Page 1

TABLE OF CONTENTS

DIE PATTERNS ...............................................................4&5

ITEMS REQUIRED FOR COMPLETION..............................6

GET READY TO BUILD .......................................................8

BUILD THE TAIL SURFACES .............................................10

BUILD THE FUSELAGE.....................................................13

BUILD THE WING............................................................20

FINAL ASSEMBL Y..............................................................32

FINISHING.......................................................................40

FINAL CONTROL HOOKUPS...........................................46

PREFLIGHT.......................................................................52

FLYING .............................................................................54

FOLLOW THIS IMPORTANT SAFETY PRECAUTION TO

PROTECT YOUR MODEL, YOURSELF & OTHERS.

Your Trainer 40 is not a toy, but rather a sophisticated, working

model that functions very much like an actual airplane. Because

of its realistic performance, the Trainer 40, if not assembled and

operated correctly, could possibly cause injury to yourself or

spectators and damage property.

To make your R/C modeling experience totally enjoyable, we

recommend that you get experienced, knowledgeable help with

assembly and during your first flights. You’ll learn faster and

avoid risking your model before you’re truly ready to solo. Your

local hobby shop has information about flying clubs in your area

whose membership includes qualified instructors.

WARRANTY

Tower Hobbies guarantees this kit to be free from defects in

both materials and workmanship at the date of purchase. This

warranty does not cover an y component parts damaged by use

or modification. In no case shall Tower’s liability exceed the

original cost of the purchased kit. Further, Tower reserves the

right to change or modify this warranty without notice.

In that Tower has no control ov er the final assembly or material

used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the userassembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability

associated with the use of this product, they are advised to

return this kit immediately in new and unused condition to

Tower Hobbies.

READ THROUGH THIS INSTRUCTION BOOK BEFORE BEGINNING

CONSTRUCTION. THIS BOOKLET CONTAINS WARNINGS AND

PRECAUTIONS REGARDING THE USE OF THIS PRODUCT.

2

® ®

TTOOWWEERR TTRRAAIINNEERR 4400

RADIO CONTROLLED MODEL AIRPLANE KIT

INSTRUCTION MANUAL

O

UR ALL-TIME FAVORITE TRAINER

...

N

OW IN KIT FORM

TTR4P03 V 1.0

Wing Span: 55 in.

Wing Area: 618 sq. in. Weight: 5 to 5.5 lb.

Length: 44.5 in. Wing Loading: 18 to 21 oz./sq. ft.

Engine: .40 2-stroke

Entire Contents © Copyright 1998

™

Page 2

3

You can also contact the national Academy of Model Aeronautics

(AMA), which has more than 2,500 chartered clubs across the

country. Through any one of them, instructor training programs

and insured newcomer training are available.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

TEL: (800) 435-9262

FAX: (765) 741-0057

or via the Internet at: http://www.modelaircraft.org

Thank you for purchasing the Tower Hobbies Trainer 40!

The Tower Hobbies Trainer 40 is an excellent trainer model designed

to get you off to a great start in learning to build and fly. After you

learn to fly, the Trainer 40 has enough maneuverability to perform

most aerobatics and provide many hours of flying enjoyment. The

easy construction, great lines and included decals make it easy for

you to build a great-looking model.

The Tower Trainer 40 is designed to fly as well as it looks. Its

thick, flat-bottom wing offers strong lift at slow speeds and great

strength. The computer designed, interlocking structure allows

you to build a straight and true model with confidence-boosting

flight qualities.

Please inspect all parts carefully before starting to build! If any

parts are missing, broken or defective, or if you have any

questions about building or flying this model, please call us at

(217) 398-8970 and we’ll be glad to help. If you are calling for

replacement parts, please look up the part numbers and the kit

identification number (a white sticker on the end of the carton)

and have them ready when calling. Our e-mail address is:

www.productsupport@hobbico.com

PRECAUTIONS

1. You must build the plane according to the plan and instructions.

Do not alter or modify the model, as this may result in an unsafe

or unflyable model. In a few cases the plan and instructions may

differ slightly from the photos. In those instances you should

assume the plan and written instructions are correct.

2. You must take your time to build straight, true and strong.

3. You must use a proper R/C radio that is in first class condition,

the correct engine size and correct components (fuel tank,

wheels, etc.) throughout your building process.

4. You must properly install all R/C and other components so the

model operates properly on the ground and in the air.

5. Y ou must test the operation of the model before the first flight

and each successive flight, to insure all equipment is

operating and to make sure the model has remained

structurally sound. Be sure to check external nylon clevises

often. Replace them if they show signs of wear.

6. You must fly the model only with the competent help of a

well-experienced R/C pilot, if you are not already an

experienced R/C pilot at this time.

