Town Food Service MBR-36 Service Manual

DO NOT DISCARD INSTRUCTIONS. THIS MANUAL MUST REMAIN WITH THE UNIT FOR FUTURE REFERENCE.

THIS EMERGENCY INFORMATION MUST BE PROMINENTLY DISPLAYED.

MONGOLIAN BARBECUE RANGE OWNER’S MANUAL

MBR 36 36” DIAMETER COOK TOP|MBR 42 42” DIAMETER COOK TOP

SECTION 1

INSTALLATION INSTRUCTIONS

FOR COMMERCIAL USE ONLY

Warning

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

For your safety

Do not store or use gasoline or other fl ammable vapors and liquids in the vicinity of this or any

other appliance.

Note

Obtain emergency procedures from your local gas supplier if you smell gas near this equipment.

This emergency information must be prominently displayed

T

R

E

E

K

T

N

I

L

I

D

S

E

T

No part of this booklet or it ’s illustrations may be copied or reproduced without written authorization from Town Food Service Equipment Co., Inc.

© Town Food Service Equipment Company, Inc.

2/13

36

42

Congratulations on your purchase of a MBR-36 or MBR-42 Mongolian Barbecue Range.

It will give you many years of trouble free use if it is properly used and maintained. Please call our customer service

department at (718) 388-5650 if you have questions regarding equipment operation or care.

Your new MBR-36 or MBR-42 Mongolian Barbecue has been carefully engineered and constructed with the best

-

possible workmanship and materials to provide many years of satisfactory service. Proper installation is vital if

best appearance and performance is to be achieved.

For your records please record the following information of your Mongolian Barbecue Range (MBR)

MODEL NUMBER ______________________________________ SERIAL NUMBER _________________________________

SUPPLIER/VENDOR TELEPHONE NUMBER _________________________________ DATE OF PURCHASE ____________

FOLLOW THESE INSTRUCTIONS CAREFULLY

PLANNING THE INST

MBR-36 AND MBR-42 MONGOLIAN BARBECUE INSTALLATION INSTRUCTIONS

ALLATION OF YOUR MONGOLIAN BARBECUE RANGE IS IMPORTANT.

PLANNING AND SITE PREPARATION

MBR-

1 Mongolian Barbecue Range installations are generally in the center of a cooking area with clear access on all sides.

Suggested clearance around the entire unit is at least 3 feet.

2 Materials such as wood, compressed paper and plant fi bers that will ignite and burn, must not be exposed

near range. Local safety codes should be complied with in respect to fi re hazard avoidance.

3 The area surrounding the unit must be kept clear to avoid combustion issues due to restricted air supply.

4 The unit must be installed in an area or room with suffi cient fresh air supply to ensure proper combustion.

Given enough fresh air this unit produces exhaust gases within ANSI limits.

5 The gas supply line must be of adequate size to ensure maximum effi ciency of the unit. Minimum manifold piping

should be 1¼” sch. 40 Gas pipe (2” Sch. 40 Gas pipe is recommended). Static pressure is 6” W.C.

for natural gas and 10” W.C. for propane. Minimum operational pressure is 5.5” W.C. for natural gas and

9.5” W.C. for propane gas.

Inlet supply pipe should be a minimum of 1¼” diameter and a minimum operating gas pressure of 6” W.C. for

natural gas or 10” W.C. for propane gas should be used.

6 Use of the supplied regulator is mandatory. The regulator must be installed in a location where it remains

cool and is accessible for pressure adjustment (ANSI Z83.11-1996 Sect. 1.15.5).

NEVER INSTALL REGULATOR UNDERNEATH THE UNIT

a. If installed in a facility with a high pressure gas system a 1st stage line regulator must be supplied by

others. The supply appliance regulator must be installed downstream from the 1st regulator.

Never install the appliance regulator underneath or in the center of the unit.

7 Equipment should be under hood with adequate ventilation.

2

36

2

UNCRATING AND PLACING THE UNIT

CLEARANCES FROM NONCOMBUSTIBLE CONSTRUCTION ARE THE SAME AS COMBUSTIBLE CLEARANCES.

THIS APPLIANCE IS SUITABLE FOR INSTALLATION ONLY ON NONCOMBUSTIBLE FLOORS.

1 The top is shipped in a separate crate. Position crate next to the location that the unit will occupy.

Uncrate the range, place it in position and take note of the position of gas feed line.

