I N S T A L L A T I O N M A N U A L

Universal flat-panel mount

3130 E. Miraloma Ave. Anaheim, CA 92806 Phone: 800 368-9700 Fax: 800 832-4888

www.mounts.com

PREMIER MOUNTS ©2004/ REV 02

R

LISTED

E176225

www.touchboards.com 205 Westwood Ave.Long Branch, NJ 07740 1-866-942-6273 Sales@touchboards.com

g

jury

Contents

- Assembly drawing - Securing the bottom wall plate

- Fine tune tilt adjustments - Securin

- Flat panel list - Securing the flat panel to the wall mount

- Parts list - Lateral shift adjustment

- Checking thread depth

- Finding the center of the flat panel

- Positioning the mounting brackets

- Securing the mounting brackets

- Finding the wood stud behind the wall structure

- Marking the bottom plate mounting points

The wall structure should be capable of supporting a max weight of 160 Lbs., the weight of the flat panel. More than 160 Lbs the wall must

be reinforced. Proper installation procedure by qualified personnel as outlined in the installations instructions must be adhered to. Failure to

do so could result in serious personal injury.

WARNING: Safety precaution measures must be practiced at all times during the installation of this product. Use proper safety gear and

tools for the installation procedure to prevent personal injury.

The entire installation instructions should be fully read and understood, including all of the safety symbols and safety precautions, before

beginning installation. The installation instructions should be read, understood and followed to prevent personal in

Keep these installation instructions in an easily accessible location for future reference.

Indicates that the power plug is to be disconnected from

the power outlet.

Safety precautions must be taken at all times.

Warning and caution in general

A secured structure wooden stud wall must always support the weight or load of the flat panel. Always confirm the center of the wood

stud before beginning the installation.

Do not install in locations where there is vibration, movement or danger of impact. Failure to do so could result in flat panel cracking or

falling from the wall causing damage and injury.

Do not install near heater, fireplace, direct sunlight or air conditioning or any other source of direct heat energy. Failure to do so may

result in damage to the flat panel and could cause a risk of fire.

At least two qualified people should always perform the installation work. Injury and damage can result from dropping or mishandling

the flat panel.

- 2 -

Mounting structure recommended wood studs, solid-flat concrete. Use a min dia of 5/16” x 2 ¼” lg concrete wedge anchor

(commercially available). or a min dia of 5/16” x 3” lg wood screws.

the top plate

or property damage.

