TOUGH-WORKS DP8 Instruction Manual

DP8

8- INCH DRILL PRESS

IMPORTANT:

For your own safety, read and follow all of the Safety

Guidelines and Operating Instructions before operating

this product.

INSTRUCTION

MANUAL

TABLE OF CONTENTS

TABLE OF CONTENTS ...............................................................................................

SPECIFICATIONS ......................................................................................................

SAFETY GUIDELINES ................................................................................................

ELECTRICAL SAFETY .................................................................................................

PACKAGE CONTENTS ..............................................................................................

KEY PARTS DIAGRAN

ASSEMBLY INSTRUCTIONS........................................................................................

OPERATION .................................................................................................................

MAINTENANCE ............................................................................................................

TROUBLESHOOTING GUIDE .....................................................................................

EXPLONED VIEW .........................................................................................................

PARTS LIST ..................................................................................................................

WARRANTY ..................................................................................................................

..................................................................................................

DP8

2

2

8

9

10

11

12

2

13

15

16

18

19

20

TABLE OF CONTENTS

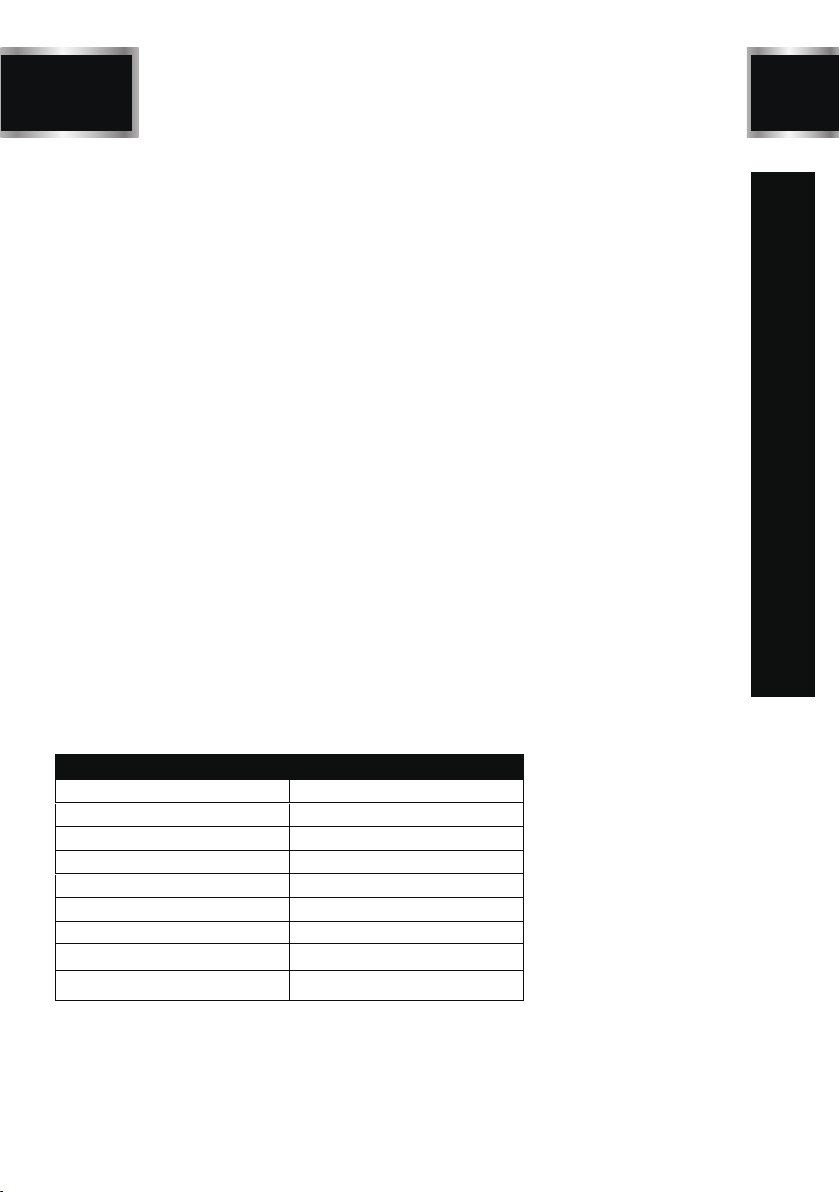

SPECIFICATIONS

Model

Motor 120V, 60Hz

Speed

Chuck size 1/2 in.

