Town & Country Fireplaces Architectural Series, The Architectural Series, A Series Installation Manual

INSTALLATION MANUAL

The Architectural Series

BY TOWN & COUNTRY

CONFIGURATION

See-Thru

FOR YOUR SAFETY

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier call

the fire department.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

This is a decorative product and is not intended

to be used as a heating appliance.

This appliance is suitable for installation in a

bedroom or bed sitting room.

This appliance may be installed in an aftermarket

permanently located, manufactured home (USA only)

or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of

gas indicated on the rating plate. This appliance

is not convertible for use with other gases,

unless a certified kit is used.

WARNING: If the information in these instructions is

not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

160919-48

Architectural Series

100000454-50

Table of Contents

Caution .......................................................................................................... 3

Safety ............................................................................................................ 3

Important Note for the Commonwealth of Massachusetts ........................... 4

Congratulations on your Town & Country purchase ...................................... 5

Installation Requirements/Appliance Specications ..................................... 5

Installation Requirements .............................................................................. 5

Vent Terminal Minimum Clearances .............................................................. 6

Minimum Clearances to Combustible Material ............................................. 7

Btu Values and Weights ................................................................................. 7

Appliance Dimensions ................................................................................... 8

Locating the Unit ......................................................................................... 10

Framing and Finishing ..................................................................................11

Framing ................................................................................................... 12

Facing Material ....................................................................................... 13

Venting Conguration .................................................................................. 14

Venting plenum ....................................................................................... 14

NOTE: Plenum must not be shared with other appliances. ................... 14

Venting Specications ................................................................................. 15

Air Intake ..................................................................................................... 16

Optional Motorized Damper ........................................................................ 17

Power Vent ..................................................................................................18

Power Vent Hood ........................................................................................19

Power Vent Clearance to Adjacent Structures ........................................... 19

Bafe Installation and Adjustment ............................................................... 20

Black Glass Option Installation ....................................................................21

Crushed Glass Media Installation ................................................................ 22

Gas Connection ........................................................................................... 23

Inside Glass Plate Installation ..................................................................... 24

Inside glass plates installation ................................................................ 24

Side Securing Panel Installation .................................................................. 25

Outside Glass Plate Installation ................................................................... 26

Electrical Connection .................................................................................. 27

Electrical Diagram ....................................................................................... 28

Control Panel Installation ............................................................................ 29

LED Strip Replacement ............................................................................... 34

Removing an LED section ...................................................................... 34

Gas Pressure and Orice Figures ................................................................ 36

Lighting Instructions .................................................................................... 37

Maintenance ................................................................................................ 38

Replaceable Parts ....................................................................................... 39

Rating labels ................................................................................................ 40

100000454

2

Architectural Series

160919-48

Caution

This appliance and its individual shut off valve must be disconnected from gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

This appliance must be isolated from the gas supply piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

Do not use the re feature if any part has been under water. Immediately call a qualied service technician

to inspect the re feature and to replace any part of the control system and any gas control which has been

under water.

We recommend that our gas hearth

products be installed and serviced

by professionals who are certified

in the United States by the National

Fireplace Institute® (NFI) as NFI Gas

Specialists

Safety

Any grill, panel or door removed for servicing the unit must be replaced prior to operating. Failure to do so

may create a hazardous condition.

Installation and repair should be done by a qualied service person. The appliance should be inspected

before use and at least annually by a professional service person. More frequent cleaning may be required

due to excessive lint from car-peting, bedding material, etc. It is imperative that control compartments,

burners and circulating air passageways of the appliance be kept clean.

It is our policy that no responsibility is assumed by the Company or by any of its employees or

representatives for any damages caused by an inoperable, inadequate, or unsafe condition which is the result,

either directly or indirectly, of any improper operation or installation procedures.

This appliance must not be connected to a chimney ue serving a separate solid fuel burning appliance.

160919-48 Architectural Series

3

100000454

Important Note for the Commonwealth of Massachusetts

From Massachusetts Rules and Regulations 248 CMR 5.08:

(a) For all side wall horizontally vented gas fuelled equipment installed in every dwelling, building or structure used in whole or in part for residential

purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet

above nished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall be satised.

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fuelled equipment, the

installing plumber or gas tter shall observe that a hard wired carbon monoxide detector with an alarm and battery back-up is installed on the oor

level where the gas equipment is to be installed, in addition, the installing plumber or gas tter shall observe that a battery operated or hard-wired

carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure served by the side wall horizontal

vented gas fuelled equipment. It shall be the responsibility of the property owner to secure the services of qualied licensed professionals for the

installation of hard-wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fuelled equipment is installed in a crawl space or an attic, the hard-wired carbon monoxide

detector with alarm and battery back-up may be installed on the next adjacent oor level.

b. In the event that the requirements of this subdivision cannot be met at the time of completion of installation, the owner shall have a period of thirty

(30) days to comply with the above requirements; provided, however, that during said thirty (30) day period, a battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034 listed as IAS certied.

3. SIGNAGE. A metal or plastic identication plate shall be permanently mounted to the exterior of the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent terminal for the horizontally vented gas fuelled heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fuelled equipment shall not approve the installation unless,

upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR 5.089(2)

(a) 1 through 4.

(b) EXEMPTIONS. The following equipment is exempt from 248 CMR 5.089(2)(a) 1 through 4.

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current edition of NFPA 54 as adopted by the

Board; and

2. Product Approved side wall horizontal vented gas fuelled equipment installed in a room or structure separate from the dwelling, building or structure

used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting system design or venting system components with the equipment, the instructions provided

by the manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the manufacturer of a Product Approved

side wall horizontally vented gas fuelled equipment does not provide the parts for venting the fuel gases, but identies “special venting systems”, the

following requirements shall be satised by the manufacturer.

1. The referenced “special venting system” instructions shall be included with the appliance or equipment installation instructions; and

2. The “special venting systems” shall be Product Approved by the Board, and the instructions for that system shall include a parts list and detailed

installation instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts

lists for venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of the installation.

100000454

4

Architectural Series

160919-48

Congratulations on your Town & Country purchase

Your Architectural Series Zero Clearance linear appliance has been professionally installed by:

Dealer name: _____________________________________________

Phone Number: ___________________________________________

If you discover any problems with your linear appliance, contact your dealer immediately to have the unit

repaired.

Caution: Do not attempt to repair the linear appliance because you may cause injury to yourself or others,

and risk causing damage to the unit.

Before operating your linear appliance carefully read this manual and pay close attention to all Safety

Warnings. The manual contains important information on the unit’s safe operation and maintenance.

Installation Requirements/Appliance Specifications

Town and Country Architectural Series linear appliance.

Specifications

• This unit has been tested to ANSI Z21.50 and CSA P.4.1 specications.

• Single wall (min. 26 ga) galvanized ducting (zero clearance).

