Page 1

Installation and Owner’s Manual

Manual de Instrucciones y del Propietario

Manuel d’Installation et d’Utilisation

Manual de Instalação e do Proprietário

EcoPower® Flush Valve

Fluxómetro EcoPower

Valve de Chasse EcoPower

®

®

Fluxômetro Self Power

Warranty Registration and Inquiry

For product warranty registration, TOTO U.S.A. Inc. recommends online warranty registration. Please visit our web site

http://www.totousa.com.If you have questions regarding warranty policy or coverage, please contact TOTO U.S.A. Inc.,

Customer Service Department, 1155 Southern Road,Morrow, GA 30260 (888) 295-8134 or (678) 466-1300 when calling

from outside of U.S.A.

Page 2

TABLE OF CONTENTS

Thanks for Choosing TOTO!...................................................................................................................2

Included Parts.............................................................................................................................................2

Common Tools Needed............................................................................................................................3

Care & Cleaning..........................................................................................................................................3

Features..................................................................................................................................3

Specifications..........................................................................................................................4

Technical Information.................................................................................................................................5

ENGLISH

Warnings..........................................................................................

................................................6

Before Installation.......................................................................................................................................6

Installation Procedures...............................................................................................................................7

Test Run.....................................................................................................................................................14

Note to the Installer..................................................................................................................................15

Using the Flush Valve.............................................................................................................................15

Periodic Maintenance...............................................................................................................................15

Troubleshooting.................................................................................................................................16

Warranty....................................................................................................................... ..................20

Rough-In Dimensions...............................................................................................................................78

THANK YOU FOR CHOOSING TOTO!

The mission of TOTO is to provide the world with healthy, hygienic and more comfortable

lifestyles. We design every product with the balance of form and function as a guiding principle.

Congratulations on your choice.

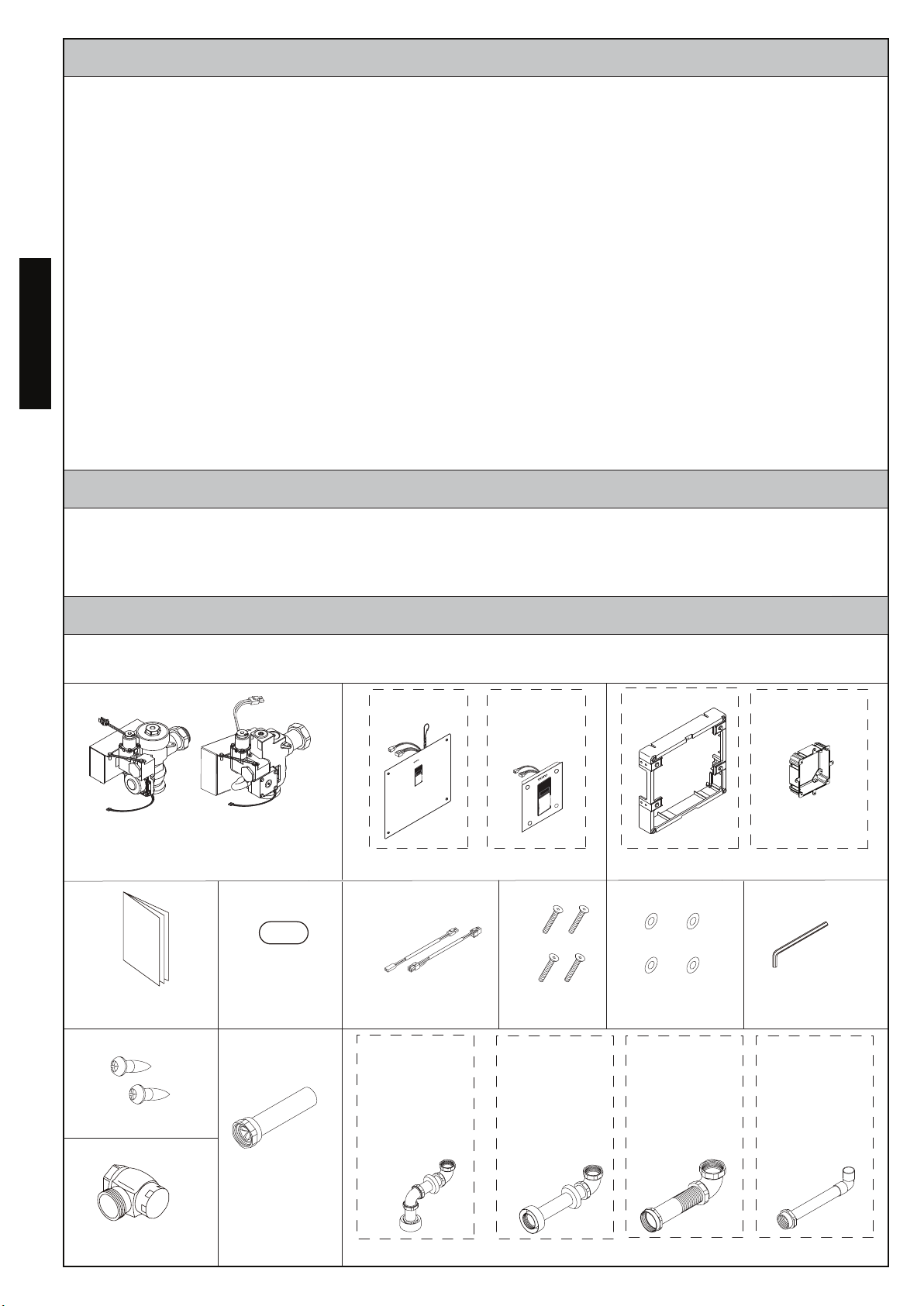

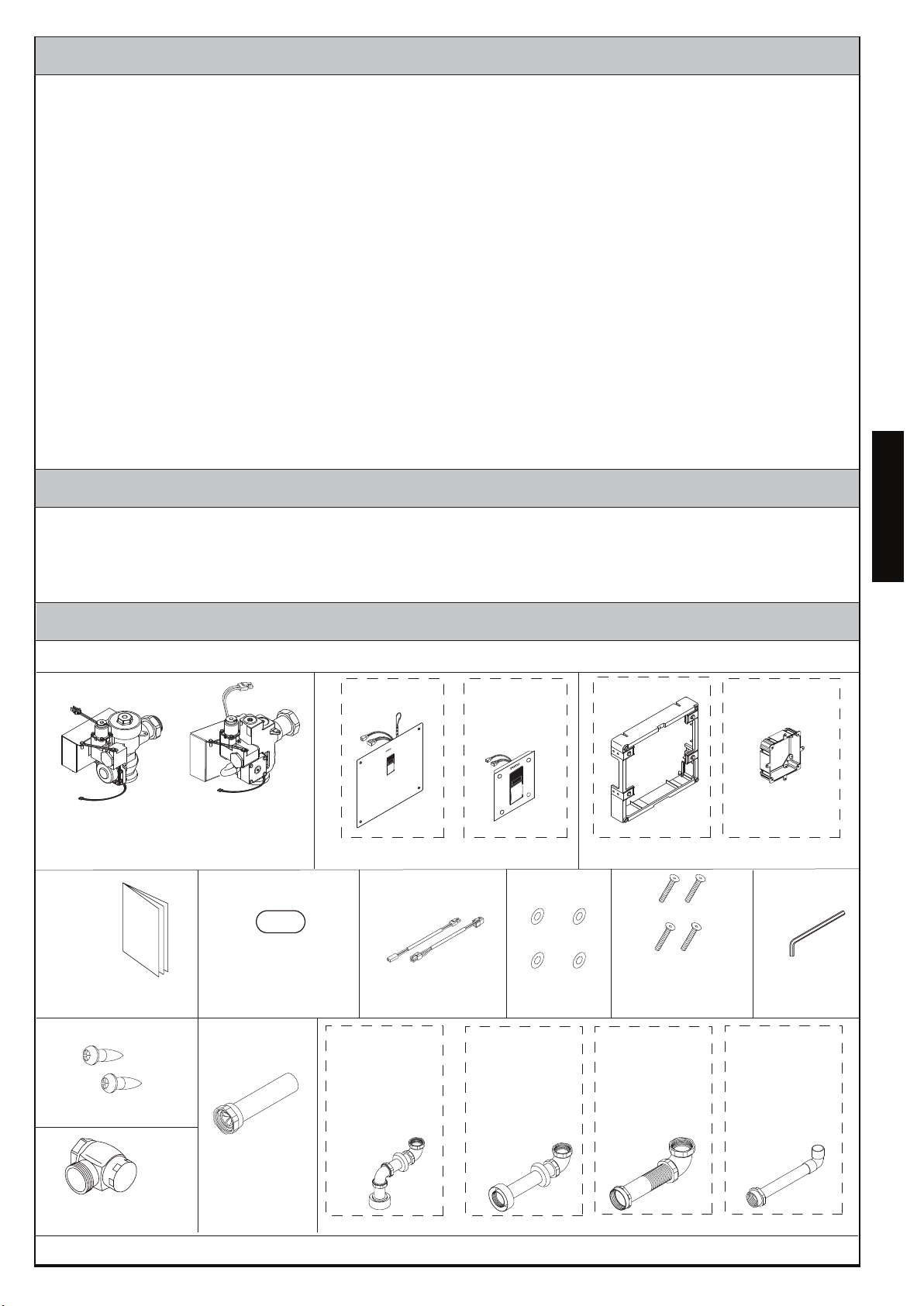

INCLUDED PARTS

Check to make sure you have all these parts from the package:

Large cover Small cover Large cover Small cover

(TEU2UA only)

(TEU3UA only)

Valve body assembly

Front cover

Base frame

Installation And

Owner's Manual

Small cover only

Screws

Control stop

Notice label

Vacuum

breaker tube

Connection cables

TET3GA32

TET3LA32

TET2GA32

TET2LA32

TEU3LA12

TEU3UA12

TEU2LA12

TEU2UA12

2

Vandal proof

hex screws

TET3GA33

TET3LA33

TET2GA33

TET2LA33

Washer

TET3GA31

TET3LA31

TET2GA31

TET2LA31

Flush pipe

Hex wrench

TEU3LA11

TEU3UA11

TEU2LA21

TEU2UA11

TEU3LA21

TEU2LA11

Page 3

COMMON TOOLS NEEDED

Adjustable wrench

Screwdrivers (Phillips and Slotted )

Offset pipe wrench

CARE & CLEANING

IMPORTANT! Do not scratch the sensor when cleaning.

Avoid using any cleaning materials that may scratch the surface.

Never use polishing powder, detergent that includes coarse particles, thinners,

benzene, acids, alkaline detergents, or nylon scrub brushes.

To safely clean the surface, wipe it using a dampened soft cloth with diluted

dishwashing detergent and dry it with another soft cloth. If this does not adequately

clean the surface, wipe the area with a neutral detergent and wet cloth.

FEATURES

Fully Automatic and Hygienic

The EcoPower Flush Valve uses an infrared sensor to detect the user using and departing the

fixture, to provide an automatic flush of the fixture after a short delay. No manual operation is

required, improving the experience of use and hygiene of the fixture.

System Protection Timer

When the fixture is not used for 24 hours for toilet or 12 hours for urinal the protection

timer commands the system to flush in order to maintain the trap seal.

Manual Functionality

For maintenance and emergency use, the EcoPower Flush Valve is equipped with a manual

flushing button.

Green Features

Conserves Power

The flushing of the fixture activates a hydropower generator which generates electric power for

the next flush. (See About TOTO’s Hydropower Generator)

Conserves Water

Two functions help the EcoPower Flush Valve conserve water:

Fuzzy Logic Control

The EcoPower Flush Valve can sense how often and how long the fixture has been used to

deliver the correct amount of water. (See About Fuzzy Logic Control)

Anti Consecutive Flushing

The EcoPower Flush Valve offers water saving consecutive flush prevention. After a flush, the

valve will not automatically flush again for 10 seconds for urinals and 30 seconds for toilets.

ENGLISH

TOTO EcoPower Flush Valves are designed to work for 10 years, under normal conditions,

with no minimum usage required.

3

Page 4

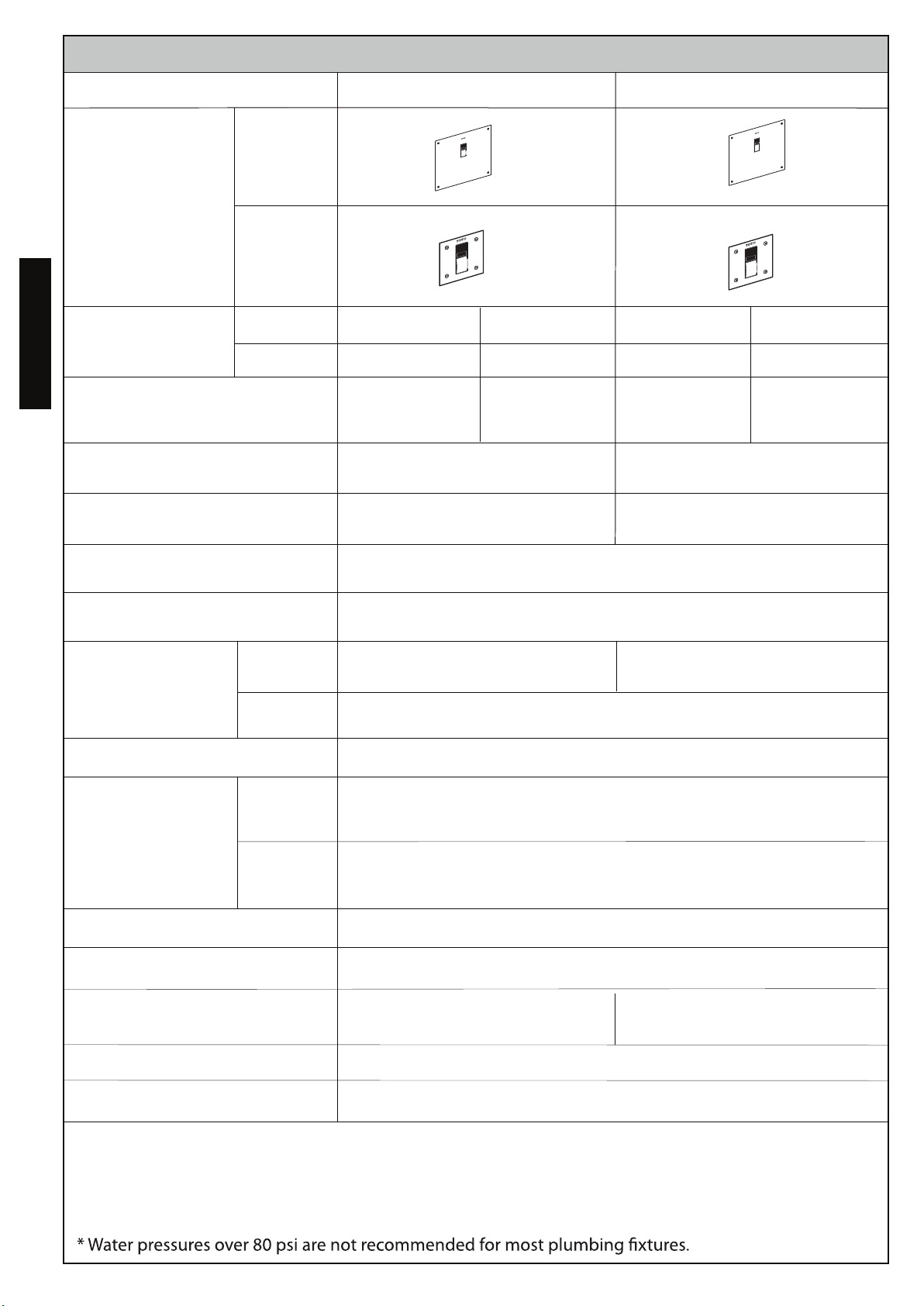

SPECIFICATIONS

Toilet

Large cover

Figure

ENGLISH

Model number

Rated Flush Volume

at 28 psi (196kPa)

