Toyopuc PC3/PC2 Ethernet Driver

© 2016 PTC Inc. All Rights Reserved.

Toyopuc PC3/PC2 Ethernet Driver

Table of Contents

2

Toyopuc PC3/PC2 Ethernet Driver

Table of Contents

Toyopuc PC3/PC2 Ethernet Driver

Overview

Setup

Channel Properties - General 6

Channel Properties - Ethernet Communications 7

Channel Properties - Write Optimizations 8

Channel Properties - Advanced 9

Device Properties - General 9

Device Properties - Scan Mode 11

Device Properties - Timing 12

Device Properties - Communications Parameters 13

Device Properties - Redundancy 13

Diagnostics Tags

Multi-Point Read Support

Data Type Description

1

2

4

4

5

14

15

19

Address Descriptions

PC2/PC2 Interchange Mode Address Descriptions

PC3 Address Descriptions

PC10G Address Descriptions

Error Descriptions

Address Validation

Missing address. 31

Device address <address> contains a syntax error. 31

Address <address> is out of range for the specified device or register 31

Data Type <type> is not valid for device address <address>. 32

Device address <address> is read only. 32

Array size is out of range for address <address>. 32

Array support is not available for the specified address: <address>. 32

Device Status Messages

Device <device name> is not responding. 33

Unable to write to <address> on device <device name>. 33

Device Error Codes

20

20

22

26

31

31

33

34

Error Response Data: Error Code Table 34

Appendix: Configuring Modules

www. kepware.com

36

3

Toyopuc PC3/PC2 Ethernet Driver

Configuring the PC10G-CPU for Ethernet Communications

Configuring the FL/ET-T-V2 Ethernet Module

Configuration Ladder for EN-I/F Ethernet Module

Index

36

41

46

48

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Toyopuc PC3/PC2 Ethernet Driver

Help version 1.042

CONTENTS

Overview

What is the Toyopuc PC3/PC2 Ethernet Driver?

Device Setup

How do I configure a device for use with this driver?

Data Types Description

What data types does this driver support?

Address Descriptions

How do I address a data location on a Toyopuc PC3/PC2 Ethernet device?

Error Descriptions

What error messages does the Toyopuc PC3/PC2 Ethernet Driver produce?

4

Overview

The Toyopuc PC3/PC2 Ethernet Driver provides a reliable way to connect Toyopuc PC3/PC2 Ethernet devices

to OPC client applications; including HMI, SCADA, Historian, MES, ERP, and countless custom applications. It

is intended for use with Toyopuc PC3, PC2 and PC10G series PLCs using the Ethernet communications

interface. The Toyopuc PC3/PC2 Ethernet Driver supports extensive diagnostics tags and the Toyopuc

PC3/PC2 multi-point read features. For more information, refer to Diagnostics Tags and Multi-Point Read

Support .

www. kepware.com

5

Toyopuc PC3/PC2 Ethernet Driver

Setup

Supported Devices

Toyopuc PC3, PC2 and PC10G series

The PC2 model selection can be used with PC3 > PLCs operating in the PC2 Interchange mode.

Note: This driver is limited to 1024 devices.

Communication Protocol

Toyopuc PC3/PC2 Ethernet Computer Link Protocol

Connection Timeout

This property specifies the time that the driver will wait for a connection to be made with a device.

Depending on network load, the connect time may vary with each connection attempt. The default setting is

5 seconds. The valid range is 1 to 30 seconds.

Note: Making a connection with a device can be very time consuming. When connecting with multiple

devices located at different IP addresses or port numbers, define an additional Toyopuc Ethernet channel in

the OPC Server project for this unique device. Connecting to multiple devices using the Relay Command

through a single IP and port number will not cause a new connection to be opened and will not incur a

connection delay.

Port Number

This property specifies the port number that will be used to connect to the Toyopuc PLC. The Toyopuc EN-I/F

Ethernet PC3/PC2 module supports eight ports for communications. Each port must be dedicated to a single

connection. When specifying a port number, ensure that no other Ethernet node will attempt to use this port

number on the target Toyopuc PLC. The same port number can be used when communicating with multiple

Toyopuc PLCs.

Device IDs

The Device ID, specified as YYY.YYY.YYY.YYY[P1,L1, S1, L2, S2, P3, L3, S3], is used to specify the Device IP

address along with Relay Command Link/Exchange information on the Ethernet network. YYY designates the

Device IP address: each YYY byte should be in the range of 0 to 255.

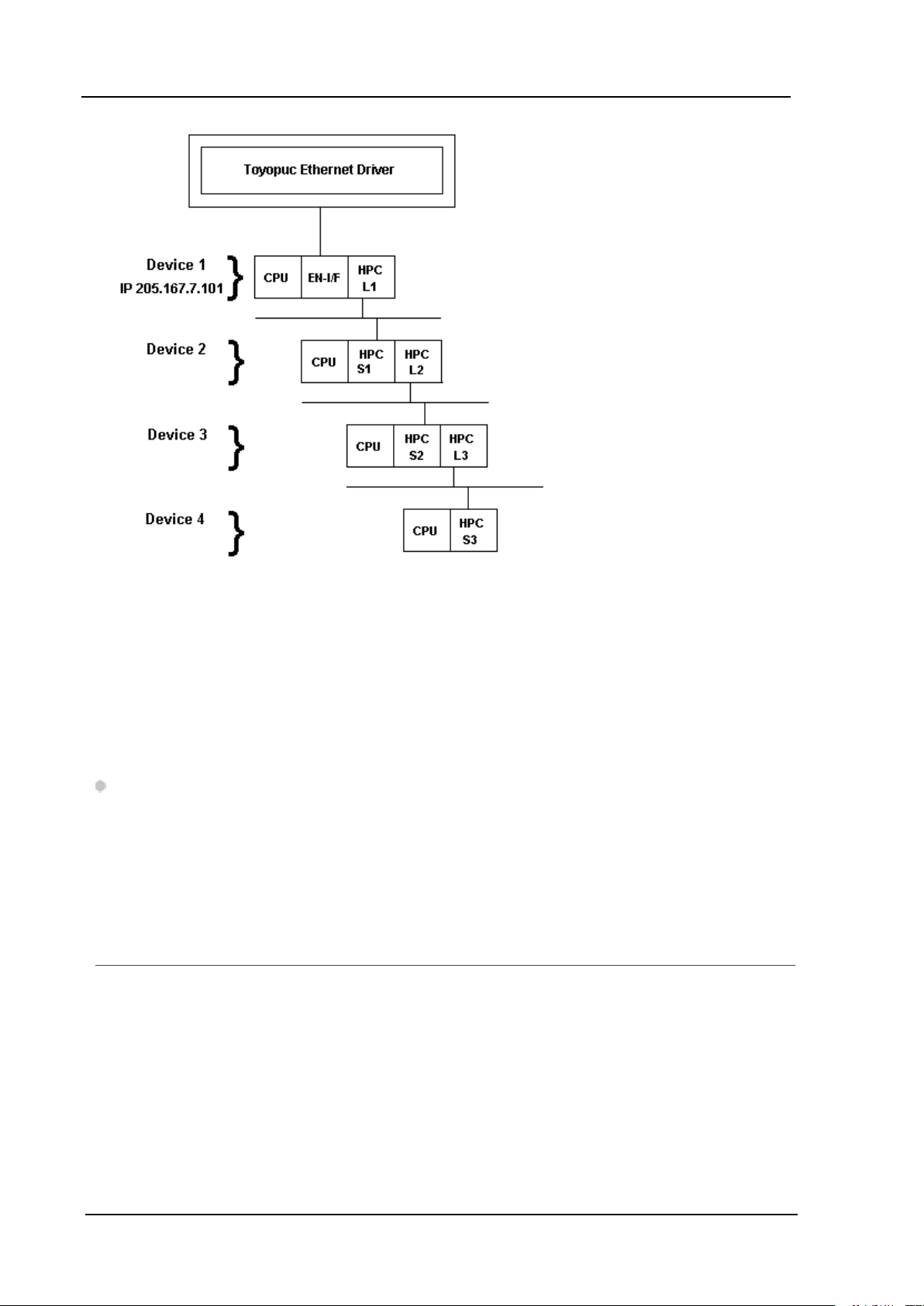

Note: A request can be relayed through one device to another device configured with the same link

module, such as HPC-Link or FL-net. This relay connection is established by appending a link/exchange path

to the device IP address. The following image illustrates the use of the routing path between HPC-linked

devices:

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

6

A routing command can only be issued through a maximum of four devices. Routing allows the Ethernet

driver to request data from non-Ethernet devices. To request data from Device 3, the driver can route a

command through Device 1 onto Device 2 then to Device 3.

Examples

1. Defining a Device ID to request data from Device 1. Device ID: 205.167.7.101.

2. Defining a Device ID to request data from Device 3. Device ID: 205.167.7.101[L1,S1,L2,S2].

Note: Lx and Sx represent the Link/Station numbers assigned to a device. . Consult the Toyopuc PC2 EN-I/F

manual, HPC Link manual, or FL/ET-T-V2H manual for more information on link/station numbers.The L and S

must be included as part of the Relay routing information when specifying a Device ID. The Px represents the

program number for PC3J systems. The Px value should precede the link variable on each layer of the route.

Example

Device ID: 205.167.7.101[P2,L1,S1,P1,L2,S2].

