TOUGH-WORKS TLGS625 Instruction Manual

TLGS625

2" X 28" BELT AND 6" WHEEL

BENCH GRINDER SANDER

IMPORTANT:

For your own safety, read and follow all of the Safety

Guidelines and Operating Instructions before operating

this product.

INSTRUCTION

MANUAL

TLGS625

TABLE OF CONTENTS

TABLE OF CONTENTS ...............................................................................................

SPECIFICATIONS ......................................................................................................

SAFETY GUIDELINES ................................................................................................

ELECTRICAL SAFETY .................................................................................................

PACKAGE CONTENTS ..............................................................................................

KEY PARTS DIAGRAN

ASSEMBLY INSTRUCTIONS........................................................................................

OPERATION .................................................................................................................

MAINTENANCE ............................................................................................................

TROUBLESHOOTING GUIDE .....................................................................................

EXPLONED VIEW .........................................................................................................

PARTS LIST ..................................................................................................................

WARRANTY ..................................................................................................................

..................................................................................................

2

2

4

6

7

8

10

12

15

17

18

19

20

2

TABLE OF CONTENTS

SPECIFICATIONS

Motor 120V, 60Hz , 2.5A

Speed (no load) 3450RPM

Belt size 2" x 28"

Wheel size

6"x3/4"x1/2"

3

BD4603

TLGS625

GENERAL SAFETY GUIDELINES

BEFORE USING THIS POWER

TOOL

• Operate in a safe work environment. Keep

your work area clean, well lit and free of

distractions.

• Keep anyone not wearing the appropriate s

afety equipment away from the work area.

• Store tools properly in a safe and dry location.

Keep tools out of the reach of children.

• Do not install or use in the presence of flam mable gases, dust or liquids.

• Always wear impact safety goggles that

provide front and side protection for the eyes.

Wear a full-face shield if your work creates

metal filings or wood chips. (Eye protection

equipment should comply with ANSI Z87.1

standards.)

• Wear gloves that provide protection based on

the work materials or to reduce the effects of

tool vibration.

• Non-skid footwear is recommended to main-

SAFETY GUIDELINES

tain footing and balance in the work environment.

• Wear the appropriate rated dust mask or

respirator.

• Do not operate any tool when tired or under

the influence of drugs, alcohol or medications.

• Avoid wearing clothes or jewelry that can b ecome entangled with the moving parts of a

tool. Keep long hair covered or bound.

• Do not overreach when operating the tool.

Proper footing and balance enables better

control in unexpected situations.

• Securely hold the material using both hands.

Applying the material to the grinder with only

one hand can result in a loss of control.

• Never use a tool with a cracked or worn gri nding wheel. Change the grinding wheel

before using.

• Replace cracked wheel immediately. Use only

flanges supplied with the grinder.

• Clean dust and debris from beneath the gri nding wheels frequently.

• Do not start the tool if the grinding wheel is in

contact with the workpiece.

• Always ensure the safety guards are attached

correctly and do not operate the bench grinder

without the guards attached. Adjust the dista nce between the wheel and the tool rest to

maintain a 1/16 in. or less separation as the

diameter of the wheel decreases with use.

• Use an appropriate dust respirator when working

for an extended period of time. This will help

prevent breathing in the fine dust created while

grinding.

• Do not grind on the sides of grinding wheels

unless they are specifically designed for that

purpose.

• Before using the tool on the workpiece, run the

tool at the highest speed, without a load, for at

least 30 seconds in a safe position. Stop im mediately if there is any vibration or wobbling

that could indicate poor installation or a poorly

balanced grinding wheel. Check the tool to

determine the cause.

• Do not allow the motor to overload or overheat.

Take breaks to rest the tool.

• Do not subject the grinding wheel to any lateral

pressure as it may damage the tool or cause

it to kickback.

ADDITIONAL SPECIFIC SAFETY

RULES

1. Only use a grinding wheel with the correct arbor

size and shape that matches the grinder’s

spindle.

2. Ensure the grinding wheel has a clean edge.

Check the grinding wheel for wear or chipping

and replace if necessary.