Toilet/Urinal type

Control stop inlet

Small cover

Large cover

Small cover

TET2LA

TET3LA

1.28 G (4.8L) 1.6 G (6L) 0.5 G (1.9L)

Flushometer type bowl Wash down flush

1"NPT 3/4"NPT

TET2GA

TET3GA

TEU2LA

TEU3LA

Urinal

TEU2UA

TEU3UA

0.125 G (0.47L)

Flush Valve inlet

Flush Valve outlet

Supply water

pressure

Min

(Flowing)

Max*

35 psi (241kPa)

(Static)

Shutoff pressure

12-5/8" (H) ×14-3/16"(W)

Dimension

of cover

Detection range from the front Within 33-1/2" (850mm)

Detection time

Trap seal protection

Large cover

Small cover

Automatic flushing every

24 hours of non-use

(320mm(H) ×360mm(W) )

4-23/32" (H) ×4-23/32"(W)

(120mm(H) ×120mm(W) )

1-1/4"NPSM

1-1/2"NPSM

125 psi (862kPa)

7 psi (48kPa)

6 seconds

Automatic flushing every

12 hours of non-use

15psi (103kPa)

Ambient temperature

Water temperature

NOTE:

The type of fixture determines the minimum pressure required for the valve. Consult

fixture manufacturer for the pressure requirement.

32-104˚F (0-40˚C)

34-104˚F (1-40˚C)

4

Page 5

TECHNICAL INFORMATION

About TOTO's Hydropowered Generator

The flow of water causes the turbine in the power generator to rotate. This process generates

electric power and enables the automatic flushometer valve to operate. See ill. 1 below.

TET2LA

TET2GA

TET3LA

TET3GA

TEU2LA

TEU3LA

TEU2UA

TEU3UA

3) The Automatic

Flush Valve uses the

charged power.

2) Electric power is

stored in a capacitor.

1) A turbine rotates to

generate electric

power.

Sensor Eye

3)

The Automatic

Flush Valve uses the

charged power.

2)

Electric power is

stored in a capacitor.

1)

A turbine rotates to

generate electric

power.

Sensor Eye

Controller

Controller

Piston

Flush Valve

Water Supply

Coil

Cover

Turbine

Flush Valve

Water Supply

Turbine

Coil

Cover

ill. 1 Hydropowered Generator

ENGLISH

About Fuzzy Logic Control (TEU1GA only)

The Fuzzy Logic Control function automatically adjusts the discharge of water according to the

frequency and duration of usage (see ill. 2 and ill. 3).

The Fuzzy Logic

Control system judges

the frequency of

usage by the idle time

of the fixture and

causes the Flush Valve

to discharge water in

an optimal flushing

pattern.

The Fuzzy Logic Control

system predicts the

quantity of flush water

needed based on the

user's duration of use.

High Frequency of Usage Low Frequency of Usage

Less Less Less Less Less LessTypical

If the idle time is short, the system assumes frequent use

and the Flush Valve discharges less water.

Examples of high frequency use would be during a lunch

break or an intermission in a movie theatre.

If the idle time is long, the system

assumes infrequent use, causing the

Flush Valve deliver a typical quantity of

water for thorough flushing.

Examples of low frequency use would be

during after hours at the office or a slow

day at the park.

Typical

ill. 2 Frequency of Usage

Long duration of usage Short Duration of Usage

Less

A long duration of use indicates

there may be more to flush,

requiring the Flush Valve to

deliver a typical quantity of flush

water for thorough flushing.

Typical

A short duration of use

indicates there may be

less to flush, requiring the

Flush Valve to discharge

less flush water.

ill. 3 Duration of Usage

5

Page 6

WARNINGS

Please read and adhere to these notes. Failure to do so could result in personal injury and/or

property damage.

Never splash water on the controller. The EcoPower Flush Valve is an electric appliance.

Risk of product malfunction.

Do not strike or kick the EcoPower Flush Valve. Risk of product malfunction or water

ENGLISH

leakage.

Do not use the EcoPower Flush Valve at temperatures exceeding what local codes or

product specification allow. Risk of product malfunction.

Do not place an item in a room with high humidity such as shower area or sauna. Risk of

product malfunction.

Never attempt to disassemble, reassemble, repair or modify the EcoPower Flush Valve

unless you are a professional. Risk of product malfunction and electric shock.

BEFORE INSTALLATION

Important: Plumbing installation must be in accordance with applicable codes and

regulations. Water supply lines must be sized to provide an adequate volume of water for

each fixture. Flush all waterlines prior to operation.

1. Prior to installing your Flush Valve, install the items listed below:

Bowl fixture/Urinal fixture

Drain line

Water supply line

The supply piping to these devices must be securely anchored to the building structure to

prevent the installed device moving during use. Prevent marring to the exposed surface

during installation.

2. Avoid damaging the surface of the infrared sensor.

3. For Toilet Flush Valve:

The toilet Flush Valve may not function if toilet seat or lid cover are left upright and block the

sensor.

For Urinal Flush Valve:

The urinal Flush Valve is designed for optimal performance with a washout urinal, but a

siphon jet urinal may be substituted. Blowout urinals are not recommended.

4. The detection range of the infrared sensor is shown on p.19.

To prevent valve malfunction, do not install a handrail or any other object within the detection

range of the sensor. Do not install the Flush Valve where sensor faces a mirror, stainless steel

wall, other highly reflective surfaces or another infrared sensor.

6

Page 7

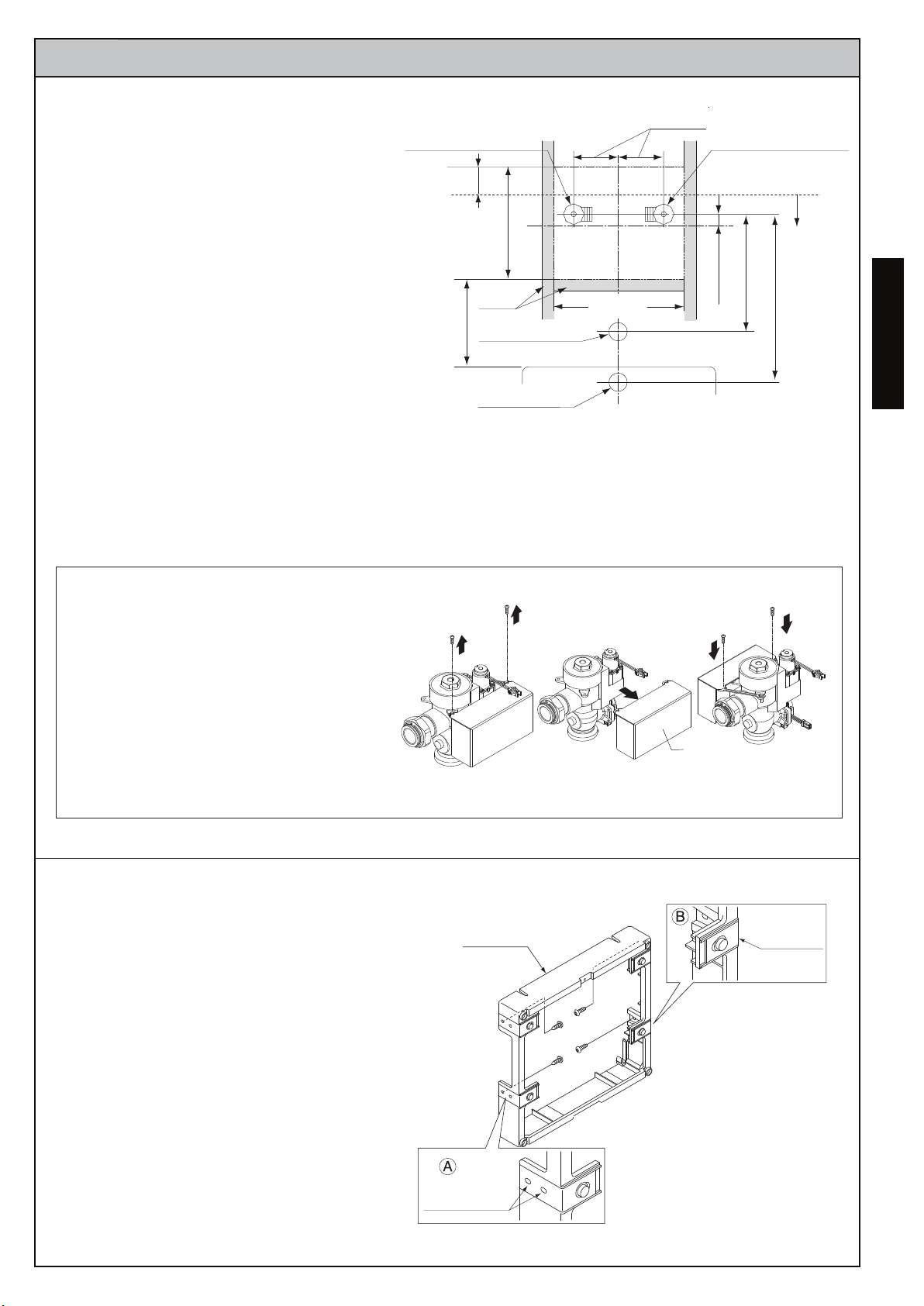

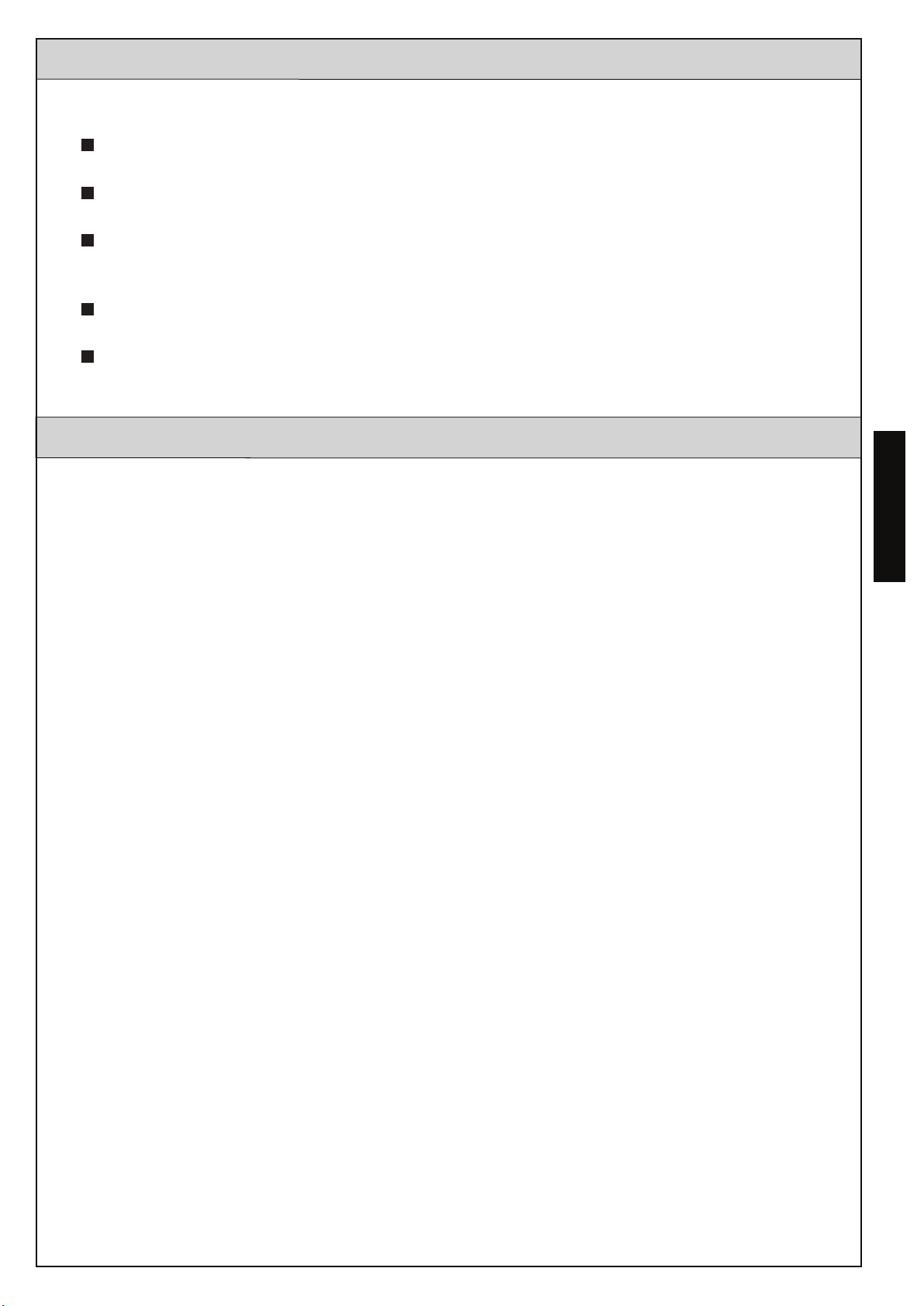

INSTALLATION PROCEDURE — LARGE COVER

1. Determine the installation location of

the studs and water supply pipe

relative to the position of the

toilet/urinal.

2. Attach the control stop to the pipe.

3. Bore a guide hole for the flush pipe

into the wall.

4. If needed, slide a thread solder

adapter on the water supply pipe.

NOTE:

Attach the control stop

before installing the box

fixing frame. Thread sealing

compounds should only be

used on the male NPT

threads only.

