touchbga.com

TOUCHBGA

BGA Rework Station

IR6000

User Manual

touchbga.com

Table of contents

1. IR6000 BGA rework station features

1.1.Safety Instrouctions

1.1.1.Electric Safety

1.1.1.Operation Safety

1.1.3.Environmental requirements of operation and conservation

2.The operation and conservation condition of products

2.1.The parameters of IR6000 BGA Rework Station

2.2.Hardware description and Self-help install

2.3.Temperature-controlled meter Operation instructions

2.4.BGA Rework operation steps

2.5.Prompt

touchbga.com

1. IR6000 BGA rework stations features

IR6000 BGA Rework Station is designed to meet the ever-changing demands of today’s fast BGA Rework

manufacturing environments.

This model have following characteristics:

1. Rework station for laptop motherboards, desktop computer motherboards, server boards, industrial

computer boards, all kinds of game boards, communications equipment motherboards, LCD TVs and other

large circuit board BGA rework.

2. Innovative designs. An effective solution to general of infrared rework station vulnerable to the impact

of air flow. Will lead an inaccurate of temperature control. Maximum temperature up to 400C. Can easily

deal with lead-free soldering rework.

3. Can set up 8 rising temperature segments and 8 constant temperature segments to control. It can save

10 groups of temperature curves at one time.

4. Can be connected to a computer to be controlled more conveniently with a built-in PC RS232 serial port

and proprietary Software attached to it. Programmable.

5. Can easily rework the variety of CPU's seat, all kinds of shielding enclosures, replacement of various

components slotCan easily deal with lead-free soldering rework.

6. Sensitive temperature measurement sensor to obtain an accurate and instantaneous temperature

reading and monitoring.

7. BGA rework station the technology of closed-loop temperature control ensures accurate temperature

process and even heat distribution.

8. Machine overall system integration design. Rework station more integrated workbench area occupied by

smaller. Didn't mixed and disorderly of cables.

9. Linear guide type Bracket for BGA Reworks can be locking adjusted by rotating the handle. Can be very

easily fixed PCB board, effectively prevent the deformation of PCB board.

10. Detachable K type thermocouple.

11. Taiwan FOTEK SSR’s inside. Popular programmers inside.

touchbga.com

1.1.Safety Instrouctions

1.1.1.Electric Safety

1. Make sure the supply power voltage accord with the standards 220V-250V/50hz alternating current

before installing.

2. To avoid possible electric shock caused serious damage, please disconnect the power cord from the

outlet temporary before moving machines.

3. If the machine damages, please contact us for maintenance. If the damage caused by the users when

they dismantle or repair independently, they should take on the loss by themselves.

1.1.2.Operation Safety

1. Please carefully read the relevant information provided by the manual before starting using this product.

2. Make sure the power cord has been properly connected properly before using the products.

3. Installed the equipment in stable work platform to use, where the air mobility should be small as

possible. Avoid it closing to air conditioners, fans and the other outlet.

4. In case of electrical short-circuit, avoid the products contacting with water.

5. Forbid using this equipment in flammable and explosive substances.

6. The operators’ hands or other parts of the body should maintain a safe distance from the heater. Forbid

touching the heater to avoid scalding.

7. If you have any technical questions or suggestions in the course of using this product,please contact with

our technology department. We will try our best to solve.

1.1.3.Environmental requirements of operation and conservation

1. Operation environment of products

- Operation temperature: 15 – 45C

- Operation humidity: 5% to 95%, non-condensing

- Products should be kept in the air mobility of a smaller environment under the welding operation.

