Page 1

MKII EP Rx-R

®

Tower

Hobbies®

guarantees

this kit to be

free from defects

in both material and

workmanship at the

WARR ANTY

date of purchase. This

warranty does not cover any

component parts damaged by

use or modication. In no case shall

Tower Hobbies’ liability exceed the

original cost of the purchased kit. Further,

Tower Hobbies reserves the right to change

or modify this warranty without notice.

In that Tower Hobbies has no control over the nal

assembly or material used for nal assembly, no

liability shall be assumed nor accepted for any damage

resulting from the use by the user of the nal user-assembled

product. By the act of using the user-assembled product, the

user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the

use of this product, the buyer is advised to return this kit immediately in

new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at

the address below:

Hobby Services • 3002 N. Apollo Dr. Suite 1 • Champaign IL 61822 • USA

Include a letter stating your name, return shipping address, as much contact information as

possible (daytime telephone number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon receipt of the package the problem

will be evaluated as quickly as possible.

LENGTH

34 in [ 864 mm ]

WINGSPAN

40 in [1016 mm]

WING AREA

282 sq in [18.2 dm2]

READ THROUGH THIS MANUAL

BEFORE STARTING CONSTRUCTION.

IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE

ASSEMBLY AND USE OF THIS MODEL.

WEIGHT

30 –34 oz [850–964g]

WING LOADING

15.3 – 17.2 oz/ ft2 [46.7–52.5 g/dm2]

RADIO

4-Channel minimum required

5–6 if optional aps/retracts are used

TOWER HOBBIES

Champaign, Illinois

(217) 398-8970 ext. 6

airsupport@hobbico.com

®

v1.1© 2016 Towe r H o bbi es .® A subsidiary of Hobbico, Inc.

1

Page 2

TABLE OF CONTENTS

AMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

REQUIRED ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Radio Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery and Charger . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Optional Flaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Optional Retracts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Adhesives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . 3

KIT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

BEFORE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ASSEMBLE THE FUSELAGE. . . . . . . . . . . . . . . . . . . . . . 5

RADIO SETUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPTIONAL FLAP INSTALLATION . . . . . . . . . . . . . . . . . . 7

INSTALL THE FIXED LANDING GEAR (Optional) . . . . .9

OPTIONAL RETRACT INSTALLATION . . . . . . . . . . . . . . 9

GET THE MODEL READY TO FLY. . . . . . . . . . . . . . . . . 10

As a new owner of an unmanned aircraft system (UAS), you

are responsible for the operation of this vehicle and the safety

of those around you. Please contact your local authorities

to nd out the latest rules and regulations.

In the United States, please visit:

knowbeforeyou y.org faa.gov/uas

AMA

We urge you to join the AMA (Academy of Model Aeronautics)

and a local R/C club. The AMA is the governing body of model

aviation and membership is required to y at AMA clubs.

Though joining the AMA provides many bene ts, one of the

primary reasons to join is liability protection. Coverage is not

limited to ying at contests or on the club eld. It even applies

to ying at public demonstrations and air shows. Failure to

comply with the Safety Code (excerpts printed in the back of

the manual) may endanger insurance coverage. Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way. There are over

2,500 AMA chartered clubs across the country. Contact the

AMA at the address or toll-free phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: www.modelaircraft.org

IMPORTANT: Two of the most important things you can do

to preserve the radio controlled aircraft hobby are to avoid

ying near full-scale aircraft and avoid ying near or over

groups of people.

Check the Controls & Control Direction . . . . . . . . . . 10

Check the Control Throws. . . . . . . . . . . . . . . . . . . . . 11

Install the Propeller & Spinner . . . . . . . . . . . . . . . . . . 11

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . . 12

APPLY THE DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Charge the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MOTOR SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . 13

FLYING THE P-51 MUSTANG . . . . . . . . . . . . . . . . . . . . 13

Find a Suitable Flying Site . . . . . . . . . . . . . . . . . . . . . 13

Perform a Range Check . . . . . . . . . . . . . . . . . . . . . . 14

Monitor Your Flight Time . . . . . . . . . . . . . . . . . . . . . . 14

Take Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ROG Take Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

AFTER EACH FLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . 15

REPAIRING YOUR MODEL . . . . . . . . . . . . . . . . . . . . . . 15

SAFETY PRECAUTIONS

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your Mustang should not be considered a toy, but rather a

sophisticated, working model that functions very much like

a full-size airplane. Because of its performance capabilities,

this model, if not assembled and operated correctly, could

possibly cause injur y to yourself or spectators and damage

to property.

2.

You must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result

in an unsafe or un yable model. In a few cases the

instructions may differ slightly from the photos. In those

instances the written instructions should be considered

as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in rst-class

condition.

5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and

in the air.

6. You must check the operation of the model before every

ight to insure that all equipment is operating and that

the model has remained structurally sound. Be sure to

check clevises or other connectors often and replace

them if they show any signs of wear or fatigue.

7. If you are not an experienced pilot or have not own this

type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for

your rst ights. If you’re not a member of a club, your

local hobby shop has information about clubs in your area

whose membership includes experienced pilots.

2

Page 3

8.

