touch bionics i-limb select User Manual

i-limbTM select

Manual

Part number: MA 01155: Issue No. 4, January 2015

This is an i-limb ultra that has been refurbished. This document provides instruction for prosthetists in the

tting and servicing of the i-limb select and should be read in full prior to tting. It is highly recommended

that the use of this manual is made in conjunction with instruction from a clinician experienced in upper limb

and myo-electric prostheses.

This symbol signies important information and is used throughout the manual.

2

Table of Contents

1. i-limb select 1.1 Product Description

1.2 Intended Use

1.3 Prosthesis Overview

1.4 Features catalogue

2. Socket 2.1 Control Sites

2.2 Socket Fabrication

2.3 Charge Port Placement Assembly

2.4 Battery Options

2.5 Battery Conguration

2.6 Battery Installation

2.7 i-limb Power Pack

2.8 Battery Charging

3. Wrist 3.1 Wrist Connection Options

3.2 Quick Wrist Disconnect (QWD)

3.3 Wrist Disarticulation

4. Adjustments 4.1 Digit Conguration

4.2 Digit Installation

4.3 Thumb Installation

5. Covers 5.1 Cover Options

6. biosim app clinician version 6.1 biosim app Overview

6.2 Getting Started

7. my i-limb patient version 7.1 my i-limb Overview

7.2 Getting Started

8. Support Information 8.1 General Safety, Warnings and Precautions

8.2 Troubleshooting

9. Appendix 9.1 Technical Information

9.2 i-limb select Information

9.3 Component Compatibility

9.3.1 EMC and Electrical Information

9.4 Warranty

Part number: MA 01155 Issue No. 4, January 2015

3 of 50

1.0 i-limb select

1.1 Product Description

The i-limb select is an externally powered, multi-articulating

prosthetic hand which oers a range of features beyond the

functions of the traditional prosthetic hand.

Individually motorized digits and the unique biosim and my i-limb

app used to control the i-limb select result in one of the most

versatile prosthetic hand currently available to the global market.

Users can choose from a wide selection of automated grips and

gestures to help complete daily tasks. Grips and gestures can

then be customized further for precise control.

The i-limb select oers compliant grip through individually

powered digits with stall out ability. A manually rotating thumb

in conjunction with a pulsing, enhanced grip (vari-grip), and the

wide range of automated grip patterns lead to broad functionality.

1.2 Intended Use

The i-limb select is intended to be used by patients with upper

limb loss or deciency

1.3 Prosthesis Overview

The i-limb select is available in small or medium sizes. The hand

serial number is positioned proximal to the base of the thumb on

the connection plate. The serial number will start with a “Q” and

be followed by four numbers.

Part number: MA 01155 Issue No. 4, January 2015

4 of 50

Motorized Digit

Knuckle

Palmar Fairing

Manual Thumb Rotator

On / O Switch

Part number: MA 01155 Issue No. 4, January 2015

1.4 Features Catalogue

The i-limb select has 12 dierent grip options available. These grips can be accessed through biosim and the my i-limb app. This

following Features Catalogue will review the various available grips and provide a functional description of each.

Precision Pinch Grip Options

Precision pinch grip options are best for picking up small items between and the thumb and index nger. There are 4 options

available depending on how you want the other digits to perform while doing the pinch. The most popular is Thumb Precision Pinch

Closed.

Standard Precision Pinch Opened

middle, ring and little nger remain fully

opened and switch o. Index nger and

thumb provide grip.

Thumb Precision Pinch Opened

middle, ring and little nger remain

fully opened and switch o. Thumb

automatically moves to a partially closed

position. Index nger will move to provide

grip against a xed thumb.

Standard Precision Pinch Closed

middle, ring and little nger automatically

close and switch o. Index nger and

thumb provide grip.

Thumb Precision Pinch Closed

middle, ring and little nger automatically

close and switch o. Thumb automatically

moves to a partially closed position. Index

nger will move to provide grip against a

xed thumb.

