Town & Country Fireplaces TC36 AR Installation And Operating Instructions Manual

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE

HOMEOWNER

FOR YOUR SAFETY

WARNING: If the information in this

manual is not followed exactly, a re or

explosion may result causing property

damage, personal injury or loss of life.

-- Do not store or use gasoline or other

ammable vapours and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbour’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the re department.

--Installation and service must be performed

by a quali ed installer, service agency or

the gas supplier.

This appliance may be installed in an

aftermarket permanently located, manufactured home (USA only) or mobile home,

where not prohibited by local codes.

MODEL

TC36 AR

SERIES B

MODULAR

This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases, unless a certi ed kit is

used.

DIRECT VENT FIREPLACE

INSTALLATION

AND OPERATING

INSTRUCTIONS

050505-36 36ARB2 5056.428091

Contents

CAUTION ..............................................................................................................3

SAFETY ................................................................................................................3

INSTALLATION REQUIREMENTS ....................................................................... 5

TOP STANDOFFS ................................................................................................. 5

LOCATING THE FIREPLACE ..............................................................................5

FRAMING AND FINISHING ..................................................................................6

HEARTH EXTENSION .......................................................................................... 8

CONTROL BOX .................................................................................................... 8

VENTING ............................................................................................................. 10

WALL TERMINATION VENTING ........................................................................10

ROOF TERMINATION VENTING .......................................................................15

VENT TERMINAL CLEARANCE ........................................................................ 17

INSULATED COLLAR SHIELD .......................................................................... 18

VENT PIPE SEALANT ........................................................................................ 18

VENT RESTRICTOR ADJUSTMENT ................................................................. 19

MANUFACTURED (MOBILE) HOME ................................................................. 19

GAS SUPPLY ...................................................................................................... 20

OPTIONAL WALL SWITCH ................................................................................ 20

WINDOW FRAME REMOVAL ............................................................................ 21

FIREBOX PANELS INSTALLATION ..................................................................22

FIRST FIRE .........................................................................................................23

OPERATING .......................................................................................................23

LIGHTING INSTRUCTIONS - Millivolt Valve .................................................... 23

LIGHTING INSTRUCTIONS - Electronic Valve ................................................ 24

MAINTENANCE .................................................................................................. 25

APPENDIX A ....................................................................................................... 25

REPLACEMENT PARTS .............................................................................. 26

REPLACEMENT PARTS-MILLIVOLT CONTROL ASSEMBLY ................... 27

REPLACEMENT PARTS - ELECTRONIC CONTROL ASSEMBLY ............ 28

ELECTRONIC VALVE WIRING DIAGRAM .................................................. 29

WALL TERMINATION KIT ........................................................................... 30

WALL SHIELD/CEILING FIRESTOP THIMBLE .......................................... 30

ROOF TERMINATION KIT ........................................................................... 31

VENT PIPE DIMENSIONS ............................................................................ 32

VENT OFFSET CHART ................................................................................ 33

VARIOUS GAS SUPPLY CONNECTIONS ................................................... 34

SAFETY LABEL LOCATION ........................................................................ 35

2 36ARB2 050505-36

CAUTION

SAFETY

FOR YOUR SAFETY - Do not install or operate your Town

and Country replace without rst reading and understanding

this manual. Any installation or operational deviation from the

following instructions voids the Town and Country FireplacesTM

Warranty and may prove hazardous.

This appliance and its individual shutoff valve must be disconnected from gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig

(3.5 kPa).

This appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa).

Note: When lit for the rst time, the appliance will emit a slight

odour for a couple of hours. This is due to the curing of paints,

sealants and lubricants used in the manufacturing process. This

condition is temporary. Open doors and windows to ventilate

area. Smoke and fumes caused by the curing process may

cause discomfort to some individuals.

Do not use the replace if any part has been under water.

Immediately call a quali ed service technician to inspect the

replace and to replace any part of the control system and

any gas control which has been under water.

Due to high temperatures, this gas appliance should

be located out of traf c and away from furniture and

draperies.

Children and adults should be alerted to the hazards of

high surface temperatures and should stay away to avoid

burns or clothing ignition.

Young children should be carefully supervised when they

are in the same room as the appliance.

Clothing or other ammable material should not be placed

on or near the appliance.

Any grill, panel or door removed for servicing the unit

must be replaced prior to operating. Failure to do so

may create a hazardous condition.

Installation and repair should be done by a quali ed service

person. The appliance should be inspected before use

and at least annually by a professional service person.

More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is imperative

that control compartments, burners and circulating air

passageways of the appliance be kept clean.

It is our policy that no responsibility is assumed by the

Company or by any of its employees or representatives

for any damages caused by an inoperable, inadequate,

or unsafe condition which is the result, either directly

or indirectly, of any improper operation or installation

procedures.