• 120VAC / single phase

• 24VAC Honeywell direct ignition valve system.

• Power vented only. Programmed with pre and post-purge safety functioning. Certied to use provided

Town & Country power vent only.

• Horizontal or Vertical Termination.

• Zero clearance unit ( no non-combustible board required).

• 12” rigid exhaust - 150 ft max lengnth plus up to 6 elbows.

• 7” rigid intakes - (All bottom intake models) 150 ft max length plus up to 6 elbows (zero clearance).

• 10” rigid intakes - (All top intake models) 150 ft max length plus up to 6 elbows (zero clearance).

Installation Requirements

The replace installation and venting must conform to the current CAN/CGA-B149 installation code (in

Canada) or the current National Fuel Gas Code, ANSI Z223.1 (in the USA), and approved per local codes.

Only qualied (licensed or trained) personnel should install this product.

In the state of Massachusetts, only a licensed Plumber and Gas Fitter may install this product.

160919-48 Architectural Series

5

100000454

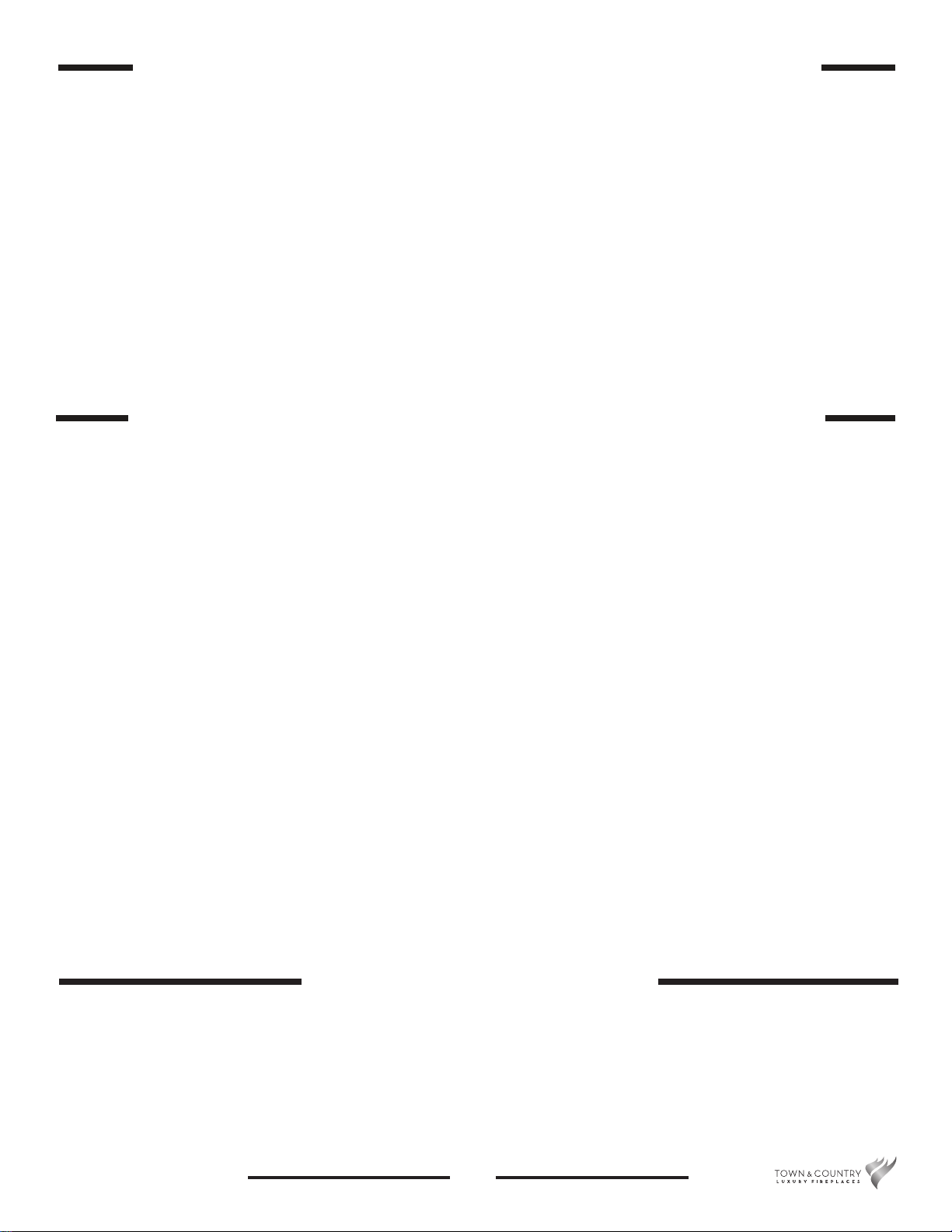

Vent Terminal Minimum Clearances

G

V

A

D

E

V

B

L

C

FIXED

V

CLOSED

F

OPEN-

ABLE

V

B

OPEN-

V

ABLE

B

B

A

FIXED

CLOSED

V

B

V

A

J

H

I

G

M

V

A

K

VENT TERMINAL

V

AIR SUPPLY INLET

A

AREA WHERE TERMINAL

IS NOT PERMITTED

GAS METER

G

Figure 1: Vent terminal minimum clearances.

A= *12 inches (30 cm) min. Clearances above grass, top of plants, wood, combustible veranda, porch, deck, or balcony.

B= *12 inches (30 cm) min. Clearance beside or below a window or door that may be opened.

C= 12 inches (30 cm) min. Clearance to permanently closed window recommended to prevent condensation on window.

D= 16 inches (40 cm) min. Vertical clearance to ventilated soft located above the terminal within a horizontal distance of 16 inches (40 cm) .

E= 30 inches (76 cm) min. Clearance to unventilated soft.

F= 6 inches (15 cm) min. Clearance to outside corner.

G= 6 inches (15 cm) min. Clearance to inside corner.

H= 3 feet (90 cm) min. *Not to be installed above a meter/regulator assembly within 3feet (90 cm) horizontally from the center-line of the

I= *6 feet (1.8 m) min. Clearance to service regulator vent outlet.

J= *12 inches (30 cm) min. Clearance to non mechanical air supply inlet to building or the combustion air inlet to any other appliance.

K= *6 feet (1.8 m) min. Clearance to a mechanical air supply inlet.

L= 7 feet (2.1 m) min. ^ Clearance above paved side-walk or a paved driveway located on public property

M= 30 inches (76 cm) min. Clearance under veranda, porch, deck, or balcony

regulator.

