Page 1

INSTRUCTION MANUAL

®

WINGSPAN

100 in [2540 mm]

LENGTH

49.5 in [ 1257mm ]

Tower Hobbies® guarantees this kit to be free

from defects in both material and workmanship

at the date of purchase. This warranty does not

cover any component parts damaged by use or

modication. In no case shall Tower Hobbies’ liability

exceed the original cost of the purchased kit. Further, Tower

Hobbies reserves the right to change or modify this warranty

WARRANT Y

without notice.

In that Tower Hobbies has no control over the nal assembly or

material used for nal assembly, no liability shall be assumed nor accepted for any damage resulting from the use by the user of the nal user-assembled product. By the act of using the user-assembled product, the user accepts

all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this

product, the buyer is advised to return this kit immediately in new and unused condition

to the place of purchase.

To make a warranty claim, contact: airsupport @hobbico.com

14.1– 15.7 oz/ ft2 [43.0– 47.9 g/dm2]

READ THROUGH THIS MANUAL

WING AREA

616 sq in [39.7 dm2]

WING LOADING

BEFORE STARTING CONSTRUCTION.

INSTRUCTIONS AND WARNINGS

WEIGHT

3.8– 4.2 lb [1724–1905g]

RADIO

4+ Channel

IT CONTAINS IMPORTANT

CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

TOWER HOBBIES

®

WARNING! This product may use a lithium polymer (LiPo) battery. Improper handling may result in FIRE! You are responsible for

following all safety precautions as outlined in this instruction manual.

© 2018 Tower Hobbies .® A subsidiary of Hobbico, Inc.

TOWA2045 v1.1

1

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

ELECTRIC MOTOR SAFETY PRECAUTIONS . . . . . . . . 3

LITHIUM BATTERY WARNING!. . . . . . . . . . . . . . . . . . . . 3

REQUIRED ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Radio Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery and Charger . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adhesives and Building Supplies . . . . . . . . . . . . . . . .4

Optional Supplies and Tools . . . . . . . . . . . . . . . . . . . . 4

Covering Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Building Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . 5

KIT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WING ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

As a new owner of an unmanned aircraft system (UAS), you

are responsible for the operation of this vehicle and the safety

of those around you. Please contact your local authorities

to nd out the latest rules and regulations.

In the United States, please visit:

knowbeforeyou y.org faa.gov/uas

INTRODUCTION

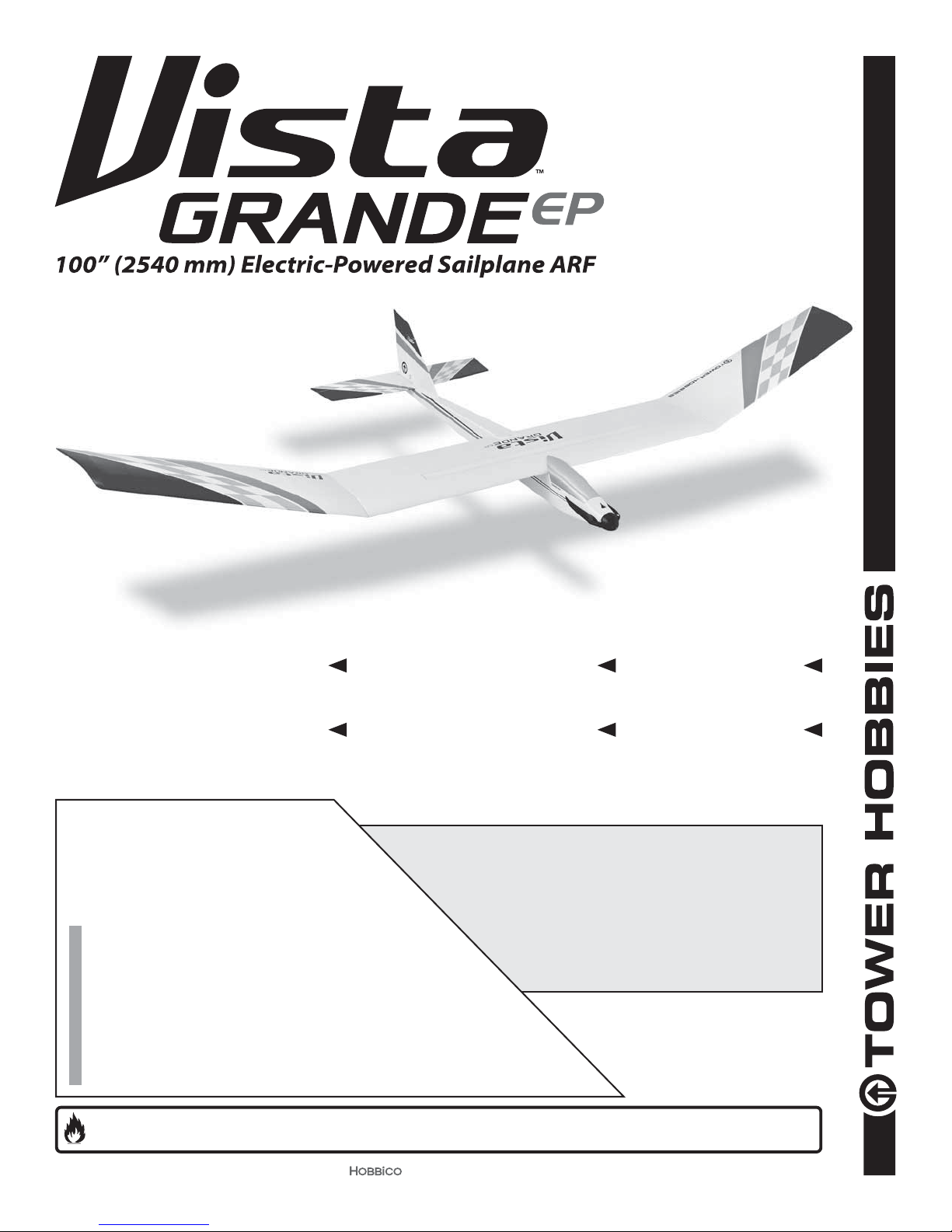

Congratulations on your purchase of the TOWER HOBBIES

Vista Grande powered glider! The Vista Grande is the largest

of the Tower Hobbies Vista sailplane series. The Grande

boasts a long 100" wingspan with a dedicated spoiler and

comes equipped with the powerful RimFire .32 (42-50-800)

brushless outrunner motor, 13.5 x 7 folding propeller and

capable 70A ESC that will get your glider to soaring altitude in

seconds! No need to bring along any launching equipment…

all you need is a charged up LiPo battery and you’re ready

for some thermal hunting. The huge wing area of the Vista

Grande will collect the rising air and your glider will coast

effortlessly for long ying sessions. When you’re ready to

land, ip a switch on your transmitter to raise the spoiler and

make the perfect touch down right on your target!