Contact Premier Mounts for any questions

A

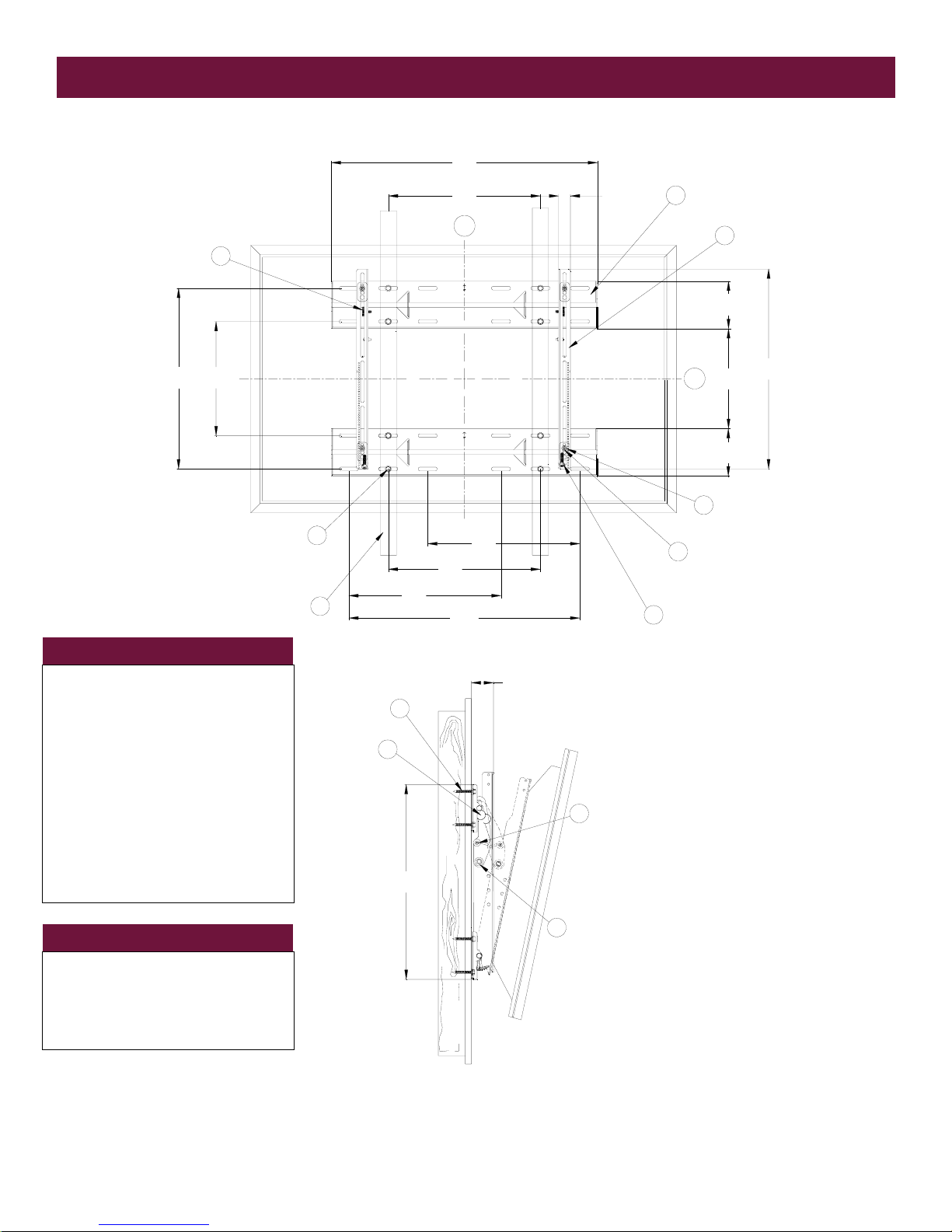

Assembly drawing

Dimensions are in Inches and (mm)

H

28.000

(171.2)

16.000

(406.4)

C

L

1.245

(31.75)

A

B

5.000

(127)

12.000

19.000

(482.6)

(304.8)

C

L

10.500

(266.7)

21.000

(533.4)

5.000

(127)

C

16.000

(406.4)

(616.97)

24.290

16.000

(406.4)

2.331

(59.21)

D

E

1

Description

. Wall plates

B. Mounting brackets

C. Griplate™

D. Mounting hardware

E. M6 x 30 (mm) Phillip screws

F. Wood stud

G. 5/16” x 3” Lag screws and flat washers

H. Safety knobs

G

16.000

H

(406.4)

G

20.500

(520.7)

F

Fine tune tilt adjustments

1. M5 Phillips screws for fine tension

2. M8 Hex nut coarse tension

NOTE: The 8 (mm) hex nut is for your coarse

tension adjustment and the 5 (mm) screws are for

your fine tension adjustment.

2

- 3 -

Flat panel list

Acer

PDP7859: M6 x 20

Akai

CTA42AR7A, PDP4247, PDP4290, PDP4294,

PDP5090, HPT500AN: M8 x 25 – ½” nylon spacers -

sleeves

Akira

EPM420, SV4201: M5 x 16

Albatron

PWV46AC: M6 x 20

Barco

Cineversum 50: M8 x 20

BenQ

PDP7843E: M6 x 20 – ¼” nylon spacers (small)

PDP46W1: M6 X 12

Cornea

MP4200, MP4204: M5 x 16

Dream Vision

Revolution One, Revolution Five: M4 x 16

Dukane

P37: M6 x 12

P42: M6 x 12

P50: M8 x 20

Dwin

HD50: M8 x 30 – ½” nylon spacers - sleeves

EIKI

PLD32: M5 x 20 - ¼” nylon spacers (small)

PLD42XU: M5 x 20 - ¼” nylon spacers (small)

NOTE: If your flat panel display is not listed, go to (page 8) to determine the thread pitch for your flat panel.

- 4 -

Eizo

5420T: M8 x 30

Electrograph

DTS42W: M8 x 30 – ¼” nylon spacers (large)

DTS4230: M8 x 30 – ½” nylon spacers - sleeves

DTS42DD, DTS42GBDD, DTS42GB: M6 x 20

Faroudja

FPP42HD10, FPP50HD10: M4 X 16

Fujitsu

4211, 4212, 4221, 4222, 4208, 4209, 4213, 4214, 4229,

4241 4242, 4233: M5 x 16

5001, 5002, 5003, 5004, P50XHA10, P50XCA11UH,

P50XHA30WS: M8 x 25 – flat washers

PDS6101, PDS6001, PDS6002: M8 x 30 – ½” Nylon

spacers - sleeves

Gateway

GTWP42M102: M8 x 20, M8 x 35 – ¼” nylon spacers

(large)

GATEWAY 42: M8 x 30 – ¼” nylon spacers

GATEWAY 46: M6 x 20

GATEWAY 50: M8 x 30 – ¼” nylon spacers

Helios

4200: M8 x 20

Hitachi

32HDT20,CMP307XJ,CMP307XU,32HDT20

CMP401HDU, CMP402HDE, CMP402HDU,

CMP4120HDU,CMP4121,CMP4121HDU,CMP4201U,

CMP4202U, 42HDW10,42HDT20, 42HDT50, 42HDT55

M6 x 12

CMP5000WXU, CMP5003WXU, 50HDT50, 50HDT55:

M8 X 20

Idex

PDM4260: M4 x 16

Ikegami

PTM4202: M5 x 20

Integra

PLA50V1: M4 X 16

JVC

GDV4200PZW, 4210, GDV4210PZWGA, 4211,

GMP420UG, GMV42UG, JVP042WV74, PD42WV74,

PD42WX84: M5 x 16

GDV500PZU, GDV501U, 502U: M8 X 30 – ½” nylon

spacers – sleeves

LG Electronics

Flatron MU40PA10B, MU40PA15B: M5 x 20- ¼” nylon

spacers

Flatron MN42PZ10, MN42PZ11, MU42PZ10,

MU42PZ11B, MU42PZ15B: M5 x 20

MU50PZ41, MU50PZ90: M5 x 20

Flatron MU60PZ10, MU60PZ11B, MU60PZ12B,

MU60PZ90V: M8 x 25

Luce

PDTV4220A: M5 x 25 – ½” nylon spacers

Marantz

PD4280D, PD4282D, PD4290D, PD4292D,

PD4293: M4 x 20

PD4298HD: M6 X 20

PD501OD, PD5020, PD5040:

Max

4600, 4600T: M6 x 20

5000: M8 x 30- ½” nylon spacers - sleeves

A

Mitsubishi

PD5010HD, PD5030: M4 x 16

Monivision

PWV46AC, PD46W00: M6 x 20

NEC

4200W, 4210W, M4A,MP2, PX42M3A, 42PD1W, PD2

M5A,M5G, 42MP1, 42PD1, PX42VM1A, PX42VP1A,

PX42VP2A, 42MP3, 42PD3, PX42VP3A, 42MP4,

42VP4A, 42MX2: M4 X 16, 5000W, PX50M5A, 50PD1,

PX50VP1A, PX50MX1A, 50MP1, 50MP2, 50PD2,

50VP2, 50MP3,

50XM3: M4 X 16

Norcent

46WGA850: M6 x 12

Orion

PM4202: M5 x 16

Panasonic

TC42P1, PT42PD3P, PT42PD1P, TC42P1F, PT37P1,

TH42PWD3, TH37PWD4UZ, PT37PD4, TH37PW5EX,

TH37PA20UP, TH42PD4UY, TH42PWD4EX, PT42P1,

42PD2, TH42PWD3U, TH42PHD5U, PT42PD3P,

PT42PD4, PT42PHD4P, TH42PWD5UY, TH42PW5UZ,

TH42PWD6UY, TH42PA20UP, TH42PL20E,

TH42PAX20, TH50PHD3U, PT50PD3P, PT50PHD4P,

TH50PHD3E, TH50PHW3, TH50PD4, TH50PHD5UY,

TH50PHD6UY, TH50PL20E, TH50TX20UP:

M8 X 30 – ½” Nylon spacers – sleeves

TH42PX20U, TH50PX20U: M8 X 70 – 1-1/2” Nylon

spacers

Philips

42FD9934, 42FD9952, 42FD9954, 42PH9555,

42FD9935: M5 x 25 ½” Nylon spacers

BDS4611: M6 x 20

50FD9934/17S: M4 X 16

Pioneer

PDPV401, V402, PDP4330HD, PDP433HDE,

PDP433CMX, PDP433PU, PDP4300, PDP4340HD,

PRO800HD, PRO800HDI, PRO910HD, PDP4310,

PDP501X, V502MX, V502X, PDP503MX, V505,

PDP505HD, PRO1000HD, PDP503CMX, PDP5030HD,

PDP503HDE, PDP5031HD, PDP5040HD,

PRO1000HDI,PRO1110HD: M8 X 20

Planar

42N: M4 x 16

50P: M8 x 20

Princeton Graphics

R3.4FTW,AR4.6PDP: M6 x 20

Rainbow

Spectrum 3750: M6 x 20

RCA

PR42300, PHD42600, PHD50300, PHD50400: M4 X 16

PHD50500: M8 X 20

Revox

E1042: M6 x 20

E1050: M8 x 20

Runco

PL42C, CW42: M4 X 16

PL42CXPL50CX: M8 X 30, ½” Nylon spacers –

sleeves

E1050, PL50C, PL50HDX, CW50MC: M8 X 20

Sampo

PME42S6: M8 x 30 – ¼” nylon spacers (large)

PME42F61: M8 x 20, M8 x 35 – ¼” nylon spacers

(large)

PME50X6: M8 x 30 – ¼” nylon spacers (large)