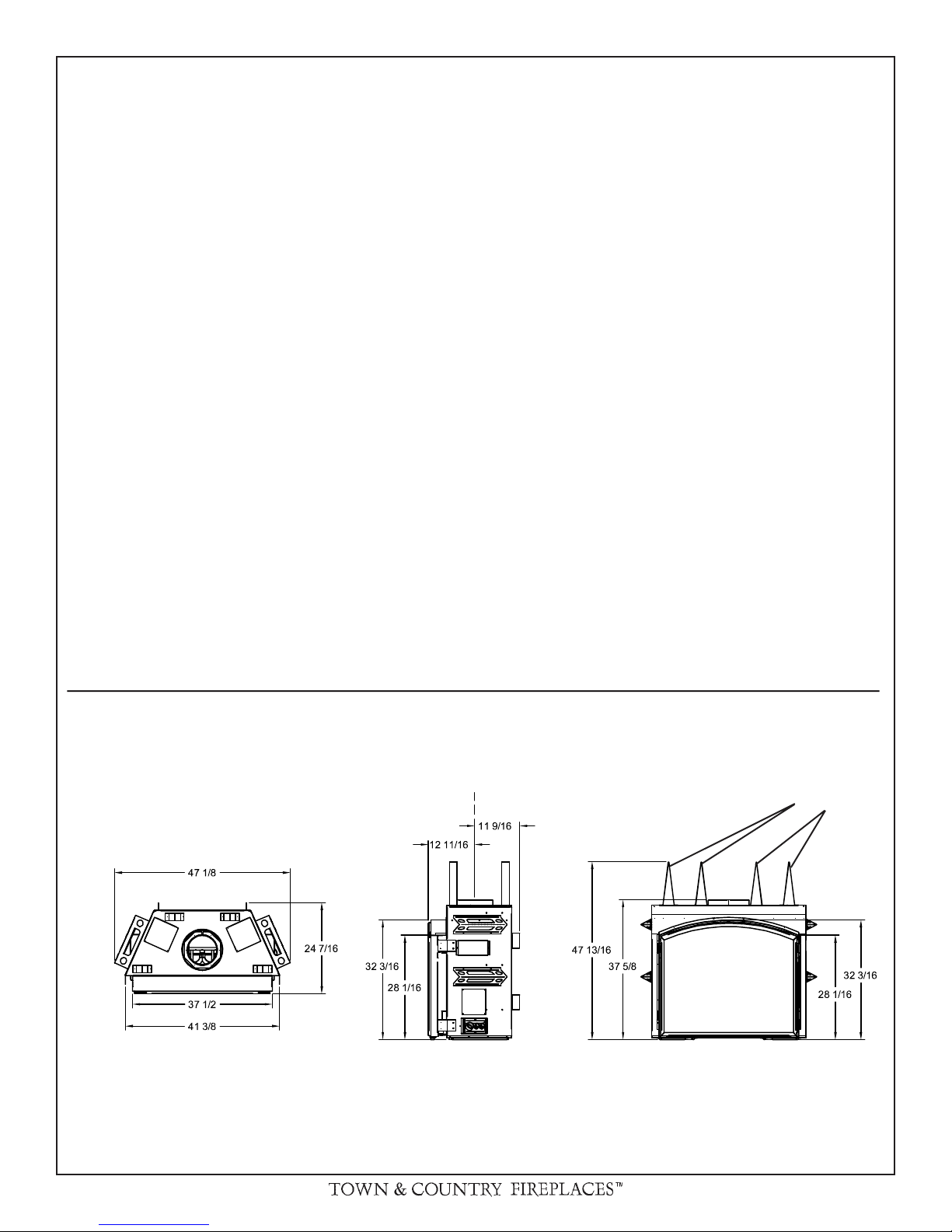

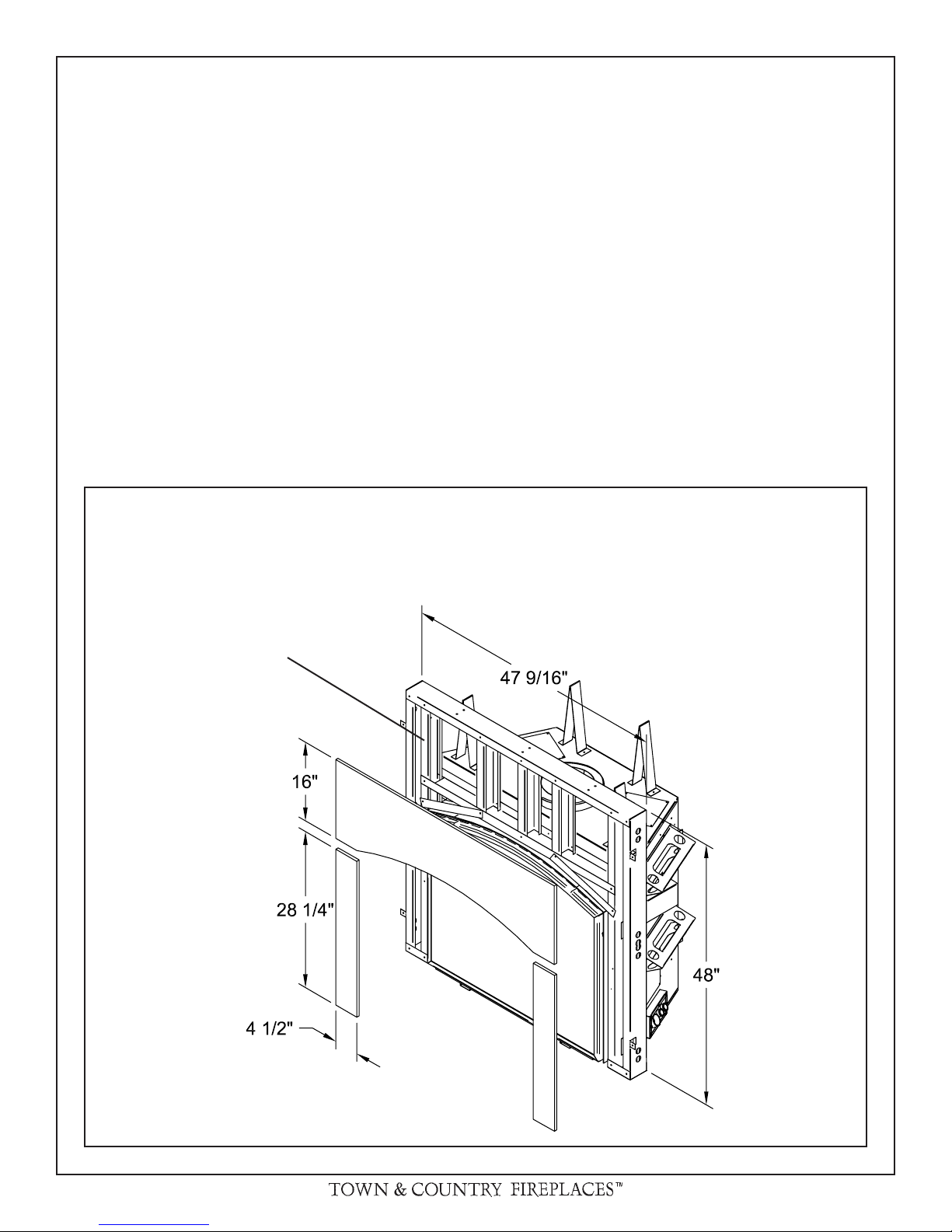

Fig # 1

FIREPLACE DIMENSIONS

CENTER OF

FLUE OUTLET

TOP

STANDOFFS

050505-36 36ARB2 3

COMBUSTIBLE FRAMING AND

FINISH WALL ABOVE STANDOFFS

