Page 1

TOTO U.S.A., INC. • 1155 Southern Road, Morrow, GA 30260

Tel. (770) 282-86 8 6 • Fax. (770) 282-8701

www.totousa.com

Printed in U.S.A. © TOTO LTD.

* Check for correct dimension

3

5

TSU01W

14"

B

12"

10"

A

3/4"

D

C

4-1/2" *

8" *

(Only for MS904114)

10" *

NOTE: Water supply rough-in

significantly wider than standard 5"rough-in.

Consult your builder or contractor.

IMPORTANT

Read these instructions thoroughly

before beginning

work.

You have purchased

one of the best

working toilets

available today,

backed by TOTO’s

worldwide finest

reputation.

Please leave instructions for customers. These instructions

contain maintenance and warranty information.

COMMON TOOLS NEEDED:

• 12” pipe wrench

• 10” adjustable wrench

• Carpenter’s level

• Tape measure

• Plier

• Screwdriver

• Putty knife

• Drill motor, 11/64” drill bit (for wood floor

installation) & 1/4” masonry drill bit (for masonry/tile

floor installation)

MATE R IALS REQU I RED:

• Supply tube / connector

• Supply stop

• Mounting bolts (2)

• Wax ring / seal

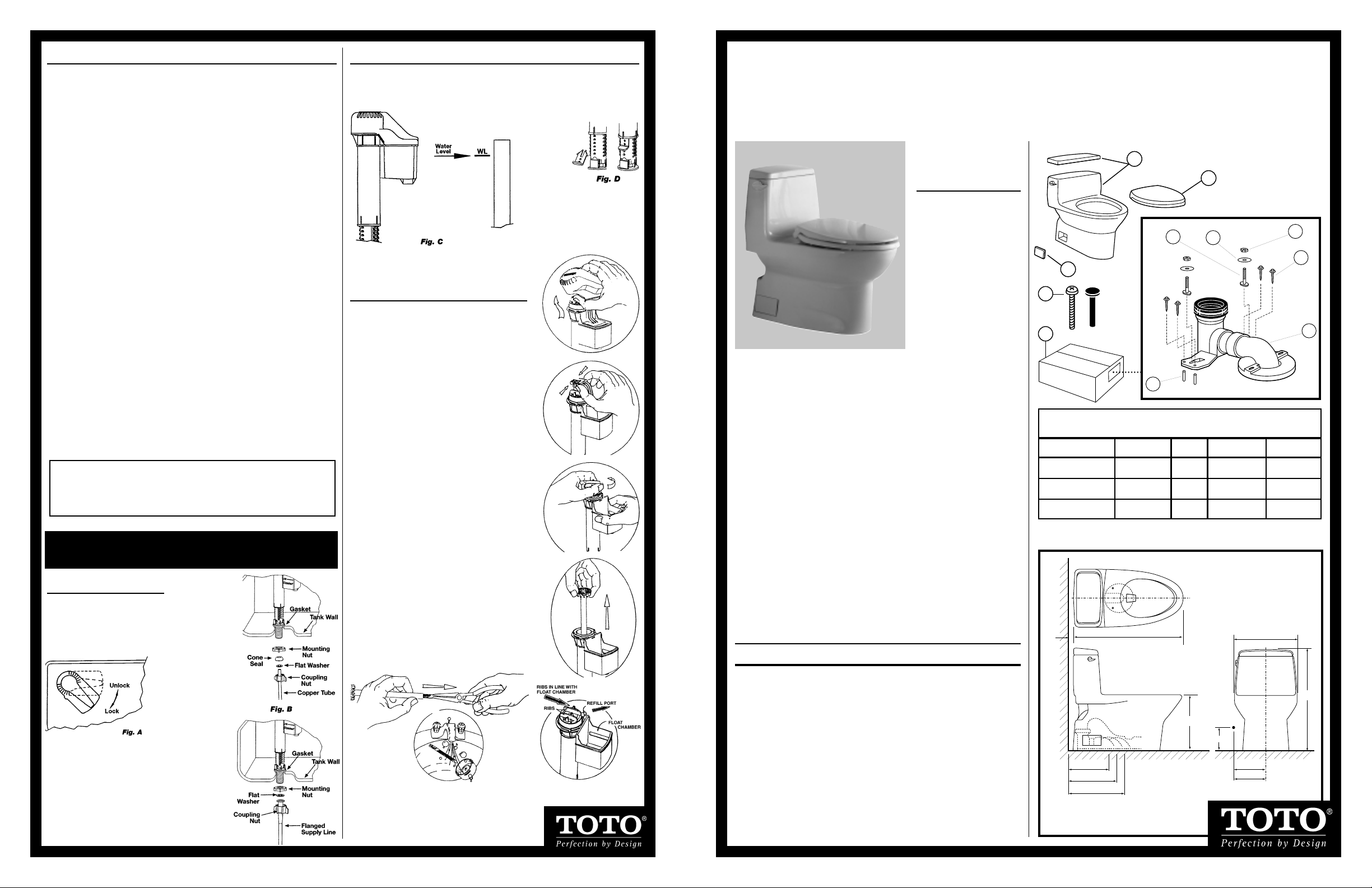

Package Content:

No. Item Quantity

1. Vitreous China Bowl w/lid..............................................1

2. Cover Plate..............................................................................2

3. Top Mount Bolt Set (for seat)........................................1

4. Toilet Seat Set........................................................................1

5. UN IFIT Rough-In (TSU01W.12).................................1

5a. Toilet Mounting Bolt (T-Bolt) ...............................2

5b. T- Bolt Washer................................................................2

5c. T-Bolt Nut.......................................................................2

5d. Mounting Screw w/ washer....................................4

5e. Anchor..............................................................................4

5f. PVC Outlet Connection* ..........................................1

For MS904114 / MS884114 / MS874114S / MS914114

For MS904114 / MS884114 / MS874114S / MS914114

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

SERVICING

INSTRUCTIONS

1. Turn off water supply, then

flush toilet.

2. Snap off cover.

3. Gently press float arms inward and

remove float.