FUSELAGE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 10

GET THE MODEL READY TO FLY. . . . . . . . . . . . . . . . . 15

Check the Control Directions . . . . . . . . . . . . . . . . . . 15

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . . 15

Preparing to Balance the Model . . . . . . . . . . . . . . . . 16

Balance the Model Laterally . . . . . . . . . . . . . . . . . . . 17

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . . 17

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Charge the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ground Check and Range Check . . . . . . . . . . . . . . . 18

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . 18

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Mount the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

way. There are over 2,500 AMA chartered clubs across the

country. Contact the AMA at the address or toll-free phone

number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: www.modelaircraft.org

IMPORTANT: Two of the most important things you can do

to preserve the radio controlled aircraft hobby are to avoid

ying near full-scale aircraft and avoid ying near or over

groups of people.

SAFETY PRECAUTIONS

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your Vista Grande should not be considered a toy, but rather

a sophisticated, working model that functions very much like

a full-size airplane. Because of its performance capabilities,

this model, if not assembled and operated correctly, could

possibly cause injury to yourself or spectators and damage

to property.

AMA

We urge you to join the AMA (Academy of Model Aeronautics)

and a local R/C club. The AMA is the governing body of model

aviation and membership is required to y at AMA clubs.

Though joining the AMA provides many bene ts, one of the

primary reasons to join is liability protection. Coverage is not

limited to ying at contests or on the club eld. It even applies

to ying at public demonstrations and air shows. Failure

to comply with the Safety Code may endanger insurance

coverage. Additionally, training programs and instructors are

available at AMA club sites to help you get started the right

2. You must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result in

an unsafe or un yable model. In a few cases the instructions

may differ slightly from the photos. In those instances the

written instructions should be considered as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in rst-class

condition.

5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

2

Page 3

6. You must check the operation of the model before every

ight to ensure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

7. If you are not an experienced pilot or have not own this

type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for

your rst ights. If you’re not a member of a club, your

local hobby shop has information about clubs in your area

whose membership includes experienced pilots.

8. While this model has been ight tested to exceed normal

use, if a motor larger than the one recommended is used,

the modeler is responsible for taking steps to reinforce the

high stress points and/or substituting hardware more

suitable for the increased stress.

WARNING: Drilling, sawing, sanding, or machining

wood products can expose you to wood dust, a

substance known to the State of California to cause cancer.

Avoid inhaling wood dust or use a dust mask or other

safeguards for personal protection. For more information

go to www.P65Warnings.ca.gov/wood

We, as the ARF manufacturer, provide you with a top quality,

thoroughly tested plane and instructions, but ultimately

the quality and yability of your nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

REMEMBER: Take your time and follow the instructions

to end up with a well-built model that is straight and true.

ELECTRIC MOTOR

SAFETY PRECAUTIONS

WARNING! A spinning propeller has the potential to cause

serious and permanent injury.

WARNING! Once the motor batteries are connected, the

propeller can start spinning at any time. Make sure the fail

safe is set on your radio to prevent the motor from starting

if the signal is lost.

WARNING! Stand clear of the propeller when handling

the aircraft. Make sure the aircraft is held securely until the

battery has been disconnected.

ALWAYS remove the propeller if the motor batteries will be

connected while working on your plane.

ALWAYS remove the motor batteries from the plane

when charging.

ALWAYS switch on the transmitter rst, then the receiver.

ALWAYS unplug the motor batteries rst before switching

off the receiver then transmitter.

NEVER touch the motor during or right after operation. The

motor gets HOT!

NEVER switch off the transmitter with the motor batteries

plugged in.

NEVER reach through the arc of the propeller when plugging

the battery into the ESC.

LITHIUM BATTERY WARNING!

This product requires the use of a lithium polymer

(LiPo) battery. Improper handling of a LiPo battery

could result in FIRE! A lithium battery re has the

potential to ignite surrounding areas and may cause property

damage or cause personal injury.

For safe LiPo handling, follow ALL of these guidelines:

MOST IMPORTANT! Never leave the battery or charger

unattended during charging or discharging.

WARNING: Read the entire instruction sheet included with

your motor batteries. Failure to follow the instructions could

cause permanent damage to the battery and its surroundings

and cause bodily harm!

ALWAYS follow the charging instructions included with your

charger for charging LiPo batteries. LiPo batteries can cause

serious damage or re if misused.

ALWAYS use a LiPo-approved charger.

ALWAYS set the charger’s output volts to match the

battery volts.

ALWAYS charge a LiPo battery in a reproof location.

ALWAYS balance charge the battery.

ALWAYS store and transport LiPo batteries in a reproof

container away from combustible materials.

ALWAYS KEEP OUT OF THE REACH OF CHILDREN.

ALWAYS keep LiPo batteries out of the reach of animals. A

punctured battery may cause a re.

ALWAYS disconnect the battery and unplug the charger

after the charge is complete.

ALWAYS keep a supply of sand accessible when charging

a LiPo battery. Dumping sand on the battery will assist in

extinguishing a LiPo chemical re.

ALWAYS remove the batteries from the plane after a crash.

Set them aside in a safe location for at least 20 minutes. If

the batteries are damaged in the crash, they could catch

re. If the battery starts to swell, quickly move the battery to

a safe location, preferably outside away from combustible

material. Place it in a bucket, covering the battery with sand.

NEVER use water to try and extinguish a LiPo re.

NEVER charge or use a battery that is deformed, bent,

crushed, swollen, or has any type of visible damage.

3

Page 4

NEVER use a NiCd/NiMH peak charger to charge a

LiPo battery.

NEVER charge in excess of 4.20V per cell unless the battery

is rated for a higher voltage.

NEVER charge at currents greater than 1C unless the battery

is rated for a higher charge rate.

NEVER trickle-charge a LiPo battery.

NEVER allow the battery temperature to exceed 140°F (60°C).

NEVER disassemble or modify the pack wiring in any way

or puncture the cells, as this may result in a re.

NEVER discharge below 3.2V per cell.

NEVER charge the battery or set the charger on combustible

materials.

NEVER charge the battery inside a vehicle or in a location

that could be damaged in the event of a LiPo re.

NEVER put a LiPo battery in the pocket of any clothing.

NEVER charge the batteries in the plane. Disconnect the

batteries and remove them from the plane immediately

after landing.

NEVER allow the battery to short circuit by touching exposed

wires together. This may cause a re.

NEVER operate or store batteries below 40˚F (4˚C) or above

110˚F (43˚C) ambient temperature.

Battery and Charger

The Vista Grande can use a 4S 14.8V 2200-3600mAh

LiPo battery. A smaller capacity battery will bene t you by

being lighter weight and the Vista will balance close to the

recommended C.G. without the need for ballast. A larger

battery will give you more motor power time but the glider will

y heavier with a more forward C.G. NOTE: There are many

other batteries that will t. Provided here are two batteries

with acceptable capacity and discharge rate.

