Town Food Service YF Installation Manual

Dragon Class Chinese Ranges by Town:

Models E, EF, Y, YF, M, MF

Express

THE WORLD'S FINEST CHINESE COOKING EQUIPMENT

OWNER’S MANUAL

SECTION I: INSTALLATION INSTRUCTIONS

For units shipped after June 2005 with new ue design

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE

OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR

DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

KEEP THIS BOOKLET HANDY FOR FUTURE REFERENCE

FOOD SERVICE EQUIPMENT CO., INC.

OBTAIN EMERGENCY PROCEDURES

FROM YOUR LOCAL GAS SUPPLIER IF

YOU SMELL GAS NEAR THIS EQUIPMENT.

THIS EMERGENCY INFORMATION MUST

BE PROMINENTLY DISPLAYED.

72 Beadel St., Brooklyn, NY 11222

(718) 388-5650 fax (718) 388-5860

customerservice@townfood.com

NOTE

1

CONGRATULATIONS

on your purchase of the new Dragon Class Express, York or MasteRRange. It will give you many years of

trouble free use if it is properly used and maintained. Feel free to call our Customer Service Department

if you have questions regarding operation or care of your Town range.

INSTALLATION INSTRUCTIONS

Express, YORK and MASTERRANGE

DRAGON SERIES CHINESE RANGES

Your Dragon class range has been carefully engineered and constructed with the best possible workmanship and materials to provide many years of satisfactory service. Proper installation is vital if appearance

and performance is to be achieved.

FOLLOW THESE INSTRUCTIONS CAREFULLY!

Express/YORK/MASTERRANGE INSTALLATION AREA MUST BE FREE AND CLEAR FROM COMBUSTIBLES

1. Position crate in approximate location that the unit will occupy. Uncrate range and locate sealed cartons on the range top containing the following accessories: One (1) set of adjustable legs; one (1) drip

pan for each chamber; and one (1) extension chimney for each opening in returnsplash if your unit is

equipped with a ue riser. "E" units do not have a ue riser and the chimney extension is not a part of

these ranges. Find the legs and set one leg by each range gusset into which it will be inserted. Raise

one end of the unit at a time; insert legs; and tighten set screws with 1/4" Allen wrench. If your range

has ue risers, slip the extension chimney over each riser.

2. Range is now ready for nal positioning. Carefully lift range into desired position to avoid damage to

adjustable legs. Clearances from combustible construction are 6" at rear and sides. Remove burner tie

wires and other packing materials. Check gas burners that may have shifted in transit and center them

by eye if required. Turn all gas valve lever handles to “OFF” (horizontal) position. Check air mixer

alignment to gas burner nipple and tighten set screws if necessary.

3. Clearances for noncombustible construction are the same as combustible clearances. This range is for

installation only on noncombustible oors.

INSTALLATION:

1. The gas supply line must be of adequate size to insure maximum efciency of the unit.

2. The installation must conform with the National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation

Code, CAN/CGA-B149.1 or the Propane Installation Code, CAN/CGA-B149.2, as applicable, including:

a. The appliance and its individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psi (3.45 kPa).

b. The appliance must be isolated from the gas supply piping system by closing its individual manual

valve during any pressure testing of the gas supply piping system at test pressures equal or less than

1/2 psig (3.45 kPa).

2

FOOD SERVICE EQUIPMENT CO., INC. • 72 BEADEL ST • BKLYN • NY 11222

3. Local regulations governing gas appliance installations must be complied with.

4. Equipment should be under hood with adequate ventilation.

5. Minimum spacing of 6" to combustible construction is required along back and side walls. Clearances

for noncombustible construction are the same as combustible clearances. For use only on noncom-

bustible oors.

6. Materials such as wood, compressed paper and plant bers that will ignite and burn, Must Not Be

Exposed Near Range Especially at Rear. Local safety codes should be complied with in respect to re

hazard avoidance.

7. Use of the supplied pressure regulator is mandatory.

8. The front of the unit must be kept clear to avoid restriction of air supply for combustion.

9. The unit must be installed in an area or room with sufcient fresh air supply to ensure proper combus

tion.

