Toto ZL Series, TLP02301U, TLP02304U, TLP02307U Installation And Owner's Manual

Warranty Registration and Inquiry

For product warranty registration, TOTO U.S.A. Inc. recommends online warranty registration. Please visit

our web site http://www.totousa.com. If you have questions regarding warranty policy or coverage, please contact TOTO U.S.A. Inc., Customer Service Department, 1155 Southern Road, Morrow, GA 30260

(888) 295-8134 or (678) 466-1300 when calling from outside of U.S.A.

Installation and Owner’s Manual

Manual de instalación y del propietario

Manuel d’installation et d’utilisation

Manual de Instalação e do Proprietário

Single Handle Lavatory Faucet

Grifo de Lavabo de Una Manija

Robinet de Lavabo à une Manette

Faucet de Alça Única com Balcão de Banheiro

ZL

TLP02301U

TLP02304U

TLP02307U

2

ENGLISH

Installation Procedure.....................4

Care and Cleaning..........................8

Maintenance....................................9

Warranty..........................................12

Rough-In Dimensions.....................46

Thanks for Choosing TOTO!..........2

Warnings..........................................2

Before Installation...........................2

Included Parts..................................3

Tools You Will Need........................3

Specifications...................................3

TABLE OF CONTENTS

THANK YOU FOR CHOOSING TOTO!

The mission of TOTO is to provide the world with healthy, hygienic and more

comfortable lifestyles. We design every product with the balance of form and

function as a guiding principle. Congratulations on your choice.

WARNINGS

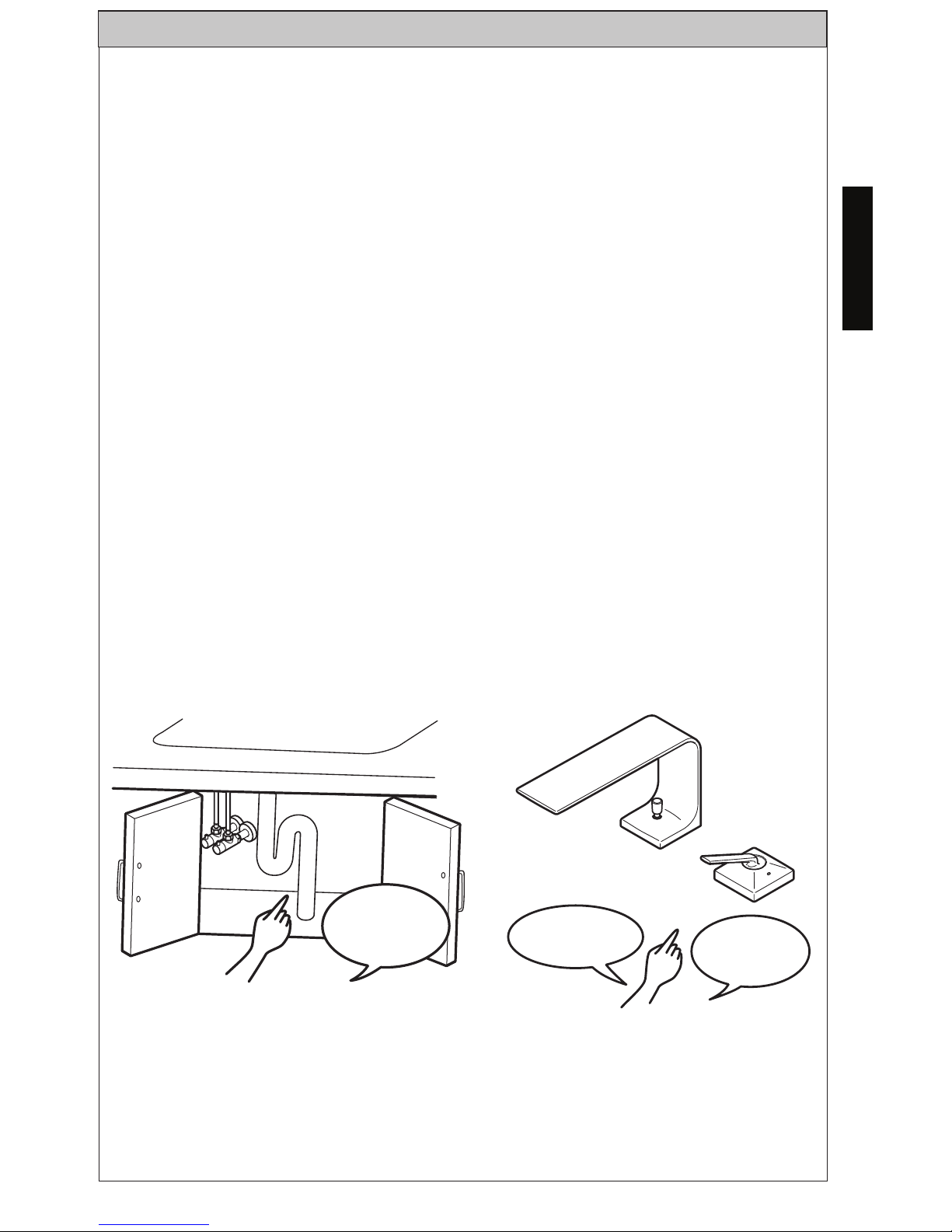

BEFORE INSTALLATION

For safe operation of the faucet, please observe the following:

Operating Pressure:

Minimum Pressure....................20 psi (138 kPa), dynamic

Maximum Pressure...................80 psi (551 kPa), static

Do not use the product at an ambient temperature below 32º F (0º C)

Observe all local plumbing codes.

Before installing the faucet, be sure to thoroughly flush the supply pipes of dirt

and debris.

Make sure the water supply is shut off at the stop valve.

Read these instructions carefully to ensure proper installation.

TOTO reserves the right to update product design without notice.