100000454

6

Architectural Series

160919-48

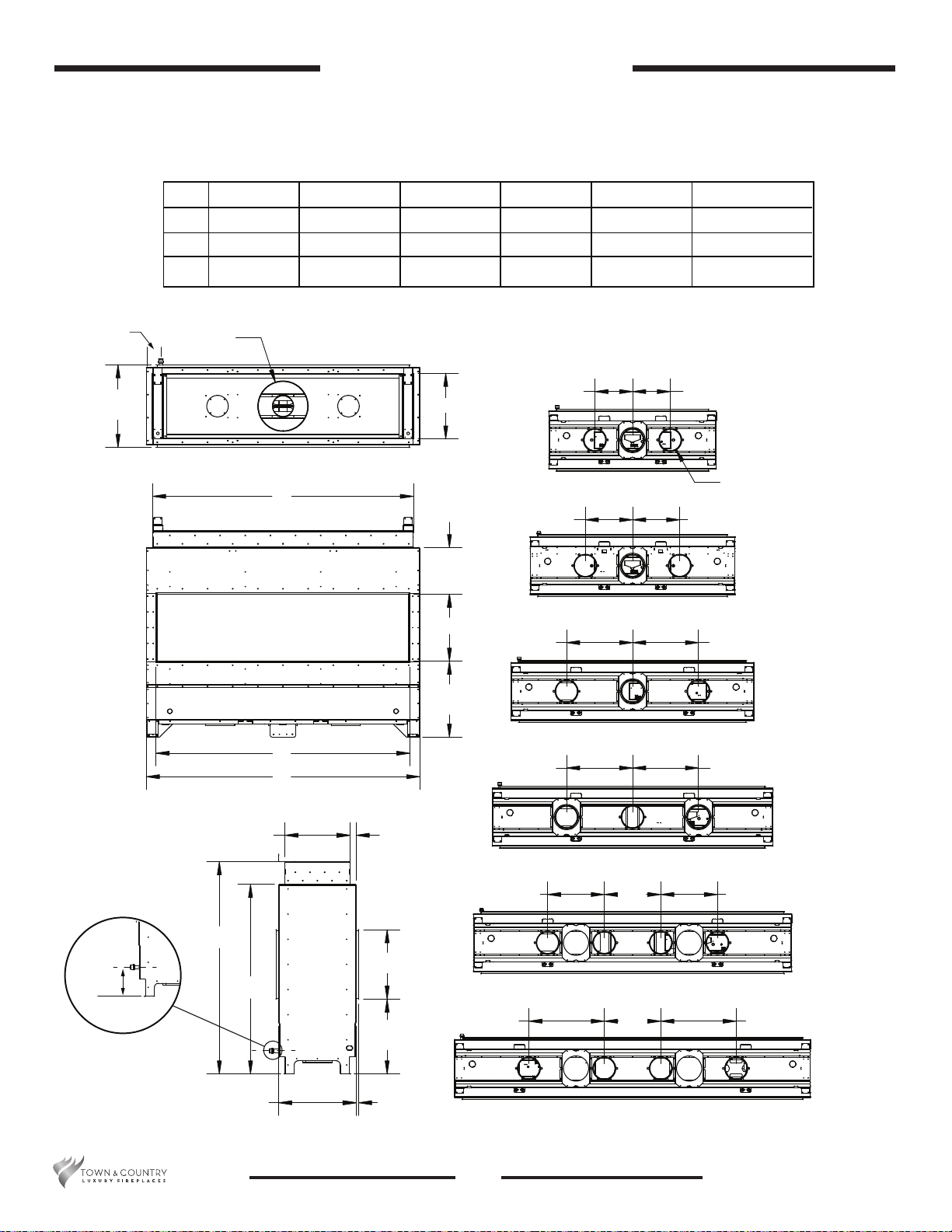

Minimum Clearances to Combustible Material

See Through 3FT 4FT 5FT 6FT 7FT 8FT

BTR/HR 48000 64000 80000 96000 112000 128000

16” Glass 383 448 530 599 668 735

24” Glass 460 503 592 669 750 821

32” Glass 537 580 669 746 827 898

This See-Thru Linear appliance is a zero clearance re feature. Combustible material may be use to

frame the unit in.

Venting for this unit is also zero clearance. Combustible material is permitted to come into direct contact with venting material.

Btu Values and Weights

Weight lbs

Weight lbs

Weight lbs

160919-48 Architectural Series

7

100000454

C

A

16"

B

19 3/4”

Ø 11 7/8”

15 3/4”

11 1/8”

18 1/8”

15 1/2”

1 1/2”

16 5/8”

17 7/8”

5/8”

45 1/4”

50 5/8”

18 1/2”

24”

18”

24”

18” 18” 18”

21” 21”

21” 21”

15”

15”

15”

15”

Ø 7”