10. There must be adequate clearance for air openings into the combustion chamber.

11. This equipment must be installed with adequate clearance for servicing and proper operation.

12. This unit should be operated only with drip trays in place.

13. If your unit is supplied with casters, the installation shall be made with a connector that complies with

the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or Connectors for Moveable

Gas Appliances, CAN/CGA-6.16, and a Quick Disconnect device that complies with the Standard

for Quick-Disconnect Devices for Use with Gas Fuel ANSI Z21.41, or Quick Disconnect Devices for

Use with Gas Fuel, CAN1-6.9, and adequate means must be provided to limit the movement of the

appliance without depending on connector and the quick-disconnect device or its associated piping

to limit the appliance movement.

-

14. If your unit is provided with casters on legs, the legs with locking casters must be installed in front of

the unit. An approved restraining device must be secured to unit rear or side.

IMPORTANT

1. Before connecting gas and water supply, the range deck must be pitched so water will drain off range

top into the gutter, and into the internal or external slop sink.

2. Range deck pitch is adjusted by raising or lowering each leg as necessary at the adjustable foot. Raise

front legs or lower rear legs of the unit to provide pitch for water to drain into gutter at rear. Ranges

with external sinks: Observe that water drains out of gutter at open end. If water remains in gutter,

lower legs on discharge end, or raise legs at opposite end.

3. Connect the gas supply line to unit using the pressure regulator provided. A readily accessible ap-

proved type gas shutoff should be supplied by others. Water supply line on back of unit and sprinkler

should be connected with a shutoff valve in readily accessible location.

4. Check that all gas valves on the unit are turned “OFF” (lever handles in horizontal position) before

turning “ON” main gas line. Check for leaks using soapy water or other suitable leak detector. DO

NOT USE OPEN FLAME FOR TESTING. Check that swing faucets and sprinkler valve are in “OFF”

position (spout parallel to backsplash), open water valve and check for leaks.