While this kit has been ight tested to exceed normal use,

if the plane will be used for extremely high stress ying,

such as racing, or if a motor larger than the one included

is used, the modeler is responsible for taking steps

to reinforce the high stress points and/or substituting

hardware more suitable for the increased stress.

Optional Flaps

❍ (2) TOWM5500 Tower Hobbies servo (for optional

aps)

❍ (1) TOWA6116 Y-Harness

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and yability of your nished model depends on how

you build it; therefore, we cannot in any way guarantee the

performance of your completed model, and no representations are expressed or implied as to the performance or

safety of your completed model.

REMEMBER: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

REQUIRED ITEMS

Radio Components

A transmitter and receiver with 4-channels minimum

(6-channel for optional retracts and aps) is required. The

Tactic TTX650 6-channel or Futaba 6J 6-channel radio system

are great low-cost radio systems perfect for the P-51 Mustang

EP Series ARF.

❍ TACJ2650 Tactic TTX650 6-channel SLT Computer

Transmitter

OR

❍ FUTK6000 Futaba 6J 6-channel S-FHSS System

Battery and Charger

A 3S 1800mAh – 2200mAh LiPo battery is required to power

the P-51 Mustang ARF.

❍ ElectriFly 3S 1800mAh 30C (GPMP0855)

❍ ElectriFly 3S 2200mAh 30C (GPMP0861)

❍ FlightPower 3S 1800mAh 50C (FPWP5183)

❍ FlightPower 3S 2200mAh 30C (FPWP3223)

❍ FlightPower 3S 2200mAh 50C (FPWP5223)

Most modelers may already have a suitable LiPo charger,

but for those that do not, the Duratrax Onyx 235 AC/DC

Advanced Peak Charger (DTXP4235) is one of the suitable

chargers recommended. The Onyx charger is perfect for

3S batteries used with the P-51 Mustang ARF and may be

powered either by an external DC power source (such as

a 12V battery), or a 110V AC outlet. The Onyx also has an

adjustable charge rate to charge your batteries in as little

as a half-hour or less (depending on the condition of your

batteries and the manufacturer’s speci ed charge rate). The

Onyx can also charge large batteries and batteries other than

LiPo. So it is a versatile charger you can grow into. The 235

also has an LCD digital display screen, so you can see how

much capacity it took to recharge the battery (required for

monitoring the condition of your batteries and calculating

how long your plane can y).

Optional Retracts

❍ (1-set) Electric Retracts (FLZA6603)

❍ (1-set) Retract Gear Covers (See included parts list.)

❍ (1) TOWA6116 Y-Harness

Required Tools

❍ #1 Phillip Screwdriver ❍ CG Machine (GPMR2400)

❍ Scissors ❍ String

❍ Pliers, ❍ Adjustable Wrench

regular and ❍ #11 Knife Blades

needle-nose

❍ Hobby Knife

Adhesives

❍ Pro Threadlocker (GPMR6060)

❍ 2 oz. Build-It CA+ Medium (TOWR3801)

ORDERING REPLACEMENT PARTS

Replacement parts are available from Tower Hobbies for

your P-51. Our order assistance representatives are ready

to answer your questions or to place your order. Call us at

(800) 637-6050.

Please see the included parts list for your speci c P-51.

Order No. Description

GPMA3177

FLZA6214

TOWG2000

TOWM5500

FLZA6218

TOWA6075

TOWA6115

TOWA6116

TOWA6117

Propeller 10x7

Prop Adapter (3mm)

Motor 30-35-1000

Servo

30amp ESC

Fixed Landing Gear

Wing Bolt

Y-Harness

Fixed Landing Gear Mount

KIT INSPECTION

If any parts are missing or damaged, consult Tower Hobb ies

Order Assistance. (See phone numbers below.)

Note: All parts are one per kit unless otherwise stated.