2. Conservation environment of products

- Storage temperature: -20 – 70C

- Storage humidity: 5% to 95%, non-condensing

touchbga.com

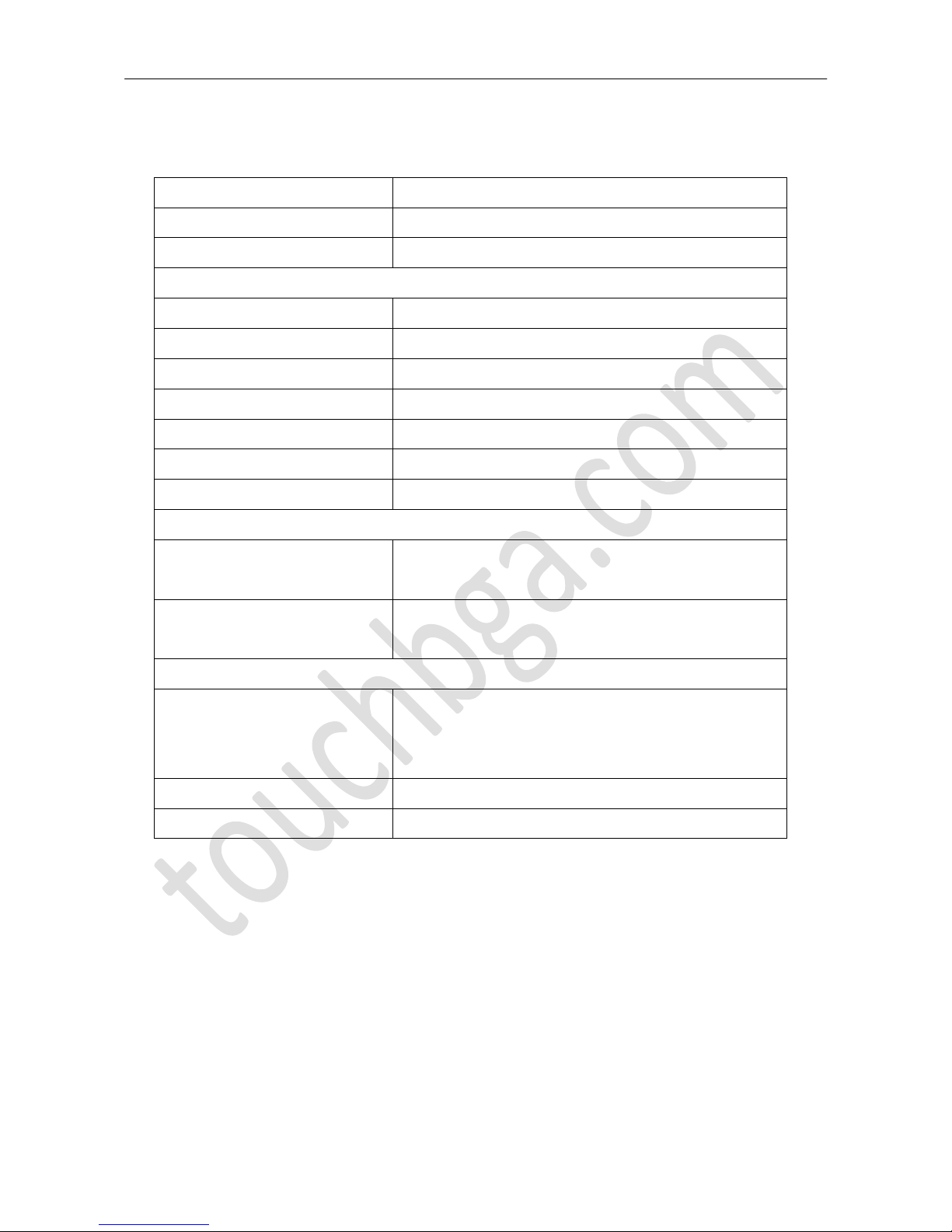

2.1.The parameters of IR6000 BGA Rework Station

Heating kind

IR

Dimension

450x340x430mm

Weight

12kg

Electrical Parameters

Power

220V AC

Upper Heating

IR

Size of Upper heating

IR-80x80mm

Consumption of upper heating

IR-450W

Size of Bottom heating

180x180mm (heating area 190x190mm)

Consumption of Bottom heating

1x800W

General power

IR+IR-1250W

Temperature Control

Control mode of Upper

Independent temperature control, high-precision closed-

loop control, precision ± 0.5%, Alarm

Control mode of Bottom

Independent temperature control, high-precision closed-

loop control, precision ± 0.5%, NO Alarm

Rework Function

BGA

Suit for welding, remove or repair packaged devices such

as BGA,PBGA,CSP,multi-layer substratesEMI metallic

shield product and solder/lead free Rework welding

Size of applicable chips

<=80x80mm

Size of applicable PCB

<=400x305mm

touchbga.com

2.2. Hardware description

IR6000 BGA Rework Station is composed of upper part of Heating Components / Bottom Preheat Module /

Bracket / Temperature Control Parts!

Temperature control Table is control the upper and lower heating, Can Simultaneously heated or first

preheat, then the upper part of heating.

