Page 1

WARRANTY

Tower Hobbies

®

guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This warranty

does not cover any component parts damaged by use or modification. In no case shall Tower Hobbies' liability exceed the original

cost of the purchased kit. Further, Tower Hobbies reserves the right to change or modify this warranty without notice.

In that Tower Hobbies has no control over the final assembly or material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the final user-assembled product. By the act of using the user-assembled

product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this

kit immediately in new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822

USA

Include a letter stating your name, return shipping address, as much contact information as possible (daytime telephone number, fax

number, e-mail address), a detailed description of the problem and a photocopy of the purchase receipt. Upon receipt of the package

the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

© Copyright 2005 V1.0 TOWZ1110 for TOWA4010

Tower Hobbies

P.O. Box 9078

Champaign, IL 61826

(800) 637-6050

www.towerhobbies.com

Wingspan: 78.5 in [2000mm]

Wing Area: 678 sq in [43.7dm

2

]

Weight: 28 – 32 oz [795 – 905g]

Wing Loading: 5.9 – 6.7 oz/sq ft [18 – 21g/dm

2

]

Length: 41 in [1035mm]

Radio: Two-channel, two standard servos

™

®

®

Page 2

TABLE OF CONTENTS

INTRODUCTION...................................................................2

AMA ......................................................................................2

SAFETY PRECAUTIONS.....................................................2

ADDITIONAL ITEMS REQUIRED........................................3

Hardware & Accessories ................................................3

Adhesives & Building Supplies .......................................3

Optional Supplies & Tools ...............................................3

ORDERING REPLACEMENT PARTS..................................3

Replacement Parts List...................................................3

METRIC CONVERSIONS.....................................................3

KIT INSPECTION..................................................................4

KIT CONTENTS ....................................................................4

ASSEMBLY...........................................................................5

Join the Wings ................................................................5

ASSEMBLE THE FUSELAGE..............................................6

Join the Stabilizer............................................................6

Join the Fin .....................................................................7

Hook Up the Controls .....................................................8

Install the Receiver & Battery .......................................10

GET THE MODEL READY TO FLY .....................................10

Final Assembly..............................................................10

Check the Control Directions ........................................11

Set the Control Throws .................................................11

Balance the Model (C.G.) .............................................11

PREFLIGHT........................................................................12

Identify Your Model........................................................12

Charge the Batteries.....................................................12

Range Check ................................................................12

AMA SAFETY CODE (excerpts) .......................................13

CHECK LIST .......................................................................13

FLYING................................................................................13

Mount the Wing.............................................................13

Trim Flights....................................................................14

First Flights ...................................................................14

INTRODUCTION

Thank you for purchasing the Tower Hobbies Vista

™

sailplane. Easy-to-fly sailplanes such as this serve many

purposes–they are an excellent way for beginners to get

into R/C, they are great for experienced pilots who want to

take a break from their powered models, and they are even

suitable for thermal competition. Check the weather report

now because in just a few hours your Tower Vista sailplane

will be ready to launch and seek thermals with the best.

AMA

We urge you to join the AMA (Academy of Model

Aeronautics) and a local R/C club. The AMA is the

governing body of model aviation and membership is

required to fly at AMA clubs. Though joining the AMA

provides many benefits, one of the primary reasons to join

is liability protection. Coverage is not limited to flying at

contests or on the club field. It even applies to flying at

public demonstrations and air shows. Failure to comply with

the Safety Code (excerpts printed in the back of the

manual) may endanger insurance coverage. Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way. There are over

2,500 AMA chartered clubs across the country. Contact the

AMA at the address or toll-free phone number that follows.

IMPORTANT!!! Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to

avoid flying near full-scale aircraft and avoid flying near or

over groups of people.

PRO TECT YOUR MODEL,Y OURSELF &

OTHERS.....FOLLO W THESE IMPORT ANT

SAFETY PRECAUTIONS

1. Your Tower Hobbies Vista sailplane should not be

considered a toy, but rather a sophisticated, working model

that functions very much like a full-size airplane. Because of

its performance capabilities, the Tower Vista sailplane, if not

assembled and operated correctly, could possibly cause

injury to yourself or spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unflyable model. In a few cases

the instructions may differ slightly from the photos. In those

instances the written instructions should be considered

as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in firstclass condition.

5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

6. You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

7. If you are not an experienced pilot or have not flown this

type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for your

first flights. If you’re not a member of a club, your local

hobby shop has information about clubs in your area whose

membership includes experienced pilots.

8. While this kit has been flight tested to exceed normal use,

if the plane will be used for extremely high-stress flying the

modeler is responsible for taking steps to reinforce the

high-stress points.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Tele: (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

2

Page 3

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and flyability of your finished model depends on

how you build it; therefore, we cannot in any way

guarantee the performance of your completed model, and

no representations are expressed or implied as to the

performance or safety of your completed model.

Remember:Take your time and follow the instructions to

end up with a well-built model that is straight and true.

ADDITIONAL ITEMS REQUIRED

ORDERING REPLACEMENT PARTS

Replacement parts for the Tower Hobbies Vista sailplane are

available using the order numbers in the Replacement Parts

List Replacement Parts may be ordered from Tower Hobbies at

www.towerhobbies.com or by calling (800) 637-6050.

Parts may also be ordered from Hobby services by calling

(217) 398-0007, or via facsimile at (217) 398-7721. but full

retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax.

If ordering via fax, include a Visa®or MasterCard®number

and expiration date for payment.

Hardware & Accessories

This is the list of hardware and accessories required to

finish the Vista sailplane. Order numbers are provided in

parentheses.