3. Never install more than one grinding wheel at

a time unless the tool and wheels are design ed for that purpose.

4. A large amount of sparks will be created when

working with a grinding wheel. Hold the tool

so that sparks fly away from you and other

persons or flammable materials. Have a fully

charged fire extinguisher present.in the event

of a fire.

5. Do not subject the grinding wheel to any

lateral pressure as it may damage the

tool or cause it to kickback.

TLGS625

4

6. Disconnect tool from power source before

cleaning, servicing, changing parts/accessor ies or when not in use.

7. Protect yourself against electric shocks when

working on electrical equipment. Avoid body

contact with grounded surfaces. There is an

increased chance of electrical shock if your

body is grounded.

8. Do not expose tool to rain or water entering a

power tool will increase the risk of electric shock.

9. Do not disconnect the power cord in place of

using the ON/OFF switch on the tool. This will

prevent an accidental startup when the power

cord is plugged into the power supply.

10. Do not alter any parts of the tool or accessories.

All parts and accessories are designed with

built-in safety features that may be compro mised if altered.

11. Make certain the power source conforms to

requirements of your equipment.

12. Do not allow the tool to run without load for an

extended period of time, as this will shorten

its life.

13. Do not cover the air vents. Proper cooling of

the motor is necessary to ensure normal life

of normal life of the tool.

14. Avoid unintentional starting. Ensure the switch

is off when connecting to the power source.

15. In the event of a power failure, turn off the

machine as soon as the power is interrupted.

interrupted. The possibility of accidental injury

could occur if the power returns and the unit is

not switched off.

16. Disconnect the power source before installing

or servicing the tool.

17. After making adjustments, make sure that any

adjustment devices are securely tightened.

18. Remove adjusting keys and wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool increases

the risk of personal injury.

19. Never force the tool. Excessive pressure could

break the tool, resulting in damage to your

workpiece or serious personal injury. If your tool

runs smoothly under no load, but does not run

smoothly under load, then excessive pressure

is being used.

20. Do not touch an operating motor. Motors can

operate at high temperatures.

21. Only use accessories that are specifically

designed for use with the tool. Ensure the

accessory is tightly installed.

22. Only use an accessory that exceeds the No

Load Speed rating.

23. Do not touch an operating motor. Motors can

operate at high temperatures and can cause

a burn injury.

24. Insert the power cord plug directly to the power

supply whenever possible. Use extension cords

or surge protectors only when the tool's power

cord cannot reach a power supply from the work

area.

25. Do not operate this tool if the power cord is fr ayed or damaged as an electric shock may

occur, resulting in personal injury or property

damage.

26. Inspect the tool's power cord for cracks, fraying

or other faults in the insulation or plug before

each use.

27. Discontinue use if a power cord feels more than

comfortably warm while operating the tool.

28. Keep all connections dry and off the ground to

reduce the risk of electric shock. Do not touch

plug with wet hands.

29. Do not allow people, mobile equipment or ve hicles to pass over unprotected power cords.

30. This tool vibrates during use. Repeated or long term exposure to vibration may cause tempo rary or permanent physical injury, particularly

to the hands, arms and shoulders.

SAFETY GUIDELINES

5

BD4603

TLGS625

A separate electrical circuit should be used for your

machines. This circuit should

wire and should be protected with a 20-A time-lag

fuse. If an extension cord is used, use only 3-wire

extension cords which have 3-pronged grounding

type plugs and matching receptacle which will

accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch

is in the "OFF" position and be sure that the ele ctric current is of the same characteristics as

indicated on the machine. All line connections

should make good contact. Running

will damage the machine.