3

ENGLISH

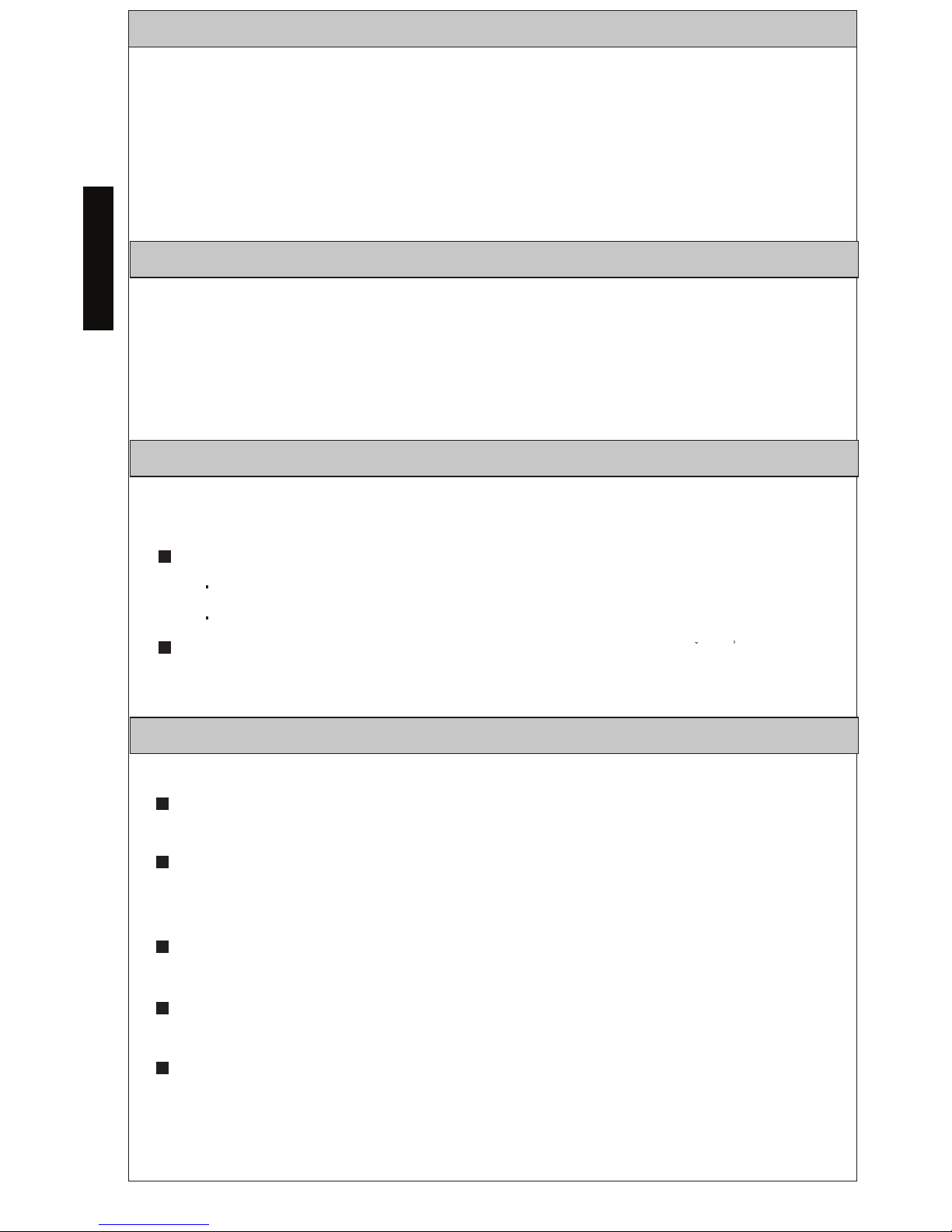

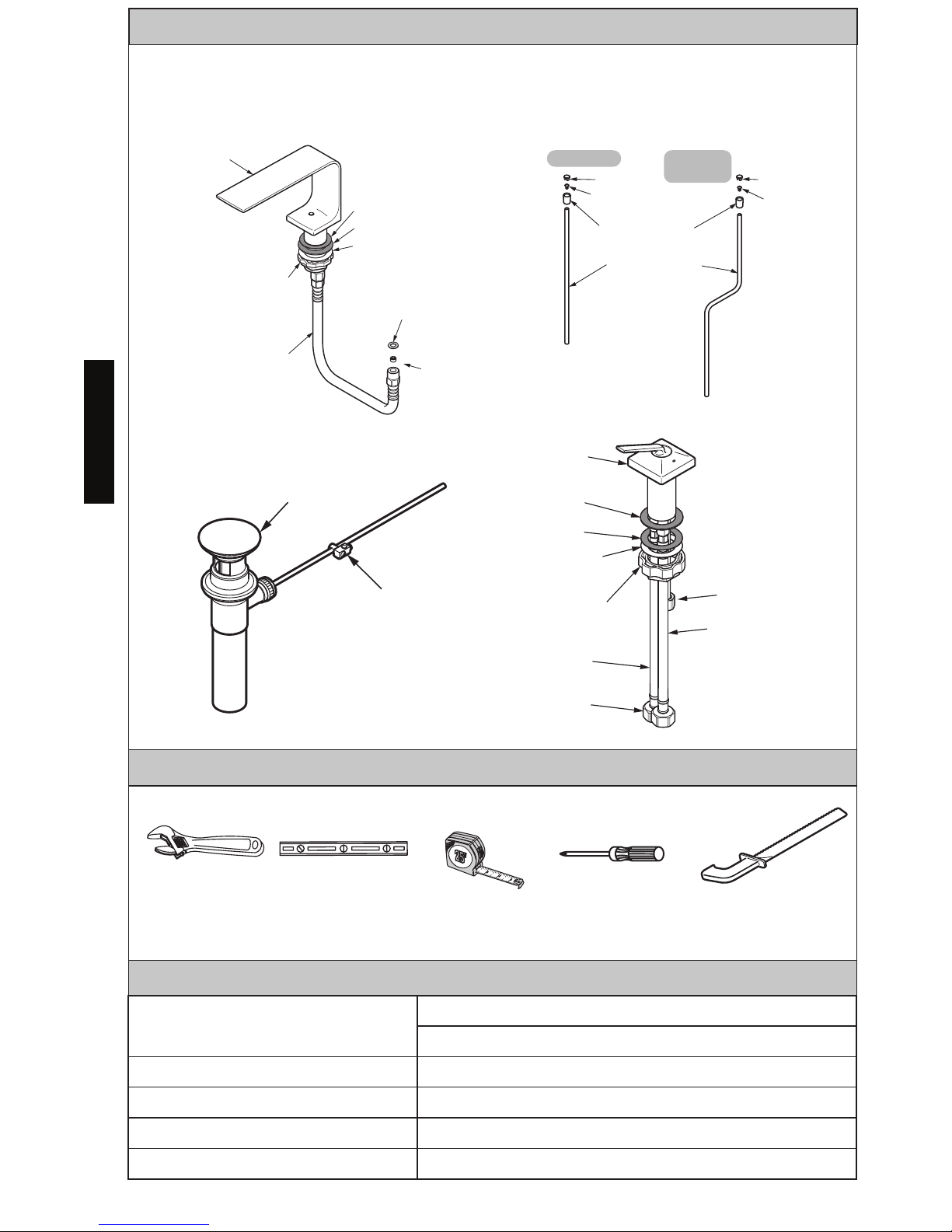

Check to make sure you have the following parts indicated below:

INCLUDED PARTS

TOOLS YOU WILL NEED

Level

Tape

Measure

SPECIFICATIONS

Water Supply Pressure

Minimum required: 20 psi (138 kPa) (Flowing)

Maximum allowed: 80 psi (551 kPa)

Water Supply Connection

3/8 Comp

Ambient Temperature 32~104°F (0~40°C)

Humidity Max. 90% RH

Flow Rate Maximum 1.2 gallon/min (4.5 L/min)

Adjustable

Wrench

.

