Town & Country Fireplaces TCVT.FMPV3 Installation And Operating Instructions Manual

IMPORTANT:

THESE INSTRUCTIONS ARE TO REMAIN

WITH THE HOMEOWNER

These instructions are supplementary to the Installation

and Operating Instructions supplied with the replace

and should be kept together. Refer to the Installation

and Operating Instructions for proper gas supply, safety

requirements and operating instructions.

LOW NOISE

HORIZONTAL FLUSH

MOUNT POWER

VENT KIT

(FOR MAXIMUM 6’ HORIZONTAL RUNS)

Flush Mount Power

Vent Assy.

For use with

any TC Series

“C” unit,

except TC54.

Wall Sleeve

Assembly

Inner Wall Plate

Wall Pipe Cover

Vent Adaptor

111011-16 TCVT.FMPV3 5056.4265C3

TCVT.FMPV3

INSTALLATION AND

OPERATING

INSTRUCTIONS

PAINT:

Power Vent Installation

The vent terminal comes pre-painted

with Thurmalox 230 Series paint by

Dampney Co., but can be painted

to match your wall nish color

using high temperature paint that

can withstand temperatures of at

least 250 degrees Fahrenheit or 120

degrees Celcius.

Ensure the your paint is compatible

with Thurmalox 230 Series paint.

MINIMUM CLEARANCES TO

COMBUSTIBLE

Terminal casing:

0in. (0mm)

Vertical vent pipe:

1.5 in. (38mm)

Horizontal vent pipe:

1.5 in. (38mm)

All other clearances are as per the replace

installation instructions.

Locate the replace as per the main instructions supplied.

Make the following modi cations to add the components used with the Flush

Mount Power Vent Kits. This Kit can only be used in conjunction with the “C” series

versions of Town and Country replaces, except the TC54.CE2. This installation

must conform with local codes or, in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation

Code, CSA B149.1.

All electrical installations should be performed by a quali ed electrician to the

Canadian and U.S. National Electrical Codes (CSA C22.1 for Canada), (ANSI/NFPA

70 for the U.S.) and/or local electrical codes.