❍ ONXP2269 LiPo 4S 14.8V 2200mAh 30C

❍ ONXP3363 LiPo 4S 14.8V 3600mAh 50C

A charger capable of charging LiPo batteries is required.

The Triton EQ (GPMM3155) is a suitable charger as it has

plenty of power for charging the LiPos recommended for the

Vista Grande (and larger LiPos as well). The Triton EQ is also

recommended for its versatility in charging all other types of

batteries used in RC and may be powered by either a 12V DC

power source or 110V AC. For an inexpensive alternative we

recommend the Onyx 225 (DTXP4225) charger. It is not as

feature packed as the Triton EQ but we like its easy-to-use

programming and digital display.

Adhesives and Building Supplies

REQUIRED ITEMS

Radio Components

At least 4 channels are needed to operate the Vista Grande

controls. Because the spoiler needs to be operated by a

switch, dial, or slider, we recommend the Tactic TTX610

transmitter as a capable, inexpensive radio system suitable

for this type of model. If it’s likely you will grow your radio

control interest beyond the Vista Grande in the future, we

recommend the TTX660. This is a computerized transmitter

which has a 30 model memory and several built-in mixing

functions along with programmable mixes and many other

convenient features. These functions will suf ce for most

types of radio control models in addition to the Vista Grande.

NOTE: The TTX610 includes the 6-channel receiver but it is

a separate purchase with the TTX660.

You’ll also need (2) 36mm long mini servos for the elevator

and rudder and (1) 23mm long micro servo for the spoiler.

NOTE: The opening in the plywood servo tray for the tail

servos can be lengthened some if the servos of your choice

are slightly longer than 36mm. A nylon servo tray for the

spoiler servo is included and will not accommodate a micro

servo longer than 23mm.

❍ TACJ2610 Tactic TTX610 6-Channel SLT System

(includes TR625 receiver)

❍ TACJ2660 Tactic TTX660 6-Channel Computer

Transmitter (does not include receiver)

❍ TACL0625 Tactic TR625 6-Channel SLT Receiver

❍ TACM0220 Tactic TSX20 Mini High-Speed 2BB Servo

❍ TACM0205 Tactic TSX5 Micro High-Speed Servo

❍ FUTM0004 Futaba S3004 Standard Ball Bearing Servo

❍ FUTM0414 Futaba S3114 Micro High-Torque Servo

❍ Tower Hobbies 6-minute Epoxy (TOWR3806)

❍ Tower Hobbies 30-minute Epoxy (TOWR3810)

❍ Mixing Sticks (50, GPMR8055)

❍ Mixing Cups (GPMR8056)

❍ Epoxy Brushes (GPMR8060)

❍ Tower Hobbies Build-It CA Thin Glue (TOWR3800)

❍ Tower Hobbies Build-It CA Medium Glue (TOWR3801)

❍ Denatured Alcohol (for epoxy clean-up)

❍ Masking Tape

❍ 1/16" [1.5mm], 5/64" [2mm], 3/32" [2.5mm] drill bits

❍ Drill

❍ Phillips Head Screwdriver

❍ Wire Cutters

❍ Pliers

❍ Stick-on Segmented Weights (GPMQ4485)

❍ CG Machine (GPMR2400)

❍ Paper Towels

❍ #1 Hobby Knife (RMXR6903)

❍ #11 Blades (5-pack, RMXR6930)

❍ Clamp

Covering tools

❍ Top Flite MonoKote Sealing Iron (TOPR2100)

❍ Top Flite Hot Sock Iron Cover (TOPR2175)

❍ Top Flite MonoKote Trim Seal Iron (TOPR2200)

❍ Top Flite MonoKote Heat Gun (TOPR2000)

❍ Coverite 21st Century Sealing Iron (COVR2700)

❍ Coverite 21st Century Cover Sock (COVR2702)

❍ Coverite 21st Century Trim Sealing Iron (COVR2750)

4

Page 5

Optional Supplies and Tools

IMPORTANT BUILDING NOTES

Here is a list of optional tools that will help you build the

Vista Grande.

❍ CA Applicator Tips (HCAR3780)

❍ CA Debonder (GPMR6039)

❍ Servo Horn Drill (HCAR0698)

❍ AccuThrow De ection Gauge (GPMR2405)

❍ Precision Magnetic Prop Balancer (TOPQ5700)

Covering Material

The lm covering on this model is not a product that is

packaged and sold separately. Fortunately, if you need to

repair the covering on your Vista Grande, TopFlite MonoKote

offers colors that are a close match and are readily available

from Tower Hobbies or your local R/C hobby supplier. The

rolls are sold in either 6' or 25' lengths (part numbers for

the 6’ lengths are provided below) and are great to keep on

hand for quick repairs. Please note: These colors are not a

perfect match. We recommend replacing damaged covering

in complete “panels” so the slight difference in color shades

between the original covering and the MonoKote cannot be

seen. For example, if the red wing tip becomes damaged,

replace all of the red covering on that wing tip.

Missile Red 6' (TOPQ0201)

Jet White 6' (TOPQ0204)

Aluminum 6' (TOPQ0205)

Sky Blue 6' (TOPQ0206)

● Anytime a sheet metal screw is installed in wood, rst

install the screw, remove the screw and apply a couple of

drops of thin CA in the hole to harden the threads. After

the CA has cured, reinstall the screw.

● Photos and sketches are placed before the step they

refer to. Frequently you can study photos in following steps

to get another view of the same parts.

● You will see this symbol anytime cyanoacrylate

glue is required.

.

● You will see this symbol anytime a threaded

screw or nut is installed.

● You will see this symbol anytime

epoxy is recommended.

● Anytime a hole needs to be drilled you will see

this symbol with the recommended size drill bit.

● When you see this symbol, use a glue of your

choice.

Building Stand

A building stand or cradle comes in handy during the build.

We use the Robart Super Stand II (ROBP1402).

ORDERING REPLACEMENT PARTS

Replacement parts are available from Tower Hobbies for

your Vista Grande. Our order assistance representatives are

ready to answer your questions or to place your order. Call

us at (800) 637-6050.

Order No. Description

TOWA2081

TOWA2082

TOWA2083

TOWA2084

TOWA2085

TOWA2086

GPMA5307

GPMA5308

GPMA5310

GPMA5311

GPMG4700

GPMM2160

Wing

Fuselage

Tail Surface Set

Canopy

Decals

Spoiler Hardware Set

Propeller Adapter

Spinner Set

Complete Folding Propeller Set

Folding Propeller Blade Set 13.5" x 7

Great Planes RimFire .32 42-50-800 Outrunner Brushless

60A 2S-6S Programmable 5V BEC ESC

KIT INSPECTION

If any parts are missing or damaged, consult Tower Hobbies

Order Assistance.

