Page 1

INSTRUCTION MANUAL

®

Tower

Hobbies®

guarantees

this kit to be

free from defects

in both material and

workmanship at the

WARRANTY

date of purchase. This

warranty does not cover any

component parts damaged by

use or modica tion. In no case shall

Tower Hobbies’ liability exceed the

original cost of the purchased kit. Further,

Tower Hobbies reserves the right to change

or modify this warranty without notice.

In that Tower Hobbies has no control over the nal

assembly or material used for nal assembly, no

liability shall be assumed nor accepted for any damage

or injury resulting from the use by the user of the nal

user-assembled product. By the act of using the user-assembled

product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the

use of this product, the buyer is advised to return this kit immediately in

new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at

the address below: (Visit hobbyservices.com for more information.)

Hobby Services • 3002 N. Apollo Dr. Suite 1 • Champaign IL 61822 • USA

Include a letter stating your name, return shipping address, as much contact information as

possible (daytime telephone number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon receipt of the package the problem

will be evaluated as quickly as possible.

WINGSPAN

60.2 in [1529mm]

RADIO

4– 5 channel

4–5 servos

72 –76oz. [2041– 2155 g]

LENGTH

48.7 in [1237mm]

WING AREA

592.8 sq in [38.24 dm2]

WEIGHT

READ THROUGH THIS MANUAL

BEFORE STARTING CONSTRUCTION.

IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE

ASSEMBLY AND USE OF THIS MODEL.

WING LOADING

17.49 – 18.46 oz /ft2 [53 –56 g/dm2]

POWER

.46 – .55 cu in [7.5 – 9.0cc] 2-stroke glow,

.70 cu in [11.5cc] 4-stroke glow,

Motor: 1.65" [42mm] 925W,

Castle Creations Edge Lite 75 ESC (not included)

ESC: 60A - 4S (not included)

TOWER HOBBIES

Champaign, Illinois

(217) 398-8970 ext. 6

airsupport@hobbico.com

®

®

© 2016 Tow er Ho bb ies.

A subsidiary of Hobbico, Inc.

TOWA2030

1

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . . 2

Radio/Servos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Glow Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Brushless Electric Motor . . . . . . . . . . . . . . . . . . . . . . . 3

ADHESIVES, HARDWARE &

OTHER ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . 3

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

REPLACEMENT PARTS LIST. . . . . . . . . . . . . . . . . . . . . . 3

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLE THE WING. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hook Up the Ailerons. . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mount the Landing Gear . . . . . . . . . . . . . . . . . . . . . . . 6

Join the Wing Halves . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ASSEMBLE THE FUSELAGE . . . . . . . . . . . . . . . . . . . . . . 7

Install the Pushrods and Mount the Nose Gear. . . . . . 8

Mount a Glow Engine . . . . . . . . . . . . . . . . . . . . . . . . 10

INTRODUCTION

Congratulations and thank you for purchasing the Tower

Hobbies Sport .46/EP ARF. After you’ve mastered the basics

with a high-wing trainer, the “Sport” is a great 1st low-wing

model, or an every day, all-around sport model for experienced

yers too!

For the latest technical updates or manual corrections, nd

the Sport .46/EP ARF on the Tower Hobbies web site at

towerhobbies.com. If there is new technical information or

changes to this model a “tech notice” box will appear on

the page.

ADDITIONAL ITEMS REQUIRED

Radio/Servos

A minimum of 4-channels is required to y the Sport .46/EP

ARF. The Tactic TTX650 is recommended because of its simple,

exible computer programming and multiple model memory:

❍ Tactic TTX650 6-channel programmable radio

(TACJ2650)

❍ Tactic TR625 6-channel receiver (TACJ0625)

❍ Hobbico 2S 6.6V 1300mAh LiFe battery

(HCAM6411)*

❍ On-off receiver switch (TACM2000)*

Servos nowadays are smaller and stronger, so we’ve designed

the servo mounts in the Sport to accommodate mini servos,

but full-size servos may still be used simply by enlarging the

opening in the servo mounts with a hobby knife. Four or 5

channels are required depending on whether you connect

the aileron servos to separate channels and mix them with

programmable mixing in your transmitter, or if you use a

Y-harness to connect the aileron servos to the same channel.

Install the Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Assemble the EP Motor Mount Box . . . . . . . . . . . . . 12

Mount the Brushless Motor . . . . . . . . . . . . . . . . . . . . 13

Cut the Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mount the Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install the Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PREPARE THE MODEL FOR FLIGHT . . . . . . . . . . . . . . 19

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . . 19

Check the C.G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Balance the Model Laterally . . . . . . . . . . . . . . . . . . . 21

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Engine/Motor Safety Precautions . . . . . . . . . . . . . . . 21

Battery Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

AMA SAFETY CODE (excerpts) . . . . . . . . . . . . . . . . . . . 23

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Radio Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

❍ Tactic TSX25 mini digital high-speed 2 ball bearing

servo (TACM0225)

❍ Tactic TSX20 mini high-speed 2 ball bearing servo

(TACM0220)

OR

❍ Tactic TSX35 standard sport servo (TACM0235)

❍ (2) 12" [300mm] universal servo extensions

(TACM2130)

If mixing the aileron servos electronically with programmable

mixing in the transmitter:

❍ (2) 6" [150mm] universal servo extensions

(TACM2092)

If connecting the servos with a Y-harness:

❍ Futaba dual servo extension (FUTM4130)

*If powering your Sport .46/EP with a brushless electric motor

the BEC in the ESC may be used to power your receiver and

servos, so no receiver battery or on/off receiver switch will

be required. If using servos or an ESC different than those

recommended in the instruction manual, be certain the servos

do not overload the BEC or voltage regulator.

Glow Engine

The Sport is suited for a .45 - .55 2-stroke or .70 4-stroke. The

O.S. Max .46AXII (OSMG0548) is illustrated in this manual.

Other Accessories for a Glow Engine

❍ 1/4" [6.4mm] R/C foam rubber (HCAQ1000)

❍ Great Planes Dead Center Hole Locator (GPMR8130)

❍ 4-40 (DUBR0505) or 3mm (DUBR0560) tap and drill

set (see step 6, page 10)

❍ Suitable propeller for your engine

2

Page 3

Brushless Electric Motor

The electric setup for the Sport is straightforward: a Great

Planes Electri y RimFire .32 on a 13 x 8 E prop with a minimum

60A ESC powered by a 4S battery in the 3300mAh – 4000 mAh

range. A Castle Creations Edge Lite 75 was selected and is

illustrated in the instruction manual because it is compact,

easily programmable and features data logging.