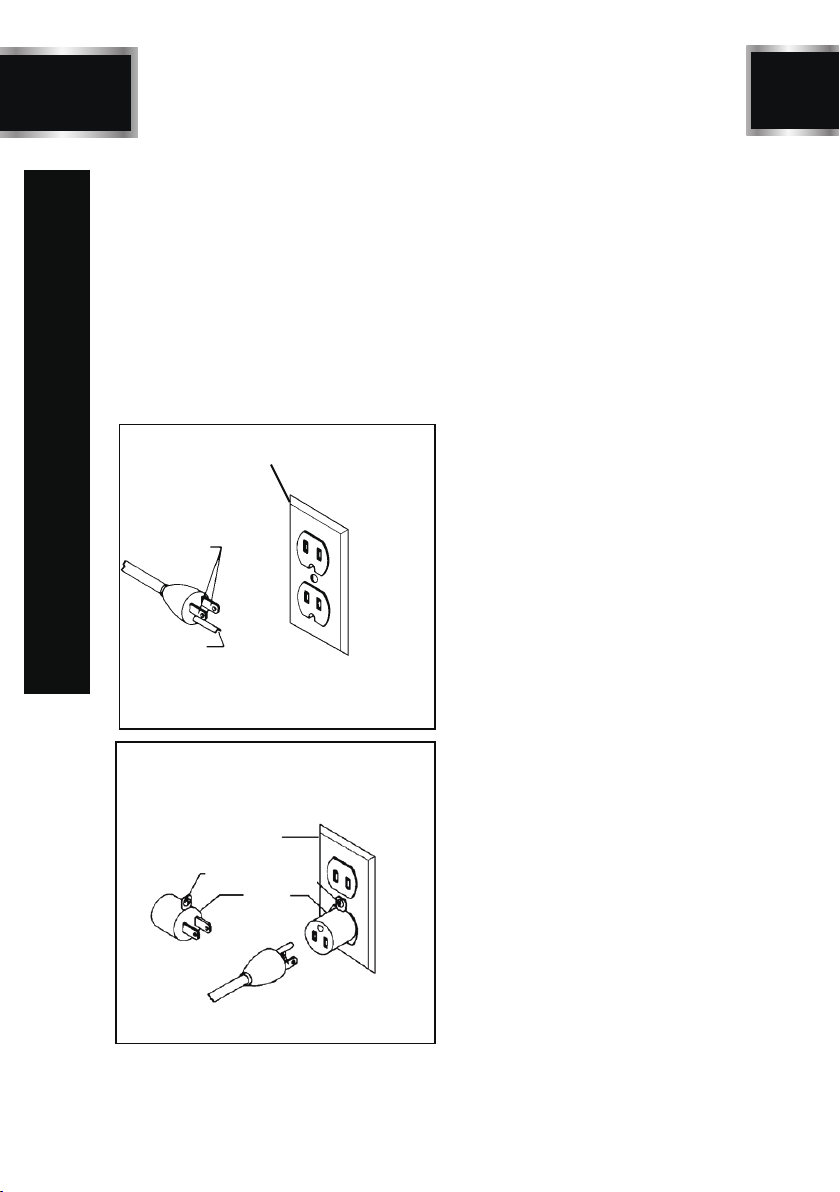

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

not be less than #12

on low voltage

ELECTRICAL SAFETY

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

Figure. 1

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

Figure. 2

MOTOR SPECIFICATIONS

Your machine is wired for 120 V, 60Hz

alternating current. Before connecting the

machine to the

power source, make sure

the switch is in the "OFF" position.

GROUNDING INSTRUCTIONS

All grounded, cord-connected machines: In the

event of a malfunction or breakdown,grounding

provides a path of least resistance for electric

current to reduce the risk of electric shock. This

machine is equipped with an electric cord having

an equipment grounding conductor and a grounding plug.

DANGER!

DO NOT EXPOSE THE MACHINE TO RAIN OR

OPERATE THE MACHINE IN

THIS MACHINE MUST BE GROUNDED

WHILE IN USE TO PROTECT THE

FROM ELECTRIC SHOCK.

The plug must be plugged into a matching outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided–if it will not fit

the outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the

machine is properly grounded.

Use only 3-wire extension cords that have 3-pronged

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown

in Fig. A.Repair or replace damaged or worn cord

immediately.

!

DAMP LOCATIONS.

