Page 1

INSTRUCTION MANUAL

®

Tower

Hobbies®

guarantees

this kit to be

free from defects

in both material and

workmanship at the

WARR ANTY

date of purchase. This

warranty does not cover any

component parts damaged by

use or modication. In no case shall

Tower Hobbies’ liability exceed the

original cost of the purchased kit. Further,

Tower Hobbies reserves the right to change

or modify this warranty without notice.

In that Tower Hobbies has no control over the nal

assembly or material used for nal assembly, no

liability shall be assumed nor accepted for any damage

resulting from the use by the user of the nal user-assembled

product. By the act of using the user-assembled product, the

user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the

use of this product, the buyer is advised to return this kit immediately in

new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at

the address below:

Hobby Services • 3002 N. Apollo Dr. Suite 1 • Champaign IL 61822 • USA

Include a letter stating your name, return shipping address, as much contact information as

possible (daytime telephone number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon receipt of the package the problem

will be evaluated as quickly as possible.

WINGSPAN

43.2 in [1097mm]

38.0– 42.3 oz [1077– 1199g]

LENGTH

33.8 in [ 859 mm ]

WING AREA

318.0 in2 [20.51 dm2]

WEIGHT

READ THROUGH THIS MANUAL

BEFORE STARTING CONSTRUCTION.

IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE

ASSEMBLY AND USE OF THIS MODEL.

WING LOADING

17.2 – 19.2 oz/ ft2 [52.5–58.6 g/dm2]

MOTOR

RimFire .10 35-30-1250 kV

3S 11.1V 2200 mAh – 3200 mAh LiPo

40A ESC

RADIO

4 – 5 channels, 4 servos

TOWER HOBBIES

Champaign, Illinois

(217) 398-8970 ext. 6

airsupport@hobbico.com

®

®

© 2018 Tower Hobbies .

A subsidiary of Hobbico, Inc.

TOWA2200 EP ARF / TOWA2202 EP RxR

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . . 2

Radio/Servos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Brushless Electric Motor . . . . . . . . . . . . . . . . . . . . . . . 2

LiPo Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Adhesives, Hardware & Other Accessories . . . . . . . . . 2

ELECTRIC MOTOR SAFETY PRECAUTIONS. . . . . . . . . 3

LITHIUM BATTERY WARNING. . . . . . . . . . . . . . . . . . . . . 3

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLE THE WING. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Join the Wing Halves . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hook Up the Ailerons. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mount the Landing Gear . . . . . . . . . . . . . . . . . . . . . . . 7

INTRODUCTION

Thank you for purchasing the Tower Hobbies Cherokee EP.

This Cherokee is intended for electric power only, so the

structure has been lightened accordingly to make it a nice

little scale yer. Tricycle landing gear is the icing on the cake

for easy ground handling, takeoffs, and landings.

NOTE: This instruction manual illustrates all the steps

necessary to assemble the ARF (almost ready-to- y) edition

of the Cherokee EP. However, the Rx-R (receiver-ready)

edition requires less assembly, so if assembling the Rx-R,

simply skim through the manual and perform only steps

that apply.

ASSEMBLE THE FUSELAGE . . . . . . . . . . . . . . . . . . . . . . 8

Join the Vertical & Horizontal Stabilizer. . . . . . . . . . . . 8

Mount the Nose Gear . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mount the Motor & ESC. . . . . . . . . . . . . . . . . . . . . . . . 9

Mount the Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hook Up the Elevator and Rudder. . . . . . . . . . . . . . . 11

FINAL ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install the Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . . 13

Arm the ESC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Set the Fail Safe and the Motor Brake. . . . . . . . . . . . 14

Check the C.G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Balance the Model Laterally . . . . . . . . . . . . . . . . . . . 15

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

❍ LiPo 30C 3S 11.1V 2200 Star (ONXP2263)

❍ LiPo 30C 3S 11.1V 3200 Star (ONXP1953)

❍ Programmable ESC 40A BL 2S-6S (GPMM2140)

❍ APC 9x6E Thin Electric Propeller (APCQ4118)

LiPo Battery Charger

To charge a 3S 3200mAh LiPo at 1C a charger capable of

at least 40 watts is required (3S x 4.2V/cell = 12.6V x 3.2A =

40 watts). The Triton EQ (GPMM3155) is more than enough

charger with 50W output using AC and 63W output using DC.

Adhesives, Hardware & Other Accessories

For the latest technical updates or manual revisions, nd the

Tower Hobbies Cherokee EP page on the Tower Hobbies

website. If there is new technical information or changes

to this model a “tech notice” box will appear on the page.

ADDITIONAL ITEMS REQUIRED

Radio/Servos

A 4-channel radio is required to y the Cherokee. The Tactic

TTX660 is recommended because of its simple, exible

computer programming and multiple model memory. The

servo mounts in the Cherokee are sized for Tactic TSX10 micro

servos, but the mounts may be enlarged for other servos.