❍ 42-50-800 RimFire .32 (GPMG4700)

❍ APC 13 x 8 thin E prop (APCQ3080)

❍ Castle Creations Edge Lite 75 (CSEM1200)

❍ FPWP2234 FlightPower 4S 3300mAh 25C

❍ FPWP2404 FlightPower 4S 4000mAh 25C

❍ 3/16" heat shrink tubing (GPMM1056)

❍ T-style Star connector (HCAM4001)

If your servos draw more current than the BEC in your ESC

is rated for, one option is to use a voltage regulator with a

higher Amp rating that draws power from the 4S LiPo motor

battery. The Castle Creations 10A BEC is suitable (CSEM0005).

Another option is to use a receiver battery.

LiPo Battery Charger

To charge a 4S 4000mAh LiPo at 1C, a charger capable of

at least 70 Watts is required (4S x 4.2V/cell = 16.8V x 4A =

67 Watts). The Triton EQ2 (GPMM3156) is more than enough

charger with 100W output AC and 120W output DC.

ADHESIVES, HARDWARE AND

OTHER ACCESSORIES

Other than common hobby tools here is a list of the rest of

the items required:

❍ 30-minute epoxy (GPMR6043)

❍ Epoxy brushes (GPMR8060)

❍ Mixing cups (GPMR8056)

❍ Mixing sticks (GPMR8055)

❍ Threadlocker thread locking cement (GPMR6060)

❍ Thin CA (GPMR6001)

❍ Medium CA (GPMR6007)

❍ CA applicator tips (HCAR3780)

❍ CA accelerator (GPMR6035)

A covering iron with a cover sock may be required for tightening

and re-bonding covering to the model that may have loosened

between the time the plane was manufactured and the time

the model was removed from the box. The 21st Century iron

is preferred because of its long cord, contoured shoe and

precisely adjustable temperature range:

❍ Coverite 21

❍ Coverite 21st Century Cover Sock (COVR2702)

st

Century Sealing Iron (COVR2700)

KIT INSPECTION

Before starting to build, take an inventory of this kit to make

sure it is complete, and inspect the parts to make sure

they are of acceptable quality. If any parts are missing or

are not of acceptable quality, or if you need assistance

with assembly, contact Product Support. When reporting

defective or missing parts, use the part names exactly as

they are written in the Kit Contents list.

Tower Hobbies Product Support

3002 N. Apollo Drive, Suite 1 Ph: (217) 398-8970, ext. 6

Champaign, IL 61822 Fax: (217) 398-7721

E-mail: airsupport@hobbico.com

REPLACEMENT PARTS LIST

Order No. Description

TOWA4070

TOWA4071

TOWA4072

TOWA4073

TOWA4074

TOWA4075

TOWA4076

TOWA4077

TOWA4078

TOWA4079

TOWA4080

Wing Set

Fuselage

Tail Surface Set

Cowl

Hatch/Canopy

Landing Gear Set

EP Motor Mount Parts Set

10-24 x 2 Nylon Wing Bolts ( 2 pcs. )

2" Spinner

Fuel Tank 260cc

Decals

A Robart Super Stand II (ROBP1402) is also indispensable

for working on your Sport.