Note: All parts are one per kit unless otherwise stated.

Toll Free Order Assistance . . . . .800 637-6050

or airsupport@hobbico.com

5

Page 6

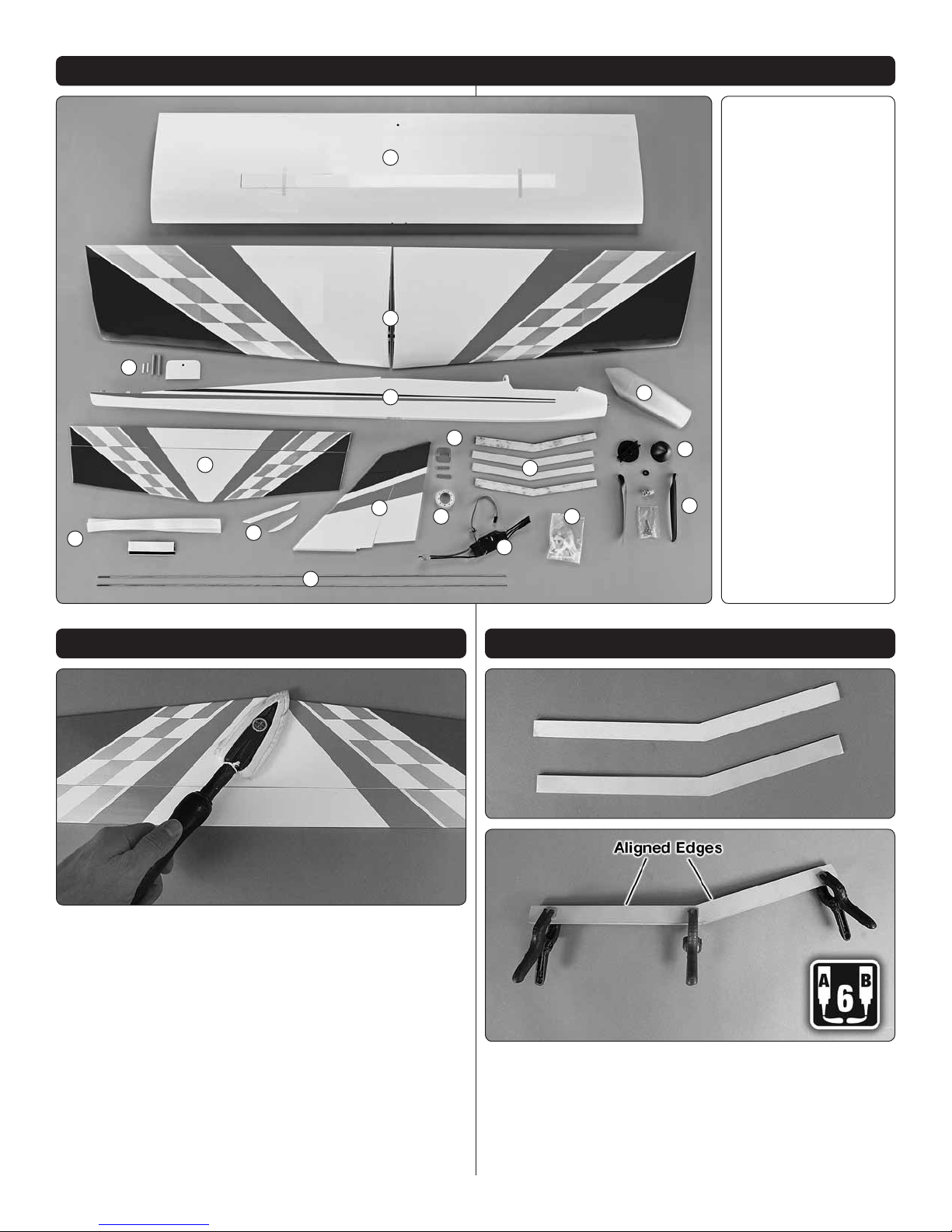

CONTENTS

1

1. Center Wing w/ Spoiler

2. Outer Wing Panels

3. Fuselage

4. Canopy Hatch

5. Horz. Stab w/Elevator

6. Vert. Fin w/Rudder

7. Wing Joiners

2

8. ESC

9. Spinner Cone

12

3

11

5

6

14

13

15

7

17

8

4

10. Folding Prop Blades

11. Spoiler Servo Tray

12. Wing Dowels, Bolt

9

Plate, Alignment Pins

13. Vert. Fin Gussets

14. Hook & Loop Material

10

15. Hinge Tape

16. Tail Pushrods

16

PREPARATION

WING ASSEMBLY

17. Hardware Bag

Use a model airplane covering iron with a protective covering

sock to remove any wrinkles present in the covering. The

best temperature setting, with a covering sock on the iron,

is approximately 300° F. If this doesn’t seem to be enough

heat to shrink the wrinkles, increase iron temperature in small

increments until the wrinkles disappear.

1. You will need to make two wing joiners. Each joiner

❏

should be made from one piece of plywood and one piece

of aluminum. Look at the pieces and notice that they can

only match up one way (be sure you will be joining the layers

together correctly). Coat one side of one of the pieces with

epoxy (6-minute or 30-minute) and sandwich them together.

6

Page 7

Any epoxy that squeezes out can be wiped away with a paper

towel dampened with denatured alcohol. Use a few clamps

to hold the pieces together while the epoxy hardens. Note:

Make sure the pieces are carefully aligned with each other!

to con rm the anti-rotation pins t properly into the holes

in the outer panels. If necessary, make adjustments to the

holes so they t.

4. It is not necessary to permanently epoxy the outer

❏

panels to the center section. All of our test ying was done

with the outer panels attached to center section with regular,

clear of ce tape. This allows the outer panels to be removed

from the center section for easier transport and storage. At

this time you can remove the outer panels and wing joiners

and set them aside until it is time to balance the plane. Only

the center section is needed to continue assembly.

2. Test t the wing joiners into the wing sections. The

❏

larger end of each joiner ts into the wing center section. You

may need to make adjustments to the joiners for them to t

properly. NOTE: If you need to sand the joiners some to t,

remove only small amounts of material at a time while testing

the t frequently. Do not over-sand the joiners, resulting in a

loose t. When satis ed with the t of the joiners in the wing

sections, slide the outer wing sections on and con rm the

panel ends mate up ush. Make adjustments to the ribs by

sanding them at if the panels do not mate up ush.

5. Align the wing bolt plate on the top of the wing over the

❏

wing bolt hole. Use a ne, felt-tip pen to trace around the

plate onto the wing. Remove the plate and follow the Expert

Tip below or use a sharp hobby knife with a straightedge to

remove the covering within the lines. If using a hobby knife

to cut the covering, take great care not to cut into the wood.