❍ Tactic TTX660 6-channel programmable radio

(TACJ2660)

❍ Tactic TR625 6-channel receiver (TACL0625)

❍ (4) Tactic TSX10 micro digital, high-torque, metal gear,

ball bearing servos (TACM0210)

Brushless Electric Motor

The Cherokee ies on a RimFire .10 with a 3S 2200mAh–

3200mAh LiPo and a 9 x 6E propeller (APCQ4118) and 40A

ESC (GPMM2140):

❍ Great Planes RimFire .10 35-30-1250 Outrunner

Brushless (GPMG4595)

Other than common hobby tools, here is a list of items

required:

❍ 30-Minute epoxy (GPMR6043)

❍ Epoxy brushes (GPMR8060)

❍ Mixing cups (GPMR8056)

❍ Mixing sticks (GPMR8055)

❍ Threadlocker thread locking cement (GPMR6060)

❍ Thin CA (GPMR6001)

❍ Medium CA (GPMR6007)

❍ CA applicator tips (HCAR3780)

❍ CA accelerator (GPMR6035)

A covering iron with a cover sock will probably be required

for tightening and re-bonding to the model any covering

that may have loosened between the time the covering was

applied and the time the model was removed from the box.

The 21st Century iron is preferred because of its long cord,

contoured shoe, and precisely adjustable temperature range:

❍ Coverite 21st Century Sealing Iron (COVR2700)

❍ Coverite 21st Century Cover Sock (COVR2702)

Great Planes Product Support

3002 N Apollo Drive, Suite 1 Ph: (217) 398-8970, ext. 6

Champaign, IL 61822 Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

2

Page 3

ELECTRIC MOTOR

SAFETY PRECAUTIONS

WARNING! A spinning propeller has the potential to cause

serious and permanent injury.

WARNING! Once the motor batteries are connected, the

propeller can start spinning at any time. Make sure the Fail

Safe is set on your radio to prevent the motor from starting

if the signal is lost.

WARNING! Stand clear of the propeller when handling

the aircraft. Make sure the aircraft is held securely until the

battery has been disconnected.

ALWAYS remove the propeller if the motor batteries will be

connected while working on your plane.

ALWAYS remove the motor batteries from the plane

when charging.

ALWAYS switch on the transmitter rst, then the receiver.

ALWAYS unplug the motor batteries rst before switching

off the receiver then transmitter.

NEVER touch the motor during or right after operation. The

motor gets HOT!

NEVER switch off the transmitter with the motor batteries

plugged in.

NEVER reach through the arc of the propeller when plugging

the battery into the ESC.

LITHIUM BATTERY WARNING!

This product recommends the use of a lithium polymer

(LiPo) battery. Improper handling of a LiPo battery

could result in FIRE! A lithium battery re has the

potential to ignite surrounding areas and may cause property

damage or cause personal injury.

For safe LiPo handling, follow ALL of these guidelines:

MOST IMPORTANT! Never leave the battery or charger

unattended during charging or discharging.

WARNING: Read the entire instruction sheet included with

your batteries. Failure to follow the instructions could cause

permanent damage to the battery and its surroundings and

cause bodily harm!

ALWAYS follow the charging instructions included with your

charger for charging LiPo batteries. LiPo batteries can cause

serious damage or re if misused.

ALWAYS use a LiPo-approved charger.

ALWAYS set the charger’s output volts to match the

battery volts.

ALWAYS charge a LiPo battery in a reproof location.

ALWAYS balance charge the battery pack.

ALWAYS store and transport LiPo batteries in a reproof

container away from combustible materials.

ALWAYS KEEP OUT OF THE REACH OF CHILDREN.

ALWAYS keep LiPo batteries out of the reach of animals. A

punctured battery may cause a re.

ALWAYS disconnect the battery and unplug the charger

after the charge is complete.

ALWAYS keep a supply of sand accessible when charging

a LiPo battery. Dumping sand on the battery will assist in

extinguishing a LiPo chemical re.

ALWAYS remove the batteries from the plane after a crash.

Set them aside in a safe location for at least 20 minutes. If

the batteries are damaged in the crash, they could catch

re. If the battery starts to swell, quickly move the battery to

a safe location, preferably outside away from combustible

material. Place it in a bucket, covering the battery with sand.

NEVER use water to try and put out a LiPo re.

NEVER charge or use a battery that is deformed, bent,

crushed or has any type of visible damage.

NEVER use a NiCd/NiMH peak charger to charge a

LiPo battery.

NEVER charge in excess of 4.20V per cell unless the battery

is rated for a higher voltage.

NEVER charge at currents greater than 1C unless the batter y

is rated for a higher charge rate.

NEVER trickle-charge a LiPo battery.

NEVER allow the battery temperature to exceed 140 degrees

F (60 degrees C).