Contents of Power Vent Kit

ITEM PART No. DESCRIPTION QTY

1 TCVT.8043 Flush Mount Power Vent Assy. 1

2 5096.816 Venting Adaptor 1

3 TCVT.506271C Pressure Switch Wiring 1

4 5027.15 Pressure Switch 1

5 8024 Tubing, TYSC-516316-100 2

6 5093.01 Hose Clamp 2

7 5093.02 Hose Clamp 2

8 TCVT.507156C Power Vent Switch Wire 1

9 8271 TCWS.54CE2 Pressure Switch Bracket 1

10 9280 TC Pressure Switch Bracket 1

Fig. #1

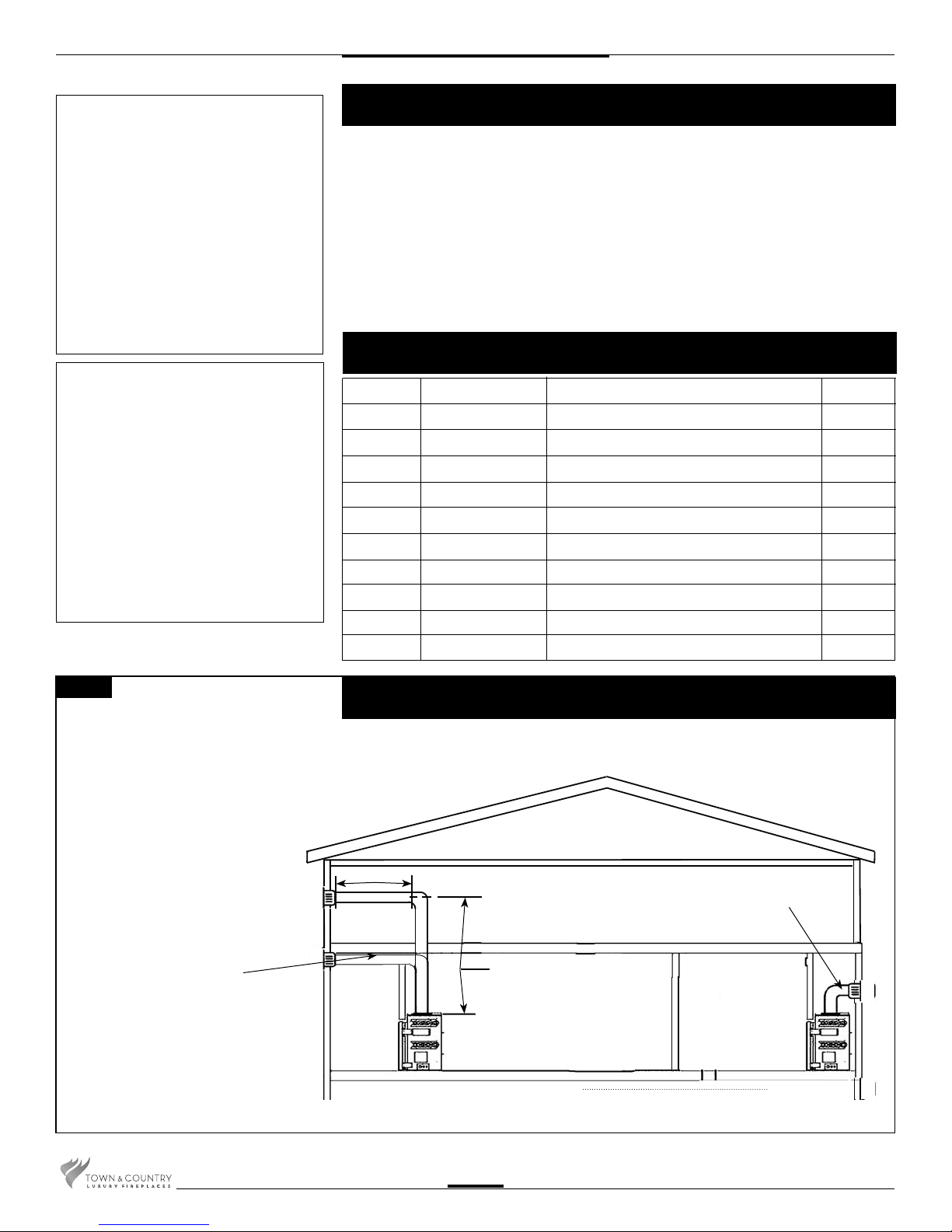

VENTING CONFIGURATIONS

Maximum total horizontal vent

length is 6ft. Minimum total

vent length is 3 ft plus one

90-degree elbow. Ensure vent

pipe is properly supported.

For every 90-degree elbow

after the rst transition,

subtract 2’ from max.

horizontal run.

Min. 1 1/2” Clearance to

combustible surfaces from

vent pipe.

Power Vent

MAX. 6’

Min. venting - 3 ft plus

one 90-degree elbow

66’ MAX. VERTICAL

111011-16 TCVT.FMPV3

2

Minimum Vent Length Chart

Fig. #2

Minimum Rise Pipe Min.