❍ 2-channel radio with two standard servos

❍ 1/4" [6mm] R/C foam rubber (HCAQ1000)

❍ Spare #64 rubber bands (TOWQ1220)

❍ Great Planes

®

Self Adhesive Lead Weights (GPMQ4485)

❍ Launching system: Standard Hi-Start (up to 500' launches

at sites with 800' or more launch area) (DYFP8301)

-or-

❍ Up-Start 2m (up to 200' launches at sites with 300' or

more launch area) (DYFP8305)

Adhesives & Building Supplies

In addition to a few common household tools, this is the

"short list" of the most important items required to assemble

the Tower Vista sailplane.

❍ Tower Hobbies Build-It

™

30-minute epoxy (TOWR3811)

❍ #1 Hobby knife (TOWR1010)

❍ #11 blades (5-pack, TOWR1015)

❍ Drill bits: 1/16" [1.6mm] , 3/32" [2.4mm], 1/8" [3.2mm]

❍ Drill

Optional Supplies & Tools

Here is a list of optional items mentioned in the manual that

will help you assemble the Tower Vista sailplane.

❍ Model airplane covering iron with covering sock

❍ Epoxy brushes (6, GPMR8060)

❍ Mixing sticks (50, GPMR8055)

❍ Mixing cups (GPMR8056)

❍ Builder’s Triangle Set (HCAR0480)

❍ Denatured alcohol (for epoxy clean up)

❍ CG Machine

™

(GPMR2400)

Mail parts orders and payments by personal check to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Be certain to specify the order number exactly as listed in

the Replacement Parts List. Payment by credit card or

personal check only; no C.O.D.

If additional assistance is required for any reason, contact Product

Support by e-mail at productsupport@greatplanes.com,

or by telephone at (217) 398-8970.

Replacement Parts List

Order Number Description How to Purchase

Missing pieces Contact Product Support

Instruction manual Contact Product Support

Full-size plans Not available

TOWA4011 Wing Kit Contact Hobby Supplier

TOWA4012 Fuselage Kit Contact Hobby Supplier

TOWA4013 Tail Set Contact Hobby Supplier

METRIC CONVERSIONS

1" = 25.4mm (conversion factor)

1/64" = .4 mm

1/32" = .8 mm

1/16" = 1.6 mm

3/32" = 2.4 mm

1/8" = 3.2 mm

5/32" = 4.0 mm

3/16" = 4.8 mm

1/4" = 6.4 mm

3/8" = 9.5 mm

1/2" = 12.7 mm

5/8" = 15.9 mm

3/4" = 19.0 mm

1" = 25.4 mm

2" = 50.8 mm

3" = 76.2 mm

6" = 152.4 mm

12" = 304.8 mm

18" = 457.2 mm

21" = 533.4 mm

24" = 609.6 mm

30" = 762.0 mm

36" = 914.4 mm

3

Page 4

4

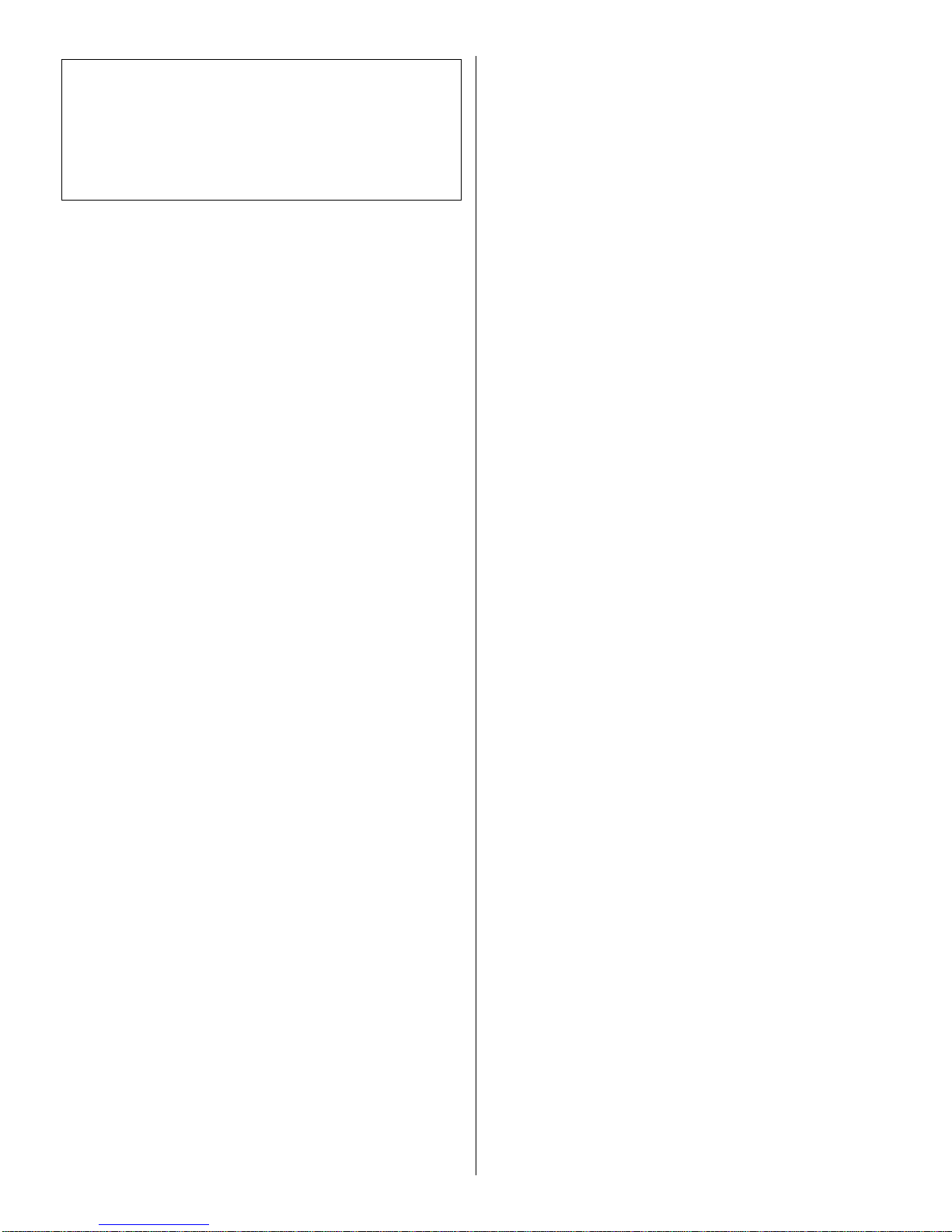

KIT INSPECTION

Before starting to build, take an inventory of this kit to make sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not of acceptable quality, or if you need assistance with assembly,