NEVER disassemble or modify the battery pack wiring in

any way or puncture the cells, as this may result in a re.

NEVER discharge below 2.7V per cell. It is recommended

to not discharge below 3.7V per cell.

NEVER charge the battery or set the charger on combustible

materials.

NEVER charge the battery inside a vehicle or in a location

that could be damaged in the event of a LiPo re.

NEVER put a LiPo battery in the pocket of any clothing.

NEVER charge the batteries in the plane. Disconnect the

batteries and remove them from the plane immediately

after landing.

NEVER allow the battery to short circuit by touching exposed

wires together. This may cause a re.

NEVER operate or store batteries below 40˚F or above

110 ˚ F (4- 43 ˚C)

3

Page 4

KIT CONTENTS SPARE PARTS

TOWA4100 Wing Set

2

1

4

5

3

7

8

6

9

TOWA4101 Fuselage

TOWA4102 Tail Surfaces Set

TOWA4103 Cowl

TOWA4104 Hatch

TOWA4105 Landing Gear Set

TOWA4106 Wheel Pants Set

TOWA4107 Decals

GPMA4045 1-3/4" White

Spinner

10

1. Cowl

2. Canopy Hatch

3. Fuselage

4. Right Wing

11

12

5. Left Wing

6. Horizontal Stabilizer

7. Wing Fairing

8. Vertical Stabilizer

PREPARATION

13

14

16

9. Wing Joiners

10. Wheel Pants

11. Wheels

12. Landing Gear Wires

15

13. Spinner

14. Plastic Hardware

15. Metal Hardware

16. Pushrods

1. The canopy hatch is removed by pushing the hatch

❏

forward to disengage the magnets and tabs, then lifting the

back of the hatch upward and pulling the canopy back and out.

2. Use a covering iron with a protective cover sock to

❏

remove any wrinkles or areas of loose covering that may have

developed after the covering was originally applied. Start

with low or medium heat to nd the setting that works best

(approximately 300º F measured on the surface of the cover

sock). Gradually increase the heat as necessary to get the

covering to tighten. Too much heat may cause seams and

edges to pull away or damage the color graphics printed onto

the covering. As you proceed, push down on the iron over

sheeted areas to bond the covering to the wood underneath.

4

Page 5

3. Test the security of all the control surfaces and the

❏

hinges by pulling to make sure they remain secure. Add a

few drops of thin CA to any hinges that aren’t secure.

4. Stack two or three paper

❏

towel squares on top of each

other and cut them into small

squares. During various

stages of assembly these

squares may be dampened

with denatured alcohol for

epoxy and other kinds of

cleanup.