Left water supply

1” NPT (toilet), 3/4” (urinal)

Sensor location

3-7/16” (87mm)

(303mm)

** 11-15/16”

* 14-3/4” ‡

from top of

xture (toilet)

* X”, ‡ = At least 5” clearance from sensor to tip of toilet seat up position or

to top of grab bar is required to avoid false detection.

** Opening in wall

Stud

Toilet top spud

Ø2-3/16” (Ø56mm) hole

Urinal top spud

Ø1-1/2” (Ø38mm) hole

Toilet back spud

Ø2-3/16” (ø56mm) hole

Urinal back spud

Ø1-5/16” (ø33mm) hole

** 13-1/2”

(343mm)

4-3/4” ± 1/2”

(120 ± 13mm)

Right water supply

1” NPT (toilet),3/4” (urinal)

CL of sensor

3/4” (19mm)

11” (279mm)

16” (406mm)

* X”

ENGLISH

For use with a left water supply,

detach the controller and remount it

to opposite side of valve body.

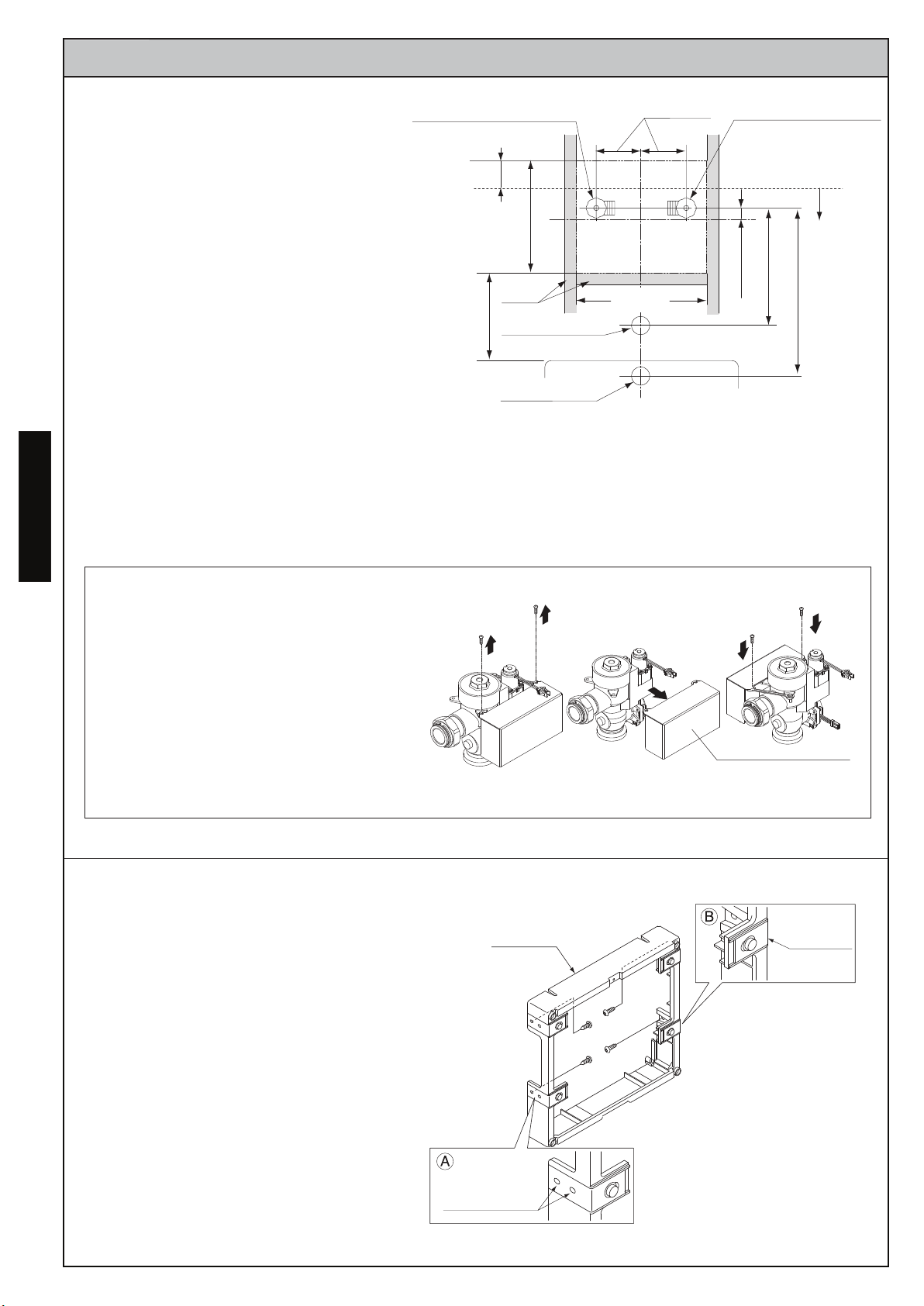

5. Fasten the base frame to the studs with

four screws (prepared on site) after

adjusting it. ( A )

6. Secure the box with four screws in the

adjustable plate. ( B )

Valve body

Detatch Remount

Base frame

Adjustable

plate

Adjustable holeAdjustable hole

7

Page 8

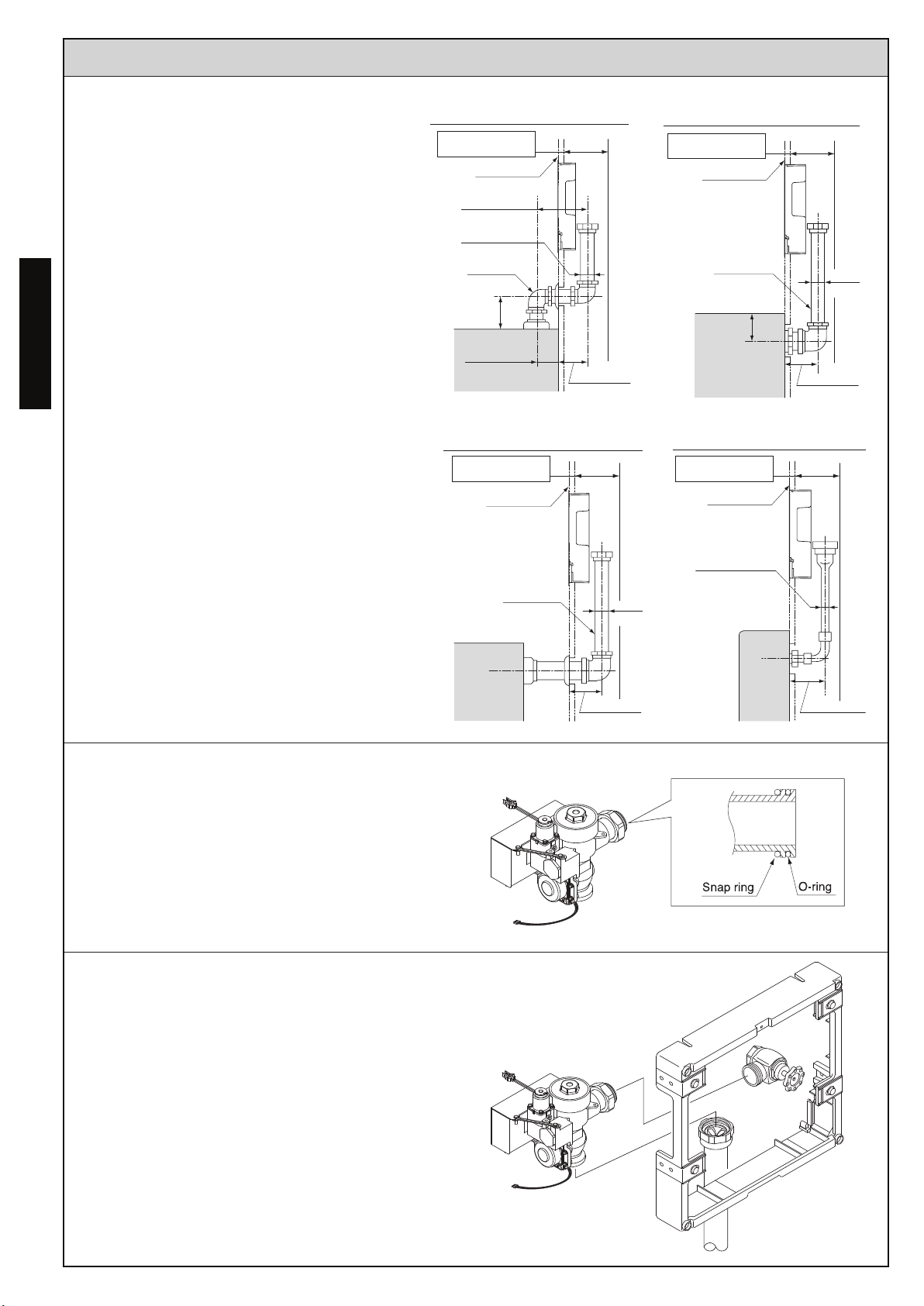

INSTALLATION PROCEDURE

— LARGE COVER

7. Pass the flush pipe and the vacuum

breaker through the guide hole (Step

3) and mount them on the bowl.

8. If required, cut the vacuum breaker

tube to the proper length.

ENGLISH

TET2LA32, TET2GA32

TEU2LA12, TEU2UA12

7” (178mm) Min space

requirement in wall

Wall surface

6~6-1/2”

(152~165mm)

1-1/2” (38mm)

or 3/4” (19mm)

Top spud

5”

(127mm)

2-1/4”~2-3/4”

(57~70mm)

Bowl or Urinal

TET2LA33

TET2GA33

7” (178mm) Min space

requirement in wall

Wall surface

3-3/4”~4-7/8”

(95~124mm)

TET2LA31

TET2GA31

7” (178mm) Min space

requirement in wall

Wall surface

Back spud

Wall mount

3”

(76mm)

Bowl

TEU2LA11, TEU2LA21

TEU2UA11

7” (178mm) Min space

requirement in wall

Wall surface

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

9. Make sure that the o-ring fits in the

groove at the end of the Flush Valve

tailpiece.

NOTE: Exercise care to avoid damaging the

o-ring when inserting the tailpiece

into the control stop. If lubrication is

needed, wet the o-ring with water.

10. Connect the Flush Valve with the control

stop and vacuum breaker tube.

Back spud

Floor mount

Bowl

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

1-1/4” (32mm)

or 3/4” (19mm)

Urinal

3-3/4”~4-7/8”

(95~124mm)

8

Page 9

INSTALLATION PROCEDURE — LARGE COVER

11. Connect the cables of infrared sensor

and controller with the connection

cable. ( , )

1 2

12. Connect the cables of manual button

and controller with the connection

4

cable. ( 3 , 4 )

3

13. Before the supply water is turned on,

be sure all water leaks are eliminated

by tightening all the pipe connections.

NOTE: If for any reason it becomes

necessary to remove the control

stop make sure the water is shut off

at the main supply valve.

The Flush Valves are preset for flush volume

as marked on the valve carton. The valve

does not require adjustment for variation

in water pressure within its operating

range.

14. To set the Flush Valve for proper

operation, open the control stop

completely and activate the Flush

Valve several times.

1

1

4

3

3

2

2

Control stop

4

ENGLISH

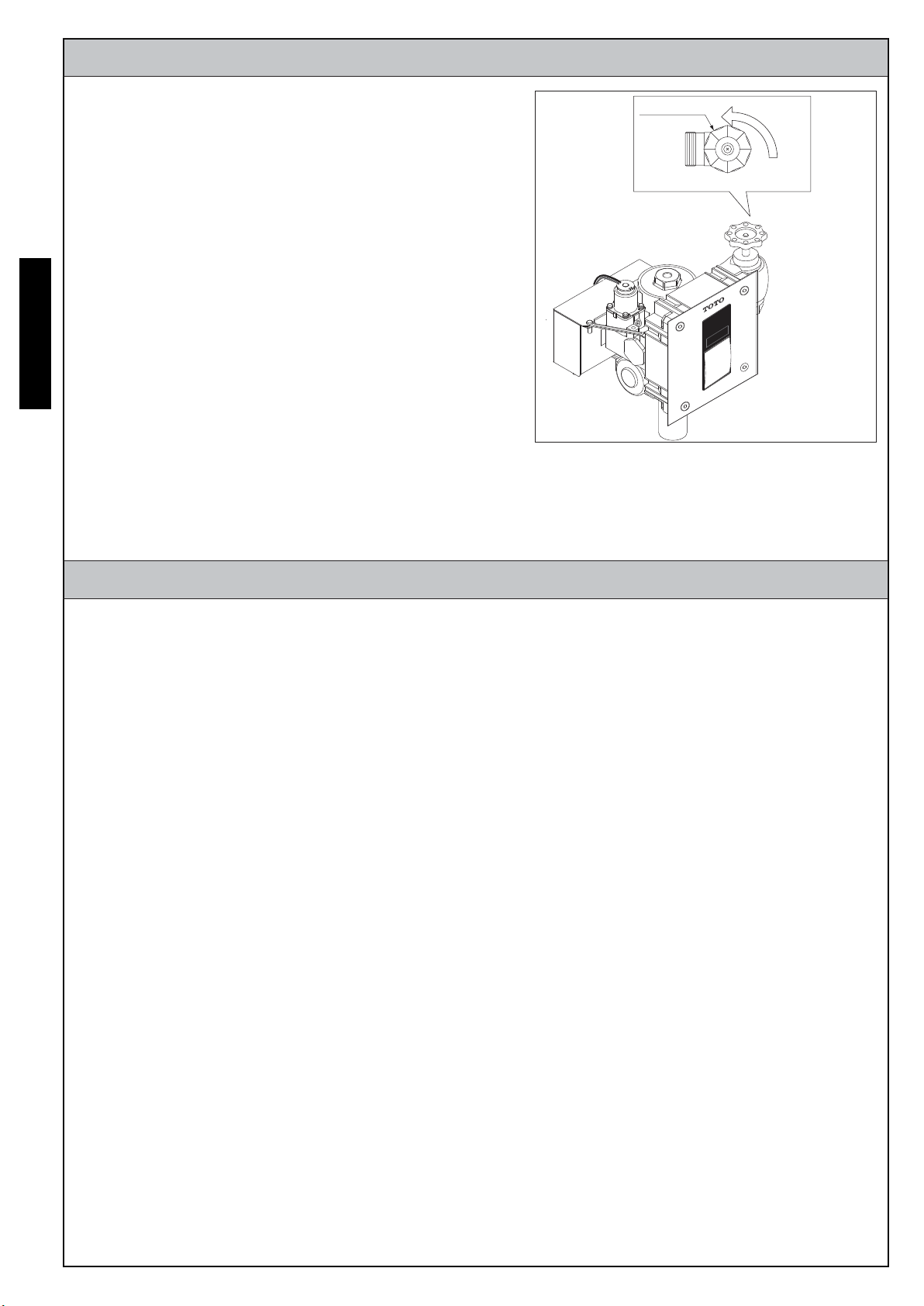

15. In the case of excessive flow rate

because of high water pressure,

gradually adjust the control stop

clockwise (towards the closed position)

until there is suitable water flow into

the fixture.