Spout Assembly

Spout

Gasket

Gasket

Gasket

Flow

regulator

Slip Washer

Mounting nut

(without

groove)

Mixed

supply

hose

TLP02301

TLP02304

TLP02307

Drain lift rod

Lid Lid

Screw

Screw

Pushbutton

Drain lift rod

Handle assembly

Handle

assembly

Gasket

Gasket

Slip

Washer

Mounting nut

(with groove)

Hot water

supply hose

Cold water

supply hose

Drain assembly

Drain assembly

Drain lift rod

connecting part

Nut

9/16-24 UNEF

Phillips

Screwdriver

Hacksaw

4

ENGLISH

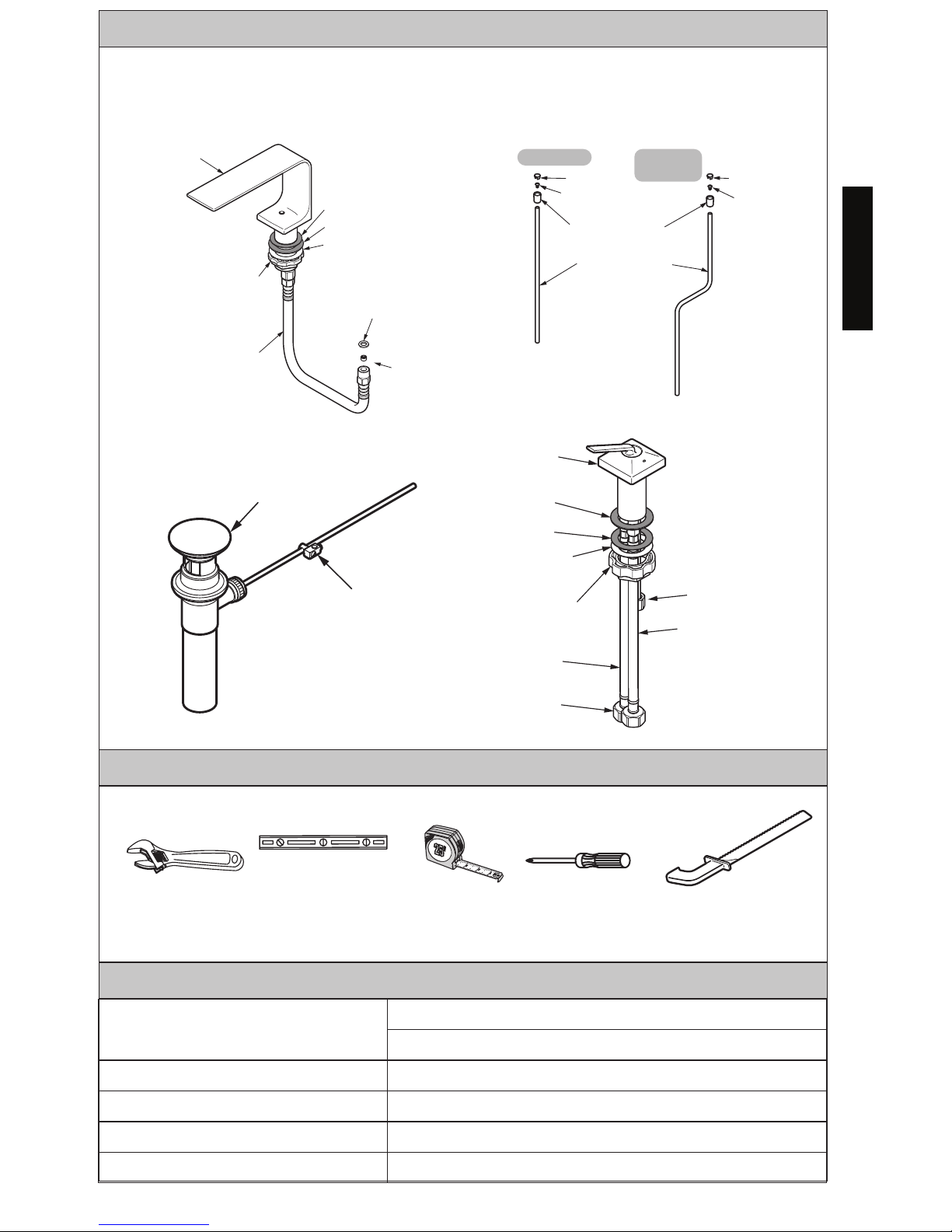

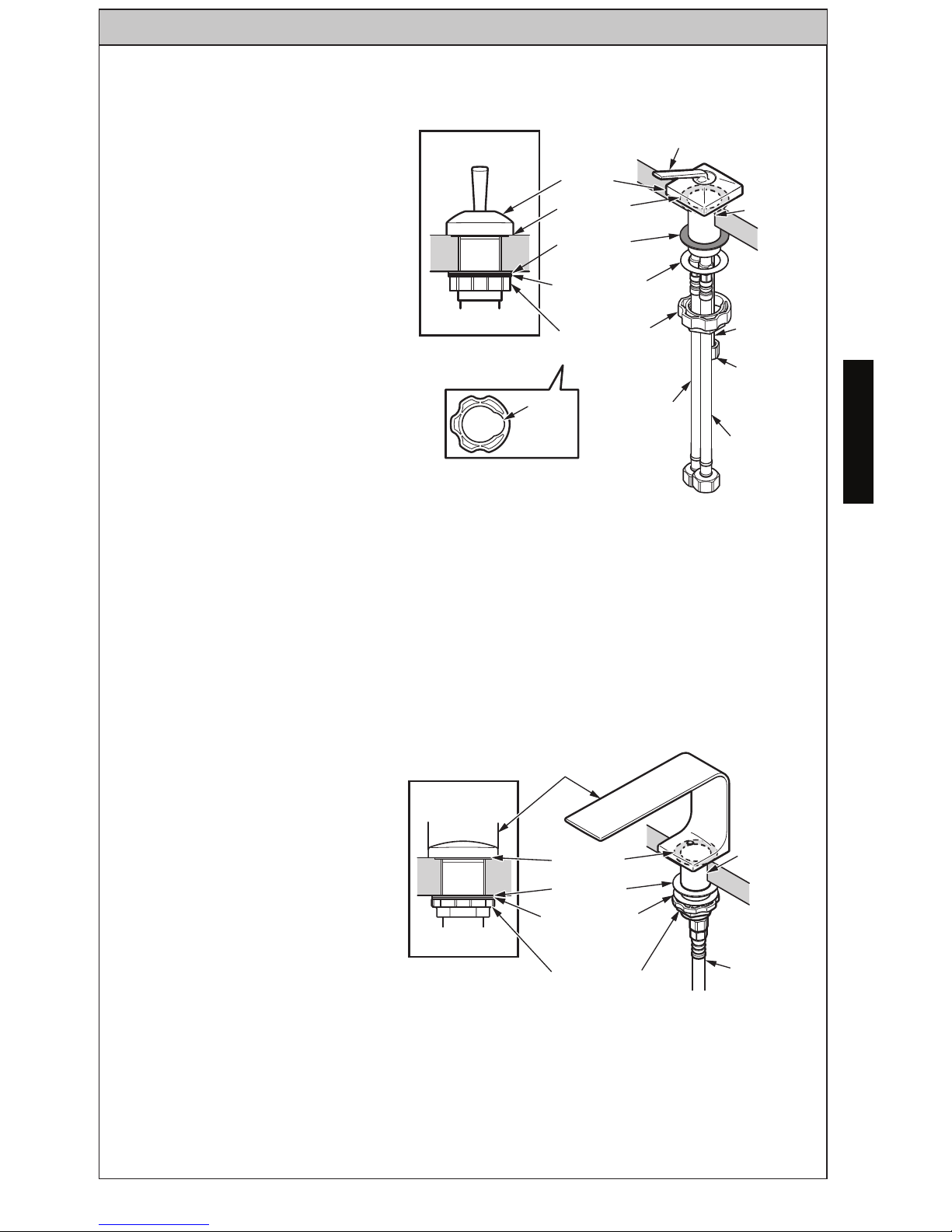

INSTALLATION PROCEDURE

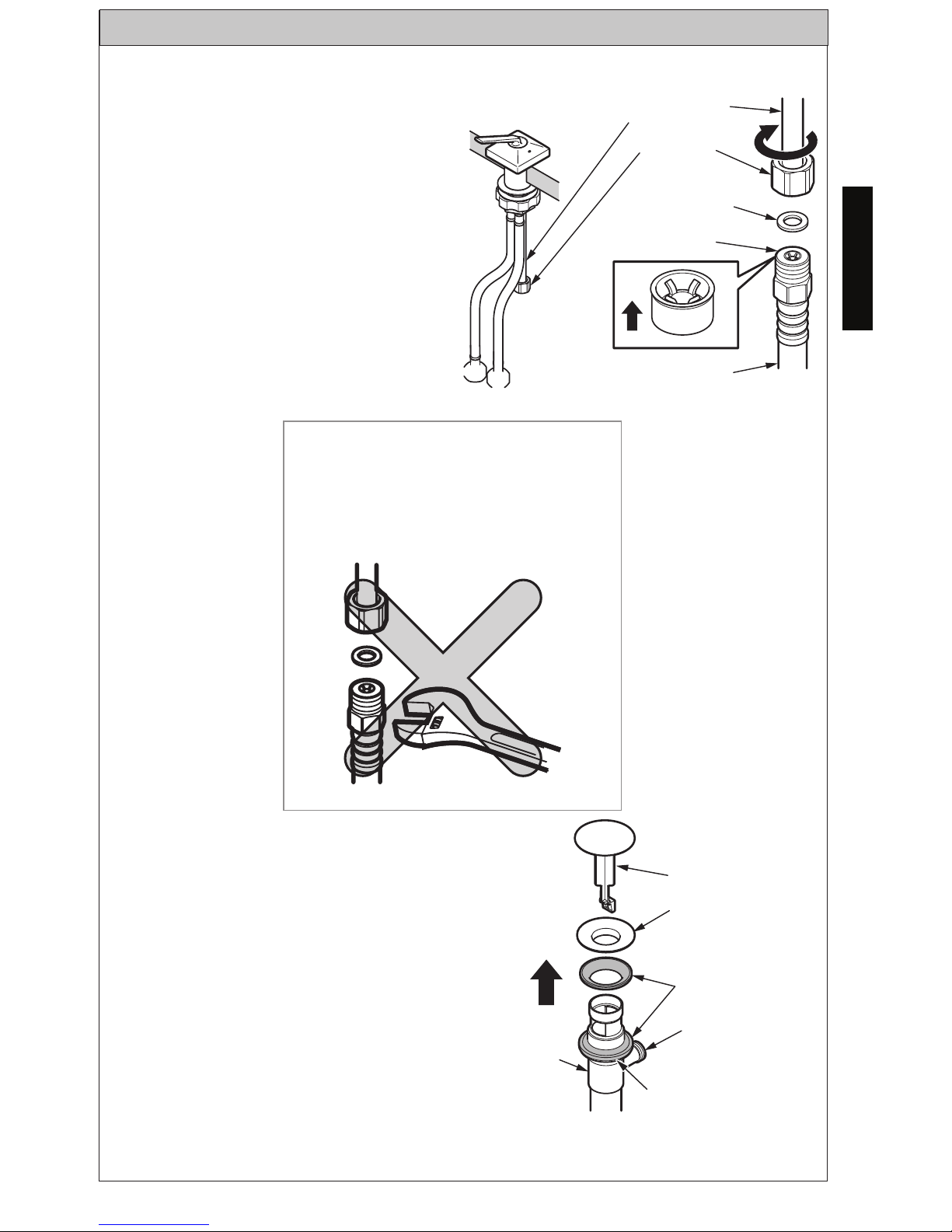

1. Mount the handle

assembly.

(1) Insert the HOT/COLD

water supply hoses into the

mounting hole.

(2) Pass the HOT/COLD

water supply hoses through

the gasket, the slip washer

and the mounting nut

(with groove) one by one.

Then, pass the nut of the

connecting pipe through

the groove and secure the

handle assembly. (ill. 1)

2. Mounting the spout

assembly.

(1) Set the gasket, the slip

washer and the mounting nut

(without groove) on the spout

and secure the spout. (ill.2)

IMPORTANT: Align the spout so that it comes out the center of the

mounting hole.

ill. 1

Section View

Handle

assembly

Lever