Cutting into the wood will weaken the wing in that area.

EXPERT TIP

How to cut covering from balsa.

3. Remove the outer wing sections and glue a nylon anti-

❏

rotation pin into each hole at the ends of the center wing

section. Test t the outer panels to the center section again

Rather than using a hobby knife which could inadvertently

cut into the balsa, use a heated soldering iron. Move the

iron at a pace that will just melt the covering without burning

into the wood–the hotter the soldering iron, the faster you

will have to move it. A sharp tip isn’t necessary, but a nepoint does work best.

7

Page 8

6. Peel the covering from the wing. Glue the wing bolt

❏

plate onto the wing.

8. Use sand paper to roughen the underside of the spoiler

❏

servo tray (180 or 220 grit is ne). Glue the servo tray with

medium (or thick) CA or epoxy into the center wing section

at the location shown. The tray should be approximately

centered between the servo lead exit hole and the wing rib.

Use a hobby knife or rotary tool to cut away the wood from

the spoiler framework just above the servo tray screw hole.

Remove as little wood as possible.

7. Choose a spoiler servo arm that has a hole approximately

❏

5/8" [16mm] from the servo spline center. The other arms

can be cut off. Enlarge that hole with a 3/32" [2.4mm] drill

bit. Use a nut to install the 2-56 x 3/8" [9.5mm] screw into

the arm as shown. Temporarily connect the servo to your

radio system. Set up the switch or dial that you plan to use

to operate the spoiler. Use the control to rotate the servo

all the way in the “spoiler up” direction, and then install the

servo arm as shown. This will get you close for having the

spoiler operate correctly. You can ne tune the throw and

arm position after it’s been tested.

9. Use CA glue to attach the spoiler control bracket onto

❏

the underside of the spoiler. Take care not to put pressure

in the middle of the bracket when pushing it into the slot in

the spoiler. Your best bet would be to slide the bracket into

place rather than pushing down on it.

8

Page 9

10. A roll of clear tape is included to hinge the spoiler to

❏

the wing center section (if you ever need to replace the hinge

tape, regular, clear of ce tape will work ne). Center the

spoiler in the opening on the wing and con rm the t. The

spoiler should lay at in the opening and the leading edge

must be tight to the sheeting. If you see any warping, remove

the spoiler from the wing and use your covering iron or heat

gun to heat the warped end while bending the spoiler gently

in the opposite direction of the warp. Let the covering cool

before releasing the spoiler. Check your results and repeat

if necessary.

7/8" [ 22 mm]

12. The simplest way to get the screw on the servo arm

❏

into the spoiler bracket slot is to use pliers to ex the servo

arm as shown. You can also loosen the screw and nut from

the servo arm. Now would be a good time to temporarily hook

up the spoiler servo to your receiver and test it using your

transmitter. Use your end point adjustments in the transmitter

to ensure the servo isn’t binding when the spoiler is moved

from down to up. If your transmitter does not have end point

adjustment, you will need to adjust the servo arm position

on the output spline and/or the hole position of the bracket

screw on the servo arm.

11. Place the spoiler servo into the servo tray. Install the

❏

top plate over the servo using the two 2.5 x 10mm selftapping screws.

9

Page 10

13. Use sand paper to round one end of each wing dowel.

Equal DistanceEqual Distance

❏

Glue the dowels into the holes in the leading edge of the

wing center section. The dowels should protrude beyond the

leading edge approximately 1/2" [13mm]. The dowels should

be perpendicular to the leading edge of the wing. adjust the

holes accordingly if needed.

FUSELAGE ASSEMBLY

1. Use a sharp hobby knife to cut off 1" [25mm] from the

❏

10-24 x 2" [51mm] nylon wing bolt.

2. Use the wing bolt to mount the wing center section to

❏

the fuselage. The wing will be used to align the horizontal

stabilizer in the next step.

3. Fit the horizontal stab over the alignment tabs without

❏

using any glue. A clamp is useful in this step. If you don’t

have a clamp to secure the stab to the fuse then tape can

also be used. We used another clamp to hold the elevator

in the center position. Stand back several feet behind the

model and con rm that the stab is parallel with the wing. If

it isn’t, remove the stab and lightly sand the stab saddle on

the high side (for a stab just slightly out of level, try adding

some weight to the high side). Check the stab again and

repeat this process until the stab and wing are parallel.

We recommend also con rming

the stab is square with the fuse

centerline. Measure from the

centerline of the fuselage just

above the slot for the front

canopy hatch wire to each aft

stab corner. These distances

should be equal. If not, make

any necessary adjustments to

the slots in the stab until they are.

When satis ed, use 30-minute

epoxy to glue the stab in place. When applying the epoxy,

brush a coat onto both the saddle and the stab. This will

ensure a strong bond. Excess epoxy can be wiped away with

a paper towel dampened with denatured alcohol. Allow the

epoxy to cure completely before moving on to the next step.

10

Page 11

beneath the gussets like you did with the wing bolt plate.

Hinge Line Hinge Line

Correct Incorrect

The short gusset should be installed on the left side toward

the aft end of the n.

4. Use 30-minute epoxy to glue the vertical n in place.

❏

Ensure the n is perpendicular to the stab while the epoxy

cures. Use masking tape as shown to hold the n square to

the stab and allow the epoxy to cure undisturbed. After this

step is completed, the center wing section can be removed

and set aside until it’s time to balance the model.

6. Insert one of the 36" [914mm] pushrods into the rudder

❏

pushrod tube in the fuselage. The aft end of the pushrod

should be used to align and mark the screw holes onto the

rudder for the rudder control horn. The clevis holes in the

control horn should be aligned over the rudder hinge line. Use

a felt-tip pen to mark the control horn screw hole locations.

5. Two vertical n gussets are included and should be

❏

glued in place as shown here. Trim away the covering from

11

Page 12

BUILDER TIP

MUST-HAVE ACCESSORY

Installing clevises onto pushrods can be tedious using pliers

and your ngers. Using a wrench is a little easier but it has

a tendency to slip off the hexagonal base and is awkward

to use. Picking up a clevis installation tool will make short

work of getting clevises threaded onto pushrods and is way

easier on your ngers. We keep one within reach during

every ARF and kit build we do. Our favorite version is the

Great Planes Clevis Tool GPMR8030.

7. Drill 5/64" [2mm] holes at the marks you made. Install the

❏

rudder control horn using two 2-56 x 1/2" [13mm] machine

screws and a control horn backplate. Trim off the part of the

backplate that overhangs the rudder hinge line.

9. Prepare your rudder servo by rst using your radio

❏

system to electronically center it. Choose a servo arm that

has a hole 1/2" [13mm] from the servo arm center. Enlarge

that hole with a 5/64" [2mm] drill bit and cut off the unused

arms. Install the servo arm onto the servo as shown. Install

the servo grommets and eyelets.