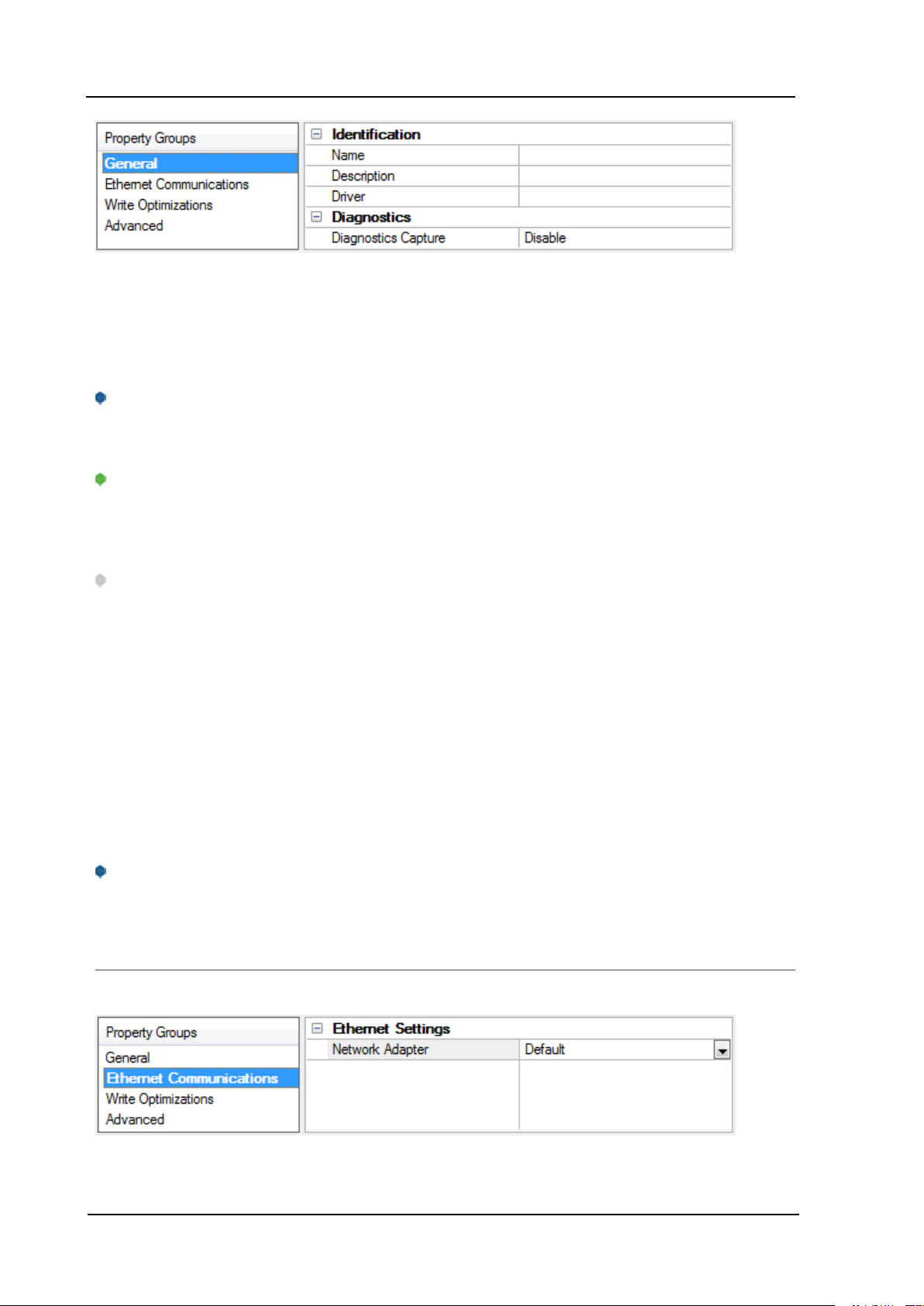

Channel Properties - General

This server supports the use of simultaneous multiple communications drivers. Each protocol or driver used

in a server project is called a channel. A server project may consist of many channels with the same

communications driver or with unique communications drivers. A channel acts as the basic building block of

an OPC link. This group is used to specify general channel properties, such as the identification attributes

and operating mode.

www. kepware.com

7

Toyopuc PC3/PC2 Ethernet Driver

Identification

Name:User-defined identity of this channel. In each server project, each channel name must be unique.

Although names can be up to 256 characters, some client applications have a limited display window when

browsing the OPCserver's tag space. The channel name is part of the OPC browser information.

For information on reserved characters, refer to "How To... Properly Name a Channel, Device, Tag, and Tag

Group" in the server help.

Description: User-defined information about this channel.

Many of these properties, including Description, have an associated system tag.

Driver:Selected protocol / driver for this channel. This property specifies the device driver that was selected

during channel creation. It is a disabled setting in the channel properties.

Note: With the server's online full-time operation, these properties can be changed at any time. This

includes changing the channel name to prevent clients from registering data with the server. If a client has

already acquired an item from the server before the channel name is changed, the items are unaffected. If,

after the channel name has been changed, the client application releases the item and attempts to reacquire using the old channel name, the item is not accepted. With this in mind, changes to the properties

should not be made once a large client application has been developed. Utilize the User Manager to prevent

operators from changing properties and restrict access rights to server features.

Diagnostics

Diagnostics Capture: When enabled, this option makes the channel's diagnostic information available to

OPC applications. Because the server's diagnostic features require a minimal amount of overhead

processing, it is recommended that they be utilized when needed and disabled when not. The default is

disabled.

For more information, refer to "Communication Diagnostics" in the server help.

Not all drivers support diagnostics. To determine whether diagnostics are available for a particular driver, open

the driver information and locate the "Supports device level diagnostics" statement.

Channel Properties - Ethernet Communications

Ethernet Communication can be used to communicate with devices.

Ethernet Settings

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Network Adapter:Specify the network adapter to bind. When Default is selected, the operating system

selects the default adapter.

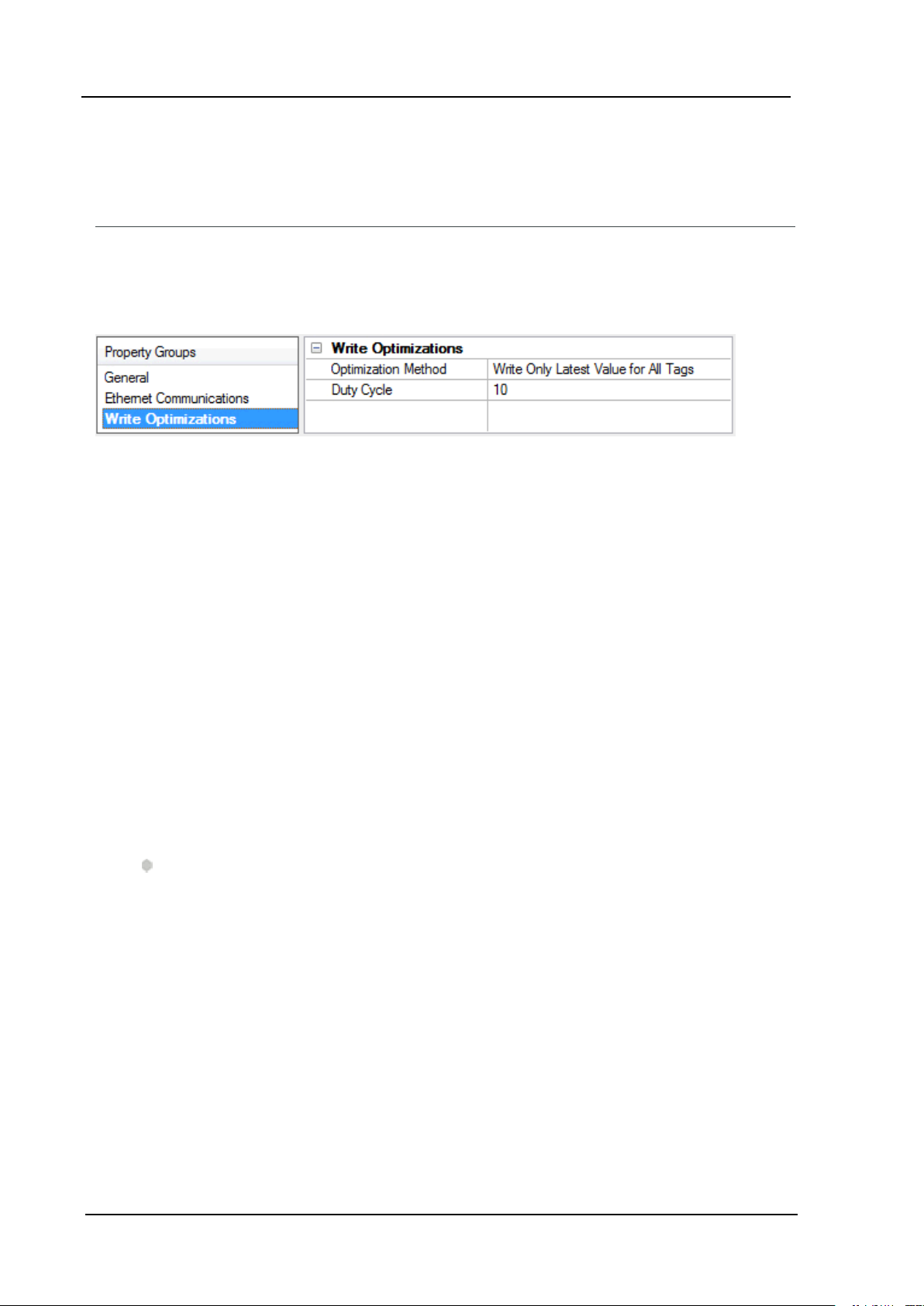

Channel Properties - Write Optimizations

As with any OPC server, writing data to the device may be the application's most important aspect. The

server intends to ensure that the data written from the client application gets to the device on time. Given

this goal, the server provides optimization properties that can be used to meet specific needs or improve

application responsiveness.

Write Optimizations

OptimizationMethod: controls how write data is passed to the underlying communications driver. The

options are:

8

l Write All Values for All Tags:This option forces the server to attempt to write every value to the

controller. In this mode, the server continues to gather write requests and add them to the server's

internal write queue. The server processes the write queue and attempts to empty it by writing data

to the device as quickly as possible. This mode ensures that everything written from the client

applications is sent to the target device. This mode should be selected if the write operation order or

the write item's content must uniquely be seen at the target device.

l Write Only Latest Value for Non-Boolean Tags: Many consecutive writes to the same value can

accumulate in the write queue due to the time required to actually send the data to the device. If the

server updates a write value that has already been placed in the write queue, far fewer writes are

needed to reach the same final output value. In this way, no extra writes accumulate in the server's

queue. When the user stops moving the slide switch, the value in the device is at the correct value at

virtually the same time. As the mode states, any value that is not a Boolean value is updated in the

server's internal write queue and sent to the device at the next possible opportunity. This can greatly

improve the application performance.

Note: This option does not attempt to optimize writes to Boolean values. It allows users to

optimize the operation of HMI data without causing problems with Boolean operations, such as a

momentary push button.

l Write Only Latest Value for All Tags:This option takes the theory behind the second optimization

mode and applies it to all tags. It is especially useful if the application only needs to send the latest

value to the device. This mode optimizes all writes by updating the tags currently in the write queue

before they are sent. This is the default mode.

Duty Cycle: is used to control the ratio of write to read operations. The ratio is always based on one read for

every one to ten writes. The duty cycle is set to ten by default, meaning that ten writes occur for each read

operation. Although the application is performing a large number of continuous writes, it must be ensured

that read data is still given time to process. A setting of one results in one read operation for every write

operation. If there are no write operations to perform, reads are processed continuously. This allows

optimization for applications with continuous writes versus a more balanced back and forth data flow.

www. kepware.com

9

Toyopuc PC3/PC2 Ethernet Driver

Note: It is recommended that the application be characterized for compatibility with the write

optimization enhancements before being used in a production environment.