Samsung

PPM42S2, PPM42S3, SPL4225K, SPN4235, SPN4239:

SPK4215M, PK42P2S: M8 x 25 – ½” nylon spacers

PPM50H2, HPL5025K: M8 x 30 – ½” Nylon spacers -

sleeves

PPM50H3, HPN5039: M8 x 25 – ½” nylon spacers

Sanyo

PDP421A: M5 x 20 - ¼” nylon spacer (small)

PDP42H1NA: M5 x 20 - ¼” nylon spacer (small)

Sharp

PZ42H2U, PZ43HV2U, PD50U, PZ50HV2U: M8 X 20

SONY

PFM42B1,PFM42B2: M6 x 20 - 5/16” flat washers

PFM-42V1,PFM-42V2: M6 x 25 – 9/16” nylon spacers

PFM50C1: M6 x 20 - 5/16” flat washers

KE-42XBR900: M6 x 20 - 5/16” flat washers

KE50XBR900: M6 x 20 - 5/16” flat washers

KE42XS910: M6 x 20 - 5/16” flat washers

KDE61XBR950: M6 x 20 - 5/16” flat washers

SVA

HD4208TIII: M6 x 20 - ¼” nylon spacers

Tatung

P46T: M6 x 20

Toshiba

42HP82: M4 X 16

PD42W, PD42W1: M8 X 30 – ½ ” nylon spacers

(large) - sleeves

50HP81: M8 X 30 – ½” nylon spacers (large) - sleeves

50HP82: M4 X 16

Tredex

TXP4600: M6 x 20

V-Inc

Vizio P1, Vizio P4: M6 x 12

Vidikron

VPW420: M8 X 30, ½” Nylon spacers (large) - sleeves

VIEWSONIC

VPW420: M8 x 30 – ½” nylon spacers - sleeves

VPW425: M8 x 30 – ¼” nylon spacers (large)

VPW450HD: M8 x 30 – ¼” nylon spacers (large)

VPW500: M8 X 20

VPW505: M8 x 30 – ¼” nylon spacers (large)

Yamaha

PDM1: M8 x 30 – ½” nylon spacers - sleeves

Zenith

DPDP40W, P40V22,DPDP40V, P40V24: M5 x 20 – ¼”

nylon spacers (small)

P42W22, P42W22B, P42W24P, P42W34P: P40V24:

M5 x 20 – ¼” nylon spacers (small)

P50W26, P50W28, P50W38: M5 x 16

NOTE: If your flat panel display is not

listed, go to (page 8) to determine the

thread pitch for your flat panel.