8. Remove the pushrod from the rudder pushrod tube.

❏

Thread a nylon clevis 20 complete turns onto the pushrod.

Slip a silicone clevis retainer onto the clevis. Reinstall the

pushrod into the pushrod tube and clip the clevis into the

second outer hole in the rudder control horn.

10. Place the servo in the tray as shown and position it so

❏

that the rudder pushrod passes over the enlarged servo arm

hole. Mark and drill holes in the tray to mount the servo. If

12

Page 13

installing the recommended Tactic servo, drill the holes with

90 Degree

Pushrod Connector

2-56 (.074") Pushrod Wire

Servo Horn

1/16"

a 1/16" [1.6mm] drill bit. Threading a servo mounting screw

into each hole and then removing it, followed by a drop of

thin CA in the hole, will harden the surrounding wood for a

very secure servo installation. When the CA glue is dry, install

the servo with the screws included with the servo.

bend at your mark. Cut off the excess pushrod 1/4" [6mm]

beyond the bend. Fit the bent end of the pushrod wire into

the servo arm hole and secure it with a 90 degree pushrod

connector. Reinstall the clevis into the second outer hole in

the rudder control horn. Slide the silicone clevis retainer up

to the end of the clevis and you can now remove the clamp

or tape holding the rudder centered.

11. Use a small clamp or tape to hold the rudder in the

❏

neutral position. Mark the pushrod where it crosses the hole

in the servo arm. Temporarily disconnect the clevis from the

control horn, turn the pushrod sideways and make a 90 degree

12. The elevator pushrod should be installed into the hole

❏

in the servo arm closest to 13/32" [10.3mm] from the center

of the servo arm. Install the elevator servo and pushrod and

elevator control horn in the same manner that you did the

rudder servo.

13. Apply a couple drops of CA glue to the tail skid barbs

❏

before you press it into place to secure it.

13

Page 14

14. Mix up a small batch of epoxy (6-minute is ne) and

❏

apply a thin coating in the dashed areas shown here. This

will provide a smooth surface for the self-adhesive hook and

loop material. Allow the epoxy to completely cure before

moving on.

1" [25mm]. Be sure the strap will be long enough to wrap

through the slots in the battery tray and around your battery.

Apply the hook side from the self-adhesive hook and loop

material to the battery tray.

17. Feed the ESC motor leads underneath the battery tray

❏

up to the motor. Connect the motor leads to the motor and

the ESC to the receiver. There is no need to secure the ESC

down. It will stay in place beneath the battery tray. Route the

battery connector up through the cutout in the battery tray.

15. Connect the tail surface servos and a 6" servo extension

❏

(for the spoiler servo) to the appropriate channels on your

receiver. Because this model doesn’t have ailerons, we

recommend connecting the rudder servo to the aileron

channel on the receiver. Use some of the included selfadhesive hook and loop material to attach the receiver in

the fuselage. We taped the receiver antennas to the sides

of the fuselage.

18. Now is a good time to test the operation of the motor

❏

without the propeller attached. If you are using a Tactic or

Futaba transmitter, you will need to move the servo reversing

to the REVERSE position for your throttle channel. With the

throttle stick in the lowest position, turn on your transmitter

and plug in the ight battery to the ESC. Move the throttle

stick to full throttle. The ESC will beep twice con rming the

full throttle position. Lower the throttle stick and the ESC will

beep 4 times. The ESC is now armed. Advance the throttle

and check the rotation of the motor. When looking at the

motor from the front, it should rotate COUNTER-CLOCK WISE.

If rotating the wrong direction, swap any two of the three

motor lead connectors.

16. Make a battery strap from the non-adhesive hook and

❏

loop strap by overlapping two mating pieces by approximately

14

Page 15

FAIL SAFE AND BRAKE FUNCTION

FULL THROTTLE ELEVATOR MOVES DOWN

RUDDER MOVES RIGHT

While you have your radio operational and

without the propeller mounted, set and check

the Fail Safe function in your transmitter. Refer to

the instructions that came with your radio control system

to set Fail Safe on the throttle channel so that, in the event

of signal loss, the motor will stop. To test the Fail Safe, with

the propeller removed and the radio control system turned

on, advance the throttle slightly (just enough to make the

motor turn) and turn off the transmitter. If the Fail Safe is

correctly set the motor will stop when the transmitter is

turned off.

While you still have your radio system powered up, check

the motor brake: Advance the throttle stick to run the motor,

then move the throttle stick all the way down to stop the

motor. The motor should stop abruptly (not coast gradually

to a stop). If the motor does not come to an abrupt stop

and the brake in the ESC is not activated, activate the

brake as described below:

A. Disconnect the ESC from the battery so it will not

receive power.

B. With the transmitter turned on, advance the throttle

stick to full throttle.

C. With the prop removed, connect the battery to the ESC

to power the motor and listen for the beeps:

GET THE MODEL READY TO FLY

Check the Control Directions

DO NOT INSTALL THE PROPELLER UNTIL

INSTRUCTED TO.

1. Switch on the transmitter with the throttle stick in the

❏

lowest position and connect the ight battery to the ESC.

2. Center the control surfaces.

❏

BEEP SEQUENCE FUNCTION

Beep <pause> Beep Brake OFF

Beep Beep <pause> Beep Beep Brake ON

To change the brake operation, lower the throttle stick

during the <pause> of the beep sequence of the desired

brake function. The ESC will con rm the setting with a

higher pitched beep. There will be another pause, then a

single beep indicating the ESC is ready to be armed.

To arm the ESC, move the throttle stick to full throttle. The

ESC will beep twice con rming the full throttle position.

Lower the throttle stick and the ESC will beep 4 times.

CAUTION! The ESC is now armed and the motor will

rotate when the throttle stick is advanced. Always be alert

whenever working on or preparing to y the Vista Grande

when the battery is connected to the ESC. Stay safe by

keeping everything clear of the front of the plane.

3. Make certain that the control surfaces and throttle

❏

respond in the correct direction as shown in the diagram.

If any of the controls respond in the wrong direction, use

the servo reversing in the transmitter to reverse the servos

connected to those controls. Be certain the control surfaces

have remained centered. Adjust if necessary.

Set the Control Throws

1. Hold a ruler against the control surface and measure

❏

the high rate throw rst.

15

Page 16

Pushrod Farther Out

Pushrod Farther Out

LESS

THROW

Pushrod Closer In

MORE

THROW

MORE THROW

Pushrod Closer In

LESS THROW

Preparing to Balance the Model

1. Assemble the folding propeller as shown. Fit the propeller

❏

blades into the hub and then install the pins. The locknuts

should be just tight enough so the blades still rotate freely

on the pins.