3

Page 4

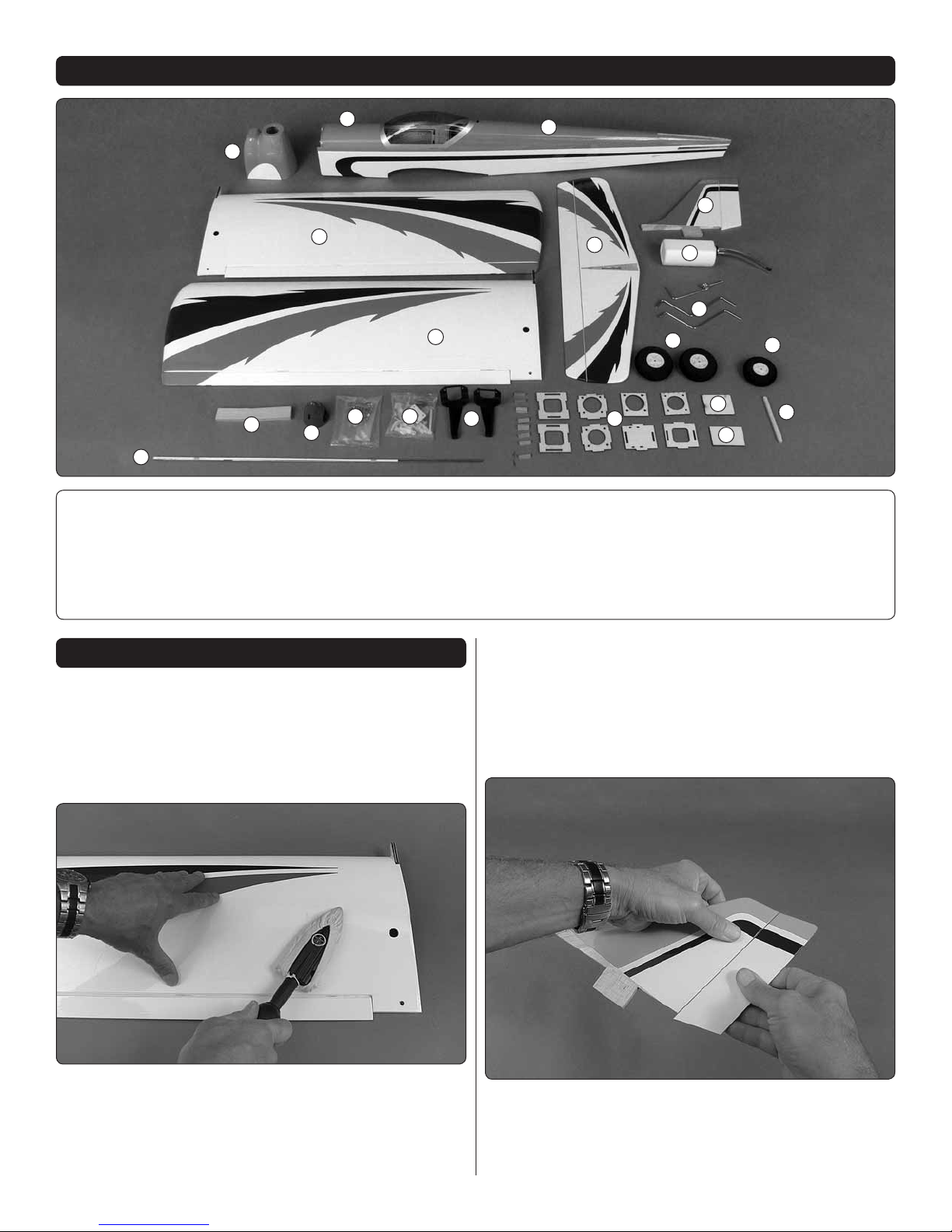

CONTENTS

16

1. Cowl

2. Canopy Hatch

3. Fuselage

4. Wing

5. Horizontal Stabilizer

6. Vertical Stabilizer

2

1

4

11

12

7. Fuel Tank

8. Landing Gear Wires

9. 75mm Main Wheels

10. 65mm Nose Wheel

11. Wing Joiner

12. 2” Spinner

3

6

5

4

13

14

15

17

13. Metal Hardware

14. Nylon Hardware

7

8

9

18

10

20

19

19. Pilot Mount Plate

20. Balsa Stick

15. L& R Engine Mount

16. Pushrods

17. EP Motor Mount Box

18. Hatch Cover

PREPARATION

NOTE: The covering on your Sport requires less heat than

you may be used to if you’re already familiar with iron-on

coverings – too much heat causes seams and edges to

pull and draw away from each other causing wavy, uneven

edges or exposed balsa. Follow the instructions below

to tighten the covering on your model.

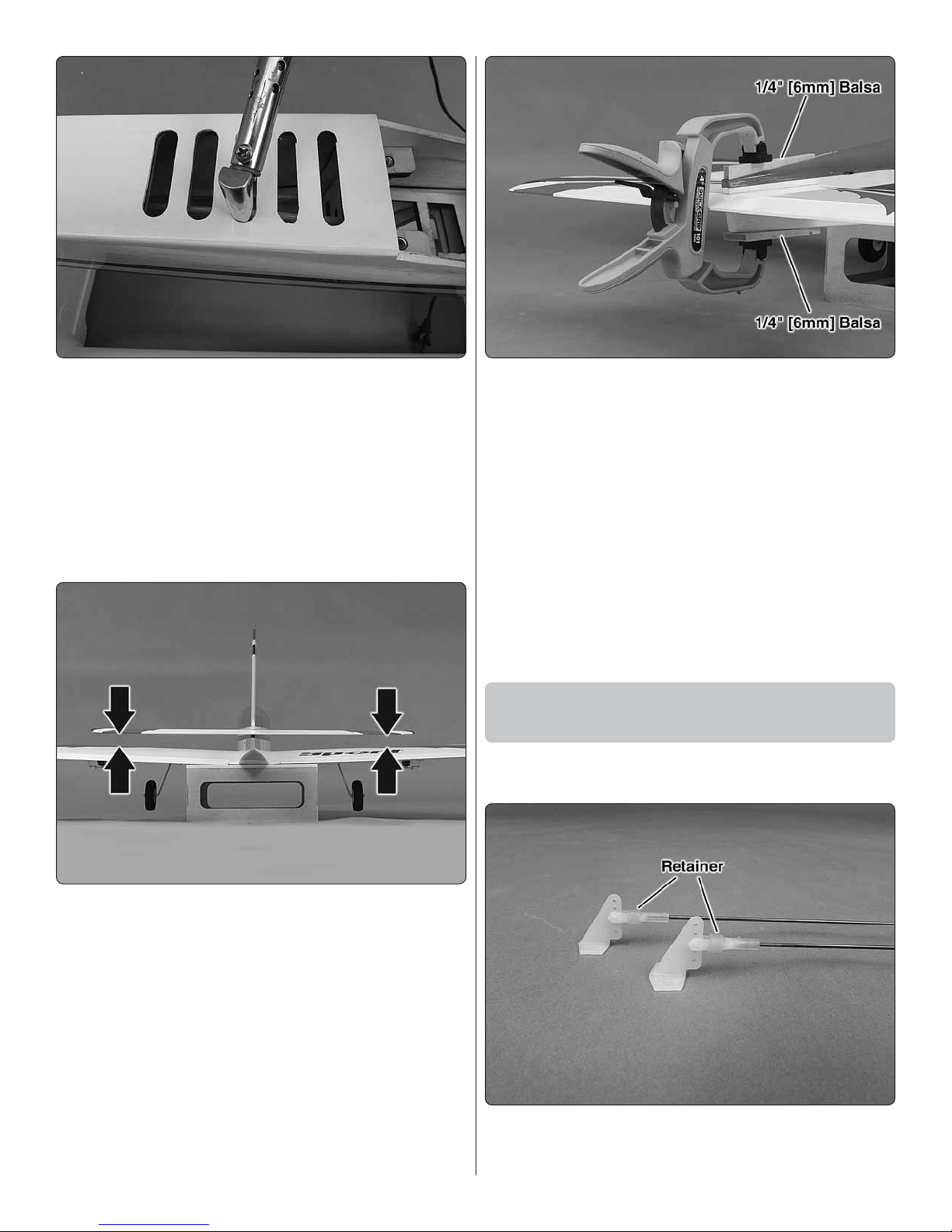

1. Use a covering iron with a cover sock to tighten any loose

❏

covering and thoroughly bond it to the wood structure. The

optimum temperature measured on the surface of a covering

iron with a protective cover sock is about 280ºF [140ºC] which

requires a dial setting of about 300ºF [150º C] or “medium”

heat on most covering irons. Wherever the covering is over

wood (especially on the sheet balsa tail surfaces) press down

on the iron to thoroughly bond the covering to the balsa

underneath. If the covering blisters up over balsa and cannot

be pressed back down, the iron may be too hot or you are

leaving it in one location for too long—try reducing the heat

or moving the iron a little faster.

2. Give a generous tug on all control surfaces to check the

❏

hinges. Add thin CA where necessary to any loose hinges.

