Page 1

™

TOXALERT’S Model TOX-REFRIG Refrigerant Leak

Monitoring System consists of a remote refrigerant sensor

or sensors and a controller/annunciator panel. The TOXREFRIG system is designed to continuously monitor

mechanical refrigeration equipment rooms for refrigerant

leaks and upon detecting a leak, the unit shall start

ventilation equipment and annunciate alarm conditions.

ANSI/ASHRAE Standard 15-2010 calls for the use of

refrigerant leak detectors.

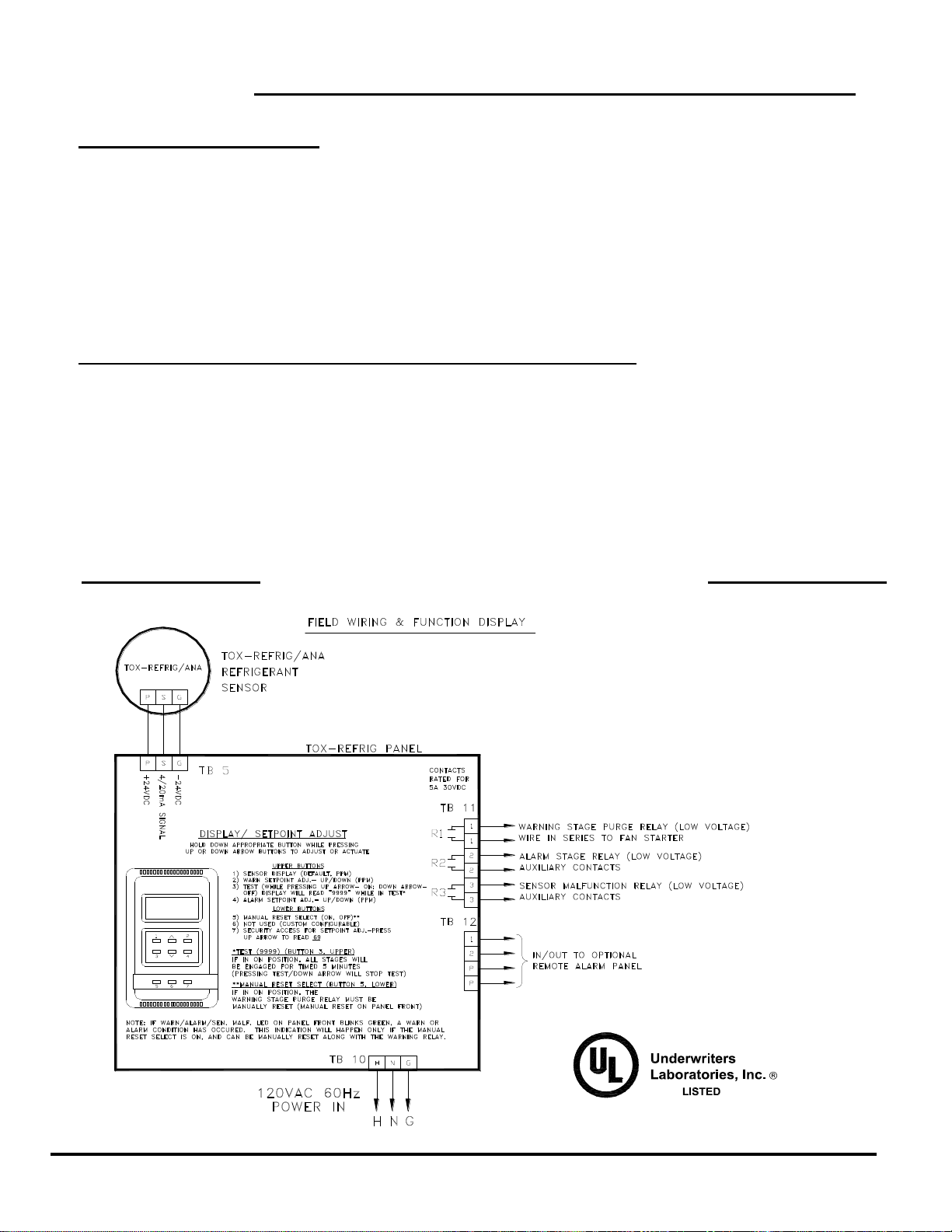

The controller’s first stage or “Warning (Purge) Stage”