16. Tighten the front cover screws into

the base frame firmly with the hex

wrench.

Make sure no cord, wire or chain is

caught between the front cover and

base frame.

NOTE:

The control stop should never

be opened to the point where

the flow from the Flush Valve

exceeds the flow capability of

the fixture. In case of a valve

failure, the water must overflow

from fixture.

Hex wrench

9

Page 10

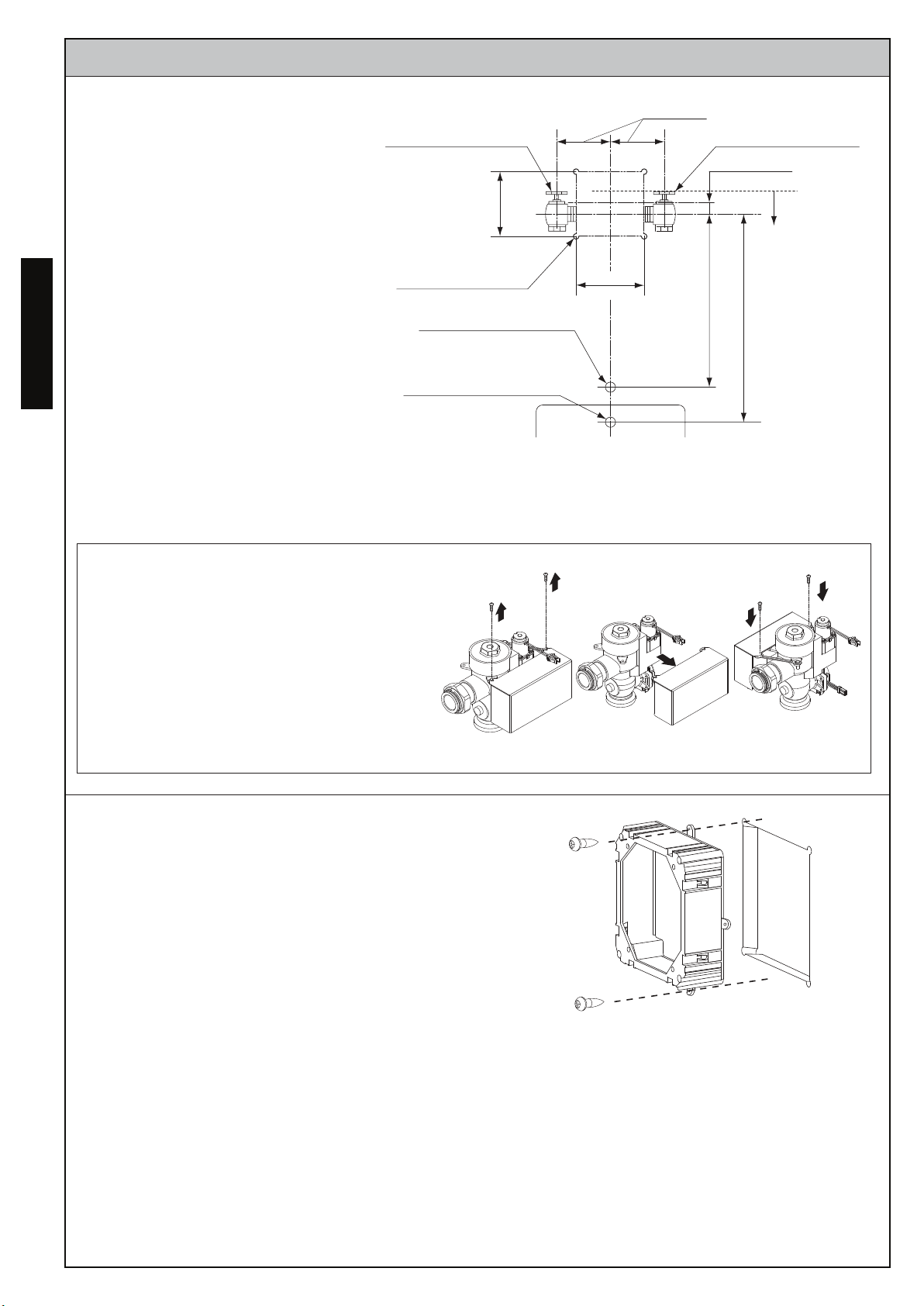

INSTALLATION PROCEDURE — SMALL COVER

1. Determine the location of the

water supply pipe.

Left water supply pipe

1”NPT (toilet), 3/4” (urinal)

2. Attach the control stop to

the pipe.

ENGLISH

3. Bore a guide hole for the flush

pipe into the wall.

4. Solder a sweat solder adapter

on the water supply pipe if

applicable.

NOTE: Thread sealing

compounds should be

used on the male NPT

threads only.

** 3-11/16”

(94 mm)

4 x Ø5/16" (Ø8mm) hole

Urinal top spud

Ø1-5/16” (Ø33 mm) hole

Toilet top spud

Ø2-3/16” (Ø56 mm) hole

Urinal back spud

Ø1-5/16” (Ø33 mm) hole

Toilet back spud

Ø2-3/16” (Ø55 mm) hole

* X”, ‡ = At least 5” clearance from sensor to tip of toilet seat up position or

to top of grab bar is required to avoid false detection.

** Opening in wall

** 3-11/16”

(94mm)

4-3/4” ± 1/2”

(120 ± 13mm)

Right water supply pipe

1”NPT (toilet), 3/4” (urinal)

1-1/4” (31 mm)

CL of sensor

X”

16” (406mm)

11” (279mm)

To use with a left water supply, detach

the controller and remount it to

opposite side of valve body.

Detatch

5. Secure back frame to the wall with two screws the

base frame. Other base frame installation options

with stringer and for concrete wall on next page.

NOTE:

Wall thickness must be 1/2" (13mm)

minimum and 1-3/8"(35mm) maximum.

If your wall thickness is less than

1/2" (13mm), please attach wooden

frame behind the wall.

Remount

10

Page 11

11

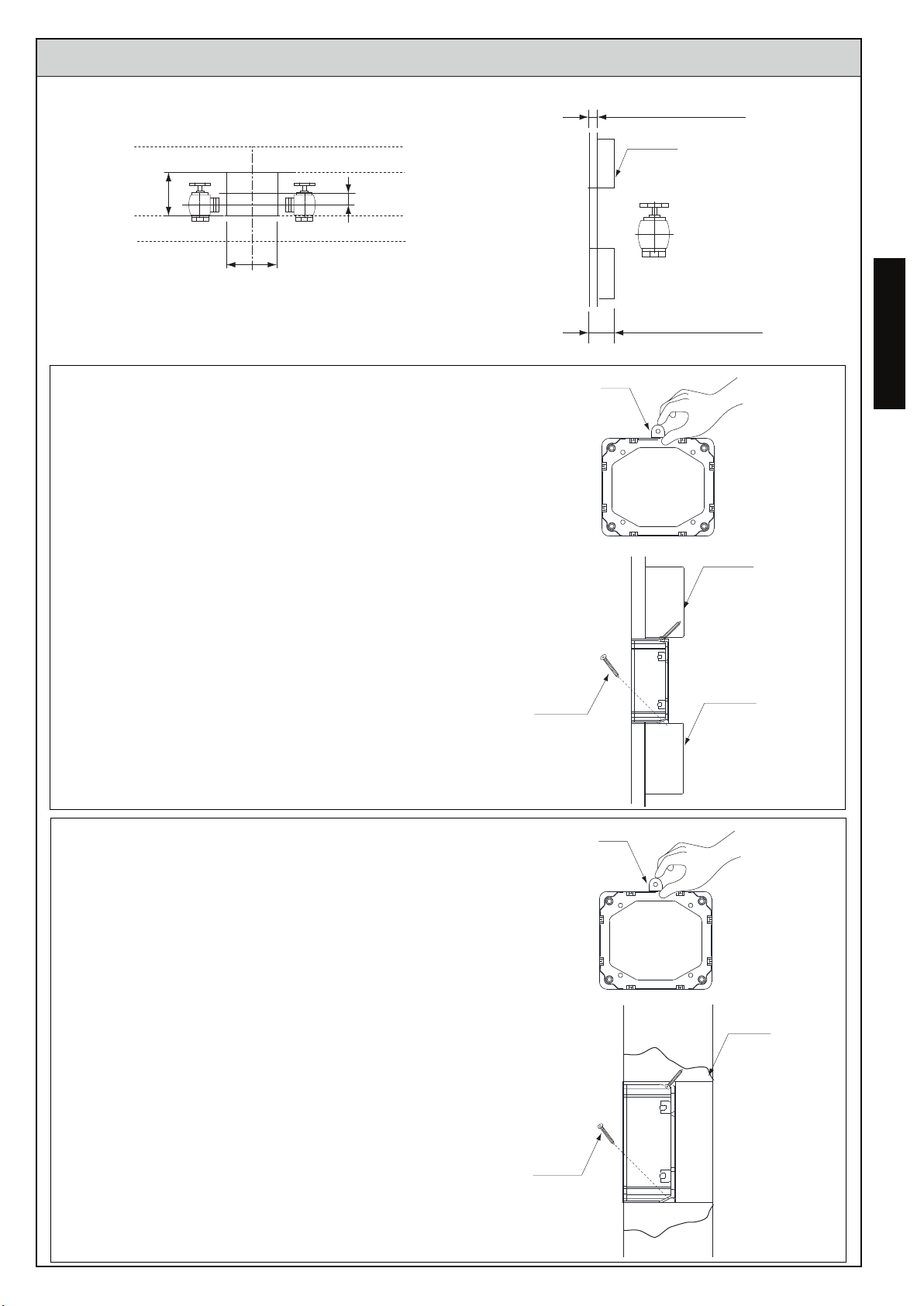

INSTALLATION PROCEDURE— SMALL COVER

Other base frame installation options

4-1/3”

(110mm)

4-1/3”

(110mm)

3/4”

(19mm)

Option 5A (with stringer)

1. Remove all tabs on side of the base frame.

2. Fasten the base frame to stringer with 4 screws

(prepared on site).

Max.1”(25mm)

Stringer

Min.1-3/8”(35mm)

Tab

ENGLISH

Option 5B (for concrete wall)

1. Cut out a place for the cover into the wall.

2. Remove all tabs on side of the base frame

before installation.

3. Fix the base frame into place with mortar.

4. Secure the base frame with 4 screws

(prepared on site), if needed.

Stringer

Stringer

Screws

Tab

Mortar

Screws

Page 12

INSTALLATION PROCEDURE — SMALL COVER

6. Pass the flush pipe and the vacuum

breaker through the guide hole (Step 3)

and mount them on the bowl.

7. If required, cut the vacuum breaker

tube to the proper length.

ENGLISH

TET3LA32, TET3GA32

TEU3LA12, TEU3UA12

7" (178mm) min space

in wall with a min

12" x 12" access panel

or walk-in chase

Wall surface

6~6-1/2”

(152~165mm)

1-1/2” (38mm)

or 3/4” (19mm)

Top spud

5”

(127mm)

2-1/4”~2-3/4”

(57~70mm)

Bowl or Urinal

TET3LA33

TET3GA33

7" (178mm) min space

in wall with a min

12" x 12" access panel

or walk-in chase

Wall surface

3-3/4”~4-7/8”

(95~124mm)

TET3LA31

TET3GA31

7" (178mm) min space

in wall with a min

12" x 12" access panel

or walk-in chase

Wall surface

Back spud

Wall mount

3”

(76mm)

Bowl

TEU3LA11, TEU3LA21

TEU3UA11

7" (178mm) min space

in wall with a min

12" x 12" access panel

or walk-in chase

Wall surface

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

8. Make sure that the o-ring fits in the

groove at the end of the Flush Valve

tailpiece.

9. Exercise care to prevent damage to

the o-ring when inserting the tailpiece

into the control stop. For additional

lubrication, wet the o-ring with water.

10. Connect the Flush Valve with the control

stop and vacuum breaker tube.

Back spud

Floor mount

Bowl

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

1-1/4” (32mm)

or 3/4” (19mm)

Urinal

Snap ring

3-3/4”~4-7/8”

(95~124mm)

O-ring

11. Tighten the coupling nut with a wrench to

prevent a water leak.

12

Page 13

INSTALLATION PROCEDURE — SMALL COVER

12. Connect the battery cable with the

controller and set the battery in place.

13. Attach the vandal proof screws the

front cover using washers.

14. Connect the cables of infrared sensor

and controller with the connection

( , )

cable.

1 2

Washer

Battery

Screw

ENGLISH

3

4

15. Connect the cables of manual button

and controller with the connection

( , )

cable.

3 4

16. Before the supply water is turned on, be

sure all water leaks are eliminated by

tightening all the pipe connections.

If for any reason it becomes necessary to

remove the control stop, make sure the

water is shut off at the main supply valve.

1

2

17. Fasten the front cover to the base frame

by tightening the screws with the

supplied hex wrench.

18. Take care so that any cord, wire or chain

might not be caught between the front

cover and the box.

Hex wrench

13

Page 14

INSTALLATION PROCEDURE — SMALL COVER

The Flush Valves are preset for flush volume as

marked on the valve carton. The valves do not

require adjustment for variation for water pressure

within its operating range.

19. Open the control stop completely.

ENGLISH

20. Activate the Flush Valve several times.

21. In the case of excessive flow rate, adjust the flush

volume, gradually adjust the control stop clock

wise, towards the closed position, until there is

suitable water flow into the filter.

WARNING: Do not open the control stop to the point where the flow from the Flush Valve

exceeds the flow capability of the fixture. In case of a valve failure, the water

must not overflow from the fixture.