- 5 -

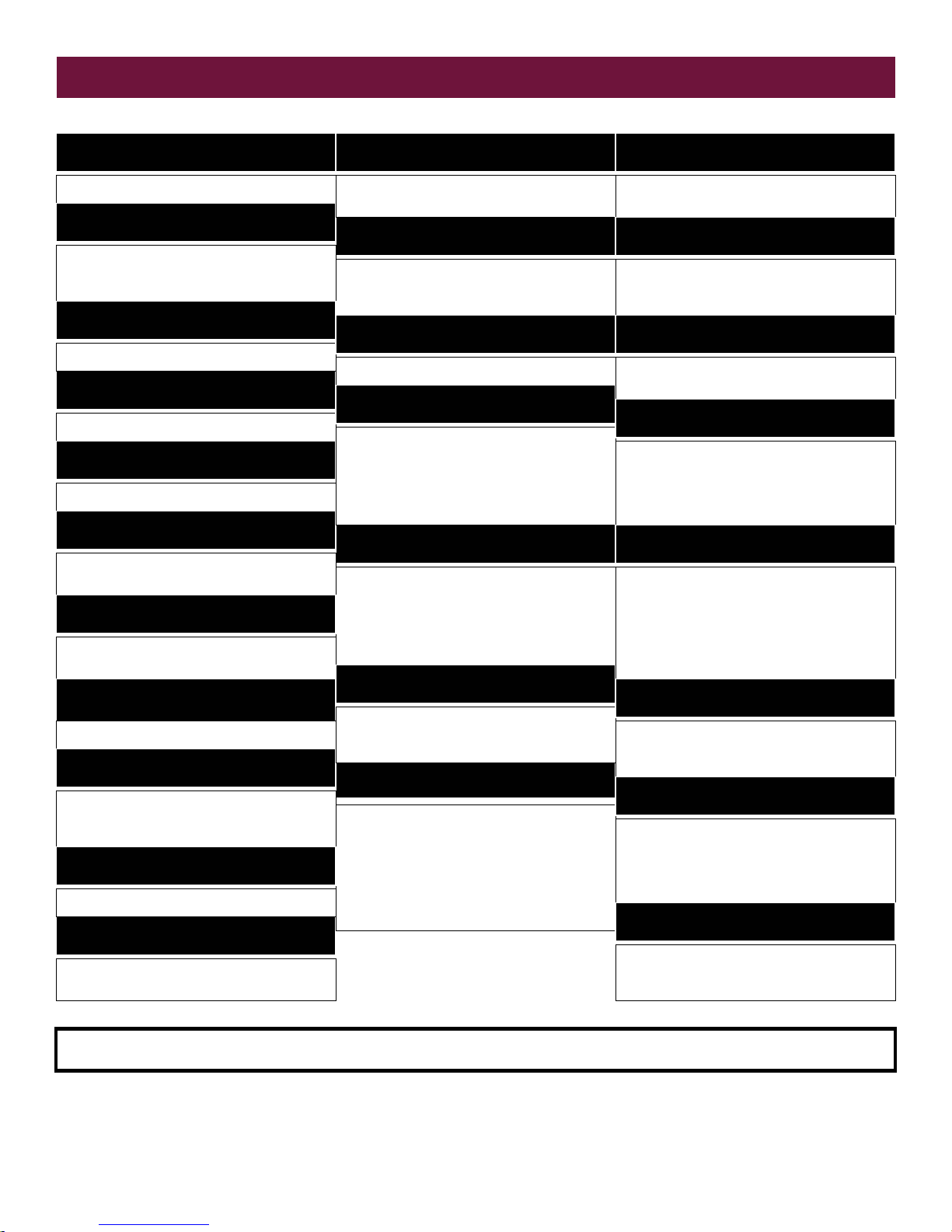

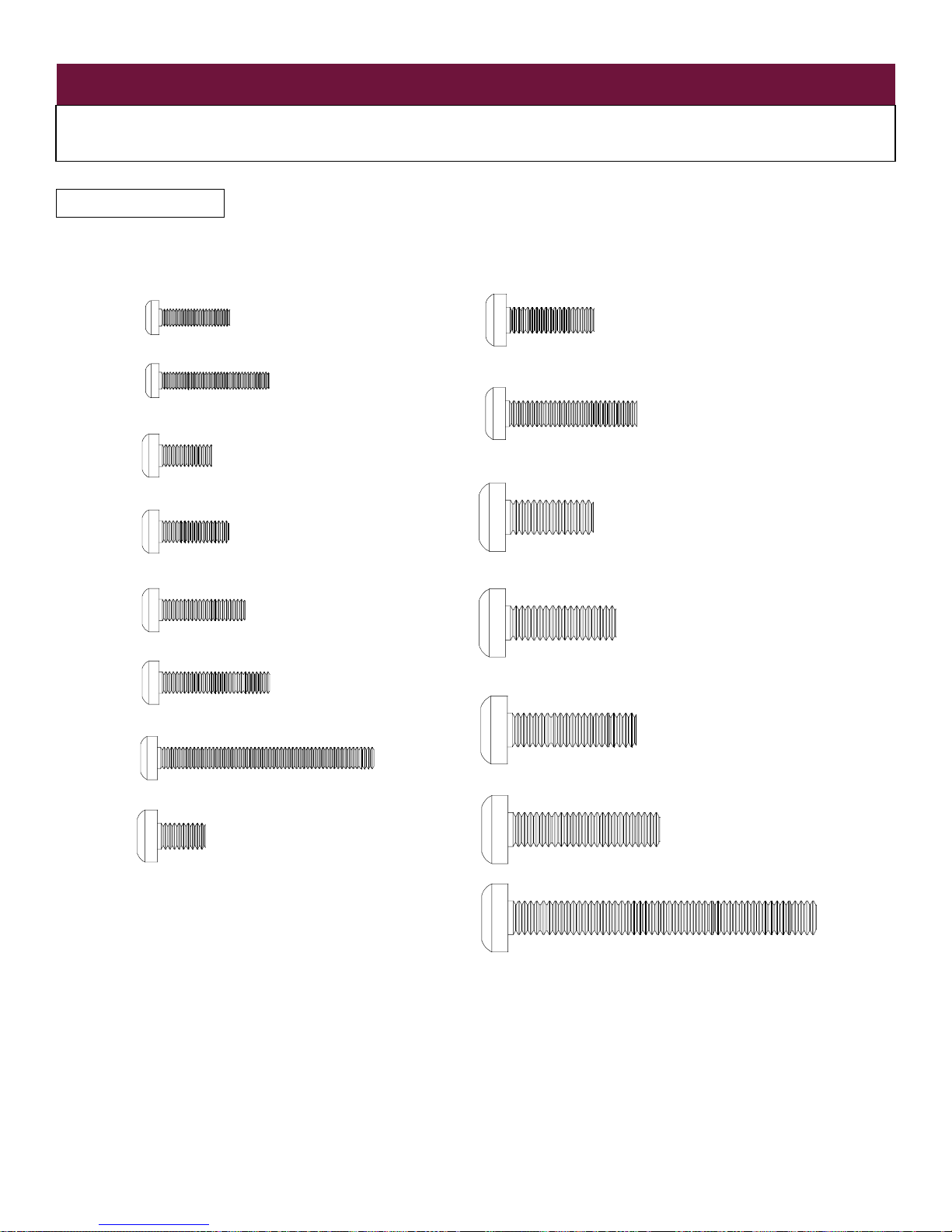

Parts list

NOTE: This wall mount is shipped with all proper installation hardware and components. Make sure that none of these parts are missing before