activates a set of relay contacts to operate exhaust fan(s) or

other mechanical equipment, and the sensor LED on panel

front will light green. The second stage or “Alarm Stage”

activates an audible alarm with reset and silence

pushbutton switch, an auxiliary set of relay contacts, and

the sensor LED on panel front will light red. On a

decrease in refrigerant concentration, the alarm stage

automatically resets and the warning stage is field

selectable for manual or automatic reset- (manual reset

select). If the manual reset select option is turned on and

the sensor detects a warning or alarm condition, the

warning relay will remain activated and the sensor LED on

panel front will blink green, even after the concentration

has decreased. That function can be manually reset via a

reset button located on panel front.

A “Purge” switch on the controller front has two positionsON & AUTO. In the AUTO position, the warning stage

relay energizes automatically from sensor monitoring; in

the ON position, the warning contacts are manually

energized.

TOXALERT

REFRIGERANT MONITOR MODEL: TOX-REFRIG

MECHANICAL ROOM REFRIGERANT LEAK

DETECTION SYSTEM

TYPICAL APPLICATIONS:

Mechanical Rooms in:

Commercial Buildings

College/Universities

Hospitals

Sports Facilities

Refrigerant Warehouses

GENERAL DESCRIPTION:

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 • 952/472 -4541 • 952/472-4960

Industrial Chemical Plants

Resorts

Supermarkets

Blood Banks

Tox-Refrig

Tox-Refrig/ANA

www.toxalert.com

Page 2

The remote refrigerant sensor(s) is continuously monitored by the controller for sensor failure. If the

sensor malfunctions, the controller shall cause the sensor LED to blink red, and activate the warning stage

relay as well as a sensor malfunction relay contact.

FEATURES

Warning (purge) stage indication

Alarm stage indication

Sensor malfunction indication

Relay outputs for control of ventilation

equipment and remote alarming (Warn,

Alarm, Sensor Malfunction)

Optional auxiliary relay contacts for

shutdown of combustion equipment

Operation meets ANSI/ASHRAE 15-2010

Digital readout (Refrigerant in PPM)

Field adjustable setpoints with security

Test function

Field selectable warning stage reset

(manual/auto)

Audible alarm (integral to control unit)

Interface to automation system (digital and/or

optional analog)

Multiple sensor inputs (optional)

Remote Alarm Capabilities

BACnet MS/TP Protocol

Optional Strobe Light

MECHANICAL ROOM REQUIREMENTS

In the Forward of ASHRAE Standard 15-2010, it states in part, “All machinery rooms are required to have detectors

that actuates an alarm and mechanical ventilation at a value not greater than the corresponding TLV-TWA (or

toxicity measure consistent therewith”. ASHRAE Standard 15-2010, section 7 & 8 requires detectors to monitor for

refrigerant leaks. The standard reads as follows:

Paragraph 8.11.2.14 reads-

“Each machinery room shall contain a detector, located in an area where refrigerant from a leak will

concentrate, that actuates an alarm and mechanical ventilation in accordance with 8.11.4 at a value not

greater than the corresponding TLV-TWA (or toxicity measure consistent therewith).”

Paragraph 8.11.6

“Combustion equipment shall not be installed in the same machinery room with refrigerant containing

equipment except under one of the following conditions:

(b) a refrigerant detector ….. is employed to automatically shut down the combustion process in the

event of refrigerant leakage.

Exception: For ammonia refer to paragraph 8.12(h).

SENSOR LOCATION:

ASHRAE Std. 15-2010- “locate in an area where refrigerant from a leak will concentrate” is very ambiguous and for

good reason. There are a wide variety of equipment room configurations and sizes.

A few keys to locating refrigerant sensors are: (1) remember that occupant safety is the primary motive for installing

the sensor; (2) determine the air flow pattern in the room; (3) the primary hazard of a refrigerant to a room occupant

is the inhalation of the toxic refrigerant.