MAY USE COMBUSTIBLE FACING

MATERIAL IN THIS AREA

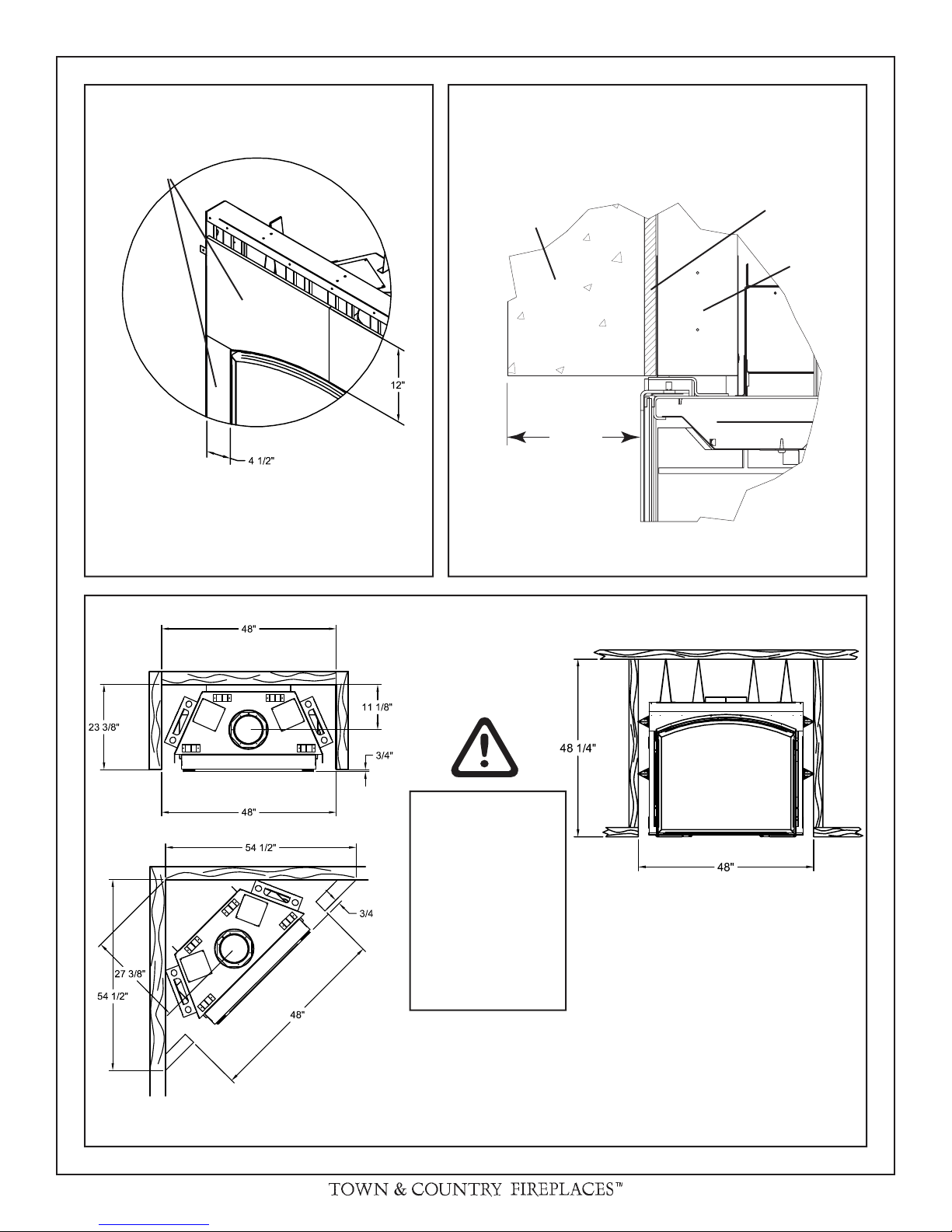

Fig. # 2

STEEL FRAMING

STANDOFFS

NON-COMBUSTIBLE

FINISH MATERIAL

SEE FIG #7

A

TOP OF LINTEL BAR

FIREPLACE FRONT

REF.

