Town & Country Fireplaces TCVT.PVCV Installation And Operating Instructions Manual

IMPORTANT:

THESE INSTRUCTIONS ARE TO REMAIN

WITH THE HOMEOWNER

These instructions are supplementary to the Installation and

Operating Instructions supplied with the fireplace and should

be kept together. Refer to the Installation and Operating

Instructions for proper gas supply, safety requirements and

operating instructions.

VERTICAL

POWER VENT KIT

310317-20

TCVT.PVCV

INSTALLATION AND

OPERATING

INSTRUCTIONS

Visit www. townandcountryfireplaces.net for the most recent version of this manual

TCVT.PVCV

5056.42665-A

Power Vent Installation

Locate the replace as per the main instructions supplied. Make the following modications to add the components used with the Power Vent kits. This kit can only be used in conjunction with the “B”, “C” & “D” series

versions of Town and Country Fireplaces. This installation must conform with local codes or, in the absence

of local codes, with the Natural Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

All electrical installation should be performed by a qualied electrician to national codes (CSA C22.1, ANSI/

NFPA 70) and/or local electrical codes.

under no circumstances shall a rheostat be used to alter the voltage supply to this unit.

Contents of Power Vent Kit

ITEM PART No. DESCRIPTION QTY

1 TCVT.502462 Power Vent Terminal 1

2 TCVT-8074 Vertical Rain Cap 1

3 TCVT-8075 Vertical Standoff 1

4 8082.001 Flashing 1

5 8085 Drip Shield 1

Note: The adapter kit TCVT.PVKIT is required for all units except the TCWS.54CSTE.