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 • 952/472-4541 • 952/472-4960

www.toxalert.com

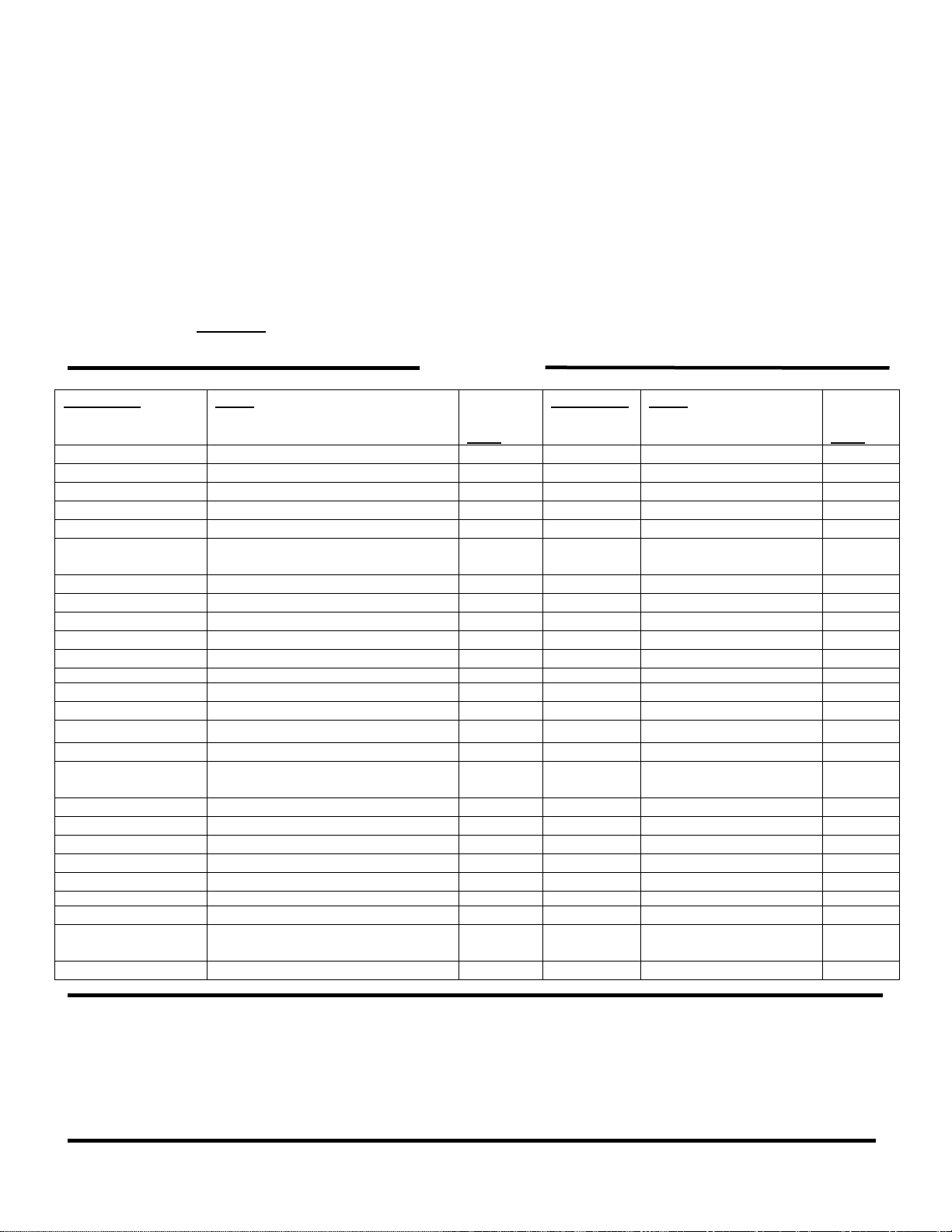

Page 3

Refrigerant

Name

TLVTWA

(a)

PPM

Refrigerant

Name

TLVTWA

PPM

Safety Group A1

(b)

R-11

Trichoroflouremethane

1100

R-402A

R-125/290/22

1000

R-12

Dichlorodifluoromethane

18000

R-404A

R-125/143a/134a

1000

R-13

Chlorotrifluoromethane

1000

R-407C

R-32/125/134a

1000

R-13B1

Bromotrifluoromethane

1000

R-410A

R-32/125

1000

R-14

Tetrafluoromethane (Carbon

Tetrafluoride)

1000

R-500

R-12/152a

1000

R-22

Chlorodifluoromethane

1000

R-502

R-22/115

1000

R-113

Trichorotrifluoroethane

1000

R-503

R-23 & R-13

1000

R-114

Dichlorotetrafluoroethane

1000

R-507

R-125 & R-143a

1000

R-115

Chloropentafluoroethane

1000

R-740

Argon

…..

