Toto LFC991GQ01 Installation Manual

0GU3018-2

2009.4

Neorest Counter Lavatory with Automatic Faucet

Warranty Registration and Inquiry

For product warranty registration, TOTO U.S.A. Inc. recommends online Warranty Registration. Please visit our web site http://www.totousa.com. If you have questions regarding warranty policy

or coverage, please contact TOTO U.S.A. Inc., Customer Service Department, 1155 Southern Road, Morrow, GA 30260 (888) 295-8134 or (678) 466-1300 when calling from outside of U.S.A.

For best results, be sure to follow the installation instructions and use the product only as described in the manual.

Important Safeguards

(For your safety, please follow the instructions below.)

Read the “Important Safeguards” section thoroughly before installing the product.

● The following symbols indicate safe and proper use

of the product. Failure to observe them may result

in injury or property damage.

The symbols and their meanings are as follows:

Sign

Warning

Caution

Ignoring these symbols may result in

serious personal injury.

Ignoring this symbol may result in injury

or property damage.

Meaning

Warning

Do not use an unstable wall outlet

May cause fire or electric shock.

● The following table demonstrates

the use of safety symbols in this

manual.

Do not disassemble

Absolutely “Do Not”.

Do not touch.

Mandatory!

Do Not

No water

No impact

Do not

disassemble

Do not overload the wall outlet or the wiring facilities

Otherwise,it will result in fire due to heat.

Do not reverse the HOT/COLD water supply.

Burns may result from confusing hot water with cold water.

Do not place the product in a room with high

humidity such as shower room or sauna.

May cause product malfunction or electric shock.

Do not strike or kick the product.

May cause damage or water leakage.

Never attempt to disassemble, reassemble, repair

or modify the product, unless you are an electrician

or qualified service person.

May results in property damage and/or personal injury

Do not unplug with a wet hand

May cause electric shock.