4

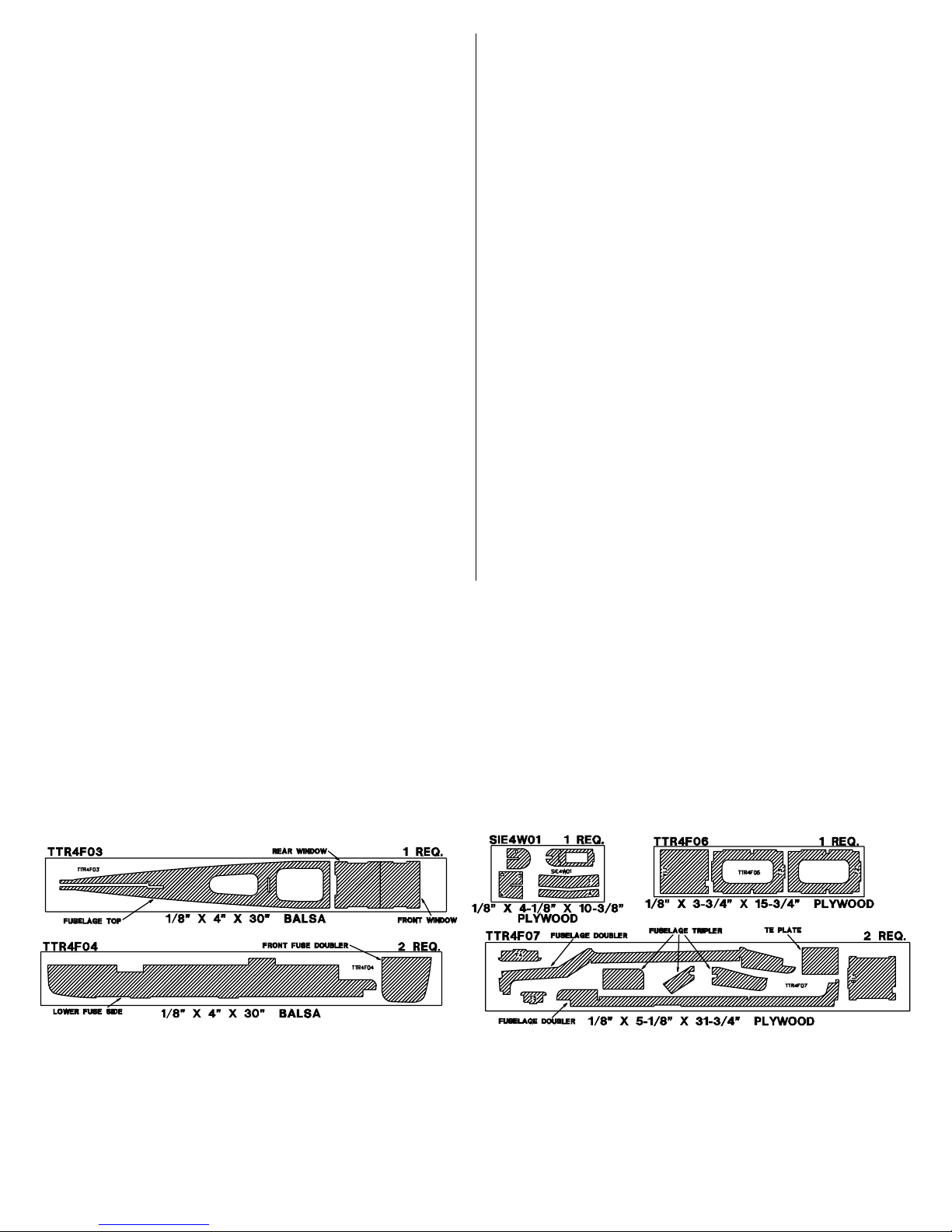

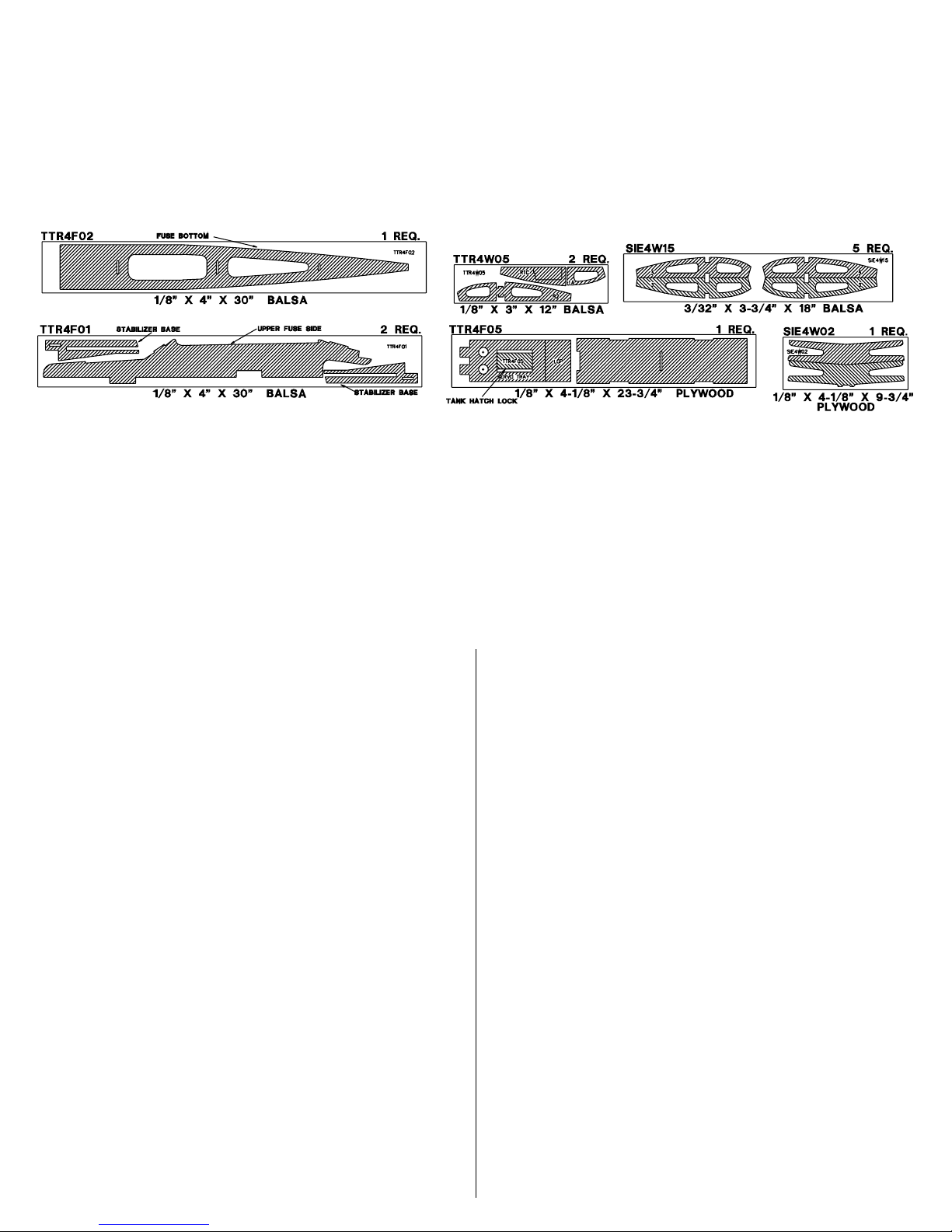

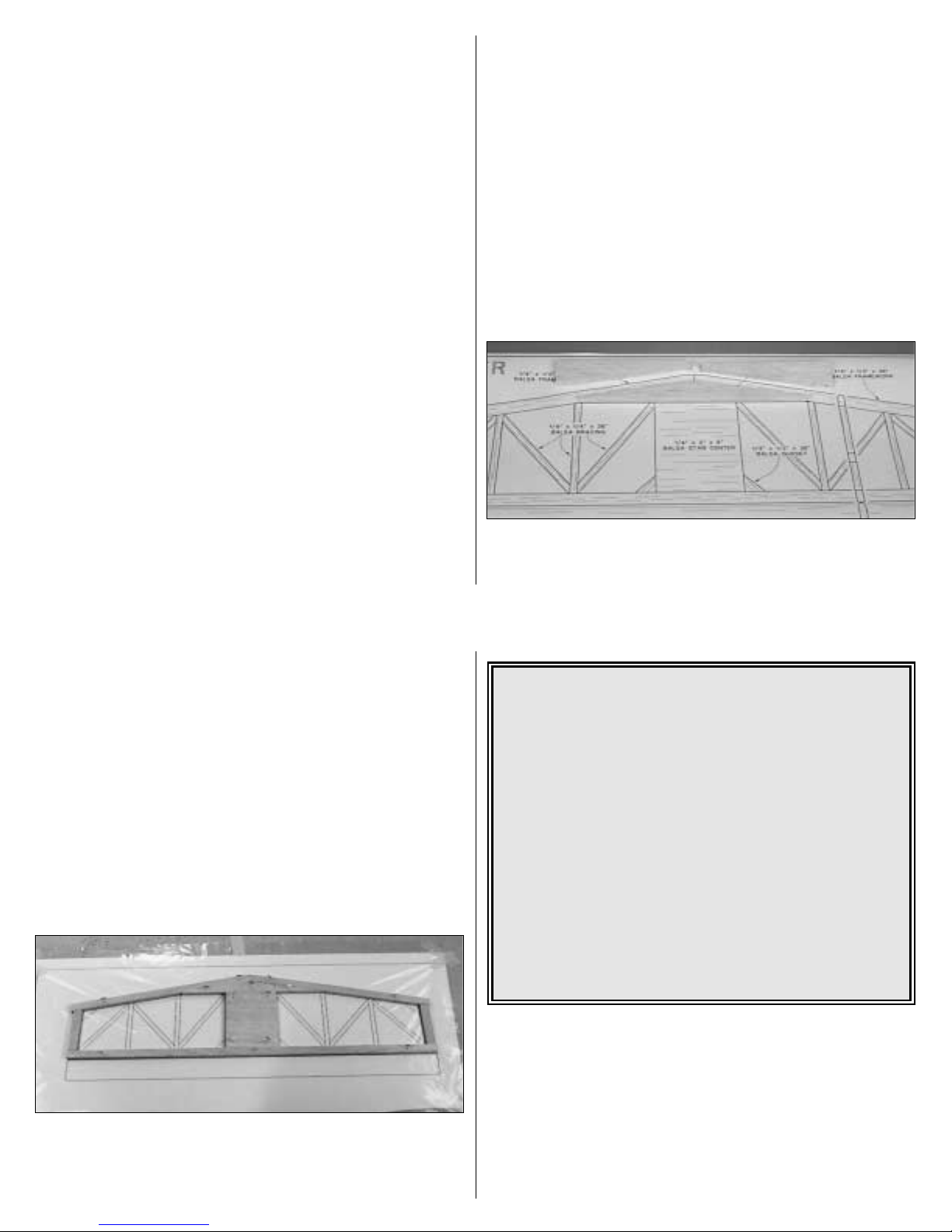

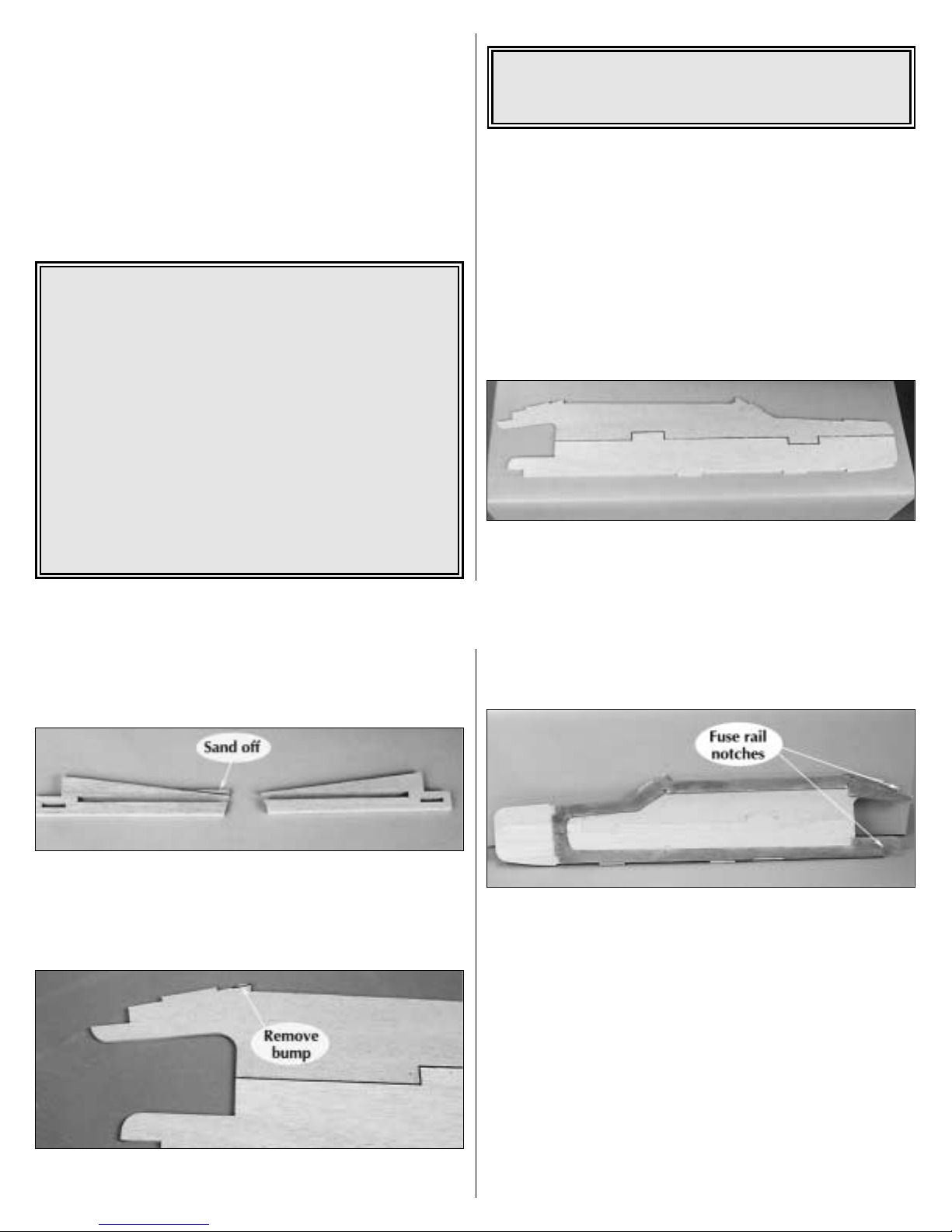

Die Patterns

Page 3

6

5

NOTE: We, as the kit manufacturer, provide you with a top quality

kit and great instructions, but ultimately the quality and flyability

of your finished model will depend on how you build it; therefore,

we cannot in any way guarantee the performance of your

completed model and no representations are expressed or implied

as to the performance or safety of your completed model.

Remember: Take your time and follow the directions to

complete a well-built model which is straight and true.

EARLY IN THE BUILDING SEQUENCE

Engine selection:

There are sever al engines that will work well in the Tower Trainer

40. The following engines will provide the best all-around flight

performance: O. S.®.40FX, Super Tigre®GS .40, Tower Hobbies

.40 or O. S. .52 Surpass (4-stroke). Your choice of a 2-stroke or

4-stroke engine will determine the location of the throttle servo

and pushrod exit.

Note: T he displacement in bold type is the most highly recommended.

However, all of these engines will fly the Tower T r ainer 40.

Selection of wheels

The standard recommended wheels are 2-1/2" for the main and

nose wheels. If you are flying off grass or an uneven surface, you

may wish to use larger wheels than those recommended. The

standard wheels have been tested on grass and work fine, but 3"

wheels would work even better.

“ITEMS REQUIRED FOR COMPLETION”

❍ 4 Channel radio with 4 servos

❍ Engine: .40 - .46 2-stroke or .52 4-stroke

❍ Propeller (Top Flite®Power Point®)

❍ 10 oz. Fuel tank (Great Planes®#GPMQ4104)

❍ 12" Medium fuel tubing (Great Planes #GPMQ4131)

❍ (3) 2-1/2" Wheels (Great Planes #GPMQ4223)

❍ (6) 5/32" Wheel collars (Great Planes #GPMQ4306)

❍ 2-1/2" Spinner (Great Planes #GPMQ4520)

❍ (2) Rolls covering film (TowerKote™)

❍ 1/2" Latex Foam Rubber Padding (Hobbico®# HCAQ1050)

❍ #64 Rubber Bands (Tower Hobbies #TOWQ1220)

❍ Throttle Pushrod (Great Planes #GPMQ3716)

❍ Steering Pushrod (Great Planes #GPMQ3700)

❍ Connector for Throttle (Great Planes #GPMQ3840)

❍ Engine Mount (Great Planes #GPMG1061)

❍ Hardware for engine mount (Great Planes #GPMQ3509)

❍ Screw-Lock connectors (Great Planes #GPMQ3870)

SUGGESTED SUPPLIES AND TOOLS

We recommend Great Planes Pro™CA and Tower Epoxy

❍ 2 oz. CA (Thin) (Great Planes #GPMR6003)

❍ 2 oz. CA+(Medium) (Great Planes #GPMR6009)

❍ 1 oz. CA- (Thick) (Great Planes #GPMR6014)

❍ CA Accelerator (Great Planes #GPMR6035)

❍ 6-Minute Epoxy (Tower Hobbies #TOWR3300)

Die Patterns

Page 4

7

8

❍ 30-Minute Epoxy (Tower Hobbies #TOWR3350)

❍ ProWood glue (Great Planes #GPMR6160, optional)

❍ Hand or Electric Drill

❍ Drill Bits: 1/16", 5/64", 3/32", 1/8", 5/32", 3/16", 1/4"

❍ Sealing Iron (Top Flite #TOWR3250)

❍ Heat Gun (Top Flite #TOWR3200)

❍ Hobby Saw (X-acto®Razor Saw)

❍ Hobby Knife, #11 Blades

❍ Razor Plane (Master Airscrew)

❍ Pliers

❍ Screw Drivers (Phillips and Slot tip)

❍ Round file (or similar)

❍ T-Pins

❍ String

❍ Straightedge with scale

❍ Masking Tape (required for construction)

❍ Sandpaper (coarse, medium, fine grit)*

❍ T-Bar Sanding Block (or similar)

❍ Wax paper or Plan Protector

❍ Lightweight Balsa Filler such as Hobbico HobbyLite

™

❍ Isopropyl Rubbing Alcohol (70%)

❍ Dremel Multi-Pro®or similar (optional)

*NOTE: On our workbench, we have four 11" T-Bar sanders,

equipped with #50, #80, #150 and #220-grit sandpaper. This

setup is all that is required for almost any sanding task. Custom

sanding blocks can be made from balsa for sanding hard-toreach spots. We also keep some #320-grit wet-or-dry sandpaper

handy for finish sanding before covering.