handle

Mounting

hole

Connecting

pipe

Gasket

Gasket

Slip

Washer

Mounting

nut

(with groove)

Hot water

supply hose

Groove

Cold water

supply hose

ill. 2

Section View

Spout

Gasket

Gasket

Slip washer

Mounting nut

Mixed supply

hose

Mounting

hole

IMPORTANT: Align the shaft

position so that the handle

assembly comes to the center

of the mounting hole.

(3) Connect the hoses to the supply lines. The left hose (marked with red

band) connects to the hot water supply. The right hose connects to the

cold water supply. Thighten with wrench as needed.

5

ENGLISH

INSTALLATION PROCEDURE

ill. 3

Handle Assembly

Connecting

pipe

Nut

Gasket

(black)

Flow regulator

Up

Mixed supply hose

3. Connection of the

mixed supply hose.

(1) Turn the nut of the

connecting pipe and

connect the mixed supply

hose. (ill. 3)

Never turn the nut on the

mixed supply hose side.

The hose may twist and

cause water to leak.

4. Install drain assembly.

(1) Remove the plunger,

flange and gasket from

the drain assembly by

unfastening the flange and

pulling these parts from

the drain. (ill. 4)

ill. 4

Plunger

Flange

Deformed

gasket

Kick lever

box

Flanged nut

Drain

assembly

6

ENGLISH

INSTALLATION PROCEDURE

(113)

(145)

(113)

(145)