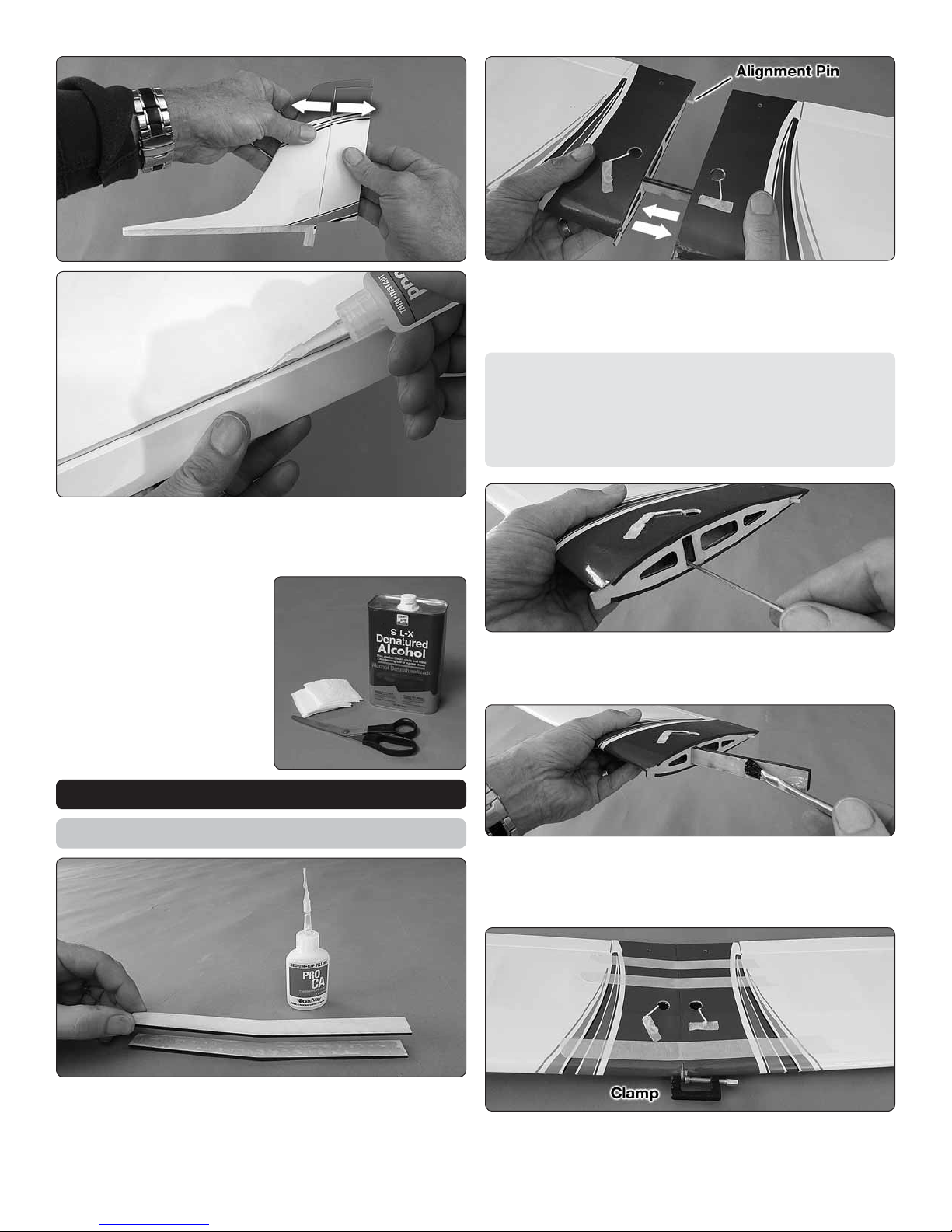

3. Tape the ends of the servo strings that are inside the

❏

wings to the outside of the wings. Test- t the wing halves

together with the wing joiner and the alignment pin. Make

any adjustments necessary for a good t.

NOTE: Even though you may be using 30-minute epoxy,

some brands of epoxy harden faster than others and time

seems to y when working time is limited, so make sure you

have everything you need to glue the wing halves together

and work ef ciently so you don’t run out of working time

before the epoxy begins to harden.

4. Mix approximately 1/4 oz. of 30-minute epoxy. Working

❏

quickly, pour some epoxy into the spar cavities in both wings

and distribute with a wire or small dowel.

ASSEMBLE THE WING

Join the Wing Halves

1. Use medium CA or epoxy to glue together the two

❏

pieces of the plywood wing joiner.

2. Glue the nylon alignment pin (visible in the following

❏

image) halfway into one of the wing halves.

5. Coat one end of the joiner and insert it into one of the

❏

wing halves. Coat the protruding sides of the joiner and both

root ribs of each wing half. Then, join them together and wipe

away excess epoxy as it squeezes out.

6. Clamp the front of the wing together at the tab and apply

❏

strips of masking tape to tightly pull the wings together. Use

the paper towel squares dampened with denatured alcohol

5

Page 6

to wipe away excess epoxy as you proceed. Allow the epoxy

Aileron servo arm

7/16" [11mm]

#48 (.076")

Pushrod Wire

Servo Arm

1/16"

to fully harden before removing the clamps and tape.

7. After the epoxy has hardened, remove the clamps

❏

and carefully peel off the tape. Any residual tape adhesive

may be cleaned with naptha (lighter uid) and areas of the

covering that may have lifted from removing the tape may

be retightened with your covering iron.

Hook Up the Ailerons

1. The servo openings are sized for the recommended

❏

servos (Tactic TSX10 servos). If using larger servos, enlarge

the openings as necessary.

Refer to this image while mounting the aileron servos

and hooking up the ailerons.

4. Drill 1/16" [1.6mm] holes for the servo mounting screws

❏

and mount the servo in the wing with the mounting hardware

that came with it.

2. Attach a 6" [150mm] servo extension to each

❏

aileron servo. Secure the connections using tape or a

product designed specifically for this purpose.

Install the left aileron servo rst…

5. The single-arm servo arms with Tactic TSX10 servos

❏

were used. Use a #48 (.076") drill to enlarge the hole in

the servo arm that is closest to 7/16" [11mm] out from the

center—this will provide about the correct high-rate aileron

throw with the transmitter end points set to 100%.

6. Align the aileron horn with the hinge gap as shown. Then,

❏

drill 1/16" [1.6mm] holes into (but not all the way through) the

aileron and mount the horn with M2 x 8 Phillips wood screws.

7. Remove the M2 x 8 horn mounting screws from the

❏

aileron. Add a few drops of thin CA to each screw hole, allow

to harden, and then re-mount the horn with the screws.

3. Use the string in the wing to pull the aileron servo

❏

extension through and t the servo into the wing.

8. Thread a clevis fteen full turns onto a 6" [150mm]

❏

pushrod. Center the aileron and the servo arm, mark, bend

6

Page 7

and cut the pushrod. Then, hook up the aileron with a

90-degree pushrod connector on the servo arm as shown.