Toll Free Order Assistance . . . . .800 637-6050

Fax Ordering . . . . . . . . . . . . . . . .217 398-7721

E-mail: airsupport@towerhobbies.com

3

Page 4

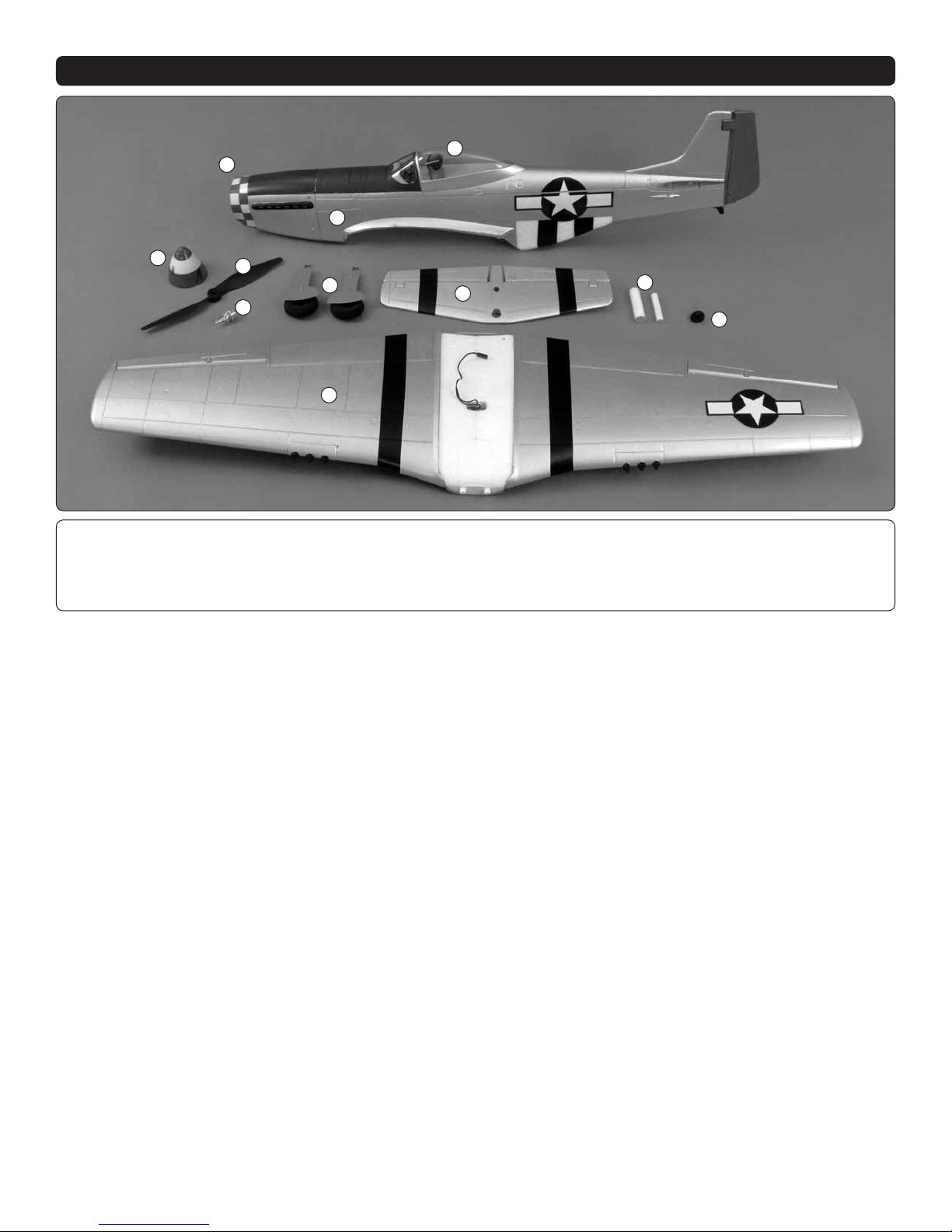

CONTENTS

2

11

1

3

1. Fuselage

2. Canopy Hatch

3. Spinner

4. Propeller

4

6

5

10

7

5. Propeller Adapter

6. Fixed Landing Gear w/ Covers

7. Horizontal Stabilizer

8

9

9. Tail Wheel

10. Wing

11. Cowl

8. Foam Plugs

4

Page 5

BEFORE ASSEMBLY

1. Read the Motor Safety Precautions section on page

❏

13 of this manual. Charge the battery pack following the

instructions that came with your charger.

2. Remove all of the components from the plastic packaging

❏

and lay them out on your work surface. Set the wing aside

and begin the fuselage assembly.