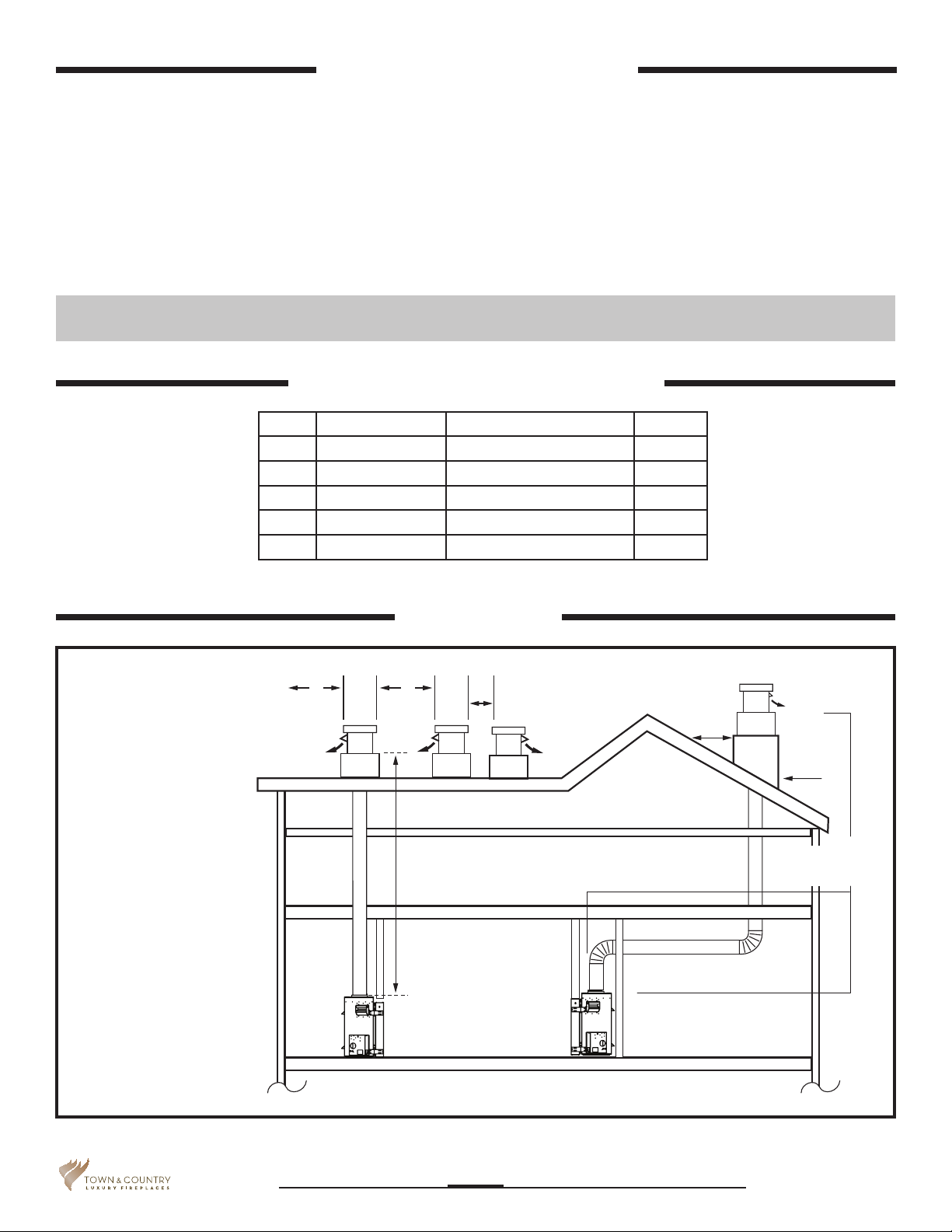

VENTING

CONFIGURATIONS

Maximum vent length is

110 ft plus six 90-degree

elbows or combination

of other elbows equaling 90-degrees, with a

maximum 66 foot vertical rise.

Minimum vent length is

3 ft plus one 90-degree

elbow. The vent can

be installed with any

combination of rise and

run between the gures including up to 3 ft

below the unit. Ensure

vent pipe is properly

supported.

Power Vent

4’ 4’

Max 66’

vertical rise

1’

Distance

as per

local

code

Total maximum

vent length is 110’

Vent outlet

direction

Site

fabricated

chase

66’ maximum

vertical rise

Figure 1: Power vent congurations.

5056.42665-A

310317-20 TCVT.PVCV

2

Minimum Clearances to Combustibles

Vertical vent pipe: 1.5 in. (38mm)

Horizontal vent pipe: Top 1.5 in. (38mm)

Sides 1.5 in. (38mm)

Bottom 1.5 in. (38mm)

All other clearances are as per the replace installation instructions.

Vertical (Through Roof) Venting

VENT PIPE

This kit uses either Simpson Duravent GS direct vent pipe, Secure Vent direct vent pipe, Selkirk Direct-temp

vent pipe or ICC Excel Direct vent pipe with a 5” inner pipe and an 8” outer pipe. For part numbers see the

table of venting components on page 10 of this manual.

CAUTION: The adjustable vent restrictor located on the underside of the firebox top must be fully open.

The vertical standoff can only be installed on a at surface. Sloped surfaces require the construction of a

chase which provides the minimum interior, square opening of 11” x 11” for the venting and wiring to pass

through. Flat roofs may require a chase depending on local codes and roof construction. (If in doubt check

with local inspector). The terminal must be located in accordance with the clearances outlined in Figure 1.

Installation:

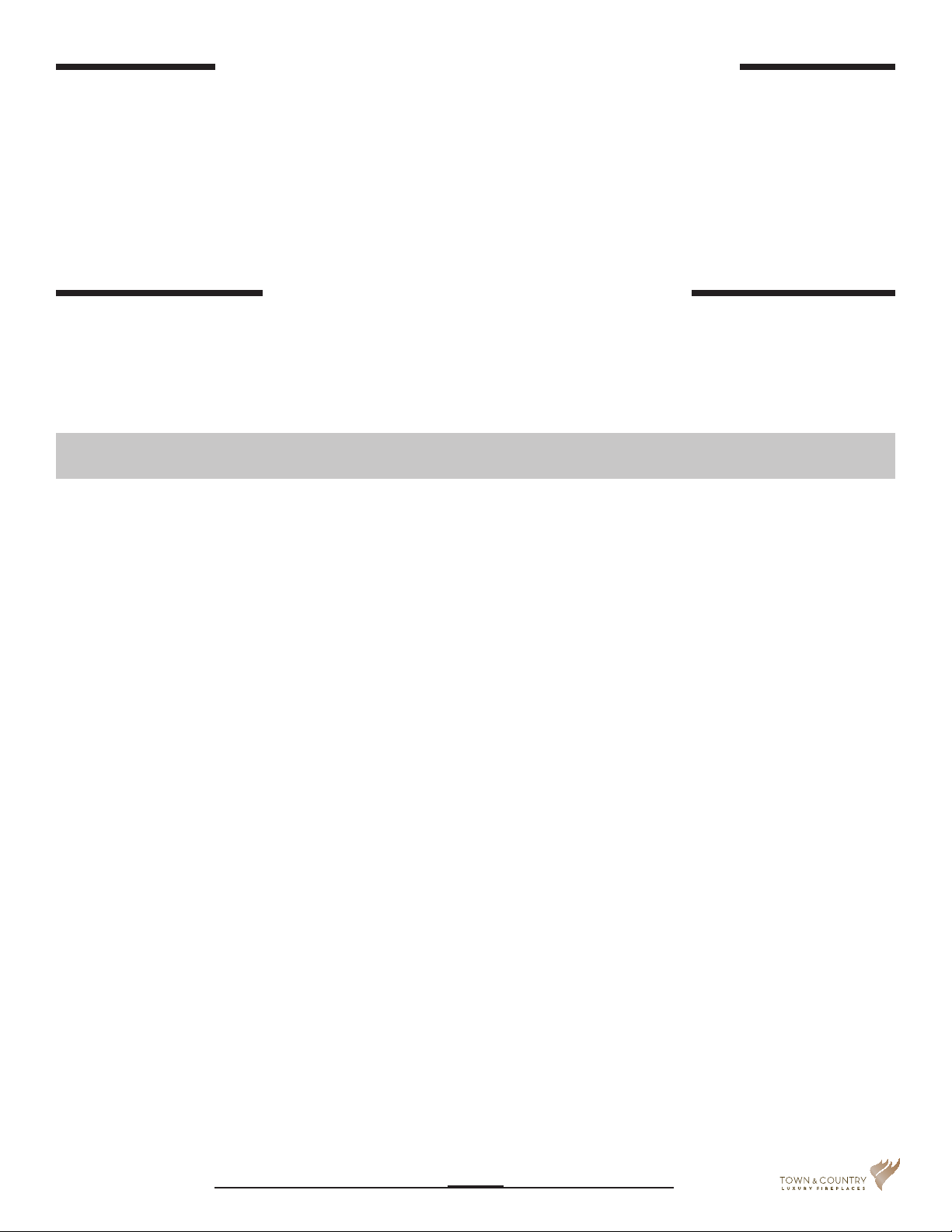

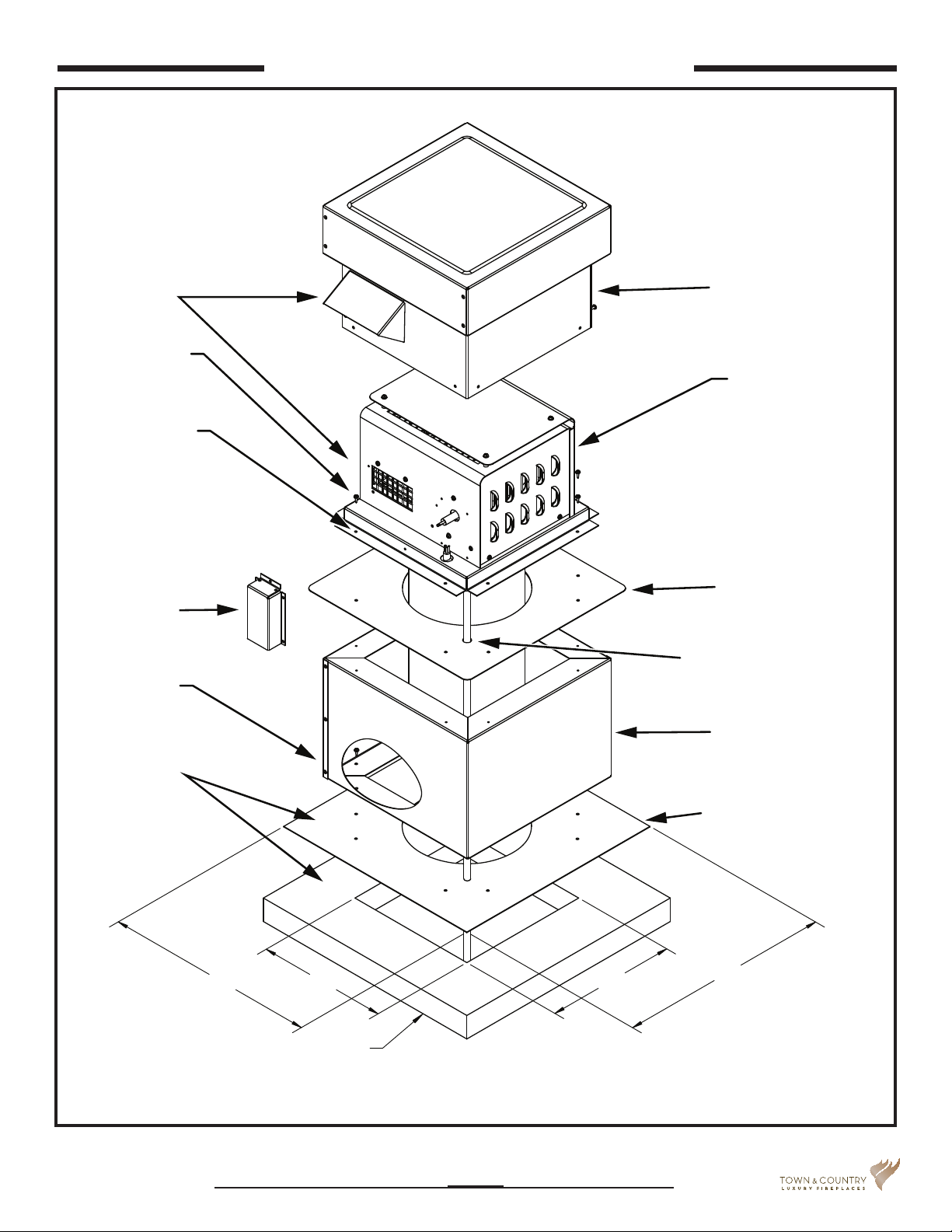

All part numbers in the following section are shown in Figure 3.

1. Place the ashing onto the chase and seal using silicone.

2. Put a bead of silicone on the underside of the vertical standoff and place it on top of the ashing. Align the

eight holes and secure both parts to the chase using eight #8 x 1 1/2” screws provided.

3. Install the drip shield onto the top of the vertical standoff using a bead of silicone between the two. Do not

screw this part in place.

4. Bring the 14-2 electrical wire (not supplied) up through the holes in both the ashing and the drip shield

leaving at least 12” of excess wire above the drip shield.

5. IMPORTANT: Attach an appropriate length(s) of the vent to the power vent terminal, sufcient to pass

through the chase.

NOTE: DO NOT CONNECT AN ADJUSTABLE LENGTH VENT PIPE TO THE TERMINAL.

6. Seal the connection of the rst length of pipe at the terminal and any other pipe to pipe joint by both

screwing and taping the outside joint using high temperature foil tape.

7. Remove the junction box cover.

8. Remove and discard the exhaust outlet.

310317-20 TCVT.PVCV

5056.42665-A

3

9. Apply a bead of silicone on the bottom ange of the power vent terminal.

10. Slide the vent through the drip shield and at the same time thread the electrical lead through the hole in

the bottom of the terminal.