Common abbreviations used in this book and on the plan

Elev. = Elevator

Fuse = Fuselage

LE = Leading Edge (Front of a wing)

Ply = Plywood

Stab = Stabilizer

TE = Trailing edge (Rear of Wing)

" = Inches

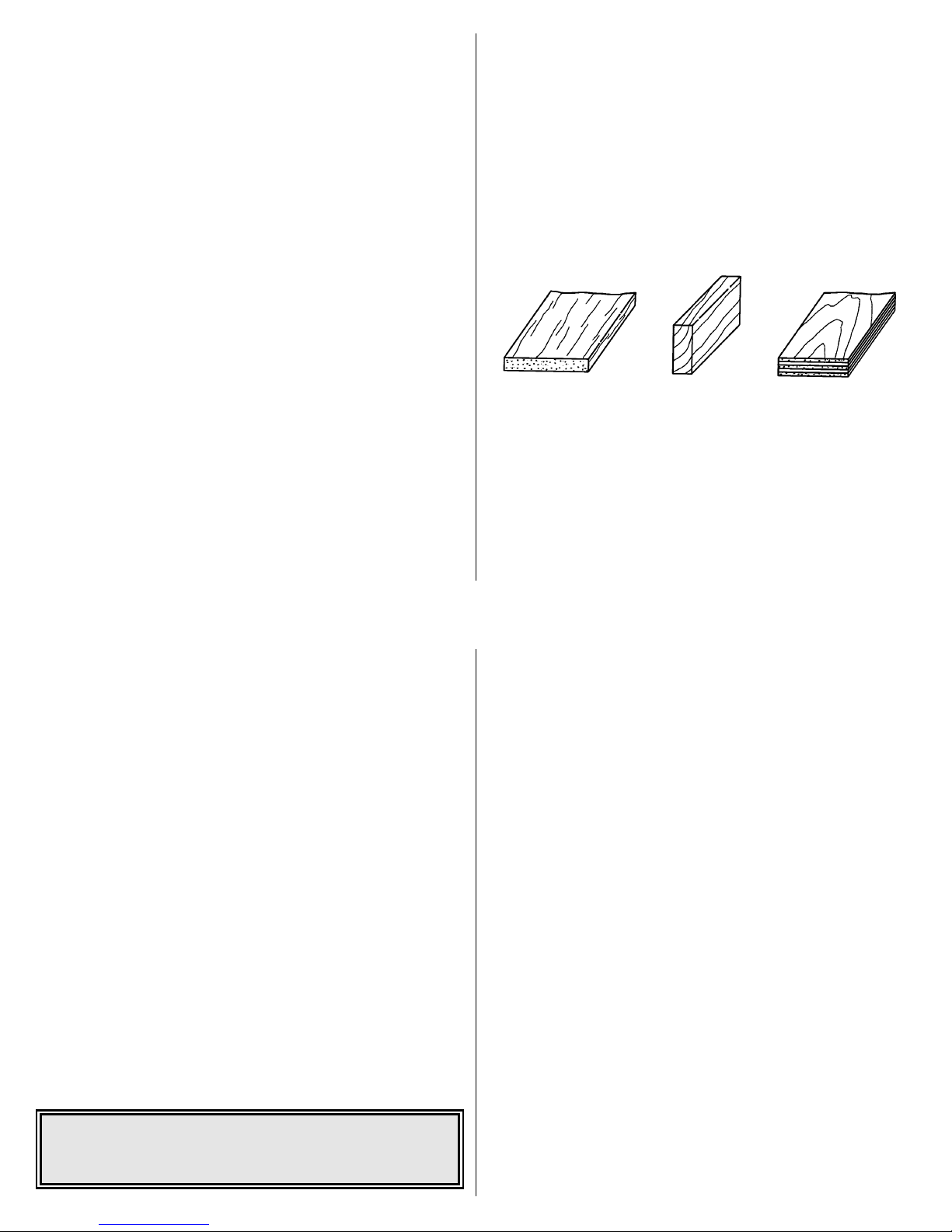

Types of wood

BALSA BASSWOOD PLYWOOD

GET READY TO BUILD

• Unroll the plan sheets. Reroll the plans inside out to make

them lie flat. If you have a small building space, you may fold

or cut the plans to fit onto your building surface.

• Remove all parts from the box. As y ou do, figure out the name

of each part by comparing it with the plans and the parts list

included with this kit. Using a felt tip or ball point pen, lightly

write the part name or size on each piece to avoid confusion

later. Use the die-cut patterns shown on pages 4 and 5 to

identify the die-cut parts and mark them before removing

them from the sheet. Save all leftovers. If any of the die-cut

parts are difficult to punch out, do not force them! Instead, cut

around the parts with a hobby knife. After punching out the

die-cut parts, use your bar sander or sanding block to lightly

sand the edges to remove any die-cutting irregularities.

• As you identify and mark the parts, separate them into

groups, such as fuse (fuselage), wing, fin, Stab (Stabilizer),

and hardware.

NOTES ON USING GLUES

There are two types of glue recommended for building this

model, which are CA and Epoxy.

CA (cyanoacrylate) glue is used for general construction. It is

available in a v ariety of viscosities. We recommend you hav e the

following two types...

Thin CA: Has a viscosity similar to water and is used to glue

together parts fitting together very well and which do not require

repositioning after glue is applied. Thin CA is especially effective

for gluing balsa to balsa. It can be used to glue hardwoods such

as plywood, spruce or basswood, but it is usually necessary to

fillet the joint later with medium CA. Thin CA has the ability to

“wick” into joints. This means it will be drawn into very fine gaps

between parts. This characteristic makes thin CA very useful for

a lot of tasks, such as gluing seams already clamped together or

installing CA hinges. Thin CA usually sets very rapidly, so do not

expect to move parts at all after glue is applied. This rapid

reaction may also produce annoying fumes and heat. Always use

CA glues in a well-ventilated area.

Medium CA: Used in general construction for parts which have

gaps, require slight repositioning or involve hardwoods. Medium

CA can be used to make small fillets between parts in high stress

areas. Medium CA is a very good general purpose glue and many

people use it for the majority of their building. The Tower Trainer

40 uses Medium CA in many areas, so it is suggested that y ou ha ve

a 2 oz. bottle to make sure there is enough to complete the kit.

★★★★ Pro Tip: Zipper top food storage bags are handy to

store your parts as you sort, identify, and separate them into

sub-assemblies.

Page 5

9

Some medium CA glues can be slow to set, especially w hen used to

fill gaps. A product known as C A Accelerator is available to speed

up the curing process. It is sprayed onto the joint after the glue is

applied and chemically reacts with the glue, causing it to set very

rapidly. There are a few precautions when using an accelerator...

Use it in a well-ventilated area. The rapid reaction can release

irritating fumes at a much higher rate than normal. Do not use

CA accelerators with thin CA!

Be careful when using the accelerator around plastics. Certain

accelerators will attack plastics and the vapors may fog clear

canopies. It is best to test the glue and accelerator on a leftover

piece of plastic if one is available.

Using too much accelerator may cause the CA glue to react very

rapidly and literally boil. This will result in a joint with a chalky

white color which is not nearly as strong as a normal joint.

Epoxy is used on high-stress joints requiring strength and vibration

resistance. Epoxy also works well in areas encountering fuel. The

slower cure time allows parts to be clamped, checked and

realigned if necessary before it cures. Epoxy is available in many

different formulas having different cure times. The single best type

of epoxy to have when building your Tower Trainer 40 is one

which sets up in 30 minutes, but you may also find 6-minute

epoxy handy to have around.

NOTES ON SANDING

Use a block or bar sander whenever possible. The flat block will

“ignore” glue and variations in wood hardness and give you a

true and even shape.

Always use fresh, sharp sandpaper. Sharp sandpaper will cut

through glue and hard materials easily, giving an even surface.

Older , dull sandpaper will require more pressure and may gouge

the surface. Now on to building your Tower Trainer 40!

“BUILD THE TAIL SURFACES”

Build the Stabilizer and Elevator

❍ 1. Cut the "Stabilizer/Elevator" section from the fuselage plan

sheet and tape it on your building board. Tape a piece of wax

paper or Plan Protector over the plan.

10

❍ 2. Place the 1/4" x 1" x 10" balsa stick over the portion of the

plan marked "Stab Forward Center," and line up the back edge of

the stick with the straight line. Draw two angled lines where you

will cut this stick. Remove the stick from the plan and cut the

stick along the lines using a hobby knife or razor saw. Straighten

and square the cut edges with a sanding block. Trim the ends

slightly to match the length shown on the plans.

❍ 3. Pin the Stab Forward Center into position on the plans. Test

fit the balsa 1/4" x 3" x 4" Stab Center into place. There should

be no gaps between the center and forward pieces. After fitting,

glue and pin the center to the forward using Medium CA.

❍ 4. Use two 1/4" x 1/2" x 36" balsa sticks to build the outside

framework of the Stabilizer. Start by placing the longest piece

first, working until you are placing the shortest (end) pieces. Glue

each piece together using Medium CA as you proceed.

❍ 5. Cut the corner gussets from the 1/4" x 1/2" balsa stick and

glue them into position.

★★★★ Pro Tip: If you are unfamiliar with "Built-up"

construction, we have found that the following method is

very easy and accurate.

A. Position an uncut stick directly over the plan and pin it

in place.

B. Mark each side of the stick where it ends or butts with

another part.

C. Remove the stick from the building surface and flip it over.

Draw a line between the marks you made previously using

a straight edge.

D. Using a razor sa w, cut as close to the line as possible. T hen,

with your sanding block, true-up the ends to the line. Flip

the part over and pin back in place over the plan.

Page 6

❍ 6. Cut and install the Stab Bracing using 1/4" x 1/4" x 36" balsa

sticks. Note: It is best to start with the straight pieces, then go to

the angled pieces. The alignment of each piece to the plan is not

critical, just as long as it is close and fits snugly into position.

❍ 7. Remove the Stabilizer from your building surface. Examine

and add thick CA glue to any open joints, then use your sanding

block with medium (150-grit) sandpaper to sand both sides of the

Stabilizer framework smooth.

❍ 8. Cut the Elevator from the 1/4" x 1-3/8" x 30" balsa stick. Save

the remaining section for making the Rudder.

❍ 9. Use your sanding block with medium (150-grit) sandpaper

to sand both sides of the Elevator smooth. Round the corners of

both pieces as shown on the plan.

BUILD THE FIN AND RUDDER

❍ 1. Cut the "Fin/Rudder" section from the fuselage plan sheet

and tape it on your building board. Tape a piece of wax paper or

Plan Protector over the plan. Build the frame of the Fin using a

1/4" x 1/2" x 36" balsa stick.

❍ 2. Install the Inner Fr amework of the F in using 1/4" x 1/4" x 36"

balsa. Cut and install the corner gusset from the remaining

1/4" x 1/2" balsa.

❍ 3. Remove the Fin from your building surface. Examine and

add thick CA glue to an y open joints, then use your sanding bloc k

or bar sander with medium (150-grit) sandpaper to sand both

sides of the Fin smooth.

❍ 4. Build the Dorsal Fin from the remaining 1/4" x 1/2" and 1/4"

x 1/4" pieces. Examine and add thick CA glue to any open joints,

then use your sanding block or bar sander with medium

(150-grit) sandpaper to sand both sides of the Dorsal Fin smooth.

11

❍ 5. Use the remaining section of 1/4" x 1-3/8" x 30" balsa to

make the Rudder.

❍ 6. Place the Fin, Dorsal F in and Rudder flat on your work surface

and sand them flat using a sanding block or bar sander and

120-grit sandpaper. Don’t forget to sand both sides smooth. Once

they are sanded, round the corners of the fin, dorsal fin and rudder

to match the plans.