contact Product Support. When reporting defective or missing parts, use the part names exactly as they are written in

the Kit Contents list on this page.

Tower Hobbies Product Support

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: airsupport@towerhobbies.com

Kit Contents

1. Left Wing Panel

2. Right Wing Panel

3. Wing Joiner

4. Servo Rails (2)

5. Wing Dowels (2)

6. Rubber Bands (6)

7. Horizontal Stabilizer (Stab) w/Elevator

8. R&L Vertical Stabilizer Braces

9. Vertical Stabilizer (Fin) w/Rudder

10. Fuselage

11. Pushrods (2)

Kit Contents (not photographed)

Nylon Control Horns w/Mounting Plates (2)

Nylon Clevises (2)

Nylon 90° Pushrod Connectors (2)

Nylon Tail Skid

Tow Hook

Washer

2 x 10mm Screws (4)

Silicone Clevis Retainers (2)

3mm Nut

1/8" x 3/8" x 8" [3 x 10 x 200mm] Balsa Stick

1

2

5

9

8

11

7

10

3

4

6

Page 5

ASSEMBLY

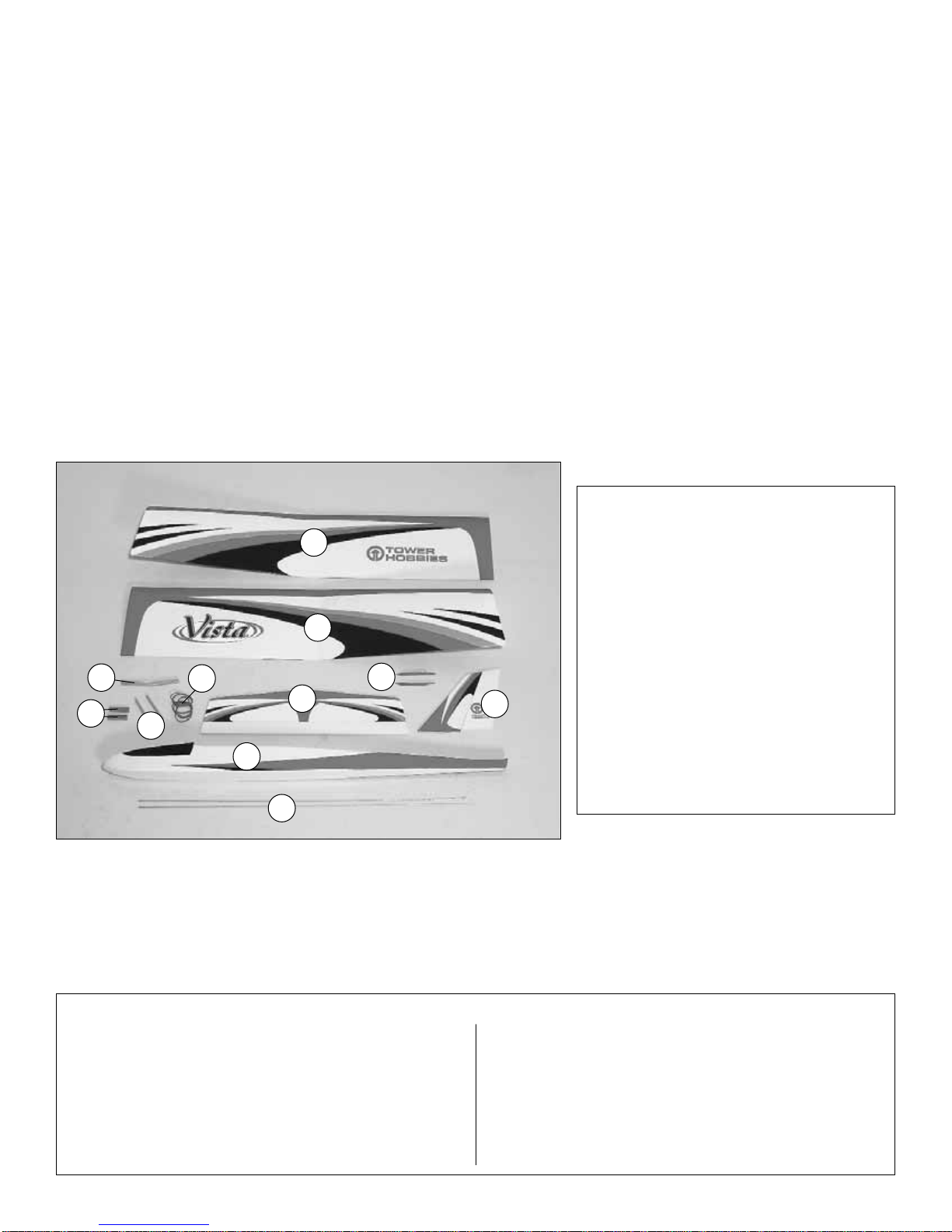

Join the Wings

❍

1. Without using any glue, test fit both wing halves

together with the wing joiner. Make sure the halves fit

together well and there is no gap. If there is a problem with

the fit, look for obstructions such as glue bumps or wood

slivers inside the wings where the joiners fit. Make any

adjustments necessary to get a good fit.