-

Control stop

Open

TEST RUN

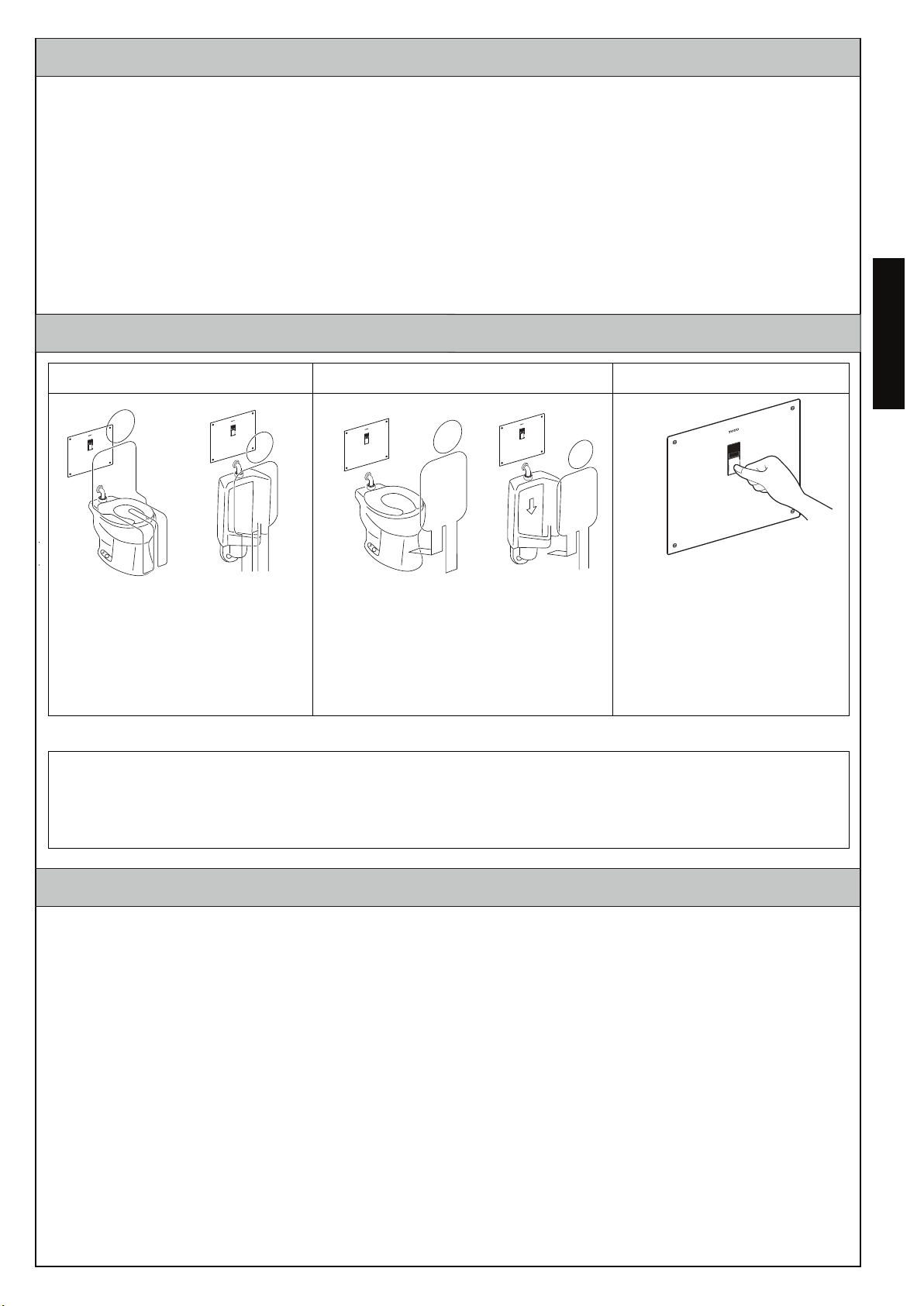

1. For Toilet: Sit on the toilet seat.

For Urinal: Stand within two feet from the front of the Flush Valve.

2. Stay there for 6 seconds or more and then leave the toilet seat or the urinal. The valve

will automatically flush.

3. Press the manual flushing button and make sure the valve flushes properly and the sensor

red light of the sensor is on for 2 seconds.

4. Recheck all the pipe connections for water leaks. If the Flush Valve is not operating

properly following the test run consult the Troubleshooting section on p.16.

14

Page 15

15

NOTE TO THE INSTALLER

After the Flush Valve unit has been installed correctly, please explain to your customer how to

use it and tell them to observe the following instructions:

1. Do not put any object in front of the sensor window which could obstruct the sensor,

causing it to malfunction.

2. In case of any trouble, consult the troubleshooting section on p.16. If you lack the

necessary skills required or have difficulty following the directions for installation,

maintenance, repairs, troubleshooting or adjustments of the product, do not proceed

without help from a qualified person to assist you.

USING THE FLUSH VALVE

Infrared Sensor Flushing

The infrared sensor detects a user

of the toilet or within 2 ft (600mm)

of the urinal.

When the user stays in place for at

least 6 seconds before departure,

the controller signals the operating

unit to trip the Flush Valve after 3

seconds delay for toilets and no

delay for urinals.

Manual Flushing Button

Use the manual flush switch for

maintenance or emergencies.

ENGLISH

Flushing Every 12/24 hours

When the fixture is not used for 24 hours for toilet or 12 hours for urinal the protection

timer commands the system to flush in order to maintain the trap seal.

PERIODIC MAINTENANCE

Please check the piping to your EcoPower Flush Valve at least once a month

to avoid risk of property damage.

Page 16

TROUBLESHOOTING

Problem

The main valve in water supply

line or the control stop is shut off

The connector is not

connected

ENGLISH

No water comes

from the flush

valve

The surface of the glass in front

of the infrared sensor is dirty

The glass is broken

There is a reflective surface in

front of the sensor

The infrared sensor or the

solenoid is out of order

The small holes in the solenoid

diaphragm are clogged

Hydropower generator clogged

Suggested ActionPossible Cause

Open the main valve or the

control stop

Connect the wire

Clean the surface of the

glass

Contact distributor for

replacement

Remove the reflective

surface from the sensor

Contact distributor for

replacement

Clean the small hole in the

diaphragm and filter

Service Hydropower

Generator

Ref.Page

-

-

-

-

19

-

18

17

Water does not

stop flowing

The discharge

quantity is too small

The discharge

quantity is too much

The flow rate is too

low

The small hole in the piston is

clogged. (not for TEU*UA)

The sealing area of the piston is

dirty. (not for TEU*UA)

The sealing area of the solenoid

diaphragm is dirty.

Piston U-packing damaged.

(not for TEU*UA)

The screw of the control stop or

the screw of the piston valve are

not adjusted properly

Water supply pressure is too low.

(below 15 PSI(103kPa))(Flowing)

(below 35 PSI(241kPa) for TET*LA

units) For TET*LA#: Water flow

rate is lower than 23 gpm (87Lpm)

Clean the small hole in the

piston

Clean the sealing area of

the piston

Clean the sealing area of

the diaphragm and filter

Inspect & replace if

necessary

Adjust the discharge quantity

by the screw of the control

stop and the screw of the

piston valve

Consult with a plumbing

contractor

18

17

18

17

18

-

The control stop is not open enough.

The flow rate is too

high

A red light in the

sensor window blinks

NOTE: Do not dismantle parts of the flush valve which are not specified in the

troubleshooting guide.

If you need further assistance, please call TOTO Tech Support at (888) 295-8134.

The control stop is not adjusted

properly.

The battery is weak

16

Adjust the control stop properly

Adjust the control stop

properly.

Replace with battery provided

by TOTO

18

18

18

Page 17

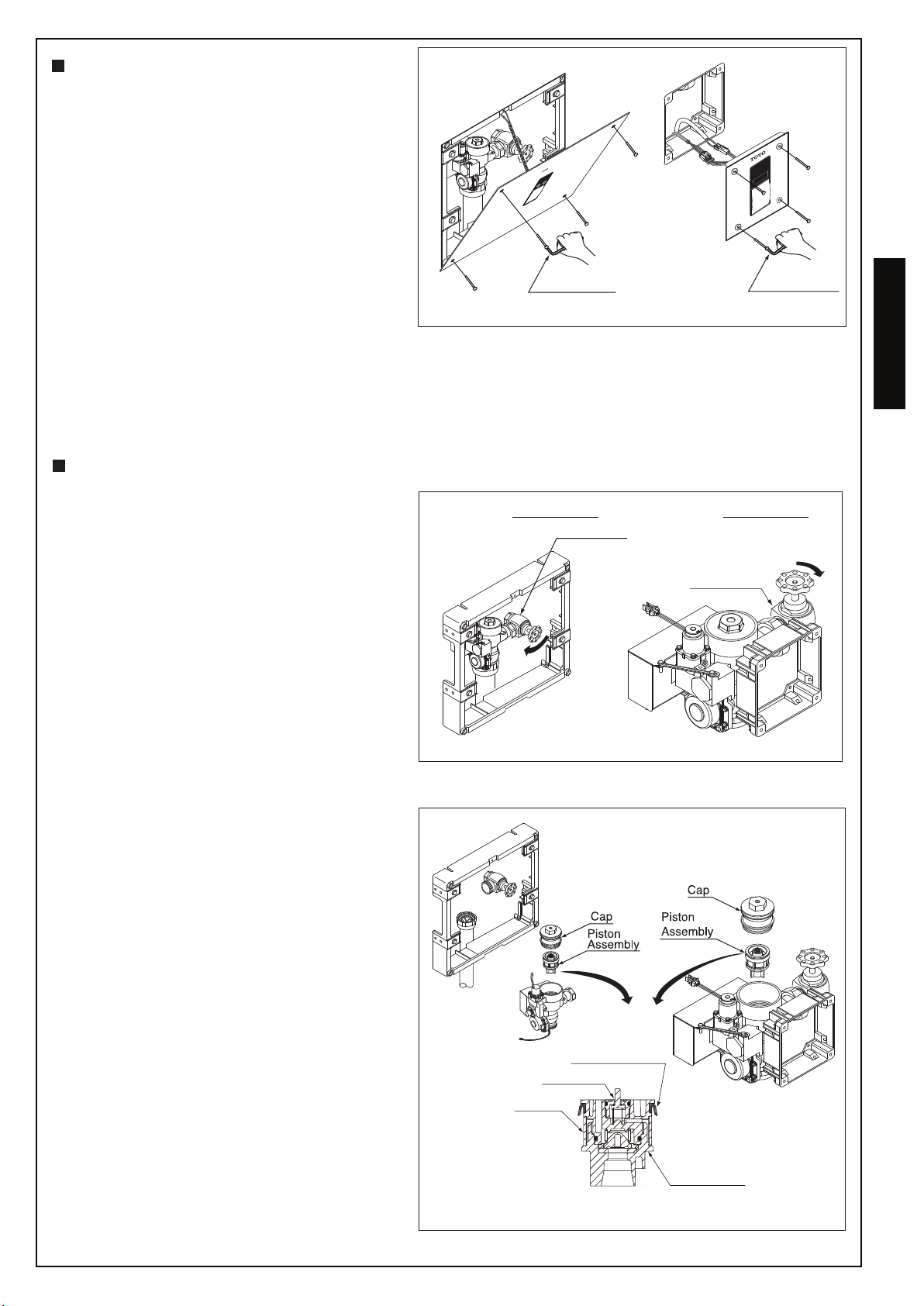

DISASSEMBLY

If the whole valve needs to be

removed from the water supply for

servicing, please be aware of the

cautions below:

1. Be careful not to lose or tear the

friction washer at the outlet

connection to the vacuum breaker

tube nut. To maintain a proper seal,

replace the washer if necessary.

2. Be careful when re-installing the

valve to the water supply to avoid

pinching the o-ring.

CLEANING PISTON ASSEMBLY

ENGLISH

Supplied

hex wrench

Supplied

hex wrench

1. Turn the screw of the control stop

clockwise to turn off the water.

2. Take out the piston assembly.

3. Check the small hole in the piston to

see if it is clogged with debris, insert

a small wire to unclog hole.

Large cover

Control stop

Small cover

Control stop

4. Check the filter to see if it is

clogged with debris and gently

brush it to clean.

5. Check the sealing area of the piston

and clean it if it is dirty.

6. Check the U-Packing for cracks or

damage.

Piston U-Packing

Small Hole

Filter

Sealing Area

17

Page 18

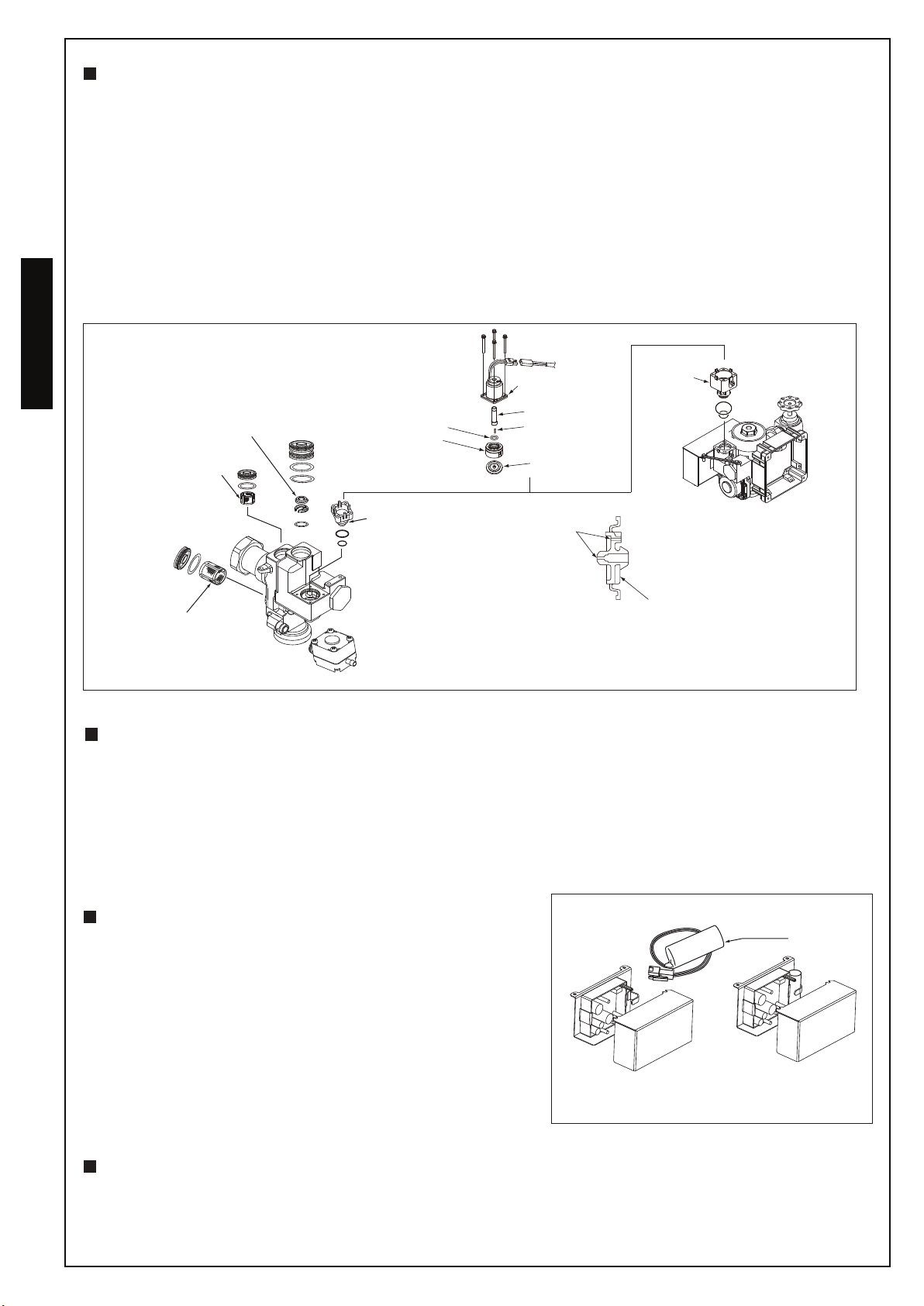

CLEANING DIAPHRAGM AND FILTER

1. Turn the screw on the control stop clockwise to turn off the water.

2. Disconnect the solenoid.

3. Remove the solenoid and take out the diaphragm.

4. Check the small holes and sealing.

NOTE: See this page below for disassembly.