Warning

C

Hot side

Cold side

H

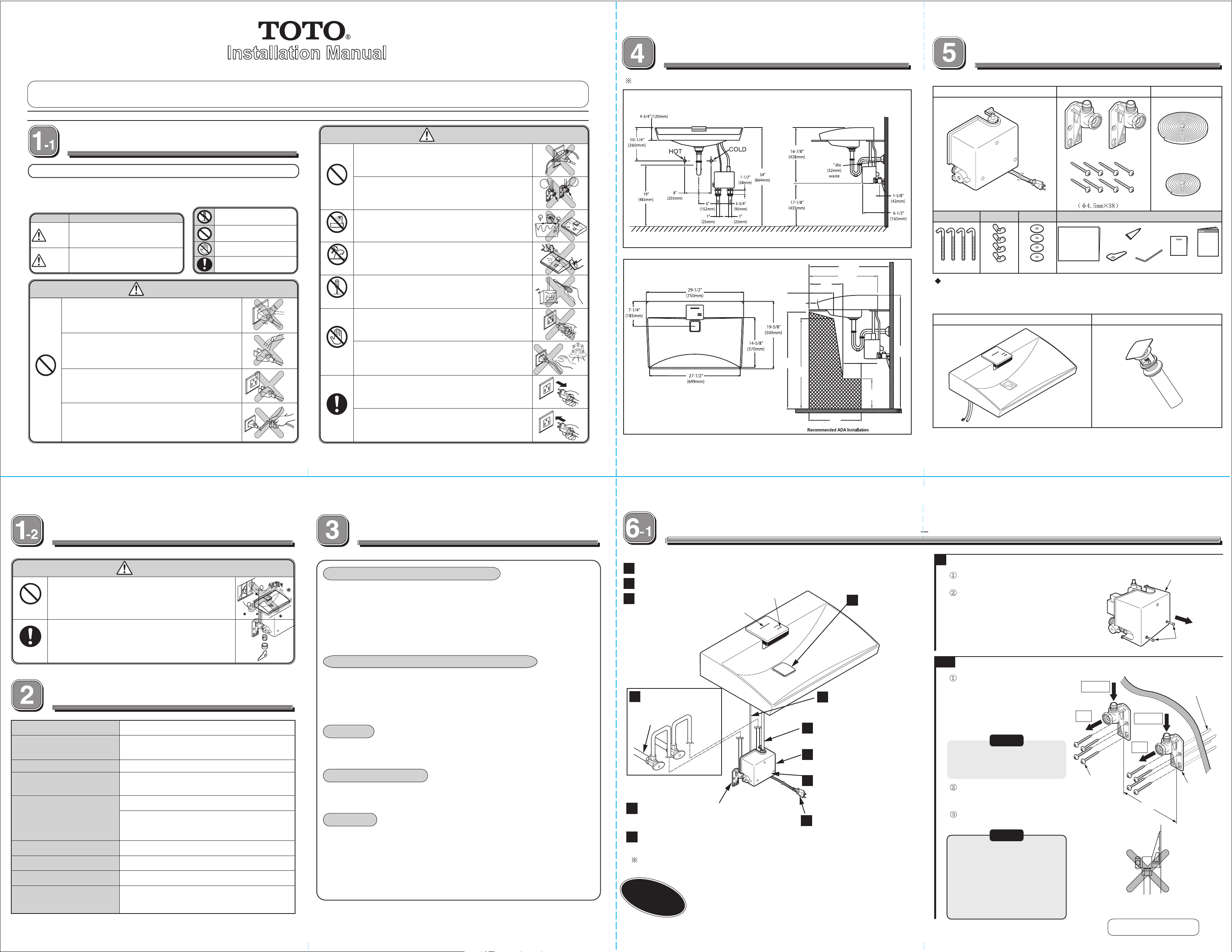

Set-Up Drawing

Some models may have different components as illustrated below.

1-1/4

8”

(203mm)

2-3/4”

(70mm)

11”

(279mm)

26-1/4”

(667mm)

22-3/8”

(568mm)

Installation

Some models may have different components as illustrated below.

Controller

Hook bolts Wing nuts

(4 pcs) (4 pcs) (4 pcs)

Washers

Necessary tools

Adjustable Wrench, Screw Drivers, Drill, Jig Saw, Wrench and Cutters

Lavatory, Automatic faucet and drain

Lavatory with Automatic Faucet

Water inlet bracket Packing material

Water supply bracket (2 pcs)

Tapping screw s (8 pcs)

Others

caulking

template

strainer tool Allen wrench

Installation

Manual Set

Drain

(Large)

(Small)

(1 of each)

Operation

Manual

Do not wet the electric plug or controller

May cause fire or electric shock.

Do Not

Do Not

Mandatory

Only the designated power supply (100-120 V AC,

50-60 Hz ) can be used.

If a port or AC power supply other than the designated is used,

it will result in fire or failure.

Do not handle the power cord violently by folding

it or pressing on it with heavy load

May cause fire or electric shock.

Do not install outdoor or where temperature is likely

to fall below freezing point.

If parts are damaged, property damage may occur due to leakage.

Always close the stop valves before cleaning the

strainer.

Hot or cold water may flow out and cause personal

injury or property damage.

Specification

Model #

Duration of water supply

Power supply

Detection range from

sensor unit

Water supply pressure

Water supply connetion

Ambient temperature

Humidity

Discharge Quantity

Other than the

designated port

or power

supply

Caution

LFC991G, Complete Set

Hand sensor: 60 seconds

Start/Stop Switch on: Continual water Supply

100-120 V AC 50-60HZ

Hand Sensor: within 10 inches (250 mm)

Body Sensor: within 3 feet ( 900 mm)

Lower limit: 15PSI(100kPa) (when flowing)

Upper limit: 125PSI (862kPa)

Check local building codes for maximum water pressure

allowed.

1/2” NPSM

32°F - 104°F (0~40ºC)

Maximum 90%RH

1.7Gal./Cycle (6.5 L/Cycle)

(with built-in regulating valve)

Do not

touch

Mandatory

Do not touch the power plug if there is lightning

May cause electric shock.

Hold the plug body to pull the plug out of the outlet. If

pulled by the cord, it could damage the plug or cord and

could result in fire or electric shock.

Confirm that the power plug is pushed in all the way.

TOTO recommends that the AC adapter be

connected to a GFCI-protected outlet.

May cause fire or electric shock.

Before installation

1. Confirm cold /hot water pressure

● Confirm the cold water pressure is equal to or higher than that of the hot water

If water pressure is higher than 125PSI (862kPa), use a pressure-reducing

valve to reduce it to between 20 and 80 PSI (138 and 551 kPa).

●The optimal pressure ranges is 15PSI to 125PSI (100kPa to 862kPa)

Confirm that the water supply pressure is within this range.