From Floor to Flue Center Length Pipe

Length

TCWS54 TCWS38 TC30 TC36* TC 42 TC36ST

49” 45” 47” 51” 57” 56” 0” 3 feet

61” 57” 59” 63” 69” 68” 12” 2 feet

73” 69” 71” 75” 81” 80” 24” 1 foot

*TC36 and TC36AR have the same dimensions

This power vent kit cannot be used on model TC54.CE2

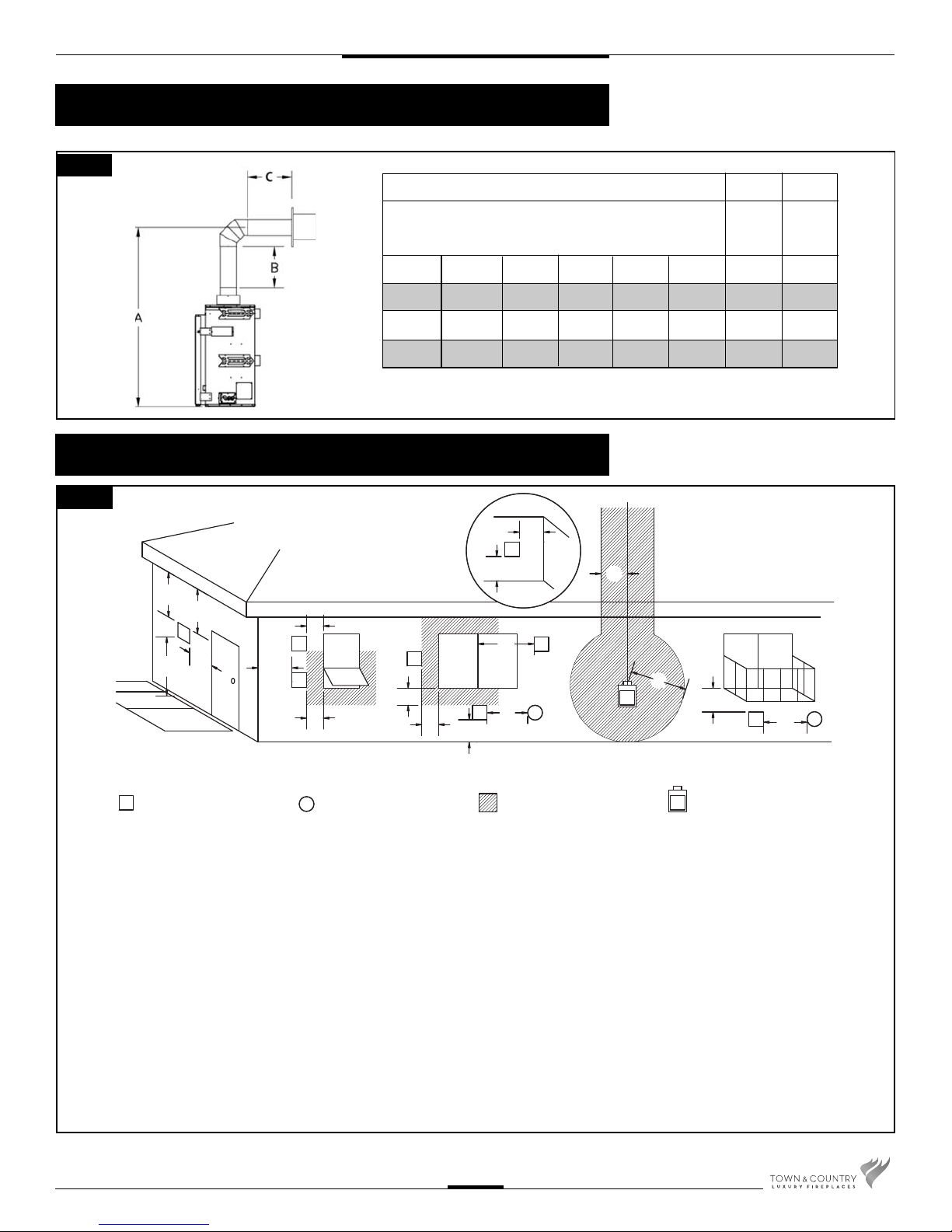

Vent Terminal Minimum Clearances

Fig. #3

A B C

INSIDE

CORNER

DETAIL

D

E

V

B

L

VENT TERMINAL GAS METER

V

C

FIXED

V

CLOSED

F

OPEN ABLE

V

B

AIR SUPPLY INLET

A

OPEN-

V

ABLE

B

B

V

A

A= clearances above grade, veranda, porch, deck, or balcony [*

12 inches (30 cm) minimum]

B= clearance to window or door that may be opened [* 12

inches (30 cm) minimum]

C= clearance to permanently closed window [minimum 12

inches (30 cm) recommended to prevent condensation on

window]

D= vertical clearance to ventilated soffit located above the ter-

minal within a horizontal distance of 2 feet (60 cm) from the

edge of the terminal [0 inches (0 cm) minimum]

