Page 1

TM

DATA

TOXALERT

SHEET

DIESEL EXHAUST SMOKE/VOC SENSOR MODEL GVU-VOC

TYPICAL INSTALLATIONS:

• Bus Garages • Vehicle Maintenance & Storage

• Fire Stations Highway Departments

• Tunnels Utilities

• Truck Warehouses Public Works

• Welding Shops

GENERAL DESCRIPTION:

The model GVU-VOC diesel smoke full spectrum sensor is designed

to interface with Toxalert International’s GVU series control units.

The GVU-VOC is a microprocessor-based air quality sensor utilizing

metal-oxide semi conductor technology. This is a full spectrum sensor

sensitive to a wide variety of air pollutants such as smoke,

hydrocarbons, gasoline fumes, acetone, toluene, etc. (see Table 3).

The GVU-VOC indicates its status with indicators for auto-power

on and processor normal, ok, low, mid or high for level of

contaminant detected.

BACKGROUND:

The diesel engine exhausts a great percentage of smoke (soot) as

well as, many hydrocarbons (e.g., ethylene, formaldehyde, methane,

benzene, and polynuclear aromatic hydrocarbons) and toxic gases

(e.g., nitric oxide, nitrogen dioxide and oxides of sulfur). The smoke

is particularly evident at the beginning of a work shift, when all

the buses or tracks are started in a maintenance/storage facility.

Even though, the exhaust smoke is not classified as a toxic, it is considered a carcinogen (reference:

carcinogenic effects of exposure to diesel exhaust - NIOSH Publication No. 88-116). Therefore many facility

owners are monitoring the smoke/hydrocarbons (VOC) as well as, the toxic oxides of nitrogen.

Model GVU-VOC

FEATURES:

• Micro processor based

• Power Indication

• Low, mid, high reading indicators

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

• Humidity and Temperature compensated

• Completely solid state for long life

• Low voltage class two (2) wiring

Page 2

SPECIFICATIONS

•

Type: Metal semi conductor

• Input voltage: 20- 30VAC from GVU controller

• Operating Temperature: 32º to 104ºF (0-40ºC)

•

Display: 5 indicaators ok, low, mid, high

• Sample Method: Diffusion

• Supply Current: 220 MA(max)

• Operating Humidity: 0-85% non-condensing

• Enclosure: AE wall mount

2.75”W x 4.65”H x 1.25”D

(70 x 118 x 32mm)