Residual CA or CA “fog” is removable with a paper towel

square dampened with CA debonder.

4

Page 5

3. If powering your Sport with a glow engine, apply a lm

Cut out

1/16" [1.5 mm]

Servo Arm

90º Connector

❏

of epoxy or CA to edges of the covering around the nose

and rewall to seal from fuel and exhaust residue. It would

also be a good idea to use an epoxy brush to fuelproof the

back of the rewall and the fuel tank area as well.

ASSEMBLE THE WING

Do the left wing rst…

2. If necessary, enlarge the servo cutout to t your servo.

❏

3. Use the string to pull the aileron servo wire through the

❏

wing and t the servo into the servo openings.

Hook Up the Ailerons

1. Attach a 12" [300mm] servo extension to each aileron

❏

servo. Use 1/2" [13mm] heat shrink tubing, tape or a dab of

glue to secure the connections.

4. Drill 1/16" [1.6mm] holes for the servo mounting screws

❏

in the wing and in the aileron for the control horn screws (use

care not to drill through the top of the aileron).

5. Enlarge the holes in the servo arm with a #50 [.070"]

❏

drill. Mount the servo and horn, make the pushrod and

hook up the aileron using the hardware shown for servo

arms for pushrods.

Refer to this image while mounting the aileron servos

and hooking up the ailerons.

6. After mounting the aileron horns, remove the screws,

❏

harden the holes with a few drops of thin CA, allow to harden,

and then reinstall the screws.

7. Install the aileron servo and linkage in the right wing

❏

the same way.

5

Page 6

Mount the Landing Gear

Landing gear

angled back.

3. Use two at landing gear straps as a guide to drill 3/32"

❏

[2.4mm] holes into the landing gear block in the left wing.

4. Enlarge the holes in the two landing gear straps with

❏

a 1/8" [3.2mm] drill.

1. Use a metal le to grind a at spot in the back of one

❏

of the main landing gear wires. Note: The landing gear wires

angle back toward the wing trailing edge.

5. Mount the main landing gear to the rail in the wing with

❏

two straps and four M3 x 10 screws. Trim the slots as needed

so the wires t ush.

6. Mount the other landing gear and wheel to the other

❏

wing the same way.

Join the Wing Halves

2. Mount a 3" [75mm] main wheel to the landing gear

❏

wire with two wheel collars and two M3 x 5 Phillips screws

and threadlocker.

1. Test- t both wing halves together with the nylon alignment

❏

pin and the hardwood wing joiner. Make any adjustments for

a good t.

6

Page 7

2. Stack two or three paper towels over each other and

❏

cut them into small squares. Have the paper towel squares

and denatured alcohol ready for epoxy clean up while joining

the wing in the next few steps.

4. Use plenty of masking tape to tightly clamp the wing

❏

halves together and use a small clamp to clamp the front

of the wing together at the leading edge tab. Use the paper

towel squares dampened with denatured alcohol to wipe

away excess epoxy as you proceed. Allow the epoxy to fully

harden before removing the clamps and tape.

5. Residual tape adhesive may be cleaned with naptha

❏

(lighter uid). Areas of the covering that may have lifted

from removing the tape should be retightened with your

covering iron.

3. Mix approximately 1-1/2 to 2 oz. of 30-minute epoxy.

❏

Working quickly, pour some epoxy into the spar cavities in

both wings and distribute with a wire or small dowel. Coat

one end of the joiner and insert it into one of the wing halves.

Coat the protruding end of the joiner and both ends of both

wing halves. Insert the nylon alignment pin and join the wing

half, removing excess epoxy as it squeezes out.

ASSEMBLE THE FUSELAGE

1. If you haven’t yet done so, use a covering iron with a

❏

cover sock to tighten the covering over the fuselage and

horizontal and vertical stabilizer.

7

Page 8

2. If powering your Sport with a brushless motor, cut the

❏

covering from the air exit vents in the bottom of the fuselage.

For a better nish, cut the covering about 1/32" [1mm] inside

the edges of each opening and use a trim iron with a rounded

tip to seal the covering neatly down around the edges.

3. Mount the wing to the fuselage with two 10-24 x 2"

❏

[50mm] nylon wing bolts (for convenience, you may shorten

the wing bolts by cutting off up to 5/8" [15mm]).

4. Test t the horizontal and vertical stabilizers (stab and

❏

n) into the fuselage.

6. Remove the stab and n and prepare for gluing into

❏

the fuselage. Typically, the n and stab are glued into the

fuselage together. An alternate method is to glue in the stab

rst, clamping the n fairing to the top of the stab with 1/4"

[6mm] balsa (not included) for a perfectly tight glue joint. If

done this way, be certain to temporarily position the n to

center the stab laterally. After the epoxy has hardened glue

in the n.

If gluing in the stab and n together, apply 30-minute epoxy to

all joining areas, t them into position and wipe away excess

epoxy before it hardens. If any weight was required to level

the stab don’t forget to reposition the weight and doublecheck the alignment before the epoxy hardens.

7. After the epoxy gluing the stab and n to the fuselage

❏

has hardened remove the wing.

Install the Pushrods and

Mount the Nose Gear

1. Cut two of the long wire pushrods including the threaded

❏

end to a length of 27" [685mm].

5. View the model from behind and check the alignment

❏

of the stab to the wing. If necessary, adjust the slot in the

fuselage to get the stab horizontally aligned with the wing—

in most cases, all that will be required is a small amount of

weight on the high side of the stab. If necessary, the stab

saddle can be sanded slightly to get the stab to align.

2. Prepare the two pushrods as shown with control horns,

❏

clevises and silicone tube retainers.

8

Page 9

Hinge Line Hinge Line

CORRECT INCORRECT

5. If installing a brushless motor, cut the rest of the way

❏

through the partially cut air inlet in the rewall and remove

the piece as shown in the photo in the following step.

6. Cut the threaded end off another pushrod to a length of

❏

16" [400mm]. Make an “L” bend in one end of the pushrod

and insert it into the guide tube for the nose steering.

3. Slide one of the pushrods into the elevator tube in the

❏

fuselage. Position the horn on the elevator as shown in the

sketch, then mark and drill 5/64" [2.5mm] holes through the

elevator for the horn mounting screws. Mount the horn with

two M2 x 14 Phillips machine-thread screws and the back

plate on the top of the elevator – don’t over tighten the screws

so much that you squish the balsa.