4. While holding valve with one hand,

twist cap 1/8 turn counter clockwise and remove.

5. Lift out center tube as shown.

6. Remove strainer form center tube

as shown. Clean strainer and cap

by rinsing off under faucet.

7. Carefully reassemble the valve in

the reverse order.

IMPORTANT:

Note position of cap when properly

assembled to the body. The ribs on

the cap are in line with the float

chamber and the refill port is aligned

as shown.

INSTALLATION

1. Shut off water supply. Flush toilet;

sponge remaining water from tank.

Remove old ballcock.

2.

Slide threaded valve-shaft through hole in

bottom of tank. Note:

Be sure to install

valve in the locked

position at the angle

shown in fig. A.

Thread mountingnut onto exposed

shaft under tank and tighten nut.

DO NOT OVERTIGHTEN.

3. Connect water supply as shown in fig. B.

Pipe dope is not recommended. Hand tighten only; do not overtighten coupling nut.

4. Finally attach refill tube to valve and clip

other end to overflow pipe.

WATER LEVELADJUSTMENT

1. To adjust, simply turn upper half of valve counter-clockwise

to unlock, pull up til water level is where the water line is marked on

the overflow pipe, Fig. C, then turn clockwise till valve

snaps into locked position.

2. Turn on

water supply

to fill tank.

3. Tamper

proof key is

optional, and may be used

simply to prevent further

adjustment once final setting

is achieved, Fig. D.

2

3

4

5

6 7

TROUBLE SHOOTING GUIDE

1. PROBLEM:

Fill valve turns on/off without toilet being flushed

a. PROBABLE CAUSE: No proper slack in flapper chain

SOLUTION: Adjust for proper slack

b. PROBABLE CAUSE: Flush valve flapper dirty

SOLUTION: Inspect and clean

2. PROBLEM: Fill valve continues running

a. PROBABLE CAUSE: Dirty fill valve seal

SOLUTION: Shut off water supply. Open fill valve

cap and clean valve seal

b. PROBABLE CAUSE: Flush valve flapper does not

seat properly

SOLUTION : Inspe ct, clean or adjust flapper position

3. PROBLEM: Poor Flush

a. PROBABLE CAUSE: Trapway is obstructed

SOLUTION: Unclog trapway

b. PROBABLE CAUSE: Supply stop is partially closed

SOLUTION: Open supply stop

c. PROBABLE CAUSE: Venting is obstructed

SOLUTION: Clear venting pipe

d. PROBABLE CAUSE: Water supply is too low

SOLUTION: The minimum required supply pressure

is 20 psi. Consult your plumber.