9. Hook up the aileron servo in the right wing the same way.

❏

Mount the Landing Gear

1. Fit the landing straps into the wing. Then, use the holes

❏

in the straps as a guide to drill 1/16" [1.6mm] holes into the

landing gear rails for the mounting screws.

2. Enlarge the holes in all the landing gear straps with a

❏

3/32" [2.4mm] drill.

5. Fasten the gear to the pant with a strap and a M2.5 x

❏

10 washer-head Phillips wood screw. Use the other hole in

the strap as a guide to drill the hole for the second screw.

6. Fasten the other side of the strap to the pant with

❏

another M2.5 x 10 screw.

7. Remove the strap and the gear from the pant. Lightly

❏

wet the threads of two M3 set screws with threadlocker

and thread them each into a wheel collar with a 1.5mm hex

driver wrench.

3. Fit one of the main landing gear wires into one of the

❏

wheel pants—be certain the end of the wire engages the

plywood disc inside the pant. Hold a nylon landing gear

strap into position, and then mark one of the holes in the

strap onto the pant.

4. Drill a 1/16" [1.6mm] hole through the pant at the mark.

❏

8. Install the landing gear wire back into the pant with a

❏

wheel and a wheel collar on both sides of the wheel. Fasten

the gear with the strap and screws. Then, tighten the collars

to the gear with the wheel centered in the pant. Make sure

the wheel rotates smoothly. A small amount of oil on the

axle is recommended.

7

Page 8

9. Mount the landing gear to the wing with two straps

1" [ 25 mm ]

❏

and four more M2.5 x 10 washer-head Phillips wood screws.

10. Prepare the other landing gear and mount to the other

❏

wing in the same way.

ASSEMBLE THE FUSELAGE

Join the Vertical & Horizontal Stabilizer

3. If necessary, adjust the slot for the stab in the fuselage

❏

to get the stab horizontally aligned with the wing. Usually

though, all that will be required is a small amount of weight

on the high side of the stab.

4. Remove the stab and n from the fuselage. Make

❏

sure you have your paper towel squares and denatured

alcohol handy.

5. Mix up a batch of 30-minute epoxy. Apply epoxy to all

❏

joining areas of the stab, n and fuselage. Fit the stab and

n into position. 1/16" [1.6mm] balsa strips are handy for

quickly wiping away most of the excess epoxy—follow with

paper towel squares dampened with denatured alcohol. If

any weight was required to level the stab, don’t forget to

reposition the weight and double-check the alignment until

the epoxy has fully hardened.

1. Cut the 10-24 x 2" [50mm] wing bolts to a length of 1"

❏

[25mm]. Mount the wing to the fuselage with the bolts.

2. Test t horizontal stabilizer (stab) and vertical stabilizer

❏

( n) to the fuselage. View the model from behind to check

that the stab is parallel with the wing and the n is vertical.

6. While the wing is mounted to the fuselage, use a hobby

❏

knife to trim any dimples from the bottom of the wing fairing

followed with sandpaper where the fairing contacts the

bottom of the wing.

7. Use medium CA to glue the wing fairing into position.

❏

8

Page 9

8. After the epoxy gluing the stab and n to the fuselage

L-bend

1/4" [6 mm]

❏

has hardened, remove the wing.

Mount the Nose Gear

Mount the Motor & ESC

1. Mount the motor to the motor mount box with four M3

❏

x 10 Phillips machine-thread screws, M3 lock washers and

at washers with a touch of threadlocker on the threads.

1. Mount the nose wheel pant and nose wheel to the nose

❏

gear the same way as the main gear wheel and pant. Fasten

the nose gear mount and steering arm as shown.

2. Cut the threaded end off a 17-3/4" [450mm] pushrod so

❏

you have a non-threaded pushrod that is 10-1/2" [265mm] in

length. Make a 1/4" [6mm] “L” bend in one end of the pushrod

and install it into the pushrod guide tube for the nose steering.

3. Slide the nose steering pushrod into the guide tube in

❏

the fuselage. Attach the pushrod to the steering arm and

mount the nose gear to the fuselage with four M3 x 12 Phillips

machine-thread screws, M3 lock washers and at washers

and a dab of threadlocker on the threads.

2. Use double-sided foam mounting tape or adhesive-

❏

backed hook and loop material and the included small zip

ties to mount the ESC to the bottom of the motor mount

box. Note how the three wires from the ESC to the motor

are guided in and back out the side of the motor mount box

providing an easy path away from the cowl. On top, another

zip tie was used to hang the wires from the top of the motor

mount box keeping them away from the end of the motor shaft.

9

Page 10

3 . Do not install the propeller. Power up the ESC and

❏

use the transmitter to run the motor to make sure it turns

counter-clockwise when viewed from the front. If the motor

turns the wrong direction, disconnect the battery, and switch

any two of the three motor wires with each other. Then, retest.