beginning installation. If there are parts missing stop the installation and contact Premier Mounts.

Actual screw size

M4 x 16

(Qty 8)

M6 x 20

(Qty 6)

M4 x 25

(Qty 4)

M6 x 30

(Qty 2)

M5 x 12

(Qty 8)

M5 x 16

M5 x 20

M5 x 25

M5 x 50

M6 x 12

(Qty 6)

(Qty 8)

(Qty 6)

(Qty 4)

M8 x 20

M8 x 25

M8 x 30

(Qty 4)

M8 x 35

M8 x 70

(Qty 6)

(Qty 6)

(Qty 6)

(Qty 4)

(Qty 4)

- 6 -

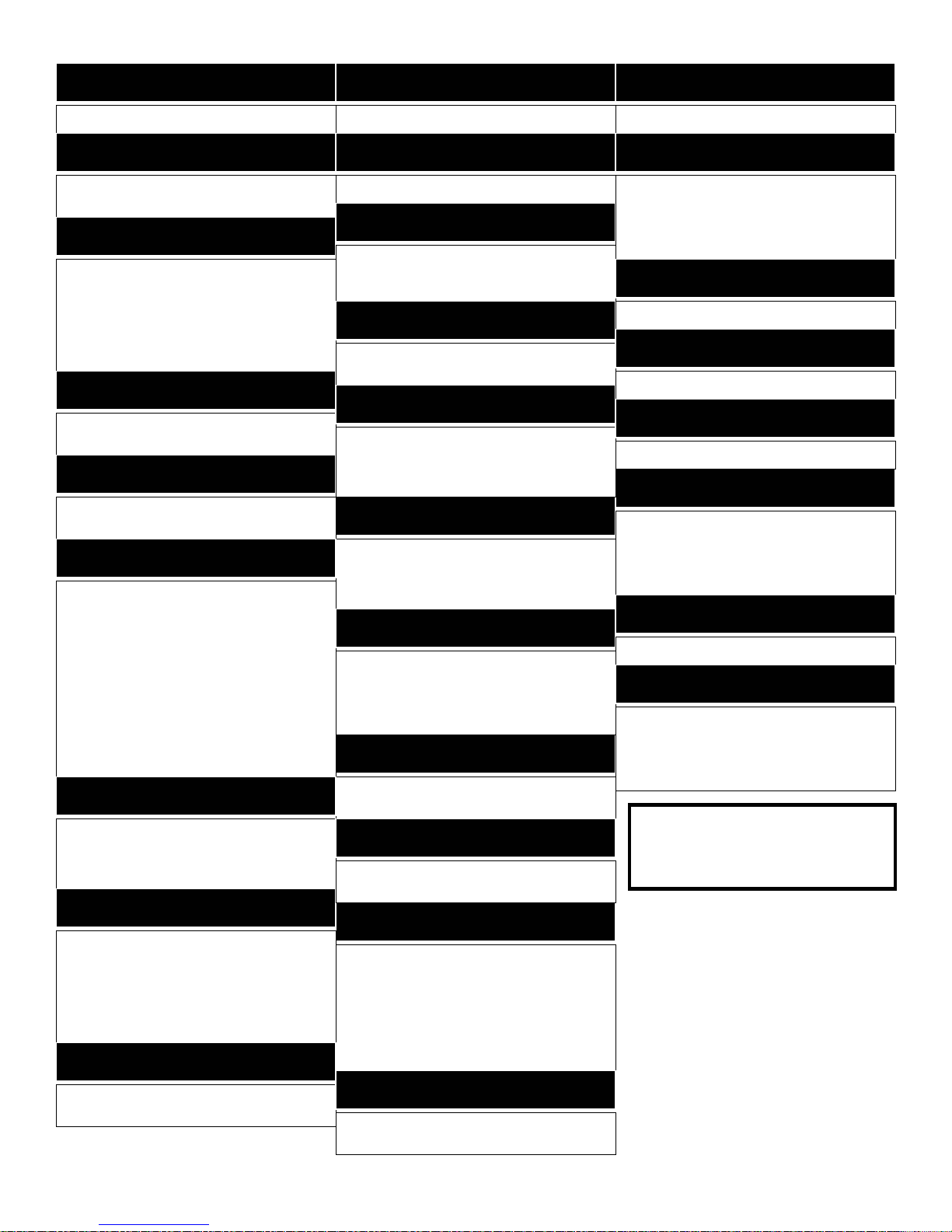

Parts list (con’t)

Nylon spacers and flat washers

actual size

NOTE: The nylon spacers may be staked to achieve proper spacing.