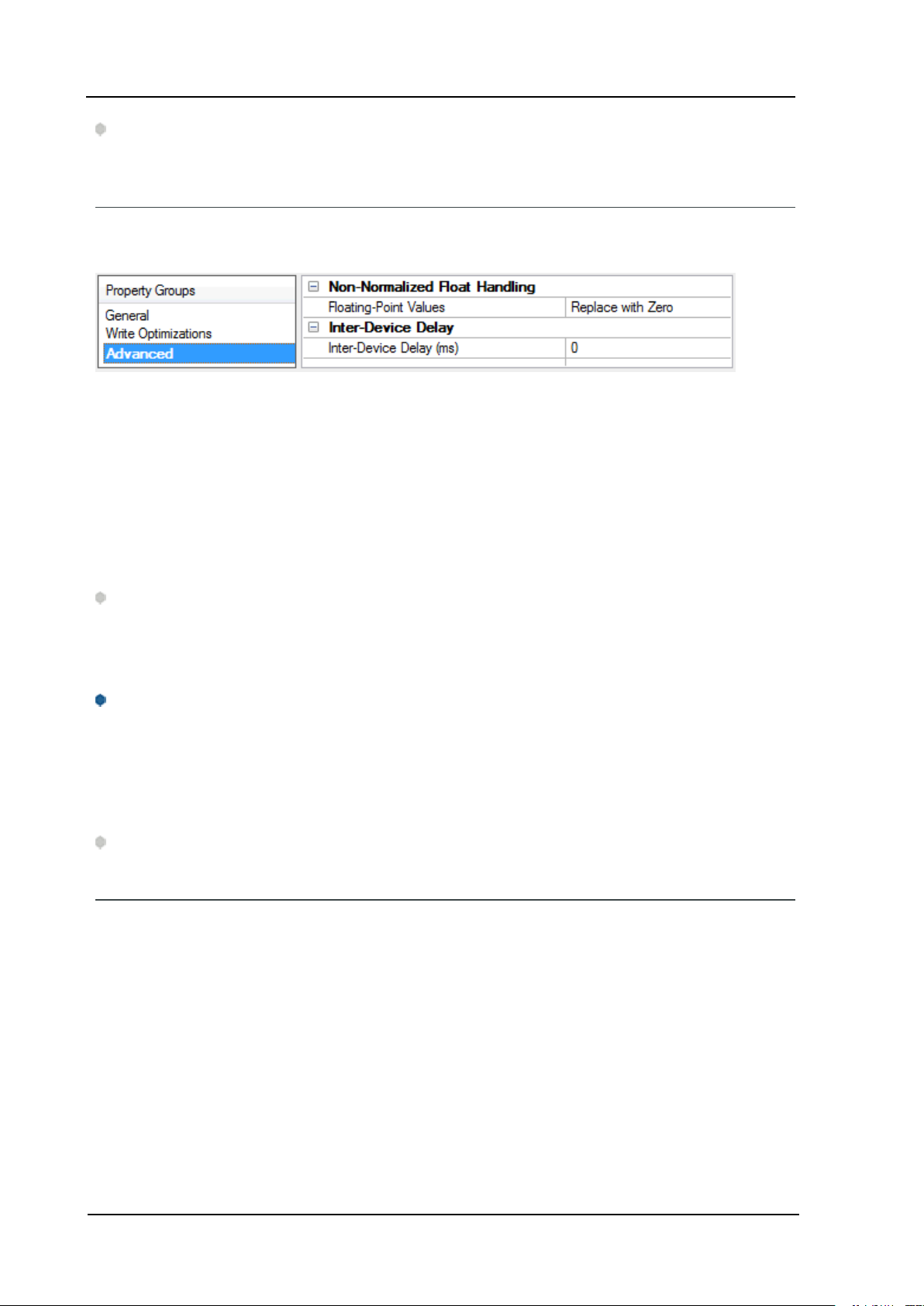

Channel Properties - Advanced

This group is used to specify advanced channel properties. Not all drivers support all properties; so the

Advanced group does not appear for those devices.

Non-Normalized Float Handling: Non-normalized float handling allows users to specify how a driver

handles non-normalized IEEE-754 floating point data. A non-normalized value is defined as Infinity, Not-aNumber (NaN), or as a Denormalized Number. The default is Replace with Zero. Drivers that have native

float handling may default to Unmodified. Descriptions of the options are as follows:

l Replace with Zero:This option allows a driver to replace non-normalized IEEE-754 floating point

values with zero before being transferred to clients.

l Unmodified:This option allows a driver to transfer IEEE-754 denormalized, normalized, non-

number, and infinity values to clients without any conversion or changes.

Note:This property is disabled if the driver does not support floating point values or if it only supports the

option that is displayed. According to the channel's float normalization setting, only real-time driver tags

(such as values and arrays) are subject to float normalization. For example, EFM data is not affected by this

setting.lin

For more information on the floating point values, refer to "How To ... Work with Non-Normalized Floating

Point Values" in the server help.

Inter-Device Delay: Specify the amount of time the communications channel waits to send new requests to

the next device after data is received from the current device on the same channel. Zero (0) disables the

delay.

Note:This property is not available for all drivers, models, and dependent settings.

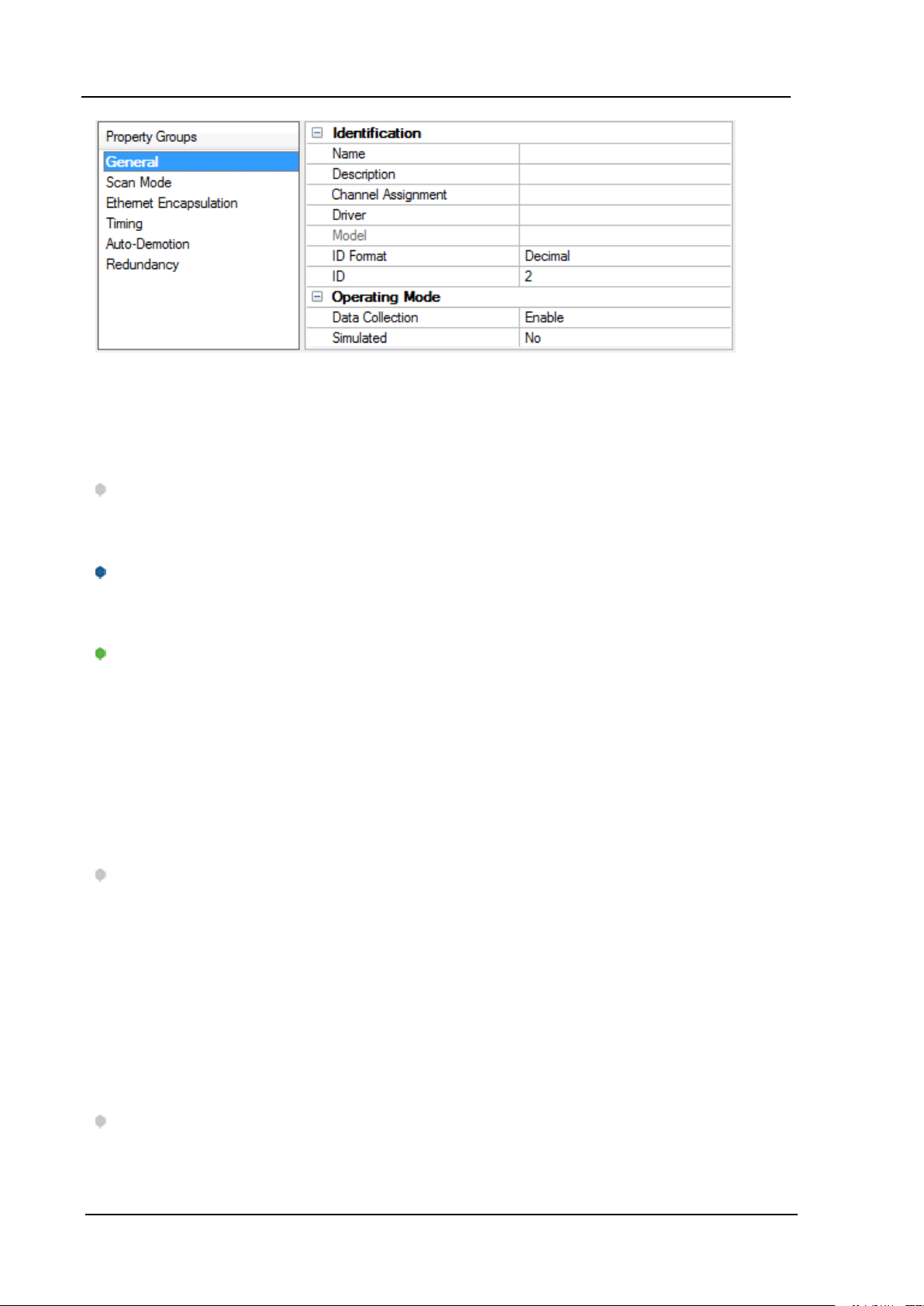

Device Properties - General

A device represents a single target on a communications channel. If the driver supports multiple controllers,

users must enter a device ID for each controller.

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Identification

Name:This property specifies the name of the device. It is a logical user-defined name that can be up to

256 characters long, and may be used on multiple channels.

Note: Although descriptive names are generally a good idea, some OPC client applications may have a

limited display window when browsing the OPC server's tag space. The device name and channel name

become part of the browse tree information as well. Within an OPC client, the combination of channel name

and device name would appear as "ChannelName.DeviceName".

For more information, refer to "How To... Properly Name a Channel, Device, Tag, and Tag Group" in server

help.

10

Description: User-defined information about this device.

Many of these properties, including Description, have an associated system tag.

Channel Assignment:User-defined name of the channel to which this device currently belongs.

Driver:Selected protocol driver for this device.

Model:This property specifies the specific type of device that is associated with this ID. The contents of the

drop-down menu depends on the type of communications driver being used. Models that are not supported

by a driver are disabled. If the communications driver supports multiple device models, the model selection

can only be changed when there are no client applications connected to the device.

Note:If the communication driver supports multiple models, users should try to match the model

selection to the physical device. If the device is not represented in the drop-down menu, select a model that

conforms closest to the target device. Some drivers support a model selection called "Open," which allows

users to communicate without knowing the specific details of the target device. For more information, refer

to the driver help documentation.

ID:This property specifies the device's driver-specific station or node. The type of ID entered depends on

the communications driver being used. For many communication drivers, the ID is a numeric value. Drivers

that support a Numeric ID provide users with the option to enter a numeric value whose format can be

changed to suit the needs of the application or the characteristics of the selected communications driver.

The ID format can be Decimal, Octal, and Hexadecimal.

Note: If the driver is Ethernet-based or supports an unconventional station or node name, the device's

TCP/IP address may be used as the device ID. TCP/IP addresses consist of four values that are separated by

periods, with each value in the range of 0 to 255. Some device IDs are string based. There may be additional

www. kepware.com

11

Toyopuc PC3/PC2 Ethernet Driver

properties to configure within the ID field, depending on the driver. For more information, refer to the

driver's help documentation.

Operating Mode

Data Collection:This property controls the device's active state. Although device communications are

enabled by default, this property can be used to disable a physical device. Communications are not

attempted when a device is disabled. From a client standpoint, the data is marked as invalid and write

operations are not accepted. This property can be changed at any time through this property or the device

system tags.

Simulated:This option places the device into Simulation Mode. In this mode, the driver does not attempt to

communicate with the physical device, but the server continues to return valid OPC data. Simulated stops

physical communications with the device, but allows OPC data to be returned to the OPC client as valid data.

While in Simulation Mode, the server treats all device data as reflective: whatever is written to the simulated

device is read back and each OPC item is treated individually. The item's memory map is based on the group

Update Rate. The data is not saved if the server removes the item (such as when the server is reinitialized).

The default is No.