Mount the Cowl

1. Mark on the cowl where to cut out for the nose gear wire.

❏

5. Tape two strips to each side of the fuselage where

❏

shown – note that the front edge of each strip aligns with

the front of the fuselage.

6. Use a 1/4" propeller reamer to enlarge the hole in the

❏

spinner back plate to t the propeller shaft on the motor.

7. Install the cowl and the spinner back plate. Position the

❏

cowl so the back plate will be 1/16" [1.6mm] from the cowl

and the propeller shaft will rotate without contacting the cowl.

2. Use a rotary tool with a cutting bit or a hobby knife

❏

to carefully cut the cowl until it goes on far enough for the

base of the propeller adapter to protrude from the cowl

approximately 1/16" [1.6 mm].

3. Draw a line on

❏

a piece of paper 1/8"

[3.2mm] from one

edge.

4. Cut four strips

❏

from the paper.

8. Using the lines on the paper strips as a guide, use a

❏

T-pin to mark the screw hole locations onto the cowl.

9. Remove the cowl. Drill 3/32" [2.4mm] holes at the marks

❏

using a piece of balsa or similar to support the inside of the

cowl at each hole as you drill.

10

Page 11

10. Reposition and align the cowl. Drill 1/16" [1.6mm]

❏

holes into the fuselage through each screw hole in the cowl.

Hook Up the Elevator and Rudder

1. Cut one of the 27" [680mm] pushrods to a length of

❏

18-1/2" [470mm] and the other to 17-1/2" [445mm] by cutting

off the unthreaded end. Thread a nylon clevis about fteen

full turns onto each pushrod and connect each one to a

control horn as shown.

11. Mount the cowl with four M2.5 x 10 washer-head Phillips

❏

wood screws. Carefully trim the spinner cone as necessary

to accommodate the propeller. Then, temporarily mount the

propeller and spinner. A sandpaper disk is also supplied to

place between the back plate and the propeller to keep the

back plate from turning when tightening the propeller nut.

12. Remove the propeller.

❏

2. Slide the longer pushrod into the elevator guide tube

❏

in the fuselage. Position the horn so the clevis holes will

be centered over the hinge line. Drill 1/16" [1.6mm] holes

through the elevator and mount the horn to the elevator

with two M2 x 12 Phillips machine-thread screws and the

back plate on top of the elevator.

11

Page 12

3. Mount the rudder horn the same way.

Elevator servo arm

11/32" [9 mm]

#48 (.076")

Rudder

Pushrod

#48 (.076")

Connector for

Nose Steering

Pushrod

1/16" [1.6 mm]

Rudder/nose

steering

servo arm

7/16 "

[11mm]

11/ 32 "

[9 mm]

Screw-Lock

Connector

M3 Set Screw

Nylon Retainer

❏

4. Use a #48 (.076") drill to enlarge the hole in the servo

❏

arm that is nearest to 11/32" [ 9mm ] out from the center—

this will provide the correct high-rate elevator throw with the

transmitter end points set to 100%.

7. Drill 1/16" [1.6mm] holes in the servo tray for the elevator

❏

servo and mount the servo with the mounting hardware that

came with it.

5. Fit the servo arm on the elevator servo and set the

❏

servo in the servo tray in the fuselage. With the servo arm

and elevator centered, mark the elevator pushrod where it

crosses the hole in the arm.

6. Make an “L” bend in the pushrod at the mark – this can

❏

be done with the pushrod installed, but will be easier if the

pushrod is removed (unthreading the clevis, reinstalling the

pushrod and threading the clevis back on will be required).

Connect the pushrod to the servo arm with a 90-degree

pushrod connector and cut off the excess wire.

8. Using the diagrams above, connect the rudder servo to

❏

the nose steering pushrod and the rudder pushrod the same

way. A screw-lock pushrod connector with a nylon retainer

and an M3 set screw is used to connect the nose steering

pushrod to the servo arm.

12

Page 13

9. Remove the propeller before powering up the

These are the recommended control surface throws:

ELEVATOR

HIGH RATE

AILERONS

RUDDER

LOW RATE

1/4"

[6.5 mm ]

18.0°

Up

3/8"

[10mm]

18.0°

Up

1/8"

[3 mm ]

9.0°

Up

5/ 32"

[5 mm]

7.5°

Up

1/4"

[6.5 mm ]

18.0°

Down

3/8"

[10mm]

18.0°

Down

1/8"

[3 mm ]

9.0°

Down

5/ 32"

[5 mm]

7.5°

Down

5/8"

[16 mm]

22.5°

Up

7/16"

[11 mm]

15.5°

Up

5/8"

[16 mm]

22.5°

Down

7/16"

[11 mm]

15.5°

Down

❏

radio. Connect the servos to your receiver, power up the radio,

center the servos and adjust the clevises on the pushrods

so the elevator and rudder are centered.

10. If you haven’t yet done so, place a silicone retainer

❏

over the clevises on the rudder and elevator pushrods.