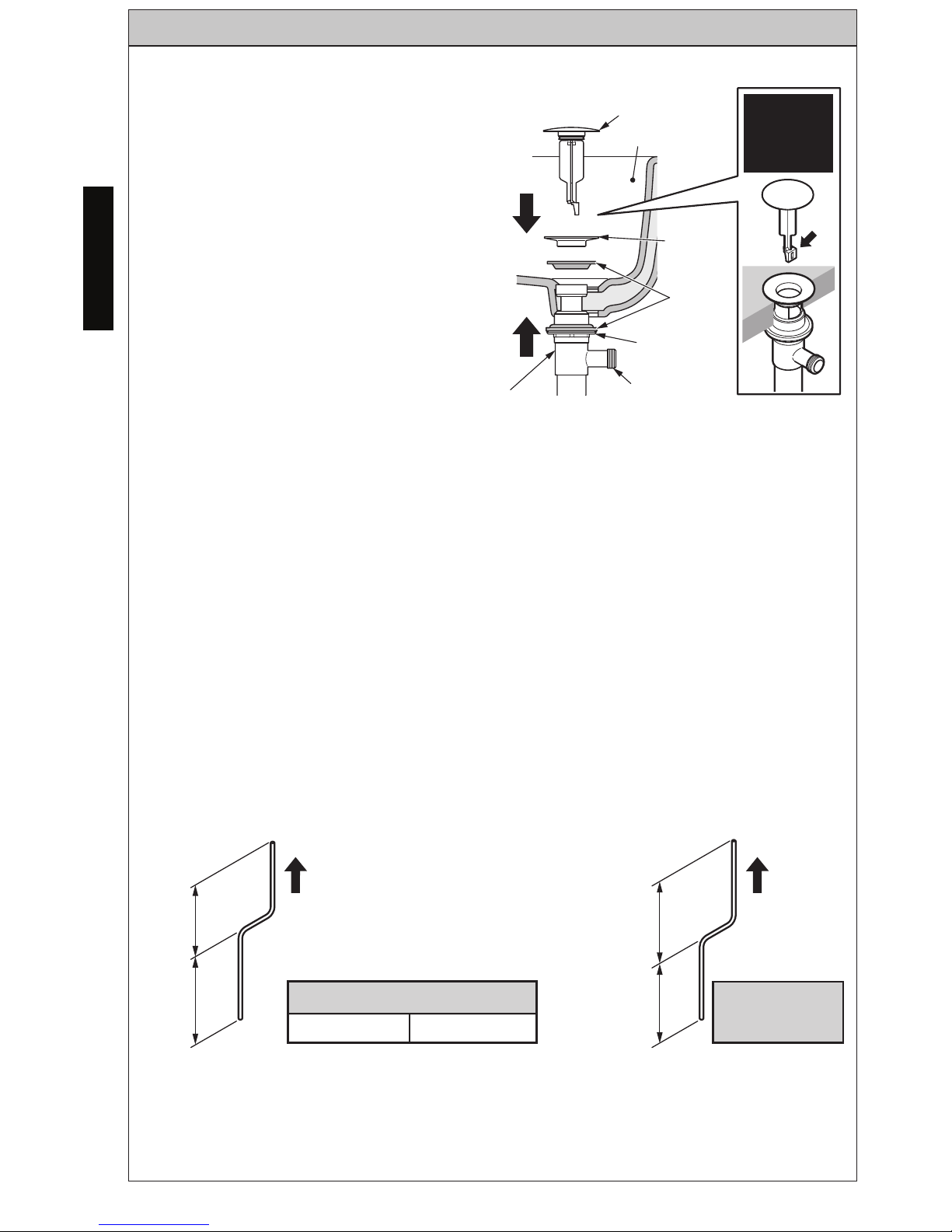

(2) Insert the drain body up

through the drain hole from

below the lavatory. If necessary,

turn the nut and push the washer

and gasket (thick) down to allow

for clearance.

While holding the drain body in

place, fasten the flange to the

drain body from the top. Ensure

that the gasket is between the

flange and the lavatory as shown.

Once the flange is fully seated,

turn the nut below the lavatory

up until a good seal is formed.

(3) Mount the drain lift rod in the proper direction. (ill. 6)

ill. 5

Lavatory

Plunger

Flange

Deformed

gasket

Flanged nut

Lever hole

Drain

assembly

Attention

to direction

of plunger

Spout

Part number of the lavatory

LT475 LT476

Spout

Unit: inch

(mm)

Other than the

part numbers

written on the left

Short

4-7/16”

Short 4-7/16”

Long

5-11/16”

Long 5-11/16”

ill. 6

Do not overtighten!

(ill. 5)

Reinsert the plunger if needed.

7

ENGLISH

INSTALLATION PROCEDURE

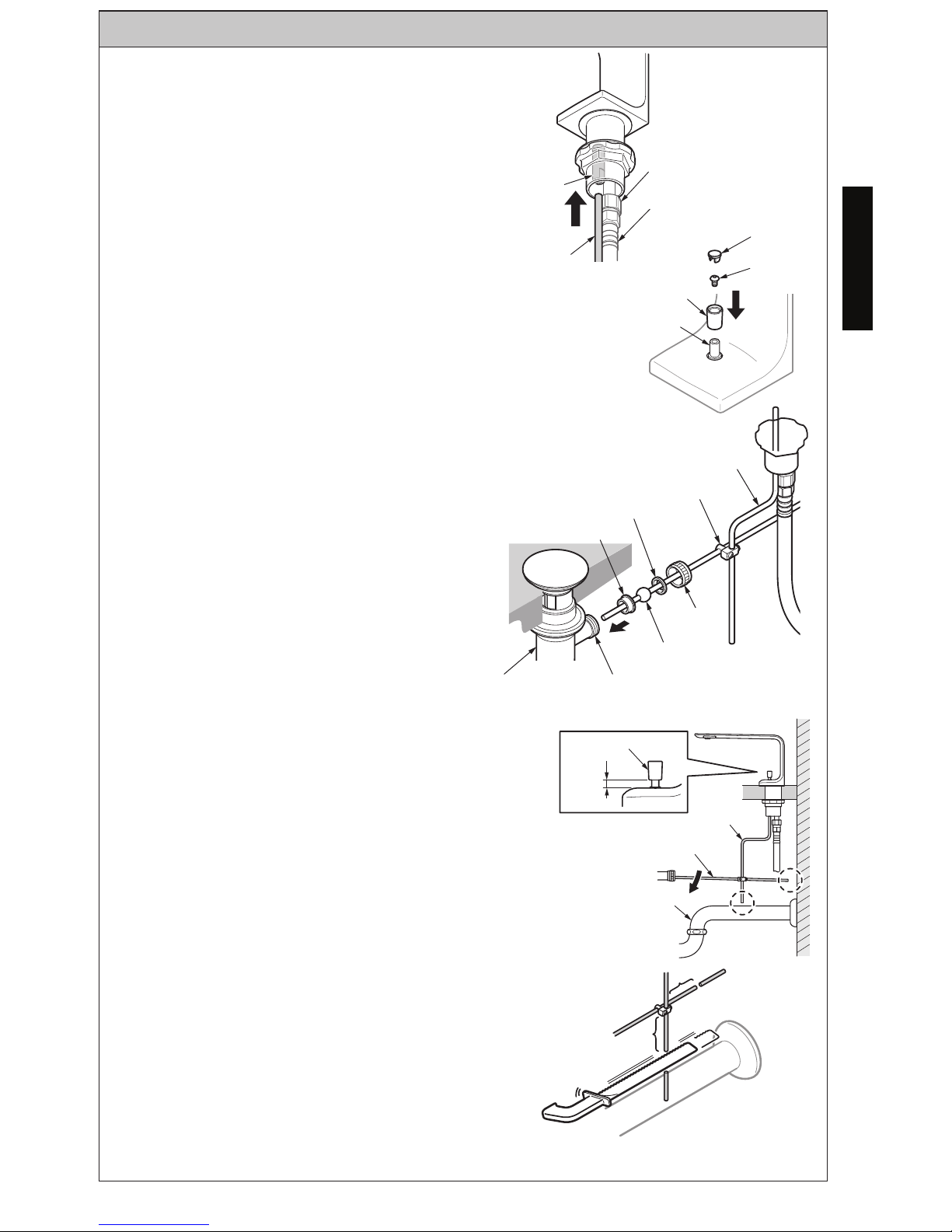

(4) Install drain assembly (continued)

(a) Insert the drain lift rod into the

guide from below the spout body.

(b) Mount the pushbutton, screw and

lid on the drain lift rod in that order.