Tripod Grip Options

Tripod Grip Options provide a grip where the thumb is meeting up with the index and middle digits. Typically the thumb is rotated

between the index and middle to provide more stability when gripping slightly larger objects than those with the precision pinch

grips. As a result of having a motor in each digit and the hand conforming to the shape of the object being held, the hand will

automatically form a tripod grip when the object is small enough to only be gripped between the thumb, index, and middle digits.

The advantage of using the tripod grip options is if you want the ring and small digits to stay either fully open or fully closed when

gripping.

Standard 3 Jaw Chuck (Tripod) Opened

ring and little nger remain fully opened and

switch o. Thumb, index and middle ngers

move to provide grip.

Standard 3 Jaw Chuck (Tripod) Closed

ring and little nger move to terminal

close. Thumb, index and middle ngers

move to provide grip.

Thumb 3 Jaw Chuck (Tripod) Opened

ring and little nger remain fully opened and

switch o. Thumb automatically moves to a

partially closed position. Index and middle

ngers move to provide grip against a xed

thumb.

Part number: MA 01155 Issue No. 4, January 2015

Thumb 3 Jaw Chuck (Tripod) Closed

ring and little nger move to terminal

close. Thumb automatically moves to a

partially closed position. Index and middle

ngers move to provide grip against a

xed thumb.

6 of 50

Additional Grip and Gesture Options

With these additional grip patterns and gestures, consider how often you perform dierent tasks and if having a program for that

activity would make it easier/faster for you to perform. Since each digit has its own motor, you can put pressure against any digit to

stop it from moving (called stalling the digit). Many of these additional grips can be performed by stalling one or more digits. If it is a

task that is not performed often (maybe using index point to press the “Shift” key on a keyboard) then you may prefer to just stall the

digit. However, if you frequently perform the task or want to go into the position without needing to put the hand against the table

or your other hand, then programming the grip may be the better option.

Thumb Park Continuous

all four ngers remain open and switch o,

only the thumb will move.

Lateral Grip

all four ngers fully close and switch o.

Only thumb will move.

Thumb Park Quick

all four ngers remain open and switch

o, for 1.5 seconds the thumb will close

and then automatically return to an open

position.

Index Point

thumb, little, ring and middle ngers close

and switch o. Only the index nger will

move.