4. Install the other pushrod and mount the horn to the

❏

rudder the same way.

7. Assemble the nose gear as shown with the hardware

❏

indicated– use threadlocker on the screws.

8. Fit the steering arm onto the pushrod and mount the

❏

nose gear to the rewall with four M3 x 12 Phillips machine

screws and M3 at washers and lock washers.

9. Rotate the nose gear from side-to-side to check for free

❏

movement. If necessary, make a slight bend in the nose gear

pushrod to ease movement.

9

Page 10

Mount a Glow Engine

If installing a brushless motor, skip to Assemble the EP

Motor Mount Box on page 12.

The engine illustrated in the instruction manual is mounted

inverted. This is the easiest, most-convenient and moststreamlined way to mount the engine, but the exhaust is

aimed directly at the wing. This presents no problems, but

you should have plenty of paper towels and cleaner on-hand

to wipe off exhaust residue after each ight. The engine could

also be mounted upright, but much of the cowl will have to

be cut away for the engine, and exhaust will still be deposited

on the fuselage.

4. Slide the engine forward or back so the drive washer

❏

(or the back plate of your spinner) will be 4-1/2" [115mm]

from the rewall.

1. If mounting your engine inverted as shown, drill a 3/16"

❏

[4.8mm] hole through the rewall at the “+” mark in the left

side of the fuselage (the same side of the fuselage as the

throttle arm on the carburetor on the engine). If mounting your

engine upright, drill the hole through the “+” mark through

the rewall on the right side of the fuselage.

2. Temporarily fasten the engine mount halves to the

❏

rewall with four M3 x 25 Phillips machine-thread screws,

M3 lock washes and at washers, but do not fully tighten

the screws yet.

3. Place your engine on the mount. Adjust the width of

❏

the mount halves to t your engine, then temporarily tighten

the screws.

5. Use a Great Planes Dead-Center Hole Locator or similar

❏

tool to mark the engine mount screw holes onto the engine

mount. Remove the engine mount from the rewall.

6. Decide what size screws you want to use to hold your

❏

engine to the mount. M3 x 12 Phillips machine-thread screws

are supplied, but will require a M3 tap. If you already have

a 4-40 tap, then 4-40 x 5/8" screws (not supplied) may be

used instead. If using the supplied M3 x 12 screws, drill

2.4mm [.096" (#41)] holes through the marks made in the

mount for the mounting screws. If using 4-40 screws, drill

#43 or 3/32" holes through the marks made in the mount for

the mounting screws.

10

Page 11

7. Tap the threads into the holes—this may be easily and

❏

quickly done with a drill.

8. Mount the engine mount to the rewall and mount the

❏

engine to the mount.

Install the Fuel Tank

1. Loosen the screw in the stopper in the fuel tank and

❏

take out the stopper/fuel line assembly. Check to make sure

the clunks are present and secure on the lines and that the

vent tube is pointed up toward the top of the tank. Also make

sure the lines on the clunks are not so long that the clunks

can contact the back of the tank (and possibly become stuck).

Make any adjustments necessary, then reassemble the tank

making sure to securely tighten the screw to expand the

stopper to seal the tank.

9. Cut the 17-3/4" [450mm] pushrod guide tube to a length

❏

of 11-1/2" [290mm]. Guide the tube through the hole you

drilled in the rewall down through the holes in the formers

for the throttle pushrod guide tube.

10. Cut the unthreaded end off another pushrod to a length

❏

of 16-1/2" [420mm]. Thread a clevis onto the threaded end.

Bend the front of the pushrod as necessary to connect to the

carburetor arm on the engine and install the pushrod. We’ll

hook up the other end to the throttle servo after the servo

is installed later.

2. Make a fuel tank strap from a 6-1/2" [165mm] piece of

❏

the rougher, “hook” side and a 6-1/2" [165mm] piece of the

softer, “loop” side of the included hook-and-loop material.

Join the strips with 2" [50mm] of overlap to complete the

fuel tank strap.

3. Make another fuel tank strap same as the rst.

❏

11

Page 12

5. Cut one of the fuel lines (from either of the two tubes

❏

on the bottom of the tank) to the correct length to t the

carburetor. Leave the other two lines (one for fueling/defueling,

the other for the pressure/vent line from the muf er) the length

they are now – we’ll cut them later after the cowl has been

cut and tted.

Proceed to Cut the Cowl on page 14. EP Version

Assemble the EP Motor Mount Box

4. Cut a 2-1/4" x 4-1/2" [55 x 115mm] sheet from a piece

❏

of 1/4" [6mm] RC foam rubber to cushion the bottom of the

fuel tank. Install the fuel tank straps under and up through

the slots in both sides of the fuel tank oor, place the foam

rubber sheet, install the tank with the lines through the hole

in the rewall, and then tightly strap the tank into place.

NOTE: There is a hatch in the fuel tank oor through which

nose weight or the receiver battery may be installed. For now,

cover the hatch with the included lite-ply cover and install

the fuel tank. Later, if it is determined that nose ballast is

required, the tank may be removed for access to the hatch.

1. Glue together two pieces of the front and back of the EP

❏

motor mount box with the arrows pointing up and the holes

and edges in each half aligned with each other.

2. Place the front of the motor mount box on your workbench

❏

with the back (the surface with the tabs) facing upward as

shown. Press M3 blind nuts into the back.

12

Page 13

3. Before using any glue, test t the sides, top, bottom,

❏

front and back of the motor mount box together. Make sure

the arrows on the front and back point toward the top of the

mount box and that the arrow on the bottom of the mount

box points toward the front of the box.

5. Glue the triangle reinforcements around the back and

❏

front—use medium CA and stick them into place with a hobby

knife. Reinforce all glue joints where necessary.

6. Round the top, forward corners of the motor mount box

❏

to clear the cowl as shown.

Mount the Brushless Motor

4. Holding the assembly together, use medium CA to glue

❏

the box together. Use care not to get any CA on your ngers.

Do not build up large glue llets until after the next step.

1. Mount the motor mount box to the rewall with four

❏

M3 x 12 Phillips machine screws, M3 at washers, M3 lock

washers and threadlocker.