11. With the power vent terminal resting on the drip shield, align the eight holes in each of the vertical standoff, the drip shield and the power vent terminal and then screw them together using the eight #8 x 1/2”

stainless screws provided.

12. Join the 14-2 wire lead to the blower wires using the appropriate connectors and attach the ground wire.

Reinstall the junction box cover.

13. Install the vertical rain cap over the power vent blower. ALIGN THE EXHAUST OUTLET ON THE POWER

VENT TERMINAL WITH THE EXHAUST PORT ON THE VERTICAL RAIN CAP.

14. Secure the vertical rain cap to the power vent blower with the remaining eight #8 x 1/2” stainless screws.

NOTE:THERE ARE NO PILOT HOLES IN THE BASE OF THE POWER VENT TERMINAL. 1/8” DIAMETER

PILOT HOLES SHOULD BE DRILLED USING THE HOLES IN THE VERTICAL RAIN CAP AS A GUIDE.

DO NOT SILICONE THE VERTICAL RAIN CAP TO THE POWER VENT TERMINAL AS IT NEEDS TO BE

REMOVABLE FOR SERVICING.

15. Attach the vent adaptor directly to the appliance with three screws (Figure 2).

Note: The inner pipe does not need to be sealed.

16. Connect one of the high temperature silicone tubes to the upper pressure tap on the adaptor (Figure

2) Secure with the hose clamp provided and route the tube through any hole back to control box. This

tube will be connected to the “low” side of the vacuum switch inside the control compartment (Figure 9).

Connect the second tube to the lower pressure tap and route to the control box as before. Connect this

tube to the remaining port on the vacuum switch. Tubes may touch unit and be trimmed if required. Note:

Ensure that there are no blockages in these tubes, as this will cause the control to malfunction.

17. Run the required Simpson Duravent GS / Secure Vent / Selkirk Direct-temp pipe from the adaptor to the

terminal assembly. Assemble as per the vent pipe manufacturer’s instructions including all shields and

restops.

Secure with 3 screws and

seal with aluminum tape

Power Vent Adaptor.

Must be installed

at the unit

*

Upper pressure

tap, marked

“LOW”

Figure 2: Power vent adapter.

Lower pressure tap,

marked “HIGH”

*

5056.42665-A

Power vent adapter not required on models

TCWS.54DST and TCWS.54STOK.

310317-20 TCVT.PVCV

4

Vertical (Through Roof) Venting

MUST ALIGN

#8 x 1/2" S.S.

(16 Required)

NOTE: Holes to

secure rain cap

are

not predrilled

Junction box

cover

#8 x 1-1/2" S.S.

(8 Required)

Vertical Rain Cap

TCVT-8074

Power Vent

TCVT.502462

Drip Shield

14-2 Wire w/ Ground

Vertical Standoff

TCVT-8075

8085

Silicone all

connecting faces

18”

Site Fabricated Chase

Final Installation Height: 21"

Figure 3: Power vent components.

310317-20 TCVT.PVCV

11”

Flashing 8082.001

11”

18”