Part number: MA 01155 Issue No. 4, January 2015

2.0 Socket

2.1 Control Sites

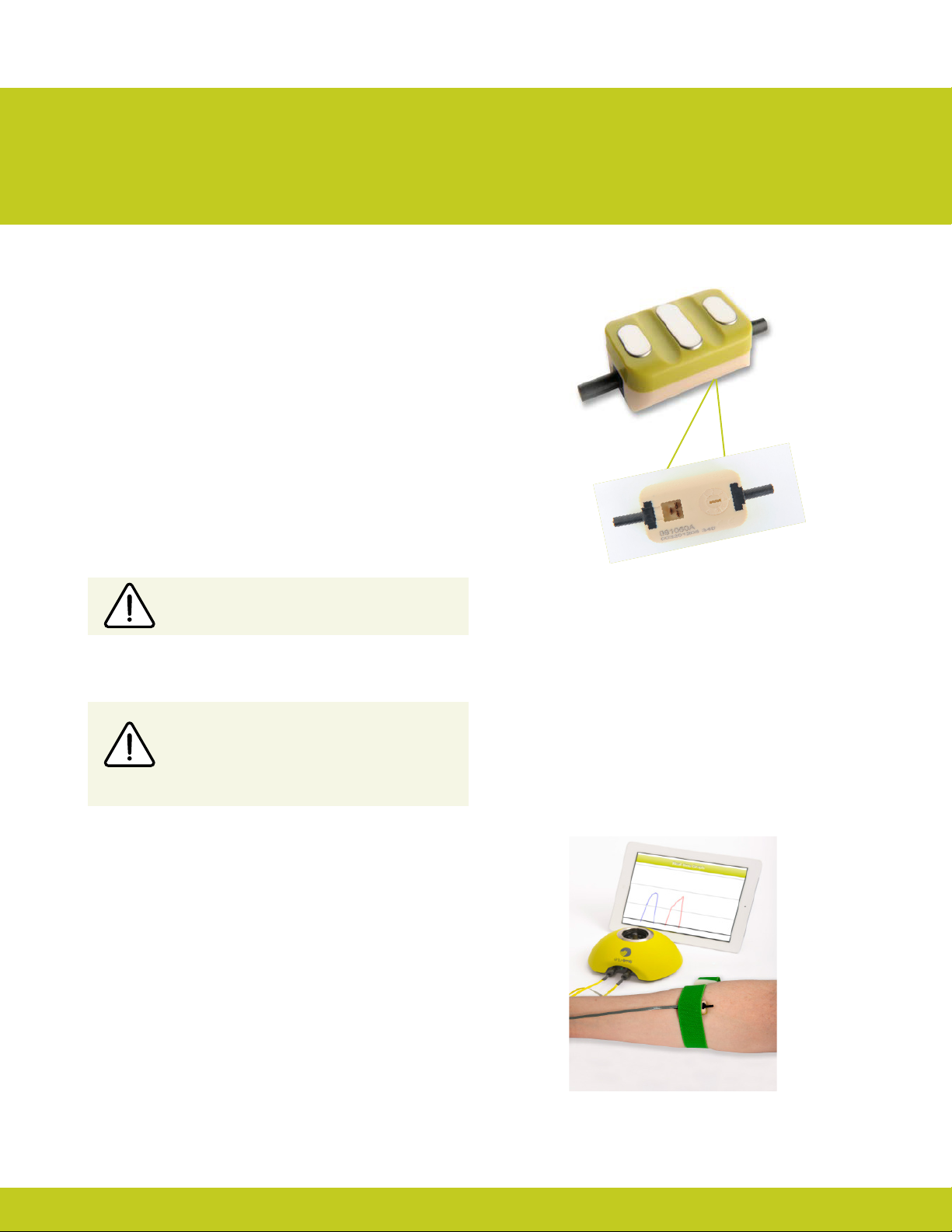

The i-limb select is controlled by compact electrodes

(g. 1).

For information regarding the tting of the Touch Bionics

electrode, review the manual provided with the electrode.

Electrode Site Selection

The use of virtu-limb, the Touch Bionics’ myo-testing system,

is recommended to determine the optimal placement of

electrodes (g. 2). virtu-limb is not included with the i-limb

select. Contact Touch Bionics for information about ordering

virtu-limb.

Do not rely on previous myo-electrical

testing.

Consult Touch Bionics training materials for information on myotesting.

Figure 1. Compact Electrode

Use anatomical sites where the electrode will

maintain constant, even contact with the skin.

Avoid placing electrodes near socket interface

trim lines, bony areas, skin grafts or fatty tissue.