1. PCB Table

2. Highly Sensitive K-temperature sensor

3. Upper Heater

4. X-Y Lifting Regulators

5. LED Auxiliary Lighting

6. Bottom Heater (Pre-Heater)

7. Lighting Switch

8. Upper fan Switch

9. Start Switch

10. Stop Switch

11. Upper Programmable Temperature Controller

12. Bottom Temperature Controller

13. Power Switch

1

11

12

13

9

10 8 7

6

5

3

2

4

touchbga.com

Self-Installation Instruction

PCB Table

1. Installation side support.

2. Installation Slip.

3. Installation side support.

touchbga.com

Upper Heater

Top head cable connector, RS232, power connector

Temperature sensor

Installation of RS232 communication interface for Desktop & Laptop

touchbga.com

2.3. Temperature-controlled meter Operation instructions

TOP Programmer/Controller General Description

The programmable controller contains an in-built setpoint generator in addition to the controller function.

This setpoint generator can produce a temperature/time profile with 10*16 segments (0910 Sets of

Curves). When the program is running, the current setpoint from the setpoint generator is fed to the

control algorithm. The current setpoint is continuously shown on the lower display.

The sixteen segments are defined in the order: Ramp 1, Dwell period 1, Ramp 2, Dwell period 2..., and are

executed in succession.

touchbga.com

Program Parameters Setting

touchbga.com

Program Parameter List

touchbga.com

BOTTOM Programmer/Controller General Description

Hold down the SET button of bottom heater temperature control instrumentation for 5 seconds, the

display will blinking and using up/down buttons temperature of bottom heater. Using left arrow you can

change one of four number positions.

The factory temperature is set is 180°C. Generally the user needn’t to change the data.

touchbga.com

2.4. Rework Operation Steps

1.Be all set

1.1.Fixed motherboard

1.2.Shift sensor close to BGA chip.

1.3.Adjust the height of heating head with adjustment knob

(Prompt: BGA chip in the middle of heating head, heating head away from BGA chip >= 2cm)

2.Start heating

touchbga.com

2.1.Select the appropriate temperature program segment, and then press the start switch. In the operation

can press the stop switch, stop operating.

2.2.After the program runs, automatic alarm 8sec. and automatically cut off the heating power, this time

you can check the following solder ball is completely liquefied, BGA chips should be subject to settlement,

floating state .

3.Rework completed

3.1. Moving Heating head and Sensor, open the Upper fan Switch.

3.2.Remove motherboard. Clear insulating tape.

3.3.BGA Rework Station Cooled, Then close Total Power.

Warning

1.If BGA Rework Station NO Cooling, Do not close the Total Power !

2.When the temperature is not cooled, do not touch heating module!

touchbga.com

Prompt

1. Keep the equipment at a steady working environment where the air mobility should be as small as

possible. Avoid it closing to air conditioners, fans and the other outlet.

2. IR 6000 Rework Station sensor is directly contacted with motherboards, So the display temperature is

Actual temperature.

3. In order to avoid damages to the motherboard capacitor, please use insulation tape. After Maintenance

is completed, Remove the insulation tape to prevent from short-circuit.

4. After removal of BGA chip PCB bonding pad needs to be cleaned up, Avoid cold solder joint. See BGA chip

tin completely liquefied, then move the BGA chip to avoid Bonding Pad Damage.

5. During the reflow of the new ball in a typical tin/lead (Sn63/Pb37) com position, there are “self

alignment” properties that are quite forgiving. According to IPC Spec, landing on 75% of the pad is

acceptable for BGA rework.

6. To improve success rate of Rework, PCB and chips need drying and processing in principle PCB board or

chip moist heat process will occur in the burst phenomenon, the Rework process may hear the blasting

sound of a minor. According to actual situation Please self-control.

7. PCB board heating time is too long or repeated several times the surface heating will lead to

discoloration.

8. Users from modifying temperature parameters. Please use scrap PCB tested heating whole time about 10

seconds before the end of solder balls should be fully liquefied f the liquefaction advanced or delayed,

should be regulating up/down the temperature setting. To prevent heat damage to your chips or low-

temperature sealing off.

9. Common setting of temperature

Reflow temp Sn63Pb37 : 185 - 190C, Reflow time: 10sec.

Reflow temp Sn96,5Ag3Cu0,5: 220 - 225C, Reflow time: 15sec.

10. The meaning of“ Hb”:

touchbga.com

“Hb” means the max heating temperature of the upper heating. We set the max temperature at 230°C

according to the max temperatrue of lead-free Reweork and other technical reasons. The data needn’t to

be changed.

11.The meaning of “r1” “L1” “d1” “r2” “L2” “d2” “r3” “L3” “d3” ……

Please pay attention to The following pictures and tables:

12.IR6000 can be managed by dedidated software using RS232 cable.

touchbga.com

Rework temperature curve to set examples

Loading...

Loading...