ENGLISH

NOTE: Do not stretch or alter the shape of the spring in the solenoid valve in any way. It

will void the warranty.

Filter

Flow regulator

Filter

O-ring

Cap

Filter

TEU2UA and TEU3UA

Solenoid

Plunger

Spring

Diaphragm

Small holes

Sensor unit

Diaphragm

Filter

Sealing area

CHECKING SOLENOID

1. Make sure that the batteries are properly placed and wires are connected.

2. With water supply turned off, place your hand in front of the sensor for 6 seconds

3. Remove and listen for a “click” sound after 3 seconds. This indicates the solenoid

plunger has been activated.

BATTERY REPLACEMENT

Battery

A special lithium back-up battery is used. Replace

only with the included TOTO back up battery. If a red

light in the sensor window blinks with the cycle of

4 seconds, it is time to replace the battery.

1. Remove the old battery.

2. Set the new battery at the proper position.

ADJUSTMENT OF THE FLOW RATE

1. Adjust the flow rate by the turning screw on the control stop.

2. Turn the screw to the right to decrease the flow rate and turn to the left to increase.

18

Page 19

THE DETECTION RANGE

The detection range of the infrared sensor is set at the factory and does not need further

adjustment.

33-1/2"

(850mm)

15°

Max 19-11/16”

(Max 500mm)

ENGLISH

PRECAUTION

DO NOT place the infrared sensor

of one Flush Valve so that it

is in line with the sensor of

another Flush Valve sensor.

Another infrared sensor.

Infrared sensor of the automatic

Flush Valve.

PRECAUTION

DO NOT place the infrared sensor in

front of a mirror, stainless steel wall,

or other highly reflective surface.

Mirror, stainless steel wall or other

highly reflective surface.

Infrared sensor of the automatic

Flush Valve.

NOTE: In some cases, the valve may not

detect a user if the toilet seat is left

in an upright position. This can be

due to the rough-in dimension or

gap of the open front commercial

seat. Please lower the seat or

arrange with a TOTO or other

plumbing contractor to change the

height of the valve.

The sensor can have trouble

detecting users wearing black

clothes in some conditions.

Infrared sensor

19

Page 20

WARRANTY

1. TOTO ® warrants its electronic flush valves, faucets and soap dispensers (“Product”) to be free from defects in

materials and workmanship during normal use when properly installed and serviced, for a period of three (3) years

from date of purchase. This limited warranty is extended only to the ORIGINAL PURCHASER of the Product and is

not transferable to any third party, including but not limited to any subsequent purchaser or owner of the Product.

This warranty applies only to TOTO Product purchased and installed in North, Central and South America.

ENGLISH

2. TOTO’s obligations under this warranty are limited to repair, replacement or other appropriate adjustment, at

TOTO’s option, of the Product or parts found to be defective in normal use, provided that such Product was properly

snoitcepsni hcus ekam ot thgir eht sevreser OTOT .snoitcurtsni htiw ecnadrocca ni decivres dna desu ,dellatsni

ni strap ro robal rof egrahc ton lliw OTOT .tcefed eht fo esuac eht enimreted ot redro ni yrassecen eb yam

connection with warranty repairs or replacements. TOTO is not responsible for the cost of removal, return and/or

reinstallation of the Product.

3. This warranty does not apply to the following items:

a. Damage or loss sustained in a natural calamity such as fire, earthquake, flood, thunder, electrical storm, etc.

b. Damage or loss resulting from any accident, unreasonable use, misuse, abuse, negligence, or improper

care, cleaning, or maintenance of the Product.

c. Damage or loss resulting from sediments or foreign matter contained in a liquid soap system.

ro/dna hsrah a ni tcudorP eht fo noitallatsni morf ro noitallatsni reporpmi morf gnitluser ssol ro egamaD .d

hazardous environment, or improper removal, repair or modification of the Product.

e. Damage or loss resulting from electrical surges or lightning strikes or other acts which are not the fault of

TOTO or which the Product is not specified to tolerate.

f. Damage or loss resulting from normal and customary wear and tear, such as gloss reduction, scratching or

fading over time due to use, cleaning practices or water or atmospheric conditions, including but not limited

to, the use of bleach, alkali, acid cleaners, dry (powder) cleaners or any other abrasive cleaners or the use

of metal or nylon scrubbers.

4. In order for this limited warranty to be valid, proof of purchase is required. TOTO encourages warranty registration

upon purchase to create a record of Product ownership at http://www.se is required. TOTO encourages warranty

registration upon and failure to register will not diminish your limited warranty rights.

5. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE, PROVINCE TO PROVINCE OR COUNTRY TO COUNTRY.

6. To obtain warranty repair service under this warranty, you must take the Product or deliver it prepaid to a TOTO

service facility together with proof of purchase (original sales receipt) and a letter stating the problem, or contact

a TOTO distributor or products service contractor, or write directly to TOTO U.S.A., INC., 1155 Southern Road,

Morrow, GA 30260 (888) 295 8134 or (678) 466-1300, if outside the U.S.A. If, because of the size of the Product

or nature of the defect, the Product cannot be returned to TOTO, receipt by TOTO of written notice of the defect

esoohc yam OTOT ,esac hcus nI .yreviled etutitsnoc llahs )tpiecer selas lanigiro( esahcrup fo foorp htiw rehtegot

to repair the Product at the purchaser’s location or pay to transport the Product to a service facility.

THIS WRITTEN WARRANTY IS THE ONLY WARRANTY MADE BY TOTO. REPAIR, REPLACEMENT OR OTHER APPROPRIATE

ADJUSTMENT AS PROVIDED UNDER THIS WARRANTY SHALL BE THE EXCLUSIVE REMEDY AVAILABLE TO THE ORIGINAL

PURCHASER. TOTO SHALL NOT BE RESPONSIBLE FOR LOSS OF THE PRODUCT OR FOR OTHER INCIDENTAL, SPECIAL

OR CONSEQUENTIAL DAMAGES OR EXPENSES INCURRED BY THE ORIGINAL PURCHASER, OR FOR LABOR OR OTHER

COSTS DUE TO INSTALLATION OR REMOVAL, OR COSTS OF REPAIRS BY OTHERS, OR FOR ANY OTHER EXPENSE NOT

SPECIFICALLY STATED ABOVE. IN NO EVENT WILL TOTO’S RESPONSIBILITY EXCEED THE PURCHASE PRICE OF THE

PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTIES, INCLUDING THAT

OF MERCHANTABILITY OR FITNESS FOR USE OR FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, OR THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND EXCLUSION MAY NOT

APPLY TO YOU.

20

Page 21

ÍNDICE

¡Gracias Por Elegir TOTO!......................................................................................................................21

Incluía Partes..............................................................................................................................................21

Herramientas Que Necesita......................................................................................................................22

Cuidado y Limpieza...................................................................................................................................22

Características.................................................................................................................................22

Especificaciones.........................................................................................................................23

Información Técnica..................................................................................................................................24

Advertencias.................................................................................

........................................................25

Antes de la Instalación...............................................................................................................................25

Procedimiento de Instalación...................................................................................................................26

Prueba de Funcionamiento......................................................................................................................33

Después de la instalación.................................................................................................. .......................34

Uso de l Fluxómetro ..................................................................................................................................34

Mantenimiento Periódico.........................................................................................................................34

Resolución de Problemas.........................................................................................................................35

Garantía......................................................................................................................................... 39

Bosquejo.................................................................................................................................. ..................78

¡GRACIAS POR ELEGIR TOTO!

ESPAÑOL

La misión de TOTO es dar al mundo estilos de vida más saludables, higiénicos y cómodos.

Diseñamos cada producto guiándonos por el principio del equilibrio entre forma y función.

Felicitaciones por su elección.

INCLUÍA PARTES

Asegúrese que todas estas partes estén incluidas en su empacado*:

Cubierta Gran Cubierta Pequeña Cubierta Gran Cubierta Pequeña

(TEU2UA sólo)

Montaje de cuerpo

del fluxômeter

Manual de

Instalación y

del Propietario

(TEU3UA sólo)

Etiqueta de aviso

Cubierta frontal

Cables de conexión

Arandela

Bastidor base

Tornillos hexagonal

es a prueba

de vandalismo

Llave

hexagonal

Sólo para pequeña cubierta

Tornillos

Llave de paso

Tubo rompedor

de vacìo

TET3GA32

TET3LA32

TET2GA32

TET2LA32

TEU3LA12

TEU3UA12

TEU2LA12

TEU2UA12

TET3GA33

TET3LA33

TET2GA33

TET2LA33

21

TET3GA31

TET3LA31

TET2GA31

TET2LA31

Tubo de descarga

TEU3LA11

TEU3UA11

TEU2LA21

TEU2UA11

TEU3LA21

TEU2LA11

Page 22

HERRAMIENTAS QUE NECESITA

Llave ajustable

Destornillador (Phillips y Plano )

Llave de tubo

CUIDADO Y LIMPIEZA

¡IMPORTANTE! No raye el sensor al limpiar el producto.

Evite utilizar cualquier material de limpieza que pueda rayar la superficie.

Nunca utilice polvo para pulir, detergente que incluya partículas corrosivas, thinners,

ESPAÑOL

benceno, ácidos, detergentes alcalinos ni estropajos de nylon, ya que pueden dañar la

superficie.

Para limpiar la superficie con seguridad, límpiela con un trapo remojado en detergente para

trastes diluido y séquelo con otro trapo. Si esto no limpia adecuadamente la superficie,

límpiela con un detergente neutro y un trapo mojado.

CARACTERÍSTICAS

Completamente Automático e Higiénico

El fluxómeter EcoPower utiliza un sensor infrarrojo para detectar al usuario que utiliza y acciona

el aparato, para proporcionar una descarga automática después de un breve retraso. No se

requiere ninguna operación manual para mejorar la experiencia de uso y la higiene del aparato.

Temporizador de Protección del Sistema

Cuando el inodoro no se utiliza durante 24 horas y 12 horas para urinario el temporizador

de protección da la orden al sistema para activar una descarga a fin de mantener el sello

de la trampa.

Funcionalidad Manual

El fluxómeter EcoPower tiene un botón de descarga manual para el mantenimiento y el uso de

emergencia.

Características Ecológicas

Conserva la Energía

Cada descarga activa un generador de energía hidráulica que genera energía eléctrica para la

siguiente descarga. (Consulte Acerca del Generador de Energía Hidráulica de TOTO)

Conserva el Agua

Existen dos funciones que ayudan al fluxómeter EcoPower a conservar el agua:

Control Lógico Difuso

El fluxómeter EcoPower puede detectar con qué frecuencia y durante cuánto tiempo se ha

utilizado el aparato para entregar la cantidad correcta de agua. (Consulte Acerca de

Control Lógico Difuso )

Antidescarga Consecutiva

El fluxómeter EcoPower ofrece la prevención de descargas consecutivas que ahorran agua.

Después de una descarga, la válvula no se volverá a descargar de manera automática durante

10 segundos para los urinarios y 30 segundos para los inodoros.

Los

fluxómeters

condiciones normales, sin uso mínimo requerido.

EcoPower de TOTO están diseñadas para funcionar durante 10 años, en

22

Page 23

Figura

ESPECIFICACIONES

Inodoros Urinarios

Cubierta

Gran

Cubierta

Pequeña

Cubierta

Número de modelo

Volumen

Nominal a 28 psi (196 kpa)

Tipo de Inodoro/Urinario

Entrada de parada de control

Entrée de valve de chasse

Sortie de valve de chasse

Gran

Cubierta

Pequeña

Mínimo

Presión de

suministro de

agua

(Fluir)

Máximo*

(Estática)

TET2LA

TET3LA

galón (4.8L) 1.6 galón (6L)

1.28

Tipo de fluxómetro Mingitorio de baldeo

1"NPT 3/4"NPT

35 psi (241kPa)

TET2GA

TET3GA

TEU2LA

TEU3LA

0.5 galón (1.9L)

1-1/4"NPSM

1-1/2"NPSM

125 psi (862kPa)

TEU2UA

TEU3UA

0.125 galón (0.47L)

15 psi (103 kPa)

ESPAÑOL

Presión de apagado

Cubierta

Dimensión de

la cubierta

Rango de detección de frente Dentro de 33-1/2" (850mm)

Tiempo de detección

Protección del sello

de la trampa

Temperatura ambiente

Temperatura de agua

NOTA:

Consulte al fabricante del aparato para la presión mínima requerida para la válvula.

Gran

Cubierta

Pequeña

Descarga automática cada 24 horas

de no utilización

7 psi (48kPa)

12-5/8" (H) ×14-3/16"(W)

(320mm(H) ×360mm(W) )

4-23/32" (H) ×4-23/32"(W)

(120mm(H) ×120mm(W) )

6 s

Descarga automática cada 12 horas

de no utilización

32-104˚F (0-40˚C)

34-104˚F (1-40˚C)

* No se recomiendan las presiones de agua de más de 80 psi para la mayoría de los accesorios de plomería.

23

Page 24

Controlador

INFORMACIÓN TÉCNICA

Acerca del Generador de Energía Hidráulica

El flujo de agua hace que la turbina gire en el generador de energía. Este proceso genera energía

eléctrica y permite que funcione el fluxómetro automática. Ver ilustración 1 a continuación.

TET2LA

TET2GA

TET3LA

TET3GA

TEU2LA

TEU3LA

TEU2UA

TEU3UA

ESPAÑOL

El fluxómetro

3)

automática utiliza la

energía cargada.

La energía eléctrica se

2)

almacena en un

condensador.

Una turbina gira para

1)

generar energía

eléctrica.

El fluxómetro

3)

automática utiliza la

energía cargada.

La energía eléctrica se

2)

almacena en un

condensador.

