Page 1

TM

DATA

TOXALERT

CO / CO

/ NO2 / OR VOC MONITOR MODEL GVU-1

2

SHEET

VEHICLE EXHAUST GAS DETECTOR

GENERAL DESCRIPTION:

The GVU-1 ventilation control monitor combines toxic gas sensing and time-based fan control modes in an all solidstate, low maintenance, cost effective product.

The GVU-1 controller consists of the power supplies, solid state clocks, time delays, and output relays. It can continuously monitor one of the following Toxalert sensors: GVU-CO carbon monoxide sensor, GVU-CO

GVU-VOC diesel smoke/air quality sensor. See last page for ordering information. (Please refer to applicable sensor data sheets).

TIME CONTROL:

The systems hourly timeclock outputs to the fan-on relay once per hour causing it

to energize. The on time of the fan-on relay is user adjustable, in one minute

increments from 1 to 8 minutes. The hourly timeclock operates in this manner

irrespective of sensor reading, and may be disabled, if desired. To disable the

hourly clock operation, place switch S3 to RST (RESET) position.

carbon dioxide sensor, GVU-NO2 nitrogen dioxide sensor or

2

VENTILATION CONTROL:

Should a high toxic concentration occur (above user adjustable alarm level), a 30

second delay timer will start. Should the concentration persist through the delay

period, the “alarm” clock is activated. The “on” time of this clock is user adjustable in discrete settings from 1 to 8 minutes and its setting is independent of the

hourly clock setting. Upon activation of the “alarm” clock, the “fan-on” relay

energizes and remains energized until the “alarm clock” times out. Should the

concentration still be above the alarm level, the “fan-on” relay shall remain ON

and the alarm relay shall energize. This condition is maintained until the concentration drops.

In the event of a power failure, the control unit sets itself to an alarm condition

upon power restoration. Thus, fan activation is assured, clearing out any accumulated toxic gases.

FEATURES

• User adjustable alarm setting

• User adjustable minimum fan run time

• User adjustable 2nd stage activation

• Completely solid-state for long life

• Controller LED indicators for high

concentration signal and fan on

• Operating range meets OSHA std. 1910.1000.

• UL listed upon request.

• Automatic fan start-up upon power r estoration

following power outage if desired.

• User adjustable clock activation of fans, if desired.

• NEMA 1 enclosure standard- others available.

OPTIONS

GVU-1A

(Control unit w/ integral CO sensor)

U

® L

Underwriters

Laboratories, Inc. ®

LISTED

• Audible alarm with silence switch

• Power on indicator

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

• Fan on indicator

• High gas concentration indicator

Page 2

SPECIFICATIONS

• Automatic fan run upon power restoration

• Input power: 120VAC, 60 Hz, 1A (fused)

• Relay contacts: 24VAC, 2A resistive, 1.5A inductive

• Timers: 30 second delay on

Min. Fan Run Time 1-8 minutes

Hourly Fan Run: 0-8 minutes

INSTALLATION INSTRUCTIONS

1. INTRODUCTION

Your TOXALERT ventilation control system incorporates the latest in solid state technology to give you

maximum reliability and performance. The system

alarm setpoint can be adjusted to activate fans upon

detection of an unsafe gas concentration such as carbon

monoxide, carbon dioxide, diesel smoke. In addition, a

user definable hourly repeat cycle is provided, allowing

time based, as well as concentration based fan activation. In both modes of fan control, the “on “ time is

user adjustable from 1 to 8 minutes in one minute

increments. For optimum performance, install, burn-in,

and check out your TOXALERT system exactly as

instructed. If your TOXALERT can’t be calibrated or

fails checkout, please contact your local representative

or TOXALERT International for servicing.

• Enclosure:

Nema 1 standard, others available

Dimensions: 12”H x 12”W x 4”D

(305mm x 305mm x 102mm)

Finish: Gray enamel

Weight: 8 lbs. (3.6kg)

FIG. 1

2. INSTALLATION

Locate a mounting location for the sensor away from

direct fresh air intakes, exhaust and/or supply fans, and

mount vertically on wall or support column normally 5

to 6 feet above floor (NO2 and CO2 sensor height may

differ per application). Mount GVU-VOC sensor in

ceiling. Refer to figs. 1, 2 and 3, to install and connect

the TOXALERT control unit and sensors as following.