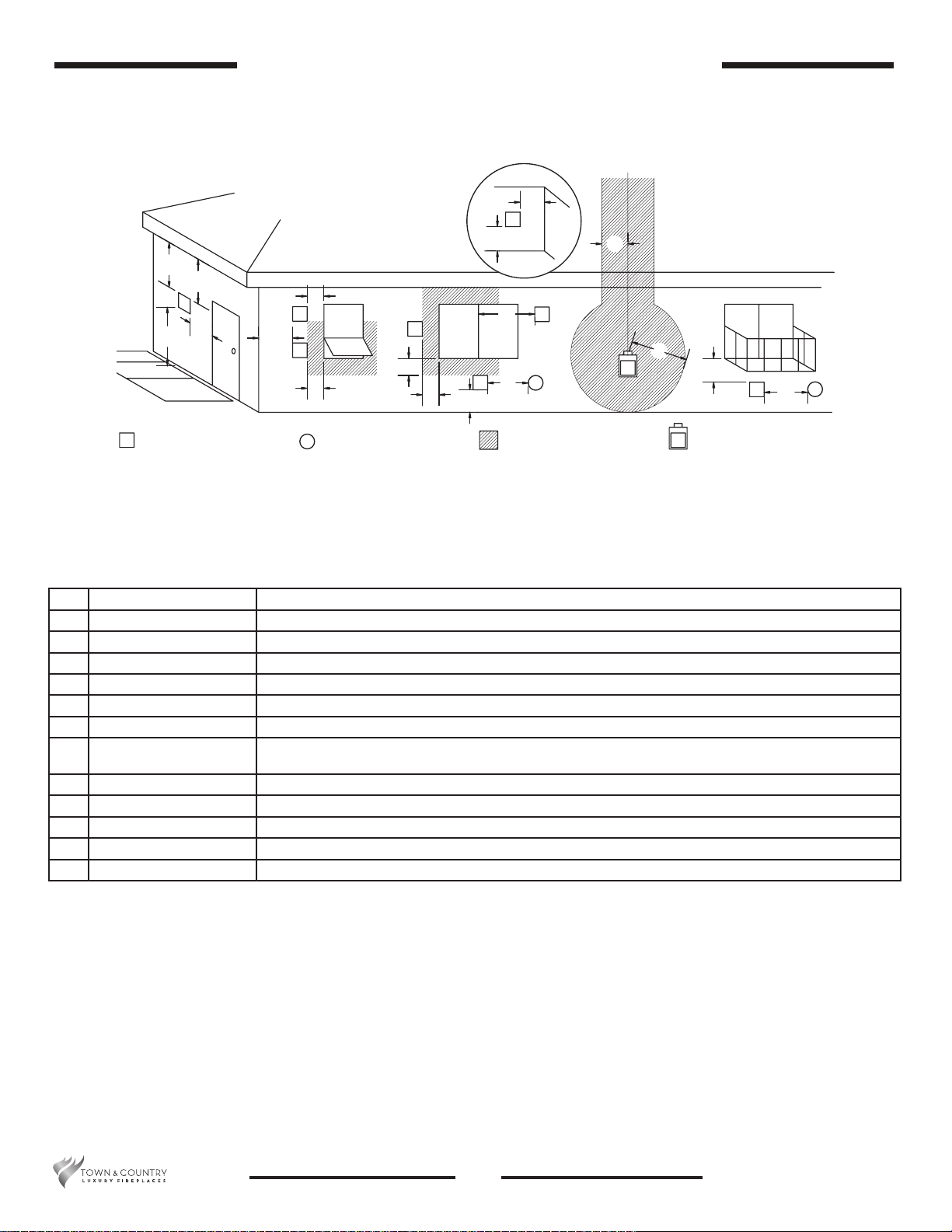

3 foot

4 foot

5 foot

6 foot

7 foot

8 foot

3’ 4’ 5’ 6’ 7’ 8’

A 48 5/8” 60 5/8” 72 5/8” 84 5/8” 96 5/8” 108 5/8”

B 53 1/4” 65 1/4” 77 1/4” 89 1/4” 101 1/4” 113 1/4”

C 50 1/4” 62 1/4” 74 1/4” 86 1/4” 98 1/4” 110 1/4”

See Thru model with 16 inch glass and bottom intake

Bottom view

Top view

5 3/4”

6 1/4”

Appliance Dimensions

Figure 2: See Through unit with 16 inch glass & top intake.

100000454

8

Architectural Series

160919-48

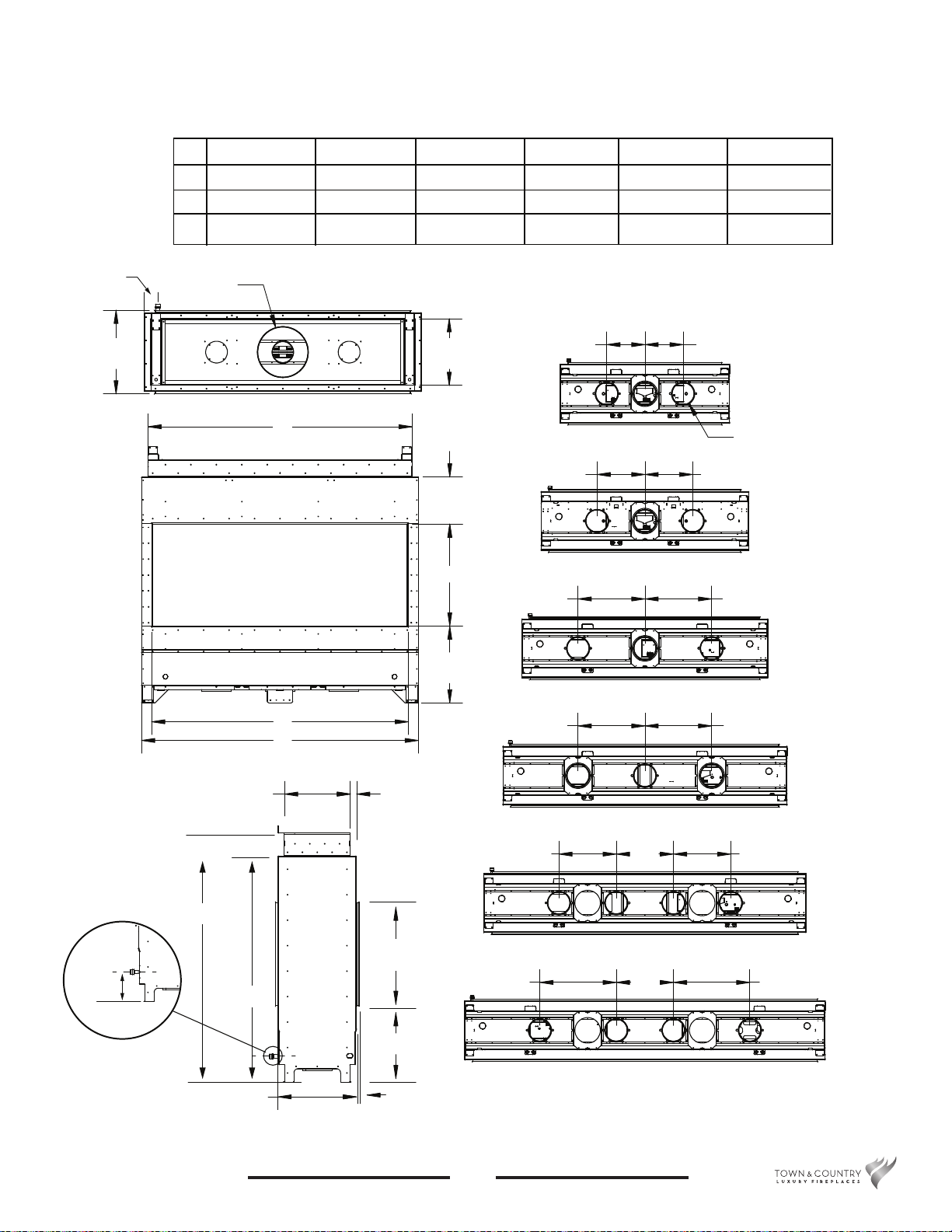

See Thru model with 24 inch glass and bottom intake

6 1/4”

3’ 4’ 5’ 6’ 7’ 8’

A 48 5/8” 60 5/8” 72 5/8” 84 5/8” 96 5/8” 108 5/8”

B 53 1/4” 65 1/4” 77 1/4” 89 1/4” 101 1/4” 113 1/4”

C 50 1/4” 62 1/4” 74 1/4” 86 1/4” 98 1/4” 110 1/4”

5 3/4”

19 3/4” 15 3/4”

Ø 11 7/8”

Top view

C

11 1/8”

24"

18 1/8”

A

B

Bottom view

15”

15”

21” 21”

21” 21”

15”

Ø 7”

15”

3 foot

4 foot

5 foot

Figure 3: See Through unit with 24 inch glass & top intake.