Una turbina gira para

1)

generar energía

eléctrica.

Sensor

Sensor

Controlador

Pistón

Fluxómetro

Línea de suministro de agua

Resorte

Cubierta

Fluxómetro

Línea de suministro de agua

Turbina

Resorte

Turbina

Cubierta

ill. 1 Generador de Energía Hidráulica

Acerca de Control Lógico Difuso (TEU1GA)

La función de Control Lógico Difuso ajusta de manera automática la descarga de agua de

acuerdo con la frecuencia y la duración de uso (ver ilustración 2 y ilustración 3).

El sistema Control Lógico

Difuso del sistema

determina la frecuencia

de uso por el tiempo

de inactividad del

urinario y hace que la

fluxómetro

suelte agua en un

patrón óptimo de

descarga.

El sistema Control Lógico

Difuso predice la

cantidad de agua de

descarga necesaria, con

base en la duración de

uso del usuario.

Tiempos Cortos de Inactividad Tiempos Largos de Inactividad

Menos

Menos

Menos Menos Menos Menos

Para los tiempos cortos de inactividad, el sistema asume

el uso frecuente del urinario y el fluxómetro

suelta menos agua.

Ejemplos de uso frecuente sería durante una pausa para

almorzar o un intermedio en una sala de cine.

Típica

Para tiempos largos de inactividad, el

sistema asume un uso poco frecuente, y

hace que el fluxómetro

entregue una cantidad típica de agua

para una limpieza a fondo.

Ejemplos de uso poco frecuente sería

después de las horas en la oficina o un día

lento en el parque day.

Típica

ill. 2 Frecuencia de Uso

Largo Período de Uso Corto Período de Uso

Menos

Un largo período de uso indica

que puede haber más para

descargar, lo que requiere que el

fluxómetro suministre una

cantidad típica de agua de

descarga para una descarga a

fondo.

Típica

Un corto período de uso

indica que puede haber

menos para descarga, lo que

requiere que el

fluxómetro libere menos

agua para de descarga.

24

ill. 3 Duración de Uso

Page 25

ADVERTENCIAS

Lea y cumpla estas instrucciones. No hacerlo podría dar lugar a lesiones personales o daños

materiales.

Nunca salpique agua en el controlador. El

Riesgo de mal funcionamiento del producto.

No golpee ni patee el

agua.

No utilice el

códigos locales o las especificaciones del producto. Riesgo de mal funcionamiento del

producto.

No coloque el

de la ducha o en la sauna. Riesgo de mal funcionamiento del producto.

Nunca intente desmontar, volver a montar, reparar o modificar el

menos que usted sea un profesional. Riesgo de mal funcionamiento del producto y

descargas eléctricas.

fluxómetro

fluxómetro

fluxómetro

EcoPower a temperaturas superiores a las permitidas por los

EcoPower en una habitación con alta humedad, como el área

EcoPower. Riesgo de mal funcionamiento o fuga de

fluxómetro

EcoPower es un aparato eléctrico.

fluxómetro

EcoPower a

ANTES DE LA INSTALACIÓN

Importante: La instalación de la plomería debe hacerse de acuerdo con los códigos y

reglamentos aplicables. Las líneas de suministro de agua deben dimensionarse para

proporcionar un volumen adecuado de agua para cada aparato. Descargue todas las líneas

de agua antes de utilizarlas.

ESPAÑOL

1. Antes de instalar su fluxómetro, instale los elementos que se enumeran a

continuación:

Accesorio Taza/Accesorio Urinario

Línea de drenaje

Línea de suministro de agua

La tubería de suministro de estos dispositivos debe estar anclada firmemente a la estructura

del edificio para evitar que el dispositivo instalado se mueva durante el uso. Tenga cuidado al

instalar el dispositivo para evitar estropear la superficie expuesta.

2. Tenga cuidado de no dañar la superficie del sensor infrarrojo.

3. Para el fluxómetro del Inodoro:

El fluxómetro del inodoro puede no funcionar si el asiento y/o la tapa del inodoro

se dejan en posición vertical, ya que puede bloquear el sensor.

4. Para el fluxómetro del Urinario:

El fluxómetro del urinario está diseñada para un rendimiento óptimo con urinarios

de lavado para un rendimiento óptimo, pero se puede sustituir un urinario de chorro. No se

recomiendan los urinarios Blowout.

5. Ver rango de detección del sensor infrarrojo en p. 38.

Para evitar el mal funcionamiento del

fluxômeter

, no instale un pasamanos o cualquier otro

objeto dentro del rango de detección del sensor. No instale el fluxómetro donde el

sensor esté al frente de un espejo, una pared de acero inoxidable, otras superficies altamente

reflectantes u otro sensor infrarrojo.

25

Page 26

PROCEDIMIENTO DE INSTALACIÓN — GRAN CUBIERTA

Tubería del suministro derecho

1” NPT (inodoro), 3/4” (urinario)

CL de sensor

* X”

1. Determine la ubicación de la

instalación de los pernos y la tubería

del suministro de agua en relación

con la posición del orificio del aparato.

2. Coloque la llave de paso a la tubería.

Tubería del suministro izquierda

1” NPT (inodoro), 3/4” (urinario)

Sensor

3-7/16” (87mm)

4-3/4” ± 1/2”

(120 ± 13mm)

3. Perfore un agujero guía para la

(303mm)

tubería de descarga en la pared.

4. Si es necesario, deslice un adaptador

de soldadura de rosca en la tubería

del suministro de agua.

NOTA:

ESPAÑOL

Coloque la llave de paso

antes de instalar el bastidor

base. Debe utilizarse

compuestos de sellado de

rosca solo en roscas NPT

* 14-3/4” ‡

desde la parte

superior del inodoro

* X”, ‡ = Se requiere al menos 5" de espacio libre desde el sensor hasta la punta

del asiento del inodoro o hasta la parte superior de la barra de apoyo para

evitar una detección falsa. Para la instalación del inodoro.

** Abertura en la pared

** 11-15/16”

Montant

Escoplo superior (inodoro)

Ø2-3/16” (Ø56mm) hole

Escoplo superior (urinario)

Ø1-1/2” (Ø38mm) hole

Escoplo posterior (inodoro)

Ø2-3/16” (Ø56mm) hole

Escoplo posterior (urinario)

Ø1-5/16” (Ø33mm) hole

** 13-1/2”

(343mm)

3/4” (19mm)

11” (279mm)

16” (406mm)

macho.

Para el uso con el suministro de agua

residual, extraiga el controlador y

vuelva a montarlo al lado opuesto

del cuerpo de la

fluxómetro

5. Fije el bastidor base a los pernos con

cuatro tornillos (preparado en el lugar)

después de ajustarlo. ( A )

6. Asegure el bastidor base con cuatro

tornillos en la placa ajustable. ( B )

Cuerpo de la fluxómeter

Despegar Volver al montar

Bastidor base

Placa

ajustable

Agujero ajustable

26

Page 27

PROCEDIMIENTO DE INSTALACIÓN — GRAN CUBIERTA

7. Pase el tubo de desagüe y el

regulador de vacío a través del

agujero guía (Paso 3) y móntelos en la

taza.

8. Si es necesario, corte el tubo

regulador de vacío a la longitud

apropiada.

TET2LA32, TET2GA32

TEU2LA12, TEU2UA12

7” (178mm) espacio

mínimo en la pared

Pared

6~6-1/2”

(152~165mm)

1-1/2” (38mm)

o 3/4” (19mm)

Escoplo superior

5”

(127mm)

2-1/4”~2-3/4”

(57~70mm)

Inodoro o urinario

TET2LA33

TET2GA33

7” (178mm) espacio

mínimo en la pared

Pared

3-3/4”~4-7/8”

(95~124mm)

TET2LA31

TET2GA31

7” (178mm) espacio

mínimo en la pared

Pared

Escoplo posterior

TEU2LA11, TEU2LA21

TEU2UA11

7” (178mm) espacio

mínimo en la pared

(Pared)

3”

(76mm)

Inodoro

Pared

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

ESPAÑOL

9. Asegúrese de que la junta tórica encaja

en la ranura en el extremo del tubo de

desagüe del fluxómetro.

NOTA: Tenga cuidado de no dañar la junta

tórica al insertar el tubo de desagüe

en la llave de paso. Si se necesita

lubricación, moje la junta tórica con

agua.

10. Conecte el fluxómetro con la

llave de paso y el tubo regulador

de vacío.

Escoplo posterior

(Piso)

Inodoro

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

1-1/4” (32mm)

o 3/4” (19mm)

Urinario

Anillo de

retención

3-3/4”~4-7/8”

(95~124mm)

Junta

tórica

27

Page 28

PROCEDIMIENTO DE INSTALACIÓN — GRAN CUBIERTA

11. Conecte los cables del sensor infrarrojo y el controlador con el cable de

conexión. ( )

1 2

12. Conecte los cables del botón de descarga

1

manual y del controlador con el cable de

4

conexión. ( )

3

3

4

13. Antes de abrir el suministro de agua,

asegúrese de que todas las fugas de

agua se eliminan al ajustar todas las

2

conexiones de la tubería.

NOTA: Si por alguna razón es necesario

ESPAÑOL

retirar la llave de paso, asegúrese

de que el agua está cerrada en la

válvula de suministro principal.

Los

fluxómetros

están predefinidas

para volumen l de desgarga como está

marcado en la caja de la válvula. E

no requiere ajuste para la variación en la

Llave de paso

Abierto

presión de agua dentro de su rango de

operación.

14. Para colocar el fluxómetro en

su funcionamiento correcto, abra la

llave de paso por completo y active la

fluxómetro varias ocasiones.

15. En el caso de flujo excesivo debido a

la alta presión del agua, ajuste gradualmente la llave de paso hacia la

derecha (hacia la posición cerrada)

hasta que haya un flujo de agua

adecuado en el aparato.

16. Ajuste los tornillos de la cubierta

frontal en el bastidor de la base firmemente con la llave hexagonal.

Asegúrese de que no haya ningún

cable, alambre o cadena atrapados

entre la cubierta frontal y el bastidor

base.

NOTA:

La llave de paso nunca deberá

abrirse hasta el punto donde el

flujo del fluxómetro

excede la capacidad de flujo del

aparato. En caso de una falla de

la válvula, el agua debe

desbordarse del aparato.

Llave hexagonal

28

Page 29

PROCEDIMIENTO DE INSTALACIÓN — CUBIERTA PEQUEÑA

1. Determine la ubicación de la

instalación de tubería del

Tubería del suministro izquierda

1”NPT (inodoro), 3/4” (urinario)

suministro de agua

2. Coloque la llave de paso a la

tubería.

3. Perfore un agujero guía para la

tubería de descarga en la

4 x Ø5/16" (Ø8mm) agujero

pared.

4. Si es necesario, deslice un

adaptador de soldadura de

rosca en la tubería del

suministro de agua.

NOTE: Debe utilizarse compuestos

Escoplo posterior (urinario)

Ø1-5/16” (Ø33 mm) agujero

Escoplo posterior (inodoro)

Ø2-3/16” (Ø55 mm) agujero

de sellado de rosca solo

en roscas NPT macho.

Para utilizar con un suministro de agua

izquierda, separe el controlador y vuelva

a montarlo al lado opuesto del cuerpo

de la válvula.

4-3/4” ± 1/2”

(120 ± 13mm)

** 3-11/16”

(94 mm)

** 3-11/16”

(94mm)

Escopolo superior (urinario)

Ø1-5/16” (Ø33 mm) agujero

Escopolo superior (inodoro)

Ø2-3/16” (Ø56 mm) agujero

* X”, ‡ = Se requiere al menos 5" de espacio libre desde el sensor hasta la punta del asiento

del inodoro o hasta la parte superior de la barra de apoyo para evitar una detección falsa.

Para la instalación del inodoro.

** Abertura en la pared

Tubería del suministro derecho

1”NPT (inodoro), 3/4” (urinario)

1-1/4” (31 mm)

CL of sensor

X”

16” (406mm)

11” (279mm)

ESPAÑOL

Extraer

5. Asegure el bastidor a la pared con dos tornillos del

bastidor base. Vea otras opciones de instalación del

bastidor base en la página siguiente.

NOTA:

El espesor de la pared debe ser de 1/2"

(13 mm) como mínimo y 1-3/8" (35 mm)

como máximo. Si el grosor de la pared es

menor que

1/2" (13 mm), adjunte un bastidor de

madera detrás de la pared.

Volver a montar

29

Page 30

PROCEDIMIENTO DE INSTALACIÓN — CUBIERTA PEQUEÑA

Otras opciones de instalación del bastidor base

4-1/3”

(110mm)

4-1/3”

(110mm)

3/4”

(19mm)

Max.1”(25mm)

Tirante

Min.1-3/8”(35mm)

Opción 5A (con tirante)

ESPAÑOL

1. Retire todas las pestañas al lado del bastidor base.

Pestaña

2. Fije el bastidor base al tirante con 4 tornillos

(preparado en el lugar).

Opción 5B (para pared de hormigón)

1. Recorte un lugar para la cubierta en la pared.

2. Retire todas las pestañas al lado del bastidor

base antes de la instalación.

3. Fijar el bastidor base en su lugar con un

mortero.

Tirante

Tirante

Tornillos

Pestaña

4. Asegure el bastidor base con 4 tornillos

(preparado en el lugar), si es necesario.

Mortero

Tornillos

30

Page 31

PROCEDIMIENTO DE INSTALACIÓN — CUBIERTA PEQUEÑA

6. Pase el tubo de cola y el tubo

regulador a través del agujero

guía y móntelos en la taza.

7. Si es necesario, corte el tubo

regulador de vacío de presión

a la longitud apropiada.

TET3LA32, TET3GA32

TEU3LA12, TEU3UA12

7” (178mm) espacio mínimo

en la pared conun panel de

acceso de 12” x 12” mínimo

o corredor de acceso posterior

Raccord supérieure

7” (178mm) espacio mínimo

en la pared conun panel de

acceso de 12” x 12” mínimo

o corredor de acceso posterior

Pared

6~6-1/2”

(152~165mm)

1-1/2” (38mm)

o 3/4” (19mm)

5”

(127mm)

2-1/4”~2-3/4”

(57~70mm)

Inodoro o Urinario

TET3LA33

TET3GA33

Pared

3-3/4”~4-7/8”

(95~124mm)

TET3LA31

TET3GA31

7” (178mm) espacio mínimo

en la pared conun panel de

acceso de 12” x 12” mínimo

o corredor de acceso posterior

Pared

Escoplo posterior

TEU3LA11, TEU3LA21

TEU3UA11

7” (178mm) espacio mínimo

en la pared conun panel de

acceso de 12” x 12” mínimo

o corredor de acceso posterior

Pared

3”

(76mm)

Inodoro

(Pared)

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

ESPAÑOL

8. Asegúrese de que la junta tórica encaja

en la ranura en el extremo del tubo de

desagüe del fluxómetro.

