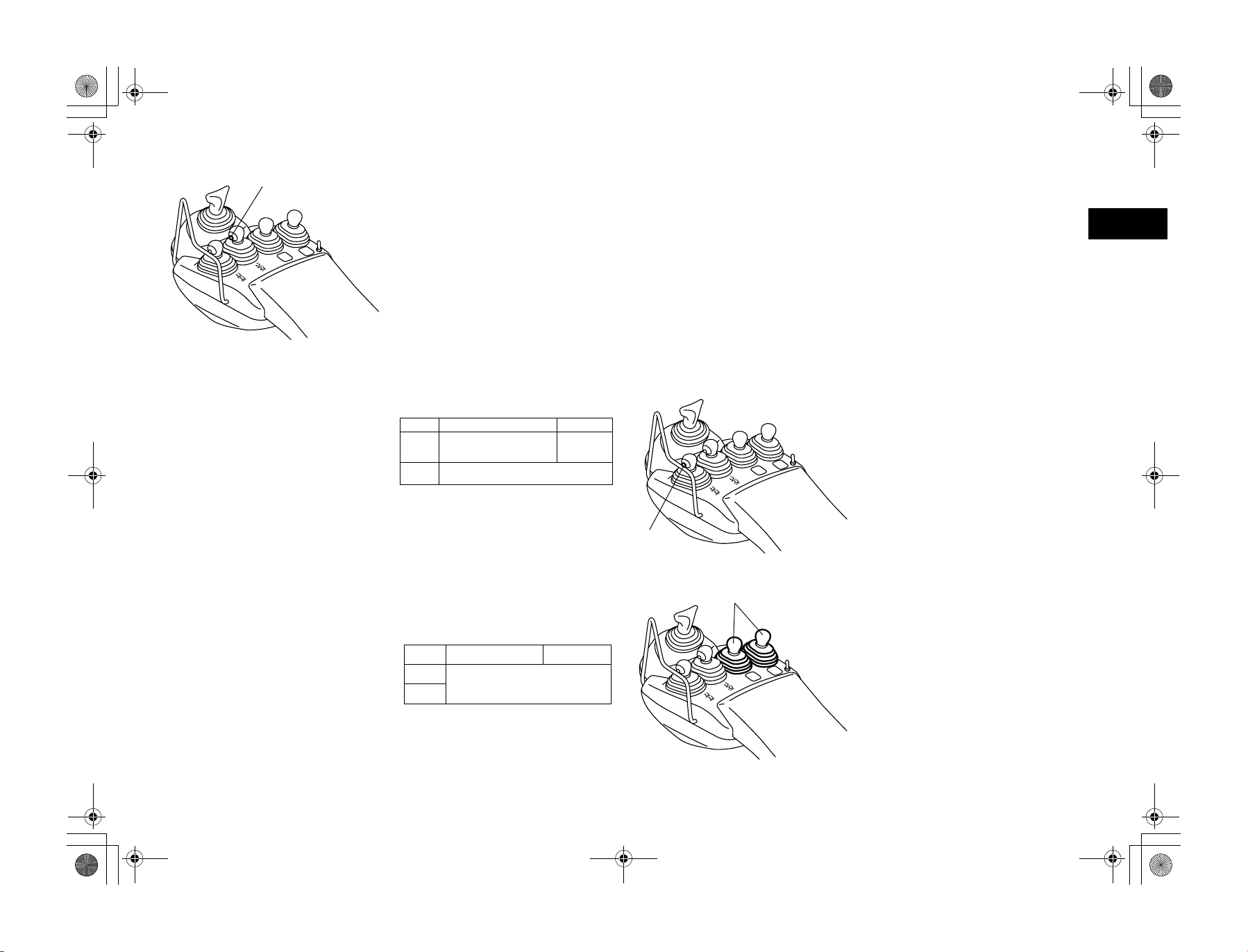

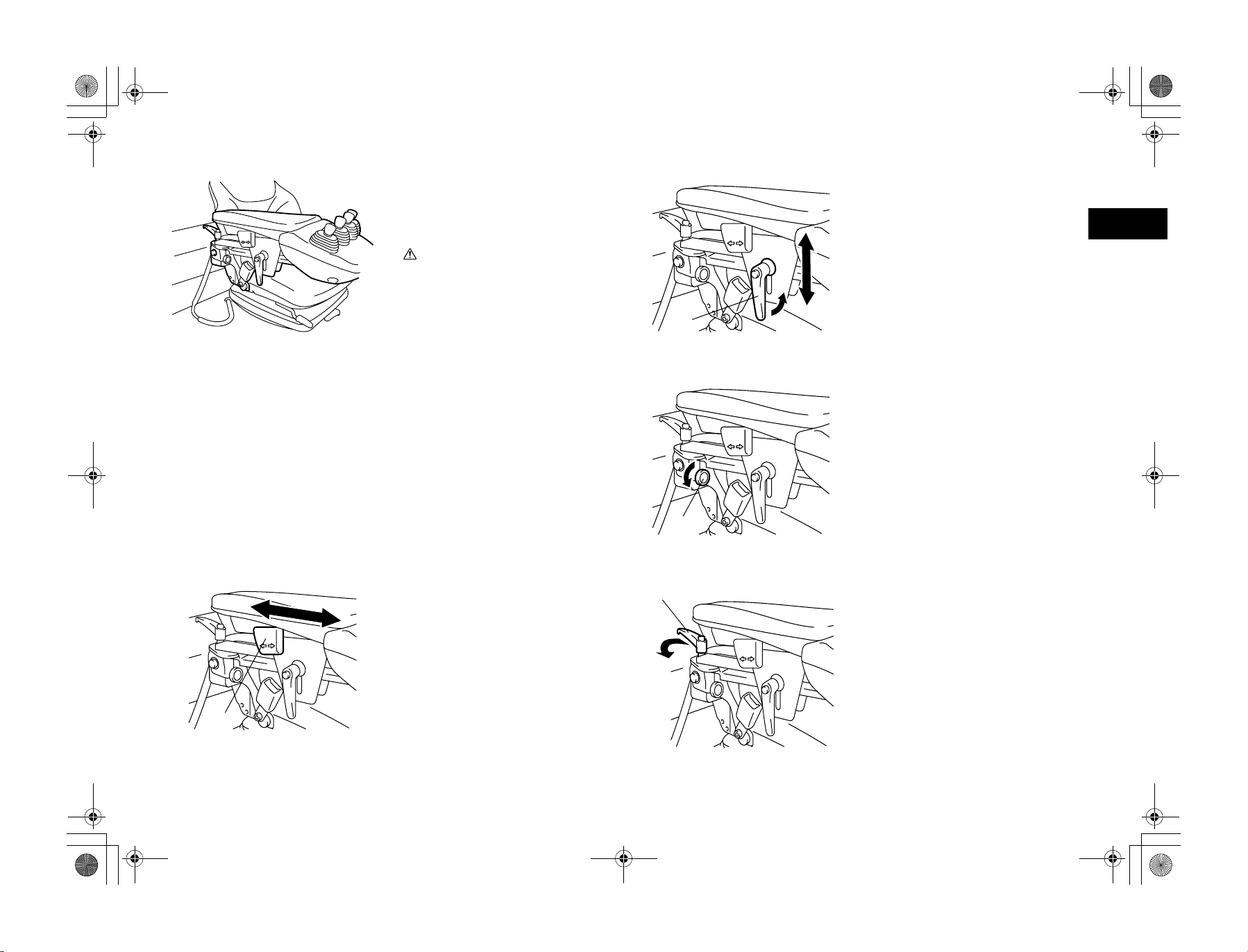

(1)

(1) Automatic forks leveling switch

Automatic fork leveling switch

(Works same as the tilt lever knob

switch.)