(ill. 7)

5. Connect the drain assembly.

(1) Adjust the position of the drain lift rod so

that the clearance between the spout and the

pushbutton is 3/16”- 3/8” (5~10mm).

(2) Lower the pivot arm to the lowest position

in the condition described in part (a), secure

the screw of the drain lift rod connecting part

to anchor the pivot arm and the drain lift rod.

(ill. 9)

(c) Fit bushing B, the pivot ball nut and the drain

lift rod connecting part on the pivot arm and fit

bushing A on the drain assembly.

(d) After passing the drain lift rod

through the drain lift rod connecting

part, pass the pivot arm through

the hole of the plunger of the

lever hole and secure it with

the pivot ball nut. (ill. 8)

*

*

CAUTION

If the pivot arm and the drain lift rod interfere with

the wall and the water drain pipe, cut them to a

length that they do not interfere. (ill. 10)

Make sure water is flowing properly after installing

the faucet.

ill. 10

ill. 7

Guide

Drain lift rod

Connecting pipe

Mixed supply hose

Lid

Screw

Pushbutton

Drain lift rod

ill. 8

.

Drain lift rod

Drain lift rod

connecting part

Bushing B

Bushing A

Drain assembly Lever hole

Pivot arm

Pivot Ball

Nut

*Cut 3/8”- 13/16”(10~20) from

the anchoring metal fittings.

ill. 9

Water drain pipe

Pivot arm

Drain lift rod

Pushbutton

Wall

3/16”~ 3/8”

(5~10)

8

ENGLISH

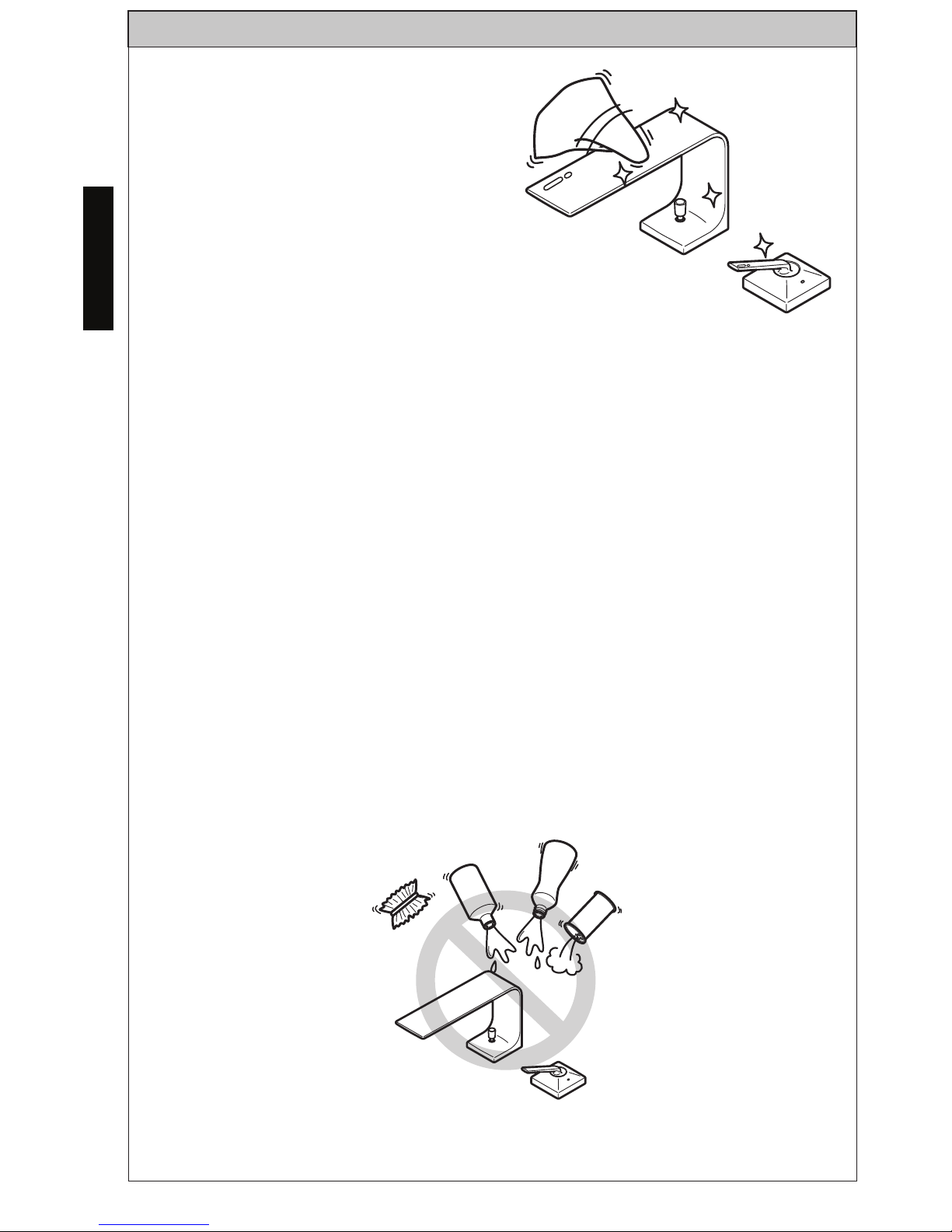

Clean the parts regularly to prevent the

accumulation of dirt and lime-scale.

For daily cleaning, use a neutral cleaner.

Acids are necessary ingredients of

cleaning materials for removing lime.

However, please pay attention to the

following points when cleaning fittings

(ill. 11):

Only use cleaning materials which

are explicitly recommended for this type of application.

Never use cleaning materials which contain hydrochloric, formic or

acetic acid, as they may cause considerable damage.

Do not use phosphoric acid as it can also cause damage.

Never use cleaning materials or appliances with an abrasive effect,

such as cleaning powders, sponges or microfiber cloths.

Please follow the cleaning material manufacturer’s instructions.

When using spray cleaners, spray first onto a soft cloth or sponge.

Never spray directly onto the fittings, as drops could enter openings

and gaps, which can then cause damage.

After cleaning, rinse thoroughly with clean water to remove any

cleaner residue.

Components with damaged surfaces must be exchanged, otherwise

this can cause an injury. Damage caused by improper treatment will

not be covered by our warranty.

CARE AND CLEANING

ill. 11

Thinner

Acidic/alkali detergents

Cleansers

9

ENGLISH

Check your faucet at least once a month for the following potential

problems and to do the following maintenance procedures:

Inspect for Leakage

• Check all water connections for signs of leakage. (ill. 12)

Looseness of the product

• Check for any parts that seem abnormal such as being loose as

compared when you first began using the product. (ill. 13)

Tighten the Spout and Handle Assembly

• If the spout or handle is loose, tighten the mounting nut underneath

the spout or handle assembly.

If you continue to use the product with loose piping, weight is applied to

the pipe(s) and may result in water leakage.

If you leave any abnormality like looseness unfixed, part(s) may break or

plated surfaces may crack whereby injuring you.

If you find a loose part, remove the cap and retighten the screw that secures the main body. In case the looseness cannot be repaired, ask your

dealer or seller for repairs (subject to billing).

MAINTENANCE

No

abnormality

No

looseness

ill. 13

ill. 12

No Water

Leaks!