9. Tenga cuidado de no dañar la junta

tórica al insertar el tubo de desagüe en

la llave de paso. Si se necesita lubricación, moje la junta tórica con agua.

Escoplo posterior (Piso)

Inodoro

1-1/2”

(38mm)

3-3/4”~4-7/8”

(95~124mm)

1-1/4” (32mm)

o 3/4” (19mm)

Urinario

Anillo de

retención

3-3/4”~4-7/8”

(95~124mm)

Junta

tórica

10. Conecte el fluxómetro con la llave

de paso y el tubo regulador de vacío.

11. Ajuste la tuerca de unión con una llave lo

suficiente para evitar cualquier fuga de agua.

31

Page 32

E P Ñ L

PROCEDIMIENTO DE INSTALACIÓN — CUBIERTA PEQUEÑA

12. Conecte el cable de la batería con el

Batería

controlador y coloque la batería en su

posición.

13. Coloque la cubierta frontal a la

pared con arandelas entre la cubierta y la pared y los tornillos a

Arandela

prueba de vandalismo.

Tornillo

ESPAÑOL

14. Conecte los cables del sensor infrarrojo y el controlador con el cable de

conexión.

( , )

1 2

3

4

15. Conecte los cables del botón de descarga

manual y del controlador con el cable de

( , )

conexión.

3 4

16. Antes de abrir el suministro de agua,

asegúrese de que todas las fugas de

agua se eliminan al ajustar todas las

conexiones de la tubería.

Si por alguna razón es necesario retirar la

llave de paso, asegúrese de que el agua

está cerrada en la válvula de suministro

principal.

1

2

17. Ajuste los tornillos de la cubierta frontal

en el bastidor de la base firmemente con

la llave hexagonal.

Asegúrese de que no haya ningún

cable, alambre o cadena atrapados

entre la cubierta frontal y el bastidor

base.

Llave hexagonal

32

Page 33

PROCEDIMIENTO DE INSTALACIÓN — CUBIERTA PEQUEÑA

El fluxómetro están predefinidas para el

volumen del aparato como está marcado en la caja

de la válvula. El fluxómetro no requiere ajuste para la

variación en la presión de agua dentro de su rango

de operación.

18. Para establecer el funcionamiento correcto de la

fluxómetro, utilice el tornillo de ajuste

para abrir la llave de paso por completo.

19. Active el fluxómetro varias veces.

20. En caso de flujo excesivo, ajuste gradualmente la

llave de paso hacia la derecha hasta la posición

cerrada utilizando el tornillo de ajuste, hasta que

haya un flujo de agua adecuado en el aparato.

ADVERTENCIA: La llave de paso nunca deberá abrirse hasta el punto donde flujo del

fluxómetro excede la capacidad de flujo del aparato. En caso de una

falla de la válvula, el agua no debe desbordarse del aparato.

Llave de paso

Abierto

ESPAÑOL

PRUEBA DE FUNCIONAMIENTO

1. Para Inodoros: Siéntese en el asiento del inodoro.

Para Urinarios: Sitúese a menos de dos pies de distancia del frente del fluxómetro.

2. Quédese ahí durante 6 segundos o más y luego deje el asiento del inodoro o el urinario.

La válvula se descargará de forma automática.

3. Pulse el botón de descarga manual y asegúrese de que la válvula se descarga correctamente

y que la luz roja del sensor está encendida durante 2 segundos.

4. Vuelva a revisar todas las conexiones de las tuberías para buscar fugas de agua.

Si el fluxómetro no funciona correctamente después de la prueba de

funcionamiento, consulte la sección Solución de problemas p.35.

33

Page 34

DESPUÉS DE LA INSTALACIÓN

Después que la unidad del fluxómetro se ha instalado correctamente, explique a sus clientes

cómo utilizarla y dígales que sigan estas instrucciones:

1. No coloque ningún objeto delante de la ventana del sensor que podría obstruirlo y provocar

un mal funcionamiento.

2. En caso de algún problema, consulte la sección Solución de problemas en la p.35. Si usted

carece de los conocimientos necesarios requeridos o tiene dificultad para seguir las instrucciones de instalación, mantenimiento, reparaciones, solución de problemas o ajustes del

producto, no proceda sin la ayuda de una persona calificada para ayudarle.

USO DEL FLUXÓMETRO

Sensor infrarrojo Descarga

ESPAÑOL

El sensor infrarrojo detecta a un

usuario del inodoro o que está de

pie dentro de los 2 pies de

distancia (600 mm) del frente

del urinario.

Cuando el usuario permanece en el

lugar más de 6 segundos antes de salir,

el regulador le indica al equipo de

operación que active la Válvula de

Descarga después de 3 segundos de

retraso para inodoro o sin demora

para urinario.

Botón de descarga manual

Utilice el botón de descarga

manual para el mantenimiento

o las emergencias.

Descarga cada 24/12 horas

Cuando el inodoro no se utiliza durante 24 horas (12 horas para urinario) el temporizador

de protección da la orden al sistema para activar una descarga a fin de mantener el sello

de la trampa.

MANTENIMIENTO PERIÓDICO

Revise su fluxómetro EcoPower al menos una vez al mes de acuerdo a estas

instrucciones para evitar el riesgo de daños a la propiedad.

Revise la tubería para ver si hay alguna fuga.

34

Page 35

RESOLUCIÓN DE PROBLEMAS

Problemo

No sale agua de la

fluxómetro

La válvula principal en la línea de

suministro de agua o la freno del

control está cerrada

Uno o más cables no están conectados

La superficie del vidrio en frente del

sensor infrarrojo está sucia

El vidrio está roto

Hay una superficie reflectante en

frente del sensor

El sensor infrarrojo o el solenoide

está malogrado

Los pequeños agujeros en el diafragma

del solenoide están atascados

El generador de energía hidráulica

está atascado

Acción SugeridaCausa Posible

Abra la válvula principal o la

llave de paso

Revise todas las conexiones

de cable

Limpie la superficie del vidrio

Contacte a su distribuidor para

obtener repuestos

Retire la superficie reflectante

frente al sensor

Contacte a su distribuidor para

obtener repuestos

Limpie el agujero pequeño en el

diafragma y en el filtro

Mantenimiento del generador de

energía hidráulica

Página

-

-

-

-

38

-

37

36

ESPAÑOL

El agua no deja

de fluir

Volumen

es demasiado

pequeño

Volumen

es demasiado

La velocidad del flujo

es demasiado baja

El pequeño agujero en el pistón está

atascado. (no para TEU*UA)

El área de sellado del pistón está

sucia. (no para TEU*UA)

El área de sellado del diafragma del

solenoide está sucia.

El empaque U del pistón está

dañado. (no para TEU*UA)

El tornillo de la llave de paso no

está ajustado correctamente

La presión de agua es demasiado baja

La llave de paso no está abierta lo

suficiente

Limpie el agujero pequeño en

el pistón

Limpie el área de sellado

del pistón

Limpie el área de sellado del

diafragma y del filtro

Inspeccione y reemplace si es

necesario

Ajuste la cantidad

con el tornillo de la freno del

control

Consulte a un contratista de

plomería

Ajuste la llave de paso

correctamente

37

36

37

36

37

-

37

La velocidad del flujo

es demasiado alto

Una luz roja parpadea

en la ventana del

sensor

La llave de paso no está abierta lo

suficiente

La batería tiene poca carga

Ajuste la llave de paso

correctamente

Reemplace con la batería

proporcionada por TOTO

NOTA: No desmonte las piezas del fluxómetro que no se especifican en la

guía de solución de problemas.

Si necesita más ayuda, por favor llame a TOTO Tech Support at (888) 295-8134.

®

35

37

37

Page 36

DESMONTAJE

Si necesita desmontar toda la válvula

del suministro de agua para darle

mantenimiento, tome las siguientes

precauciones:

1. Tenga cuidado de no perder o

romper la arandela de fricción en la

conexión de salida a la tuerca del

tubo regulador de vacío. Para

mantener un sellado adecuado,

reemplace la arandela si es

Llave hexagonal

suministrada

Llave hexagonal

suministrada

necesario.

2. Al volver a instalar el fluxómetro al

suministro de agua, evite pellizcar la

junta tórica.

ESPAÑOL

ESPAÑOL

LIMPIEZA DEL MONTAJE DEL PISTÓN Y DEL FILTRO

1. Gire el tornillo de la llave de paso

hacia la derecha para cerrar el

agua.

2. Saque el montaje del pistón.

3. Revise el agujero pequeño en el

pistón para ver si está atascado con

desechos. Inserte un alambre

pequeño para destapar el agujero si

es necesario.

Cubierta gran

Llave de paso

Tapa

Montaje del pistón

Cubierta pequeño

Llave de paso

Tapa

Montaje del pistón

4. Revise el filtro para ver si está

atascado con desechos y cepille

suavemente para limpiar.

5. Revise el área de sellado del pistón

y límpiela si está sucia.

6. Revise el empaque u para buscar

fisuras o daños.

Empaque u

Agujero pequeño

Filtro

Área de sellado

36

Page 37

LIMPIEZA DEL DIAFRAGMA DEL FILTRO

1. Gire el tornillo de la llave de paso hacia la derecha para cerrar el agua.

2. Desconecte el solenoide.

3. Quite el solenoide y saque el diafragma. Luego, revise los agujeros pequeños y el área

de sellado.

NOTA: Ver a continuación para el desmontaje.

NOTA: No estire o altere la forma del resorte en el fluxómetro del solenoide de ninguna

manera. Se anulará la garantía.

Unidad de sensor

Filtro

Área de sellado

Diafragma

Filtro

Regulador

Filtro

Tapa

Filtro

TEU2UA y TEU3UA

Solenoide

Émbolo

ResorteJunta tórica

Diafragma

Agujeros pequeños

MÉTODO DE REVISE EL SOLENOIDE

1. Asegurarse de que las baterías están colocadas correctamente y que los cables están

conectados.

2. Con el suministro de agua cerrado, coloque su mano delante del sensor durante

6 segundos.

3. Retire y escuche un "clic" después de 3 segundos. Esto indica que el émbolo del solenoide

se ha activado.

-

ESPAÑOL

REEMPLAZO DE LA BATERÍA

Reemplace solo con la batería suministrada por

TOTO. Se utiliza una batería especial de litio de

respaldo.

Si una luz roja en la ventana del sensor parpadea

con el ciclo de 4 segundos, es hora de reemplazar

la batería.

1. Retire la batería vieja.

2. Coloque la batería nueva en la posición

correcta.

AJUSTE DEL FLUJO

1. Ajuste el flujo en la llave de paso.

2. Gire hacia la derecha para disminuir el flujo y gire a la izquierda

para aumentarlo.

37

Battería

Page 38

RANGO DE DETECCIÓN

El rango de detección del sensor infrarrojo se ha fijado en la fábrica y no necesita ajuste

adicional.

33-1/2"

(850mm)

15°

Max 19-11/16”

(Max 500mm)

ESPAÑOL

ADVERTENCIA

NO coloque el sensor infrarrojo de

una fluxómetro de tal

manera que esté en línea con el

sensor de otra fluxómetro.

ADVERTENCIA

NO coloque el sensor infrarrojo

delante de un espejo.

ES OL

Sensor infrarrojo de la otra

fluxómetro

Sensor infrarrojo del fluxómetro Sensor infrarrojo del fluxómetro

NOTA: El fluxómetro puede no detectar a un

usuario si el asiento del inodoro se

deja en posición vertical. Esto puede

ser debido a la dimensión aproximada

o a la brecha del hueco del asiento

comercial frontal. Baje el asiento o

coordine con TOTO o otro contratista

de plomería para cambiar la altura de

el fluxómetro.

En algunos casos, el sensor puede

tener problemas para detectar a los

usuarios que usen ropa negra.

Espejo, pared sin mancha de

acero y otra superficie altamente

reflectante

Sensor infrarojo

38

Page 39

GARANTÍA

1. TOTO® garantiza que sus uxómetro grifos y dispensadores de jabón automáticos (“Producto”) no

tienen defectos en los materiales y mano de obra durante su uso normal, cuando son adecuadamente

instalados y cuidados, por un periodo de tres (3) años a partir de la fecha de compra. Esta garantía limitada se

extiende únicamente al COMPRADOR ORIGINAL del Producto y no es transferible a ninguna tercera persona,

incluyendo, pero sin limitarse a, cualquier comprador o dueño subsecuente del Producto. Esta garantía aplica

únicamente al Producto TOTO adquirido e instalado en América del Norte, Central y del Sur.

2. Las obligaciones de TOTO bajo esta garantía se limitan a reparar, reemplazar u otro ajuste adecuado, a elección

de TOTO, del Producto o partes que estén de

adecuadamente instalado, utilizado y cuidado de determinar la causa del defecto. TOTO no cobrará por el

trabajo o partes relacionados con las reparaciones o cambios de la ga-rantía. TOTO no es responsable por el

costo de remoción, devolución y/o reinstalación del Producto.

3. Esta garantía no aplica a los siguientes puntos:

a. Daño o pérdida ocurridos en una calamidad natural, tal como un incendio, terremoto, inundación, truenos,

tormenta eléctrica, etc.

fectuosas con el uso normal, dado que dicho Producto haya sido

b. Daño o pérdida resultado de cualquier accidente, uso no razonable, mal uso, abuso, negligencia o cuidado,

limpieza o manten-imiento inadecuado del Producto.

c. Daño o pérdida resultado de sedimentos o materia extraña contenidos en un sistema de aguas.

d. Daño o pérdida resultado de una instalación inadecuada o de la instalación del Producto en un ambiente

e. Daño o pérdida resultado de sobrecarga eléctrica o rayos u otros actos que no sean culpa de TOTO o que

f. Daño o pérdida resultado del desgaste normal y acostumbrado, tal como reducción del brillo, rayado u

opacamiento en el tiempo debido al uso, prácticas de limpieza o agua o condiciones atmosféricas,

incluyendo pero sin limitarse a, el uso de cloro, limpiadores alcalinos o ácidos, limpiadores secos (talco) u

otros limpiadores abrasivos o el uso de estropajos de metal o nylon.

registro de la garantíaal momento de la compra para crear un registro de la propiedad del Producto en

http://totousa.com. El registro del Producto es completamente voluntario y no hacerlo no disminuirá los

derechos de su garantía limitada.

5. ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS. USTED PUEDE TENER OTROS DERECHOS QUE

PUEDEN VARIAR ENTRE ESTADOS, PROVINCIAS O PAÍSES.