1/4" Nylon spacers

(large)

(Qty 6)

1/2" Nylon spacers

(large)

(Qty 12)

5/16" Flat washers

(metal)

(Qty 6)

1" Nylon spacers

(Qty 6)

1/4" Nylon spacers

(small)

(Qty 6)

9/16" Nylon spacers

(Qty 6)

Nylon sleeves

(Qty 4)

- 7 -

Checking the thread depth on your flat panel

1. Insert the thread depth

indicator (supplied) through

the thread inserts found on

the back of the flat panel to

make sure the inserts

measure the same full depth

and mark it.

(see figure 1)

2. Locate the correct diameter

screw for the thread insert.

Compare your marking to the

screws (supplied). If your

selected screw is longer than

the marking on the thread

depth indicator DO NOT USE

this screw.

The screw length must not

bypass the marking. Select

another screw size

(see figure 2 and 3). Until you

find one that comes closest to

your mark without going past.

Figure 1

Inverted flat panel

display

Figure 2

Thread depth indicator

Figure 3

- 8 -

Thread depth indicator

Marking the depth

Thread insert

Thread depth

indicator

Screw

Marking

Screw

Marking

Parts list (con’t)

All of these parts are used to install the mounting bracket. Make sure that none of these parts are missing before beginning installation. If there

are parts missing stop the installation and contact Premier Mounts.

Level (1)

Griplates™ (8)

M6 x 12 Safety knobs (2)

Wall plates (2)

5/16" flat washers (8)

Mounting brackets

(left & right)

5/16" x 3" Lag bolts (8)

(used on wood studs only)

M6 x 30 Lateral shift

locking screws (2)

Template (1)

Thread depth

indicator (1)

- 9 -

p

Finding center of the plasma TV

WARNING : Proper installation procedure by qualified personnel as outlined in the installation instructions must be adhered to. Failure to do so could

result in serious

INVERT THE FLAT PANEL PLACE IT ON A SOFT, FLAT SUFRACE TO PREVENT DAMAGE TO THE FLAT PANEL. USE A BLANKET, FOAM, ETC.

FAILURE TO DO SO WILL RESULT IN DAMAGING THE FLAT PANEL. DO NOT LAY THE FLAT PANEL ON THE FLOOR WITHOUT ANY PROTECTION

TO THE GLASS. THE FLAT PANEL IS HEAVY AND FRAGILE. AT LEAST (2) QUALIFIED PERSONNEL ARE STRONGLY RECOMMENDED FOR

INSTALLATION OF THIS PRODUCT. FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY AND POSSIBLE DAMAGE TO THE FLAT PANEL.

ersonal injury and possible damage to the flat panel.

WARNING!

Once the flat panel is inverted, use a measuring tape to

find the center of your flat panel measuring from outside to

outside of the chassis. See figure 1.

Top of flat panel

Measuring

tape

C

L

Inverted flat panel

Bottom of flat

panel

Using a pencil lightly mark the center of your flat panel.

See figure 2.

Inverted flat panel

Mark the center of

the flat panel

C

L

- 10 -

Positioning the mounting brackets

Center mark

Lay the left and right mounting brackets

(stamped arrows facing out). See figure 4.

Nylon spacers if

Applicable

(see chart) on page 4 and 5

Inverted flat panel

Left mounting

bracket

CAUTION: Check the chart on page 4 and 5 to see if

your flat panel needs nylon spacers. The nylon spacers

provided, must be used. Failure to do so will result in

damaging the flat panel.

Install the nylon spacers to the mounting points on the flat

panel see figure 3.

NOTE: See chart (if the nylon spacers apply to your

flat panel).

Left mounting

bracket

Bottom of flat panel

Arrows facing out

- 11 -

A

lign the mounting

brackets

The mounting brackets are designed with a center of

viewing guide on the side of them.

See figure 6.

Center of flat panel

- 12 -

Match the center of viewing guide with the center line you

marked in step 1.

See figure 5.

C

L

Bottom of flat panel

Mounting bracket

Bottom of flat panel

Center of

viewing guide

Securing the mounting brackets

DIMPLES

M4

Phillips screw driver

DIMPLES

FACING UP

M8

M6

M5

DIMPLES

FACING UP

NOTE: Secure the two (2) M6 x 30 Phillip pan

screws to the left and right mounting bracket.