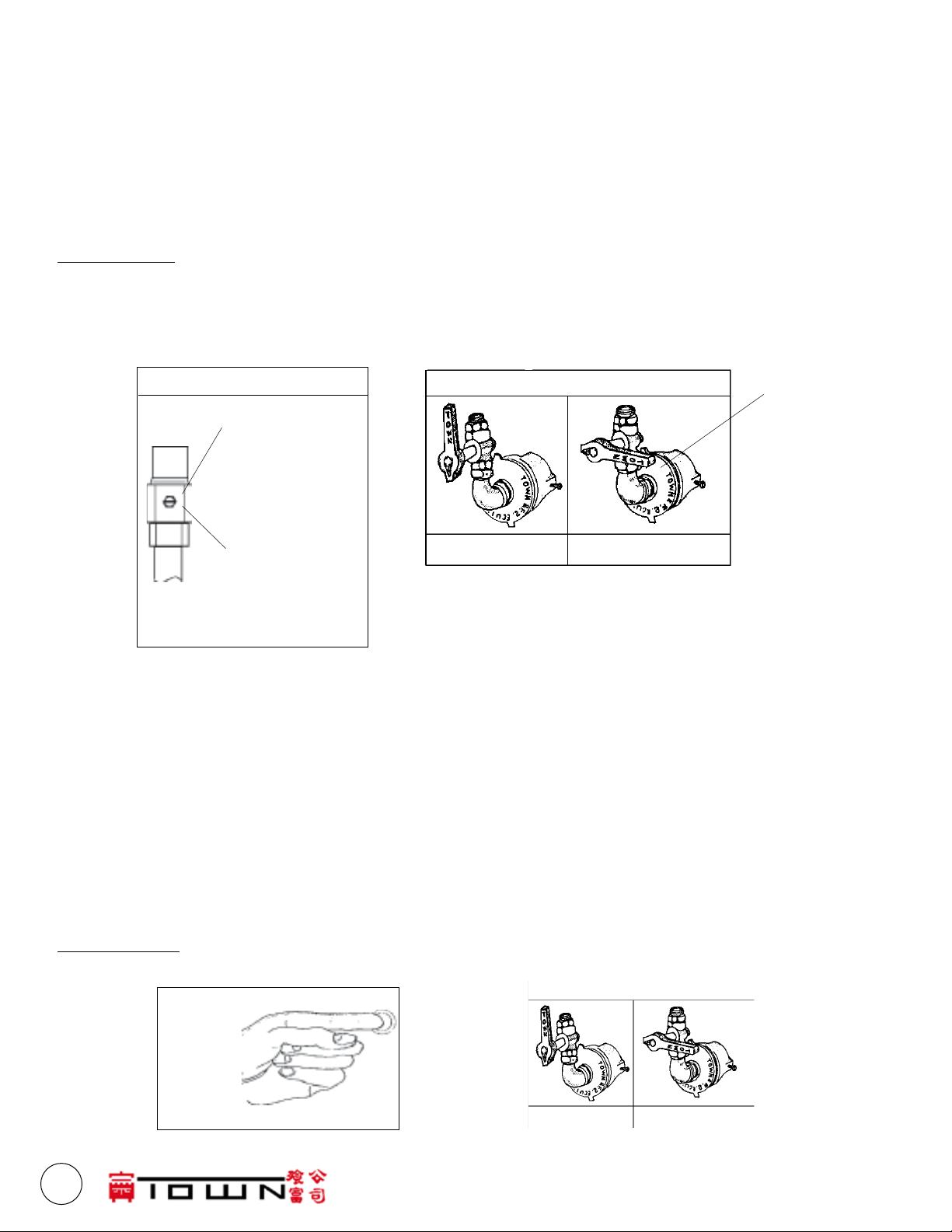

5. UNITS WITHOUT SAFETY VALVES: LIGHTING AND SHUT DOWN INSTRUCTIONS

Be sure that all piping is gas tight and that all air is purged from lines. With Main Burner Valve in “OFF”

position (see g.2), using a screw driver turn pilot screw counter clockwise to “ON” (see g. 1) and light

(718) 388-5650 (800) 221-5032 except NY fax: (718) 388-5860 townfood.com

3

pilot located in the combustion chamber. Make sure the pilot stays lit.

All units are equipped with xed orices which cannot be adjusted for gas ow. Only ring burners have

adjustable air mixers to adjust the air/gas mixture.

Turn right hand burner valve to full “ON” position (see g.2) and adjust air shutter until proper blue ame is

burning on both inner rings. Repeat operation for left hand valve only if your range is equipped with three

ring burners.

SHUTDOWN: Turn burner valves to "OFF" position (see g.2) and turn the pilot screw clockwise (see g.

1) until it cannot be turned further. Repeat this step for each chamber.

OPERATING INSTRUCTIONS

1. INSTALLATION AREA MUST BE FREE AND CLEAR FROM COMBUSTIBLES. Local safety codes should

be complied with in respect to re avoidance.

PILOT VALVE

FIGURE 1

OFF position:

turn clockwise

until screw cannot be turned

further

ON position

MAIN BURNER VALVE

ON position OFF position

air shutter

(ring

burners

only)

FIGURE 2

turn counterclockwise

6. UNITS WITH SAFETY VALVES: LIGHTING AND SHUT DOWN INSTRUCTIONS.

Always follow these lighting and shutdown instructions when operating your unit. A ve minute com-

plete shutoff period is required before lighting or relighting pilot. See diagram below.

a) Check that all gas valves on the unit are turned “OFF” (lever handles in horizontal position) before turn-

ing “ON” main gas line. Check for leaks using soapy water or other suitable leak detector. DO NOT

USE OPEN FLAME FOR TESTING.

b) Main burner valve shall be in “OFF” position (gure 2). Place a burning match by the pilot burner in the

combustion chamber of the range. Depress safety control red button on (g.1 below) and light pilot.

c) The pilot should light. Continue to hold the button for one minute or until the pilot stays lit.

SHUT DOWN: For temporary Shut Down turn all burner valves to "OFF" position. For an extended period of time, turn all burner valves "OFF" and also turn off gas supply to the range.