OPERATOR

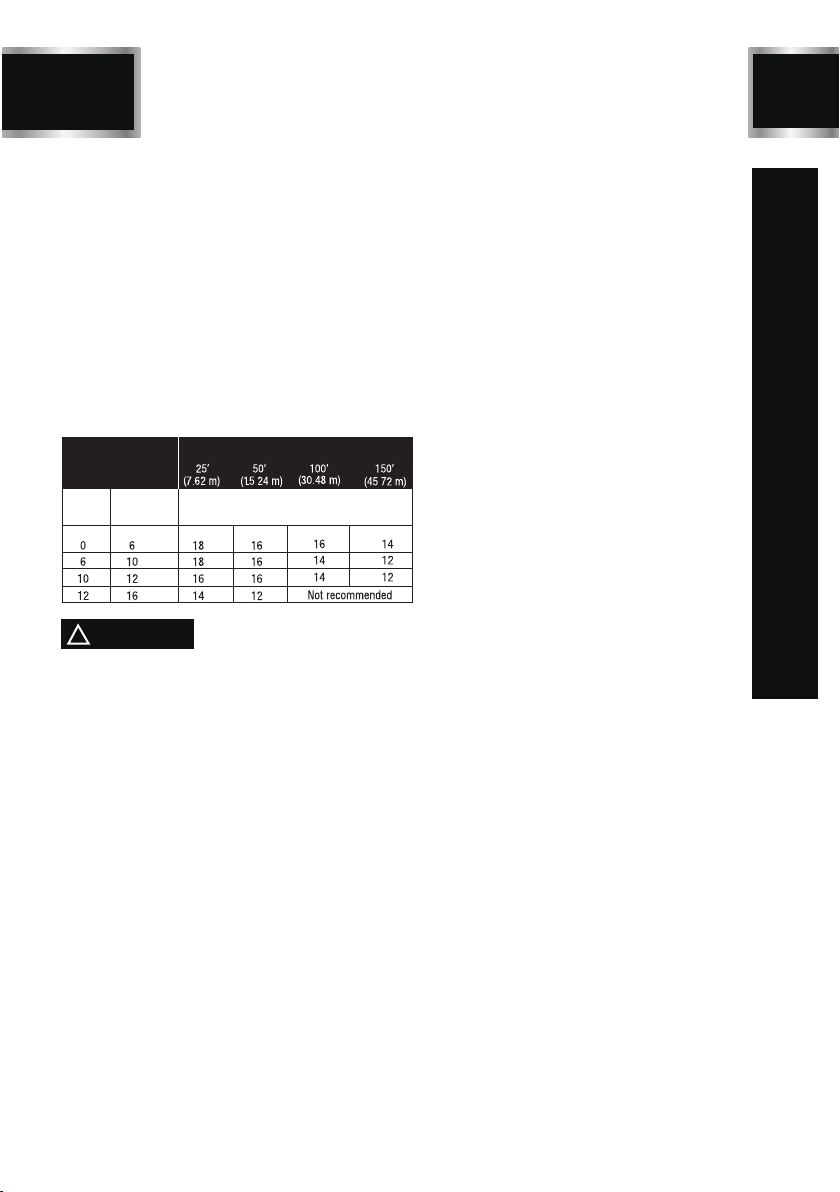

MINIMUM GAUGE FOR CORD SETS

Use proper extension cords. Make sure your extension

cord is in good condition and is a 3-wire extension

cord which has a 3-pronged grounding type plug

and matching receptacle which will accept the machine’s plug. When using an extension cord, be

sure to use one heavy enough to carry the current

of the machine. An undersized cord will cause a

drop in line voltage, resulting in loss of power and

overheating. The table shows the correct gauge

to use depending on the cord length. If in doubt,

use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Ampere rating of

the tool

(120V circuit only)

More

Not more

than

than

Total length of cord

Minimum Gauge for the

extension cord (AWG)

TLGS625

6

!

WARNING!

In all cases,make certain the receptacle in question is properly grounded.

If you are not sure,have a electrician check the

receptacle.

ELECTRICAL SAFETY

Loading...

Loading...