Figure 2. virtu-limb

Part number: MA 01155 Issue No. 4, January 2015

8 of 50

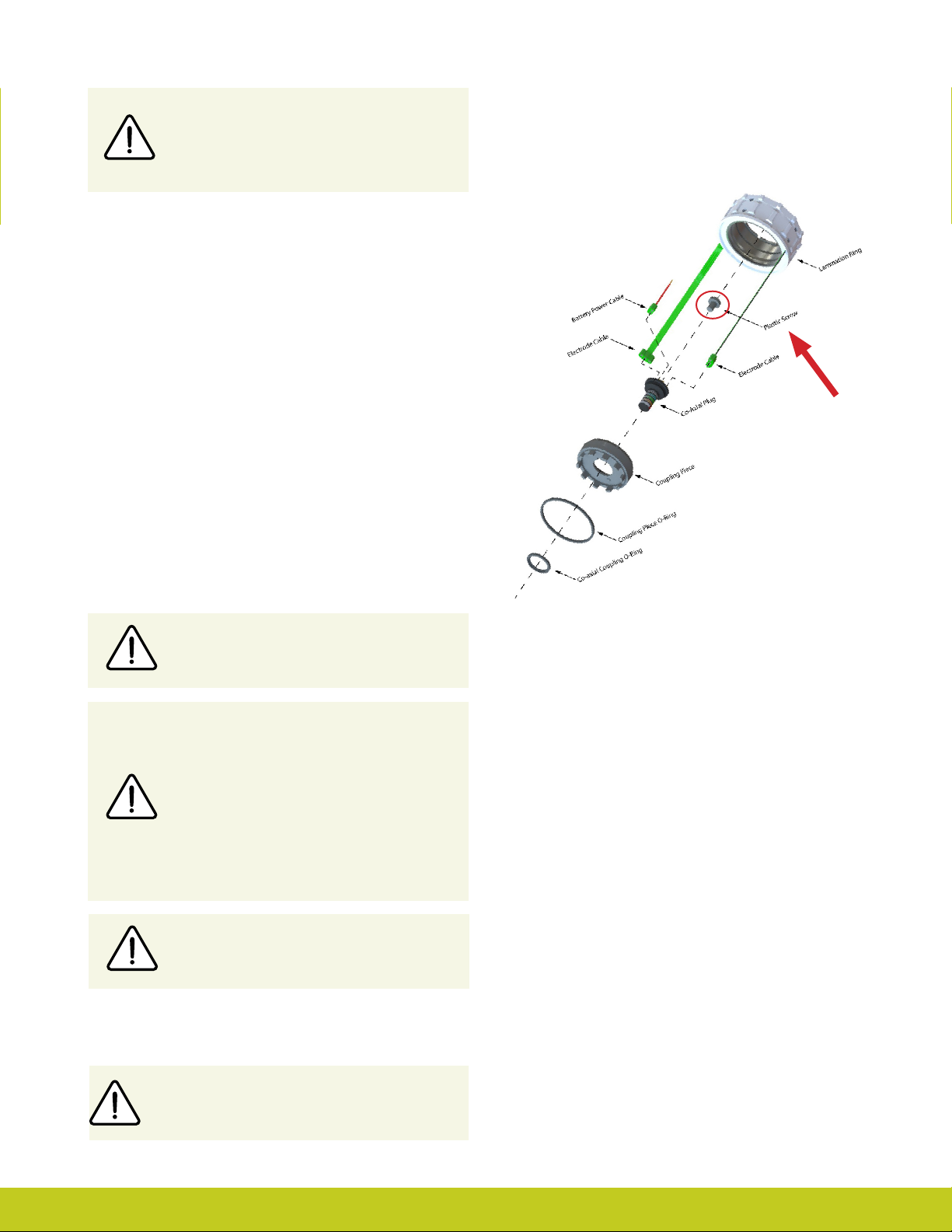

Prosthetist must ensure that the plastic screw provided

is utilized and properly tightened on the coaxial plug

(g.3) where the battery and electrodes connect, to

prevent loose connections .

2.2 Socket Fabrication

While fabricating the socket for the i-limb select, special

considerations will need to be given to:

1. Battery placement, size and conguration

2. Electrode position

3. Charge port placement

4. Socket length and the overall length of the prosthesis in

comparison to the opposite side.

Clinicians should have prior experience with building externally

powered prosthetic sockets before tting the i-limb select.

Touch Bionics’ batteries, charger port and switch block

components should always be used with the i-limb select.

Figure 3. Coaxial Plug

We recommend that a rubber grommet or plastic cap

is placed over any socket holes to protect the integrity

of the electrode.

During socket fabrication, appropriate measures must

be taken to prevent sweat entering into the battery

connector within the lamination ring, which may result

in a short circuit and compromise use of the device.

Conventional sweat prevention methods include the

use of drain holes and suction sealing electrodes.

Alternatively, silicone may be used to seal the interface

area between the battery connector and co-axial plug

into the prosthetic socket.

During socket maintenance, ensure a check of the

battery connector/co-axial plug interface is carried out.

Socket Material

The use of Carbon ber is not recommended due to

electrical conductivity.

Part number: MA 01155 Issue No. 4, January 2015

Coupling Piece Assembly for QWD Wrist

Insert the castelation ring (coupling piece) into lamination ring

and turn until seated. Insert retaining ring around outside edge

of coupling piece and use QWD release tool to seat the retaining ring. The QWD release tool is available to order from Touch

Bionics.