Notes:

1. This System tag (_Simulated) is read only and cannot be written to for runtime protection. The System

tag allows this property to be monitored from the client.

2. In Simulation mode, the item's memory map is based on client update rate(s) (Group Update Rate for

OPC clients or Scan Rate for native and DDE interfaces). This means that two clients that reference

the same item with different update rates return different data.

Simulation Mode is for test and simulation purposes only. It should never be used in a production

environment.

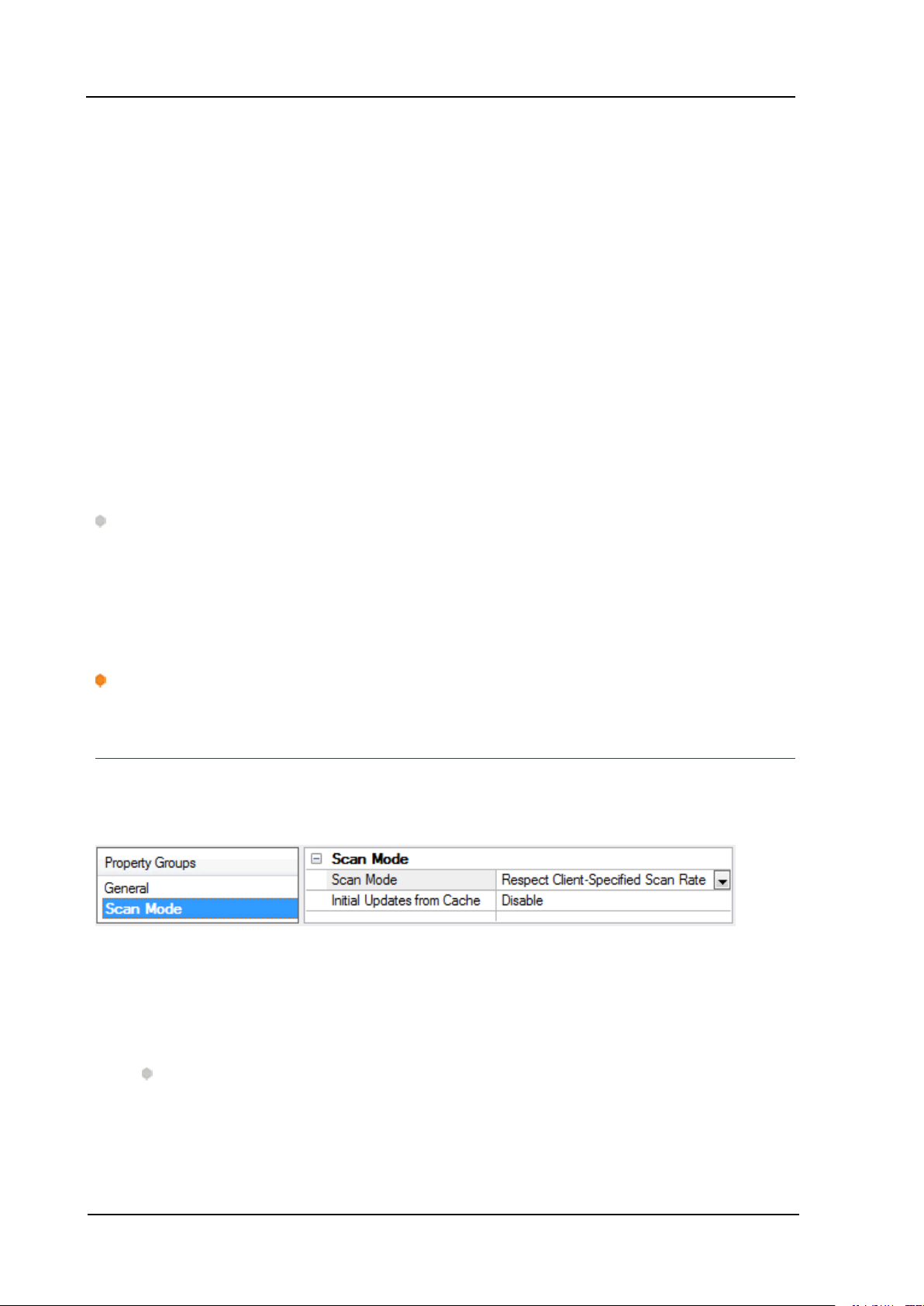

Device Properties - Scan Mode

The Scan Mode specifies the subscribed-client requested scan rate for tags that require device

communications. Synchronous and asynchronous device reads and writes are processed as soon as

possible; unaffected by the Scan Mode properties.

Scan Mode: specifies how tags in the device are scanned for updates sent to subscribed clients.

Descriptions of the options are:

l Respect Client-Specified Scan Rate:This mode uses the scan rate requested by the client.

l Request Data No Faster than Scan Rate:This mode specifies the maximum scan rate to be used.

The valid range is 10 to 99999990 milliseconds. The default is 1000 milliseconds.

Note:When the server has an active client and items for the device and the scan rate value is

increased, the changes take effect immediately. When the scan rate value is decreased, the changes

do not take effect until all client applications have been disconnected.

l Request All Data at Scan Rate:This mode forces tags to be scanned at the specified rate for

subscribed clients. The valid range is 10 to 99999990 milliseconds. The default is 1000 milliseconds.

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

l Do Not Scan, Demand Poll Only:This mode does not periodically poll tags that belong to the

device nor perform a read to get an item's initial value once it becomes active. It is the client's

responsibility to poll for updates, either by writing to the _DemandPoll tag or by issuing explicit device

reads for individual items. For more information, refer to "Device Demand Poll" in server help.

l Respect Tag-Specified Scan Rate:This mode forces static tags to be scanned at the rate specified

in their static configuration tag properties. Dynamic tags are scanned at the client-specified scan

rate.

Initial Updates from Cache: When enabled, this option allows the server to provide the first updates for

newly activated tag references from stored (cached) data. Cache updates can only be provided when the

new item reference shares the same address, scan rate, data type, client access, and scaling properties. A

device read is used for the initial update for the first client reference only. The default is disabled; any time a

client activates a tag reference the server attempts to read the initial value from the device.

Device Properties - Timing

The device Communications Timeouts properties allow the driver's response to error conditions to be

tailored to fit the application's needs. In many cases, the environment requires changes to these properties

for optimum performance. Factors such as electrically generated noise, modem delays, and poor physical

connections can influence how many errors or timeouts a communications driver encounters.

Communications Timeouts properties are specific to each configured device.

12

Communications Timeouts

Connect Timeout:This property (which is used primarily by Ethernet based drivers) controls the amount of

time required to establish a socket connection to a remote device. The device's connection time often takes

longer than normal communications requests to that same device. The valid range is 1 to 30 seconds. The

default is typically 3 seconds, but can vary depending on the driver's specific nature. If this setting is not

supported by the driver, it is disabled.

Note: Due to the nature of UDP connections, the connection timeout setting is not applicable when

communicating via UDP.

Request Timeout:This property specifies an interval used by all drivers to determine how long the driver

waits for a response from the target device to complete. The valid range is 50 to 9,999,999 milliseconds

(167.6667 minutes). The default is usually 1000 milliseconds, but can vary depending on the driver. The

default timeout for most serial drivers is based on a baud rate of 9600 baud or better. When using a driver

at lower baud rates, increase the timeout to compensate for the increased time required to acquire data.

Retry Attempts:This property specifies how many times the driver retries a communications request

before considering the request to have failed and the device to be in error. The valid range is 1 to 10. The

default is typically 3, but can vary depending on the driver's specific nature. The number of retries

configured for an application depends largely on the communications environment.

www. kepware.com

13

Toyopuc PC3/PC2 Ethernet Driver

Timing

Inter-Request Delay:This property specifies how long the driver waits before sending the next request to

the target device. It overrides the normal polling frequency of tags associated with the device, as well as

one-time reads and writes. This delay can be useful when dealing with devices with slow turnaround times

and in cases where network load is a concern. Configuring a delay for a device affects communications with

all other devices on the channel. It is recommended that users separate any device that requires an interrequest delay to a separate channel if possible. Other communications properties (such as communication

serialization) can extend this delay. The valid range is 0 to 300,000 milliseconds; however, some drivers may

limit the maximum value due to a function of their particular design. The default is 0, which indicates no

delay between requests with the target device.

Note: Not all drivers support Inter-Request Delay. This setting does not appear if it is not supported by the

driver.

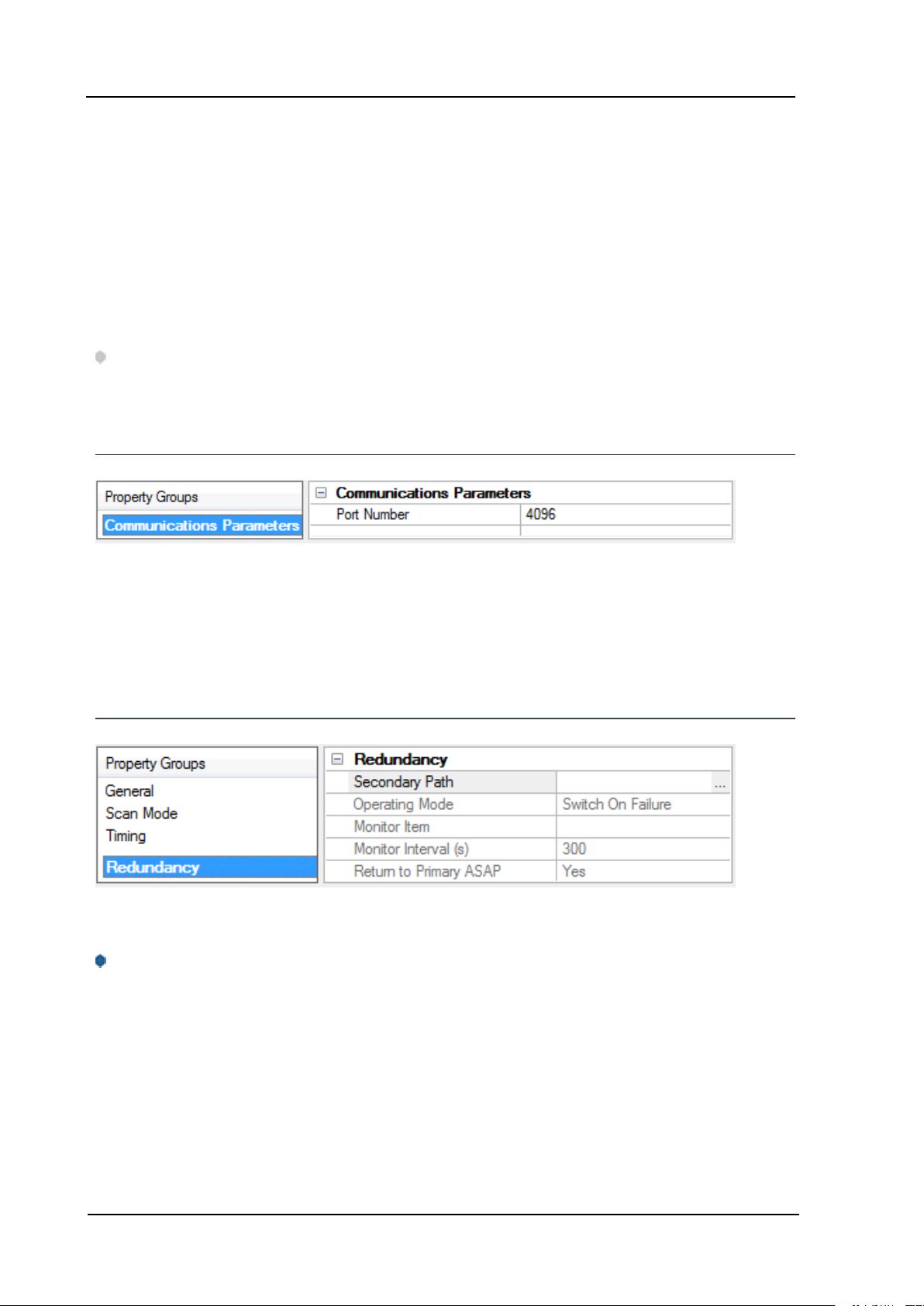

Device Properties - Communications Parameters

Port Number: Specify the port number to be used to connect to the Toyopuc PLC. The Toyopuc EN-I/F

Ethernet PC3/PC2 module supports eight ports for communications. Each port must be dedicated to a single

connection. When specifying a port number, ensure that no other Ethernet node will attempt to use this port

number on the target Toyopuc PLC. The same port number can be used when communicating with multiple

Toyopuc PLCs.