Taper

Swing 8 in.

Spindle travel 2 in.

Drilling capacity 1/2 in.

Net weight 33 lb.

DP8

250WPower

620~3100RPM

JT33

3

BD4603

SAFETY GUIDELINES - DEFINITIONS

WARNING ICONS

Your power tool and its Instruction Manual may contain “WARNING ICONS”(a

picture)symbol intended to alert you to and/or instruct you how to avoid a potentially

hazardous condition). Understanding and heeding these symbols will help you operate

your tool

SAFETY GUIDELINES

better and safer. Shown below are some of the symbols you may see.

SAFETY ALERT: Precautions that involve your safety.

PROHIBITION

WEAR EYE PROTECTION: Always wear safety goggles or safety glasses with

side shields.

WEAR RESPIRATORY AND HEARING PROTECTION: Always wear respiratory

and hearing protection.

READ AND UNDERSTAND INSTRUCTION MANUAL: To reduce the risk of injury,

user and all bystanders must read and understand instruction manual before using

this product.

KEEP HANDS AWAY FROM THE MOVING PART AND CUTTING SURFACE:

Failure to keep your hands away from the moving part and cutting surface will

result in serious

SUPPORT AND CLAMP WORK

personal injury.

DP8

DANGER

!

WARNING

!

CAUTION

!

NOTICE

WARNING

!

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to the state of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

Lead from lead-based paints.

Crystalline silica from bricks and cement and other masonry products.

Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work

DANGER: Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided,may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates potentially

hazardous situation which, if not avoided, may result in property damage.

DP8

with approved safety equipment, such as those dust masks that are specially designed

sanding, sawing, grinding, drilling, and other construction activities. Wear protective

clothing and wash exposed areas with soap and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING

!

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection.

This tool is wired at the factory for 110-120 Volt operation. It must be connected to a 110-120

Volt /15 Ampere time delay fuse or circuit breaker. To avoid shock or fire, replace power cord

immediately if it is worn, cut or damaged in any way.

Before using your tool, it is critical that you read and understand these safety rules. Failure to

follow these rules could result in serious injury to you or damage to the tool.

4

SAFETY GUIDELINES

5

BD4603

DP8

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THIS POWER TOOL

Safety is a combination of common sense,

staying alert and knowing how to use your

power tool.

WARNING

!

To avoid mistakes that could cause serious

injury, do not plug the tool in until you have

read and understood the following.

Read all instructions before operating

product. Failure to follow all instructions listed

below may result in electric shock, fire and

/or serious injury.

1. READ and become familiar with the

entire Instruction Manual. LEARN

the tool’s application, limitations and

and possible hazards.

2. KEEP GUARDS IN PLACE and in working

order.

SAFETY GUIDELINES

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DO NOT USE IN DANGEROUS

ENVIRONMENTS. Do not use power tools

in damp locations, or expose them to rain

or snow. Keep work area well lit.

5. KEEP CHILDREN AWAY. All visitors and

bystanders should be kept a safe distance

from work area.

6. DO NOT FORCE THE TOOL. It will do the

job better and safer at the rate for which it

was designed.

7. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets or other jewelry which may get

caught in moving parts. Nonslip footwear

is recommended. Wear protective hair

covering to contain long hair.

8. ALWAYS WEAR EYE

PROTECTION. Any power tool can

throw foreign objects into the eyes

and could cause permanent eye damage.

ALWAYS wear Safety Goggles (not

glasses) that comply with ANSI Safety

standard Z87.1. Everyday eyeglasses

have only impact–resistant lenses. They

ARE NOT safety glasses. NOTE: Glasses

or goggles not in compliance with ANSI

Z87.1 could seriously injure you when

they break.

9.