❍

2. Place a sheet of wax paper on your workbench and

gather all the items required for joining the wings: 30-minute

epoxy, a mixing cup, an epoxy mixing stick, an epoxy brush,

paper towels and denatured alcohol for epoxy clean up.

Hint: To cut down on waste, cut the paper towels into

several small squares as shown in the photo.

Caution: Do not use 5-minute epoxy for joining the wing

halves. It will not provide enough working time.

❍

3. Separate the wings and take out the joiner. Mix up

approximately 1/2 oz. [15cc] of 30-minute epoxy. Use an

epoxy brush to coat both ends of the wing and one half of

the joiner all the way around. Pour a generous amount of

epoxy into one of the wings where the joiner goes, and then

slowly insert the epoxy-coated half of the joiner. Wipe away

excess epoxy as it is forced out of the wing. Note: There

must be no “empty space” inside the wing where the joiner

fits–the cavity must be filled with epoxy. If no epoxy “oozes”

out when you installed the joiner, remove the joiner and add

more epoxy. Then reinstall the joiner. Proceed rapidly to the

next step.

❍

4. Coat the protruding end of the joiner all the way around

with epoxy and pour epoxy into the other wing. Join the wing

to the other joiner/wing assembly, slowly pressing the two

halves together. Allow excess epoxy to drip out as you go.

When the wings come together, wipe away excess epoxy

that is squeezed out. Then use several strips of masking

tape on both the top and bottom of the wing to tightly hold

the two halves together. If epoxy continues to work out of the

wing under the tape, remove one strip at a time and wipe off

the epoxy. Then replace the tape with another strip. Do not

disturb the wing until the epoxy has hardened.

❍

5. After the epoxy has fully hardened, slowly and carefully pull

away the masking tape. If any of the covering loosened, iron it

back down with a covering iron on medium heat. Use a covering

sock over the iron to protect the Tower Vista’s finish.

Read steps 3 and 4 all the way through before

proceeding. It is important to use the proper technique for

joining the wing halves to ensure a strong wing.

5

Page 6

ASSEMBLE THE FUSELAGE

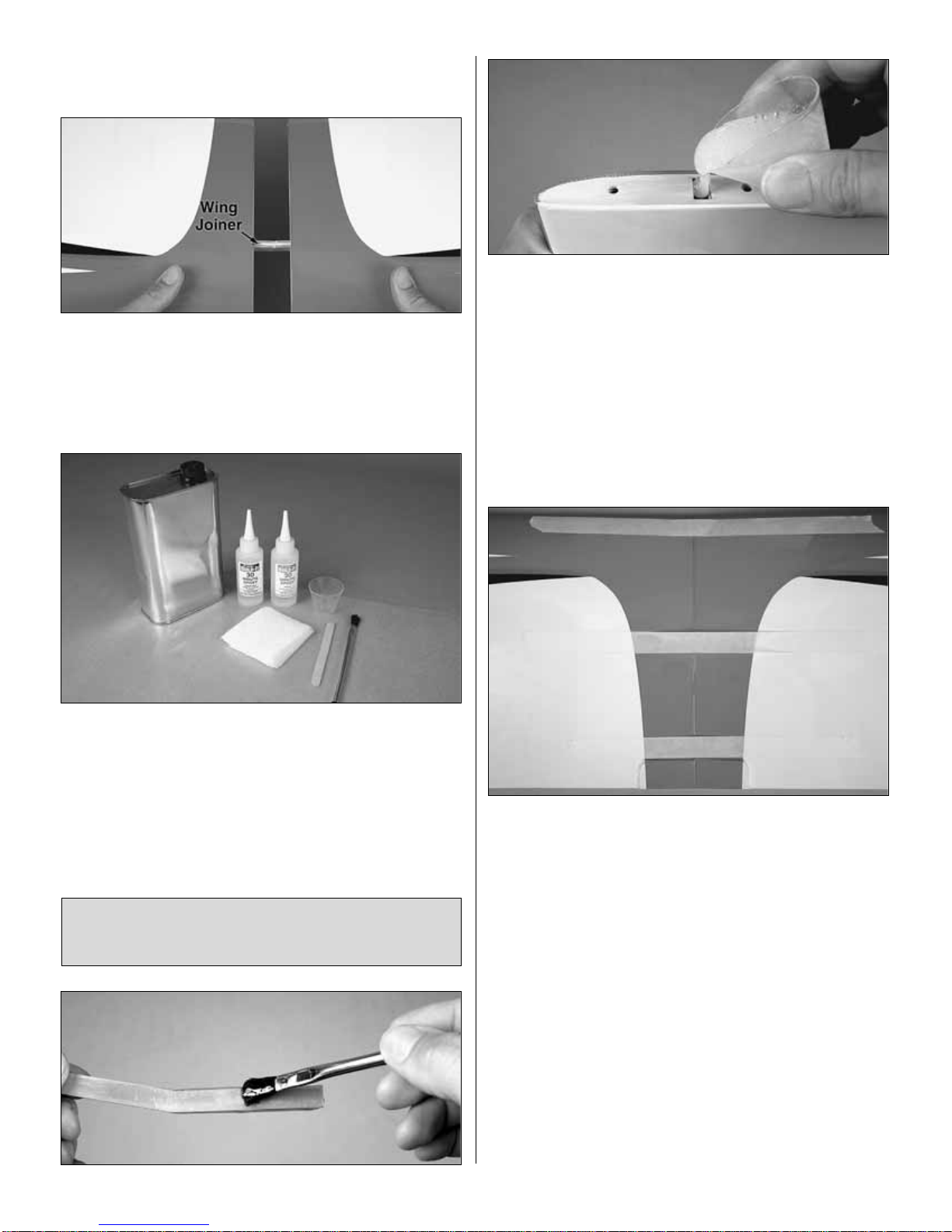

Join the Stabilizer

❍

1. If you haven’t done so already, remove the protective

foam piece from the aft end of the fuselage where the

stabilizer goes. Cut the covering at the opening from the

rudder pushrod tube and from the slot in the back of the

fuselage for the elevator pushrod.