13

Page 14

2. Assemble the “X” mount and the propeller shaft to

❏

your motor. Mount the motor mount box with four M3 x 12

Phillips machine screws and M3 at washers, lock washers

and threadlocker.

Cut the Cowl

A No. 569 or 570 Dremel grout

removal bit and a sanding

drum are indispensable for

easily and accurately cutting

a berglass cowl. Always wear

eye and breathing protection

when cutting berglass.

3. Connect the ESC to the motor and mount it to the bottom

❏

of the motor mount box. For the Castle Creations Edge Lite

75 ESC we soldered the female bullet connectors that came

with the motor to the three motor wires (protected with 3/16"

heat shrink tubing) and a Star connector to the battery wires.

Then we mounted the ESC to the box with a piece of foam

rubber and nylon ties.

4. Power up the ESC with the receiver and transmitter

❏

and run the motor to make sure it turns the correct direction.

If the motor turns the wrong direction, swap any two of the

three motor wires (or reverse the motor direction in the ESC

programming if available).

1. If you have a glow engine installed, temporarily remove

❏

the engine to position the cowl for marking the location of

the slot for the nose gear. Fit the cowl, then mark the slot.

2. Use the grout cutter or similar bit to cut the slot about

❏

3/4" [20mm] deep. Test t the cowl to make sure the slot is

wide enough and deep enough to t the cowl.

5. Cut the 1/4" x 1/4" x 4" [6 x 6 x 100mm] balsa stick

❏

into two pieces and glue them across the back of the rewall

as shown.

14

Page 15

3. Cut an inlet opening in the air scoop at the bottom of the

❏

cowl. If using a brushless motor, it may also be necessary to

enlarge the opening in the front for the prop adapter. Start with

your grout cutter, then smooth the edges with a drum sander.

4. If using a brushless motor the cowl should require no

❏

further cutting. If using a glow engine, mount the engine

back onto the engine mount. Cover any access point into

the engine where berglass dust could enter such as the

carburetor and exhaust.

5. There’s no really fast, easy way to cut holes in a cowl

❏

that ts tightly around an engine like this. The best way is to

install the cowl and, little by little, mark, cut and re t the cowl

as necessary until it will go on over the engine. We started

by using a pencil to mark the inside of the cowl where it

interfered with the sides of the carburetor.

6. Use your Dremel to cut the rst holes.

❏

15

Page 16

7. Continue to t, mark and cut the cowl until you can

❏

get it to t.

8. Once you can get the cowl to t all the way over the

❏

engine, mark and cut the hole for the muf er. This cowl was

cut so that the muf er has to be installed after the cowl

(tightening the muf er bolts through holes cut in the opposite

side of the cowl), but another way is to cut all the way to the

back of the cowl so it can be slipped past the muf er after

it has been mounted to the engine.

16

Page 17

9. Cut any other holes necessary for the nose gear, fueling

❏

line, muf er pressure line, glow plug igniter, etc.

11. Here’s a close-up of the nished cowl.

❏

Mount the Cowl

Now that the cowl can be positioned all the way over the

engine and muf er, it may be mounted to the fuselage.

1. Use a straightedge and a ne-point, felt-tip pen to mark

❏

the middle of the rewall down both sides of the fuselage.

The ink lines can be removed later with denatured alcohol,

but if you still prefer not to mark directly on the covering you

can mark over strips of tape.

10. Once all the holes are cut and the cowl will t over

❏

the engine and muf er, use 320-grit sandpaper to sand the

edges of the cutouts smooth and even.

2. Mark another line down both sides of the fuselage 2"

❏

[50mm] aft of the rst line. (We marked these lines over

masking tape so they would be easier to see over the

blue trim.)

17

Page 18

3. If necessary, enlarge the hole in the back plate of the

❏

spinner to t the crank shaft or propeller shaft, then t the

back plate onto the engine/motor. Temporarily mount a

prop to securely hold the back plate into place. (There is a

sandpaper disc included that may be used to help lock the

back plate to the motor or the prop to the back plate if either

turns while tightening the propeller.)

4. Position the canopy hatch onto the fuselage.

❏

6. Once the screw hole locations have been marked,

❏

double-check to be sure the cowl is positioned to align with the

spinner, then drill the rst cowl screw hole with a 1/16" [1.6m]

drill. Enlarge the hole in the cowl only with a 3/32" [2.4mm]

drill, then insert the rst M2.5 x 8 washer-head wood screw.

7. Remembering to switch over to the smaller drill each

❏

time a hole is drilled into the fuselage, one-at-a-time drill the

hole, enlarge the hole in the cowl only, then insert another

screw until all four screws are in.

5. Insert cardboard or balsa spacers the thickness of

❏

your preferred spinner gap (approximately 3/32" [2.5mm])

between the front of the cowl and the back plate. Tape the

cowl into place, or have an assistant hold the cowl centered

on the back plate. Mark the screw holes on the sides of the

cowl 2" [50mm] ahead of the lines on the fuselage—the top

screws should be about 5/8" [16mm] down from the top of

the fuselage and the bottom screws should be about 5/8"

[16mm] up from the bottom of the fuselage.

8. Remove the prop and cowl. Add a few drops of thin CA

❏

to each screw hole. Allow the CA to fully harden, then mount

the cowl, prop and spinner.

18

Page 19

Install the Radio

1. If necessary, enlarge the cutout in the servo tray to

❏

t your servos. Then install the servos in the tray, but don’t

screw them down yet.

2. Cut the unused arms from your servo arms and place

❏

them on your servos. Center the servos and control surfaces.

Mark the elevator and rudder pushrods where they cross the

holes in the servo arms.

6. Cut the nose steering pushrod to the correct length and

❏

bend it as necessary to connect the rudder servo. Connect

the pushrod to the servo arm using a screw-lock connector,

an M3 set screw and a retainer.

7. Install the throttle servo (if used) and use another

❏

screw-lock connector to connect the throttle pushrod to

the throttle servo.

8. Now that all the pushrods are connected, drill 1/16"

❏

[1.6mm] holes in the servo tray for the servo screws. Mount

the servos with the screws that came with them.

Refer to this photo while completing servo hookup.

3. Disconnect the clevises from the horns on the elevator

❏

and rudder and remove the pushrods from the fuselage. Make

a 90-degree bend in each pushrod at the marks. Fit each

pushrod to a servo arm, install a 90-degree pushrod keeper

and cut off the excess wire.