2 Carefully place the range into desired position to avoid damage to adjustable legs. Be sure unit is located with the

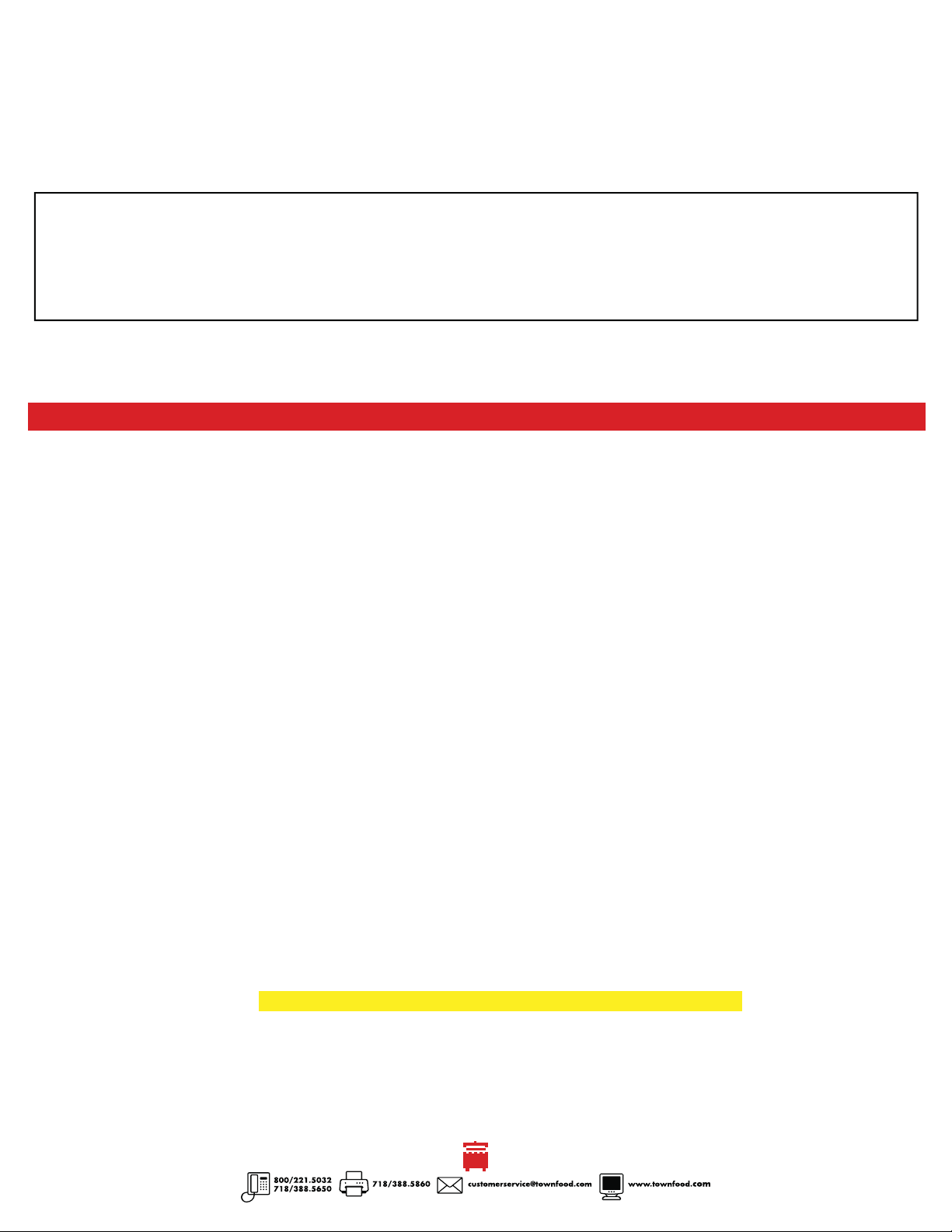

clearances away from combustible construction as indicated on the rating plate of the unit. Turn all three gas valve

lever handles to off position (fi gure 1). Check that three valves face in the position desired by customer.

3

”

/8

female gas valve

fi gure 1

3 Place cast iron top on the support tubes. CAUTION: the custom cast iron top is over 1” thick and is extremely heavy.

Make sure the “ribs” on the bottom of the cook top do not sit on the support tubes. We recommend using a licensed

rigger for installation.

4 Level the unit using the adjustable bullet feet at the end of each leg.

no. 226102F

safety pilot, out only

no. 249011

MBR-4

GAS INSTALLATION

1 The installation must conform with the National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Code,

CAN/CGA-B149.1 or the Propane Installation Code, CAN/CGA-B149.2, as applicable, including:

a The appliance and it’s individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of

b The appliance must be isolated from the gas supply piping system by closing it’s individual manual valve

during any pressure testing of the gas supply piping system at test pressures equal or less than 0.5 PSIG

(3.45 kPa).