❍

2. Cut off any covering that has been wrapped around the

side of the fuselage over the top of the stab saddle where

the stabilizer goes.

❍

3. Use a sharp hobby knife to cut the covering from the

bottom only of the horizontal stabilizer (stab) over the half-

circle notch in the trailing edge. Also cut the covering from

both sides of the stab over the half-circle notch in the

leading edge.

❍

4. Place the stab on the fuselage, keying the notches in

the stab into the pegs on the fuselage. Use a fine-point, felttip pen to mark the outline of the fuselage onto the stab.

❍

5. Take the stab off the fuselage and follow the proceeding

Expert Tip

or use a sharp hobby knife with a straightedge to

cut along the lines. If using a hobby knife to cut the covering,

take great care not to cut into the wood. Cutting into the wood

will weaken the structure which could cause it to fail in flight.

6

Page 7

❍

6. Peel the covering from the bottom of the stabilizer.

❍

7. Reposition the stabilizer onto the fuselage. Resting the

fuselage on your workbench, place a weight on top of the

stab to hold it down. View the fuselage from the rear. If the

stab is parallel with the workbench, proceed to the next step.

If the stab is not parallel with the workbench, remove the

stab and use medium-grit sandpaper to sand down the “high

side” of the stab saddle where the stab rests until you can

get the stab level.

❍

8. Use 30-minute epoxy to glue the stab into position–be

certain to coat both the bottom of the stab and the fuselage

with epoxy. Use weight or T-pins to hold the stab in position

until the epoxy hardens.

Join the Fin

❍

1. Taking accurate measurements, use a fine-point, felttip pen to mark the center of the fuselage in the two

locations shown.

❍

2. Using the marks to align a straightedge, mark a

centerline down the top of the fuselage and onto the stab as

shown—this will be used to align the fin.

❍

3. Place the fin on the fuselage, accurately aligning it over

the centerline. Without using any glue, place the tri-stock fin

braces on both sides of the fin. The same as was done with

the bottom of the stab, use a fine-point, felt-tip pen to mark the

outline of the fin braces onto the fuselage top and the fin.

How to cut covering from balsa.

Rather than using a hobby knife which could

inadvertently cut into the balsa, use a heated soldering

iron. Move the iron at a pace that will just melt the

covering without burning into the wood–the hotter the

soldering iron, the faster you will have to move it. A sharp

tip isn’t necessary, but a fine-point does work best.

7

Page 8

❍

4. Working carefully without cutting into the balsa, use

your heated soldering iron or a sharp hobby knife to cut the

covering from the sides of the fin and the top of the

fuselage. Make sure you cut just inside the

lines–approximately 1/32" [.5mm]–so that none of the balsa

will be exposed when all the parts are joined.

❍

5. Use one of your paper towel squares moistened with

denatured alcohol to wipe away the ink lines.

❍

6. Use 30-minute epoxy to glue the fin to the fuselage

with T-pins to hold the fin in position. Before the epoxy

hardens use a builder’s square to check to see if the fin is

perpendicular to the stab. If necessary, use tape to pull the

fin over to one side or the other to get the fin vertical. Allow

the epoxy to harden before proceeding.

❍

7. Take out the T-pins. Glue the tri stock braces into position

with 30-minute epoxy using T-pins to hold them in place.

❍

8. While you have some epoxy mixed, glue in both

wing dowels.

Hook Up the Controls

❍

1. Cut one of the wire pushrods to a length of 27"

[685mm] by cutting off the non-threaded end. Cut the other

pushrod to a length of 29-3/4" [685mm].

❍

2. Thread one of the pushrods halfway into one of the

clevises–this should take about fifteen full turns. Cut the

mounting plate off one of the control horns. Slide a silicone

retainer over the clevis, then connect the clevis to the third

hole out from the bottom of the horn. Prepare the other

pushrod the same way.

❍

3. Slide the longer pushrod into the elevator guide tube in

the fuselage. Mark, then drill 3/32" [2.4mm] holes through

the elevator for the two elevator horn mounting screws.

Mount the elevator horn with two 2 x 10mm screws and the

plastic mounting plate.

8

Page 9

Note: If the silicone retainer on the clevis rubs against the inside

of the fuselage sides, use a hobby knife to trim the inside of the

fuselage as necessary for free, smooth movement.

❍

4. Install the rudder pushrod and mount the control horn

the same way.

❍

5. Without using any glue, install both hardwood servo

rails into the slots. Glue the forward rail into the fuselage as

far forward as it will go.

Refer to this photo for the following four steps.

❍

6. Position the servos on the rails and slide them forward

against the forward rail. Note the position of the splined

output shaft on the servos (the elevator servo is facing aft

and the rudder servo is facing forward). Space the rail

approximately 3/32" [3mm] aft of the servos, and then

securely glue the rail into position.

❍

7. Place the servo arms on the servos–if your servos

came with a selection of servo arms, select ones that will

not interfere with the other servo or the fuselage sides. For

Futaba®and Tower servos, use the six-arm servo arms and

cut off the unused arms.

❍

8. Position the left servo all the way over to the left side

of the fuselage, then drill 1/16" [1.6mm] holes through the

rails for the servo mounting screws. Mount the servo with

the screws that came with it.

❍

9. Move the rudder servo as far over to the right as it will

go without the arm contacting the right fuselage side.