4. Remove the clevises from the back of the pushrods so

❏

they can be reinstalled into the guide tubes in the fuselage.

Install the pushrods and thread the clevises back on.

5. Adjust the length of the pushrods as necessary by

❏

threading the clevises in or out, then reinstall the servo arms

onto the servos.

9. Mount the receiver and receiver battery (if used) with

❏

remaining hook-and-loop strap and R/C foam rubber. Mount

an on/off switch (also if used). The image in this step is for a

glow setup. For a brushless motor setup, the receiver may

be mounted to the servo tray over the location for the glow

throttle servo or to the side of the fuselage in the same area.

10. Plug a Y-harness or servo extensions into your receiver

❏

to connect to the ailerons through the bottom of the fuselage

for connecting to the servo leads from the wing.

PREPARE THE MODEL FOR FLIGHT

Set the Control Throws

CAUTION: If you have installed a brushless motor, remove

the propeller before turning on the radio and checking the

throws on the workbench.

In addition to the C.G., the control throws also have a major

effect on how the model ies and whether or not your rst ight

will be successful. Do not skip this important step and make

sure the throws are within the speci ed range. If necessary

use programming in your transmitter and/or change the

locations of the pushrods in the servo arms and/or control

horns to adjust the throw.

19

Page 20

1. It’s probably easiest to check and set the control

57mm

83mm

2-1/4"

3-1/4"

The recommended C.G. is 2-1/4"− 3-1/4"

[57mm −83 mm] back from the leading edge

of the wing.

❏

throws with the wing mounted on the fuselage. Mount the

wing. Check and set the control throws according to the

measurements below:

These are the recommended control surface throws:

HIGHLOW

ELEVATOR

Up & Down

RUDDER

Right & Left

AILERONS

Up & Down

2. Adjust the control throws as necessary by using the

❏

programming in your transmitter and/or reconnecting the

pushrods to holes farther out or farther in on your servo arms

and/or the control horns.

3. Once you have the nose wheel centered and the

❏

carburetor arm working properly, tighten the set screws in

the screw-lock connectors with threadlocker.

3/8"

[10mm]

14°

3/4"

[19mm]

21°

3/8"

[10mm]

19°

1/2"

[13mm]

18°

1"

[25mm]

27°

1/2"

[13mm]

24°

Check the C.G.

Same as the control throws, the C.G. has a great effect on how

the model ies. If the C.G. is too far forward the model may

be too stable and unresponsive to control inputs. If the C.G.

is too far aft the model may be too responsive and instable.

1. The model should be completely ready to y with all

❏

components installed (and an empty fuel tank if using a

glow engine). If you’ve installed a brushless motor, leave the

battery out of the plane, but keep it handy for positioning on

the bottom of the fuselage to determine where the battery

should be mounted inside.

2. If you’ve installed a brushless motor, reinstall the propeller

❏

and spinner.

3. Use a Great Planes C.G. Machine to balance the model

❏

according to the measurements speci ed, or mark the balance

range on the top of the wing and lift the model upside-down

with your ngertips. If you’ve installed a brushless motor

position the battery on the bottom of the fuselage to get the

model to balance.

As long as the model balances anywhere within the speci ed

range it is acceptable (but less-experienced pilots should

perform rst ights with the Sport balanced in the middle or

forward half of the range (slightly nose heavy).

4. If the Sport doesn’t balance where speci ed, move the

❏

receiver battery or motor LiPo battery or add stick-on lead

ballast to the nose or tail to achieve the correct C.G.

5. If you’ve made any adjustments by adding ballast or

❏

moving components check the C.G. again before ying.

20

Page 21

6. If using a brushless motor, once you’ve determined

❏

where to install the battery, apply the strip of the rougher,

hook-side of the included adhesive-back hook-and-loop strip

to the battery tray in the fuselage. Make a battery strap from

the included hook-and-loop strap material and install the

strap through the cutouts nearest the middle of the battery.

Balance the Model Laterally

1. Lift the Sport several times by the propeller shaft and

❏

the tail to see if one wing drops.

2. If one wing drops consistently, add weight to the opposite

❏

tip by sticking it to the outside or strategically concealing

it inside the balsa tip. An airplane that has been laterally

balanced will track better in ight and maintain its heading

better during maneuvers when the plane is climbing.

● Keep these items away from the prop: loose clothing, shirt

sleeves, ties, scarfs, long hair or loose objects such as

pencils or screwdrivers that may fall out of shirt or jacket

pockets into the prop.

● Use a “chicken stick” or electric starter to start the engine.

Do not use your ngers to ip the propeller. Make certain

the glow plug clip or connector is secure so that it will not

pop off or otherwise get into the running propeller.

● Make all engine adjustments from behind the rotating

propeller.

● The engine gets hot! Do not touch it during or right after

operation. Make sure fuel lines are in good condition so

fuel will not leak onto a hot engine, causing a re.

● To stop a glow engine, cut off the fuel supply by closing

off the fuel line or following the engine manufacturer’s

recommendations. Do not use hands, ngers or any other

body part to try to stop the engine. To stop a gasoline

powered engine an on/off switch should be connected to

the engine coil. Do not throw anything into the propeller

of a running engine.

WARNING: For brushless electric motors, never have the

motor battery connected to the ESC without the transmitter

turned on – after each ight (or any time after running the

motor) always disconnect the battery before turning off

the transmitter. And when ready to y (or whenever running

the motor for any reason), always turn on the transmitter

rst before connecting the motor battery.

Also make certain your failsafe is programmed for throttle

to 0% so in the event the receiver loses signal the motor

will not turn. Follow the instructions that came with your

radio control system to check and set the failsafe.

PREFLIGHT

Engine/Motor Safety Precautions

Failure to follow these safety precautions may result in

severe injury to yourself and others.

● Keep all engine fuel in a safe place, away from high heat,

sparks or ames, as fuel is very ammable. Do not smoke

near the engine or fuel; and remember that engine exhaust

gives off a great deal of deadly carbon monoxide. Therefore

do not run the engine in a closed room or garage.

● Get help from an experienced pilot when learning to operate

engines.

● Use safety glasses when starting or running engines.

● Do not run the engine in an area of loose gravel or sand;

the propeller may throw such material in your face or eyes.