Note: The Dorsal Fin will be glued in place after the Fin is

attached to the fuselage.

Bevel the Elevator and Rudder

❍ 1. Use a smooth ball point pen to draw a centerline along the

leading edge of the Elevator and Rudder.

❍ 2. Refering to the cross sections on the plan, carefully block

sand the elevator and rudder leading edges to a "V" shape. The

centerlines you drew earlier should remain for hinging later.

❍ 3. Using 180-grit sandpaper, round the leading edge and tips

of both the Fin and Stabilizer. Leave the trailing edges square.

INSTALLING THE HINGES

❍ 1. Use a smooth ball point pen to draw a centerline along the

trailing edge of the Stabilizer and Fin. Lay the Fin and Stabilizer on

the plan and mark the hinge locations. Place the Rudder against

the Fin TE and transfer the marks onto the Fin. Place the Elevator

against the Stabilizer and transfer the marks onto the Stabilizer.

❍ 2. Cut the hinge slots on the accurate centerlines which you

previously drew, using a hobby knife or a slotting fork and slotting

hook. (The recommended hinge slotting technique is listed belo w).

12

Page 7

CAUTION!!!: You must use extreme care when cutting hinge

slots with a hobby knife, to avoid cutting yourself! If the balsa

part breaks while you are pushing on the knife, the blade could

go into your hand before you know it! A good precaution is to

wear leather gloves while performing the following steps and

always cut AWAY from yourself.

❍ 3. Insert the hinges into the slots and trial fit the Rudder and

Elevator in place on the Fin and Stabilizer. Do not glue the

hinges until after you have covered the model.

BUILD THE FUSELAGE

Fuse Side Construction

❍ 1. Cut the "Fuselage side view" section from the fuselage plan

sheet and tape it on your building board. T ape a piece of Top Flite

Plan Protector or wax paper over the plan.

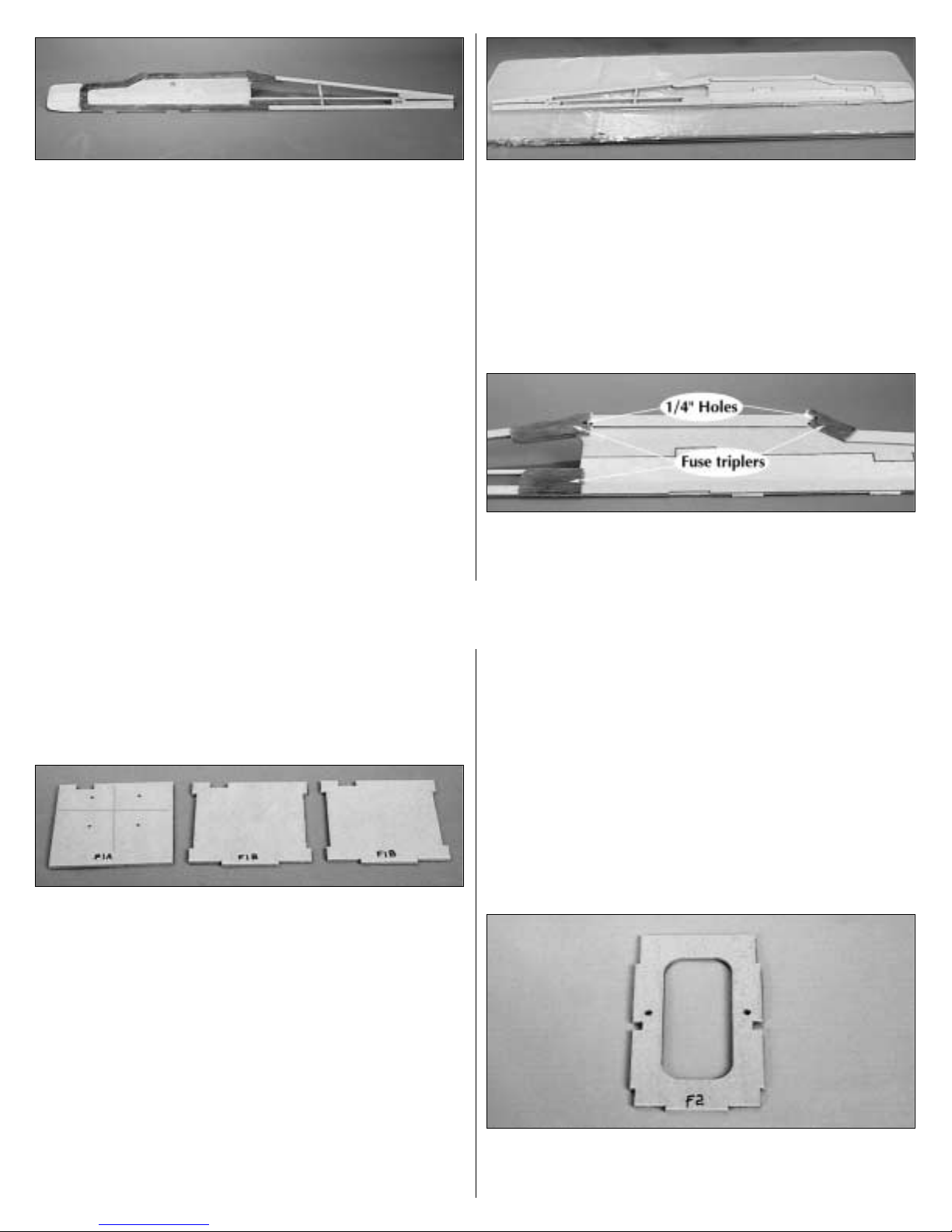

❍ 2. Glue the balsa die-cut 1/8" Upper Forward Fuse Sides to the

balsa die-cut 1/8" Lower Forward Fuse Sides using thin C A. Mark

the inside surface of the fuse sides with the letters 'R' and 'L' to

C. Trial fit the hinge into the slot. If the hinge is difficult to

push in, re-insert the knife and move it back and forth in

the slot a few times to enlarge the slot.

★★★★ Pro T ip: Hinge slotting is a procedure that is required

for every model airplane. We have found that the technique

described below is accurate and fairly easy. Just work slowly

and carefully. Remember: Hobby knives are extremely sharp!

A. Begin by carefully cutting a very shallow slit at the hinge

location. This first cut is to establish your cut in the right

place, so concentrate on staying on the centerline and

don't cut too deep!

B. Make three or four more cuts in the same line, going slightly

deeper each time. As you make these additional cuts, w ork

on going straight into the wood. Continue this process

while "wiggling" the knife handle back and forth until the

blade has reached the proper depth for the hinge.

13

designate the inside of the Right and Left fuselage sides. Be sure

to make a RIGHT and a LEFT fuselage side. Sand both sides of

the fuse sides using 150-grit sandpaper.

❍ 3. Locate the four die-cut 1/8" balsa Stabilizer Bases. Carefully

align and laminate two of the bases together using medium CA to

produce a 1/4" thick base. Repeat the procedure for the

remaining two bases. Sand the area shown in the photo using

120-grit sandpaper.

❍ 4. Use a straightedge to mark a line along the top of both fuse

sides, as there is a slight bump necessary for the die-cutting of the

part. Use a hobby knife and/or bar sander to remove the bump.

(This bump is also on the upper fuse doubler.)

❍ 5. Locate the die-cut 1/8" plywood Upper and Lower Fuse

Doublers. Make sure you are making both a Left and Right fuse

side. Test fit them onto the fuse sides as shown in the photo. Make

any necessary adjustment to allow the doublers to fit accurately

onto the fuse sides. Once all the fitting is done, glue them in

position using Thin CA. Make sure to make both a left and right

set. Sand the notches for the balsa fuse rails to provide a smooth

glue surface.

❍ 6. Place the Right Fuse Side onto the fuselage plan and pin it

in position. (The doubler should be facing away from the plan

sheet). Pin the Stabilizer Base into position on the plans.

❍ 7. Use two of the 1/4"x 1/2" x 24" balsa sticks to make the upper

and lower Fuse Rails. Use medium CA to glue them into position.

Trim the excess extending past the Stabilizer Base.

14

Page 8

❍ 8. Using a 1/4" x 1/4" x 36" balsa stick, make the Center

Stringer. Use medium CA to glue it into position. Using leftovers

saved from the assembly of the Fin and Stab, cut the center

supports and glue them into position. Position the center supports

as accurately as possible, as the installation of the formers as well

as the top and bottom of the fuse depends on their locations.

❍ 9. Once the glue sets, remove the Fuselage Side from your

building surface. Examine and add thick CA glue to any open joints,

then use your sanding block or bar sander with medium (150-grit)

sandpaper to sand both sides of the Fuselage Side smooth.

❍ 10. Place the Right Fuse Side underneath the wax paper. (The

side doesn’t have to align with the plans for this step.) The

doubler should be facing away from the wax paper or plan

protector . The remaining Fuse Side will be built directly on top of

our completed side to insure accuracy.

❍ 11. Place the Left Fuse Side directly on top of the Right Fuse

Side, carefully aligning them together. Use T-pins to lock the two

sides together. Repeat the procedure for the Stabilizer Base.

❍ 12. Make the Fuse Rails for the Left Fuse Side using the same

technique from the right side. The Left Fuse Side must match the

Right as closely as possible, or the fuselage will not be straight

when you are done. Once all the parts are cut and fit, use

Medium CA to glue them into position.

❍ 13. Once the glue sets, remove the Left Fuselage Side from the Right

Fuselage Side. Examine and add thick CA glue to an y open joints, then

use your sanding block or bar sander with medium (150-grit)

sandpaper to sand both sides of the Left Fuselage Side smooth.

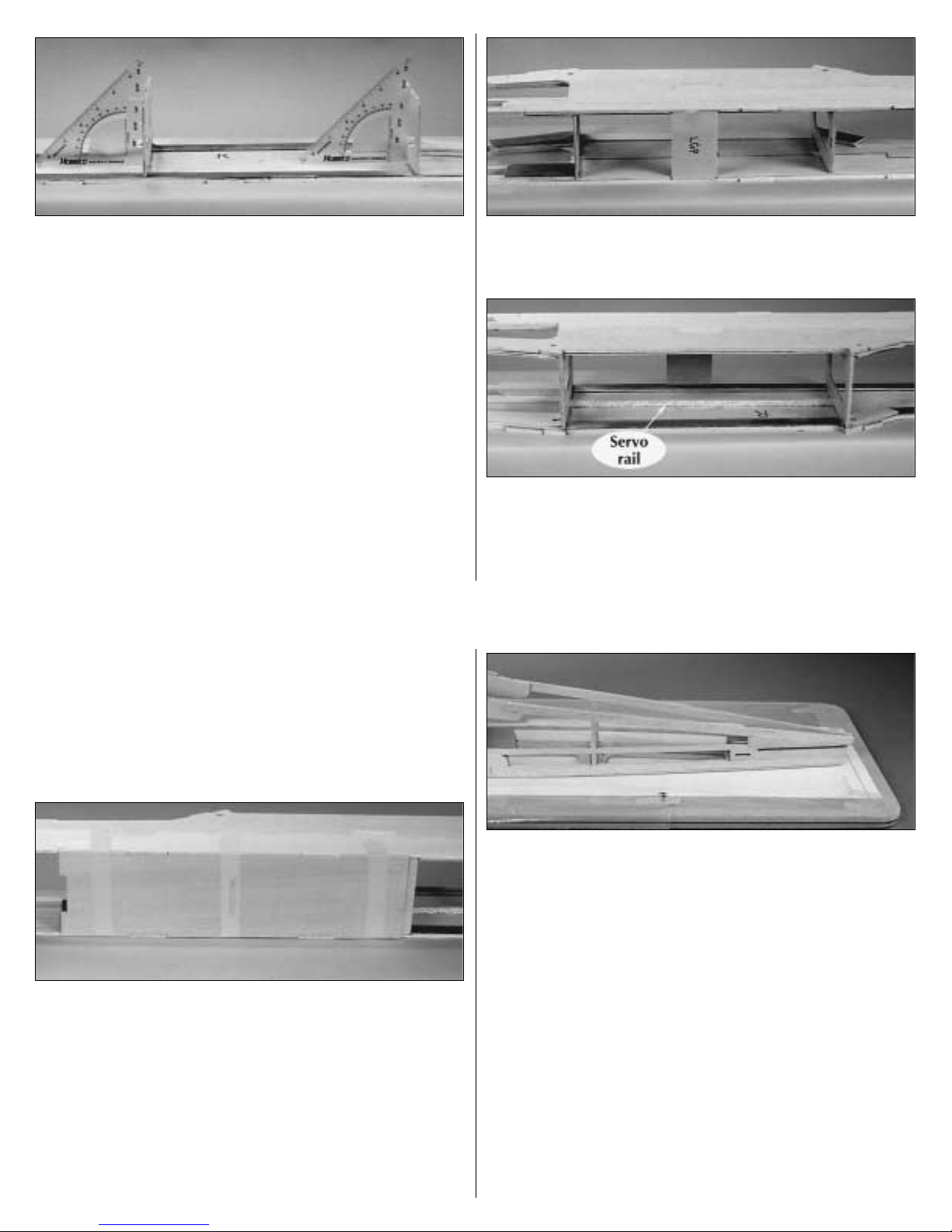

❍ 14. Locate the three fuselage triplers and glue them in their proper

locations on the inside of the fuselage. Make sure the alignment of

the triplers doesn’t interfere with the notches for the formers.