FINAL ASSEMBLY

Install the Receiver

Refer to this image for the next two steps.

1. A receiver with end-pin-type servo plugs may be

❏

mounted on top of the servo tray, but receivers with toppin receptacles (as shown) will have to be mounted on the

back end of the battery tray. Use foam mounting tape or

hook-and-loop strips to mount the receiver.

2. Connect the ESC and servos to the receiver. The signal

❏

lead from the ESC may require a 6" [150mm] servo extension.

When mounting the wing for ying, the aileron servos may

be connected to the aileron channel in the receiver with a

Y-harness, or each servo may be connected to separate

channels if they are mixed through programming in the

transmitter (as shown in the previous image).

Set the Control Throws

CAUTION: Always remove the propeller while operating

the radio for any reason.

NOTE: Most Tactic and Futaba transmitters require that the

throttle channel be set to reverse. Other brand transmitters

will vary. Be sure to con rm the correct operation of the

throttle channel WITHOUT THE PROPELLER INSTALLED

before continuing past this step.

2. If necessary, adjust the throws with the programming

❏

in your transmitter and/or adjusting where the pushrods

connect to the servo arms and/or control horns.

3. Now would also be a good time to set your Fail Safe. Set

❏

Fail Safe on the throttle channel so that, in the event of loss

of signal, the motor cuts off. With the propeller removed, test

your Fail Safe by advancing the throttle slightly (just enough

to make the motor turn) and turning off the transmitter. If the

Fail Safe is correctly set the motor will stop.

Arm the ESC

Before the motor will rotate, the ESC must be armed rst:

1. To arm the ESC, move the throttle stick to the lowest

position, turn the transmitter on, and wait for the initiation

tones followed by a single beep. Note: The ESC will autocalibrate the low throttle stick position when powered on.

Be sure that throttle stick is at its lowest point when you

plug the ight battery in (or at the highest point for setting

the brake function- see below).

2. Move the throttle stick to full throttle and the ESC will

con rm this position with a double beep.

3. Lower the throttle again and the ESC will con rm this

lowest position with a sequence of four beeps. THE ESC

IS NOW ARMED. Advancing the throttle stick will cause

the motor to rotate. The propeller should not be installed

on the motor until you are ready for ight and you have

con rmed the Fail Safe is operating correctly!

1. Measure and set the control throws according to the

❏

measurements provided here:

13

Page 14

Set the Fail Safe and the Motor Brake

FAIL SAFE: While you have your radio operational and without

the propeller mounted, now would also be a good time to set

and check the Fail Safe function of your transmitter. Refer to

the instructions that came with your radio control system to set

Fail Safe on the throttle channel so that, in the event of signal

loss, the motor will stop. To test the Fail Safe, with the propeller

removed and the radio control system turned on, advance the

throttle slightly (just enough to make the motor turn) and turn

off the transmitter. If the Fail Safe is set correctly, the motor will

stop when the transmitter is turned off.

MOTOR BRAKE: While you still have your radio system

powered up and without the propeller mounted, check

the motor brake.

Advance the throttle stick to run the motor, and then move

the throttle stick down to stop the motor.

coast gradually to a stop (not stop abruptly). If the motor does

stop abruptly, the brake is turned on. Turn off the brake function

by following the procedure below:

A. Disconnect the battery from the ESC so it will not

receive power.

B.

With the transmitter turned on, advance the throttle stick

to full throttle.

C.

Connect the battery to the ESC to power the motor. Listen

for the series of beeps. There will be three single beeps

separated by pauses (for brake OFF), then a series of

three double beeps separated by pauses (for brake ON).

To turn the brake ON, lower the throttle during the series

of double beeps. If you wish to turn the brake OFF, lower

the throttle during the three single beeps. Now the brake

is set to the desired function and you may disconnect the

battery and turn off the transmitter.

WARNING! Do not proceed with the installation

of the propeller if your Fail Safe is not functioning

as expected. Even with a properly set Fail Safe,

the propeller/motor should always be considered “armed”

and can be a potential source of injury WHENEVER the

propeller is installed on the motor and the ight battery

is connected to the ESC. ALWAYS be alert for anything

that could come in contact with the propeller (especially

yourself) should it unexpectedly start to rotate.

Also, be sure the Cherokee is ALWAYS secured to your

bench during setup or on a ight stand prior to your ight

when the propeller is installed and the ight battery is

connected to the ESC. Do not allow the Cherokee to be

able to roll if the motor were to start unexpectedly. Safe

practices at your work bench and at your ying site will

ensure an enjoyable experience with the Cherokee EP.

The motor should

1. Cut a 6" [150mm] strip of the rougher, “hook” side of

❏

the adhesive-back hook-and-loop material. Peel off the

protective backing, apply medium CA to the strip and apply

the strip to the battery tray where shown.