E= clearance to unventilated soffit [0 inches (0 cm) minimum]

F= clearance to outside corner [6 inches (15 cm) minimum]

G= clearance to inside corner [3 inches (7.5 cm) minimum]

G

V

A

V

B

FIXED

CLOSED

A

J

AREA WHERE TERMINAL

IS NOT PERMITTED

H

I

G

M

V

K

G

H= * not to be installed above a meter/regulator assembly within

3 feet (90 cm) horizontally from the center-line of the regulator

I= clearance to service regulator vent outlet [* 6 feet (1.8 m)

minimum]

J= clearance to nonmechanical air supply inlet to building or the

combustion air inlet to any other appliance [* 12 inches (30

cm) minimum]

K= clearance to a mechanical air supply inlet [* 6 feet (1.8 m)

minimum]

L= ^ clearance above paved side-walk or a paved driveway

located on public property [* 7 feet (2.1 m) minimum]

M= clearance under veranda, porch, deck, or balcony

A

[0 inches (0 cm) minimum**]

^ a vent shall not terminate directly above a side-walk or paved driveway which is located between two single family dwellings and

serves both dwellings*

** only permitted if veranda, porch, deck, or balcony is fully open on a minimum of 2 sides beneath the oor*

* as speci ed in CGA B149 Installation Codes, Note: local Codes or Regulation may require different clearances

* for U.S.A. Installations follow the current National Fuel Gas Code, ANSI Z223.1

111011-16 TCVT.FMPV3

3

CAUTION:

This terminal is designed to be

nished ush to the nished outside

wall; under no circumstances

should this terminal be recessed

into the wall past this point.

(Fig. #8)