5056.42665-A

5

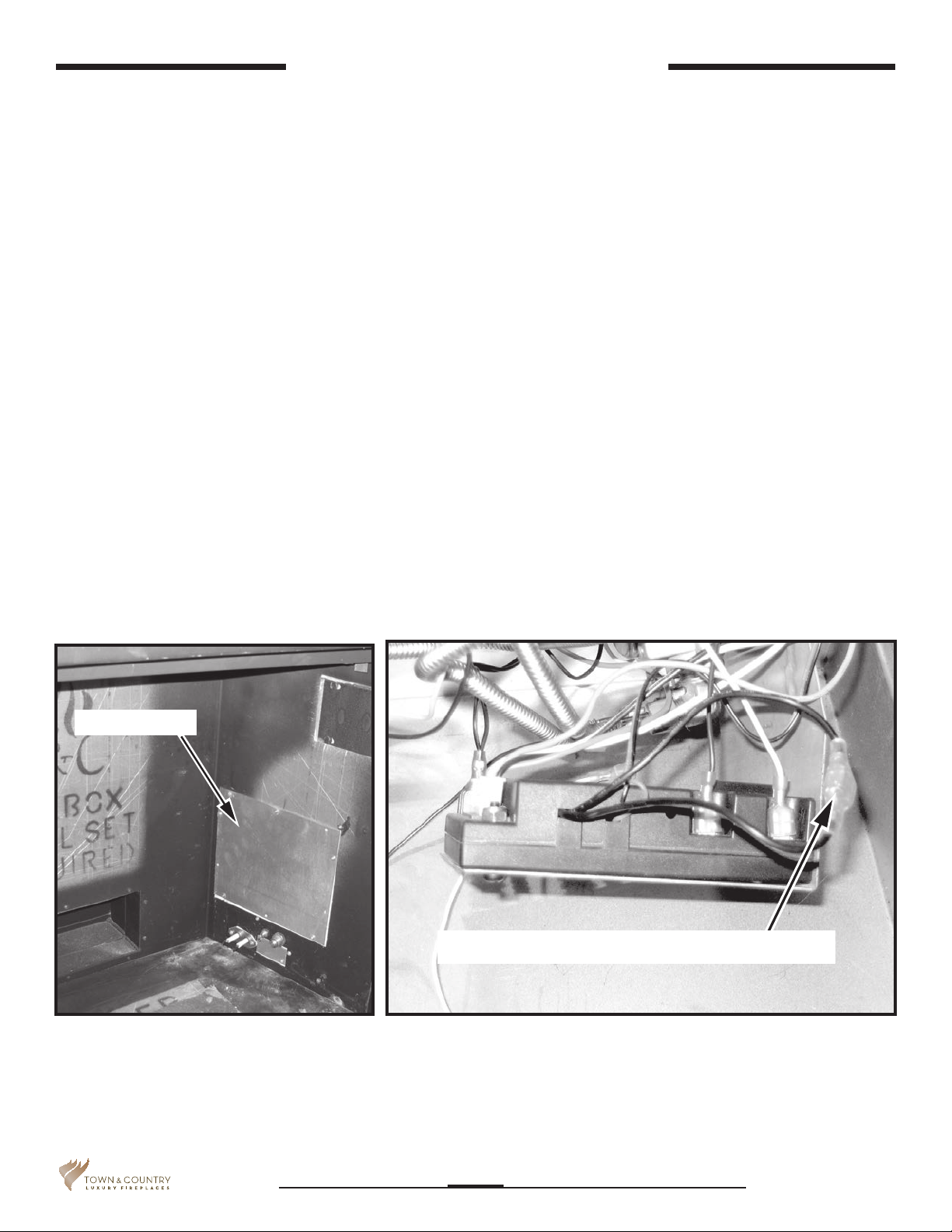

Control System Connection

For “Series C” Fireplaces

The gas control system is located on the right hand side of the rebox behind an access panel and the decorative panel.

1. Remove burner assembly, burner media and decorative panels if already installed (see main installation

manual for details).

2. Remove access panel from right hand side of the rebox (Figure 4).

3. Locate and disconnect the spade connectors in the black wire loop on the right side of the module and in

the orange wire running from the module to the socket labelled “pilot”on the valve (Figure 5 and Figure 6).

4. Using the jumper wires provided, connect the 120V “hot” supply wire to one of the black wires from the

control module. Then connect the “hot” wire from the power vent blower to the other black wire on the

control module (Figure 7). The module acts as a switch to turn on the power vent blower. (Also see wiring

diagram on Pg.14)

Access panel

Figure 4: Access panel.

Spade connector in black wire loop

Figure 5: Locating black wire spade connector.

5056.42665-A

310317-20 TCVT.PVCV

6

Loading...

Loading...