10

ENGLISH

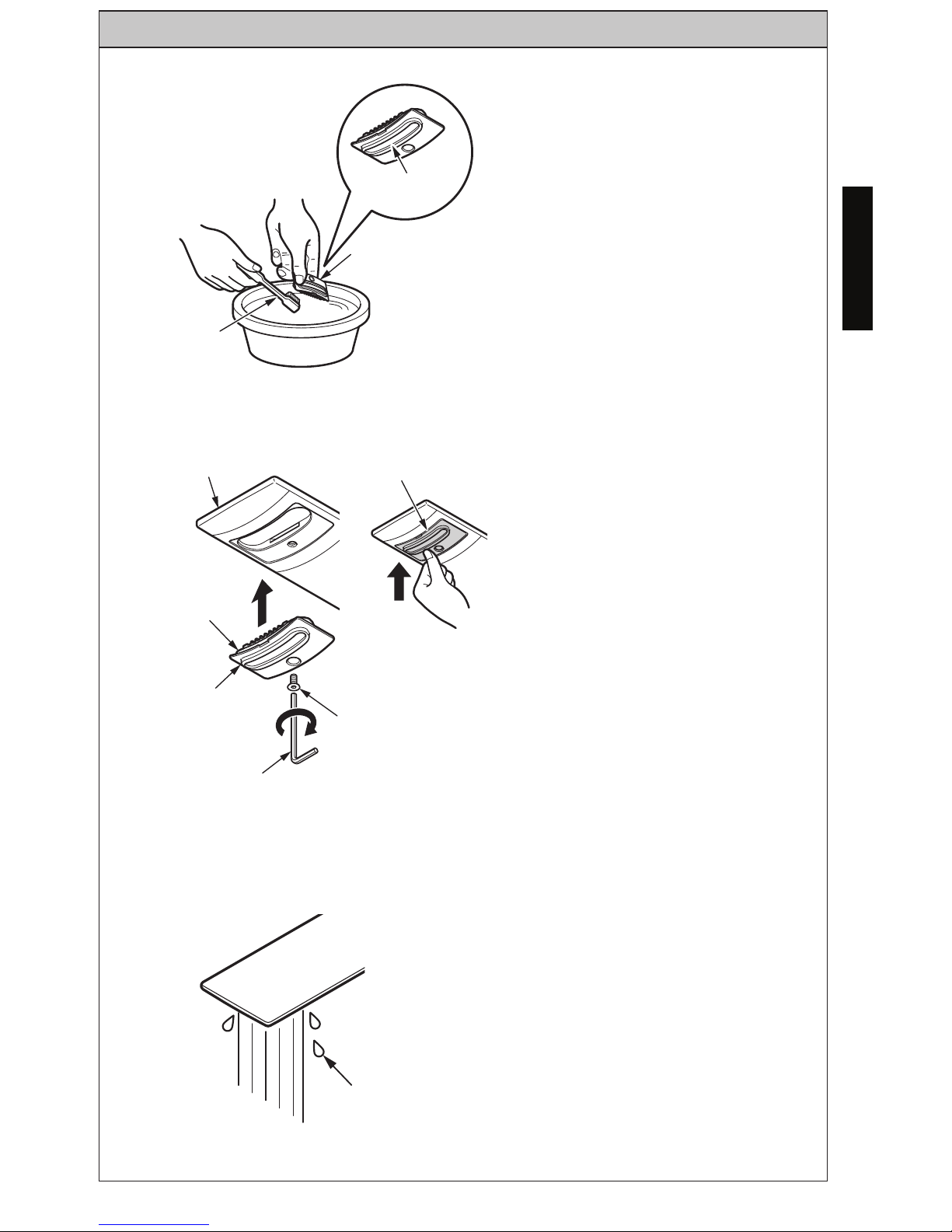

To clean the nozzle screen:

1. Loosen and remove the set screw using a hexagonal wrench (2 mm).

(ill. 16)

2. Insert the flat-blade precision screwdriver in the notch between the

nozzle screen case and the spout, and remove the nozzle screen case.

Pay attention not to lose the O-ring of the nozzle screen case.

MAINTENANCE

(M3x7)

Flat-blade

precision

screwdriver

Spout

O-ring

(Semitransparent)

Nozzle screen

case

Set screw

Notch

Hexagonal wrench

(2mm)

A

B

How to secure the lever handle.

Close the stop valve before starting work.

1. Insert a flat-blade precision screwdriver

into the clearance between the lever handle

and the cover, and lift and remove the cover.

(ill. 14)

2. Lift the lever handle and retighten the

setscrew with a hexagonal wrench (2.5mm)

3. Pass the cover over the lever handle,

press it into the counter surface and mount

it. (ill. 15)

Pay attention to the

direction of the cover.

Mount cover.

ill. 14

Flat-blade precision

screwdriver

Lever

Handle

Remove Cover

Cover

Hexagonal wrench

(2.5mm)

ill. 15

ill. 16

11

ENGLISH

MAINTENANCE

3. Remove dirt and debris

caught in the nozzle screen using

a toothbrush, etc. (ill. 17)

4. Assemble the nozzle screen

case on the spout and lock it in

place with the set screw.

Press the nozzle screen case

into the spout with a finger and

tighten the setscrew. (ill. 18)

5. When mounting work is complete, check the nozzle screen

for any water leaks. If the nozzle

screen case is not mounted properly, re-mount it. (ill. 19)

ill. 19

Leak

ill. 17

Nozzle

screen

Nozzle Screen-

Case

Toothbrush

(M3x7)

)

ill. 18

Nozzle Screen

Case

Press it IN

with a finger

O-Ring

(Semi

Transparent)

Nozzle Screen

Case

Hexagonal wrench

(2mm)

Set screw

Spout

12

ENGLISH

WARRANTY

1. TOTO ers (“Product”) to be free from defects in

materials and workmanship during normal use when properly installed and serviced, for a period of three (3) years

from date of purchase. This limited warranty is extended only to the ORIGINAL PURCHASER of the Product and is

not transferable to any third party, including but not limited to any subsequent purchaser or owner of the Product.

This warranty applies only to TOTO Product purchased and installed in North, Central and South America.

2. TOTO’s obligations under this warranty are limited to repair, replacement or other appropriate adjustment, at

TOTO’s option, of the Product or parts found to be defective in normal use, provided that such Product was properly

sa snoitcepsni hcus ekam ot thgir eht sevreser OTOT .snoitcurtsni htiw ecnadrocca ni decivres dna desu ,dellatsni

ni strap ro robal rof egrahc ton lliw OTOT .tcefed eht fo esuac eht enimreted ot redro ni yrassecen eb yam

connection with warranty repairs or replacements. TOTO is not responsible for the cost of removal, return and/or

reinstallation of the Product.

5. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE, PROVINCE TO PROVINCE OR COUNTRY TO COUNTRY.

6. To obtain warranty repair service under this warranty, you must take the Product or deliver it prepaid to a TOTO

service facility together with proof of purchase (original sales receipt) and a letter stating the problem, or contact

a TOTO distributor or products service contractor, or write directly to TOTO U.S.A., INC., 1155 Southern Road,

Morrow, GA 30260 (888) 295 8134 or (678) 466-1300, if outside the U.S.A. If, because of the size of the Product

or nature of the defect, the Product cannot be returned to TOTO, receipt by TOTO of written notice of the defect

esoohc yam OTOT ,esac hcus nI .yreviled etutitsnoc llahs )tpiecer selas lanigiro( esahcrup fo foorp htiw rehtegot

to repair the Product at the purchaser’s location or pay to transport the Product to a service facility.