160919-48 Architectural Series

15 1/2”

58 5/8”

18 1/2”

53 1/4”

1 1/2”

24 5/8”

17 7/8”

5/8”

6 foot

18” 18” 18”

7 foot

24”

9

18”

100000454

24”

8 foot

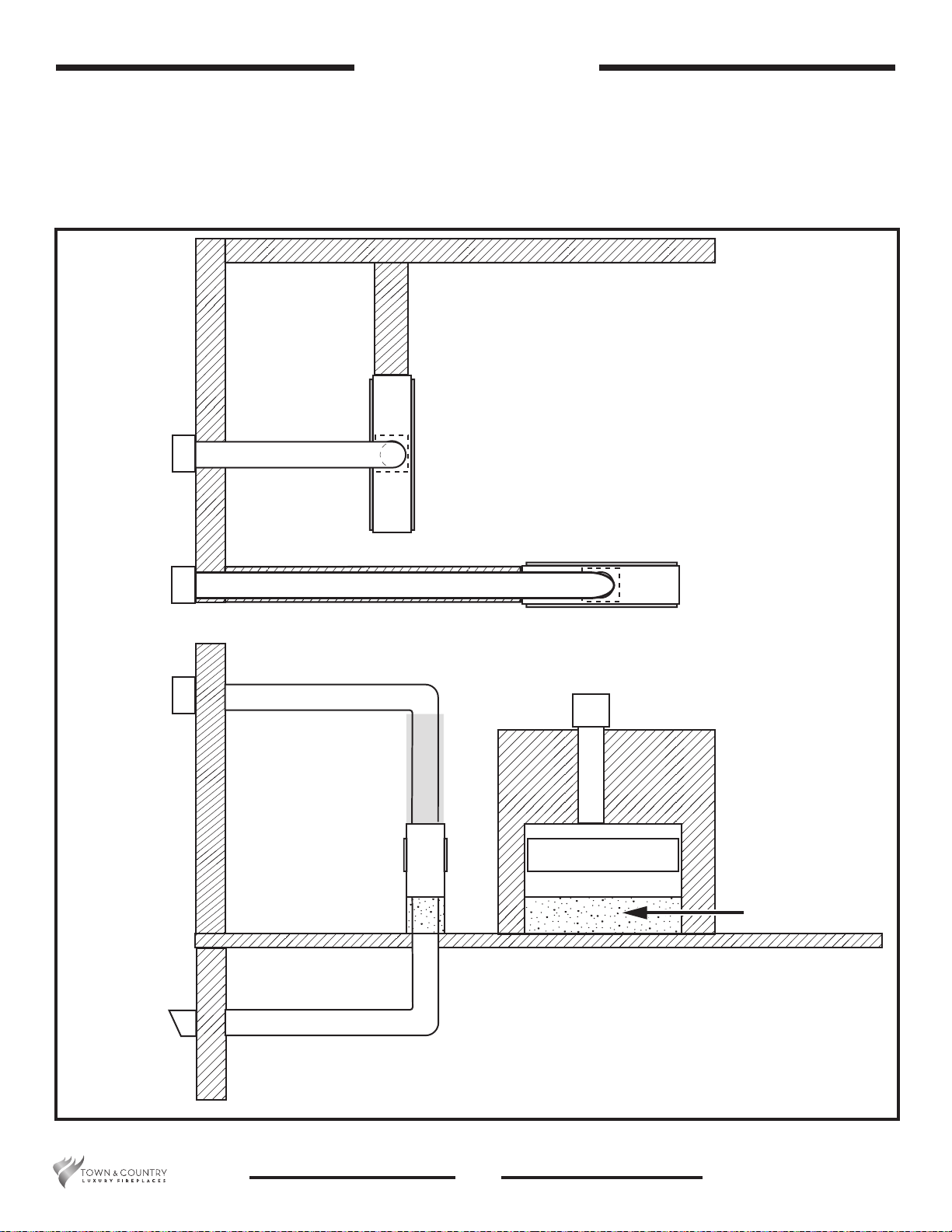

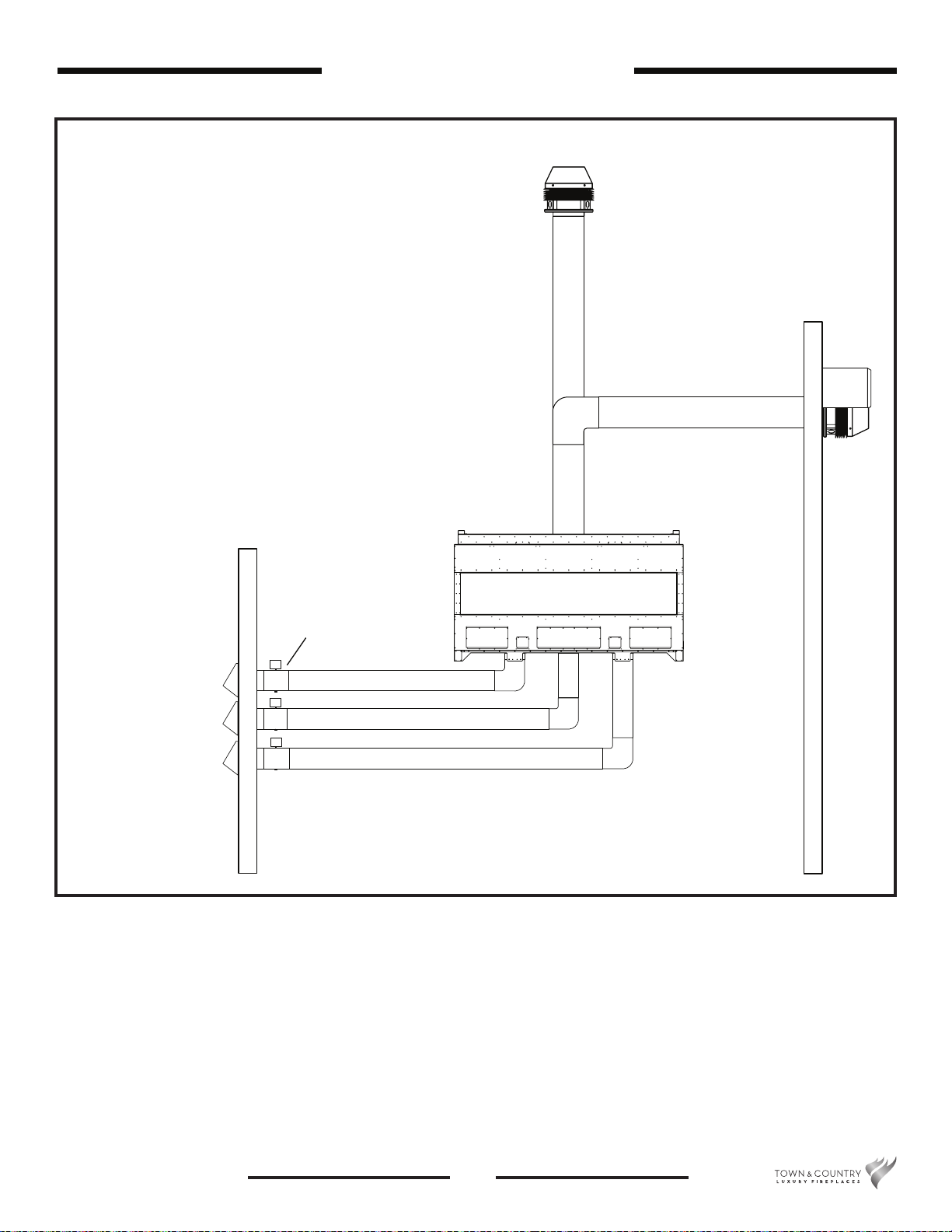

Locating the Unit

Because the Linear Appliance is power vented, it can be located in a variety of places. Consideration

must be taken for the location of the fresh air intake and the power vent unit venting. A site

fabricated platform capable of supporting approximately 525 lbs and constructed so that it can

accommodate the fresh air intake venting, gas supply and electrical supply may be used.