Battery Placement

Use Velcro® to position the batteries on the pre-prepared

at surfaces to prevent distortion.

Battery Placement for a Long Residual

Limb

Consideration of battery placement is particularly important

in longer sockets. The shape of the inner socket must also be

considered.

If the residual limb is long or bulbous, the position of the battery

dummies and charge port are best placed midway up the arm

along the inner socket ensuring they will not impact the ability

to don/do the prosthesis and that the postion will not result in

pressure from the residual limb that could distort the battery.

Placement of batteries should allow for removal of the inner

socket.

If the socket has a bulbous distal end, do not position batteries

or charger port around the narrow region of the prosthesis.

Part number: MA 01155 Issue No. 4, January 2015

10 of 50

2.3 Charge Port Placement Assembly

It is important to provide sucient space for the charge port

between the inner and outer sockets. The charge port should be

positioned so that it is unaected by forces running through the

socket to prevent damage.

Create a drill hole of 8mm through the inner surface of the

prosthetic frame. Ensure a at surface has been created to

accommodate the charge port mounting frame (if installing a

switch block as an alternative to the charger port, create a drill

hole to cater for the panel mount).

Smooth the edges of the drill hole and insert the threaded

charge port. A minimum thread height of 3.2mm above the

socket surface is required for full engagement of washers and

locking nut.

Position the M8 Lock Washer and the M8 Flat Washer before

hand tightening the the locking nut.

Use a 3/8” wrench to tighten the locking nut.

Do not overtighten.

Do not use pliers on the charge port.

Position the M8 Lock Washer and M8 Flat

Washer in place over the threaded shaft of the

charger port. Engage the M8 locking nut with

the threaded shaft and tighten rmly by hand.

The use of both the Lock Washer and Flat

Washer is vital to ensure the charge port is not

damaged by over tightening.

Do not overtighten!

Part number: MA 01155 Issue No. 4, January 2015

2.4 Battery Options

The i-limb select comes with a 1,300mAh battery. This

battery has been specically designed to meet the power

requirements of the hand.

i-limb 1,300 mAh

Battery

Capacity 1,300 mAh

Length 70mm (2.76”)

2.5 Battery Conguration

The image opposite shows the 1,300mAh battery option .

Only Touch Bionics batteries are approved

for use with the i-limb select. Use of

alternative batteries will invalidate the

warranty.

2.6 Battery Installation

The battery is designed to be mounted inside the socket

interface. Ensure there is adequate space between the residual

limb and the wrist (or elbow) to accommodate the battery, charger port and any other componentry. Use the battery dummy to

fabricate a relief for the battery in the socket interface.

Battery Dimensions

Dummy Battery

Dimensions

Application Moderate Use

Width 35mm (1.39”)

Height 6mm (0.24”)

Length 69mm (2.77”)

Width 35mm (1.39”)

Height

10mm (0.39”) Single cell

16mm (0.63”) Dual cell

When planning battery location and dummy placement for

fabrication, keep in mind a maximum distance of 135mm is

possible between cells due to wire length.

Installing i-limb Power Pack

Utilize battery dummies on top and bottom of socket to create

necessary space to accommodate battery housing.

Use standard fabrication processes and technique to create an

opening in the socket to accommodate battery housing.