(Please refer to job specific documentation for more

detailed wiring options).

CONTROL UNIT-

1) Unlock and open enclosure cover.

2) If necessary, cut access holes for wiring in enclosure

sides directly opposite terminal block TB2 and

slightly below terminal block TB1. First, remove the

four screws that secure chassis plate to enclosure

and then carefully remove plate and attached circuit

board; cut holes and remove metal chips from enclosure.

3) Mount enclosure with four screws.

4) Reinstall and secure chassis plate to enclosure with

the four screws

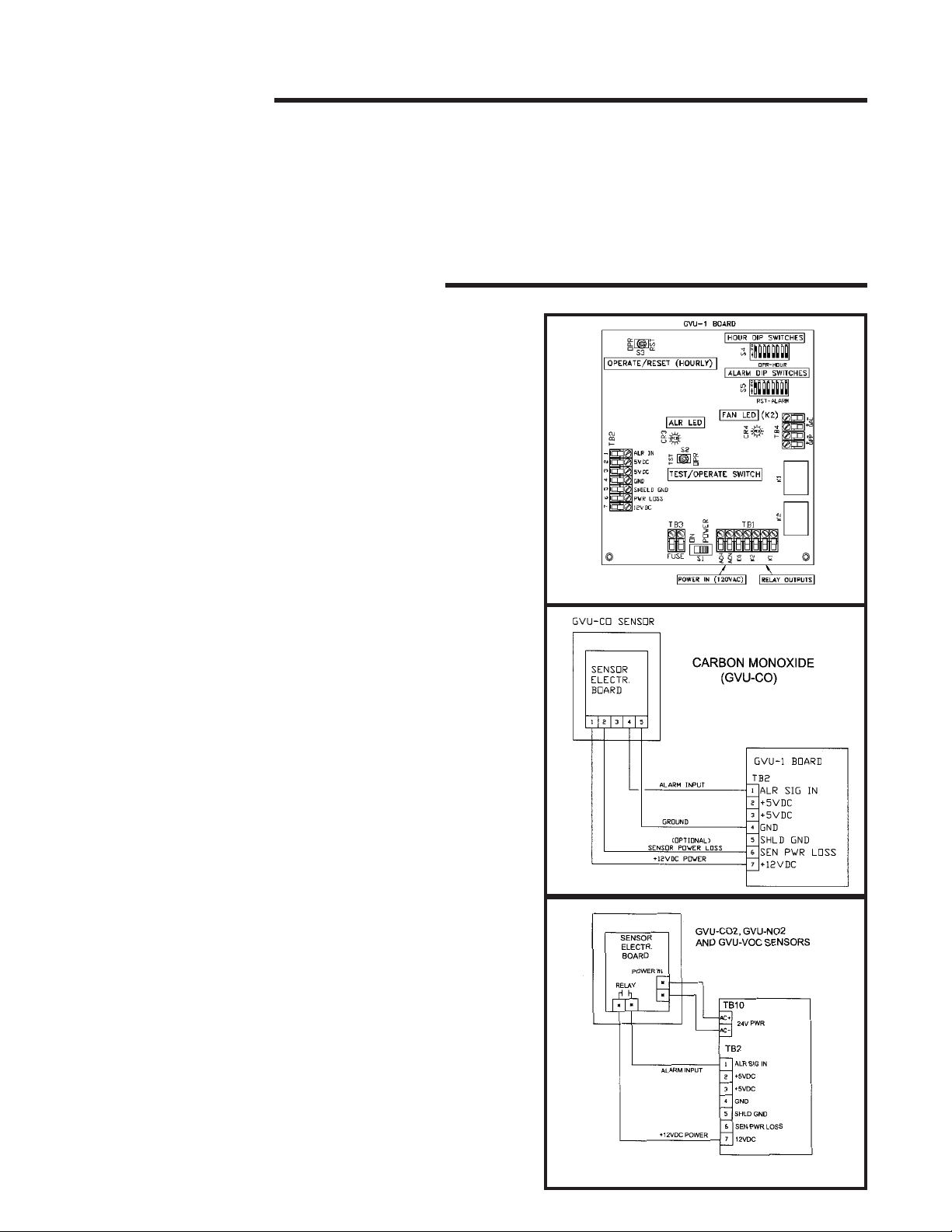

FIG. 2

SENSORS- Please refer to applicable sensor data sheets

for mounting directions.