A 9" D 12"

B 6" E 6 3/4"

D

E

F

B

C

MANTEL CLEARANCE CHART

MANTEL

*

CLEARANCE

REF.

**

NON-COMBUSTIBLE ZONE.

DO NOT INSTALL ANY

COMBUSTIBLE MATERIAL,

ELECTRICAL WIRING OR

GAS PLUMBING IN THIS

AREA.

MANTEL

DEPTH

C 3" F 1 1/2"

Minimum Clearances to Combustibles:

Side standoffs ...................... 0 in. (0 mm)

Back standoffs ..................... 0 in. (0 mm)

Top standoffs ....................... 0 in. (0 mm)

Bottom of appliance ............. 0 in. (0 mm)

Adjacent sidewall ................. 4 in. (102 mm)

Ceiling to appliance ........... 24 in. (610 mm)

*Mantel to appliance ..........See Figure #2

**Maximum

Mantel extension ..........See Figure #2

Mantel support ..................... 4 in. (102 mm)

Vertical vent pipe ........... 1-3/4 in. (45 mm)

Horizontal vent pipe

Top ...........................1-3/4 in. (45 mm)

Sides ........................ 1-3/4 in. (45 mm)

Bottom ...................... 1-3/4 in. (45 mm)

Fig. # 3

CEILING

MANTEL

ADJACENT

WALL OR

MANTEL

SUPPORT

UNIT MAY BE RECESSED UP TO

6" WITH NON-COMBUSTIBLE

MASONRY TYPE MATERIAL

4 36ARB2 050505-36

INSTALLATION REQUIREMENTS

TOP STANDOFFS

The Town & Country Fireplace installation and venting

must conform to the current CAN/CGA-B149 installation

code (in Canada) or the current National Fuel Gas Code,

ANSI Z223.1 (in the USA), and approved per local codes.

Only quali ed (licensed or trained) personnel should

install this product.

In the state of Massachusetts, only a licensed Plumber

and Gas Fitter may install this product.

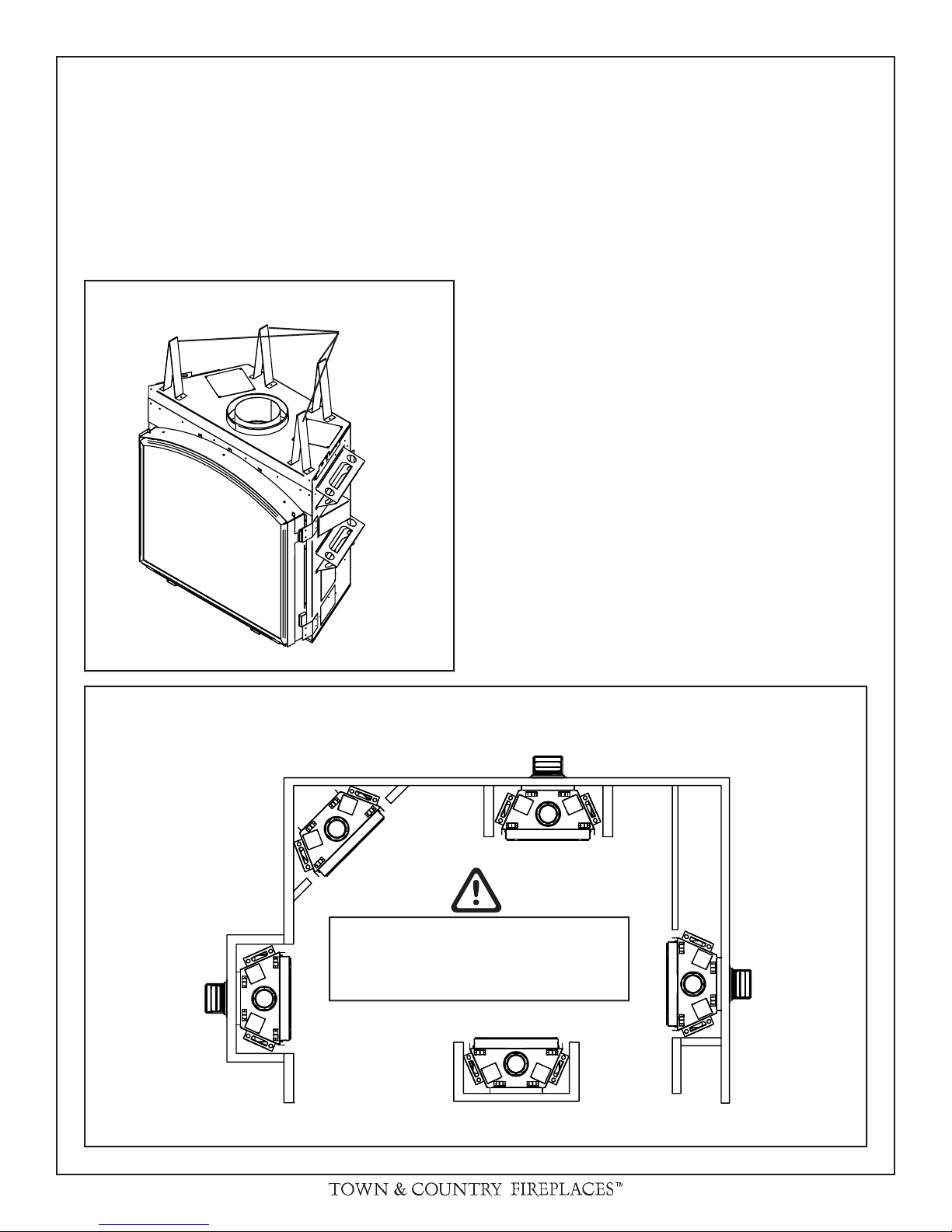

Fig. # 4

TOP

STANDOFFS

The top standoffs are shipped loose inside the replace and

must be installed on top of the replace as shown in g. #4.