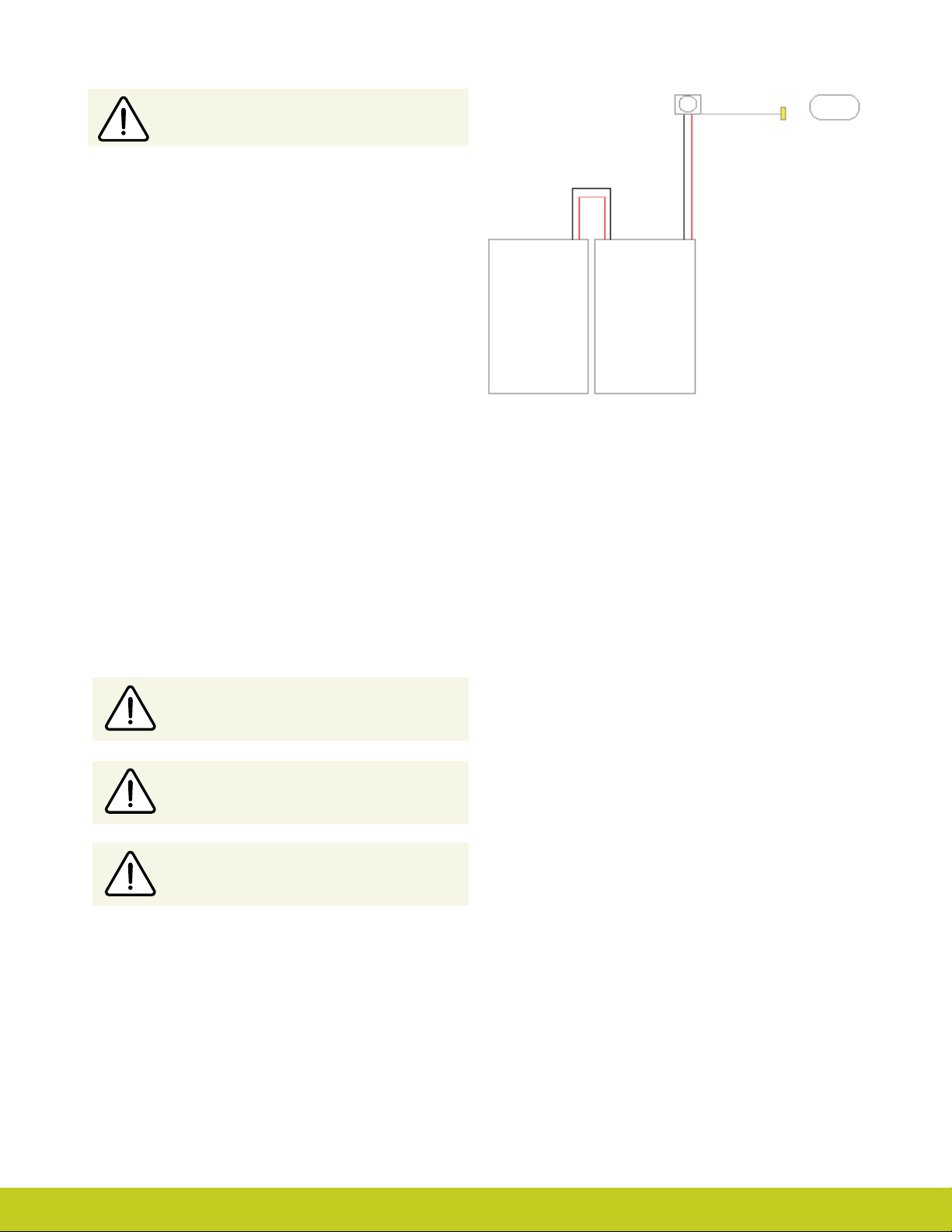

When using a switch block, it is recommended that you use the

provided Switch Template (g. 4) to guide drill holes.

Ensure there is no contact between the battery

housing and inner socket

Part number: MA 01155 Issue No. 4, January 2015

Figure 4

12 of 50

Do not apply excessive force to the charger

socket interface during assembly.

A minimum of 2mm of free space surrounding the charger port

should be provided.

A at surface is needed to secure the charger port to the socket

interface frame. This may require additional shaping of the frame

section above the dummy battery. Use the Velcro

®

strip supplied to

attach the battery to the inside of the socket interface.

Wiring Schematic for 1300mAh Low Prole

Battery with D.C. Socket

2.5mm D.C. Socket

Co-axial Bush/Rotator

If the area between the residual limb and the lamination ring is

insucient to house the battery, you will need to position the

battery between the socket interface and the frame. This will be

necessary when:

• the residual limb is longer than 60% of the humeral or forearm

section of the prosthesis

• the battery is too large for the space available in the socket

interface frame

Cutting or modifying the battery wires in any

way will invalidate the warranty.

Low Prole Battery Cells Placed Side by Side

Do not bend or shape the battery in any way.

Ensure the battery is not subject to continued

pressure once tted.