2 The installation must conform with all local authority regulations governing gas appliance installations.

3 If your unit is supplied with casters, the installation should be made with a gas connector that complies with

the standard for connectors for movable gas appliances, ANSI Z21.69 or connectors for moveable gas

appliances, CAN/CGA-6.16, and a quick disconnect device that complies with the standard for quick

disconnect devices for use with gas fuel ANSI Z21.41, or quick disconnect devices for use with gas fuel,

CAN1-6.9. Adequate means must be provided to limit the movement of the appliance without depending

on connector and the quick disconnect device or it’s associated piping to limit movement.

4 If your unit is provided with casters on legs, the legs with locking casters must be installed opposite the gas

supply line. An approved restraining device must be secured to unit near gas supply.

1

/2 psi (3.45 kPa).

MBR-

5 Connect the gas line and check for leaks. Air will be trapped in the gas supply lines. Trapped air can be bled out

by pushing the red button in on the pilot safety valve (fi gure 1) for a few minutes during initial lighting.

6 With the main valve on and the 3 burner valves off (fi gure A), check for leaks using soapy water or an electronic

leak detector. Do not use open fl

ame for testing.

3

36

42

INITIAL LIGHTING AND SHUT DOWN INSTRUCTIONS

Always follow lighting and shutdown instructions below when operating unit. A 5 minute complete shut-off period is

required before lighting or relighting.

-

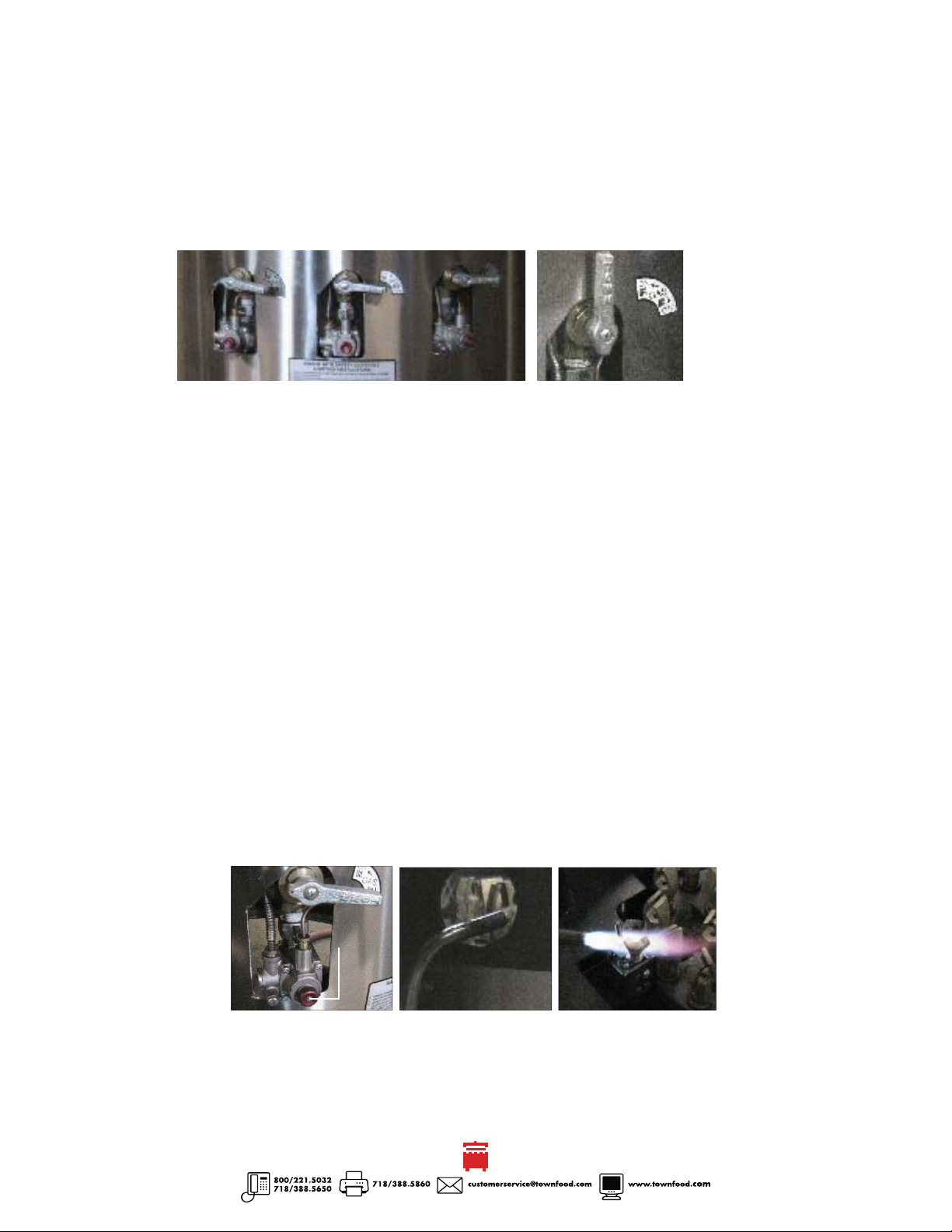

1 With burner valves

at one pilot burner in the combustion chamber (fi gure 3). Push the red safety button to turn on gas fl ow (fi gure 1).