INSTALLATION INSTRUCTIONS

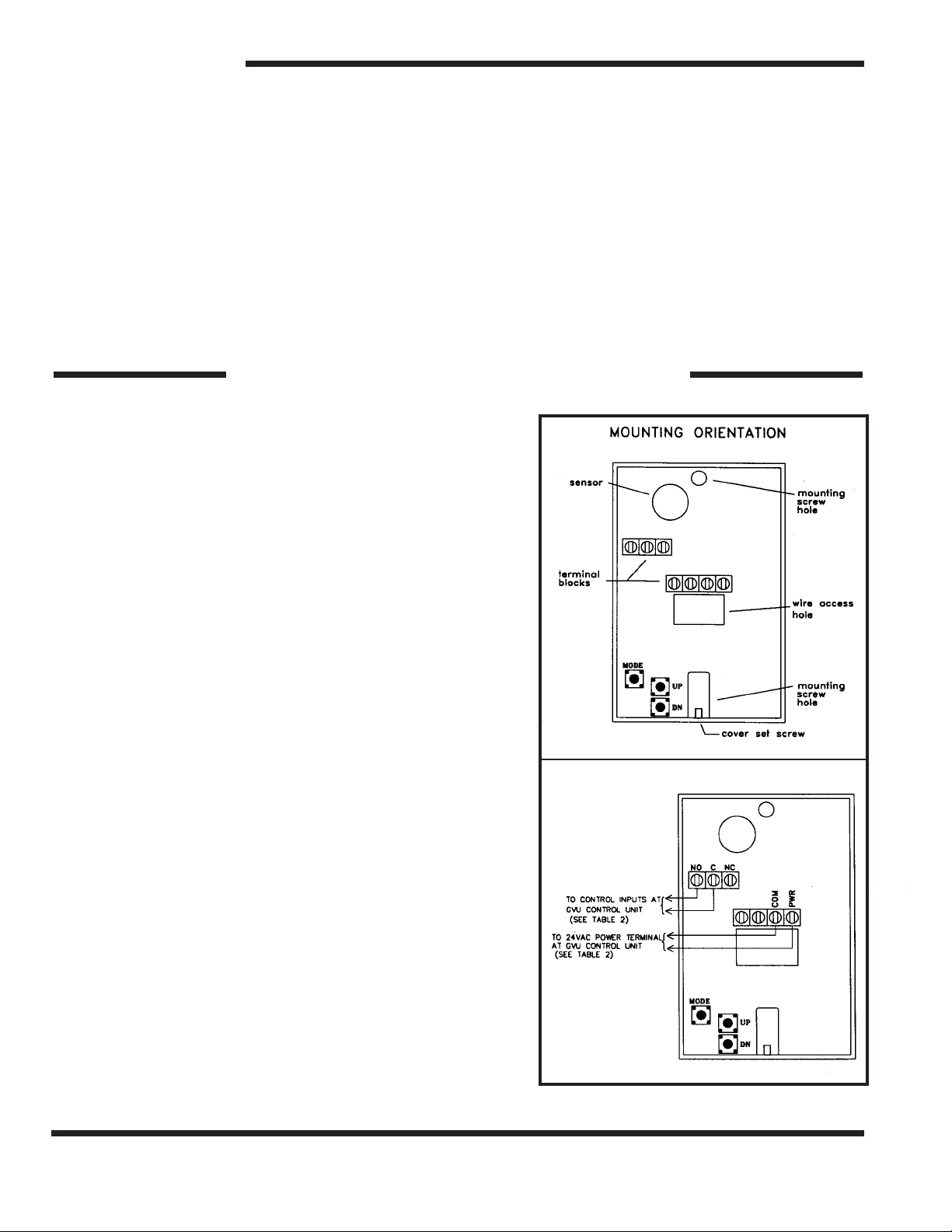

1. INSTALLATION

For best operation, locate a mounting location away from

direct fresh air intakes, doors and supply diffusers and

mount vertically on wall or support column approximately 5

to 6 feet above floor. An alternate location is in the ceiling

space of facilities with top discharge diesel vehicles. Refer to

figures 1 and 2; Table 1 and 2 and installation instructions in

GVU series control unit data sheet and install the GVUVOC sensor as follows.

2. COVER REMOVAL

Screw set-screw in bottom of cover in (clockwise) and

remove cover.

3. MOUNTING

The sensor has mounting provisions to install directly on a

standard electrical box.

4. SENSOR WIRING

WARNING: To prevent fire or shock hazard, turn

off power source to control unit before making

connections. Comply with all local building codes and

ordinances.

NOTE: Refer to Figure 2 and Tables 1 and 2. Use shield

cable to interconnect sensor and control unit if metal conduit is not used, or if conduit also contains AC wiring.

1.) Measure distance between sensing unit

and control unit and select proper wire or larger wire

from Table 1.

Figure 1:

Figure 2:

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

Page 3

2.) Run wiring between control and sensing

unit and into enclosure through access

holes. Connect wires from terminal

blocks in sensing unit to control unit per

Table 2 and GVU series control unit

data sheet.

5. START-UP

TABLE 1

AW G DO NOT EXCEED

#22 Wire 500 Ft. Sensor to Controller

#20 Wire 800 Ft. Sensor to Controller

#18 Wire 1300 Ft. Sensor to Controller

#16 Wire 2000 Ft. Sensor to Controller

1.) Verify all wiring connections are correct

and are tight.

2.) Apply power and note the status LEDs.

Initially the LEDs will flash in sequence

(OK, LOW, MID, HIGH and AUTO)

to indicate a successful start-up. The

device will then enter a three minute

warm-up cycle and this is indicated by a

TABLE 2 WIRING CONNECTIONS

GVU-VOC CONTROL UNITS

SENSOR GVU-1 GVU-3

PWR TB11-H(24VAC) TB3-H (24VAC)

COM TB11-N (COM) TB3-N (COM)

NO TB2-1 TB1-A1, B1, C1

COM TB2-7 TB1-A7, B7, C7

** TB2-5 TB1-A5, B5, C5

flashing AUTO LED and lit OK LED.

This mode will continue for three minutes

until the sensor has reached operating

** Shield of cable (if used) should be connected at control unit only.

Make sure sensor end is taped and isolated from terminals or metal.

temperature.

3.) After the initial warm-up period, the device will enter normal operation. This will be indicated by

the AUTO LED being lit and also one pollution level LED being lit (OK, LOW, MID or HIGH).

Note that the sensor is calibrated at manufacture to be suitable for use in average room conditions. The

sensor filter will accumulate dust over a period of inactive time and the sensor must be allowed to burnin before proper operation. This time will vary depending on the storage time, but the unit will be suitable for pre-commissioning after about 30 minutes.

4.) Replace cover.

TABLE 3

PARTIAL LIST OF CONTAMINATES DETECTED BY TOXALERT INTERNATIONAL GVUVOC SENSOR.

CHEMICAL COMMON SOURCE

Ethylene Diesel exhaust

Benzene, Toluene, Xylene Diesel exhaust, solvents and motor fuels

Methane Diesel exhaust, decomposition and sysnthesis

Formaldehyde Diesel exhaust, disinfectants and preservatives

Methyl Ethyl Ketone Solvents and cleaning products

Acetone Solvents and organic synthesis

Ethyl Alcohol Solvents and liquor fermentation

Hydrogen Used in synthetics

Continued on Page 4

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

Page 4

CHEMICAL COMMON SOURCE

Hydrogen Sulfide Water and putrefying matter

Methyl Alcohol Solvents, antifreeze and synthetics

Methyl Chloride Solvents, paints and refrigerants

Vinyl Chloride Textiles and polymers

Trichloroethylene Solvents and cleaning agents

Propane Fuels and chemical synthesis

Carbon Monoxide Combustion of carbon

Freon-22 Refrigerants and aerosols

Ammonia Solvents and refrigerants

GVU SERIES PRODUCTS:

CONTROLLERS -

GVU-1 Control unit for use with one sensor

GVU-3 Control unit for use with one to three remote sensors

REMOTE SENSORS -

GVU-CO Remote carbon monoxide sensor

GVU-CO

GVU-NO

Remote carbon dioxide sensor

2

Remote nitrogen dioxide sensor

2

GVU-VOC Remote smoke/air quality sensor

GVU-VOC 6/05

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

Loading...

Loading...