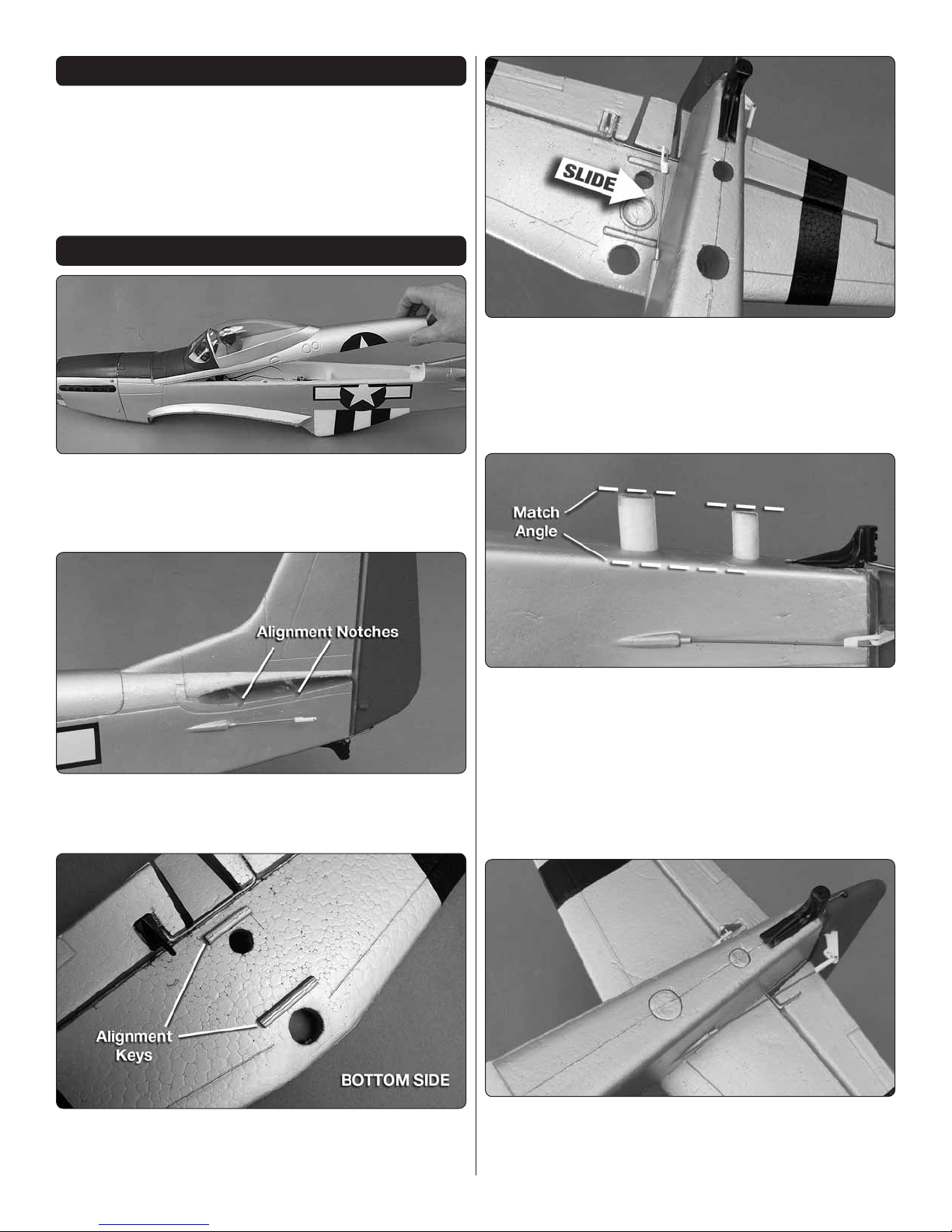

ASSEMBLE THE FUSELAGE

1. Remove the canopy hatch. This is held on by three

❏

small magnets under the base of the canopy and a molded

tab at the front edge. To remove the hatch, pull up the rear

of the hatch.

4. Slide the stabilizer into the opening in the fuselage.

❏

When you install the stabilizer, slide the right side of the

stabilizer into the left side of the fuselage. Be sure to key the

stab to the slots in the fuselage. Position the stab so that it

is centered and the holes in the bottom of the fuselage are

aligned with the holes in the stabilizer.

2. At the back of the fuselage you will see the opening

❏

for the stabilizer. Look closely and you will see alignment

notches that help locate the stab position.

3. On the bottom of the stabilizer you will nd the raised

❏

alignment keys. These match up with the alignment notches.

5. Partially install the two foam plugs into the holes in the

❏

bottom of the fuselage. When you do this be sure the painted

end of the plug is outside of the fuselage. These two plugs

lock the stab to the fuselage. Once they are installed, the

tail cannot be removed without risk of breaking them, so be

sure you follow these instructions carefully. You will notice

that each of the plugs has an end that is angled. When the

plug is positioned properly the angle will be in line with the

bottom of the fuselage.

6. When you are satis ed that you have the plugs positioned

❏

properly, insert them into the fuselage and through the

stabilizer, locking the stabilizer in place.

5

Page 6

channel of the receiver or use separate channels for each

servo if preferred. Also, plug the rudder, elevator and ESC

into the receiver. Install the receiver in fuselage and tape

the receiver antennas in position as recommended by the

radio manufacturer.

2. Separate the hook side from the loop side of the

❏

remaining adhesive-backed hook and loop material. Stick

the hook side to the fuselage and the loop side to the back

of your battery pack. To prepare your other battery packs,

you may purchase more Great Planes hook and loop material

(GPMQ4480) from Tower Hobbies.

7. Remove the nylon Faslink from the end of the elevator

❏

pushrod by rotating the Faslink until it unsnaps from the long

part of the pushrod and rotates around the L-bend. Install the

pushrod wire into the outermost hole in the elevator control

horn and secure it with the Faslink as shown.

RADIO SETUP

1. Cut a 1” (25mm) piece of adhesive-backed hook and

❏

loop material and stick the loop side (fuzzy side) to the

back of the receiver. Stick the hook side of the material just

behind the servo lead opening. Route the included aileron

Y-harness through the fuselage and plug it into the aileron

3. Attach the wing to the fuselage with a 4 mm x 50mm

❏

machine screw.

WARNING:

switch on the transmitter rst with the throttle stick in the

low position before plugging in the LiPo battery. Always

unplug the LiPo battery before switching off the transmitter.

4. Using your radio, center the elevator and rudder servos,

❏

and trims on your transmitter. Make sure that the elevator

and rudder servo arms are 90° to the servo case when they

are centered. If they are not centered, remove the servo arm

retaining screw and reposition the arm on the splined shaft.

Reinstall the servo arm and the retaining screw.

Make sure the propeller is not installed. Always

6

Page 7

5. With the servos centered, check to make sure that the

❏

control surfaces are centered. If they need to be adjusted,

loosen the locking screw on the pushrod connector and

adjust the ight control until it is centered. When you are

satis ed, tighten the locking screw to hold the pushrod wires

in position. For added security, we recommend removing the

locking screws, applying a drop of thread locking compound

to the threads and re-installing the locking screws.