Part number: MA 01155 Issue No. 4, January 2015

2.7 i-limb Power Pack

i-limb Power Pack (ordered separately) are for users who want the

ability to easily replace batteries.

Battery housing is fabricated on top and bottom of socket,

allowing for easy access.

Top of socket

Bottom of socket

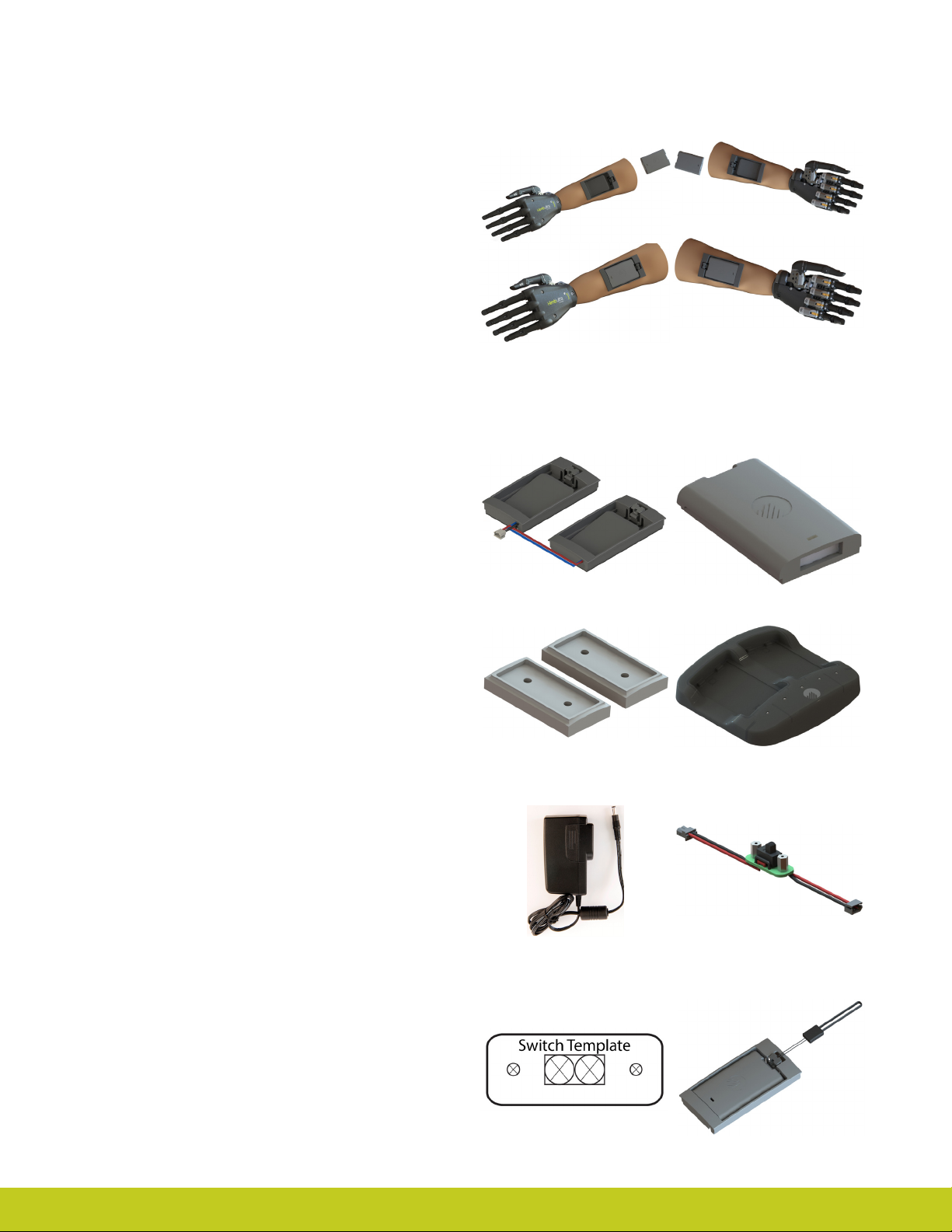

i-limb Power Pack kit

i-limb Power Pack includes the following items:

• 1 dual battery housing unit (g. 5).