10. DISCONNECT TOOLS FROM POWER

11. USE PROPER EXTENSION CORDS.

Make sure your extension cord is in

good condition. When using an extension

cord, be sure to use one heavy enough

to carry the current your product will draw.

An undersized cord will result in a drop

in line voltage and in loss of power

which will cause the tool to overheat.

The table on page 8 shows the correct

size to use depending on cord length

and nameplate ampere rating. If in

doubt, use the next heavier gauge.

The smaller the gauge number, the

heavier the cord.

12. USE RECOMMENDED ACCESSORIES.

13. NEVER STAND ON THE TOOL. Serious

14. MAINTAIN TOOLS WITH CARE. Keep

15.CHECK FOR DAMAGED PARTS.

Before further use of the tool, a guard or

other part that is damaged should be

WEAR A FACE MASK OR

DUST MASK. Sanding operation

produces dust.

SOURCE before servicing, and when

changing accessories such as blades,

bits and cutters.

Consult this Instruction Manual for

recommended accessories. The use of

improper accessories may cause risk of

injury to yourself or others.

injury could occur if the tool is tipped

or if the cutting tool is unintentionally

contacted.

tools sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

DP8

6

carefully checked to determine that it

will operate properly and perform its

intended function– check for alignment

of moving parts, binding of moving parts,

breakage of parts, mounting and any other

conditions that may affect its operation.

A guard or other part that is damaged

should be properly repaired or replaced.

16. NEVER LEAVE THE TOOL RUNNING

UNATTENDED. TURN THE POWER “OFF”.

Do not walk away from a running tool until

the blade comes to a complete stop and the

tool is unplugged from the power source.

17. DO NOT OVERREACH. Keep proper footing

and balance at all times.

WARNING

!

18.

Dust generated from certain materials

can be hazardous to your health. Always

operate saw in well-ventilated area and

provide for proper dust removal.

19.

DANGER

!

People with electronic devices, such

as pacemakers, should consult their

physician(s) before using this product.

close proximity to a heart pacemaker

could cause interference or failure of the

pacemaker.

20. WEAR HEARING PROTECTION

to reduce the risk of induced

hearing loss.

DRILL PRESS SAFETY

WARNING

!

For your own safety, do not try to use your

drill press or plug it in until it is completely

assembled and installed according to the

instructions, and until you have read and

understood this instruction manual:

1. YOUR DRILL PRESS MUST BE BOLTED

securely to a workbench. In addition,

if there is any tendency for your drill press

to move during certain operations, bolt the

workbench to the floor.

2. THIS DRILL PRESS is intended for use in

dry conditions, indoor use only.

3. WEAR EYE PROTECTION. USE a face or

dust mask along with safety goggles if

drilling operation is dusty.

USE ear protectors, especially during

extended periods of operation.

4. DO NOT wear gloves, neckties, or loose

clothing.

5. DO NOT try to drill material too small to

be securely held.

6. ALWAYS keep hands out of the path of

a drill bit.

Avoid awkward hand positions where a

sudden slip could cause your hand to move

into the drill bit.

7. DO NOT install or use any drill bit that

exceeds 175 mm (7 in.) in length or extends

150 mm (6 in.) below the chuck jaws.

They can suddenly bend outward or break.

8. DO NOT USE wire wheels, router bits,

shaper cutters, circle (fly) cutters,

or rotary planers on this drill press.

9. WHEN cutting a large piece of material,

make sure it is fully supported at the table

height.

10.DO NOT perform any operation freehand.

ALWAYS hold the workpiece firmly against

the table so it will not rock or twist. Use

clamps or a vise for unstable workpieces.

11. MAKE SURE there are no nails or foreign

objects in the part of the workpiece to

be drilled.

12. CLAMP THE WORKPIECE OR BRACE IT

against the left side of the column to

prevent rotation. If it is too short or the

table is tilted, clamp it solidly to the table

and use the fence provided.

13. IF THE WORKPIECE overhangs the table

such that it will fall or tip if not held, clamp

it to the table or provide auxiliary support.

14. SECURE THE WORK. Use clamps or a vise

to hold the work when practical. It’s safer

SAFETY GUIDELINES

Loading...

Loading...