FIG. 3

Page 3

SENSOR WIRING

NOTE: Refer to figs. 2 and 3 and tables 1 and 2. Use

shielded cable to interconnect sensing and control

unit if metal conduit is not used, or if conduit also

contains AC wiring.

NOTE: Comply with all local building codes and

ordinances.

1) Measure distance between sensing unit and control

unit and select proper size wire or larger wire from

Table 1.

2) Run wiring between control and sensing unit and

into enclosure through access holes. Connect

wires from terminal blocks in sensing unit to TB2

in control unit per figs. 2 & 3.

TABLE 1

AWGDO NOT EXCEED

#22 Wire 500 Ft. Sensor to Controller

#20 Wire 800 Ft. Sensor to Controller

#18 Wire 1300 Ft. Sensor to Controller

#16 Wire 2000 Ft. Sensor to Controller

TABLE 2

CONTROL UNIT TERMINALS

TB1-ACH (AC Power in- 120 VAC HOT)

TB1-ACN (AC Power in- 120VAC NEU)

TB1-EG (Ground)

TB1-K2(2) (Fan pilot relay contacts)

TB1-K1(2) (Alarm relay contacts)

TB2-1 (Alarm input)

TB2-2 (Sensor power loss)

TB2-3 (+5VDC)

TB2-4 (+5VDC)

TB2-5 (Cable shield*)

TB2-6 (Power loss)

TB2-7 (+12VDC)

TB10 (24VAC or 24VDC+)

TB10 (24VAC or 24VDC-)

Terminal strip TB-2 (figs. 2 & 3) is the control I/O

between the GVU-1 control unit and the sensing unit.

(NOTE: This terminal strip will supply 12VDC

power to the GVU-CO SENSOR ONLY via terminal 7. Power for any other sensor type will be

supplied at terminal strip TB-10).

*Shielding of cable should be connected at only one

end when grounded metallic conduit is not used, or

shared with AC wiring. Connect shielding at terminal

5, TB-2 of control unit. Make sure shielding at sensor

end is taped and isolated from any terminal or metal.

CONTROL UNIT WIRING

WARNING: To prevent fire or shock hazard turn off

control unit and fan power sources before making

connections to control unit. Comply with all local

building codes and ordinances.

1) Connect power to TB-1 as follows:

AC hot to TB1-1 (ACH)

AC neutral to TB1-2 (ACN)

AC ground to TB1-3 (EG)

CAUTION: Relays K1 and K2 are rated for 2.0 amps

resistive load. If a higher rated alarm or pilot control

is required, add a remote relay between the control

relay and load.

2) Connect dry contacts of alarm K1 (TB1-6 and

TB1-7) to alarm device (optional).

3) Connect dry contacts of fan relay K2 (TB1-4 and

TB1-5) to fan pilot control.

4) Set unit power switch S1 to the off position, TST/

OPR switch S2 to OPR and OPR/RST switch to

RST.

5) Turn on control unit AC power source, but do not

apply power to fans at this time.

3. BURN-IN (GVU-CO & GVU-VOC SENSORS

ONLY)

Burn-in allows sensor to stabilize before proceeding

with alarm setting procedure.

1) Be sure fan power is off, power is applied to

control unit and power switch S1 is set to

PWRON.

2) Allow system to burn-in for a minimum of 72

hours with power turned on to sensor.

3) When 72 hours have elapsed, proceed with system

check-out.

4. SETTING OF TIMING FUNCTIONS

There are two (2) eight position DIP switches in the

upper right hand corner of the GVU-1 control board,

labeled S4 and S5. These control the systems timing

functions.