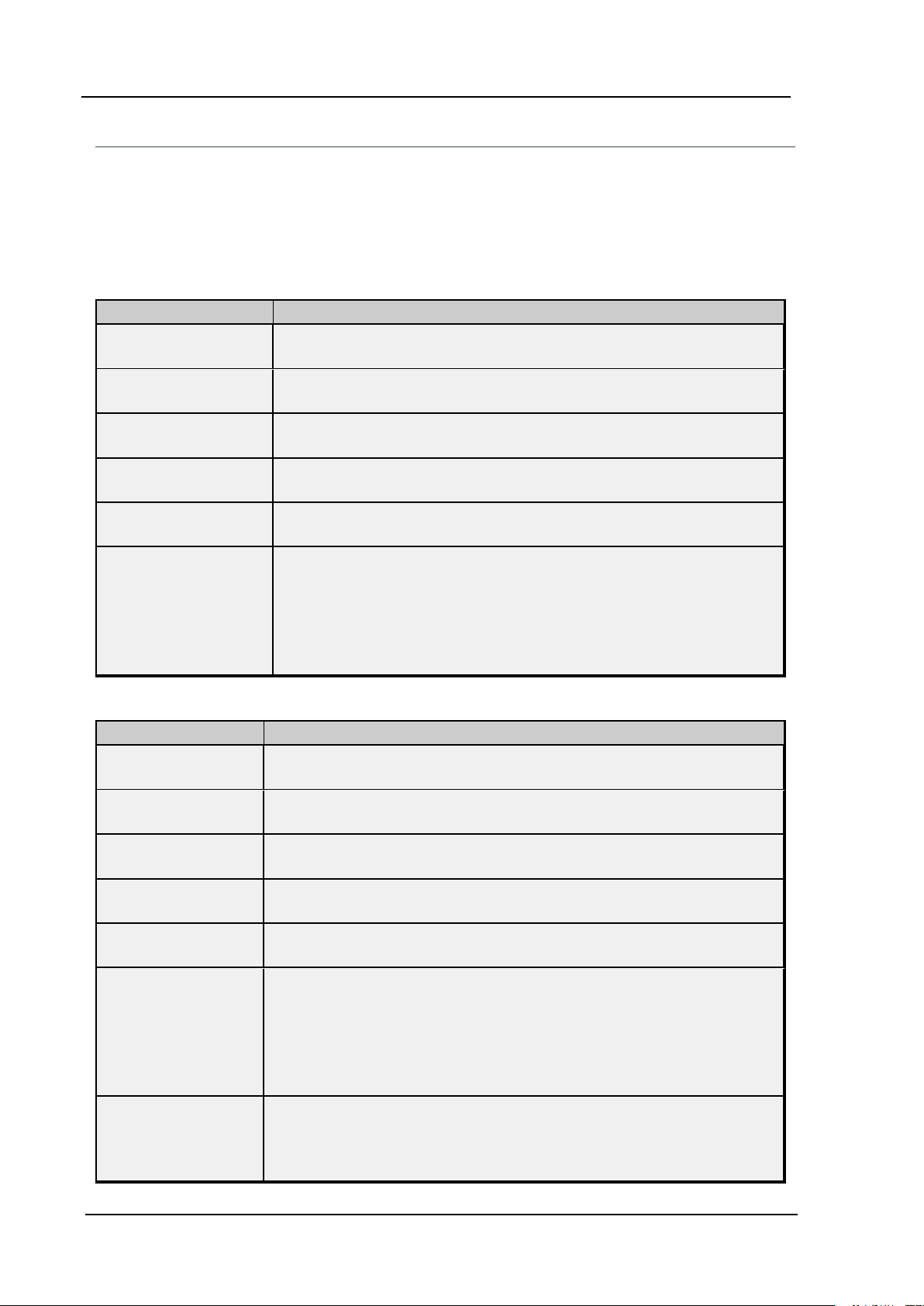

Device Properties - Redundancy

Redundancy is available with the Media-Level Redundancy Plug-in.

Consult the website, a sales representative, or the user manual for more information.

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Diagnostics Tags

Diagnostics Tags provide information on how the Toyopuc PC3/PC2 Ethernet Driver is performing at both

the channel level and device level. At the channel level, diagnostics tags provide information that covers all

operations performed by the driver when communicating with any PLC on the network. At the device level,

diagnostics tags provide information that pertains only to the device under which the diagnostic tags have

been requested.

Channel-Level Diagnostics Tags

Tag Name Functional Description

ChannelReadTime Contains the amount of time in milliseconds required to read all currently

active data for all devices on this channel. This value is a signed long.

ChannelHighTime Contains the amount of time in milliseconds of longest read cycle. This value

is a signed long.

ChannelLowTime Contains the amount of time in milliseconds of shortest read cycle. This value

is a signed long.

ChannelReadsPerformed Contains a count of the reads performed on this channel for all devices. This

is a signed long and will roll over.

ChannelWritesPerformed Contains a count of the writes performed on this channel for all devices. This

is a signed long and will roll over.

ChannelTimeouts Contains a count of the number of timeout/message failures that have

occurred for all devices. The _ChannelTimeouts count is for any error that

may occur on a message attempt. The value does not necessarily indicate

how many messages failed to be sent altogether. It should be used to

diagnose possible communication issues with specific devices. This is a

signed long and will roll over.

14

Device-Level Diagnostics Tags

Tag Name Functional Description

DeviceReadTime Contains the amount of time in milliseconds required to read a block of data

from the specified device. This value is a signed long.

DeviceHighTime Contains the longest amount of time in milliseconds required to read a block of

data from the specified device. This value is a signed long.

DeviceLowTime Contains the shortest amount of time in milliseconds required to read a block

of data from the specified device. This value is a signed long.

DeviceReadsPerformed Contains a count of the reads performed on this device. This is a signed long

and will roll over.

DeviceWritesPerformed Contains a count of the writes performed on this device. This is a signed long

and will roll over.

DeviceTimeouts Contains a count of the number of timeout/message failures that have

occurred on the specified device. The _ DeviceTimeouts count is for any error

that may occur on a message attempt. The value does not necessarily indicate

how many messages failed to be sent altogether. It should be used to diagnose

possible communication issues with this specific device. This is a signed long

and will roll over.

DeviceMultiPointReads Contains a count of the number of multi-point read requests that are currently

being used to acquire all data that is marked for multi-point operation. This tag

can be used to tune multi-point read operation. The goal of course being to

limit the number of multi-point reads being done to the lowest count possible,

www. kepware.com

15

Toyopuc PC3/PC2 Ethernet Driver

Tag Name Functional Description

preferably 1. This is a signed long and will roll over.

Note: All diagnostics tags are Read/Write. The only value that can be written to the tags is zero (which will

clear or reset them).

Multi-Point Read Support

The Toyopuc PLC supports the ability to read data spread randomly throughout the PLC using a single

command. By using this command, users can read crucial data items quickly and efficiently. The Toyopuc

PC3/PC2 Ethernet Driver automatically attempts to make the use of the multi-point command both easy and

efficient. Any memory type that can be acquired by the Toyopuc PC3/PC2 Ethernet Driver can be part of a

multi-point read command. To mark a particular data item to be part of a multi-point request, place the '#'

character in front of any current address. The table below is shown with the addition of the '#' character to

each address. For information on the maximum data that can be read with a multi-point command, refer to

Multi-Point Limitations.

There are some things that should be considered when using the multi-point read functions. The multi-point

command can increase the speed of the data acquisition but if overused, it will need to make multiple multipoint commands to read all the requested data. When this occurs, the overall performance of the driver will

be reduced. The key is to use the multi-point command wisely.

The driver will automatically group data from memory types like bit memory into 16 bit values. For example,

for the PC3 model, if P1-X1, P1-X3, P1-X4, P1-X6, P1-X9, P1-XA, P1-XB are marked as part of a multi-point

read using the '#', users would enter an address of #P1-X1, #P1-X3, #P1-X4, #P1-X6, #P1-X9, #P1-XA, #P1XB. These seven items would be placed into a single 16 bit value; therefore, users would use only one of the

128 16 bit values available in a single multi-point read command. The 7 items were grouped together

because the address of each bit fell within a single 16 bit word value of X memory. If 7 items like #P1-X1,#P1X20,#P1-X55,#P1-X77,#P1-X99,#P1-XAA,#P1-XBB are entered as part of a multi-point read, each bit in this

case would require an entire 16 bit value in the multi-point read command to receive the data. Plan the data

usage in the controller. If possible, make sure that the bits being read are grouped closely. This prudent

planning applies primarily to the bit memory types. Register memory requires a single 16 bit value (two 16

bit values in the case of DWords) for each register that is added to the multi-point read.

By using this information, users can plan the multi-point reads. The Toyopuc PC3/PC2 Ethernet Driver can

perform as many multi-point reads as are needed to acquire all the data that has been marked for multipoint operation. Remember, however, that the driver will run slower when there are many read being run. To

determine how many multi-point read requests the Toyopuc Ethernet PC3PC2 driver is using to acquire all

currently defined multi-point data, use the special diagnostic tag "_DeviceMultiPointReads". For more

information on this tag, refer to Diagnostics.

The multi-point read operation can be combined with the normal data reads of the Toyopuc PC3/PC2

Ethernet Driver. For example, if a block of 50 D registers consecutively ordered is being read, it may be

more efficient to read the 50 D registers as part of a normal block read and save the space in the multi-point

read function for data that is spread more randomly throughout the PLC memory. Use the diagnostics tags

to help determine the most efficient way of acquiring the data for the application.