Horizontal

Power Vent

Termination

Power Vent

Air Intake

Vertical Venting

& Termination

Site Fabricated

Elevated Platform

Figure 4: Locating the 8 ft Linear appliance.ai

100000454

10

Architectural Series

160919-48

Framing and Finishing

Screws must approach the wood studs through the

metal framing from the center of the appliance

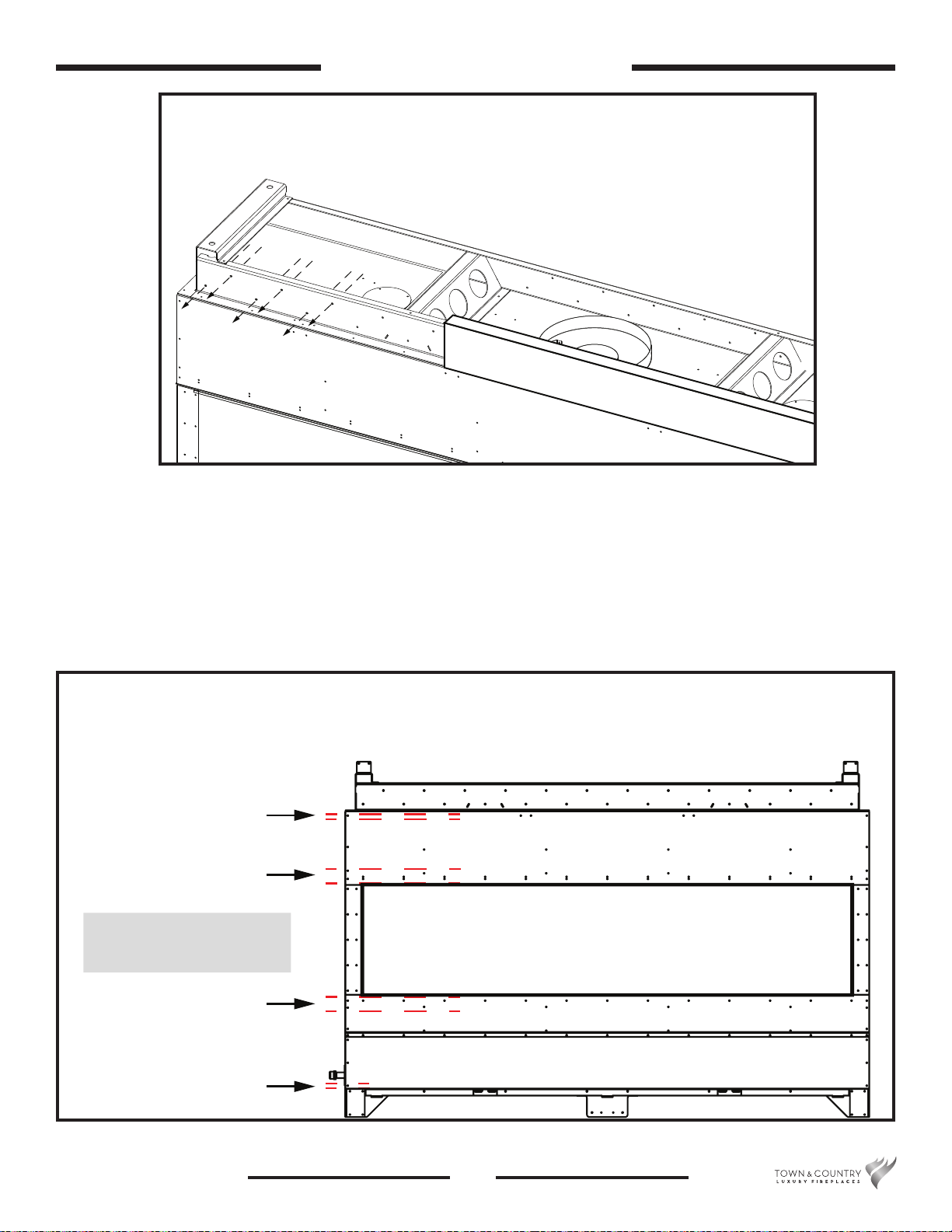

Figure 5: Stud securing points.

Before framing and nishing, there are two important thinks to keep in mind:

1. When securing the top of the unit to the wooden studs, the screws must come through the metal

framing from the center of the unit (Figure 5).