OPTIONAL FLAP INSTALLATION

6. Using your radio, center the aileron servos. Check to see

❏

that the ailerons are also centered. If they need adjustment,

loosen the locking screw and adjust the ailerons until they

are centered at zero de ection. Tighten the set screw of the

screw lock pushrod connector. Again, use threadlocker on

the threads.

1. Using a sharp hobby knife cut the end of the aps loose

❏

from the wing.

2. Cut a slot in the center of the ap control horn recess on

❏

the bottom of the wing. Do not cut through the top of the ap.

7

Page 8

3. Use CA to glue the control horn in the slot with the quick

❏

connector towards the wing root.

4. Use a sharp hobby knife to cut the ap servo opening.

❏

The foam over the opening is approximately ¼” (6mm) thick.

6. Insert the nut in the opening in the ap servo recess.

❏

Gently shake the wing to guide the nut and string to the

opening in the top center of the wing.

7. Attach the ap servo lead to the string and carefully

❏

pull it through the wing and out of the opening. Tip: Tie the

string to the retract cable and use a piece of masking tape

to position the string at the end of the connector.

8. Connect a Y-harness to the ap servo lead.

❏

5. To assist in pulling the ap servo leads through the

❏

wing, tie a small nut (not included) to a string.

9. Plug the ap servo into the ap channel on the receiver.

❏

Switch on the transmitter and then receiver. Check that the

servo arm is as shown with the ap control on the transmitter

set to aps up.

8

Page 9

10. Use CA, Canopy glue or thin double-sided tape (not

❏

included) to secure the ap servo in the wing.

11. Insert the z-bend of the ap pushrod in the outer hole

❏

of the ap servo arm. Move the ap and insert the other

end of the ap pushrod in the quick connector on the ap

control horn.

12. With the radio system on, set the ap control on the

❏

transmitter to the ap up position. Position the ap so that

it is aligned with the trailing edge of the wing and tighten

the screw in the quick connector against the ap pushrod.

Repeat for the other ap servo and linkage.

13. Operate the aps to make sure nothing binds and that

❏

they both have the correct amount of throw.

1. Install the main landing gear legs by tting them

❏

into the slots in the bottom of the wing so that the wheel

faces inboard.

2. Use the included hex wrench to remove the lower set

❏

screw. Insert the tail gear wire, apply a drop of threadlocker

to the set screw and reinstall it, tightening it against the at

spot on the tail gear wire.

OPTIONAL RETRACT INSTALLATION

INSTALL THE FIXED LANDING

GEAR (Optional)

This airplane is supplied with xed landing gear but this should

only be used if you have an asphalt or concrete runway. Any

length of grass will be too much resistance for the wheels to

roll on. Landing gear is not necessary for take off or landing.

The airplane is easily hand launched and lands very well on

its belly in grass.

1. To assist in pulling the retract lead wires through the

❏

wing, tie a small nut (not included) to a string.

9

Page 10

2. Insert the nut in the opening in the retract recess. Gently

❏

shake the wing to guide the nut and string to the opening in

the top center of the wing.

6. Snap the optional retract landing gear covers onto the

❏

landing gear wires.

GET THE MODEL READY TO FLY

Check the Controls & Control Direction

WARNI NG : Do not install the propeller!

1. Turn on the transmitter, center the trims, and move the

❏

throttle stick all the way down. Attach a charged battery.

2. With the transmitter and receiver still on, check to make

❏

sure that all of the control surfaces are correctly centered

so that they are at zero de ection. Check to see that the

locking screws on the pushrod connectors are tight and

that the servo arm locking screws are installed. Make sure

that the nylon Faslinks are also installed properly and are

holding the pushrods securely.

3. Attach the retract lead to the string and carefully pull it

❏

through the wing and out of the opening. Tip: Tie the string to

the retract cable and use a piece of masking tape to position

the string at the end of the connector.

4. Remove the xed landing gear mount and attach the

❏

retract with the four 2.5 x 8mm at head screws.

5. Connect the two retract cables with a Y-harness and

❏

plug it into the retract channel on the receiver. Check that

the retracts operate smoothly.

RUDDER

MOVES RIGHT

FULL THROTTLE

3. Make certain that the control surfaces and the throttle

❏

respond in the correct direction as shown in the diagram.

If any of the controls respond in the wrong direction, use

the servo reversing in the transmitter to reverse the servos

connected to those controls. Be certain the control surfaces

have remained centered. Adjust if necessary. To arm the

motor, move the throttle stick to full, listen for the beeps,

then move it back to OFF. If the motor turns clockwise

when viewed from the front of the plane, remove the cowl

and switch any two wires going from the ESC to the motor.

Then, reinstall the cowl.

10

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

ELEVATOR MOVES DOWN

Page 11

Check the Control Throws

Install the Propeller & Spinner

The control throws are limited by the travel of the servos and

the mechanical set up of the pushrods. You can change the

control throw using the end-points or ATV feature of your

radio, or you can change the mechanical linkage to increase

or decrease the amount of control movement in relation to

the amount of servo movement. Keep in mind that changing

the throws mechanically is preferred to changing them using

your radio’s end-point adjustment. End points should be

used to “ ne-tune” to get the proper throws.