2. If needed, adjust the location of the pushrod on the

❏

servo arm or on the control horn rst. Then, use the endpoint

adjustment in your transmitter to ne tune the throws.

3. Measure and set the low rate throws using the dual rates

❏

on the transmitter. Next, measure and set the high and low

rate throws for the rest of the control surfaces the same way.

If your radio does not have dual rates, we recommend setting

the throws at the high rate settings.

These are the recommended control surface throws:

HIGH RATE LOW RATE

ELEVATOR

RUDDER

[13mm]

1-3 /8"

[35mm]

SPOILER

Up

1/2 "

17°

Right

22°

7/8" [ 2 2 mm ]

Down

1/2 "

[13mm]

17°

Left

1-3 /8"

[35mm]

22°

Full

Up

3/8"

[10mm]

12°

Right

7/8"

[22mm]

13°

Half

7/16" [ 11mm ]

Down

3/8"

[10mm]

12°

Left

7/8"

[22mm]

13°

2. Fit the collet prop adapter onto the motor shaft. Slide it

❏

fully onto the motor. Fit the hexagonal collar onto the collet

adapter.

3. Put the spinner backplate onto the collet and tighten

❏

it down with the nylon spinner washer and prop nut. Install

16

Page 17

the spinner cone using the included 2.5 x 22mm at head

Forward C.G.

2-3/4" [70mm]

Aft C.G.

4" [102 mm]

Recommended C.G

3-1/2" [89mm]

from wing leading edge

Recommended C.G

3-1/2" [89mm]

from wing leading edge

machine screw. Con rm that the spinner backplate does

not contact the rewall. If it does, remove the assembly and

back the collet prop adapter away from the rewall slightly.

Reinstall the assembly and check the backplate spacing again.

4. Install the wing center section onto the fuselage. Use

❏

the wing joiners to attach the outer panels. You do not need

to tape the panels in place right now. Only when you are

ready to y should you tape the outer panels on.

Balance the Model Laterally

1. With the wing level, have an assistant help you lift the

❏

model by the spinner and the bottom of the fuse under the

TE of the n. Do this several times.

2. If one wing always drops when you lift the model, it

❏

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been

laterally balanced will track better.

Balance the Model (C.G.)

DO NOT OVERLOOK THIS IMPORTANT PROCEDURE.

A model that is not properly balanced may be unstable and

possibly un yable.

2. With the plane ready to y, and with motor batteries

❏

installed, use a Great Planes C.G. Machine or apply narrow

(1/16" [2mm]) strips of tape at the front and rear C.G. locations

so you will be able to feel them when lifting the model with

your ngers to check the C.G. location. Do not at any time

balance the model outside this C.G. range.

3. First, move the motor battery forward or aft to balance

❏

the plane. If needed, use Great Planes “stick-on” weight

(GPMQ4485) to balance the plane. Place incrementally

increasing amounts of weight on the bottom of the fuselage

over the location where it would be mounted inside until

the model balances. A good place to add stick-on nose

weight is to the side of the battery compartment. Once you

have determined if additional weight needs to be installed,

permanently attach the weight with glue or screws.

4. IMPORTANT: If you found it necessary to add any

❏

weight, recheck the C.G. after the weight has been installed.

1. Mark the C.G location on the underside of the wing at

❏

3-1/2" [89 mm] from the wing’s leading edge.

PREFLIGHT

Identify Your Model

You should always have your name, address, telephone

number and AMA number on or inside your model. It is

required at all AMA R/C club ying sites and AMA sanctioned

ying events. Fill out the identi cation tag on page 20 and

place it on or inside your model. You must also have your

FAA number on your plane and accessible without any tools.

Charge the Batteries

Always charge your transmitter batteries the night before

you go ying, and at other times as recommended by the

radio manufacturer.

17

Page 18

CAUTION: Unless the instructions that came with your radio

system state differently, the initial charge on new NiMH

transmitter batteries should be done for 15 hours using

the slow-charger that came with the radio system.

This will “condition” the batteries so that the next charge

may be done using the fast-charger of your choice. If the

initial charge is done with a fast-charger the batteries may

not reach their full capacity and you may be ying with

batteries that are only partially charged.

If the transmitter comes with LiFe batteries, be sure to

follow the instructions included with the transmitter and

use the correct charger designed to charge LiFe batteries.

Ground Check and Range Check

Follow the radio manufacturer’s instructions to ground check

the operational range of your radio, before the rst ight of

the day. This should be done once with the motor off and

once with the motor operating at various speeds. If the control

surfaces do not respond correctly, do not y! Find and correct

the problem rst. Look for loose servo connections or broken

wires, corroded wires on old servo connectors, loose motor

connectors or try relocating the receiver antennas away from

the motor battery.

SAFETY PRECAUTIONS

ELECTRIC MOTOR SAFETY PRECAUTIONS

WARNING: Once the motor batteries are connected the

electric motor can start at any time. Make sure the fail safe

is set on your radio to prevent the motor from starting if the

signal is lost.

WARNING: Read the entire instruction sheet included with

your motor batteries. Failure to follow the instructions could

cause permanent damage to the battery and its surroundings

and cause bodily harm!

WARNING: Get help from an experienced pilot when learning

to operate electric motors.

ALWAYS switch on the transmitter rst. Then, connect the

motor battery. After ying, unplug the motor battery rst, then

switch off the transmitter.

ALWAYS keep these items away from the prop: loose clothing,

shirt sleeves, ties, scarfs, long hair or loose objects such

as pencils or screwdrivers that may fall out of shirt or jacket

pockets into the prop.

ALWAYS keep your face and body as well as all spectators

away from the plane of rotation of the propeller as you run

the motor.

ALWAYS wear safety glasses when operating the motor.

ALWAYS remove the propeller if the motor batteries will be

connected when working on your plane.

ALWAYS remove the batteries when charging.

ALWAYS follow the charging instructions included with your

charger for charging LiPo batteries. LiPo batteries can cause

serious damage if misused.

ALWAYS unplug the motor batteries rst.

ALWAYS use a LiPo approved charger.

ALWAYS set the charger’s output volts to match the battery

volts.

ALWAYS charge a LiPo battery in a reproof location.

ALWAYS charge through the “charge” lead.

ALWAYS KEEP OUT OF THE REACH OF CHILDREN.

ALWAYS remove the batteries from the plane after a crash.

Set them aside in a safe location for at least 20 minutes. If

the batteries are damaged in the crash they could catch

re. If the battery starts to swell, quickly move the battery

to a safe location, preferably outside. Place it in a bucket,

covering the battery with sand. Never use water to try and

put out a LiPo re.

NEVER operate the motor in an area of loose gravel or sand;

the propeller may throw such material in your face or eyes.

NEVER touch the motor during or right after operation. The

motor may be HOT!

NEVER switch off the transmitter with the motor batteries

plugged in.