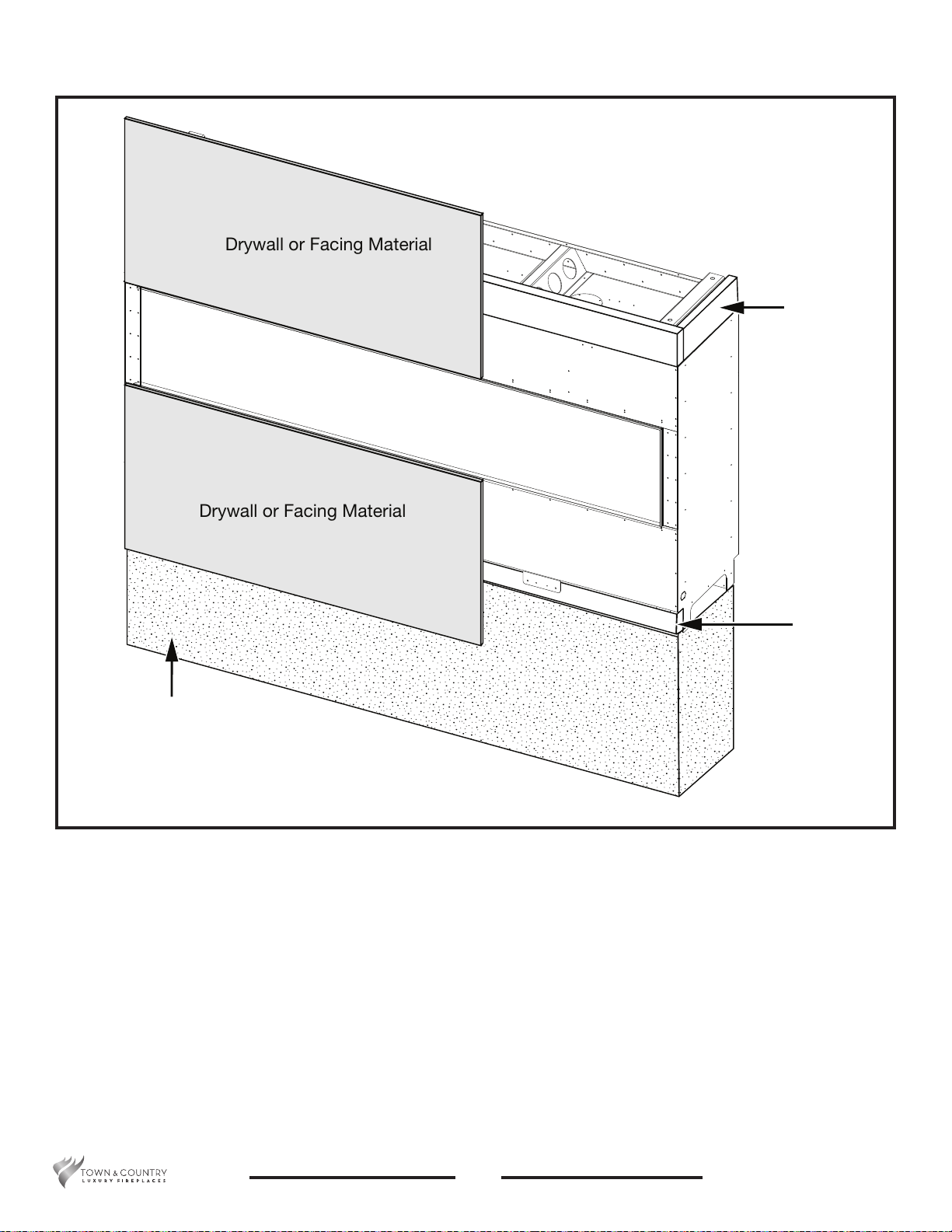

2. Facing material can be attached directly to the front and side of the unit except in the areas

indicated in Figure 6.

Facing material may be screwed directly into the body

of the appliance with the exeption of areas indicated.

1in. below rivets

3in. above trim

Do not use screws

in these areas

3in. below trim

1in. above rivets

Figure 6: Facing attachment area.

160919-48 Architectural Series

11

100000454

(Studs shown are for demonstration purposes only and do not

indicate how the nished structure should be constructed)

Drywall or Facing Material

Drywall or Facing Material

2X6” Stud

2X4” Stud

Site fabricated platform

(must support 525 lbs aprox).

(Platform shown is for demonstration purposes only and

does not indicate how the structure should be constructed)

Figure 7: Framing and facing.

Framing

Framing in the unit begins with determining how high from the oor the unit will sit. A platform

capable of supporting the weight of the unit (525 lbs approx) and able to house the fresh air intake

venting must be built. Standard 2X4”s can be used for building the frame at the bottom of the unit

and 2X6”s can be used for building the frame at the top of the unit (Figure 7).

On the top of the unit, a pony wall can be built to the ceiling. This pony wall will also accommodate

the exhaust venting material. Both supporting structure and pony wall must be tied into wall framing.

The building of the supporting structure and the pony wall must be built to local building codes.

100000454

12

Architectural Series

160919-48

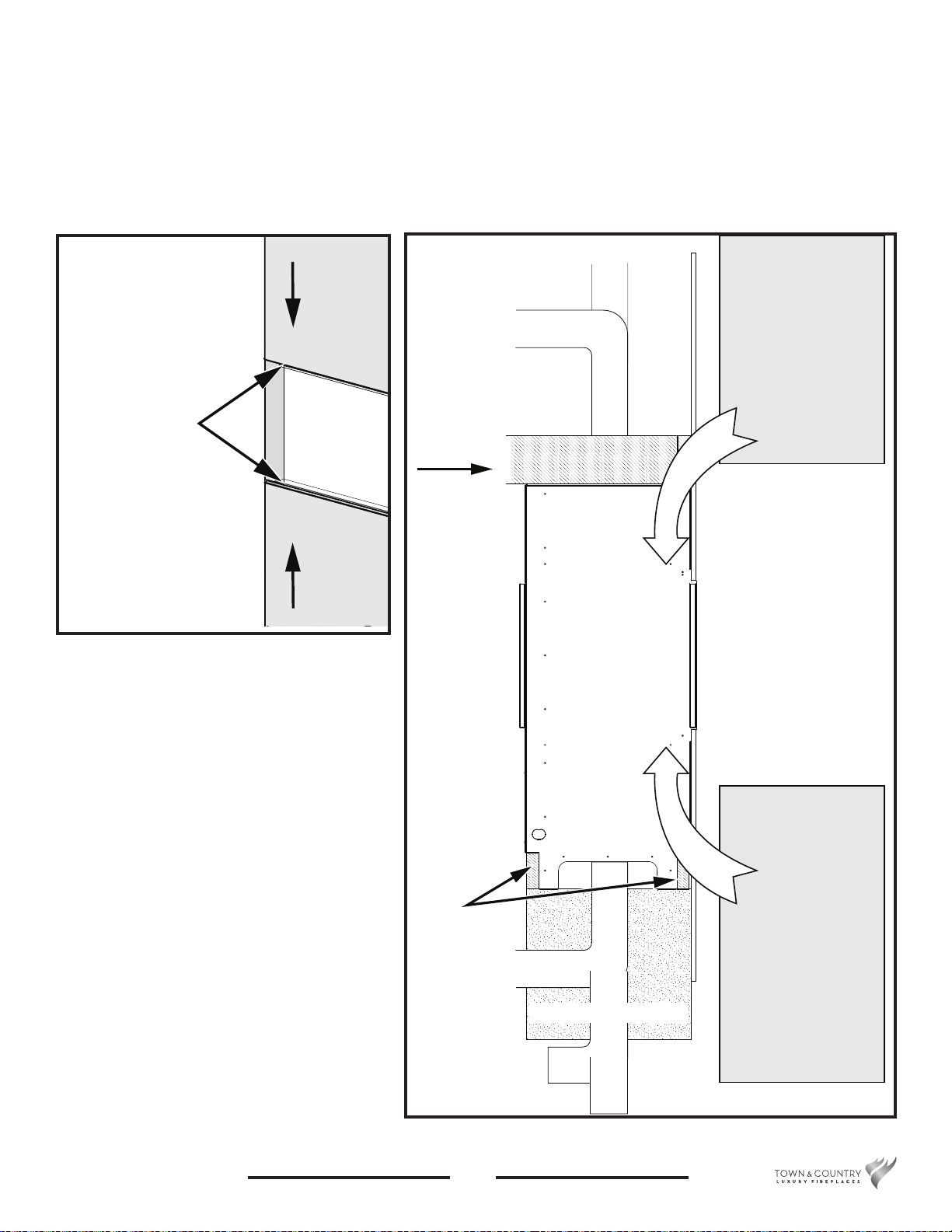

Facing Material

Because the unit requires no clearance to combustible material, drywall or other facing material can

be afxed directly to the surface of the unit. Using standard 2x4’s and 2x6’s in the framing process

allows for the edge of 1/2” drywall or other facing material to t into the channels which make up the

perimeter of the exterior glass sheets (Figure 8 and Figure 9).

