Toto EcoPower TET1GN(32)#CP, EcoPower TEU1GN(12)#CP, EcoPower TEU1LN(22)#CP, EcoPower TET6GN(32)#CP, EcoPower TEU1LN(12)#CP Installation Manual

...Page 1

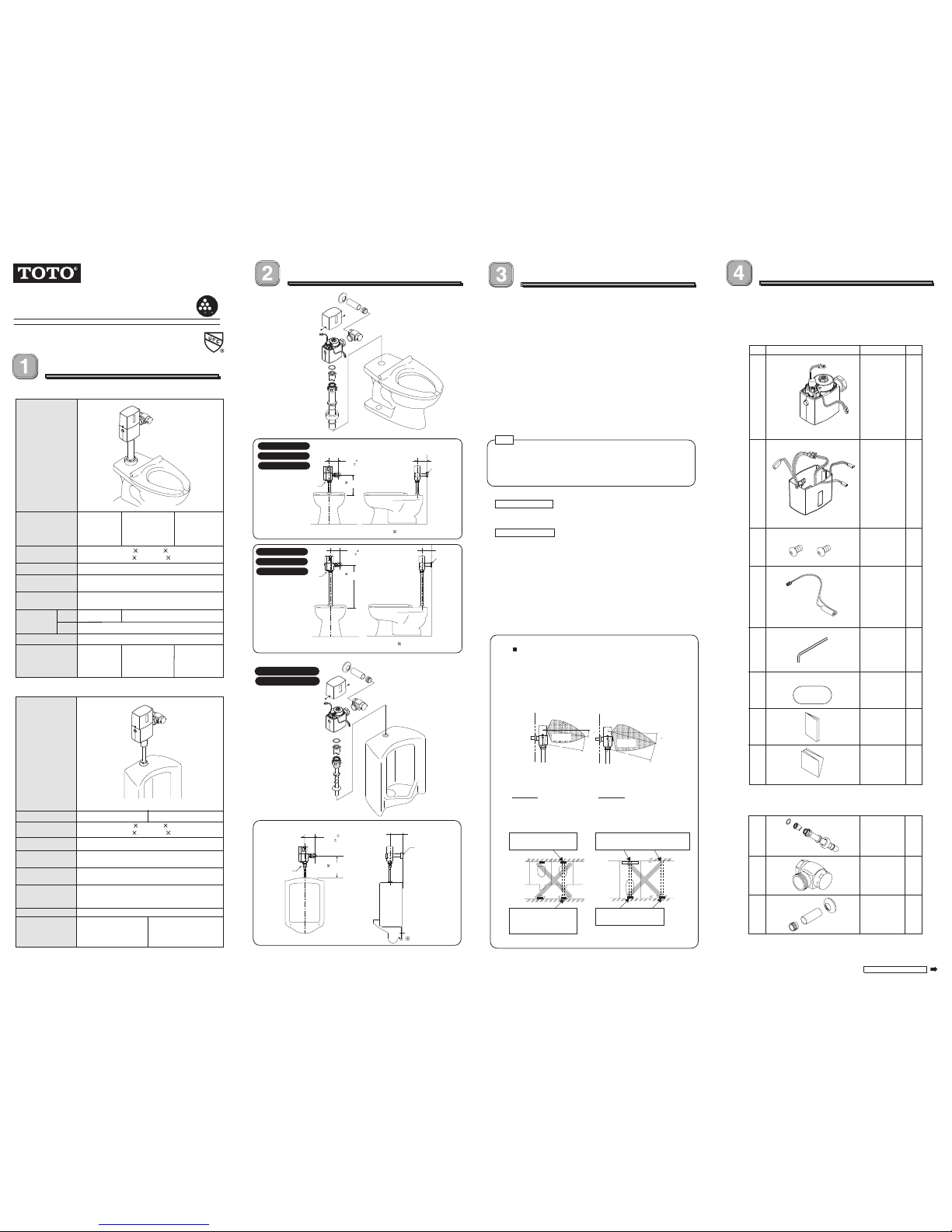

Variation & Specification

INSTALLATION MANUAL

Set-up Drawing

Model number

Figure

Approx. 1.6

gallon (6L)

Approx. 3.5

gallon (13L)

c

Connection of the

water supply pipe

Supply water

pressure

Shutoff pressure

Discharge quantity

per flush at 28 PSI

(196kPa)

(Factory set)

7 PSI (48kPa)

1"NPT

Model number

Detection time

Urinal Flush Valve

6 seconds or more

Detection time

6 seconds or more

Approx. 1.0 gallon

(3.8L)