4. PROBLEM: No flushing

a. PROBABLE CAUSE: Supply stop is closed

SOLUTION: Open supply stop

b. PROBABLE CAUSE: Flush valve chain is too loose

or disconnected

SOLUTION: Adjust chain length as needed

WARNING! DO NOT USE IN-TANK BOWL CLEANERS

The use of high concentration of chlorine or chlorine-related products can

seriously damage fittings in the tank. This damage can cause leakage and

property damage. • TOTO shall not be responsible or liable for any tank fitting failure or damage caused by the use of in-tank bowl cleaners.

TOILET TANK FILL VALVE INSTRUCTIONS

G-Max /Power Gravity

REV 03/01

OGU003Z

Model A B C D

MS9 04114

MS8 84114

MS874114S(SG)

MS914114

29-1/2”

28”

28”

28”

15”

15”

15”

15”

23-1/2”

23-3/4”

27-1/2”

24-7/8”

21-1/4”

16-1/2”

16-1/2”

17-3/4”

1

2

4

b

c

a

e

d

f

Page 2

Wall

A

Closet

Flange

C/L

Floor

4 holes

Anchor

2"

9"

Wall

"RI"

Closet

Flange

C/L

Supply

Valve

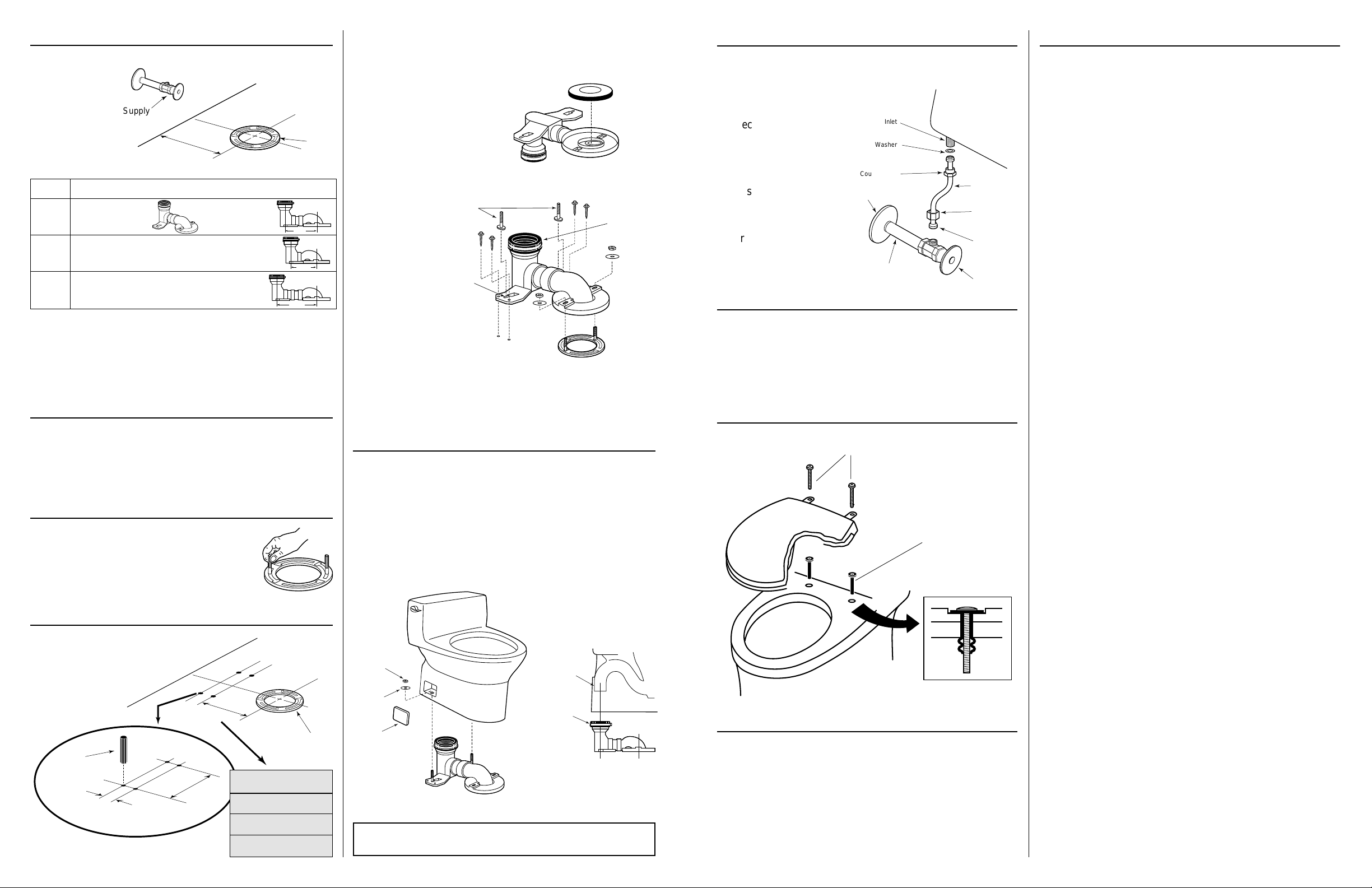

STEP 1 Piping Check and Roughing-in

In order for your new TOTO toilet to fit correctly, check the

dimensions below.

a) Distance

between

finished wall

to the center

of the toilet

outlet, Rough-In (“RI”):

Please make sure that you have the correct outlet connection part.

b) Water supply must be approx. 8 in. or 10 in. to the left

(facing bowl) from center line of closet flange and approximately 4-1/2 in. above the floor.

Removing Exhisting Toilet (If Necessary)

Turn off water supply. Flush the toilet, remove any remaining

water from tank and bowl.

Disconnect water connector. Remove tank and bowl. Remove

old wax seal and mounting bolts.

STEP 2 Installing Mounting Bolts

Clean any debris out of the closet flange, then

install the mounting bolts into the slots of the

flange. The bolt should be inserted into the

slot with its head down and threaded

shank pointed upward.

STEP 3 Installing Outlet Connection

Drill 4 holes 11/64” on the floor

at location shown. (1/4” holes

are for tile/concrete floor