Hold a ruler up to the control surface while it is at zero throw

(neutral). Move the transmitter stick to the limit and measure

the amount of linear control throw. If your radio does not have

dual rates, we recommend setting the throws at the HIGH

rate setting. NOTE: The throws are measured at the widest

part of the elevators, rudder and ailerons.

If the control throws are too high, you can move the pushrod

connectors on the servo arms inward (toward the output

shaft) to decrease total travel.

IMPORTANT! Unplug the motor battery!

1. Remove the prop nut and prop washer from the prop

❏

adapter. Slide the prop adapter onto the motor shaft as shown.

These are the recommended control surface throws:

HIGH RATE LOW RATE

Up

1/4"

ELEVATOR

RUDDERAILERONS

[6 mm]

12 °

Right

11/ 16 "

[17 mm]

18°

Up

1/2"

[13 mm]

23°

Down

1/4"

[6 mm]

12 °

Left

11/ 16 "

[17 mm]

18°

Down

1/2"

[13 mm]

23°

DownOPTIONAL FLAPS

Up

1/8"

[3mm]

6°

Right

1/2"

[13 m m]

14°

Up

3/8"

[10 m m]

18°

1" [25 mm] 24°

Down

1/8"

[3mm]

6°

Left

1/2"

[13 m m]

14°

Down

3/8"

[10 m m]

18°

IMPORTANT! IMPORTANT! IMPORTANT!

Now that you have the throws set, be sure to set the

failsafe on the radio!

2. Fit the spinner backplate to the prop adapter. Fit the

❏

propeller, prop washer, and prop nut. Position the propeller

so that the trailing edge of each blade touches the alignment

pin. Tighten the prop nut.

3. Install the spinner using the two screws included in the

❏

spinner parts bag.

11

Page 12

Balance the Model (C.G.)

WARNING! DO NOT plug the motor battery into the ESC.

1. At this stage the model should be in ready-to- y condition

❏

with all of the systems in place including the motor, propeller,

spinner, radio system, battery and battery hatch.

landing gear will have a slight effect on the C.G. position.

2. Use a felt-tip pen or 1/8" [3mm]-wide tape to accurately

❏

mark the C.G. on the top of the wing on both sides of the

fuselage. The C.G. is located 3" [76mm] back from the

leading edge of the wing at the wing root where the wing

meets the fuselage.

NOTE:

The

4. If the tail drops, the model is “tail heavy” and the battery

❏

pack must be shifted forward or weight must be added to

the nose to balance. If the nose drops, the model is “nose

heavy” and the battery pack must be shifted aft or weight

must be added to the tail to balance.

5. Using a felt-tip pen, mark the position of the battery

❏

pack in the battery compartment. This will help eliminate trim

changes or unwanted surprises each time that you change

the battery. When using different capacity batteries, you

may have to re-balance your plane and place an additional

mark in the battery compartment. If you plan to y the model

with and without landing gear, make separate marks to help

you know where to place the battery to balance correctly in

each con guration.

6. If additional weight is required, use Great Planes

❏

(GPMQ4485) “stick-on” lead. A good place to add stick-on

nose weight is to the motor box under the cowl (don’t attach

weight to the cowl—it is not intended to support weight).

Begin by placing increasing amounts of weight on the top

of the cowl over the rewall until the model balances. Once

you have determined the amount of weight required, it can

be permanently attached by removing the cowl and installing

the weight.

IMPORTANT: If you found it necessary to add any weight,

recheck the C.G. after the weight has been installed.

APPLY THE DECALS

This is where your model should balance for the rst ights.

Later, you may wish to experiment by shifting the C.G. up

to 1/4" [6mm] forward or 1/4" [6mm] back to change the

ying characteristics. Moving the C.G. forward may improve

the smoothness and stability, but the model may then

require more speed for takeoff and make it more dif cult

to slow for landing. Moving the C.G. aft makes the model

more maneuverable, but could also cause it to become too

dif cult to control. In any case, start at the recommended

balance point and do not at any time balance the model

outside the speci ed range.

3. With all parts of the model installed (ready to y) and a

❏

battery pack in place (do not connect it), place your ngers

on the marks you made and balance the model.

1. Be certain the model is clean and free from oily

❏

ngerprints and dust. Prepare a dishpan or small bucket

with a mixture of liquid dish soap and warm water – about

½ teaspoon of soap per gallon of water. Submerse one of

the decals in the solution and peel off the paper backing.

Note: Even though the decals have a “sticky-back” and are

not the water transfer type, submersing them in soap and

water allows accurate positioning and reduces air bubbles

underneath.

2. Position the decal on the model where desired. Holding the

❏

decal down, use a paper towel to wipe most of the water away.

3. Use a piece of soft balsa or something similar to

❏

squeegee the remaining water from under the decal. Apply

the rest of the decals the same way.

12

Page 13

PREFLIGHT

Identify Your Model

No matter if you y at an AMA sanctioned R/C club site or

if you y somewhere on your own, you should always have

your name, address, telephone number, AMA number and

FAA number on or inside your model. It is required at all AMA

R/C club ying sites and AMA sanctioned ying events and

simply a “good idea” even if ying somewhere else. Fill out the

identi cation tag on page 15 and place it on or in your model.