To Power Vent

1/2” Drywall or

Channels will

accommodate

1/2” Drywall or

Facing Material

2X6” Studs

Facing Material

Figure 8: Leading edge of drywall.

2X4” Studs

1/2” Drywall or

Facing Material

From Air Intake

Site fabricated platform

From Air Intake

160919-48 Architectural Series

Figure 9: Left side framing and facing view.

13

100000454

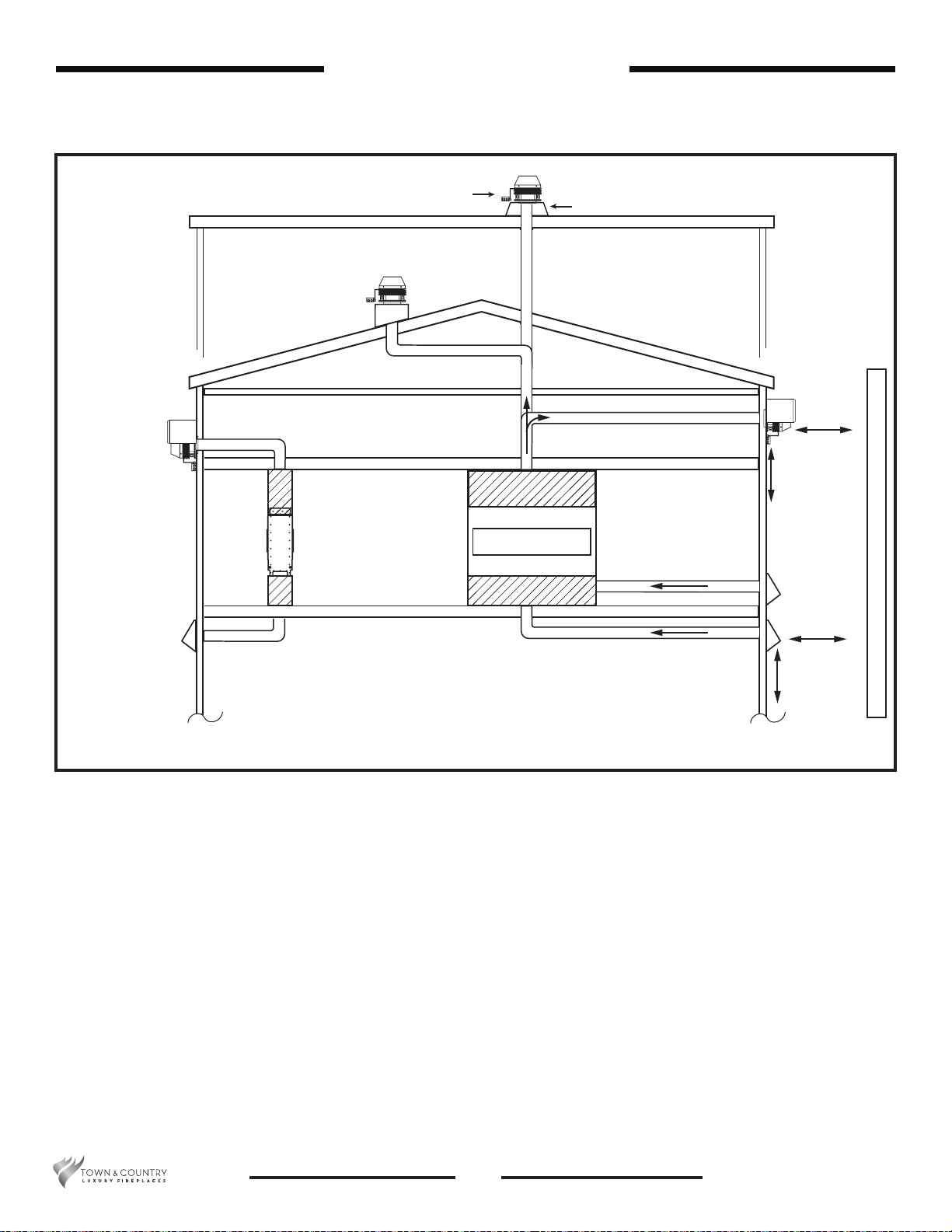

Venting Configuration

surface mount

power vent

Air intakes

Surface mount power vent

Flat roof conguration

Peaked roof

conguration

Direction of

exhaust ow

Riser required

(min. 12” high. Check local codes).

surface mount

power vent

Direction of air ow

Direction of air ow

36 “ Min.

clearance

from

outlet

36 “ Min.

clearance

from

intake

Adjacent structure

Maximum ue outlet pipe length is 150 feet plus 6 elbows and the

maximum combustion air inlet pipe is 150 feet plus 6 elbows.

Figure 10: 5 Ft venting congurations.

Venting plenum

NOTE: Plenum must not be shared with other appliances.

Some installations - particularly in new renovations or with pre-existing constraints / obstacles may require the construction of a plenum in order to accommodate multiple air intakes

when the air intakes are unable to be routed through the floor normally as shown in Figure 10.

This may be because the floor may be made of concrete.

The plenum must be made of furnace ducting or other material impervious to moisture. The

constructed plenum must have a minimum cross-section of 150 square inches and be sealed

to the collars at the base of the appliance. The plenum may be transitioned to a single intake

as long as the 150 square inch cross-section is maintained.

For a single air intake, the rule of a maximum of 150 feet plus 6 elbows still applies.

100000454

14

Architectural Series

160919-48

Air intake vents

Optional

motorized

dampers

Must use 7” intake venting lines. Each venting line can be

a maximum of 150ft plus 6 elbows.

12” exhaust venting can be a maximum

of 150ft plus 6 elbows

Venting Specifications

Figure 11: Venting specications.

• Air intake venting uses 3 - 7” standard single wall furnace grade venting material. All 3 must be

used. Each intake line can be up to a maximum of 150 ft plus 6 elbows.

• Motorized dampers are optional.

• Exhaust venting uses 12” standard single wall furnace grade venting material. Maximum length is

150 ft plus 6 elbows.

160919-48 Architectural Series

15

100000454

Loading...

Loading...