Ambient temperature

Connection of the

water supply pipe

Supply water

pressure

Shutoff pressure

Discharge quantity

per flush at 28 PSI

(196kPa)

(Factory set)

Minimum required water pressure: 15 PSI (103kPa)

(flowing)

Maximum water pressure: 125 PSI (862kPa)

7 PSI (48kPa)

32-104˚F (0-40˚C)

Water temperature 34-104˚F (1-40˚C)

3/4"NPT

Check local codes

TET1GN32#CP

Installation Precautions

Toilet Flush Valve

1. Prior to Installation

Prior to Installing your TOTO®`s E coPower®Flush Val ve, install the items

listed bellow:

· Closet fixture/Urinal fixture

· Drain line

· Water supply line

The supply piping to these devices shall be securely anchored to the

building structure to prevent the installed device from having unnecessary

movement when operated by the user. Care shall be exercised when

installing the device to prevent marring the exposed surface.

2. Important

All plumbing is to be installed in accordance with applicable codes

and regulations. Water supply lines must be sized to provide an

adequate volume of water for each fixture.

Flush all waterlines prior to operation.

The minimum pressure required to the valve is determined by the type

of fixture selected. Consult fixture manufacturer for pressure requirement.

Do not use toothed tools to install or service the valve.

Be sure to install TOTO®`s EcoPower®Flush Valve so that the control stop

is sit uated no more tha n 11- 1/2"(292 mm) above the top of the bowl or

the urinal. Referto local codes for special requirements.Except for

TET6GN#CP,

TEW6GN#CP and TET6LN#CP

, make sure that the control

stop is installed 27" adove the

top of the bowl for proper valve function.

3. Use carenot to damagethe surface ofthe infrared sensor.

4. For ToiletFlush Valve

The toilet sensor valve may not function if toilet seat and/or lid cover are

left upright as it may block the sensor.

5. For Urinal Flush Valve

The Urinal Flush Valve is designed to be used with a washout urinal

for optimum performance. However, a siph on jet uri nal may als o be

substitu ted. B lowout urinals are not recommended.

6. The detectionrange of the infrared sensoris shown in the figureabove.

Do not install a handrail or any other object within the detection zone

of the sensor, as any object blocking the sensor may cause the valve to

malfunction. Additionally, to avoid the possibility of valve malfunction, do not

install the flu sh valv e in a locatio n where the se nsor f aces a mi rror,

stainless steel wall, other highly reflective surface or another infrared sensor.

Tobe continued on the back

Figure

Note

Components

1. Required tools

Adjustabl e wrench, Phil lips and slott ed screwdriver s.

2. Inspection

Unpack the flush valve and carefully make sure the co ver, main unit and

all other parts are i ncluded a nd intact before starting installation of the

product.

Item Figure Description Q’ty

A

Valve Body

assembly

1

B

Top cover

assembly

1

C

D

Screw 2

F

Back-up

battery Pack

1

G

Tool

(Allen wrench)

1

H

Notice Label

1

Owner's

Manual

1

1

Toilet Flush Valve

For TET1GN32#CP, TEW1GN32#CP, TET6GN32#CP,

I

Vacuum

breaker tube

(with spud

joint)

1

J Control stop

1

K

Sweat

solder kit

(Escutcheon,

covering tube,

adapter)

1

E

T

O

T

O

Forthe best results, be sure to read the following installation instructions and use the product only as described in this manual.

Ambient temperature

32-104˚F (0-40˚C)

Water temperature 34-104˚F (1-40˚C)

Dimension of Cover

7-3/4" (H) 4-1/2"(W) 3-1/8"(D)

(198mm(H) 115mm(W) 80mm(D))

Dimension of Cover

7-3/4" (H) 4-1/2"(W) 3-1/8"(D)

(198mm(H) 115mm(W) 80mm(D))

Installation

Manual

(this manual)

03585T3R

11-1/2"

(292mm)

1-1/2"

NPSM

Min.2-1/4"(57mm)

3/4"NPT

inlet supply

EcoPower®Flush Valve

4-3/4" 1/2"

(120 13mm)

4-3/4" 1/2"

(120 13mm)

Min.2-1/4"

(57mm)

1"NPT

inletsupply

11-1/2"

(292mm)

Check local codes

1-1/2"

NPSM

4-3/4" 1/2"

(120 13mm)

Min.2-1/4"

(57mm)

1"NPT

inletsupply

27"

(686mm)

Check local codes

1-1/2"

NPSM

Detection zone

The detection zone is self-adjusting and is equipped with a

3-second flush delay. (No flush delay for Urinal flush valve)

The detection zone may differ according to the color of the

user’s clothes.