While pressing the switch when the forks are

tilted forward from a backward-tilted position,

or backward from a forward-tilted position, the

forks will automatically stop at a horizontal

position. Releasing the switch will allow for

normal tilt lever operation.

Forks forward-tilt automatic leveling control

When the forks are in a backward-tilted position, operating the lever forward while

depressing the automatic fork leveling switch

will automatically stop the forks at a horizontal

position. This function is convenient when

handling loads or attaching/detaching forks.

While depressing the automatic fork leveling

switch, operating the forks forward from a

backward-tilted position:

Not loaded Loaded

High lift Forks stopped at their horizontal

position

(with mast vertically positioned)

Low lift Forks stopped at their horizontal position

(with mast vertically positioned)

Forks backward-tilt automatic leveling control

When the forks are in a forward-tilted position,

operating the lever backward while depressing

the automatic fork leveling switch will automatically stop the forks at a horizontal position. This function is convenient when using

clamp-type attachments while the mast is tilted

forward from the vertical position.

While pressing the automatic forks leveling

switch, operating the forks backward from a

forward-tilted position:

Not loaded Loaded

High lift

Forks stopped at their horizontal position

(with mast vertically positioned)

Low lift

No forward tilt

(1)

(1) Load meter switch

(1)

Active mast rear tilt speed control

When the mast is raised to a high position,

backward-tilt speed will automatically slow

down.

Load meter switch (Option)

For vehicles equipped with Multifunction display DX (Option), pressing the load meter

switch will display the weight of the load.

Note:

• Operate this function when you are not performing loading operations.

• When weighing the load, always remember

to position the load at a height of about

500mm above the ground and make the

mast perpendicular.

Attachment lever

Operates the attachment.

Attachment speed can be adjusted by the

extent of pressing the accelerator pedal and

operating the lever.

Note:

• After the OPS System has been activated,

return the accelerator pedal and all of the

levers to their neutral positions and return

to the seat position before recommencing

operations.

• Always operate the attachment lever from a

properly seated position.

en

(1) Attachment lever

en-23

01_A5028-0E00_En.fm 24 ページ 2007年7月4日 水曜日 午後4時1分

(1) Attachment lever switch

(1)

(2)

(1) Forward

(2) Backward

(1)

Attachment lever switch

(Only for 5 ways series)

This switch allows attachment lever operations

to be switched between the 3rd and 4th ways.

It is for 3rd operation when the changing-over

switch is not switched. And it switches to 5th

operation while pushing it.

CautionCaution

Operate the attachment lever switch when

attachment operations are stopped.