MAIN BURNER VALVE

Put lit match

to pilot

burner, depress & hold

red button

ON position

gure 1

4

FOOD SERVICE EQUIPMENT CO., INC. • 72 BEADEL ST • BKLYN • NY 11222

OFF position

gure 2

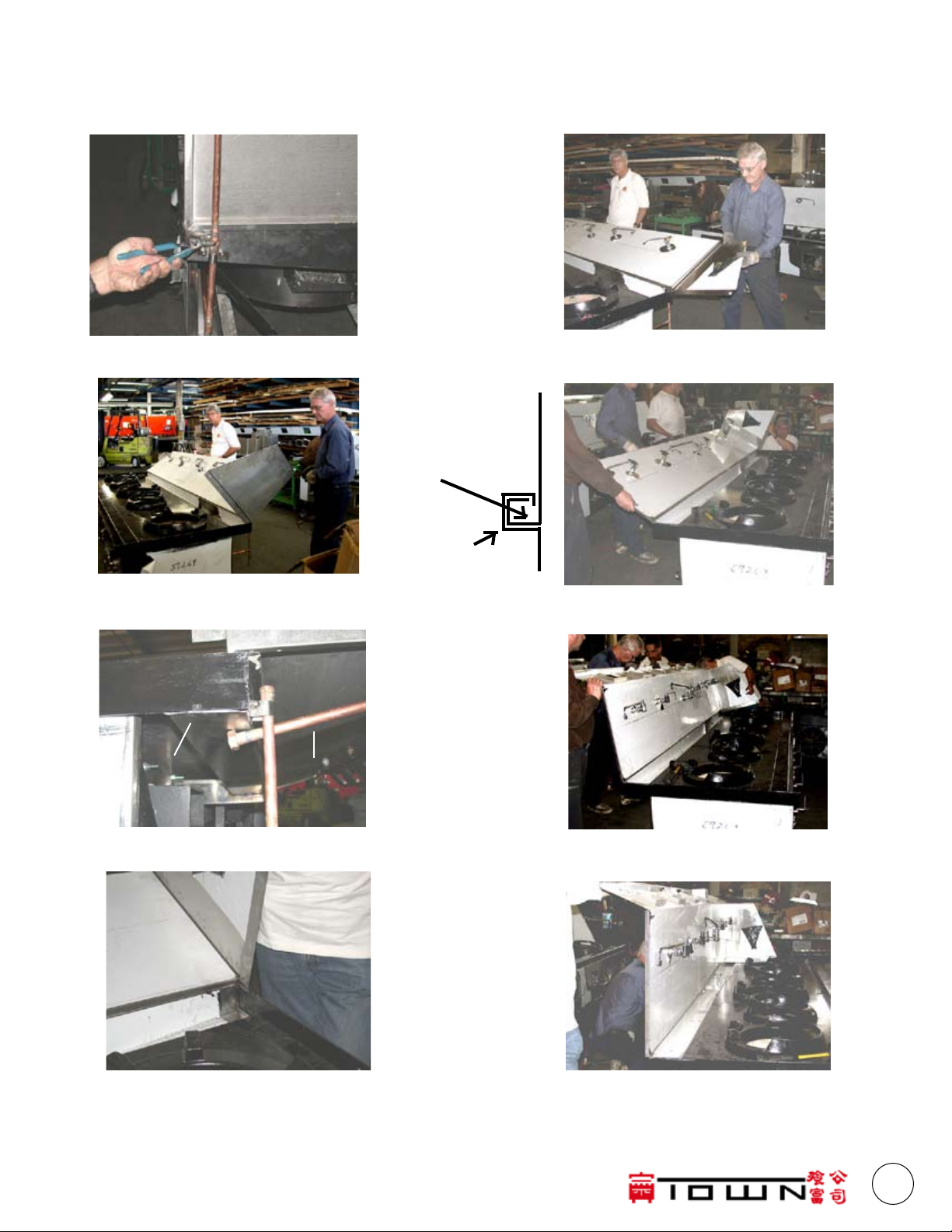

BACKSPLASH REMOVAL & REINSTALLATION

Some installations require the backsplash to be removed so the range can t through a 34" door. Town

ranges are manufactured with removable backsplashes. Follow these steps:

1. Loosen union at backsplash

backsplash "J"

gutter "J"

2. Remove sidesplash bolts and lower backsplash

gutter

faucet

manifold

5. Sidesplash may be removed. Range will

t through 34" opening.

6. Reinsert sidesplash and backsplash into gutter.

Insure backsplash "J" hooks into gutter "J".

3. Faucet manifold must beplaced below gutter

7. Raise backsplash, making sure it is locked into

the gutter "J".

4. Lower backsplash until sidesplash clears

gutter

(718) 388-5650 (800) 221-5032 except NY fax: (718) 388-5860 townfood.com

8. When raised, the gutter and backsplashed

should be aligned. Bolt side splashes to body.

5

Loading...

Loading...