Charge the Battery

Be certain to refer to the instructions that accompany the

charger to properly and safely charge the battery that goes

in the model and powers the motor and controls.

When discharging the battery, DO NOT attempt to fully

discharge the battery pack by repeatedly running the motor

to the ESC’s low voltage cutoff. This will drastically shorten

the life of your Lithium polymer (LiPo) batteries and could

cause the individual cells to become imbalanced.

MOTOR SAFETY PRECAUTIONS

● WARNING: Once the motor batteries are connected

the electric motor can start at any time. Make sure the

fail safe is set on your radio to prevent the motor from

starting if the signal is lost.

● WARNING: Read the entire instruction sheet included

with your motor batteries. Failure to follow the instructions

could cause permanent damage to the battery and its

surroundings and cause bodily harm!

● WARNING: Get help from an experienced pilot when

learning to operate electric motors.

● ALWAYS keep these items away from the prop: loose

clothing, shirt sleeves, ties, scarfs, long hair or loose

objects such as pencils or screwdrivers that may fall

out of shirt or jacket pockets into the prop.

● ALWAYS keep your face and body as well as all

spectators away from the plane of rotation of the

propeller as you start and run the engine.

● ALWAYS wear safety glasses when operating the motor.

● ALWAYS remove the propeller if the motor batteries will

be connected when working on your plane.

● ALWAYS remove the motor batteries when charging.

● ALWAYS follow the charging instructions included with

your charger for charging LiPo batteries. LiPo batteries

can cause serious damage if misused.

● ALWAYS unplug the motor batteries rst.

● ALWAYS use a LiPo approved charger.

● ALWAYS set the charger’s output volts to match the

battery volts.

● ALWAYS charge a LiPo battery in a reproof location.

● ALWAYS charge through the “charge” lead.

● ALWAYS KEEP OUT OF THE REACH OF CHILDREN.

● ALWAYS remove the batteries from the plane after a

crash. Set them aside in a safe location for at least 20

minutes. If the batteries are damaged in the crash they

could catch re. If the battery starts to swell, quickly

move the battery to a safe location, preferably outside.

Place it in a bucket, covering the battery with sand.

Never use water to try and put out a LiPo re.

● NEVER operate the motor in an area of loose gravel

or sand; the propeller may throw such material in your

face or eyes.

● NEVER touch the motor during or right after operation.

The motor gets HOT!

● NEVER switch off the transmitter with the motor

batteries plugged in.

● NEVER use a NiCd/NiMH peak charger to charge a

LiPo battery.

● NEVER charge in excess of 4.20v per cell unless the

battery is rated for a higher voltage.

● NEVER charge through the “discharge” lead.

● NEVER charge at currents greater than 1C unless the

battery is rated for a higher charge rate.

● NEVER trickle charge a LiPo battery.

● NEVER allow the battery temperature to exceed 150

degrees F (65° C).

● NEVER disassemble or modify the pack wiring in any

way or puncture the cells.

● NEVER discharge below 2.7V per cell.

● NEVER place the battery or charger on combustible

materials or leave it unattended during charge or

discharge.

● NEVER charge the batteries in the plane.

FLYING THE P-51 MUSTANG

While the P-51 is fairly easy to y, it is not a trainer. If you have

never own a model aircraft before, it is strongly suggested

that you learn to y with the assistance of an experienced

R/C pilot.

Find a Suitable Flying Site

Find a ying site clear of buildings, trees, power lines and other

obstructions. Until you know how much area will be required

and have mastered ying your P-51, a site at least the size

of two or three football elds should be adequate—a ying

eld speci cally intended for R/C planes is best. Don’t y

within six miles of R/C ying elds and never y near people.

13

Page 14

Perform a Range Check

Take Off

As a precaution, an operational ground range test should be

performed before the rst ight each time out. Performing a

range test is a good way to detect problems that could cause

loss of control such as low batteries, defective or damaged

radio components or radio interference. This usually requires

an assistant and should be done at the actual ying site you

will be using.

First, put the throttle stick in the low position and turn on the

transmitter. Then, install the fully charged battery into the

fuselage. Connect the battery and install the hatch.

Remember, use care not to “bump” the throttle stick.

Otherwise, the propeller will turn, possibly causing damage

or injury.

Begin walking away from the model operating the controls in

a predictable pattern (for example: Up, then down elevator.

Right, then left aileron. Right, then left rudder). While moving

the control surfaces, also vary motor rpm. Have your assistant

alert you if the controls fail to respond or if they move suddenly

or erratically. You should be able to maintain control up to a

distance of approximately 100' [30m].

If the controls respond erratically or if anything else seems

wrong, make certain all the servo wires are securely connected

to the receiver and that the transmitter batteries are fully

charged. If you cannot nd a mechanical problem with the

model, it is slightly possible that there is radio interference

somewhere in the area. One option would be to try another

range check at an alternate ying site.