15

❍ 15. Drill 1/4" holes as shown through the fuselage sides for the

wing dowels using the notches in the upper triplers for alignment.

Carefully sand the bottom edges of the fuselage sides flat to provide

a good surface to glue the bottom of the fuse into position.

Fuse Structure Assembly

❍ 1. Locate the die-cut 1/8" plywood F1A Former and the two

die-cut 1/8" plywood F1B Formers. Center the F1A Former on the

F1B Formers with the punch marks visible. The notches of all

formers will align when positioned correctly. Use the plans to

position the formers. Use 30-minute epoxy to glue them together.

Clamp or tape the firewall formers together until the glue sets. You

should have used enough epoxy so it will "ooze" out between the

formers. This excess epoxy can be cleaned up before it cures using

a paper towel dampened with rubbing alcohol.

Note: For the following steps, refer to the firewall cross section

drawing on the fuselage plans. At this point you must know which

engine and mount you will use. If you are using the recommended

engine and mount, the punch marks on F1A will be in the correct

locations. If you are using a different engine or mount requiring

different bolt locations, you will need to determine the locations

for your installation. To determine the center of the mount, draw

lines on the firewall as shown on the plan and in the previous

photo. Position your engine mount so it is centered on the lines.

Mark the locations for your mounting bolts. Locations for the nose

gear and throttle pushrods will be determined the same way for

any engine/mount combination.

❍ 2. If you are using the recommended mount, drill the four

punch marks in F1A with a 3/16" drill.

❍ 3. Gently tap four 6-32 blind nuts into the back (F1B) side of

the firewall. Carefully apply a small drop of Thin CA to the

perimeter of the flange on each 6-32 blind nut.

❍ 4. Locate the die-cut 1/8" plywood Former F2 and drill 3/16"

holes at the punch marks. Use the Former F2 cross section on the

fuselage plan sheet to confirm these locations.

16

Page 9

❍ 5. Test fit 1/8" plywood Former F2 in place on the Right Fuse

Side. Press it down into its slot and use a 90 degree triangle to

keep it perpendicular to the fuse side. Glue it in place with

Medium CA.

❍ 6. Test fit the die-cut 1/8" plywood Former F3 in place on the

Right Fuse Side. Press it down into its slot and use a 90 degree

triangle to keep it perpendicular to the fuse side. Glue it in place

with Medium CA.

❍ 7. Position the Left Fuselage Side onto the formers. Use

Medium CA and glue the fuse side to the formers.

❍ 8. Test fit the die-cut 1/8" plywood Landing Gear Plate (LGP).

Once satisfied with the fit, glue it with 6-minute epoxy.

❍ 9. Cut the remaining 1/4" x 1/4" x 36" balsa stick into two 12"

pieces to be used as the Servo Rails. Position the Servo Rails so

they are flush with the aft edge of the main fuse side. They will

extend forward of Former F2 when installed. Wick Thin CA along

the edges of the rails and fuse sides to glue them in place.

17

❍ 10. Cut the "Fuselage Top V iew" section from the fuselage plan

sheet and tape it on your building board. Tape a piece of wax

paper or Plan Protector over the plan.

❍ 11. Locate the die-cut 1/8" plywood Forward Fuse Bottom.

Tape the Forward Fuse Bottom onto the fuselage. Set the fuselage

assembly upright (in its normal position) on the waxed paper.

With everything in its proper place, apply thin CA glue to all the

joints, around the formers and along the bottom. Keep checking

the parts fit and alignment as you glue. Wait a minute for the glue

to set, then apply thick CA to the joints to make sure a good bond

exists, especially in the joints that do not fit perfectly.

Note: The use of CA accelerator will be helpful when using thick

CA to fill any large gaps.

❍ 12. Locate the die-cut 1/8" balsa Aft Fuse Bottom and pin it

over the top view. Carefully align the fuselage sides and glue the

LGP to the front of the die-cut 1/8" balsa Fuse Bottom with

Medium CA. Use weights and/or pins to hold the fuse sides in

position. Place one die-cut 1/8" plywood Former F4 and one

die-cut 1/8" plywood Former F5 in their respective positions

against the Aft Fuse Bottom.

❍ 13. Pull the fuse sides against Former F5. The fuselage sides

should be centered on the bottom sheet. Press the Fuselage Sides

down tightly against the sheet and snug against the former. Press

Former F5 tightly against the Stabilizer Base. Use Medium CA to

glue the Fuse Sides to the Fuse Bottom and Former F5.

❍ 14. Pull the fuse sides against Former F4. The fuselage sides

should be centered on the bottom sheet. Press the Fuselage Sides

down tightly against the sheet and snug against the former. Press

Former F4 tightly against the Balsa Center Support. Use Medium

CA to glue the Fuse Sides to the Fuse Bottom and Former F4.

18

Page 10

❍ 15. With Former F4 and Former F5 glued in position, apply

thin CA glue to all the joints, around the formers and along the

bottom. Keep checking the parts fit and alignment as you glue.

Wait a minute for the glue to set, then apply thick CA to the joints

to make sure a good bond exists, especially in the joints that do

not fit perfectly.

Note: The use of CA accelerator will be helpful when using thick

CA to fill any large gaps.

❍ 16. Place the remaining Former F4 and Former F5 into

position inside the fuselage. Pull the fuse together against the

formers and tack glue them into position with Thin CA.

❍ 17. T est fit the die-cut 1/8" balsa Fuse T op into position, making

sure the slot for the Rudder Pushrod Exit is on the left (looking

from the back to the front). Once satisfied with the fit of the fuse

top, remove it and run a bead of Medium C A along the top of the

Upper Fuse Rails from the front of the rail to in front of Former

F5. Place the Fuse Top back into position. After the CA has cured,

remove the fuse from the building board and run a bead of

Medium CA along the seam where the sides meet the fuse top.

Note: The section from F5 to the tail of the fuselage will be glued

after the Fin has been installed.

19

❍ 18. Test fit the Firewall Assembly into position. Make sure it is

fully seated against the fuse doublers. Remove the firewall and

use 30-minute epoxy to glue it in position. Check the firewall

periodically to make sure it remains pressed tight against the

fuse doublers.

❍ 19. Position the Main Landing Gear on the bottom of the fuse,

using the plans as reference. Place one of the Landing Gear

Straps onto the gear and mark the location of only one of the

holes. Drill the mark using a 1/16" drill bit, then secure the strap

with a #2 x 3/8" Sheet Metal Screw.

❍ 20. Measure the distance from each tip of the Main Landing

Gear to the tail of the fuse. Adjust as necessary to make both

measurements equal. Once the gear is in position, place and

mark the locations for the remaining three Landing Gear Straps.

Drill 1/16" holes at the marks and secure the Main Landing Gear .

In total, you should have eight #2 x 3/8" Sheet Metal Screws and

four Landing Gear Straps. The Main Landing Gear may be

removed until after covering.

❍ 21. Use Medium CA to glue the front fuse doublers to the

inside of the engine compartment.

BUILD THE WING

Note: The Tower Trainer 40 wing, much like the fuselage, is

designed with simplicity and ease of building in mind. Always

remember to test fit parts before using glue to make any

adjustments for the best possible fit.

20

Page 11

❍ 1. Cut the “Right W ing Panel” section from the wing plan sheet

and tape it on your building board. Tape a piece of wax paper or

Plan Protector over the plan.

❍ 2. Assemble the Wing Guide Tool from the plywood die-cut

1/8" pieces marked "G". The "0" degree (from vertical) side of the

tool can be used to check the ribs to see if they are vertical. The

"4" degree side will be used later. Do not glue the tool together.

❍ 3. The shaped balsa Leading Edges and Trailing Edges are joined

by a thin layer of balsa. These are cut apart in one of two ways –

Either break the pieces apart and clean up the rough edges with a

sanding block or carefully run a knife down the edge between the

parts to cut them cleanly apart.

❍ 4. Remove the die-cut 3/32" balsa Wing Ribs R-2, R-3 and the

die-cut 1/8" balsa Wing Ribs R-1 from the die-cut sheets.

❍ ❍ 5. Use the criss-cross pin tec hnique shown in the illustr ation

to pin a 3/8" x 3/8" x 30" balsa Spar over its location on the plan.

Pin the Bottom Spar in 3 or 4 places.

❍ ❍ 6. Slide Ten 3/32" balsa R-3 Wing Ribs into place on the

Bottom Spar.

❍ ❍ 7. Place the shaped balsa Leading Edge against the front of

the ribs and pin it in place.

21

❍ ❍ 8. Place the shaped balsa Trailing Edge against the rear of

the ribs and pin it in place.

❍ ❍ 9. Lay two pieces of leftover 1/16" balsa (Cut 1/4" off one

end of the 1/16" x 3" x 14-7/8" Shear Web material) near the

Leading and Trailing Edges under the location of Wing Rib R-2

(this will shim up the rib to allow for the sheeting later). Place

Wing Rib R-2 into position as shown on the plan.

❍ ❍ 10. Insert the 3/8" x 3/8" x 30" Top Spar into the notches in

the ribs.

❍ ❍ 11. Make sure all the R-3 Wing Ribs and the Leading and

Trailing Edges are resting on the flat work surface. The “Guide

Tool” is used to check that the ribs are vertical.

❍ ❍ 12. Apply Thin CA to all the joints involving the Ribs, Spars,

Leading Edge and Trailing Edge.

Note: When gluing the spars to R-2, make sure the spars are

centered between the dihedral brace notches in R-2.

❍ ❍ 13. Remove the pins holding the spar in place but leave the

panel pinned flat on the board by the leading and trailing edges.

❍ ❍ 14. Cut the shear webs from the 1/16" x 3" x 14-7/8" balsa

sheet. Use the dimensions shown on the plan to assist in making

shear webs.

22

Page 12

❍ ❍ 15. With the panel held flat on the table, use Medium CA

to glue the balsa Shear Webs to the Spars, between the R-3 ribs.

Note: The function of the shear webs is to keep the spars from

collapsing. They will not touch or be glued to the ribs. They

should be thoroughly glued to the spars.

❍ ❍ 16. Make sure the wing panel is still lined up properly over

the plan.