Drill 1/16" [1.6mm] holes through the rails and mount the

rudder servo with the screws that came with the servo.

❍

10. Center the servo arms as shown holding the elevator

pushrod so the elevator is centered. Mark the pushrod where it

crosses the holes in the elevator servo arm.

❍

11. Use pliers to make a 90° bend in the pushrod at the

mark you made.

❍

12. Take the servo arm off the servo. Enlarge the holes in

the servo arms with a servo horn drill (HCAR0698), a 5/64"

[2mm] drill bit or a hobby knife. Connect the pushrod to the

outer hole in the elevator servo using a 90° pushrod

connector. Cut the pushrod 1/16" [1.6mm] from the connector.

Then replace the servo arm on the servo.

❍

13. Connect the rudder pushrod to the rudder servo the

same way.

9

Page 10

Install the Receiver & Battery

Refer to this photo while installing the receiver and battery .

❍

1. Noting how the rubber band on the canopy hatch is

attached to the tab on the former (so you will know how to

reattach it later), unhook the rubber band and temporarily

remove the canopy hatch and set it aside.

❍

2. Connect the servos and on/off switch to the

receiver–on most four-channel airplanes, the rudder is

operated by the left stick on the transmitter. However, on

two-channel planes such as this (that do not have ailerons),

the rudder is controlled by the right stick. Connect the

rudder servo to the channel in the receiver that will allow the

rudder to be controlled by the right stick–for Futaba

receivers that is channel 1.

❍

3. Wrap the receiver and receiver battery in 1/4" [6mm]

R/C foam rubber. Use tape or small rubber bands to hold the

foam rubber in place.

❍

4. Place the receiver in the fuselage where shown.

Connect the receiver battery to the on/off switch, and then

place it in the fuselage ahead of the receiver.

❍

5. Cut the 1/8" x 3/8" x 8" [3 x 10 x 200mm] balsa stick to

the lengths required to fit between the fuselage sides where

shown. Then glue the sticks in place, holding the receiver

and battery in position.

❍

6. Use the mounting plate from your receiver on/off switch

as a template to cut and drill holes in the fuselage side. Then

mount the switch.

❍

7. Guide the receiver antenna past the servos, then through

one of the cut off servo arms as shown to make a “strain relief”

that keeps tension off the solder joint inside the receiver.

❍

8. Drill a 1/16" [1.6mm] hole through the side of the

fuselage where shown. Then guide the antenna through the

hole. Use clear tape to hold the receiver antenna to the

outside of the fuselage.

GET THE MODEL READY TO FLY

Final Assembly

❍

1. Use a piece of wire or a small, wood dowel to reattach

the rubber band and reinstall the canopy hatch.

❍

2. Thread the 3mm nut onto the tow hook and slip on the

3mm washer with a drop of thread-lock or CA. Thread the

hook into one of the three holes in the bottom of the

fuselage. Use a 5.5mm wrench or needle-nose pliers to

10

Page 11

tighten the nut and secure the hook. The forward hole is

recommended for starting out as it will provide mild

launches for first flights. Later, the hook may be moved aft

for more aggressive, higher launches.

❍

3. Cut off two of the barbs from the pegs on the tail skid.

Drill 1/8" [3.2mm] holes through the bottom of the fuselage

for the prongs. Then glue the tail skid into position.

Check the Control Directions

❍

1. Turn on the transmitter and receiver and center the

trims. If necessary, remove the servo arms from the servos

and reposition them so they are centered. Don’t forget to

install the screws that hold on the servo arms.

❍

2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered. If necessary,

screw the clevises on the pushrods in or out to center the

control surfaces.

❍

3. Make certain that the elevator and rudder respond in the

correct direction as shown in the diagram. If necessary, use the

servo reversing function in the transmitter to reverse the servos

so they respond in the right direction. Be certain the elevator and

rudder have remained centered. Adjust if necessary.

Set the Control Throws

Use a ruler to measure and set the control throw of the

elevator and rudder as indicated in the chart that follows. If

your radio does not have dual rates, we recommend setting

the throws at the low rate setting.

Note: The rudder throw is measured at the bottom of

the rudder.

Balance the Model (C.G.)

At this stage the model should be in ready-to-fly condition

with all of the systems in place including the servos, switch,

battery and receiver.

More than any other factor, the C.G. (balance point) can

have the greatest effect on how a model flies, and may

determine whether or not your first flight will be

successful. If you value this model and wish to enjoy it for

many flights, DO NOT OVERLOOK THIS IMPORTANT

PROCEDURE. A model that is not properly balanced will

be unstable and possibly unflyable.

IMPORTANT: The Tower Vista 2m sailplane has been

extensively flown and tested to arrive at the throws at

which it flies best. Flying your model at these throws will

provide you with the greatest chance for successful first

flights. If, after you have become accustomed to the way

the Tower Vista 2m sailplane flies, you would like to

change the throws to suit your taste that is fine. However,

too much control throw could make the model difficult to

control, so remember, “more is not always better.”

These are the recommended control surface throws:

High Rate Low Rate

ELEVATOR: 5/8" [16mm] up 3/8" [10mm] up

5/8" [16mm] down 3/8" [10mm] down

RUDDER: 1-1/2" [38mm] right 5/8" [16mm] right

1-1/2" [38mm] left 5/8" [16mm] left

11

4-CHANNEL

TRANSMITTER

4-CHANNEL

TRANSMITTER

Page 12

❍

1. If you will be using a Great Planes C.G. Machine™to

balance your model, set the rulers to 4" [100mm]. Place the

plane on the machine. If you will not be using the C.G.

Machine, use a felt-tip pen or narrow (1/8" [3mm] or less)

tape to mark a line, noting the C.G. on the bottom of the

wing 4" [100mm] back from the leading edge.