THIS WRITTEN WARRANTY IS THE ONLY WARRANTY MADE BY TOTO. REPAIR, REPLACEMENT OR OTHER APPROPRIATE

ADJUSTMENT AS PROVIDED UNDER THIS WARRANTY SHALL BE THE EXCLUSIVE REMEDY AVAILABLE TO THE ORIGINAL

PURCHASER. TOTO SHALL NOT BE RESPONSIBLE FOR LOSS OF THE PRODUCT OR FOR OTHER INCIDENTAL, SPECIAL

OR CONSEQUENTIAL DAMAGES OR EXPENSES INCURRED BY THE ORIGINAL PURCHASER, OR FOR LABOR OR OTHER

COSTS DUE TO INSTALLATION OR REMOVAL, OR COSTS OF REPAIRS BY OTHERS, OR FOR ANY OTHER EXPENSE NOT

SPECIFICALLY STATED ABOVE. IN NO EVENT WILL TOTO’S RESPONSIBILITY EXCEED THE PURCHASE PRICE OF THE

PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTIES, INCLUDING THAT

OF MERCHANTABILITY OR FITNESS FOR USE OR FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, OR THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND EXCLUSION MAY NOT

APPLY TO YOU.

3. This warranty does not apply to the following items:

b. Damage or loss resulting from any accident, unreasonable use, misuse, abuse, negligence, or improper

care, cleaning, or maintenance of the Product.

c. Damage or loss resulting from sediments or foreign matter contained in a liquid soap system.

ro/dna hsrah a ni tcudorP eht fo noitallatsni morf ro noitallatsni reporpmi morf gnitluser ssol ro egamaD .d

tion of the Product.

e. Damage or loss resulting from electrical surges or lightning strikes or other acts which are not the fault of

f. Damage or loss resulting from normal and customary wear and tear, such as gloss reduction, scratching or

fading over time due to use, cleaning practices or water or atmospheric conditions, including but not limited

to, the use of bleach, alkali, acid cleaners, dry (powder) cleaners or any other abrasive cleaners or the use

of metal or nylon scrubbers.

4. In order for this limited warranty to be valid, proof of purchase is required. TOTO encourages warranty registration

upon purchase to create a record of Product ownership at http://www.totousa.com is required. TOTO encourages

registration upon purchase and failure to register will not diminish you r limited warranty rights.

13

ESPAÑOL

Procedimiento de Instalación.......15

Cuidado y Limpieza.......................19

Mantenimiento...............................20

Garantía..........................................23

Bosquejo........................................46

¡Gracias por elegir TOTO!.........13

Advertencias................................13

Antes de la Instalación................13

Partes Incluidas............................14

Herramientas que necesitarás....14

Especificaciones...........................14

TABLA DE CONTENIDO

¡GRACIAS POR ELEGIR TOTO!

La misión de TOTO es proporcionar al mundo estilos de vida saludables,

higiénicos y más cómodos. Diseñamos cada producto con el equilibrio de

forma y función como principio rector. Felicidades por tu elección.

ADVERTENCIAS

ANTES DE LA INSTALACIÓN

Para un funcionamiento seguro del grifo, tenga en cuenta lo siguiente:

Presión operacional:

Presión mínima .................... 20 psi (138 k Pa), dinámica

Presión máxima ................... 80 psi (551 kPa), estático

No use el producto a una temperatura ambiente inferior a 32º F (0º C)

Observe todos los códigos de plomería locales.

Antes de instalar el grifo, asegúrese de enjuagar a fondo los tubos de

suministro de suciedad y residuos.

Asegúrese de que el suministro de agua esté cerrado en la válvula de cierre.

Lea estas instrucciones cuidadosamente para asegurar una instalación correcta.

TOTO se reserva el derecho de actualizar el diseño del producto sin previo

aviso.

14

ESPAÑOL

Asegurese de que tiene las partes indicadas a continuación:

PARTES INCLUIDAS

HERRAMIENTAS QUE NECESITARÁS

Nivel

Cinta Metrica

ESPECIFICACIÓNES

Presión de suministro de agua

Mínimo requerido: 20 psi (138 kPa) (corriente)

Máximo permitido: 80 psi (551 kPa)

Conexión de suministro de agua

3/8 Comp

Temperatura ambiente 32~104°F (0~40°C)

Humedad Max. 90% RH

Flujo Máximo de 1,2 galón/min (4,5 L/min)

Llave

Ajustable

.

Ensamblaje de salida para tina

Salida para tina

Junta

Junta

Junta

Regulador

de flujo

Arandela de

deslice

Tuerca de

montaje

(sin perforación)

Manguera

de suministro

mixto

TLP02301

TLP02304

TLP02307

Vara de Desagüe

Tapa

Tapa

Tornillo

Tornillo

Botón

Vara de Desagüe

Ensamblaje de Manija

Ensamblaje de

manija

Junta

Junta

Arandela de

deslice

Tuerca de montaje

(con perforación)

Manguera de

suministro de

agua caliente

Manguera de

suministro de

agua fria

Ensamblaje de desagüe

Ensamblaje de desagüe

Parte conectora de la

vara de desagüe

Tuerca

9/16-24UNEF

Destornillador

Phillips

Sierra

15

ESPAÑOL

PROCEDIMIENTO DE INSTALACIÓN

1. Monte el ensamblaje de la

manija.

(1) Inserte las mangueras de

suministro de agua CALIENTE/

FRÍA en el orificio de montaje.

(2) Pase las mangueras de

suministro de agua CALIENTE/

FRÍA a través de la junta, la

arandela de deslice y la tuerca

de montaje (con perforación)

una a una. Luego, pase la

tuerca de la tubería conectora

a través de la perforación y

asegure el ensamblaje de la

manija. (ill. 1)

2. Montar el ensamblaje de

la salida para tina.

(1) Coloque la junta, la

arandela de deslice y la

tuerca de montaje (sin

perforación) en la salida para

tina y asegúrela. (ill.2)

IMPORTANTE:

Alinee la salida para tina de manera que salga del centro del orificio

de montaje.

ill. 1

Vista de

Sección

Ensamblaje

de Manija

Palanca

Orificio de

montaje

Tubo de

connección

Tuerca

Junta

Junta

Arandela de

deslice

Tuerca de montaje

(con perforación)

Manguera de

suministro de

agua caliente

Perforación

Manguera de

suministro de

agua fría

ill. 2

Salida para tina

Junta

Junta

IMPORTANTE: Alinee la posición del eje de manera que el ensamblaje de

la manija llegue al centro del orificio de montaje.

(3) Conecte las mangueras a las líneas de suministro. La manguera

izquierda (marcada con una banda roja) conecta el suministro de agua

caliente. La manguera derecha conecta el suministro de agua fría. Ajuste

con la llave lo necesario.

Vista de

Sección

Orificio de

montaje

Manguera

de suministro

mixto

Tuerca de montaje

Arandela de

deslice

Loading...

Loading...