Place match or torch beneath burner to be ignited (fi gure2). It may take up to 10 minutes to bleed air trapped in the

gas line before the pilot will light. For detailed instructions on use and repair of the safety pilot system by the manu-

facturer, Inveysis/Robertshaw refer to pages 17-19.

REFER TO PAGES 17-19 FOR COMPLETE INSTRUCTIONS ON THE USE AND REPAIR OF SAFETY PILOT SYSTEM.

MBR-

2 After the pilot lights, remove the match or torch and continue to hold the red safety button in for

1 minute (fi gure 1, page 4). After releasing the button the pilot should stay lit. If pilot does not stay lit,

repeat step 1, pressing the button for approximately 90 seconds.

off light a match and place in a lighter rod, or use a LP torch (fi gure 2 and 3). Position the fl ame

fi gure A

burner valves in OFF position—

rotate counter clockwise to tur

n ON

fi gure B

burner valve in ON position—rotate clockwise to turn OFF

3 The remaining 2 pilots should light with only a 2 or 3 minute bleed time.

4 Turn all 3 burner valves counterclockwise to on position. Be sure that each burner has ignited with a clear, blue fl ame

about 2” long. Fanning or blowing on the burner to get all the tips to light may be necessary. The burners are

designed to fully light when the cast iron top is in position on the unit.

5 With burners lit, use a suitable gas leak detector to check for leaks in the entire gas train.

6 To shut down, turn burner valves clockwise to off position.

red safety

button

fi gure 1

fi gure 2

fi gure 3

4

36

2

TROUBLE SHOOTING

POOR PERFORMANCE

Most Mongolian Barbecue Range performance problems can be traced to gas supply pressure or volume

issues. If your unit is not getting hot quickly, it is necessary to determine if your unit has suffi cient gas pressure

to operate normally.

The Mongolian Barbecue Range is supplied with a gas test tap located on the internal gas manifold to check

for proper pressure. It is sealed with a

by a qualifi ed gas service mechanic to verify operating gas pressure. The unit should be restarted following

the initial lighting instructions on page 4 of this manual. With all 3 burners operating, the manometer should

indicate 6” W.C. for natural gas or 10” W.C. for propane gas. If the measured pressure differs from the

above requirements, the problem causing low pressure must be corrected. If pressure is too high, an additional

pressure regulator to the standard pressure regulator may be required (especially with propane gas). If the

pressure is too low contact your installer and/or supply company. Undersized gas supply lines are often a

cause of insuffi cient operating pressure. Undersized pipe may not allow adequate gas volume, which will

cause the unit to perform poorly.

PILOT FAILURE

If one of the safety pilot fails (assuming the unit has worked for a while), a faulty thermocouple could be the

problem. Replacement thermocouples and pilots may be purchased from Town Food or a commercial gas

supply parts company.

1

/8 ” NPT plug. A suitable manometer may be attached to this test tap

MBR-4

MBR-

item number description

252239 ________ universal “L” pilot/bracket supplied with orifi ces for natural or propane gas

252238 ________ heavy duty 36” thermocouple

The thermocouple is a consumable part—it’s life expectancy varies depending on use.

5

DO NOT DISCARD INSTRUCTIONS. THIS MANUAL MUST REMAIN WITH THE UNIT FOR FUTURE REFERENCE.

THIS EMERGENCY INFORMATION MUST BE PROMINENTLY DISPLAYED.

MONGOLIAN BARBECUE RANGE OWNER’S MANUAL

MBR 36 36” DIAMETER COOK TOP|MBR 42 42” DIAMETER COOK TOP

SECTION 1

INSTALLATION INSTRUCTIONS

FOR COMMERCIAL USE ONLY

Warning

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

For your safety

Do not store or use gasoline or other fl ammable vapors and liquids in the vicinity of this or any

other appliance.

Note

Obtain emergency procedures from your local gas supplier if you smell gas near this equipment.

This emergency information must be prominently displayed

T

R

E

E

K

T

N

I

L

I

D

S

E

T

6

Loading...

Loading...