Page 1

TM

DATA

TOXALERT

SHEET

NITROGEN DIOXIDE SENSOR MODEL GVU-NO

DIESEL EXHAUST GAS DETECTOR

TYPICAL INSTALLATIONS:

• Parking Garages • Vehicle Maintenance & Storage

• Bus Garages Highway Departments

• Fire Stations Utilities

• Warehouses Public Works

• Car Dealers • Tunnels

GENERAL DESCRIPTION:

The model GVU-NO2 nitrogen dioxide sensor is designed to interface

with Toxalert International GVU series control units. The Model GVU-

utilizes an electrochemical sensing element and is designed for

NO

2

ambient monitoring applications. It is intended for use in fixed

monitoring installations, and therefore continuous operation. The

GVU-NO

requires a four-wire connection from a controller that provides a

nominal 24VDC power source, common and return signal input. The

GVU-NO

has an effective range of 0-10 ppm. The sensor module

2

has indicators for power on, fault status and high NO2.

2

2

The Toxalert Nitrogen Dioxide (NO

energy savings. A common producer of NO

Diesel exhaust is a know cancer causing agent as reported in the U.S.

Department of Health and Human Services’ Current Intelligence

bulletin 50 dated August 1988. An electrochemical cell is required to

measure such small amounts of NO

measuring NO

in increments of 0.1 ppm.

2

) Transmitter combines safety and

2

is diesel engine exhaust.

2

. The device’s sensor is capable of

2

Model GVU-NO

2

FEATURES:

• Power on indication

• High NO

• Fault Indicator

• Low voltage class two (2) wiring

• Convenient diagnostics

• Simple maintenance

• Operating range meets OSHA standard

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Indication

2

Visit our website at www. toxalert. com

Page 2

SPECIFICATIONS

•

Type: Electro-chemical cell diffusion barrier type

•Range: 0 to 10 ppm nitrogen dioxide in air

•Response Time: 30 seconds to 90% indication

•Typical life: Two years in normal service

•Accuracy: +/–5% of full scale

•Resolution: 0.1 ppm

•Operating Temperature: 4º to 122ºF

(–20ºC to 50ºC)

•Relative Humidity: 15 to 90% RH non-condensing

ELECTRICAL DATA:

• Input voltage: 24 VDC (provided from GVU control Unit)

•Wiring: 4 wire non-isolated

UNIT CONSTRUCTION:

•Mounting: Conduit 1/2” and 3/4” NPT or flexible cable

•Housing: Polystyrene, impact-resistant, non flammable, IP66

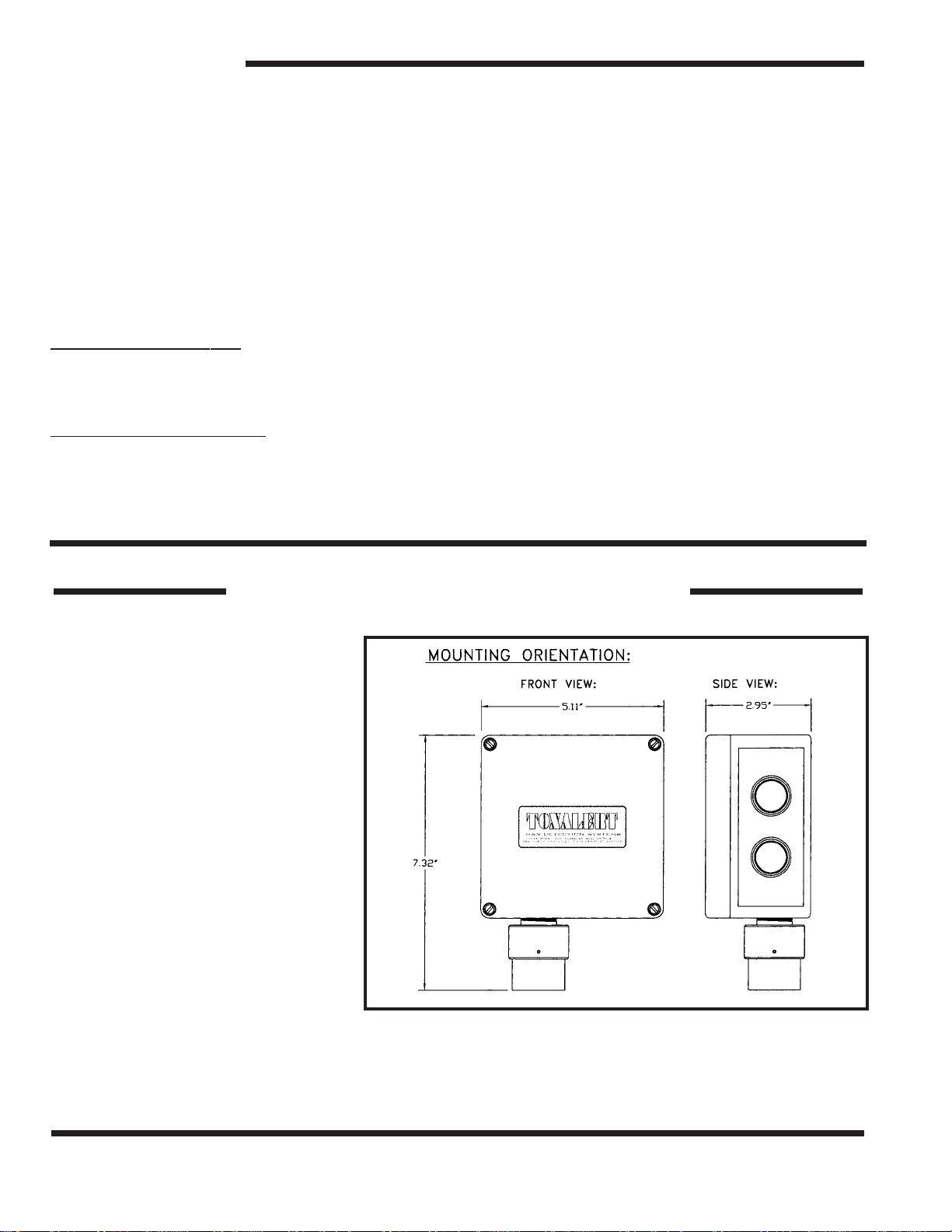

• Physical: 5.11”x 5.11” x 2.95” (13.0 x 13.0 x 7.5 cm)

•Weight: 14.2 oz.

INSTALLATION INSTRUCTIONS

1. INSTALLATION (For specific

details see sensor manual)

Locate a mounting location away

from direct fresh air intakes, and

mount vertically on wall or support

column approximately 3 to 6 feet

above floor. Refer to figures 1 and 2;

Table 1 and 2 and installation instructions in GVU series control unit data

sheet and install the GVU-NO

sensor as follows.

2. MOUNTING SENSOR

Install the module housing onto the

end of the supply conduit and bolt

into position as required.

3. SENSOR WIRING

WARNING: To prevent fire or shock hazard, turn

off power source to control unit before making

connections. Comply with all local building codes and ordinances.

2

Figure 1:

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

Page 3

INSTALLATION INSTRUCTIONS

NOTE: Refer to Figure 2 and Tables 1 and 2.

Use shielded cable to interconnect sensor and

control unit if metal conduit is not used, or if

conduit also contains AC wiring.

1.) Measure distance between sensing unit

and control unit and select proper wire

or larger wire from Table 1.

2.) Run wiring between control and

sensing unit and into enclosure through

access holes. Connect wires from terminal

blocks in sensing unit to control unit per

Table 2 and GVU series control unit data

sheet.

Figure 2:

4. START-UP

Reference Installation Manual

1.) Verify all wiring connections are correct.

2.) Electronics replacement - Carefully fit the electronics over the two posts in the enclosure and

tighten the captive panel screws.

3.) Apply Power

4.) Green power indicator should light

5.) Replace Cover

6.) Allow 1 hour to warm-up

TABLE 1

AW G DO NOT EXCEED

#22 Wire 500 Ft. Sensor to Controller

#20 Wire 800 Ft. Sensor to Controller

#18 Wire 1300 Ft. Sensor to Controller

#16 Wire 2000 Ft. Sensor to Controller

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

Page 4

TABLE 2 WIRING CONNECTIONS

GVU-NO

2

CONTROL UNITS

SENSOR GVU-1 GVU-3

J2-1 TB11-24 VDC (+) TB3-H (+24VDC

J2-3 TB11-24 VDC (–) TB3-N (–24VDC)

J3-1 TB2-1 TB1-A1, B1, C1

J3-3 TB2-7 TB1-A7, B7, C7

** TB2-5 TB1-A5, B5, C5

** Shield of cable (if used) should be connected at control unit only. Make sure

sensor end is taped and isolated from terminals or metal

GVU SERIES PRODUCTS:

CONTROLLERS -

GVU-1 Control unit for use with one sensor

GVU-3 Control unit for use with one to three remote sensors

GVU-6 Control unit for use with one to six remote sensors

GVU-12 Control unit for use with one to twelve remote sensors

GVU-18 Control unit for use with one to eighteen remote sensors

REMOTE SENSORS -

GVU-CO Remote carbon monoxide sensor

GVU-CO

GVU-NO

Remote carbon dioxide sensor

2

Remote nitrogen dioxide sensor

2

GVU-VOC Remote smoke/air quality sensor

GVU-NO2 5/07

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

Loading...

Loading...