2. Apply a strip of the softer, “loop” side of the adhesive-

❏

back hook-and-loop material to the battery. (Only a small

strip of hook-and-loop is required on the battery as a strap

will also be used to hold the battery in place.)

Check the C.G.

Since the battery location determines the C.G., the procedure

of determining where to mount the battery and checking the

C.G. are done simultaneously.

3. Place the battery in the middle of the battery tray.

❏

NOTE: The battery should not be connected to the ESC

when checking C.G.

4.

Install the prop and spinner in preparation for balancing

❏

the model. DO NOT connect the battery to the ESC at this time.

14

Page 15

1-1/2"

2-5/8"

38 mm

67mm

2-3/16"

56mm

The recommended C.G. is 2-3/16" [56mm] back from

the leading edge of the wing. The recommended C.G.

range is from 1-1/2"— 2-5/8" [ 38mm — 67mm].

5. Set a Great Planes C.G. machine to 2-3/16" [56mm],

❏

or mark the recommended, starting C.G. location on the top

of the wing where shown in the diagram.

6. Install the canopy hatch. At this point the model should

❏

be completely ready to y with the wing, propeller and spinner.

Test the C.G. by placing the model on the C.G. machine, or

lift at the lines you marked indicating the recommended,

starting C.G. Shift the battery forward or aft to get the model

to balance.

7. Once the location of the battery has been determined,

❏

make a mental note of this location, or mark the inside of

the fuselage or the battery tray to position the battery here

for the proper C.G. when ying the model.

through and under the battery tray and cut the strap to the

correct length to secure the battery.

9. Double-check the C.G. and, if necessar y, reposition the

❏

battery and adjust any marks you may have made, noting

the battery’s location for the desired C.G.

Balance the Model Laterally

1. Lift the Piper several times by the propeller shaft and

❏

the tail to see if one wing drops.

2. If one wing drops consistently, add weight to the

❏

opposite tip by sticking it to the outside or strategically

concealing it inside the balsa tip. An airplane that has

been laterally balanced will track better in ight and

maintain its heading better during maneuvers when the

plane is climbing.

MOTOR/BATTERY/PROPELLER INFORMATION

WARNING: Never have the flight battery

connected to the ESC without the transmitter

turned on – after each ight (or any time after

running the motor) always disconnect the battery before

turning off the transmitter. And when ready to y (or

whenever running the motor for any reason), always turn

on the transmitter rst before connecting the motor battery.

Also make certain your Fail Safe is programmed correctly so

in the event the receiver loses signal (or, if you inadvertently

turn off the transmitter before disconnecting the battery or

vice-versa) the motor will not turn. Follow the instructions

that came with your radio control system to check and

set the Fail Safe.

The recommended RimFire .10 is rated for 30A constant

current and 35A surge current, so it is desirable to load (prop)

the motor to operate within that limit.

For starters, an APC 9 x 6E (on a 3S LiPo) draws about

24A static, but averages a little less than 15A with “normal”

throttle use. This is a suitable propeller choice and ies the

Cherokee well—it can be zoomed around or cruise at lower

throttle for more scale-appearing ight and extended air time.

We’ve also own the Cherokee with a 10 x 5.5MR (MultiRotor). The current draw is only slightly higher, so this is

also a suitable propeller choice.

With every propeller, ight time depends greatly on how you

use the throttle.

8. Make a battery strap by overlapping 3" [75mm] of the

❏

included hook-and-loop strap material. Insert the strap

15

Page 16

In any case, use a ight

timer initially set to a

conservative time (5

minutes for example).

When the timer sounds,

land. Resting (unloaded)

voltage should not be

below 3.75V/cell measured

with a volt meter after you

land. When you charge the

battery note how much

capacity it took to recharge (indicating how much was used

for the ight). Strive to use no more than 80% of the battery’s

capacity. Adjust your timer according to the voltage and

capacity used for the ight.

You can also use the worksheet below to determine optimum

ight times based on your ying style and battery capacity.

CAUTION: Never run the motor on the ground for more

than a few seconds. Otherwise, you may overload the

motor, battery or ESC.

FLYING

The Piper Cherokee doesn’t have any particular ight

characteristics that you need to be made aware of ahead

of time. It’s an honest yer with no peculiar tendencies.

Using low rates on rudder to dampen the nose steering

sensitivity for takeoff is advised – especially if taking off

from a paved runway.

Have a ball! But always stay in control

and y in a safe manner.

GOOD LUCK AND GREAT FLYING!

A

BCDEFG

FORMULAS

Flight Time

(.10ths )

Recharge

Capacity

1

2

3

4

5

6

7

8

9

10

© 2018 Tower Hobbies .® A subsidiary of Hobbico, Inc.

B / A D x .8 E / C

mAh/minute

Battery

Capacity

Target Capacity

to Use in Flight

Recommended

Flight Time

B/1000 / (A/60)

Avg. In-Flight

Current

TOWA2200/2202

Loading...

Loading...