When a user wears black clothes, the detection zone may

become smaller and the valve may not flush.

“AVOID”

DO NOT place the Infrared

stainless steel wall, or other

highly reflective surface.

Mirror, Stainless steel wall or

other highly reflective surface.

Infrared sensor of the

another automatic

flush valve.

Infrared sensor of the

automatic flush valve.

“AVOID”

DO NOT place the Infrared

sensor of one urinal so that sensor in front of a mirror,

it is in line with the sensor

of another automatic f lush

valve sensor.

Infrared sensor of the

automatic flush valve.

L

Max19-11/16"

(Max500 mm)

Max31-1/2"

(Max800 mm)

15

L

Max21-1/4"

(Max550 mm)

Max33-1/2"

(Max850 mm)

20

TET1LN(32)#CP

TET6LN(32)#CP

TEU1GN(12,22)#CP

TET1GN(32)#CP

TET6GN(32)#CP

TEU1LN(12,22)#CP

TEW1GN(32)#CP

TEW6GN(32)#CP

Approx. 1.28

gallon (4.8L)

Approx. 0.5 gallon

(1.9L)

Minimum

(Flowing)

Maximum

15 PSI (103kPa)

125 PSI (862kPa)

35 PSI (241kPa)

TET6GN(32)#CP

TEW6GN(32)#CP

TET1LN(32)#CP

TEU1LN(12,22)#CP

TET1GN(32)#CP

TEU1GN(12,22)#CP

TEW1GN(32)#CP

TEW1LN(32)#CP

TEW1GN32#CP

TET1LN32#CP

TET6GN32#CP

TEW6GN32#CP

TET6LN32#CP

TEU1GN(12,22)#CP

TEU1LN(12,22)#CP

TEW6GN32#CP, TEU1GN(12, 22)#CP, TET1LN32#CP,

TET6LN32#CP AND TEU1LN(12, 22) #CP

Page 2

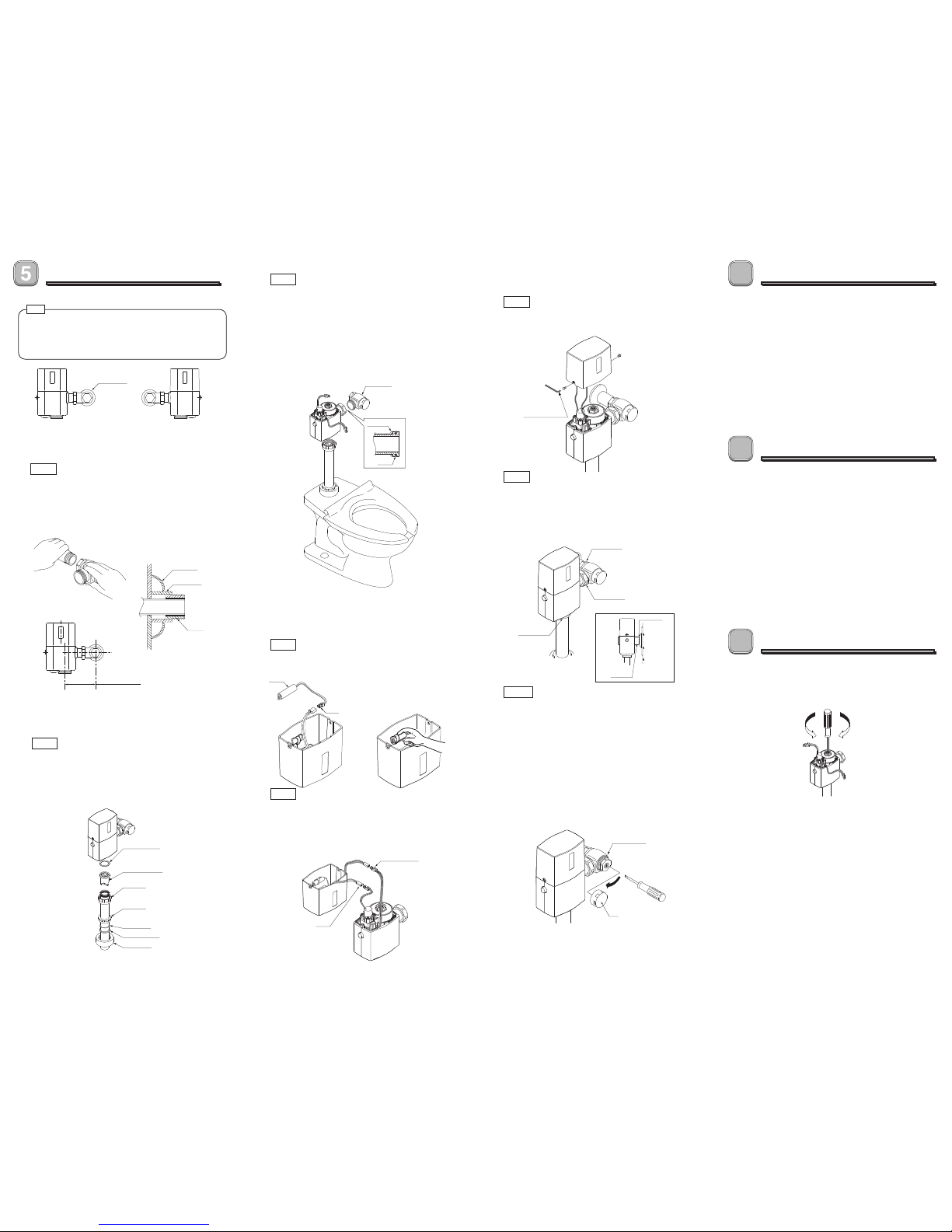

Installation Procedure Test Run

Note to the installer

7

6

Adjustment

Step 1 (For New Installation)

Escutcheon

White

White(Toilet type)

Yellow(Urinal type)

Yellow

Battery

Covering tube

Control Stop

Adapter

Min.4-1/4"(107mm)

Max.5-1/4"(133mm)

Install the control stop using a proper size escutcheon and

1. For left water supply, attach the sensor top cover in the

opposite direction so that the sensor will be at the front.

2. For retrofit installation, remove the old flush valve after

shutting off the control stop.

swea t sol der a dapter kit if applica ble. Thread seali ng

compounds should be used on male NPT threads only. The

distance from center of the control stop to center of the flush

valve should fall within 4-1/4" to 5-1/4"(107mm to 133mm).

Step 2

Determine the length of vacuum breaker tube to join the

flush valve and fixture spud. Cut the vacuum breaker tube,

if r equired, to the prope r length. Assemble t he spud nut

assembly to the fixture spud. Hand tighten spud nut to

fixture.

For sweat solder

Right Water Supply Left Water Supply

Step 5

Connect the connectors of solenoid valve

and generator with those of controller.