❍

2. Attach the wing to the fuselage with a couple of rubber

bands. The model must be totally ready to fly with all of the

components installed. Place the model on the Great Planes

CG Machine or lift it at the balance point you marked. You

should be able to feel the tape lines with your fingers.

❍

3. When supporting the model at the C.G. it is likely that

the tail will drop, indicating that it is “tail heavy” and weight

must be added to the nose. If the nose drops however, the

model is “nose heavy” and weight must be added to the tail.

Use Great Planes Self-Adhesive Lead Weights to balance

the model. Nose weight can be attached inside the fuselage

to the former as shown. Approximately 2 oz. [60g] of ballast

will be required for most models.There is also a cavity in the

balsa nose block for lead or steel shot (not included). If you

prefer to install lead or steel shot in the cavity, determine the

amount required, mix with epoxy, then pour in. Weight

installed in this manner will be permanent.

❍

4. IMPORTANT: If you found it necessary to add any

weight, recheck the C.G. after the weight has been installed.

PREFLIGHT

Identify Y our Model

No matter if you fly at an AMA sanctioned R/C club site or if you

fly somewhere on your own, you should always have your

name, address, telephone number and AMA number on or

inside your model. It is required at all AMA R/C club flying sites

and AMA sanctioned flying events. Fill out the identification tag

on page 15 and place it on or inside your model.

Charge the Batteries

Follow the battery charging instructions that came with your

radio control system to charge the batteries. You should

always charge your transmitter and receiver batteries the

night before you go flying, and at other times as

recommended by the radio manufacturer.

Range Check

Ground check the operational range of your radio before the

first flight of the day. With the transmitter antenna collapsed

and the receiver and transmitter on, you should be able to walk

at least 100 feet away from the model and still have control.

Have an assistant stand by your model and, while you work

CAUTION: Unless the instructions that came with your

radio system state differently, the initial charge on new

transmitter and receiver batteries should be done for 15

hours using the slow-charger that came with the radio

system. This will “condition” the batteries so that the next

charge may be done using the fast-charger of your choice.

If the initial charge is done with a fast-charger, the batteries

may not reach their full capacity and you may be flying with

batteries that are only partially charged.

This is where your model should balance for the first

flights. Later, you may wish to experiment by shifting the

C.G. up to 1/2" [13mm] forward or 1/2" [13mm] back to

change the flying characteristics. Moving the C.G.

forward may improve wind penetration and stability, but

the model will then fly and land a little faster. Moving the

C.G. aft makes the model lighter and more responsive to

thermals, but could also cause it to become too difficult to

control. In any case, start at the recommended balance

point and do not at any time balance the model outside

the specified range.

12

Page 13

the controls, tell you what the control surfaces are doing. If the

control surfaces do not respond correctly, do not fly! Find and

correct the problem first. Look for loose servo connections or

broken wires, corroded wires on old servo connectors, poor

solder joints in your battery pack or a defective cell, or a

damaged receiver crystal from a previous crash.

AMA SAFETY CODE (excerpts)

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to

Model Aviation

magazine, the AMA web site

or the Code that came with your AMA license.

General

1) I will not fly my model aircraft in sanctioned events, air

shows, or model flying demonstrations until it has been

proven to be airworthy by having been previously,

successfully flight tested.

2) I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airport operator. I will give right-of-way and avoid flying in

the proximity of full-scale aircraft. Where necessary, an

observer shall be utilized to supervise flying to avoid having

models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

flying site I use, and I will not willfully and deliberately fly my

models in a careless, reckless and/or dangerous manner.

5) I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model. Note: This

does not apply to models while being flown indoors.

7) I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

Radio Control

1) I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of

spectators until I become a qualified flier, unless assisted by

an experienced helper.

3) At all flying sites a straight or curved line(s) must be

established in front of which all flying takes place with the

other side for spectators. Only personnel involved with flying

the aircraft are allowed at or in the front of the flight line.

Intentional flying behind the flight line is prohibited.

4) I will operate my model using only radio control frequencies

currently allowed by the Federal Communications Commission.

5) I will not knowingly operate my model within three

miles of any pre-existing flying site except in

accordance with the frequency sharing agreement

listed [in the complete AMA Safety Code].

9) Under no circumstances may a pilot or other person

touch a powered model in flight; nor should any part of the

model, other than the landing gear, intentionally touch

the ground except while landing.

CHECK LIST

❍

1. Check the C.G. according to the measurements

provided in the manual.

❍

2. Be certain the battery and receiver are

securely mounted.

❍

3. Extend your receiver antenna and make sure it has a

strain relief inside the fuselage to keep tension off the

solder joint inside the receiver.

❍

4. Make sure the tow hook is securely tightened.

❍

5. Confirm that all controls operate in the correct direction

and the throws are set up according to the manual.

❍

6. Make sure all the servo arms are mounted to the

servos with the screws included with your radio.

❍

7. Place your name, address, AMA number and

telephone number on or inside your model.

❍

8. Cycle your receiver battery pack (if necessary) and

make sure it is fully charged.

❍

9. If you wish to photograph your model, do so before

your first flight.

❍

10. Range check your radio when you get to the flying field.

FLYING

Mount the Wing

Mount the wing to the fuselage with the six #64 rubber

bands that came with the model. Install them one at a time,

crisscrossing the last two. Never use torn, cracked or oily

rubber bands.

If the rubber bands you will be using are different from those

recommended, consult an experienced modeler to make

certain they are strong enough, and that you have used

enough of them. If uncertain, force the front of the wing off

of the wing saddle. There should be considerable

resistance! If the wing can be forced from the fuselage

without having to strain your hands, then there are probably

not enough rubber bands. If launching the Tower Vista 2m

sailplane with launch systems stronger than those

recommended in this manual, additional #64 rubber bands

will be necessary.