• 4 Removable 800 mAh batteries (g. 6) with low battery LED indicator.

Battery LED will glow RED when batteries are below 10% charge.

• 2 Battery housing dummies (g. 7).

• Dual battery charger base unit (g. 8).

• Wall charging unit (g. 9).

• Switch Assembly. Switch Block is typically used in conjunction with

a wrist rotator or for patients who would like a power o control on

the socket) (g. 10).

• Switch template Switch Assembly (if Switch Assembly is ordered)

(g. 11). This template is to be applied to the desired position on the

socket to help guide drill holes.

• 2 Battery Pull cords (g. 12). Benecial for bi-lateral patients, the

battery pull cord provides a simple solution for removing the battery

in your socket.

Figure. 5 Figure. 6

Figure. 7

Figure. 9 Figure. 10

Figure. 8

• Country specic charger plugs.

• Car charger.

Part number: MA 01155 Issue No. 4, January 2015

14 of 50

Figure. 11

Figure. 12

2.8 Battery Charging

Please review the below Instructions for proper internal battery

charging.

Only use supplied Touch Bionics charger to charge

battery. Depending on your location, you will

receive one of the below chargers (g. 14, or g. 15)

The patient will need to remove the socket from their arm and

turn the i-limb device o. The on/o switch is pictured in g 13.

i-limb device is o when switch is in left position.

Insert the charger (g. 14 or g. 15) into the power outlet. The

charger will need to be inserted into the power outlet prior to

connecting to the charge port. To charge, insert the charger

lead connector into the charge port. A “click” should be heard

on connection. If the green light is on when you rst plug in the

device, ensure the switch block is o.

Charging time is approximately:

1,300 mAh battery- 90 minutes

2,000 mAh battery- 180 minutes

The light display for g. 14 is:

• Solid Red – charging

• Solid Green – fully charged or idle

• Continuous ashing red – fault condition

• Rapid ashing amber – Threshold state between charging

and fully charged ( should only last for 1-2 seconds)

• Continuous ashing red or green – Connection Error.

Remove charger lead connector from the charge port.

Ensure charger is plugged in and switched on at the mains.

Re-insert the charger lead connector into the charge port.

The light display for g. 15 is:

• Solid Amber – on standby

• Slow ashing amber – pre-charge mode

• Rapid ashing amber – Error

• Slow ashing green – maintenance charge

• Rapid ashing green – rapid charge

• Solid green – fully charged

To remove the charger lead connector from the i-limb select,

grip the connector and pull directly away from the port. Consult

Warnings and Precautions for additional information.

Figure. 13

On/O Switch

Figure 14

Figure 15

If the patient intends to travel outside of their home country,

they will need to ensure they have a Touch Bionics charger that

will work in the country to which they are traveling. Additional

chargers are available from Touch Bionics.

To ensure the i-limb select is continually

functional, charge at the end of each day.

Replace the battery annually for optimal

performance.

Part number: MA 01155 Issue No. 4, January 2015

Do not pull cable to remove the lead.

Switch the hand OFF to preserve battery power

when not in use.

i-limb Power Pack Charger

i-limb Power Pack batteries for i-limb select should only be

charged using the Touch Bionics battery charger (g. 16)

supplied. Place the batteries in the charger as illustrated. Insert

the charger lead from the battery powerpack into the charge

port. Insert the charger into the power outlet.

Charging time from full discharge is approximately 2 hours.

Figure. 16

On the base plate of the charger (g. 17) you will see the various

light sequences:

• Middle light on: Charger is plugged in

• 2nd and 5th lights blinking Green: Batteries are charging

• 2nd and 5th lights solid Green: Batteries are charged

• 1st and 4th Red lights on: Battery fault, unplug and try

again. If lights continue to illuminate, contact Touch Bionics

Customer Support.

Only use the plug to disconnect the charger, never

pull the cable to remove the lead.

Figure. 17

Part number: MA 01155 Issue No. 4, January 2015

16 of 50

Loading...

Loading...