using anchors.)

Turn the PVC outlet connection upside down. Firmly press a

new wax seal onto the circular recess around the outlet opening.

Turn the outlet connection upright and lower it into position

over closet flange. With the unit properly

aligned, press down firmly to set

wax seal.

CAUTION: DO NOT move

the outlet connection after

the wax seal is set.

Insert washers

and thread

nuts onto

mounting bolts

and hand tighten.

Then tighten bolts

an additional

1/2 turn.

Secure back side

of outlet connection to the floor using

the 4 screws and

washers.

Insert the T- Bolts into the slots with its

head down and threaded shank pointed upward.

NOTE: Do not remove the white tie-wrap from rubber sleeve.

Level the PVC outlet.Do not use excessive force.

STEP 4 Installing Toilet

Lift the toilet and gently lower it into position over closet

flange. Make sure that the spigot outlet of toilet slips into

rubber sleeve and T-Bolts fit through the openings in the

base of toilet.

NOTE: A petroleum lubricant can be used on the rubber

sleeve to lubricate the spigot outlet for an easier installation.

Insert washer and thread nuts on to bolts and hand tighten.

Then tighten bolts an additional 1/2 turn. Install cover plates.

“RI”

12 inch

10 inch

14 inch

TSU01W.12

(supplied)

TSU01W.10

(optional - must be purchased separately)

TSU01W.14

(optional - must be purchased separately)

Outlet Connection Part No.

9-1/2"

7-1/2"

11-1/2"11-1/2"

RI A Dimension

10” A = 3-1/2”

12” A = 5-1/2”

14” A = 7-1/2”

T-Bolts

nut

washer

slot

rubber

sleeve

Wax seal

WAR N ING: DO N OT over tighten the nuts, damage to

china or plastic parts may result.

FIVE YEAR LIMITED WARRANTY

Warranty applies to select Augusta Products only.

1. TOTO warrants its vitreous china pro ducts to be free from manufacturing defects under normal use and service for a period of five (5)

years from date of purchase. This warranty is extended only to the

ORIGINAL PURCHASE.