Multi-Point Limitations

For tags belonging to device models PC3 Device and PC10G Device, the maximum data requested for the

data types are as follows:

Boolean: 1024*

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Byte: 128

Word: 64

DWord: 32

*If contiguous Booleans are requested, the request will be done in one multi-point read.

Combination of any of the above data types in a single multi request has to be within the following limit:

(No. of Booleans/16) + (No. of Bytes/2) + No. of Words + (No. of DWords * 2) <= 64

For tags belonging to device model PC2/PC2 Interchange, the maximum data requested for the data types

are as follows:

Boolean: 2048*

Byte: 256

Word: 128

DWord: 64

*If contiguous booleans are requested, the request will be done in one multi-point read.

Combination of any of the above data types in a single multi request has to be within the following limit:

(No. of Booleans/16) + (No. of Bytes/2) + No. of Words + (No. of DWords * 2) <= 128

16

Memory Types Shown with the Multi-Point Marker

Memory Type Syntax Data Types Access

Edge Relay (P) #P0000-#P01FF

#P000-#P01F

#P000-#P01E

Keeping Relay (K) #K0000-#K02FF

#K000-#K02F

#K000-#K02E

Specific Relay (V) #V0000-#V00FF

#V000-#V0F

#V000-#V0E

Timer Bits (T) #T0000-#T01FF

#T000-#T01F

#T000-#T01E

Count Bits (C) #C0000-#C01FF

#C000-#C01F

#C000-#C01E

Link Relay (L) #L0000-#L07FF

#L000-#L07F

#L000-#L07E

I/O Relay (X) #X0000-#X07FF

#X000-#X07F

#X000-#X07E

I/O Relay (Y) #Y0000-#Y07FF

#Y000-#Y07F

#Y000-#Y07E

Internal Relay (M) #M0000-#M07FF

#M000-#M07F

#M000-#M07E

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

www. kepware.com

17

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax Data Types Access

Specific Register (S) #S0000-#S03FF

#S0000-#S03FE

Timer/Present Value Register

(N)

Link Register (R) #R0000-#R07FF

Data Register (D) #D0000-#D2FFF

File Register (B) #B0000-#B1FFF

Extended I/O Relay (EX) #EX0000-

Extended I/O Relay (EY) #Y0000-#Y07FF

Extended Internal Relay (EM) #EM0000-

Extended Keep Relay (EK) #EK0000-

Extended Special Relay (EV) #EV0000-

Extended Timer Bits (ET) #ET0000-

Extended Counter Bits (EC) #EC0000-

Extended Link Relay (EL) #EL0000-

Extended Edge Direction (EP) #EP0000-

Extended Data Register (U) #U0000-#U7FFF Byte, Word, Short, BCD DWord, Long, Read/Write

#N0000-#N01FF

#N0000-#N01FE

#R0000-#R07FE

#D0000-#D2FFE

#B0000-#B1FFE

#EX07FF

#EX000-#EX07F

#EX000-#EX07E

#Y000-#Y07F

#Y000-#Y07E

#EM1FFF

#EM000-

#EM1FF

#EM000-

#EM1FE

#EK0FFF

#EK000-#EK0FF

#EK000-#EK0FE

#EV0FFF

#EV000-#EV0FF

#EV000-#EV0FE

#ET07FF

#ET000-#ET07F

#ET000-#ET07E

#EC07FF

#EC000-#EC07F

#EC000-#EC07E

#EL1FFF

#EL000-#EL1FF

#EL000-#EL1FE

#EP0FFF

#EP000-#EP0FF

#EP000-#EP0FE

Byte, Word, Short, BCD DWord, Long,

LBCD

Byte, Word, Short, BCD DWord, Long,

LBCD

Byte, Word, Short, BCD DWord, Long,

LBCD

Byte, Word, Short, BCD DWord, Long,

LBCD

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Boolean

Byte, Word, Short, BCD DWord, Long,

LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax Data Types Access

#U0000-#U7FFE LBCD

Extended Timer/Counter Value

(EN)

Extended Setup Value Register

(H)

Extended Special Register #ES0000-

#EN0000#EN07FF

#EN0000-

#EN07FE

#H0000-#H07FF

#H0000-#H07FE

#ES07FF

#ES0000-

#ES07FE

Byte, Word, Short, BCD DWord, Long,

LBCD

Byte, Word, Short, BCD DWord, Long,

LBCD

Byte, Word, Short, BCD DWord, Long,

LBCD

Read/Write

Read/Write

Read/Write

18

www. kepware.com

19

Data Type Description

Data Type Description

Boolean Single bit

Byte Unsigned 8-bit value

bit 0 is the low bit

bit 7 is the high bit

Word Unsigned 16-bit value

bit 0 is the low bit

bit 15 is the high bit

Short Signed 16-bit value

bit 0 is the low bit

bit 14 is the high bit

bit 15 is the sign bit

DWord Unsigned 32-bit value

Toyopuc PC3/PC2 Ethernet Driver

bit 0 is the low bit

bit 31 is the high bit

Long Signed 32-bit value

bit 0 is the low bit

bit 30 is the high bit

bit 31 is the sign bit

BCD Two byte packed BCD

Value range is 0-9999. Behavior is undefined for values beyond this range.

LBCD Four byte packed BCD

Value range is 0-99999999. Behavior is undefined for values beyond this range.

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Address Descriptions

The Toyopuc PC3 driver supports the PC2 PLC, PC3 PLC and PC10G PLC. When configuring the OPC Server

application, users must choose a PLC model type when defining a device connection. Based on that model

selection, two different PLC data addressing modes will be available to access data within the PLC. Select a

link from the following list to obtain specific address information for the model of interest.

PC2/PC2 Interchange

PC3 Device

PC10G

PC2/PC2 Interchange Mode Address Descriptions

When the PC2 model has been selected, the Toyopuc Computer Link Protocol supports the following

addresses. These address types are only available when using a PC2 PLC or using a PC3 PLC in PC2

Interchange mode. For more information, refer to Addressing Examples.

Note: The valid address range of each memory type depends on the data type being accessed. Please refer

to the Syntax and Data Types columns below. The valid range (syntax) is shown on the same line as the data

type(s). For example, the valid range for Edge Relay is P0000-P01FF if the data type being accessed is

Boolean. If the data type being accessed is byte, word, short or BCD, the valid range is P000-P01F. If the data

type is DWord, Long or LBCD, the valid range is P000-P01E. The default data types for dynamically defined

tags are shown in bold.

20

Memory Type Syntax Data Type Access

Edge Relay (P) P0000-P01FF

P000-P01F

P000-P01E

Keeping Relay (K) K0000-K02FF

K000-K02F

K000-K02E

Specific Relay (V) V0000-V00FF

V000-V0F

V000-V0E

Timer Bits (T) T0000-T01FF

T000-T01F

T000-T01E

Count Bits (C) C0000-C01FF

C000-C01F

C000-C01E

Link Relay (L) L0000-L07FF

L000-L07F

L000-L07E

I/O Relay (X) X0000-X07FF

X000-X07F

X000-X07E

I/O Relay (Y) Y0000-Y07FF

Y000-Y07F

Y000-Y07E

Internal Relay (M) M0000-M07FF Boolean Read/Write

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

www. kepware.com

21

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax Data Type Access

M000-M07F

M000-M07E

Specific Register (S) S0000.0...S0000.F-S03FF.0...S03FF.F

S0000-S03FF

S0000-S03FE

Present Value Register

(N)

Link Register (R) R0000.0...R0000.F-R07FF.0...R07FF.F

Data Register (D) D0000.0...D0000.F-D02FFF.0...D2FFF.F

File Register (B) B0000.0...B0000.F-B01FFF.0...B1FFF.F

N0000.0...N0000.F-N01FF.0...N01FF.F

N0000-N01FF

N0000-N01FE

R0000-R07FF

R0000-R07FE

D0000-D2FFF

D0000-D2FFE

B0000-B1FFF

B0000-B1FFE

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte*, Word, Short, BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

*Low/High Byte Modifier

An optional Low (L) or High (H) byte modifier can be appended to any address. This modifier instructs the

driver that the low or high byte of the address word is requested. For more information, refer to Addressing

Examples.

Note: When adding a static tag with a low/high byte modifier, the data type must be set to Byte. For more

information on static vs. dynamic tags consult the OPC Server's online documentation.

Multi-Point Read Support

Multi-point read support allows the Toyopuc Ethernet driver to read data from multiple memory types

(based on program number) in a single request. The multi-point read function is available for both the PC3

and PC2 models and can be used across HPC Link or FL-net modules using relay routing. For more

information, refer to Multi-Point Read Support.

Diagnostics Tags

The Diagnostics Tags provide information on how the Toyopuc Ethernet driver is performing. For more

information, refer to Diagnostic Tags.

Array Support

All memory types support arrays, which can be of any data type. Only the following exceptions apply:

1. Byte arrays are not supported (this also means that low/high byte modifiers cannot be used with

array syntax).

2. Boolean arrays are not supported for bit within word type addresses. For example, addresses like

'S0000.0' cannot be used with array notation. Discrete types support Boolean arrays.

3. Multi-point read is not supported for arrays.

The array size cannot exceed the internal block size of 512 bytes. Array syntax is specified by adding '[r]'

(rows) or '[r][c]' at the end of the address string. [r]: rows, [c]: columns.

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Addressing Examples

1. Request 'Specific Relay FF' from program 1 --> P1-VFF.

2. Request High Byte of 'Data Register 10' --> D10H.

3. Request 'Data Register 1000' --> D1000.

4. Request Long value (2 consecutive 16 bit registers) starting at 'Link Register 7E' in program 1 --> P1L7E@LONG (set data type to Long for static tags, or append '@LONG' to address for dynamic tags.

For more information on static vs. dynamic tags consult the OPC Server online Help.

5. Request 20 bits starting at 'I/O Relay 256' --> X0256[20](set data type to BOOLEAN for static tags, or

append '@BOOLEAN' to address for dynamic tags).

6. Request 24 bits starting at 'Edge Relay 100' --> P0100[4][6](set data type to BOOLEAN for static tags,

or append '@BOOLEAN' to address for dynamic tags).

7. Request 16 words starting at 'Specific Register 64' --> S0064[4][4].

8. Request 50 LBCDs starting at 'File Register 6' --> B0006[50](set data type to LBCD for static tags, or

append '@LBCD' to address for dynamic tags).

22

PC3 Address Descriptions

When the PC3 model has been selected, the Toyopuc Computer Link Protocol supports the following

addresses. These address types are only available when using a PC3 PLC. For more information, refer to

Addressing Examples.

Note: The valid address range of each memory type depends on the data type being accessed. Please refer

to the Syntax and Data Types columns below. The valid range (syntax) is shown on the same line as the data

type(s). For example, the valid range for Edge Relay is P0000-P01FF if the data type being accessed is

Boolean. If the data type being accessed is byte, word, short or BCD, the valid range is P000-P01F. If the data

type is DWord, Long or LBCD, the valid range is P000-P01E. The default data types for dynamically defined

tags are shown in bold.