2. Confirm the temperature of hot water supply

● Do not use steam as hot water supply.

● Make sure that the temperature range of hot water supply side is 140 to

185ºF

This is not mandatory for the lower limit but is recommended.

● The auto faucet does not discharge hot water exceeding 122ºF (50°C) .

3. Piping

● Flush all water lines prior to installation.

4. Counter thickness

● The thickness of the counter should be made in the range of 3/8 to 1-3/8

inches (10-35mm).

5. Others

● Special cares should be taken not to damage or scratch the sensor surface.

● You should prepare the stop valve, flexible hose and steel pipe.

● When using the inverter or Infrared sensor, do not set other such devices

nearby since they may cause malfunction.

● If you find water residue in the device, it is not a defect of the product.

(60 to 85°C).

34”

29”

(737mm)

27”

(686mm)

17”

(432mm)

6”

(152mm)

9”

(229mm)

(834mm)

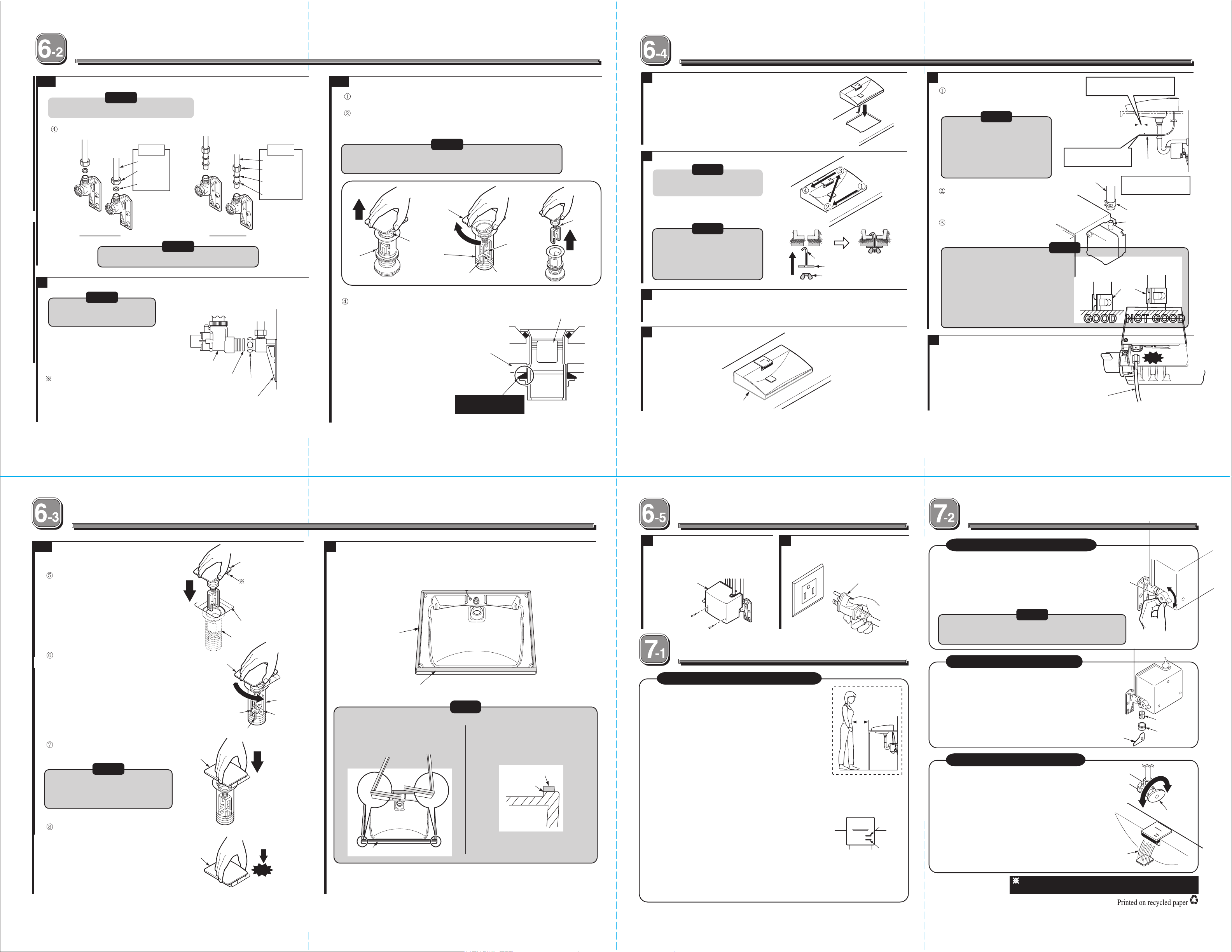

Installation procedure

Place the template on the counter-top and cut out the opening.