❍ ❍ 17. Position the "4" degree side of the guide tool exactly

where the end of the bottom spar is shown on the plan. Use a pen

to mark an angled line on the top and bottom spars. (The top spar

will be slightly shorter than the bottom spar.)

❍ ❍ 18. Use the guide tool to mark angled lines on the leading and

trailing edges from where their bottom ends are shown on the plan.

❍ ❍ 19. Unpin the wing and remove it from your building

surface. Use a razor saw to cut off the spars and the leading and

trailing edges at the marked angles. A bar sander is used to "clean

up" the angled ends of the spars, leading edges and trailing edges.

23

❍ ❍ 20. Use a razor saw and a bar sander to trim the tip ends of the

spars, leading and trailing edges flush with the outermost R-3 rib.

❍ ❍ 21. Carefully cut a 2-1/2" long piece off the 17/32" x 1-1/2"

x 30" tapered balsa aileron stock.

❍ ❍ 22. Glue the 2-1/2" long piece of aileron stock to the wing

trailing edge at the tip as shown on the RIGHT WING PANEL

drawing. (This is done to the right and left wing.)

❍ ❍ 23. T rim and sand the aileron stock flush with the tip of the wing.

❍ ❍ 24. Cut the 3/16" x 2" x 24" balsa wing tip material into two

12" lengths. Hold the wing tip up to the end of the wing. Glue the

wing tip to the wing.

❍ ❍ 25. Saw or carve the wing tip to the rough shape of the

wing, leaving it slightly oversized. Block sand it to final shape.

HINT: Put masking tape over the surrounding structure when

24

Page 13

sanding items such as the wing tips to protect areas you don’t

want sanded.

Repeat steps 5-25 over the Left Wing Panel plan to build the

Left Wing.

JOIN THE WING

❍ 1. Punch out the plywood die-cut 1/8" Dihedral Braces. Put

reference marks at the center of the braces.

NOTE: The dihedral brace with the “lock bumps” for the aileron

servo tray is positioned on the aft side of the spars.

❍ 2. Test fit the two wing panels together with the dihedral braces

in place. Check to see the spars, leading edges and trailing edges

match up well. Make adjustments if necessary.

The dihedral angle (the angle at which the wings are "bent up")

is not considered critical. This angle is established by aligning

the spars with the dihedral braces.

❍ 3. Look ahead at the next two photos of the joined wing to see

the position of the joiners. Spread a layer of 30-minute epoxy

onto the matching surfaces of the Dihedral Braces and the left

wing panel spars. Align the dihedral braces with the top and

bottom edges of the spars. Clamp or tape the braces in position

until the glue sets. You should have used enough epoxy so it will

“ooze” out between the dihedral braces and spars. This excess

epoxy can be cleaned up before it cures using a paper towel

dampened with rubbing alcohol.

Note: If there are any small gaps between the ends of the spars or

LE’s or TE’s, do not be overly concerned. They will not

significantly weaken the structure. After the wing joining process

is complete, fill them with leftover balsa and medium CA glue.

25

❍ 4. When the epoxy has cured, apply a layer of epoxy to the

Dihedral Braces and the right wing spars. Slide the two wing

panels together and carefully align the spars with the dihedral

braces. Use enough epoxy so it will “ooze” out between the

dihedral braces and spars. Clamp or tape the braces in position

until the glue sets. Clean up any excess epoxy using a paper

towel and rubbing alcohol. After the epoxy is cured, if any of the

dihedral brace joints do not appear to be thoroughly glued, apply

an extra fillet of epoxy to them.

❍ 5. The die-cut 1/8" plywood Forw ard Center Brace (F) is glued

in next. It should be centered vertically on the leading edge so

the 1/16" balsa top and bottom center sheeting will lap onto it.

Sand as necessary to get the 1/16" gap at both the top and

bottom of the LE. Align the left and right leading edges and glue

the brace in place with CA or epoxy.

26

Page 14

❍ 6. The plywood die-cut 1/8" Aft Center Brace (A) is centered

on the trailing edges. Align the left and right trailing edges and

glue the brace in place with CA or epoxy.

❍ 7. Glue the two balsa die-cut 1/8" Wing Rib R-1A’s (1A)

together to form a 1/4" thick part. Glue the two balsa die-cut 1/8"

Wing Rib R-1C’s (1C) together to form a 1/4" thick part.

❍ 8. Use Medium C A to glue Wing Rib R-1C in place. It is centered

to allow for the top and bottom center section sheeting as shown

in the cross-section drawing beside the right wing panel.

❍ 9. Put rib R-1A in place as shown in the cross section. Align the

bottom of R-1A to the forward center brace. Glue it in position with

Medium CA.

❍ 10. Cut out and remove the remaining piece of balsa from

across the servo bay in the bottom side of R-1C using a hobby

knife or razor saw.

27

❍ 11. Snap the die-cut 1/8" plywood Aileron Servo Tray Support

in place as in the photo. Use medium CA to glue in the Servo T r ay

Support while using the servo tray to hold it in position. Do not

glue the servo tray in at this time.

❍ 12. Bevel the root ends of the tapered and grooved balsa

Trailing Edge Center pieces so they will meet properly at the left

and right wing junction. Mark the parts so you can identify the

bottom of the left and right parts.

❍ 13. Holding the Trailing Edge Center Pieces over the right

wing panel plan, mark where the torque rod will exit the bottom

of the trailing edge. The root cross-section gives a view of the

cut-out. Cut a notch in the trailing edge center pieces to allow the

torque rod to exit.

28

Page 15

❍ 14. Hold the trailing edge center pieces up to the wing.

Transfer the notch locations onto the wing. Use a knife to cut

small notches into the wing TE.

❍ 15. Use coarse sandpaper to rough up the nylon tube on the bent

wire Aileron Torque Rod. Apply a small amount of Vaseline to the

ends of the nylon tube to keep glue from wicking into the bearing.

❍ 16. Assemble the parts as shown in the photo. Apply a small

amount of thin CA to glue the torque rod bearing tubes to the

balsa trailing edge center pieces.

❍ 17. Use medium CA to glue the trailing edge center assemblies

to the trailing edge of the wing. Do not get glue in the bearing tube.

❍ 18. T rim the left and right tapered aileron stock pieces to length

so they fit between the wing tip and the center pieces with about

a 1/16" gap at each end.

29

❍ 19. Draw a center line on the LE of the ailerons and the TE of

the wing. Position the aileron against the TE and mark the

location where the torque rod would enter the aileron. Carefully

drill a 3/32" hole into the aileron to the depth shown on the plan.

Use a hobby knife to cut a groove in the front of the aileron for

the aileron torque rod.

❍ 20. Use the plan as a reference to mark the location of the

hinges. Make slots for the hinges using the same technique as you

did for the Elevator and Rudder.

❍ 21. Use a razor plane (if available) and a bar sander to sand

the front edge of the ailerons to a “V” shape to match the cross

section on the plan.

SHEET THE WING CENTER SECTION

❍ 1. Locate the balsa 1/16" x 3" x 36" Wing Sheeting. Begin by

sheeting the bottom of the wing center section. Start at the rear , and

work toward the leading edge. The sheeting will butt against the

first R-3 wing rib and be positioned halfway onto the R-1 ribs.

Work slowly to get the best fit of the pieces. Start with slightly

oversize pieces, as you can always cut them smaller. Remember to

trim a slight notch for the servo tray brace. Glue the sheeting into

position using thin CA, wicking it along the joints of the sheets.

30

WRONG RIGHT

Page 16

❍ 2. Sheet the bottom of the other wing panel in the same manner .

❍ 3. Draw a line connecting the sides of the servo tray mounts

and use a sharp hobby knife to remove the sheeting to allow for

the installation of the servo.

❍ 4. Cut a couple of leftover 1/16" sheets and glue them inside of

the wing as shown, to support and strengthen the sheeting around

the servo cut out.

❍ 5. Using the remaining sheet of 1/16" x 3" x 36" balsa, sheet

the upper side of the wing. Sheet from the front (LE) to the rear

(TE). Again, work slowly to make sure all the pieces fit well with

the least amount of gaps. R-3 may be slightly higher than the

leading edge. Just glue the sheeting even with the LE and we will

sand everything smooth later.

❍ 6. Use leftover balsa to fill areas where there may be large

openings or gaps. An example would be at the ends of the

dihedral braces and the R-3 ribs. Using balsa will mean using less

filler later.

31

FINAL ASSEMBLY

❍ 1. Insert the 1/4" x 5-1/8" Hardwood Dowels into the holes

drilled earlier during the fuselage assembly. The holes can be

enlarged in the fuselage with a round file or drill bit if the fit is

too tight.

❍ 2. Test fit the balsa die-cut 1/8" Front and Rear Windows into

position. Sand as necessary to achieve the best fit. Glue the

windows using medium CA.

❍ 3. Align the wing and attach it with two #64 rubber bands. Use

care not to crush the trailing edge of the wing during this process.

Fit the wing on the fuselage wing saddle. Trim the aft edge of the

wing trailing edge at the center with a sanding block if necessary

for a good fit.

32

A

A

Page 17

MOUNT THE HORIZONTAL STABILIZER

❍ 1. Attach the wing to the fuse (for reference) and slide the

Stabilizer into its slot. Center the Stabilizer left and right in the slot.

Hold a string (with one end attached to a pin centered at F-1) out

to a wing tip. Put a piece of tape on the string to mark the

intersection of the string and the Stabilizer tip. Swing the string over

to the other Stabilizer tip and check to see if the distances are the

same (see diagram). Make slight adjustments to the angle of the

Stabilizer until the distances from F-1 to the tips are equal.

❍ 2. Stand back 8 to 10 feet and view the model from the rear.

The stab tips should be equally spaced below the level of the

wing. If not, lightly sand one side of the stab slot to correct the

problem. Work slowly and check the alignment often. Also, the

trailing edge must be flush with the aft edge of the fuse.

❍ 3. When the alignment looks good, use plenty of 30-minute

epoxy on the bottom of the Stabilizer to securely glue it to the

Stab Base. Note: Do not glue the top of the Stabilizer to the fuse

sides. Hold the Stabilizer in position with pins through the sides

of the fuse while the epoxy cures. Remove any excess epoxy on

the outside of the fuselage with a paper towel dampened with

rubbing alcohol before it cures.

33

MOUNT THE VERTICAL FIN

❍ 1. Test fit the Fin into the slot in the top of the fuselage. Slide

the Fin forward until the leading edge of the Fin is against Former

F5. Check the alignment of the Fin with the centerline of the

Fuselage. A straightedge against one side of the Fin can be used

to check alignment. Make adjustments to the slot if necessary.

Pull the Fuselage Top against the Fin. Check the alignment of the

Fin to make sure it remains at a 90 degree angle to the Stabilizer

and also in alignment with the centerline of the Fuselage. Trim

the slot for the Fin in the Fuselage Top as necessary to prevent an y

alignment changes in the Fin.

❍ 2. Use 30-minute epoxy to glue the Fin in position. Apply epoxy

to both the top of the Stabilizer as well as the bottom edge of the

Fin. Insert the Fin until it touches the Stab. Check the alignment of

the Fin to the Stab with a triangle, then secure it in position with

masking tape until the epoxy has cured. Remove any excess epoxy

with a paper towel and rubbing alcohol before the epoxy cures.

Pull the fuse sides against the fin and pin them securely to the fin.

Continually check the alignment of the Fin to the Stab and fuselage

to make sure it doesn’t shift as the epoxy cures.

34

T-PIN

B

A

A=A

B=B

B

A

Wing/Stab Align

STRING

STRING

EQUAL MEASUREMENTS

Page 18

❍ 3. Test fit the Dorsal Fin into position in front of the Fin as shown.

The Dorsal Fin should fit flush against both the Fuselage Top and Fin.