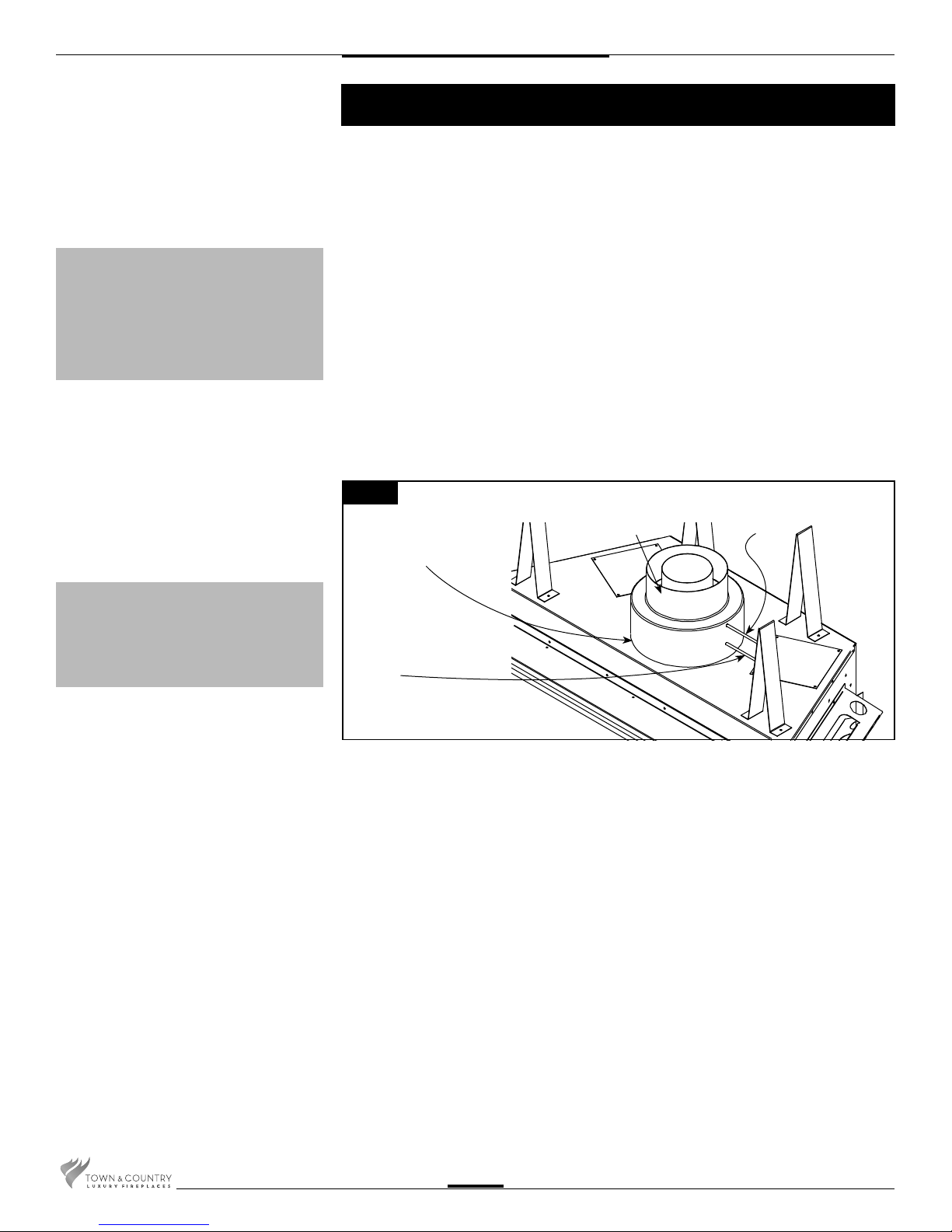

Horizontal (Side Wall) Venting

This kit uses either Simpson Duravent GS direct vent pipe, Secure Vent

direct vent pipe, Selkirk Direct-temp vent pipe or ICC Exceldirect vent pipe

with a 5” inner pipe and an 8” outer pipe. For part numbers see the table of

venting components on page 10 of this manual. This vent can only be used

as a side wall termination.

1. Attach the vent adaptor directly to the appliance with the three screws and seal outer

pipe with aluminium tape provided. (Fig. #4)

Note: The inner pipe does not need to be sealed.

2. Connect one of the high temperature silicone tubes to the upper pressure tap(marked

“LOW”) on the adaptor.(Fig.#4) Secure with the hose clamp provided and route the tube

through any hole back to the control box. This tube will be connected to the “low” side of

the pressure switch inside the control compartment.(Fig.#17) Connect the second tube to

the lower pressure tap(marked “HIGH”) and route to the control box as before. Connect this

tube to the remaining port on the pressure switch.

Tubes may touch unit and be trimmed if required.

Note: Ensure that there are no blockages in these tubes, as this will cause the

control to malfunction.

CAUTION:

The adjustable vent restrictor located

on the underside of the rebox top

must be fully open.

Fig. #4

SECURE WITH

THREE SCREWS

AND SEAL WITH

TAPE

.

LOWER PRESSURE

TAP, MARKED

“HIGH”