● Keep your face and body as well as all spectators away

from the plane of rotation of the propeller as you start and

run the engine.

The recommended RimFire .32 is rated for 50A constant

current and 80A surge current. Powered by a 4S LiPo on

an APC 13 x 8E it draws about 58A static and momentary,

maximum peaks of about 50 – 55A in the air, but averages a

little less than 20A through a “normal” ight. This is a suitable

propeller choice and ies the Sport well—it can be zoomed

around in the sky, or cruise at lower throttle settings for more

scale-appearing ight.

Typical ight time may be as low as 4 minutes or even over

8 minutes depending on how aggressive and active you are

with the throttle – more power means shorter ight times.

Always unplug and remove the battery after your ight.

21

Page 22

In any case, use a ight timer initially set to a conservative

This is a SERIES battery adapter

that connects two batteries in series.

(3-Cell) 3200 mAh

(2-Cell) 3200 mAh

11.1V

7. 4 V

These are two 3200mAh batteries (one 11.1V and the

other 7.4V). When joined in SERIES, the result will be a

18.5V, 3200 mAh battery.

This is a PARALLEL battery adapter that

connects two batteries in parallel.

(3-Cell) 1500 mAh

(3-Cell) 1500 mAh

11.1V

11.1V

These two 1500mAh batteries (both 11.1V) are being

joined in PARALLEL. The result will be one 11.1V, 3000mAh

battery.

time (4 minutes for example). When the timer sounds, land.

Use a LiPo checker to measure the resting (unloaded) voltage

when you land. The voltage should not be below 3.75V/cell.

When you charge the battery also note how much capacity

it took to recharge (indicating how much was used for the

ight). Strive to use no more than 80% of the battery’s capacity.

Adjust your timer according to the voltage and capacity used

for the ight.

You can also use the worksheet on page 24 to determine

optimum ight times based on your ying style and battery

capacity.

Before mounting the motor and setting up the ESC and

battery, read the following important battery precautions:

IMPORTANT: If using multiple battery packs that are

connected with an adapter, never charge the batteries

together through the adapter. Always charge each

battery pack separately. Charge the batteries, then read

the following precautions on how to connect multiple

packs for ying the model:

Battery Precautions:

There are two ways to connect multiple battery packs: In

Series and in Parallel.

CAUTION: Never run the motor on the ground for more

than a few seconds. Otherwise, you may overload the

motor, battery or ESC.

Charge and store LiPo batteries in a safe place!

Never leave charging LiPo batteries unattended!

Battery Precautions

1. Connecting batteries in “Series” means to connect the

+’s to the –’s and the –’s to the +’s. This combines the

batteries’ Voltages, but the capacity remains the same.

2. Connecting batteries in “Parallel” means to connect

the +’s to the +’s and the -’s to the -’s. This combines the

batteries’ capacities, but the Voltage remains the same.

22

Page 23

PARALLEL

adapter

(2-Cell)

(3-Cell)

11.1V

7. 4 V

NEVER connect battery packs with different Voltages in

(3-Cell) 3200mAh

11.1V

(3-Cell) 1250mAh

11.1V

SERIES

adapter

Parallel–only combine in Series. Otherwise, the batteries

will try to “equalize” with the larger one trying to “charge”

the smaller one, thus causing heat and likely a re.

Also NEVER connect battery packs with different capacities in Series or in Parallel.

airport operator. I will give right-of-way and avoid ying in the

proximity of full-scale aircraft. Where necessary, an observer

shall be utilized to supervise ying to avoid having models

y in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

ying site I use, and I will not willfully and deliberately y my

models in a careless, reckless and/or dangerous manner.

5) I will not y my model unless it is identi ed with my name

and address or AMA number, on or in the model. Note: This

does not apply to models while being own indoors.

7) I will not operate models with pyrotechnics (any device that

explodes, burns, or propels a projectile of any kind).

Radio Control

1) I will have completed a successful radio equipment ground

check before the rst ight of a new or repaired model.

2) I will not y my model aircraft in the presence of spectators

until I become a qualified flier, unless assisted by an

experienced helper.

3) At all ying sites a straight or curved line(s) must be

established in front of which all ying takes place with the

other side for spectators. Only personnel involved with ying

the aircraft are allowed at or in the front of the ight line.

Intentional ying behind the ight line is prohibited.

4) I will operate my model using only radio control frequencies

currently allowed by the Federal Communications Commission.

5) I will not knowingly operate my model within three miles

of any pre-existing ying site except in accordance with

the frequency sharing agreement listed [in the complete

AMA Safety Code].

9) Under no circumstances may a pilot or other person touch

a powered model in ight; nor should any part of the model

other than the landing gear, intentionally touch the ground,

except while landing.

Range Check

Don’t forget to perform your usual ground range checks as

written in the instruction manual that came with your radio

system to be certain it is operating correctly.

AMA SAFETY CODE (excerpts)

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to Model Aviation magazine, the AMA web site

or the Code that came with your AMA license.

General

1) I will not y my model aircraft in sanctioned events, air shows,

or model ying demonstrations until it has been proven to be

airworthy by having been previously, successfully ight tested.

2) I will not y my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

FLYING

There are no particular ight characteristics about the Sport

that you need to be made aware of ahead of time. If you

prefer ying on high-rates most of the time, it will be easier

to takeoff with the rudder on low rates so the nose wheel

will not be too responsive. Once airborne, you can switch

the rudder to high rates.

The Sport is a well-balanced, neutral, easy- ying plane that

exhibits no bad tendencies and will go wherever you point it.

Simply y the Sport within your capabilities and take it easy

for the rst couple of ights to give yourself time to become

acclimated to it.

Have a ball! But always stay in control

and y in a safe manner.

GOOD LUCK AND GREAT FLYING!

23

Page 24

A

FORMULAS

BCDEFG

B / A D x .8 E / C B/1000 / (A /60)

1

2

3

4

5

6

7

8

9

10

Flight Time

(.10 ths )

Recharge

Capacity

mAh/minute

Battery

Capacity

Target Capacity

to Use in Flight

Recommended

Flight Time

Avg. In-Flight

Current

®

© 2016 Tow er Ho bb ies.

A subsidiary of Hobbico, Inc.

TOWA2030

Loading...

Loading...