Memory Type Syntax* Data Type Access

Edge Relay (P) P0000-P01FF

P000-P01F

P000-P01E

Keeping Relay (K) K0000-K02FF

K000-K02F

K000-K02E

Specific Relay (V) V0000-V00FF

V000-V0F

V000-V0E

Timer Bits (T) T0000-T01FF

T000-T01F

T000-T01E

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

www. kepware.com

23

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax* Data Type Access

Count Bits (C) C0000-C01FF

C000-C01F

C000-C01E

Link Relay (L) L0000-L07FF

L000-L07F

L000-L07E

I/O Relay (X) X0000-X07FF

X000-X07F

X000-X07E

I/O Relay (Y) Y0000-Y07FF

Y000-Y07F

Y000-Y07E

Internal Relay (M) M0000-M07FF

M000-M07F

M000-M07E

Specific Register (S) S0000.0...S0000.F-S03FF.0...S03FF.F

S0000-S03FF

S0000-S03FE

Present Value Register

(N)

Link Register (R) R0000.0...R0000.F-R07FF.0...R07FF.F

Data Register (D) D0000.0...D0000.F-D02FFF.0...D2FFF.F

File Register (B) B0000.0...B0000.F-B01FFF.0...B1FFF.F

Extended I/O Relay (EX) EX0000-EX07FF

Extended I/O Relay (EY) EY0000-EY07FF

N0000.0...N0000.F-N01FF.0...N01FF.F

N0000-N01FF

N0000-N01FE

R0000-R07FF

R0000-R07FE

D0000-D2FFF

D0000-D2FFE

B0000B1FFF

B0000B1FFE

EX000-EX07F

EX000-EX07E

EY000-EY07F

EY000-EY07E

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax* Data Type Access

Extended Internal Relay

(EM)

Extended Keep Relay (EK) EK0000-EK0FFF

Extended Special Relay

(EV)

Extended Timer Bits (ET) ET0000-ET07FF

Extended Counter Bits

(EC)

Extended Link Relay (EL) EL0000-EL1FFF

Extended Edge Direction

(EP)

Extended Data Register

(U)

Extended Timer/Counter

Value (EN)

Extended Setup Value

Register (H)

Extended Special

Register (ES)

Extended Input Relay (GX) GX0000-GXFFFF

EM0000-EM1FFF

EM000-EM1FF

EM000-EM1FE

EK000-EK0FF

EK000-EK0FE

EV0000-EV0FFF

EV000-EV0FF

EV000-EV0FE

ET000-ET07F

ET000-ET07E

EC0000-EC07FF

EC000-EC07F

EC000-EC07E

EL000-EL1FF

EL000-EL1FE

EP0000-EP0FFF

EP000-EP0FF

EP000-EP0FE

U0000.0...U0000.F -U07FFF.0...U7FFF.F

U0000-U7FFF

U0000-U7FFE

EN0000.0...EN0000.FEN07FF.0...EN07FF.F

EN0000-EN07FF

EN0000-EN07FE

H0000.0...H0000.F-H07FF.0...H07FF.F

H0000-H07FF

H0000-H07FE

ES0000.0...ES0000.FES07FF.0...ES07FF.F

ES0000-ES07FF

ES0000-ES07FE

GX000-GX0FFF

GX000-GX0FFE

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

24

www. kepware.com

25

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax* Data Type Access

Extended Output Relay

(GY)

Extended Internal Relay

(GM)

GY0000-GYFFFF

GY000-GY0FFF

GY000-GY0FFE

GM0000-GMFFFF

GM000-GM0FFF

GM000-GM0FFE

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short,

BCD

DWord, Long, LBCD

*Syntax

Addresses should be prefixed with "P1-", "P2-" or "P3-" to denote which PLC program in the PC3 contains the

desired address. For example, to read data register D10 from program 2 in the PC3, use the following

address syntax: P2-D10. If the device is in PC2 Interchange mode, use "P1-" to reference data.

Note: The extended addresses do not use the "P1-", "P2-", or "P3-" program indicator. If that is done, an

error message will be generated in the OPC server message window. Extended addresses must be entered

without any program number. For example, to request Extended I/O Relay (EX) 6FF, use the following syntax:

EX6FF.

Read/Write

Read/Write

**Low/High Byte Modifier

An optional Low (L) or High (H) byte modifier can be appended to any address. This modifier instructs the

driver that the low or high byte of the address word is requested. For more information, refer to Addressing

Examples.

Note: When adding a static tag with a low/high byte modifier, the data type must be set to Byte. For more

information on static vs. dynamic tags, consult the OPC Server online help.

Multi-Point Read Support

Multi-point read support allows the Toyopuc Ethernet driver to read data from multiple memory types

(based on program number) in a single request. The multi-point read function is available for both the PC3

and PC2 models and can be used across HPC Link or FL-net modules using relay routing. For more

information, refer to Multi-Point Read Support.

Diagnostics Tags

The Diagnostics Tags provide information on how the Toyopuc PC3/PC2 Ethernet Driver is performing. For

more information, refer to Diagnostic Tags.

Array Support

All memory types support arrays, which can be of any data type. Only the following exceptions apply:

l Byte arrays are not supported (this also means that low/high byte modifiers cannot be used with

array syntax).

l Boolean arrays are not supported for bit within word type addresses. For example, addresses like

'S0000.0' cannot be used with array notation. Discrete types support Boolean arrays.

l Multi-point read is not supported for arrays.

The array size cannot exceed the internal block size of 512 bytes. Array syntax is specified by adding '[r]'

(rows) or '[r][c]' at the end of the address string. [r]: rows, [c]: columns.

Addressing Examples

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

1. Request 'Specific Relay FF' from program 1 --> P1-VFF.

2. Request High Byte of 'Data Register 10' from program 2 --> P2-D10H.

3. Request Data Register 1000 from program 3 --> P3-D1000.

4. Request Extended I/O Relay 6FF --> EX6FF.

5. Request Long value (2 consecutive 16 bit registers) starting at 'Link Register 7E' in program 1 --> P1L7E@LONG (set data type to Long for static tags, or append '@LONG' to address for dynamic tags.

For more information on static vs. dynamic tags consult the OPC Server online Help.

6. Request 20 bits starting at 'I/O Relay 256' from program 2 --> P2-X0256[20] (set data type to

BOOLEAN for static tags, or append '@BOOLEAN' to address for dynamic tags).

7. Request 24 bits starting at 'Edge Relay 100' from program 1 --> P1-P0100[4][6] (set data type to

BOOLEAN for static tags, or append '@BOOLEAN' to address for dynamic tags).

8. Request 16 words starting at 'Specific Register 64' from program 3 --> P3-S0064[4][4].

9. Request 50 LBCDs starting at 'File Register 6' from program 1 --> P1-B0006[50](set data type to

LBCD for static tags, or append '@LBCD' to address for dynamic tags).

26

PC10G Address Descriptions

When the PC10G model has been selected, the Toyopuc Computer Link Protocol supports the following

addresses. These address types are only available when using a PC10G PLC. For more information, refer to

Addressing Examples.

Note 1: The PC10G model also accepts arrays. For example, U0000[2][2].

Note 2: The valid address range of each memory type depends on the data type being accessed. Please

refer to the Syntax and Data Types columns below. The valid range (syntax) is shown on the same line as the

data type(s). For example, the valid range for Edge Relay is P0000-P01FF if the data type being accessed is

Boolean. If the data type being accessed is byte, word, short or BCD, the valid range is P000-P01F. If the data

type is DWord, Long or LBCD, the valid range is P000-P01E. The default data types for dynamically defined

tags are shown in bold.

Memory Type Syntax* Data Type Access

Edge Relay (P) P000-P1FF

P00-P1F

P00-P1E

Edge Relay (P) P1000-P17FF

P100-P17F

P100-P17E

Keeping Relay (K) K000-K2FF

K00-K0F

K00-K0E

Specific Relay (V) V00-VFF

V0-VF

V0-VE

Specific Relay (V) V1000-V17FF

V100-V17F

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

www. kepware.com

27

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax* Data Type Access

V100-V17E DWord, Long, LBCD

Timer Bits (T) T000-T1FF

T00-T1F

T00-T1E

Timer Bits (T) T1000-T17FF

T100-T17F

T100-T17E

Count Bits (C) C000-C1FF

C00-C1F

C00-C1E

Count Bits (C) C1000-C17FF

C100-C17F

C100-C17E

Link Relay (L) L000-L7FF

L00-L7F

L00-L7E

Link Relay (L) L1000-L2FFF

L100-L2FF

L100-L2FE

I/O Relay (X) X000-X7FF

X00-X7F

X00-X7E

I/O Relay (Y) Y000-Y7FF

Y00-Y7F

Y00-Y7E

Internal Relay (M) M000-M7FF

M00-M7F

M00-M7E

Internal Relay (M) M1000-M17FF

M100-M17F

M100-M17E

Specific Register (S) S000.0-S3FF.F

S000-S3FF

S000-S3FE

Specific Register (S) S1000.0-S13FF.F

S1000-S13FF

S1000-S13FE

Present Value Register

(N)

Present Value Register

(N)

Link Register (R) R000.0-R7FF.F

Data Register (D) D0000.0-D2FFF.F Boolean Read/Write

N000.0-N1FF.F

N000-N1FF

N000-N1FE

N1000.0-N17FF.F

N1000-N17FF

N1000-N17FE

R000-R7FF

R000-R7FE

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax* Data Type Access

D0000-D2FFF

D0000-D2FFE

FB Escape Area (JL) JL0000.0-JL1FFF.F

JL0000-JL1FFF

JL0000-JL1FFE

SFC (JS) JS0000.0-JSFFF.F

JS0000-JSFFF

JS0000-JSFFE

Extended I/O Relay

(EX)

Extended I/O Relay

(EY)

Extended Internal Relay

(EM)

Extended Keep Relay

(EK)

Extended Special Relay

(EV)

Extended Timer Bits

(ET)

Extended Counter Bits

(EC)

Extended Link Relay

(EL)

Extended Edge Direction

(EP)

Extended Data Register

(U)

Extended Timer/Counter

Value (EN)

Extended Setup Value

Register (H)

Extended Special Register

(ES)

EX000-EX7FF

EX00-EX7F

EX00-EX7E

EY000-EY7FF

EY00-EY7F

EY00-EY7E

EM0000-EM1FFF

EM000-EM1FF

EM000-EM1FE

EK000-EKFFF

EK00-EKFF

EK00-EKFE

EV000-…

EV00-EVFF

EV00-EVFE

ET000-ET7FF

ET00-ET7F

ET00-ET7E

EC000-EC7FF

EC00-EC7F

EC00-EC7E

EL0000-EK1FFF

EL000-EK1FF

EL000-EK1FE

EP000-EPFFF

EP00-EPFF

EP00-EPFE

U000000-U1FFFF.F

U00000-U1FFFF

U00000-U1FFFE

EN0000-EN7FFF

EN000-EN7FF

EN000-EN7FE

H0000-H7FFF

H000-H7FF

H000-H7FE

ES0000-ES7FFF

ES000-ES7FF

ES000-ES7FE

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

28

www. kepware.com

29

Toyopuc PC3/PC2 Ethernet Driver

Memory Type Syntax* Data Type Access

Extended Input Relay

(GX)

Extended Output Relay

(GY)

Extended Internal Relay

(GM)

Extended Buffer Register

(EB)

Extended Flash Register

(FR)

GX0000-GXFFFF

GX000-GXFFF

GX000-GXFFE

GY0000-GYFFFF

GY000-GYFFF

GY000-GYFFE

GM0000-GMFFFF

GM000-GMFFF

GM000-GMFFE

EB00000.0EB3FFFF.F

EB00000-EB3FFFF

EB00000-EB3FFFE

FR000000.0FR1FFFFF.F

FR000000-FR1FFFFF

FR000000-FR1FFFFE

Boolean

Byte***, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Boolean

Byte**, Word, Short, BCD

DWord, Long, LBCD

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

*Syntax

Addresses should be prefixed with "P1-", "P2-" or "P3-" to denote which PLC program in the PC3 contains the

desired address. For example, to read data register D10 from program 2 in the PC3, use the following

address syntax: P2-D10. If the device is in PC2 Interchange mode, use "P1-" to reference data.