Sand as necessary to provide for a good fit of the Dorsal Fin. Use a

straightedge to make sure the Dorsal Fin is aligned with the Fin. Glue

it to the Aft Fuselage Top and Fin as shown using Medium CA.

❍ 4. Apply Medium C A to any remaining Fin, Stab and Fuselage joints

that are not thoroughly glued. Be sure to flip the fuselage over and

check the joints on the bottom side in addition to those on the top.

❍ 5. Sand the joints at the back of the fuselage smooth. F or a nice

touch, slightly round all the corners of the fuse.

MOUNT THE ENGINE

❍ 1. Temporarily bolt the engine mount to the firewall using four

6-32 x 1" screws with #6 flat washers. Don't tighten the screws

completely until after the engine has been positioned.

Note: You will need your engine for the following steps. From

here on it is a good idea to plug the holes in your engine so balsa

dust cannot get in. Stuff a piece of paper towel into the exhaust

and carburetor to seal them off.

❍ 2. Remove the needle valve from your engine. Position the

engine on the engine mount and adjust the engine mount halves

until the engine mounting lugs will sit flat on the rails. Position

the mount so the firewall centerline is centered between the

"tick" marks on the mount. Tighten the screws to hold the mount

firmly in position against the firewall.

❍ 3. Mount the spinner backplate on the crankshaft of your

engine. Position the engine so that the spinner backplate is 3-3/4"

from the firewall. Carefully mark the engine mounting holes on

the rails with a sharpened piece of wire or a pencil.

NOTE: If installing a 4-stroke engine, the engine may be forward

of the recommended position to allow for the choke mechanism.

This is acceptable and will not cause a balance problem.

35

❍ 4. Remove the engine and engine mount from the fuse. Use a

center punch or sharpened nail to "dimple" the marks on the rails,

then drill a 3/32" hole through the rails at each punch mark. If

you have access to a drill press, this is the best tool for the job.

However, if you are using a hand-held electric drill, try to keep

the bit perpendicular to the rails.

❍ 5. Install a threaded ball stud in the bottom hole of the

carburetor arm of your engine and secure it with a 0-80 nut and

a drop of epoxy or thread locking compound. Fasten the engine

to the mount with four #4 x 5/8" screws. Hint: Add a drop of

household oil to the #4 sheet metal screws to make them a little

easier to screw into the mount.

❍ 6. Carefully and neatly cut away some of the fuselage side so

you can reach the needle valve if necessary. A Dremel®tool with

a sanding drum works well for this.

❍ 7. Use the same procedure to remove some of the fuselage

side to clear the muffler. There should be approximately 1/8"

clearance between the muffler and the fuselage.

NOTE: The THROTTLE PUSHROD location will vary, depending

on the engine used. Plan your installation carefully!

❍ 8.With the engine attached to the mount, plan the throttle

pushrod routing. The pushrod should be located as close as

possible to the fuse side (to allow room for the fuel tank) and the

guide tube should not have any tight bends. Drill a 3/16" hole in

F-1 for the throttle pushrod guide tube.

❍ 9. Cut a piece of tubing to be used for the throttle pushrod

guide tube. It should extend 1/2" past the firewall and 1/2" aft of

F-2. Temporarily install the throttle guide tube through the holes

in the firewall and F-2.

★★★★ Pro Tip: Some modelers prefer to secure the engine

to the mount with machine screws (not supplied) because

they are easier to screw in. The screws recommended for this

are 4-40 x 3/4". Use a #48 drill bit (3/32") to drill the holes,

then tap the threads with a 4-40 tap.

36

Page 19

❍ 10. From another piece of outer pushrod tube, cut the nose

steering guide tube. It should be flush with the front of the

firewall and extend 1/2" aft of F-2. Temporarily install the nose

steering guide tube in the firewall and F-2.

❍ 11. Cut 14" from a threadedend of a 36" threaded wire pushrod

(after cutting you should have a 14" long piece of wire threaded at

one end and a non-threaded piece 22" long). The threaded end

wire is for the throttle and the non-threaded piece is for the nose

wheel steering. Screw a ball link about 14 full turns onto the

threaded pushrod wire. Save the steering pushrod for later.

❍ 12. Insert the throttle pushrod through the pushrod tube. Make

one downward bend in the pushrod so that the ball link will meet

the ball stud on the engine without binding. Don't snap the ball

link onto the ball until later. The final adjustments will be done

during the radio installation.

INSTALL THE NOSE GEAR

❍ 1. Remove the engine from the engine mount. Slide a 5/32"

wheel collar (included with this kit) with a set screw installed on

the nose gear, then install the nose gear into the engine mount so

1/4" protrudes above the engine mount.

❍ 2. Position the wheel collar so it is snug against the bottom of

the engine mount, then temporarily tighten the set screw to lock

the wheel collar in position.

Look ahead to the photo's in some

of the following steps for more information

.

❍ 3. Use your "Z-bend" pliers or follow the Pro-Tip that follows

to make a Z-bend.

A. Bend the wire. This bend should be about the same angle

as the one shown in the photo.

★★★★ Pro Tip: How to make a Z-bend with regular pliers.

37

❍ 4. Place a 5/32" wheel collar inside the n ylon steering arm and

start a 6-32 x 1/4" screw into the arm and the wheel collar (see

the following sketch). Enlarge the outside hole in the steering arm

with a 5/64" drill bit (#47 for perfection), then insert the wire with

the Z-bend into the hole.

C. If there is any extra wire, cut it off so there is only 3/16"

past the bend. File the burrs off. Always wear safety

glasses when cutting wire!

D. If you didn't like the way

that

Z-bend came out and you

have enough wire, cut it off and try another.

B. Make the second bend about 1/8" ahead of the first to form

the "Z". While bending, push the wire toward the pliers.

38

Page 20

NOTE: Do not file the "flat spot" until step #3 on page 51.

❍ 5. Slide the wire through the guide tube and place the arm on

the nose gear sticking out of the engine mount. Position the

steering arm as shown on the plan, then temporarily tighten the

set screw.

NOTE: The NOSE GEAR PUSHROD location will vary, depending

on the engine mount used. Plan your installation carefully!

❍ 6. With the nose gear steering arm installed, plan the nose gear

pushrod routing. The pushrod should be located as close as

possible to the fuse side (to allow room for the fuel tank) and the

guide tube should not have any tight bends. Drill a 3/16" hole in

F-1 for the throttle pushrod guide tube. A 90 degree bend in the

pushrod wire is necessary to attach the wire to the steering arm.

FLAT

39

FINISHING

FINAL SANDING

Fill any scuffs or dents in the wing with HobbyLite™balsa filler.

After the filler has cured, final sand the wing.

FUELPROOFING

Fuelproofing may be done either before or after covering.

❍ 1. Remove the engine mount, fuel tank, landing gear and any

other hardware you may have installed in the model.

❍ 2. Fuelproof the engine and fuel tank compartments and any

other areas that may be exposed to fuel (such as the landing gear

rails, the tops of formers F-2 and F-3, the inside of the fuel

compartment hatch). You can use any fuel proof paint such as

K&B Superpoxy, model airplane dope, or 30-minute epoxy. Pay

special attention to the firewall. Refrain from allowing paint or

epoxy to clog the blind nuts. Apply petroleum jelly to the threads

with a toothpick. The petroleum jelly must be cleaned off the

wood with rubbing alcohol before fuelproofing.

BALANCE THE AIRPLANE LATERALLY

SPECIAL NOTE: Do not confuse this procedure with "checking

the C.G." or "balancing the airplane fore and aft." That very

important step will be covered later in the manual.

Now that you have the basic airframe nearly completed, this is a

good time to balance the airplane laterally (side-to-side). Here is

how to do it:

❍ 1. Temporarily attach the wing, engine (with muffler) and

landing gear to the fuselage.

❍ 2. With the wing level, lift the model by the engine propeller

shaft and the fin (this may require two people). Do this several

times.

3. If one wing always drops when you lift the model, it means that

side is heavy. Balance the airplane by gluing a weight to the inside

of the other wing tip.

NOTE: An airplane that has been laterally balanced will track

better in loops and other maneuvers.

COVER THE STRUCTURE

You may duplicate the trim scheme shown on the box or use it

as a "starting point" to create your own trim scheme.

40

SPOT

Page 21

Modelers who have not used iron-on coverings should refrain

from attempting complicated trim schemes. You may add

stripes, graphics and various designs to your Tower Trainer 40.

These are cut from different colors of covering, then ironed

directly over the base color. If you are new to iron-on coverings

try just a single color base (usually a lighter color such as white

or yellow) with perhaps a single stripe, your AMA number, or

some stick on graphics. A simple trim scheme will get you in the

air faster and look much better (not to mention give you fewer

headaches) than a model that was difficult to cover because of

too ambitious a trim scheme.

Make sure the structure is sanded smooth with 320-grit

sandpaper. Remove as much dust as possible from the structure

with a vacuum cleaner or a brush and a Top Flite

®

Tack Cloth so

the covering will stick well. Cover the aircraft with TowerKote

™

covering using the sequence that follows. Make sure the

TowerKote is thoroughly stuck down and all of the edges are

sealed. Use a Hot Sock

™

on your covering iron to a v oid scr atc hing

the TowerKote film and denting the wood.

B. When covering areas that involve sharp junctions, like

where the tail meets the fuse, apply narrow strips (3/8" to

1/2") in the corners before covering the major surfaces.

This is an area where the Top Flite Trim Seal Tool™really

comes in handy. The larger pieces of TowerKote film will

overlap and capture these smaller pieces. This technique

also bypasses the need to cut the TowerKote film in these

areas after it has been applied. DO NOT, under any

circumstances, attempt to cut the covering material after

it has been applied to the fin and stab, except around the

leading and trailing edges and the tip. Modelers who do

this often cut through the covering and part-way into the

balsa stab.

★★★★ Pro Tip: COVERING TECHNIQ UE

By following this technique, you can practically eliminate

wrinkles that sometimes occur in the covering when the

model is left out in the sun or in your car.

A. Cover your sealing iron with a Hot Sock and set the

temperature as suggested by the covering manufacturer.

41

RECOMMENDED COVERING SEQUENCE

Tail Surfaces

❍ 1. Tail Junction Strips as described above

❍ 2. Stab bottoms

❍ 3. Stab tops

❍ 4. Fin left side, then right side

❍ 5. Elevator bottom, then top

❍ 6. Rudder left side, then right side

F. Use a heat gun or your iron with the heat turned all the

way up to heat and stretch the film around curved

surfaces like the stab and rudder tips. Pull on the excess

material while you apply the heat. You may need to pull

hard to get out all of the wrinkles, so wear a glove if you

need to. Trim off the excess, then follow-up with your

sealing iron to secure the bond.

The idea behind this approach (which can be applied to any

part of the model) is to pre-stretch the TowerKote film as it's

applied removing the air pockets that can expand later

causing sags and wrinkles.

C. Cut a piece of TowerKote film for the stab about 2" larger

all around. Strip off the backing and position the film flush

with the fin, over the TowerKote corner strip. Tack the film

down at the center of the stab/fin junction.

D. Pull (as in stretch) the film toward edges of the stab,

sealing it to the balsa from the fin outward, the width of

your sealing iron. Work out any wrinkles and air pockets

as you proceed with a back and forth motion.

E. Stretch the TowerKote film toward the four corners,

sealing it down as you proceed.The trick is to shrink out

any wrinkles before you seal the film to the surface.

42

Page 22

Wing

❍ 1. Ends of ailerons

❍ 2. Bottoms, then tops of ailerons

❍ 3. TE of wing (the hinge line)

❍ 4. Wing tips

❍ 5. Bottom of left, then right wing panel (overlap the covering

1/4" at the center)

❍ 6. Top of left, then right wing panel (overlap the covering 1/4"

at the center)

Fuselage

❍ 1. Fuse bottom

❍ 2. Fuse sides

❍ 3. Fuse top

❍ 4. Front and Rear Windows

❍ 5. Fuel tank compartment hatch

❍ ❍ A. Without ironing it down, place the left side of the stab

covering on the stab, then position the fin reinforcement. The stab

and fin TowerKote film pieces shown in these steps are cut only

slightly oversize for illustration clarity though as we mentioned,

you should cut most of your covering pieces about 2" o versize all

the way around.