R-134a

1,1,1,2-Tetrafluoroethane

1000

R-744

Carbon Dioxide

5000

Safety Group A2

(b)

R-142b

1-Chloro-1, 1-Diflurorethane

1000

R-152a

1,1-Difluroethane

1000

Safety Group A3

(b)

R-170

Ethane

1000

R-600a

2-Methyl propane

(Isobutane

1000

R-290

Propane

1000

R-1150

Ethene (Ethylene)

200

R-600

Butane

1000

R-1270

Popene (Propylene)

500

Safety Group B1

(b)

R-123

2,2-Dichlor-1, 1,1-Triflurooethane

50

R764

Sulfur Dioxide

…..

Safety Group B2

(b)

R-40

Chloromethane (Methyul

Chloride)

…..

R-717

Ammonia

25

R-611

Methyl Formate

100

Mounting height of refrigerant sensors should be within 20 inches of the floor. The Forward of Std. 15-2010 states ,

“(all commonly used refrigerants, except ammonia (R-717)….. are heavier than air).” By placing the sensor below the

common breathing height of 5 to 6 feet, you will provide and added margin of safety.

Floor Plan Location- If ventilation equipment is running continuously, the sensor should be located between the

refrigeration system and room exhaust, as close to the refrigerant equipment as possible. One sensor will usually be

adequate for applications with two (or less) chillers, provided chillers are aligned for good air flow and both chillers use

the same refrigerant. If ventilation equipment is NOT running continuously or if the direction of airflow is not obviouslocate the sensor(s) next to the refrigeration system. As a general guideline, a refrigeration system should not be more

than 50 feet from a refrigeration sensor.

NOTE: See Toxalert Technical Bulletins- “ToxRefrig InstRec- Section 5 (of the product catalog)”.

The following is a partial list of refrigerants that Toxalert monitors.

TABLE 1

(a) threshold limit value time weighted average: the time – weighted average concentration for a normal 8-hour

workday and a 40 hour work week to which nearly all works may be repeatedly exposed, day after day, without

adverse effect (as defined by ACGIH®). TLV® is a trademark of the American Conference of Governmental

Industrial Hygienists (ACGIH®).

(b) Defined by ANSI/ASHRAE Standard 34-2010

Note – See Toxalert Technical Bulletin Refrig for more information on refrigerant classifications.

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 • 952/472-4541 • 952/472-4960

www.toxalert.com

Page 4

TOX-REFRIG REVISED 2/12

TOX – REFRIG MONITOR

SPECIFICATIONS

TOX-REFRIG CONTROLLERInput Power: 120VAC, 60Hz, 1 Amp(fused)

Warning Setpoint: Field adjustable, factory set

Alarm Setpoint: Field adjustable, factory set

Warning Stage: Visual indication, Form C relay contacts

Alarm Stage: Visual indication, Form C relay contacts

Sensor Malfunction: Visual indication, warning stage

activation, and separate Form C relay contacts

Digital Readout: 3 1/2 digit, red LED, in PPM

TOX-REFRIG/ANA SENSOR: (specs for most Toxalert refrigerant sensors) ─ [Order Sensor Separately]

Relay Contacts: Rated for 5 Amps @ 120VAC, resistive

load

BACnet: MS/TP communications

Operating Range: 32°F to 120°F (0°C to 49°C)

Mechanical:

Dimensions:14”H x 12”W x 4”D

Classification: NEMA 1

Weight: 12 lbs

Method: Semiconductor cell diffusion barrier

type

Range: 15 to 500 PPM

Response: 90% of concentration in less than 30

sec.

Operating Range:

Temp: 14°F to 104°F. (-10°C to 40°C)

Humidity: 5 to 95% non-condensing

Typical Life: Four years in normal service

Maintenance: Periodic calibration

Mechanical:

Dimensions: 6.75”H x 4”W x 3.5”D

Material: Cast aluminum epoxy painted

Classification: Class I Division I Groups

C, D

Weight: 2 lbs.

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 • 952/472-4541 • 952/472-4960

www.toxalert.com

Loading...

Loading...