NEVER use a NiCd/NiMH peak charger to charge a LiPo

battery.

NEVER charge in excess of 4.20V per cell unless the battery

is rated for a higher voltage.

NEVER charge through the “discharge” lead.

NEVER charge at currents greater than 1C unless the battery

is rated for a higher charge rate.

NEVER trickle charge a LiPo battery.

NEVER allow the battery temperature to exceed 150 degrees

F [65 C].

NEVER disassemble or modify the pack wiring in any way

or puncture the cells.

NEVER discharge below 3.2 V per cell.

NEVER place the battery or charger on combustible materials

or leave it unattended during charge or discharge.

NEVER charge the batteries in the plane.

18

Page 19

FLYING

CAUTION: (THIS APPLIES TO ALL R/C AIRPLANES): If,

while ying, you notice an alarming or unusual sound such

as a low-pitched “buzz,” this may indicate control surface

utter. Flutter occurs when a control surface (such as an

aileron or elevator) or a ying surface (such as a wing or

stab) rapidly vibrates up and down (thus causing the noise).

In extreme cases, if not detected immediately, utter can

actually cause the control surface to detach or the ying

surface to fail, thus causing loss of control followed by

an impending crash. If utter is detected, slow the model

immediately and land as soon as safely possible. Identify

which surface uttered (so the problem may be resolved) by

checking all the servo grommets for deterioration or signs

of vibration. Make certain all pushrod linkages are secure

and free of play. If it uttered once, under similar circumstances it will probably utter again unless the problem is

xed. Some things which can cause utter are; Excessive

hinge gap; Not mounting control horns solidly; Poor t of

clevis pin in horn; Side-play of wire pushrods caused by

large bends; Excessive free play in servo gears; Insecure

servo mounting; and one of the most prevalent causes of

utter; Flying an over-powered model at excessive speeds.

Mount the Wing

Clear Tape

AND to teach you how to y. No matter how stable or “forgiving”

the Vista Grande is, attempting to learn to y on your own

is dangerous and may result in destruction of your model

or even injury to yourself and others. Therefore, nd an

instructor and y only under their guidance and supervision

until you have acquired the skills necessary for safe and fully

controlled operation of your model.

Pilot

WIND

Launch

Assistant

The Vista Grande may be self-launched by the pilot, but

if you are a beginner it will be easier to have an assistant

launch the Vista Grande for you. Switch on the transmitter

with the throttle stick in the bottom position, then plug the

motor battery into the ESC. Be careful of the propeller!

Before ying any model, always check to be certain that all

the controls are operating and in the correct direction by

moving the control sticks on the transmitter and observing

their response. Once you have con rmed that the controls

are operating correctly, arm the motor and point the nose into

the wind and apply full power. Toss the model into the air at

a nose-level or slightly nose-up attitude. The model should

climb aggressively and at a steep angle. Be ready to apply

down elevator to prevent the Vista from looping. If possible,

set up a mix of some down elevator with full throttle. Once

at a comfortable altitude, cut the throttle and trim the Vista

for a straight and level glide path.

Install the center wing section onto the fuselage with the wing

bolt. Insert the wing joiners into the center section and then

install the wing outer panels. Being sure the outer panels are

pushed snugly up against the wing center section, use two

pieces of clear tape, one for the top and one for the underside,

to secure the outer panels to the wing center section. When

you are done ying for the day, you can carefully peel the tape

off or just run a hobby knife along the seam to cut the tape.

Takeoff

IMPORTANT: If you are an inexperienced modeler we

strongly urge you to seek the assistance of a competent,

experienced R/C pilot to check your model for airworthiness

Flight

Use your rst ight to get a feel for the controls. The purpose

of the motor is only for gaining altitude so you should have

the motor off for most of your ight. Some elevator input is

needed when rudder is applied to keep the Vista level during

turns. You will nd that the Vista Grande will be able to glide

for a while. Once you become an experienced pilot, you will

learn how to search for rising air currents where motor power

will no longer be necessary to remain aloft for ten, twenty,

thirty minutes or more.

19

Page 20

Depending on the size battery you are using, you can expect

anywhere from 6 to 12 climbs to gliding and thermal hunting

altitude. We recommend using a ight timer connected to

your throttle stick so the timer only counts while the motor is

operating. Set the timer to sound an alarm at a conservatively

low ight time (3 minutes) for your rst ight. When you

recharge your pack, make a note about how much capacity

is put back into the battery by the charger. Ideally, your ight

timer should be set so that the timer alarm will go off when

you have used 80% of the battery capacity. Use your rst

couple ights and recharge amounts to determine how long

your timer should be set for. We also recommend testing

the spoiler at altitude to see how the glider responds. The

nose will drop some when the spoiler is rst raised and you

will need to compensate for this with elevator when landing.

Landing

Prepare for your nal landing approach by ying the Vista

downwind and coming around into the wind toward your

landing area. At this time, raise the spoiler to provide

additional sink so the Vista doesn’t glide beyond your landing

area. Gauge how far you think the Vista will glide until touch

down. If it looks like you will come up short, blip the throttle

some to get the needed glide speed to reach your landing

area. If you are sure to go long and you have the space and

battery charge to do so, lower the spoiler and throttle up to

make another circuit and come around again to land, making

the necessary altitude adjustments on your approach to hit

your landing area (avoid using motor power with the spoiler

up). Be sure you have the motor off before the Vista is near

the ground.

When the Vista is nearing touch-down (a foot or two above

the ground), increasingly add some “up” elevator to slow

the model without allowing it to climb. When the model

makes contact, expect it to skid some along the grass before

coming to a stop. Make a note of the elapsed time on your

ight timer. Unplug the battery from the Vista and then turn

off your transmitter. Congratulations! You have made your

rst successful ight with your Vista Grande. Allow the motor

to cool and charge up your battery after checking the pack

voltage. Make adjustments to your ight timer if necessary.

Also, now that you know how the Vista responds to the

spoiler, we recommend doing an elevator-spoiler mix if your

radio is capable of programmable mixing which will apply a

little up elevator when the spoiler is raised to compensate

for the drop of the nose.

One nal note about ying your Vista Grande. Have a goal

or a ight plan in mind for each ight. Rather than taking

to the air without knowing what you are going to do, take a

minute to think about the next ight–whether it’s searching

for rising air currents (thermals) or learning how to control

the model in different orientations. A little planning ahead

should keep you from executing an impulsive maneuver you

weren’t actually ready for, possibly resulting in a crash.

Have a ball! But always stay in control

and y in a safe manner.

GOOD LUCK AND GREAT FLYING!

© 2018 Tower Hobbies .® A subsidiary of Hobbico, Inc.

Name

Address

City, State, Zip

Phone Number

FAA Number

AMA Number

TOWA2045 v1.1

This model belongs to:

20

Loading...

Loading...