Note: The extended addresses do not use the "P1-", "P2-", or "P3-" program indicator. If that is done, an

error message will be generated in the OPC server message window. Extended addresses must be entered

without any program number. For example, to request Extended I/O Relay (EX) 6FF, use the following syntax:

EX6FF.

**Low/High Byte Modifier

An optional Low (L) or High (H) byte modifier can be appended to any address. This modifier instructs the

driver that the low or high byte of the address word is requested. For more information, refer to Addressing

Examples.

Note: When adding a static tag with a low/high byte modifier, the data type must be set to Byte. For more

information on static vs. dynamic tags, consult the OPC Server's online documentation.

Multi-Point Read Support

Multi-point read support allows the Toyopuc Ethernet driver to read data from multiple memory types

(based on program number) in a single request. The multi-point read function is available for the PC10G

model and can be used across HPC Link or FL-net modules using relay routing.For more information, refer to

Multi-Point Read Support.

Diagnostics Tags

Diagnostics tags provide information on how the Toyopuc PC3/PC2 Ethernet Driver is performing. For more

information, refer to Diagnostic Tags.

Array Support

All memory types support arrays, which can be of any data type. The following exceptions apply:

l Byte arrays are not supported (this also means that low/high byte modifiers cannot be used with

array syntax).

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

l Boolean arrays are not supported for bit-within-word type addresses. For example, 'S0000.0' cannot

be used with array notation. Discrete types support Boolean arrays.

l Multi-point read is not supported for arrays.

The array size cannot exceed the internal block size of 512 bytes. Array syntax is specified by adding '[r]'

(rows) or '[r][c]' at the end of the address string. [r]: rows, [c]: columns.

Addressing Examples

1. Request 'Specific Relay 100' from program 1 --> P1-V100.

2. Request 'Edge Relay 1000' from program 2 --> P2-P1000.

3. Request High Byte of 'Data Register 10' from program 2 --> P2-D10H.

4. Request Data Register 1000 from program 3 --> P3-D1000.

5. Request Extended I/O Relay 6FF --> EX6FF.

6. Request Extended Buffer Register 17FFF --> EB17FFF.

7. Request Long Value (2 consecutive 16 bit registers) starting at 'Link Register 7F' in program 1 --> P1L7F@LONG (set data type to Long for static tags or append '@LONG' to address for dynamic tags).

30

Note: For more information on static vs. dynamic tags, refer to the OPC Server's help documentation.

www. kepware.com

31

Toyopuc PC3/PC2 Ethernet Driver

Error Descriptions

The following categories of messages may be generated. Click on a link for a list of messages.

Address Validation

Device Status Messages

Device Error Codes

Address Validation

The following error/warning messages may be generated. Click on the link for a description of the message.

Missing address.

Device address <address> contains a syntax error.

Address <address> is out of range for the specified device or register.

Data Type <type> is not valid for device address <address>.

Device address <address> is read only.

Array size is out of range for address <address>.

Array support is not available for the specified address: <address>.

Missing address.

Error Type:

Warning

Possible Cause:

A tag address that has been specified dynamically has no length.

Solution:

Re-enter the address in the client application.

Device address <address> contains a syntax error.

Error Type:

Warning

Possible Cause:

A tag address that has been specified dynamically contains one or more invalid characters.

Solution:

Re-enter the address in the client application.

Address <address> is out of range for the specified device or register

Error Type:

Warning

Possible Cause:

A tag address that has been specified dynamically references a location that is beyond the range of

supported locations for the device.

Solution:

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Verify the address is correct; if it is not, re-enter it in the client application.

Data Type <type> is not valid for device address <address>.

Error Type:

Warning

Possible Cause:

A tag address that has been specified dynamically has been assigned an invalid data type.

Solution:

Modify the requested data type in the client application.

Device address <address> is read only.

Error Type:

Warning

Possible Cause:

A tag address that has been specified dynamically has a requested access mode that is not compatible with

what the device supports for that address.

32

Solution:

Change the access mode in the client application.

Array size is out of range for address <address>.

Error Type:

Warning

Possible Cause:

A tag address that has been specified statically is requesting an array size that is too large for the address

type or block size of the driver.

Solution:

Re-enter the address in the client application to specify either a smaller value for the array or a different

starting point.

Array support is not available for the specified address: <address>.

Error Type:

Warning

Possible Cause:

A tag address that has been specified statically contains an array reference for an address type that doesn't

support arrays.

Solution:

Either re-enter the address in the client application to remove the array reference or correct the address

type.

www. kepware.com

33

Toyopuc PC3/PC2 Ethernet Driver

Device Status Messages

The following error/warning messages may be generated. Click on the link for a description of the message.

Device <device name> is not responding.

Unable to write to <address> on device <device name>.

Device <device name> is not responding.

Error Type:

Serious

Possible Cause:

1. The driver cannot create a socket connection between the device and the Host PC.

2. The response from the device took longer to receive than the amount of time specified in the

"Request Timeout" device setting.

3. The IP address for the device is incorrect.

4. The TCP/IP Port specified in device settings is incorrect.

Solution:

1. Verify that the Ethernet connections between the PC and the network are functional.

2. Increase the Request Timeout setting so that the entire response can be handled.

3. Verify that the Ethernet connections between the device and the network are functional.

4. Verify that the specified IP address matches the Device IP.

5. Verify that the specified TCP/IP Port matches the port used by the device.

Unable to write to <address> on device <device name>.

Error Type:

Serious

Possible Cause:

1. The driver cannot create a socket connection between the device and the Host PC.

2. The IP address for the device is incorrect.

3. The TCP/IP Port specified in device settings is incorrect.

Solution:

1. Verify that the Ethernet connections between the PC and the network are functional.

2. Verify that the Ethernet connections between the device and the network are functional.

3. Verify that the specified IP address matches the Device IP.

4. Verify that the specified TCP/IP Port matches the port used by the device.

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Device Error Codes

The following error/warning messages may be generated. Click on the link for a description of the message.

Device Error Codes

Error Response Data: Error Code Table

Error Response Data: Error Code Table

34

Error

Code

11 Inability to process data because of faulty CPU Module Hardware.

20 Fixed Data (ENQ) within relay command is not "05."

21 Faulty transfer number (there is erroneous transfer byte number within the relay command).

23 Erroneous command code.

24 Erroneous subcommand code.

25 Erroneous command-format data byte.

26 Erroneous function-call operand number.

31 Attempting to write data into the field where any writing is prohibited during a sequence

32 A command that is defeated during a stop continuity is activated during a stop continuity.

33 Attempting to execute a debug function call despite non-debug mode.

34 Access prohibited owing to access-prohibited configuration.

35 Non-executable owing to execution-priority limiting configuration.

36 Non-executable owing to execution-priority limiting configuration by another device.

39 Attempting to start scanning without any reset after writing I/O point-number parameters or I/O

3C During a fatal failure, a command has issued that is not executable during a fatal failure.

3D Non-executable due to competing process while a different-factor command is executed.

3E Non-executable command due to reset existence.

3F Non-executable command due to stop duration.

40 Address of a reading/writing command or of "address+data number" of a command is out of

41 Word/byte number is out of range.

42 Non-designated data is sent.

43 Erroneous function/call operand.

52 Though any timer or counter is employed, a command for reading/writing the set/recent values

66 No reply is sent from link module with the link exchange No. specified by a relay command

70 Non-executable module with the link exchange No. specified by a relay command (owing to

72 No reply is sent from link module with the link exchange No. specified by relay command (owing

73 Multiple relay commands were issued to the same link module from the CPU module and the

Error Description

operation or to use the function call (which is protected from any execution) during a sequence

operation.

allocation point-number parameters.

range.

is issued.

(owing to no existence of specified link module, power OFF, faulty circuit, or etc.).

erroneous link No. designation or faulty link module).

to no existence of specified link module, power OFF, faulty circuit, or etc.).

link module could not process the commands. Send commands again.

www. kepware.com

35

Note: Codes taken from Toyopuc document: TOYOPUC PC3J/PC2J FL/ET-T-V2 Instruction Manual.

Toyopuc PC3/PC2 Ethernet Driver

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

Appendix: Configuring Modules

Configing the FL_ET-T-V2 Ethernet Module

Configuration Ladder for EN-I_F Ethernet Module

Configuring the PC10G CPU for Ethernet Connections

Configuring the PC10G-CPU for Ethernet Communications

Before the PC10G-CPU can be used for Ethernet communications, it must be configured using PCWin

version 10 or above. The following example first shows how to configure the built-in Ethernet port L2 and

then shows how to connect to the PC with PCWin to the PC10G-CPU using a USB connection.

1. To start, open PCWIN.

36

www. kepware.com

37

Toyopuc PC3/PC2 Ethernet Driver

2. To setup the communication between PCWin and PC10G-CPU, click Setup | Setup Communication

Module. If it is the first time configuring PCWin, select Addition and then make the selections as

shown below.

3. Next, make sure that the COM_SERV icon (shown on the bottom right side of the screen) appears as

shown below. The red icon indicates that the connection between PCWin and PC10G-CPU hasn't been

established yet. There are two possible solutions:

l Check the cable connections.

l Reinstall the USB driver that came with the PCWin setup.

4. Optional: To monitor PC10G data from PCWin, go to the menu bar and click Option |

Configuration. Then, select Compatibility and make the selections as shown in the image below.

5. Back in the Project Window, select the Project tab. Then, click Parameters | Link Parameter.

www. kepware.com

Toyopuc PC3/PC2 Ethernet Driver

6. Click Link setup(S) and make the following selections:

l Rack No.(R) - Built-in

38

l Slot No. (S) - L2 Link

l Module Name - Ethernet

7. Click OK.

8. Click Detail(D). In this dialog, the following parameters may be specified:

l In Own Node IP Address, set the desired IP address of the Ethernet Port.