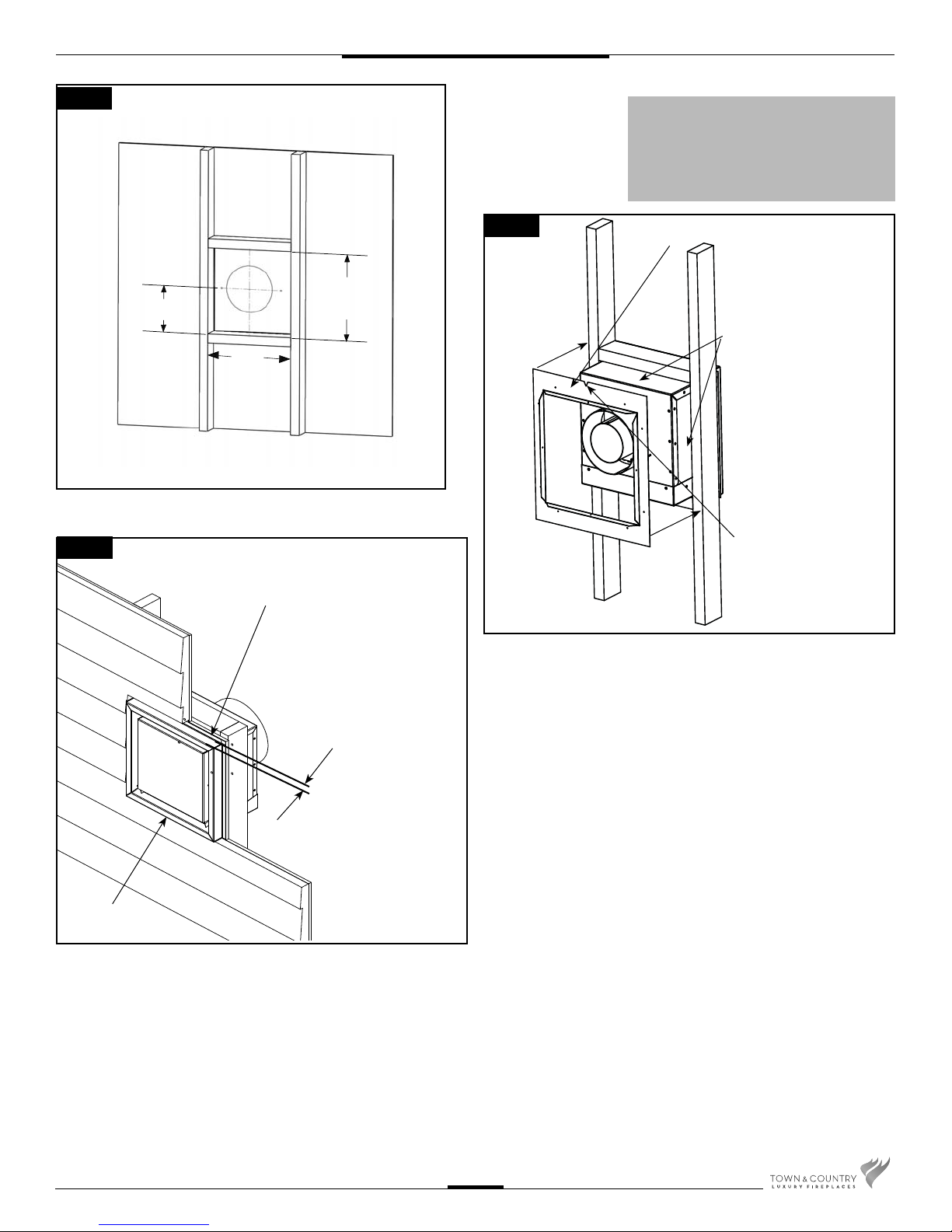

3. Locate the power vent termination following the clearance to combustible table(Page 2),

venting con guration diagram (Fig. #1 & 2), and terminal location diagram (Fig. #3).

4. Cut and frame a 14 1/2” wide by 14 3/4” high opening. For standard up and out

installations, the opening should be 3/4” lower than the minimum speci ed in Fig. #2.

Height of the opening will vary with each installation. See Fig. #5.

5. Attach the power vent terminal, by securing the outer anges on the perimeter of the

terminal to the outside wall; ensure that the terminal is the right way up (exhaust at the

bottom). Once secured to the building, the outer anges may be covered with siding/

stucco/etc. up to the level of the perimeter edge. As per local building codes. See Fig. #6.

Power Vent Adaptor.

Part # 5096.816

MUST BE INSTALLED

AT THE UNIT.

UPPER PRESSURE

TAP, MARKED

“LOW”

6. For wall thicknesses 7 1/2” or less, install the inner wall plate supplied over the terminal

as shown in Fig. #6 and secure to the framing. See Fig. #7.

111011-16 TCVT.FMPV3

4

Fig. #5

CAUTION:

The rise and run combination and the

number of elbows must not exceed

speci cations in Fig #1 and Fig #2.

Fig. #6

7 7/8”

14 3/4”

14 1/2”

TERMINAL SECURING

FLANGE

Fig. #7

INNER WALL PLATE

SEAL WITH SILICONE

ON ALL FOUR SIDES

NOTCH AT THE TOP

WALL FINISH NO

DEEPER THAN 1 1/4”

EXHAUST

111011-16 TCVT.FMPV3

5

Loading...

Loading...