Monitor Your Flight Time

Monitor and limit your ight time using a timer such as the one

on your wrist watch. When the batteries are getting low you

will usually notice a performance drop before the ESC cuts

off motor power, so when you notice the plane ying slower

you should land. Often (but not always!), power can be brie y

restored after the motor cuts off by holding the throttle stick

all the way down for a few seconds, then moving it up again.

To avoid an unexpected dead-stick landing on your rst ight,

set your timer to a conservative 5 minutes. When the alarm

sounds you should land your model.

When you learn how much ight time you are getting you

can adjust your timer accordingly. Always be conservative so

the motor won’t quit unexpectedly and you will have enough

battery to land under power. We recommend that you do

not use more than 80% of the battery capacity to ensure a

longer battery life.

Until you have become comfortable with ying your P-51,

do not y if the wind speed is greater than 10 mph [16

kilomoters/hr].

One nal check before takeoff: always double-check the

ight control response to your inputs from the transmitter

before every ight. Be certain the ailerons, elevator and

rudder respond correctly and that none of the controls has

inadvertently become reversed.

If the surface is smooth (such as pavement or blacktop)

the P-51 can take off from the ground. But most grass is

probably too tall, so if ying from grass the model will have

to be hand launched.

ROG Take Off

If taking off from the ground, place the model on your “runway”

with the nose pointing directly into the wind—this will reduce

the ground speed that must be reached and automatically

provide “heading assist” making steering and takeoff easier.

Slowly advance the throttle, adding rudder correction as

needed to keep the model rolling straight. When the plane

becomes “light” continue to apply throttle until you are at

full-power—all this will happen in a few seconds. When

suf cient liftoff speed has been reached, gradually apply

“up” elevator allowing the model to leave the ground. Do not

“yank” up on the stick—rather, be smooth and allow the plane

to establish a gentle climb.

Once you have reached a safe ying speed at a comfortable

altitude (approximately 50' [15m]), work the controls as

necessary to establish a gentle turn away from the runway,

and bring the optional retractable landing gear up.

Flying

One thing to remember is that, when the plane is ying away

from you, moving the aileron stick to the right will make

the plane bank to your right. However, when the model is

ying toward you, moving the aileron stick to the right will

make the plane move to your left. Of course, the plane is

still responding the same way, it’s just that your orientation

has reversed. This must be kept in mind while learning to

y (and is also a good reason to take ight lessons from an

experienced pilot!).

To establish a turn, “up” elevator (pulling back on the stick)

is usually required along with aileron input to get the model

into a bank. To stop the turn, apply a small amount of

opposite aileron.

Once you get the plane into the air and have climbed to a

comfortable altitude, the rst “order of business” will be to

“trim” the model for straight-and-level ight. The model ies

best at approximately 3/4-throttle. Adjust the trims on the

transmitter to make minor control surface adjustments as

necessary until the plane will y straight without any control

inputs. Often, your assistant can reach over and adjust the

trims for you.

14

Page 15

Remember to keep the model high enough to give yourself

time to make corrections, but don’t let it get too far away.

Otherwise, it will be dif cult to detect its attitude and which

way it is going.

One nal check before landing: see how the model will react

when it’s time to land and you reduce the throttle. To do this,

while still at altitude, cut the motor power. The model should

establish a gentle, downward glide path. This is how the

model will react when it’s actually time to land. Add power

and climb back up to your original altitude.

Practice a few of these “climb and glides” to judge how far

out you will need to be when it’s time to land.

If optional aps have been installed, slow the plane and lower

the aps. Check to see if it climbs with aps. If it does, a

small amount of down elevator can be mixed in.

Landing

To land, y down-wind past the landing area. Gently turn

into the wind, and reduce the throttle so that the airplane

initiates a descending glide path. If optional aps have been

installed, lower them now. If necessary, add power to extend

the glide path to reach the runway. As the model approaches

and loses altitude, gradually and proportionally add “up”

elevator to control the glide path and altitude. Continue to

apply elevator until the model touches down at which time

you should be holding full, or nearly full, up elevator. This will

cause the airplane to slow and settle to the ground.

CAUTION: If, during a rough landing, the propeller becomes jammed and cannot rotate, the battery and speed

control will become very hot if you attempt to add power.

Immediately move the throttle down to stop the motor. If

you fail to do this, the motor, speed control and/or battery

will be damaged.

AFTER EACH FLIGHT

Disconnect the battery and remove it from the airplane. Then,

turn off the transmitter. Allow the battery to cool before

recharging, or allow the motor to cool before installing another

battery for the next ight. Inspect the airplane to make sure

nothing has become loose or damaged.

REPAIRING YOUR MODEL

If your model becomes damaged, it can be repaired using

regular medium CA. Spare parts are available – please see

the parts list earlier in this manual for more details of what is

available and how to get new parts. CA debonder (GPMR6039)

is available if you ever need to dissolve the CA adhesive you

used to build or repair this model.

Have a ball! But always stay in control

and y in a safe manner.

GOOD LUCK AND GREAT FLYING!

This model belongs to:

Name

Address

City, State, Zip

Phone Number

AMA Number

FAA Number

15

Page 16

© 2016 Towe r H o bbi es .® A subsidiary of Hobbico, Inc.

v1.1

16

Loading...

Loading...