Do this once the replace is on site and in position.

LOCATING THE FIREPLACE

In planning the installation for the replace, it is necessary to

determine where the unit is to be installed, location of vent

system and where gas supply piping may be plumbed. Various installations are possible, such as, into an existing wall,

a corner, a built-in wall or a wall projection (see Fig. #5). Due

to high temperatures, do not locate this replace in areas of

high traf c or near furniture or draperies.

The minimum clearances from the replace to combustible surfaces must be adhered to and are shown on Fig.

# 2 and 3.

Fig. # 5

SEE FIG #9 FOR

DIMENSIONS

Examples of Common Locations

CAUTION: When selecting a location, ensure

that there is adequate room on the right hand

or left hand side of the replace for the control

box.

050505-36 36ARB2 5

FRAMING AND FINISHING

Note: The replace must be in place and venting installed

before framing in or building an enclosure around the

unit.

The Town & Country Fireplace must be framed in as described

below or totally enclosed with non-combustible material, such

as facing brick.

Determine the total thickness of facing material to be used.

A thickness of 3/4" will allow the nishing surface to be ush

with the front of the unit. If preferred, additional masonry type

non-combustible material can be installed above and to the

sides up to 6 inches proud of the appliance. The nishing

material must not interfere with glass frame access.

A Steel Stud Framing Kit is supplied with the replace and

must be used unless the replace is totally enclosed with

non-combustible material. Assemble the framing kit as per

it's instructions. Attach the steel frame to the replace once

the replace is in its nal position. Secure the steel frame to

the framing brackets on each side of the unit. Ensure that

the studs are set back far enough to allow for thickness of

nishing surface.

The sides, back and top of the replace can be framed in

up to the steel studs and the replace standoffs using conventional lumber. Consult local building codes for speci c

requirements.

Due to high temperatures, concrete board is supplied with

the replace and must be used to sheet in the front of the

replace, extending 12" above and 4 1/2" to the side of the

framing edge bars. See gure #7. Standard sheetrock (drywall)

may be used beyond this.

Chase Insulation: When installing this replace against a

non-insulated exterior wall or chase, it is recommended that the

outer walls be insulated to same degree as other exterior walls.

Do not place replace directly against the insulation. Cover the

insulation and plastic vapour barrier with a solid surface, such

as drywall (sheetrock). Consult local codes. Do not insulate

or use plastic vapour barrier within the framing kit.

Fig. # 6

NONCOMBUSTIBLE

ZONE. DO NOT INSTALL

ANY COMBUSTIBLE

MATERIAL, ELECTRICAL

WIRING, INSULATION,

PLASTIC VAPOUR

BARRIER OR GAS

PLUMBING WITHIN THE

STEEL STUD FRAMING

STEEL STUD FRAMING KIT

DIMENSIONS

(TC36.BFRKITA)

ALL OTHER FRAMING

CAN BE DONE WITH

CONVENTIONAL

LUMBER

6 36ARB2 050505-36

Fig. # 7

CONCRETE BOARD

DETAIL

CONCRETE

BOARD

Concrete board (or other noncombustible material) must extend 12"

above and 4 1/2" to the sides of the

framing edges.

Fig. # 8

NON-COMBUSTIBLE

MASONRY TYPE

MATERIAL

NON-COMBUSTIBLE RECESSED

6"

INSTALLATION DETAIL

CONCRETE

BOARD

STEEL

STUDS

Fig. # 9

MINIMUM COMBUSTIBLE FRAMING DIMENSIONS

Including Sheetrock

CAUTION:

When framing

for the replace,

ensure adequate

space is provided

for the control box.

Do not install the

control box above

the replace.

050505-36 36ARB2 7

WARNING: Framing dimensions will vary with location of

replace, which may need to be adjusted to accommodate

control box placement and vent installation. Fireplace should

be in it's nal location before framing.

CONTROL BOX

The gas control system is housed in a control box remote of

the replace. Flexible conduits attach the control box to the

replace and house all the plumbing and wiring to the burner.

This unique design allows the control box to be mounted in

a variety of positions on the right or left side of the replace.

The box can be framed into the front right or left face or the

right or left sidewall of the replace enclosure. As the control

system is attached at the factory to exit the right side of the

replace, please see "Control Box Relocation" section to move

the control box to exit the left side.

Caution: When positioning the control box, do not over

bend the conduit or use excessive force, as damage may

occur.

1) Remove window frame latch tool and set aside.

2) Remove 4 screws holding control panel in place and

carefully lift off over the control knobs, being sure not to

damage wires and connections to the "Pilot Flame" indicator (millivolt control system only). Carefully disconnect

wires from indicator, and set aside.

3) Attach control box to framing at predetermined depth,

allowing room for wall nishing material. Side brackets

can be adjusted for a trim t.

4) Attach control box to framing at predetermined depth,

allowing room for wall nishing material. Side brackets

can be adjusted for a trim t.

5) Replace door/inner frame assembly and fasten in place.