6

Apply packing material; carefully position the lavatory into the opening.

7

Fit it to the counter

8

(Please see the procedure

in the manual for detailed

installation.)

1

Flush water supply

lines to remove

debris

not

included

Mount the two water inlet

3

brackets to the wall

Connect the controller to

4

the water inlet brackets

The drawing may be different from what mentioned depending on the model.

Thoroughly clean and remove debris from

Important

the water supply pipes before installation to

prevent clogging the filters, causing

malfunction of the product.

2 switches

LE D cover

Install the drain

5

to the Lavatory

(provided)

Install the sensor cord

10

Connect hose to the spout

9

Remove the controller cover

2

Install the controller cover

11

Insert the power plug

12

2

Remove the controller cover

Loosen the 2 screws on the external surface of the cover.

Remove the cover in the direction as shown.

-1

3

Install the two water inlet brackets into the wall

Install the two brackets into the wall

using the screws

The distance between the two

brackets is 3-3/4” (95 mm).

To fix the controller with the

2 brackets, connect them

temporarily at first.

Hot in

Out

Caution

To install the controller, the optimal

distance between the two brackets

should be 3-3/4”

Make sure the the controller is

attached securely to the brackets.

Use 8 tapping screws to fix the water

supply brackets.

(95 mm)

.

Tapping screws

Caution

●It is necessary to use wall

anchors.

●Make sure that each water

inlet bracket is installed in

the correct direction.

Otherwise, the strainer on the

water inlet bracket will be

inaccessible for cleaning.

Continued on next page

Controller cover

Pull

Screws

Wall anchors

(not included )

Cold in

Out

Water inlet brackets

3-3/4”

(95 mm)

-2

3

Mount the two water inlet brackets on the wall (Continued)

Caution

Remove all the protective covers.

Connect the hot/cold water supply pipe with the water inlet brackets.

Not

included

Flexible hose

Nut

Packing

Copper pipe Flexible hose

Caution

Make sure Hot goes on the left side.

4

Connect the controller to the water inlet brackets.

Caution

Remove all the protective

covers.

After placing packing, attach the

controller to the water inlet bracket,

and then fix them with the nuts as

shown in the figure.

Controller

Not

included

Copper tube

Nut

Friction ring

Cone washer

-1

5

Install the drain assembly to the lavatory.

Detach the grid unit by pulling it.

Turn it clockwise (about 45 ° ) and pull the grid unit out of the cross-bar .

Caution

If Grid unit hook is trapped, restore the grid unit, Then turn it

clockwise again, while pulling it slowly out of the cross-bar.

Pull

Grid cup unit

Grid Unit

Drain

Assembly

After seperating the grid unit and drain assembly

body, install the drain assembly body on to the

Lavatory.

Then apply the Plumber’s Putty or Silicone caulking

around the lavatory waste oulet.

Draining

assembly body

Grid unit hook

lavatory

Cross bar

Notch

Grid unit

Horizontal hole

7

Install the lavatory

1. Cut the countertop using the template provided.

2. Carefully place the lavatory into the cut-out. For

proper installation, two people may be required to

lift and position the lavatory.

8

Attach to the counter

Caution

Fasten the hook bolts in the

order shown

Caution

Fasten the butterfly nut by hand

Do not use tools. Using tool may result in

overtighting and cause product damage

9

Apply Caulking

Apply caulk around the perimeter of the washbasin then wipe off excess. Allow to dry

for 30

minutes.

10

Drawing of finished model

Hook bolt

Washer

Butterfly nut

11

Connect spout connecting hose.

Cut the spout connecting hose to a proper

length that reaches controller water inlet

without being stretched.

Caution

●Be sure to cut the hose

carefully with a cutter, so the

surface is square.

●If the spout connecting hose is

too long, cut it to a proper

length.

Insert the spout connecting hose into

the controller water inlet.

Fix the hose with hose clamp.

● Check that the spout hose is

firmly inserted.

● Check that the spout hose is

not folded.