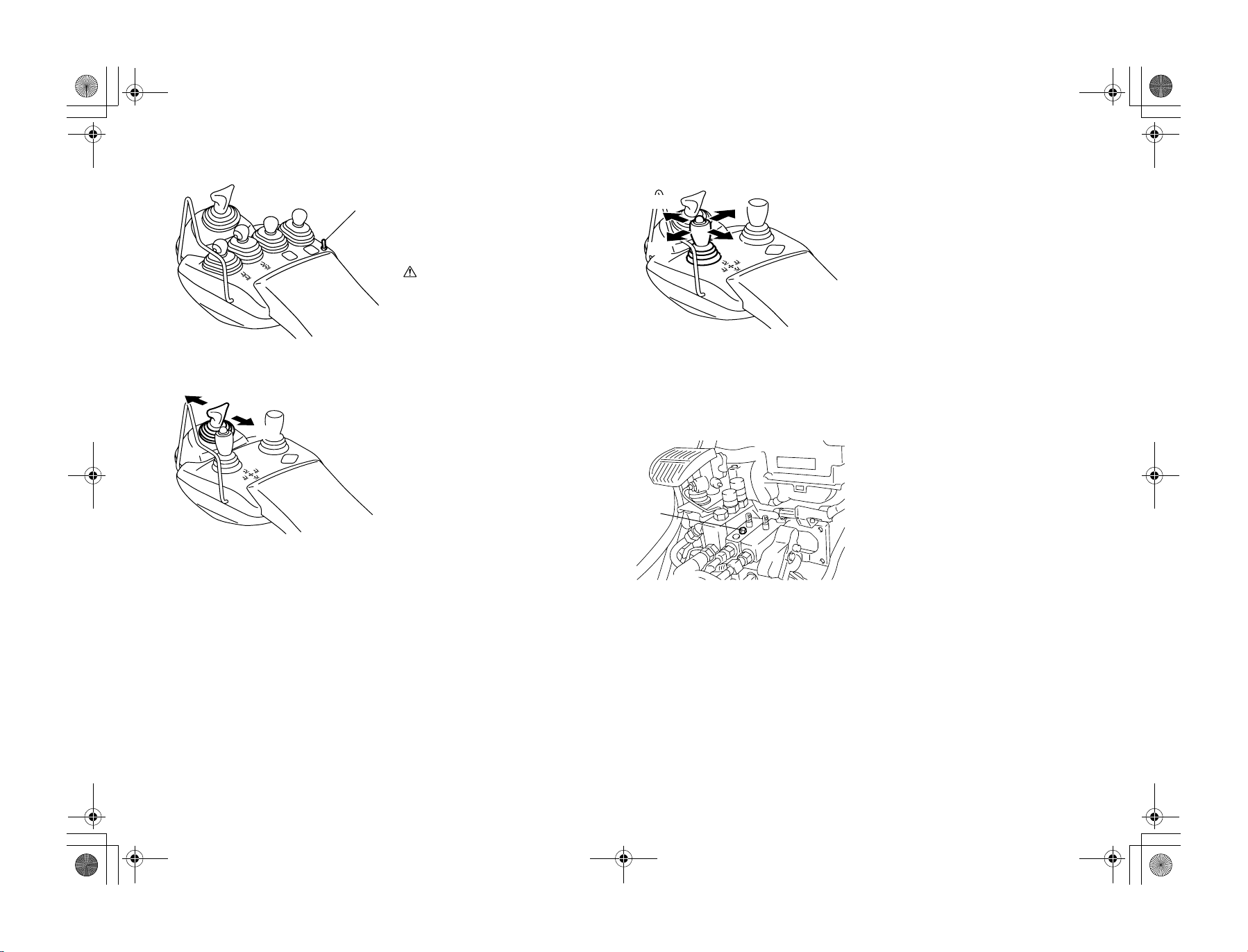

Joy stick (Option)

Control lever

Lever for shifting between forward and

reverse.

Forward.................................... Push forward

Reverse..................................... Pull backward

The speed of forward and backward traveling

can be adjusted by the extent of pressing the

accelerator pedal.

Note:

• Stop the vehicle before shifting between

forward and backward traveling.

• After the OPS System has been activated,

return the accelerator pedal and control

lever to their neutral positions and return to

the seat before recommencing operations.

• Always operate the control lever from a

properly seated position.

• Depending on the vehicle specifications,

the position of the control lever may vary.

(3)

(2)

(1) Raising

(2) Lowering

(3) Forward-tilt

(4) Backward-tilt

(1)

(1) Lift lock release bolt

(1)

(4)

Lift tilt lever

Operation to the left and right controls lift, and

forward and backward operation controls tilt.

Raising ...............Operate the lever to the right

Lowering.............. Operate the lever to the left

Forward-tilt ............Operate the lever forward

Backward-tilt.......Operate the lever backward

Raising speed and forward and backward-tilt

speed can be adjusted by the extent of pressing

down on the accelerator pedal and operating

the lever.

Lowering speed can be adjusted by operating

the lever.

Note:

• Using the idling lifting speed increase function (Option), when the lift tilt lever is

raised, the engine’s speed is automatically

increased without having to press the accelerator pedal, allowing the forks to be raised

at a constant speed.

• After the OPS System has been activated,

return the accelerator pedal and all of the

levers to their neutral positions and return

to the seat before recommencing operations.

• If you return to seated position while lowering the lift lever, the lift will not descend