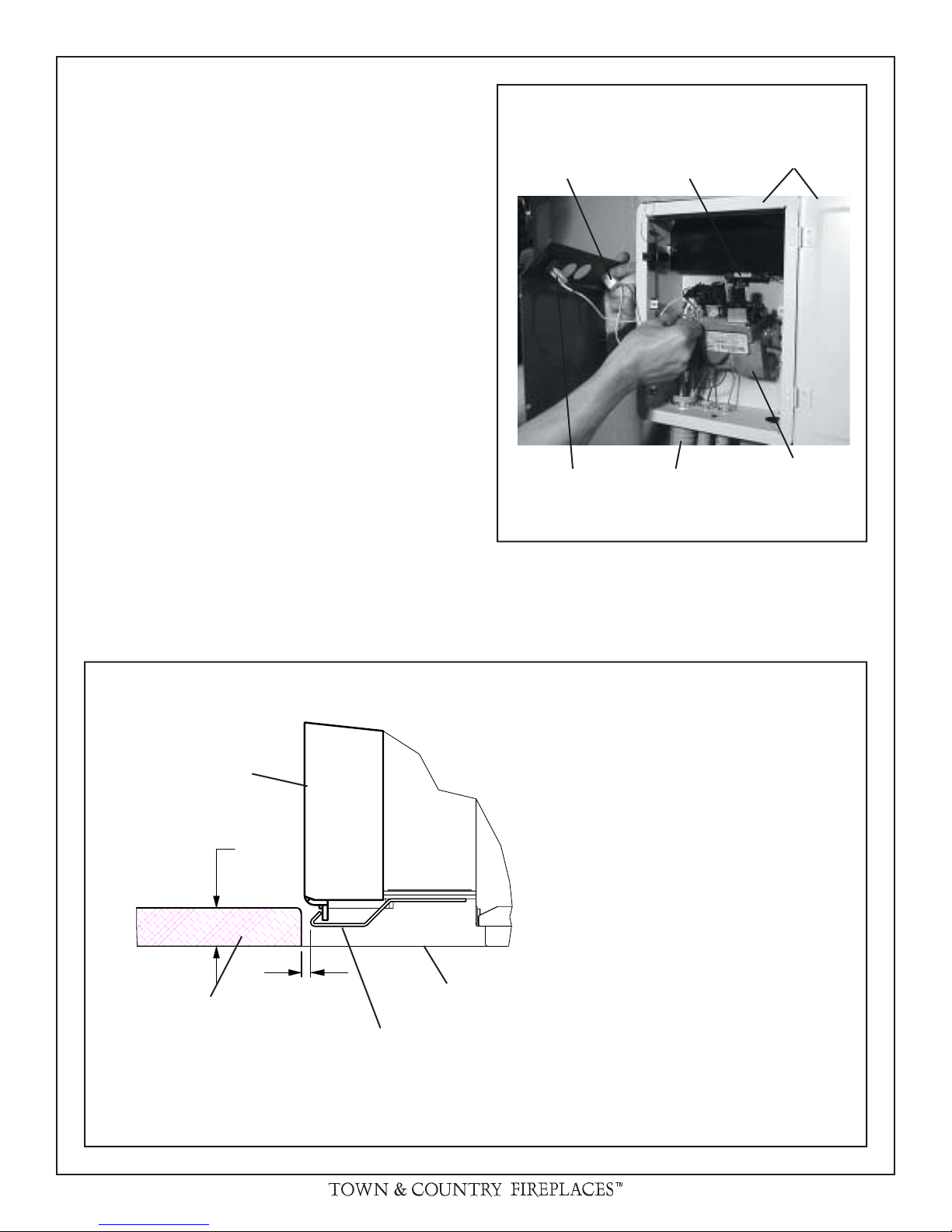

Fig. # 10

PILOT

FLAME

INDICATOR

BURNER

SWITCH

MANUAL MILLIVOLT VALVE

CONTROL

BATTERY SPARK

IGNITER

CONDUIT

DOOR AND

FRAME

GAS

VALVE

Note: Gas supply plumbing must be completed and the

spark igniter battery or backup batteries installed before

reinstalling the front control panel.

Fig. # 11

WINDOW

FRAME

1"

MAX

1/4"

HEARTH

EXTENSION

WINDOW

TRACK

FLOOR

SUB-

6) Reconnect "Pilot Flame" indicator wiring and reinstall

control panel.

HEARTH EXTENSION

While a hearth extension is not required

for this replace, one is recommended

for aesthetic reasons. The hearth

extension should be noncombustible

and must not be any more than 1"

above the bottom of the replace. If

thicker, replace must be raised up

accordingly.

Caution: Hearth extensions thicker

than 1" will interfere with the window

frame.