IMPORTANT!!! Flying a model with too few rubber bands

can be dangerous. The wing could actually detach from the

fuselage resulting in a crash. If the model exhibits any

tendencies that indicate there are not enough rubber bands,

immediately land and closely inspect the model for damage.

If no damage is found, add more rubber bands.

Use this Check List to make sure you haven’t forgotten

anything during the last few seconds of preparation.

13

Page 14

Trim Flights

Before the first flight of the day, don’t forget to do a range

check and make sure the elevator and rudder are

functioning properly and respond in the correct direction.

Turn on the transmitter first and then the receiver. Hold the

Tower Vista 2m sailplane under the wing with the nose

pointed slightly down and directly into the wind. Launch the

model with the wings level and the nose pointing at a spot

on the ground about 50 feet [15m] in front of you. If the

sailplane is launched with the nose up or launched too hard

it will climb a few feet, stall and fall nose first straight down.

Launch the plane with a gentle push forward. Adjust the

trims on the transmitter so the plane flies straight ahead in

a smooth glide path.

First Flights

Find a BIG, OPEN field for your first flights. The bigger the

better, as you won’t have to worry about where to land. Ground

based objects (trees, poles, buildings,

etc.) can cause the

beginner to become easily

disoriented. Try to find an

experienced pilot to help you with your first flights.

Although the

Tower Vista 2m sailplane is very easy to fly, an

experienced

pilot can save you a lot of time and possible aggravation by

helping you get your model in the air smoothly.

Follow the directions that came with your hi-start and lay it

out directly into the wind. Place the stake at the far upwind

edge of the flying field so the parachute will blow back onto

the flying field.

Turn on your transmitter and then your receiver and hook

the parachute onto your plane’s tow hook. Pull the plane

back until there is approximately 8 lbs. [3.5kg] of tension on

the high start. More tension can be used after you get

acquainted with the launching procedure.

Hold the plane above your head with the wings level and the

nose pointed slightly up and directly into the wind. Give the

plane a strong push forward to get it flying and it will climb

up like a kite. You should not have to touch the elevator

during the launch but use the rudder stick to keep it going

straight up.

Note: You need to remember that your radio control

responds as if you were sitting in the cockpit. When you

push the transmitter stick to the right, the rudder moves to

the plane’s right! This means that when the plane is flying

towards you, it may seem like the rudder controls are

reversed (when you give “right” rudder the plane turns to

your left–which is the plane’s “right”). It is sometimes easier

to learn to fly the plane if you always face your body in the

direction the plane is flying and look over your shoulder to

watch the model.

Use these first flights to get the “feel” of the controls and the

Tower Vista 2m sailplane’s flying characteristics. Try to keep

the plane upwind and just perform some gentle S-turns

(always turning into the wind) until it is time to set up for

landing. When it is time to land, just continue performing the

gentle S-turns upwind and let the plane glide onto the

ground. Don’t worry about where the plane lands – just use

caution to avoid hitting anything. Always try to launch and

land into the wind.

No matter how much – or how little – previous R/C flying

experience you have, you’ll thoroughly enjoy piloting the

Tower Vista 2m sailplane. Its built-in stability keeps you calm

and confident at the controls. And when your “beginner”

days are behind you, the Tower Vista 2m sailplane’s

versatile performance can even help you earn impressive

contest wins. It will be one of your favorites for many years

to come.

Happy flying!

14

Page 15

OTHER ITEMS AVAILABLE FROM

TOWER HOBBIES

Tower Hobbies 4-TH 4-Channel FM Radio

The 4-TH is as affordable as it is perfect for first-time and

sport fliers. Narrow-band FM technology and a dualconversion receiver ensure that reception is as interferenceresistant as the transmission. Rounded transmitter contours

take it easy on the hands, while length and tension

adjustments tailor all-important stick “feel” to your own

needs. Servo reversing adds installation ease to the list of

conveniences, which also includes easy-to-reach trims,

600mAh Tx and Rx NiCds, a dual-output charger, Futaba

J-compatible connectors – and a trainer system to make it

easy to teach flying skills or learn new ones. Requires

servos. 1-year warranty. 72MHz. TOWJ41**

DYNAFLITE™HI-STARTS

DYFP8301 (Standard)

DYFP8302 (Heavy-Duty)

A Dynaflite Hi-Start and 800' of clear launch area are all you

need to send your sailplane rocketing up to 500' in the air!

Easy to lay out and retrieve, Hi-Starts include everything

required for sailplane launches: 100' of UV-stabilized

surgical tubing, injection-molded reel, parachute, steel stake

and tow ring, and nylon tow line. Standard Hi-Start with 1/8"

diameter tubing offers strong, steady power for 2-meter

sailplanes. Heavy-Duty Hi-Start with 3/16" diameter tubing

provides the launch power needed for sailplanes spanning

100" or more.

Great Planes C.G. Precision Aircraft Balancer

™

Accurate balancing makes trainers more stable, low-wings

more agile, and pylon planes move at maximum speed. The

innovative C.G. Machine helps you achieve optimum balance

easily, without measuring or marking–and without the errors

that fingertip balancing can cause. You’ll quickly pinpoint your

plane’s exact center of gravity. Then you’ll know at a glance

whether weight should be added, removed or relocated. The

C.G. Machine works with kits and ARF models of any size and

wingspan. Its slanted wire balancing posts support models

weighing up to 40 pounds. GPMR2400

Cut out or copy the identification tag and put it on or inside

your model.

15

Page 16

BUILDING NOTES

Kit Purchased Date: _______________________

Where Purchased:_________________________

Date Construction Started: __________________

Date Construction Finished: _________________

Finished Weight: __________________________

Date of First Flight: ________________________

FLIGHT LOG

Loading...

Loading...