❍ ❍ B. Remove the stab and fin covering from the model. Place

the covering on your workbench (or a cutting mat if you have

one), then cut it along the outline you made of the fin

reinforcement. After cutting, remove any ink left on the covering

with a cloth dampened with alcohol.

❍ ❍ C. Cover the stab and fin with the pieces you cut earlier.

❍ ❍ D. Perform the same operation for the other side of the stab

and fin.

Note: If you have decided to cover the stab and fin before you

glue them to the fuselage, use the same procedure as described

above but glue the "pre-covered" triangular fin reinforcements in

position after you cover the stab and fin.

Cover the die-cut Trailing Edge plates. Position the plates onto the

wing, and trace the outline onto the covered wing. Trim the

covering 1/16" inside of the lines drawn using a sharp hobby

knife. Use Medium CA to glue the TE Plates onto the wing.

43

APPLYING WINDOWS

Use the patterns on the fuse plan (or make your own templates)

to cut the window shapes from TowerKote film or self-adhesive

TowerKote Trim Sheet. After cutting the pieces to size, wipe the

area on the fuselage to be covered with soapy water. A couple of

drops of dish detergent to a cup of water is sufficient. Peel the

backing from the TowerKote film or TowerKote Trim Sheet, then

"float" the covering into position. Use a piece of balsa wood to

squeegee the solution from underneath the window. Only work

in one direction, blotting moisture after each pass. Iron the film

in position if you have used TowerKote.

HINGING (USING CA HINGES)

NOTE: CA hinges are hinges made specifically to be used with

CA glue. These hinges have a plastic core which is laminated

with fibers to allow the CA to adhere to them.

❍ 1. Start with the elevator and the stab. Cut the covering from

the hinge slots – don’t just

slit

the covering but actually remove a

small strip of covering the size of the hinge slot.

❍ 2. Drill a 3/32" hole 1/2" deep in the center of each hinge slot.

A high speed Dremel®MultiPro™Tool works best for this. If you

have to use a drill, clean out the hinge slots with your #11 blade.

❍ 3. Join the elevator to the stab with the hinges but don’t glue

yet. Confirm that the hinges are equally positioned in both the

elevator and the stab. You may insert a small pin in the center of

44

TEMPORARY PIN

TO KEEP HINGE

CENTERED

Page 23

the hinges to keep them centered. Close the hinge gap to 1/32"

or less – it is better to have a

slight

gap to avoid inadvertently

gluing the control surfaces together. Remove the pins if you have

used any.

❍ 4. Add 6 drops of thin CA to the center of all the hinges on

both the top and the bottom.

❍ 5. Join the rudder to the fin using the same procedures.

❍ 6. Clean the aileron torque rod arms with rubbing alcohol to

remove skin oils or smeared petroleum jelly.

❍ 7. Prepare the hinge slots in the ailerons the same way as the

tail surfaces.

❍ 8. Use a toothpick to pack the torque rod holes in the ailerons

with 30-minute epoxy, then install the ailerons with the hinges and

thin CA using the methods we’ve described. Wipe away the epoxy

that is squeezed out of the ailerons with a paper towel and alcohol.

Do not use accelerator on any of the hinges. Do not glue the

hinges with anything but thin CA and do not attempt to glue

one half of the hinge at a time with medium or thick CA. They

will not be properly secured and the controls could separate

while the model is in flight.

45

FINAL CONTROL HOOKUPS

❍ 1. Install the Elevator and Rudder small nylon control horns in

line with the pushrod exits as shown on the plans. Hold the horns

in position and mark the location of the mounting holes. Drill

3/32" mounting holes through the marks. Wic k two to three drops

of Thin CA into the holes to harden the underlying balsa. The

horns are screwed in place using 2-56 x 5/8" machine screws and

nylon nut plates. Do not tighten the screws as to crush the

underlying balsa.

❍ 2. Mount the servos into the main servo tr a y oriented as shown

on the fuselage plan top view. Mount the aileron servo in the

aileron tray. Since the main servo tray is adjustable fore and aft

for small CG corrections, do not glue it in until told to do so.

❍ 3. For easy setup and good control response, we recommend

you start off using servo horns resembling those on the plans. The

Rudder, Throttle and Elevator horns are made using the large four

armed horns. The aileron servo used the smaller, six armed horn

to provide differential throw. In this case it will cause the ailerons

to deflect “up” more than the deflect “down.”

❍ 4. Make the Rudder and Elevator pushrods: (Use the sketch on

the plans to assist in making the pushrods. Both the Elevator and

Rudder are made using the same sketch.)

A. Locate the two 36" threaded rods. Cut each of the threaded

rods so there are two 10" rods with threads on one end. Save

the remaining wire, as it will be used in a couple of minutes.

B. Locate the two 1/4" x 16" hardwood dowels. Cut them to a

length of 14". Drill a 5/64" hole 1" from the end of the dowel.

A total of four holes need to be drilled.

C. Using a sharp hobby knife, cut a notch from the hole to the

end of the dowel as was done with the ailerons to provide

access for the torque rods.

D. Bend one end of the threaded rods, and one end of the

remaining wire, 1/4" from the non-threaded end. Insert the

bend into the hole drilled in the dowel.

46

ASSEMBLE, THEN APPLY 6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

THE CA WICKS

ALONG THE "TUNNELS"

TO THE ENTIRE

HINGE SURFACE

Page 24

E. Use medium CA to glue the wire to the rod.

F. Cut the heat shrink into 1-1/2" lengths (four total pieces). Slide

the shrink tubing onto the rods over the wire. Leave about a

1/8" overhang off the end of the dowel. Use a heat gun or

cigarette lighter to tighten the shrink over the wire and dowel.

G. Apply thin CA inside each end of the heat shrink tubing to

complete the pushrod assembly.

❍ 5. The Rudder and Elevator control rods need to be installed

into the fuselage from the radio compartment threaded end first.

Patience is the key to getting the rods in and having them exit in

their proper locations.

❍ 6. Screw the nylon clevises well onto the ends of the pushrods

(about 14 turns). Snap the clevises onto the control horns for

now, as they will be removed later to allow bending of the wire

at the servo.

❍ 7. Cut a notch in the bottom wing skin to provide an aileron

lead exit. Use medium CA to glue the aileron servo tray (with

servo) in its place as shown on the plans.

❍ 8. Hook up the nylon clevis to the nylon swivel. Thread a 12"

threaded end rod into each clevis. Screw these assemblies onto

the aileron torque rods down to the height shown on the cross

section at the centerline.

❍ 9. Mark the locations for the Z-Bends in the aileron pushrods

by holding the ailerons neutral with tape and putting marks on

the pushrods even with the holes in the servo arm. Note: When

attaching the Z-Bends to the servo arms, you’ll need to use a

5/64" drill to enlarge the holes in the servo arms. Make the

Z-Bends as shown in the following sequence

❍ 10. Hook up and make final adjustments to the aileron linkage.

❍ 11. Mount the wire main landing gear. Install your wheels and

tires using 5/32" wheel collars (not included) as shown on the plans.

❍ 12. Locate the die-cut 1/8" plywood hatch retainer (HR).

Center the hatch retainer on the 1/8" x 4" x 5" balsa tank

compartment hatch with approximately 3/8" protruding from the

edge, then glue it in position.

47

❍ 13. Position the hatch on the fuselage. Mark a cut line on the

hatch to indicate the front of the firewall. Trim the front of the hatc h

to fit flush with F1A. Mark the sides of the hatch and trim it even

with the fuselage sides. Drill 1/16" holes as shown in the photo

through the hatch and into the firewall. Remove the hatch, then

enlarge the holes in the hatch only with a 3/32" drill bit.

T empor arily mount the hatch to the fuselage with #2 x 3/8"screws.

❍ 14. Install the nose gear steering pushrod using the plans as a

reference. The exact installation will be dependent on your

particular selection of the pushrod.

❍ 15. Install the throttle pushrod using the plans as a reference.

❍ 16. Install the switch harness in the location you desire. It is

always best the switch be on the opposite side of the muffler to

prevent fuel from damaging the switch.

BALANCE YOUR MODEL

NOTE: This section is VERY important and must NOT be

omitted! A model that is not properly balanced will be unstable

and possibly unflyable.

❍ 1. Use a felt tip pen or a narrow strip of tape to accurately

mark the balance point on the bottom of the wing near both sides

of the fuselage. The balance point (CG) is shown on the plan. On

the Tower Trainer 40 the (CG) is located 3-5/8" back from the

leading edge. This is the point at which your model should

balance for your first flights. Later, you may experiment by

shifting the balance up to 1/4" forward or back to change the

flying characteristics. Moving the balance forward may improve

the smoothness and arrow-like tracking, but it may require more

speed for takeoff and make it more difficult to slow down for

48

3-5/8"

Page 25

landing. Moving the balance aft makes the model more agile

with a lighter and snappier feel. Please start at the location we

recommend and do not at any time balance your model outside

the recommended range.

❍ 2. Mount the wing to the fuselage with rubber bands or bolts.

The engine, muffler and propeller should also be mounted for the

C.G. check.

❍ 3. Set the fuel tank (empty) on top of the fuel tank hatch to

simulate the actual weight distribution of the finished model with

the tank installed. With the wing attached to the fuselage, lift the

model with your finger tips at the balance point. If the tail drops

when you lift, the model is "tail heavy" and you must move the

battery and/or the servo tray toward the nose to achieve balance.

If the nose drops, it's "nose heavy" and you must mov e the battery

and/or servo tray the tail to achieve balance. The C.G. is always

determined with the fuel tank empty.

❍ 4. Balance the model by shifting the receiv er battery, servo tra y

and receiver, then re-testing. When balance is obtained note the

position of the of the receiver, servo tray and the battery pack.

❍ 5. If the balance cannot be achieved b y positioning the battery,

servo tray and receiver, you may add stick-on lead weight to the

tail or nose if required.

❍ 6. Confirm that the battery is securely wrapped in foam and is

packed in tight enough under the tank floor so that it cannot shift

during flight or a rough landing.

❍ 7. If you haven't already done so, assemble the fuel tank

according to the manufacturer’s instructions. Connect about 6" of

medium silicone fuel line to the "vent" and about 10" of fuel line to

the "pickup" fittings on the tank (most modelers leave the third "fill"

line closed because you can fill the tank through the pickup line).

❍ 8. Cover the tank floor with 1/4" foam rubber. Insert the tank into

the tank compartment as you route the fuel lines through the holes

you drilled in the firewall (you may temporarily remove the servo

tray – or just the throttle servo). Cut the lines to the proper length

and connect them to the carburetor and muffler pressure fitting.

❍ 9. Place more foam on the sides and top of the tank.

❍ 10. Glue the servo tray securely to the fuse doublers and fuse

sides with medium CA at the position required to achiev e balance.

IMPORTANT: After the model is 100% complete, recheck

the balance.

49

CHECKS AND FINAL SETUP

❍ 1.IMPORTANT: Go back and c heck your installation. Be sure that

all servo screws, horns, and other components are secure. Confirm

that you have installed the retainers on the screw-lock connectors.

❍ 2. Apply a strip of 1/16" thick foam wing-seating tape to the

wing saddle. T his tape provides a seal against dirt and exhaust oil,

and cushions the wing from vibration.

❍ 3. Check the direction of all control functions. They must all

move in the direction shown in the following sketches. If not,

change the position of the reversing switches on your transmitter.

CONTROL SURFACE THROWS