8 36ARB2 050505-36

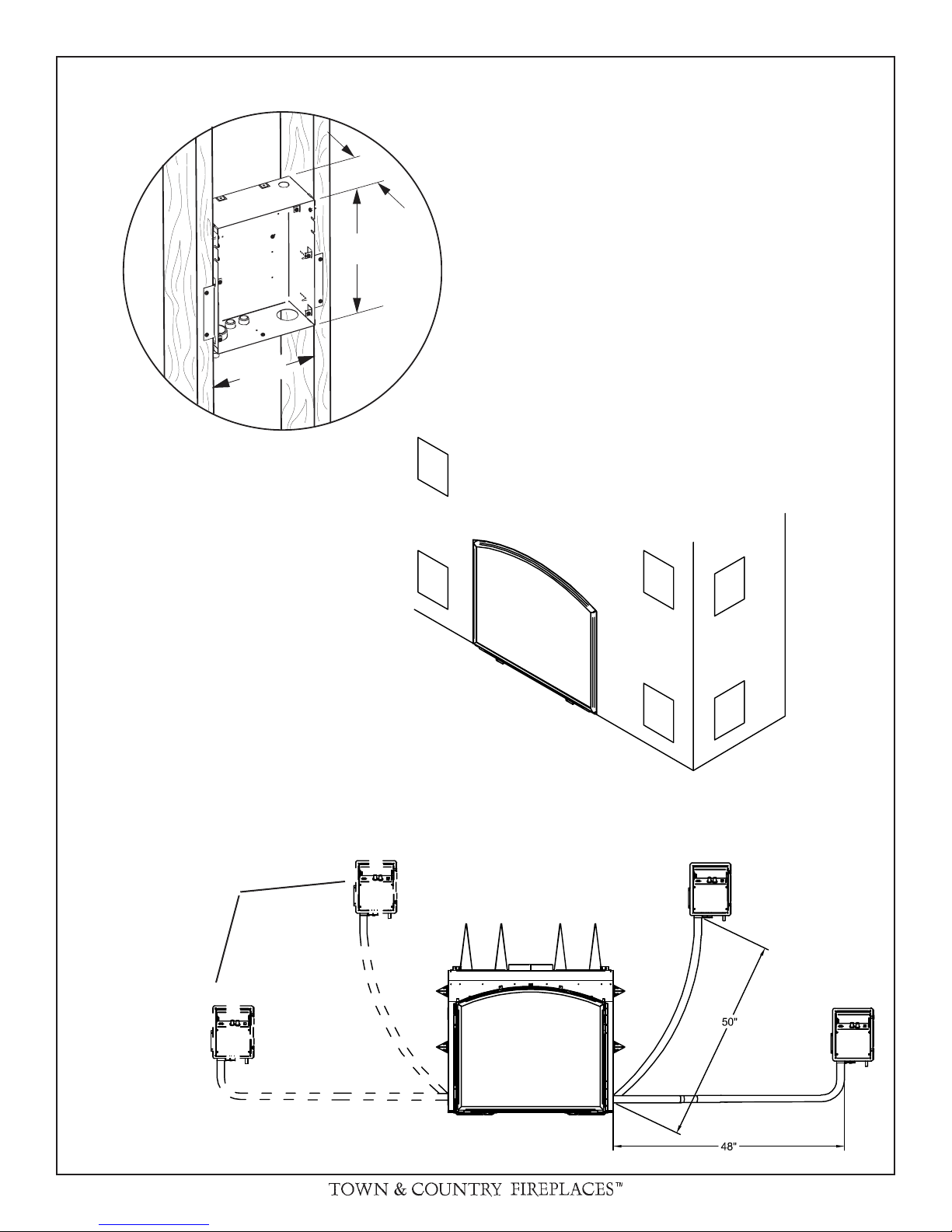

Fig. # 12

CONTROL BOX LOCATION AND

FRAMING DETAIL

4 1/4"

CAUTION:

9 3/8"

Caution: When positioning the control box,

do not over bend the

conduit or use excessive force, as damage

may occur.

12"

- A 2 foot service access clearance is recommended in front of the control box.

- If recessed into a masonry wall, allow for

control door and frame removal.

- If ush mounted on a masonry wall, allow for

conduit to exit out the bottom of control box.

DO NOT INSTALL

CONTROL BOX

OVER FIREPLACE

POSSIBLE CONTROL BOX

LOCATIONS LEFT OR RIGHT

OF THE FIREPLACE

Alternately, the

control may be repositioned from

the right side of

the fireplace to

the left side.

050505-36 36ARB2 9

DO NOT INSTALL

CONTROL BOX

OVER FIREPLACE

VENTING

WALL TERMINATION VENTING

Before installing venting for this unit, the installer should read

these instructions to insure that the proper vent con guration

has been selected.

Use only Town and Country Termination kits #:

TCVT.WTA - Wall Termination Kit

TCVT.RTA - Roof Termination Kit

Vent system components approved for use with the Town and

Country Fireplace are shown in Figure #13.

Various combinations of vertical and horizontal runs may be

used. Refer to #

and ame appearance, keep the vent length to a minimum and

limit the number of elbows. Connections between each vent

system component must be tightly joined, secured with sheet

metal screws and sealed. A horizontal run of vent should have

a 1/4" rise for every 1 ft. of run towards the termination.

CAUTION: UNDER NO CONDITION SHOULD COMBUSTIBLE MATERIAL BE CLOSER THAN 1 3/4 INCHES FROM

THE TOP AND 1 3/4 INCHES FROM THE SIDES OF A

HORIZONTAL SECTION AND 1 3/4 INCHES FROM THE

VERTICAL SECTIONS OF THE VENT PIPE.

17 and 18 for details. For optimum performance

Exterior wall opening:

Determine the exact position of the replace so that the vent

pipe is centred (if possible) between two building framing

members. Consult your local building codes prior to proceeding. The vent kit will accommodate up to a maximum wall

thickness of 12 inches.

1) Having determined the position of the replace, cut and

frame a 14 1/2 inch opening centred at a minimum height

of

68 1/2 inches above the oor. The opening may be

round or square. Height of the opening will vary with each

installation. As the horizontal vent run increases, so does

the minimum vertical rise (see Fig. #17).

IMPORTANT: When locating the opening, it should be

noted that vent terminal clearances must be maintained.

See "Vent Terminal Clearances" section for proper clearances.

A minimum 2 foot length of pipe is required for any wall termination. With this minimum vertical rise in combination with a

90° elbow, a maximum horizontal run of 18 inches is permitted

(see Fig. #17 and 18). For longer horizontal runs greater than

18 inches, increase vertical rise appropriately.