● Check that the hose clamp is located

at the right position.

● It is imperative to connect the spout

with hose clamp.

12

Fix the connector

Insert the vinyl cord (white) with connector

and make sure that you hear the click sound.

Cut the spout connecting hose

to a proper length.

Pay attention to the cut

section

Spout connecting

hose

Caution

Hose clamp shall be fixed right over

the controller water inlet

GOOD

90°

Spout connecting

hose

Be careful that the

hose is not folded

Hose clamp

Controller water inlet

Hose clamp

NOT GOOD

Click!

Packing is located on the water

inlet bracket.

5

-2

Install the drain to the

Lavatory (Continued)

Lower the grid unit into the

drain assembly body

Turn the grid unit counterclockwise

while putting the Grid hook unit into the

cross bar.

To make sure that the Grid unit is properly

placed on cross-bar, pull it upward.

Caution

If you can pull it out, repeat

installation procedure.

If the Grid unit is hooked to cross-bar and cannot be

pulled out, then push in the grid unit firmly until you hear

a click.

Grid

unit

Grid

unit

Packing

Grid unit

Notch

Nut

Water inlet

Grid unit

Now check that the stud at

the bottom of the cap is

positioned with the slit

on the Lavatory.

Slit on the Lavatory.

Drain

assembly

Drain Assembly

body

Cross bar

Angle

Click!

Push until you

hear a click

Apply Plumber’s Putty

or Silicone caulking

(around the lavatory waste outlet)

6

Apply packing material. Make sure surface is free of dirt

and dust.

・ Peel off the lining of the packing material, then stick the packing material to the

bottom of the lavatory.

Packing material

(large)

Packing material

(small)

Caution

● Apply the small packing material

to the rear part of the lavatory,

be sure there is no clearance

between the large and small

packing material.

Packing material (small)

● Appply the packing material so that

it match with the inner edge of the

lavatory.

Packing material

(small)

Match here

Caulking

Check the following

13

Install the controller cover

After confirming the controller is securely

attached and confirming the controller is

firmly mounted, install the controller cover.

Cover

14

Insert the power plug

Insert the power plug in the wall

outlet.

Power plug

Function Test

1.Checking after installation

Perform the follow checks after installation .

1) Check for water leakage

Open the stop valve and check for water leakage.

2) Operation

<Check the body dectection sensor>

●

Insert the power plug to the AC outlet. Then, walk to the

lavatory counter and when you are approximately 15-3/4”

.

(400mm) away from the counter, the LED light is ON.

<Check the hand washing sensor>

●Place your hands under the faucet, water begins to flow.

●Water will automatically stop in 1-2 sec later after your hand s are removed.

For safety and conservation reasons, water will stop

●

automatically after 60s of detection each use.

< Check the switches>

●Water flows when Start/Stop switch is pressed.

●To stop the water flowing, press the switch again.

●It will stop automatically after 50 seconds if switch is left ON.

●When hot/cold switch is pressed, LED switch turns red. Water r eaches its

optimal temperature

●Temperature will restore by pressing it again; LED turns back to blue .

If the product does not operate properly, contact TOTO or your plumbing contractor .

About 15-3/4”

(400mm)

Hot/cold

switch

Start/Stop

switch

senser cord

2. Temperature Adjustment

The water temperature has been factory set to 97°F

(36˚C).

Depending on the water supply pressure or other

site conditions, water temperature may not be

Temperature

control

handle

kept as specified. At this time, use the handle to

adjust the temperature.

Caution

If water temperature goes opposite direction,confirm if the

hot and cold water connection is correct.

3. Cleaning of the strainer

Close the stop valve with hand.

Use the open/close tool to remove the strainer cover.

- Clean the strainer regularly after installation.

If the strainer is blocked, the flow becomes weak,

and the product will not function properly.

Open/close tool

4. Adjustment of flow rate

The flow controller regulates flow rate to 1.7 gpm

(6.5L/min) and there is no need to adjust the flow rate.

Use the product with the stop valve fully opened.

But when water flow is too strong, adjust the flow rate

by turning the stop valve clockwise.

The water appears cascade with water

flow rate of more than 1.45 gpm (5.5 L/min).

The Instruction Manual attached to the delivery must be

provided to the customer.

Open

Hot

Cold

Strainer

Strainer cover

Close

Stop valve

Loading...

Loading...