Hourly Operations (S4)

S4 and toggle switch S3, in the upper left corner of

the GVU-1 board control the hourly operation of the

K-2 relay. With the number “1” switch of S4 in the

up position, the fan will run one minute each hour;

with the number “2” switch in the up position, the

system will run two minutes every hour; and so on,

up to eight minutes. The switches are not additive

and if more than one switch on S4 is in the up position, the system operates the lowest number of

minutes of the S4 switches in the up position. With

S3 in RST (reset) position, the hourly function is

Page 4

deactivated. If S3 is in the OPR position and all S4

switches are down (off), K2 will operate 8 minutes

each hour.

B) Minimum Fan Run Time (S5- Alarm setting)

Dip switch S5 controls the minimum time the K2

relay is activated once an alarm condition has been

acknowledged by the controller. With number “1”

switch of S5 in the up position, the minimum fan run

time (K2 relay closed) is one minute. With number

“2” switch of S5 in the up position, the minimum run

time is 2 minutes, and so on, up to 8 minutes. The

switches are not additive, and if more than one switch

is in the up position, K2 operates the number of

minutes of the lowest numbered switch of S5 in the

up position. If all are in the down position, minimum

run time defaults to 8 minutes.

5. ALARM SETTING PROCEDURES

All sensors are factory calibrated for their specific

setpoints. Periodic calibration is required and performed at the sensor. Please refer to the individual

sensor instruction manual (supplied with each sensor)

and calibration instruction sheet (supplied with

calibration kits, available separately). Annual sensor

calibration check is recommended as a minimum.

6. CHECKOUT

Refer to figure 1 and table 2 to check out installation

as follows:

1).Turn power off

2).Disconnect alarm input wires from sensors at

TB2-1.

3).Set alarm timer (S5) to 2 minutes and hourly

timer (S4) to 1 minute, and S2 to OPR.

4).Set power switch S1 to PWR ON. Set OPR/RST

switch S3 to RST and back to OPR; note time.

5).Check that the LED indicators CR3 and CR4 and

the fans are off.

6).Set TST/OPR switch S2 to TST, checkout that the

CR3 LED indicator is ON. After 30 sec. check

that CR4 LED and the fan(s) are on. Set S2 to

OPR (CR3 off) and check that the fans stop

running after 2 minutes. (CR4 off).

7).Set TST/OPR switch to TST, check that when

2 1/2 minutes have elapsed (this includes the

delay) alarm device activates and fans continue to

run. If optional alarm is not installed, connect an

ohm meter across TB1-K1 and check that

contacts of relay K1 are closed (continuity).

8).Set S2 to OPR. Check that fans stop and K1

deenergizes (CR3 and CR4 are off).

9).Check that 1 hour after step (4) was performed,

fans start (CR4 lights) and run for 1 minute.

10).Set power switch S1 to off position, set alarm

and hour timers to desired settings.

11).T o disable hour clock operation, move switch S3

to RST position.

12).Reconnect sensor alarm input wire removed in

step (2).

13).Set power switch S1 to PWR ON, Close and

lock enclosure cover. This completes checkout

and installation.

ORDERING INFORMATION

CONTROLLERS-

GVU-1/CO Control unit for use with remote

carbon monoxide sensor (GVU-CO)

GVU-1/CO

REMOTE SENSORS (Order separately)GVU-CO Remote carbon monoxide sensor

GVU-CO

GVU-1A Control unit with integral CO sensor

GVU-1B Control unit with integral CO2 sensor

2

Control unit for use with remote

2

carbon dioxide sensor (GVU-CO2)

Remote carbon dioxide sensor

Options, such as additional relays, indicators, local or remote horns, etc. can be ordered along with control unit.)

GVU-1 Revised 5/05

TOXALERT INTERNATIONAL, INC., P.O. BOX 159, MOUND, MINNESOTA 55364 (952) 472-4541 FAX (952) 472-4960

Visit our website at www. toxalert. com

GVU-1/NO

GVU-1/VOC Control unit for use with remote

GVU-VOC Remote smoke/air quality sensor

GVU-NO

GVU-1C Control unit with integral VOC sensor

GVU-1D Control unit with integral NO2 sensor

2

Control unit for use with remote

2

nitrogen dioxide sensor (GVU-NO2)

smoke/air quality sensor (GVU-VOC)

Remote nitrogen dioxide sensor

Loading...

Loading...