The rise and run must be constrained to the boundaries of the

chart shown in gure #17. The horizontal run of vent must have

a 1/4" rise for every 1 ft. of run towards the termination.

Fig. # 13

Vent System Town &

Components Country

12" Pipe Length ........................... TCVT.811X12

18" Pipe Length ........................... TCVT.811X18

24" Pipe Length ........................... TCVT.811X24

48" Pipe Length ........................... TCVT.811X48

18" Adjustable Pipe Length ......... TCVT.811X12ADJ

45° Elbow .................................... TCVT.811XLB45

90° Elbow .................................... TCVT.811XLB90

Wall/Offset Support ..................... TCVT.811XOS

Wall Termination Kit .................... TCVT.WTA

Roof Termination Kit .................... TCVT.RTA

Wall Shield/Ceiling Firestop ......... TCVT.THIMA

Roof Flashing, Adjustable ............ TCVT.811FLADJ

Roof Flashing, Flat ...................... TCVT.811FLFLT

Roof Flashing, Steep ................... TCVT.811FLSTP

or any that ts 11" pipe

10 36ARB2 050505-36

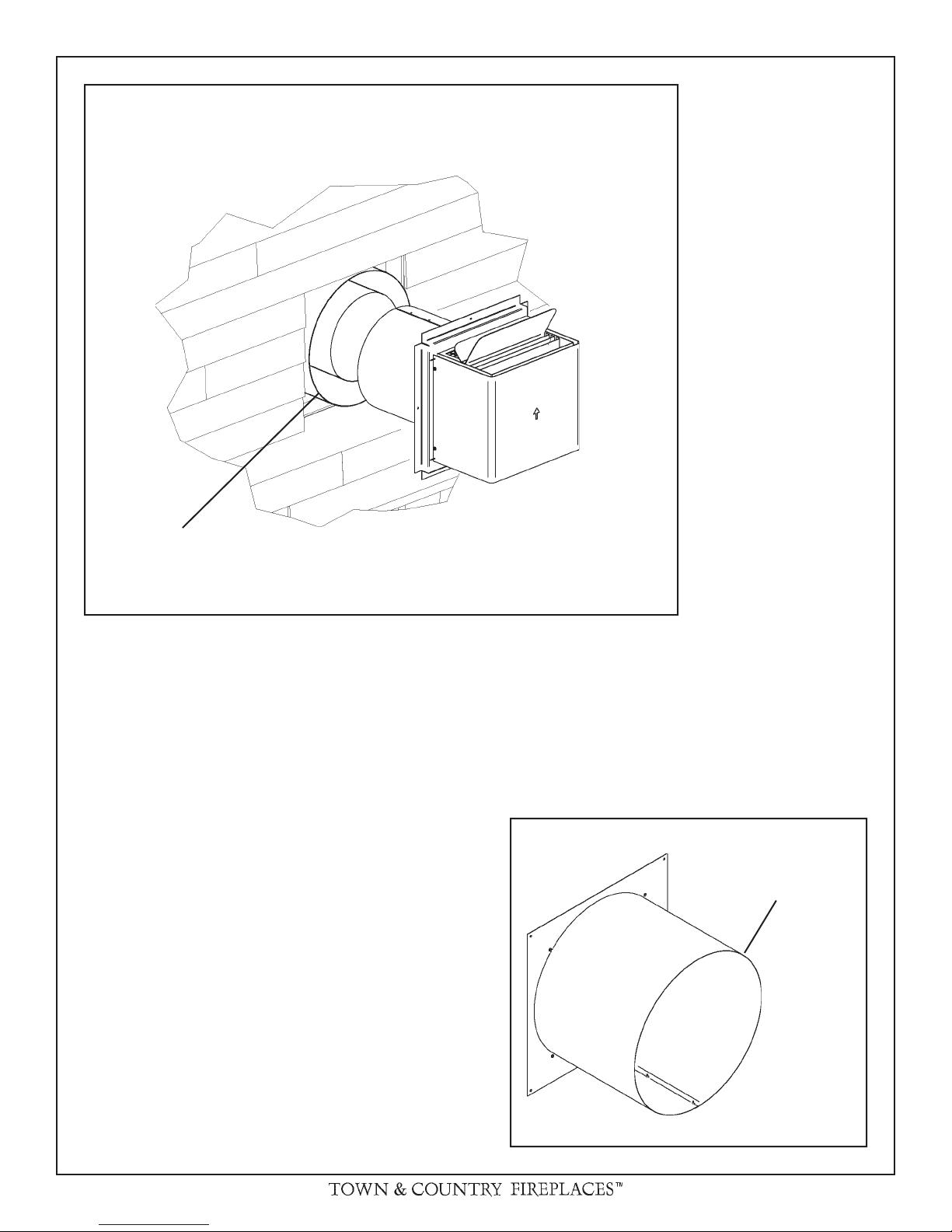

Fig. # 14

WALL THIMBLE AND VENT

MUST NOT PROTRUDE

BEYOND SIDING

Wall thimble:

Where a vent pipe passes through a combustible wall, a wall

thimble/shield must be used to retain insulation and maintain

proper clearances. The wall thimble may be cut to length for

various wall thicknesses up to 12" thick.

Measure the wall thickness including the siding. Trim the

shield to match the wall thickness. Position the wall thimble

from inside through the 14-1/2" opening. Properly adjusted,

the thimble should be ush with the outer wall surface.

Fig. # 15

TRIM TO LENGTH

050505-36 36ARB2 11

Loading...

Loading...