2. TOTO ’s obligation under this warranty are limited to repair or

replacement at TOTO’s option, of products or parts found to b e defective, provided that such products were properly installed and used in

accordance with instructions. TOTO reserves the right to make such

inspections as may be necessary in order to determine the cause of the

defect. TOTO will not charge for labor or parts in conne ction with warranty repairs or replacements. TOTO i s not responsible for the cost or

removal, return and/or reinstallation of products.

This warranty does not apply to the following items.

a. Damage or loss sustained in a natural calamity such as fire,

earthquake, flood, thunder, electrical storms, etc.

b. Damage or loss resulting from any unreasonable use, misuse,

abuse, negligence, or improper maintenance of the product.

c. Damage or loss resulting from removal, improper repair, or

modification of the product.

d. Damage or loss resulting from sediments or foreign matter

contained in water system.

e. Damage or loss resulting from improper installation or from

installation of a unit in a harsh and/or hazardous environment.

f. Tank flushing mechanisms of plastic or rubber moving parts.

g. Toilet seats of plastic, wood or metal.

4.This warranty gives you specific legal rights. You may have other

rights which vary from state to state.

5. To obtain warranty repair service under this warranty, you must take

the product or deliver it prepaid to a TOTO service facility together with

a letter starting the problem, or contract a TOTO distributor or products

service contractor, or write directly to TOTO K IK I U .S.A. INC, 1155

Southern Road, Morrow, GA 3026 0 (8 88) 295-8134. If b e cause of the

size of the product or nature of the defect, the product cannot not b e

returned to TOTO, receipt by TOTO o f written notice of the defe ct shall

constitute delivery. In such case, TOTO may choose to repair the pro duct at the purchaser’s location or to pay to transport the product to a

service facility.

This written warranty is the only warranty made by TOTO. Repair or

replacement as provided under this warranty shall be the exclusive remedy available to the purchaser. TOTO shall not b e responsible for lost of

the product or for other incidental, special or consequential damages or

expenses insured by the purchaser, or for labor or other costs due to

installation or removal, or costs of repairs by others, or for any other

expenses not specifically stated above. Except to the extent prohibited

by applicable law, any implied warranties, including that of merchantability or fitness for use, are expressly limited to the duration of

this warranty. Some states do not allow limitations on how long an

implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply

to you.

WAR N ING! TOTO shall not be responsible or liable for any failure of,

or damage to, this product or product component caused by either chloramines in the treatment of public water supply or in tank bowl cleaners

containing chlorine (calcium hypochlorite). Note: The use of high concentration of chlorine or chlorine related products can seriously damage

the fittings. This damage can cause leakage and serious property damage. For more information, please call us at (888) 295-8134.

STEP 5 Connecting Water Line

Supply stop should be installed per supply stop instructions

at location shown in Step 1.

Flush water line briefly to

ensure removal of debris.

Connect provided flexible

supply to supply stop.

CAUTION: DO NOT

OVER-TIGHTEN N UT.

Open supply stop, check

for leakage. Slightly

retighten if necessary.

Water Supply

Pressure should be:

20 to 80 psi Static

STEP 6 Operation

NO BALLCOCK/FILL VALVE ADJUSTMENT NEEDED.

Water will automatically stop at proper level.

Flush toilet several times. Check flapper valve for proper

operation. Make sure that chain is not tangled and flapper

arm is in its proper position.

STEP 7

Install toilet tank lid.

STEP 8

Install toilet seat. (Top Mount Bolt Set is included in the bowl).

Insert rubber bushing nuts into bowl seat holes.

Note: Remove existing seat if necessary.

Place seat on bowl and rotate the hinge unit into place while

holding seat down on bowl.

Fasten and tighten bolt from top with screwdriver. Replace

bolt cap and lower lid (if necessary).

;

;

y

y

Seat Bolt

Rubber

Bushing Net

spigot outlet

rubber

sleeve

nut

washer

Cover

Plate

REPLACEMENT PARTS

Model Flapper Fill Valve Flush Valve Trip Lever

MS904114 THU092-5 TSU06A.4 THU014 THU015#XX

MS884114 THU092-1 TSU04A.5 THU001N THU004#XX

MS874114S THU092-3 TSU05A.11 THU013 THU004#XX

MS914114THU092-8 TSU04A.5 THU128 THU099#XX

Water Inlet

Washer

Tank

Coupling Nut

Trim Plate

Flexible Supply

Valve Nut

Compression

Nipple

Valve

Loading...

Loading...