The Griplates™ have M4, M5 M6 and M8 hole

patterns to fit the hardware that your flat panel

requires.

EXAMPLE: If your plasma uses M8 x 20 Phillip

screws. Use the M8 mounting points. See figure 7

Pre install two (2) M6 x 30 (mm) Phillip pan screws to

the bottom of the left and right hand side mounting

brackets. Once the mounting brackets are aligned secure

the Griplate™ to the flat panel.

NOTE: The dimples of the top plates have to be facing up

and the bottom dimples must be facing down.

See figure 8.

DIMPLES

FACING DOWN

DIMPLES

FACING DOWN

CAUTION: Do not over tighten the mounting

hardware.

Bottom of flat panel

- 13 -

Finding the wood studs behind the wall structure

Wood stud finder

(commercially available)

16"

D

E

R

I

S

E

D

T

H

G

I

E

H

G

N

I

W

E

I

V

F

O

R

E

T

N

E

C

Align the center viewing port from the carton template to

the center of the wood studs horizontally. Match the center

of viewing port to the center of viewing height desired and

mark a line on the bottom of the carton template.

See figure 10.

- 14 -

Using a (commercially available) wood stud finder, locate

the 16" or 24" stud centers behind the wall. Once found,

make a pencil marking on the center of the wood studs.

See figure 9.

Mark the wall and

the center of the

wood studs.

Wood studs

behind the wall

structure

Center of viewing

port

NOTE: The wall plates have (3) 16" and (1) 24"

mounting slot positions.

(Look at the assembly drawing on page 3)

16"

16"

Mark the

bottom of the

carton template

D

E

R

I

S

E

D

T

H

G

I

E

H

G

N

I

W

E

I

V

F

O

R

E

T

N

E

C

Carton template

Center of

viewing mark

Marking the bottom plate mounting points

16"

Level

Drill four (4) ¼" pilot holes to the marked wall.

See figure 12.

Wall plate

Wall plate

Mounting slots

Wood studs

Wood studs

Place the upper portion of the bottom wall plate to the

reference line and mark the four (4) lag bolt mounting points

through the wall plate slots on the wall. Level the wall plate

with the reference arrow pointing up to the ceiling.

See figure 11.

Drill gun

Pilot holes

16"

- 15 -

Securing the bottom wall plate

When the bottom wall plate is properly installed to the

wall. Lay the carton template on top of the wall plate.

Lay the top wall plate on top of the cardboard template

and mark the four (4) lag bolt mounting points.

See figure 14.

- 16 -

Level

Level and secure the plate to the wall with the

reference arrow facing up to the ceiling. Secure the

plate using the four (4) 5/16" lag bolts and flat

washers (supplied). See figure 13.

CAUTION: Do not over tighten the lag bolts.

Wall plate

(4) 5/16" x 3" lag bolts and

(4) flat washers

(supplied)

Marked wall

Template

Wall plate

Securing the top plate

Drill four (4) ¼" pilot holes to the marked

wall. See figure 15.

Wall marks

Wall plate

- 17 -

Level and secure the plate to the wall with the

reference arrow facing up to the ceiling. Secure the

plate using the four (4) 5/16" lag bolts and flat

washers (supplied). See figure 16

CAUTION: Do not over tighten the lag bolts.

NOTE: CHECK THE MOUNT FOR PROPER

TIGHTNESS AND SECURITY.

- 18 -

Power source

area

Wall plates

Securing the plasma to the wall mount

WARNING: AT LEAST (2) QUALIFIED PERSONNEL ARE STRONGLY RECOMMENDED FOR INSTALLATION OF THIS PRODUCT. FAILURE TO DO SO

COULD RESULT IN SERIOUS INJURY AND POSSIBLE DAMAGE TO THE FLAT PANEL.

Raise the flat panel with the LEFT and RIGHT mounting brackets secured to the flat

panel and insert the top and bottom hooks from each bracket to the rods from the

wall plates. See figure 17.

TOP

BOTTOM

Make any lateral shift adjustment and lock it by

tightening the two (2) M6 x 30 (mm) Phillips screws

found on the bottom of the mounting brackets.

CAUTION: Do not over tighten the M6 screws to

the rods.

See figure 18

Lateral shift

M6 x 30 Lateral

shift screw

- 19 -

Lateral shift adjustment

Tilt the flat panel and secure the two (2) M6 x 12 (mm) safety

knobs to each of the mounting brackets.

See figure 19.

M6 x 12

Safety knobs

NOTE: To remove the display from the wall simply extend the display to its maximum tilt range, remove the two 6 (mm) safety knurl knobs push

the flat panel back to it’s flat position loosen or remove the two (2) M6 x 30 lateral shift screws and lift the unit of the wall.

- 20 -

Loading...

Loading...