Step 3

Prior to inserting the flush valve tailpiece into the control stop,

be certain that the O-ring is in the groove at the end of the

tailpiece, the locking nut and the snap ring are located as

shown. Connect the flush valve with the control stop and the

vacuum breaker tube. Care should be taken not to damage the

O-ring when inserting the tailpiece into the control stop.

If lubrication is needed, wetting the O-ring with water will be

sufficient. Align the flush valve and securely tighten fixture spud

nut, vacuum breaker tube nut and locking nut with a wrench.

Step 4

Connect the connector of the battery with that of the controller

and set it at the proper position as shown below.

Step 6

Fas ten the senso r to p c over on body cov er w ith the

supplied screws (use supplied allen wrench).

Step 7

Before the s upply wat er is turned on, be sure all wa ter

leaks are eliminated by tightening all the pipe connections.

If for a ny rea son it becom es ne cessary to r emove the

control stop , be certain the water is shut off at the main

supply valve.

Pipe connection

Pipe connection

Pipe connection

Escutcheon

Joint tube

Cap

Step 8

The flush valves are preset for fixture volume as marked

on the valve carton. The valve does not require adjustment

for variati on in water pressure within its operating range.

To s et t he fl ush valve for prop er o perati on, open the

control stop completely by using the adjusting screw and

flush the flush valve several times. Gradually adjust the

control stop closed, using the adjusting screw, so that the

rate of water flow into the fixture is not excessive, yet is

sufficient to adequately evacuate the waste. The cap for

the co ntrol stop should be placed after final adjust ments

have been made.

Tighten the cap firmly with a wrench.

1. Make sure the control stop is open.

2. Sit on the toilet seat. (for Toilet flush valve)

Stand within two feet from the front of the flush valve.

(for Urinal flush valve)

3. Stay there for 6 seconds or more and then leave the

toilet seat or the urinal. The valve will automatically flush.

4. Press the manual flushing button and make sure the

valve flushes properly and the sensor red light is on for

2 seconds.

5. Recheck all the pipe connections for water leaks. If the

flush valve is not operati ng properly following t he test

run consult the Troubleshooting section of the Owner's

Manu al.

After the flush valv e uni t has been inst alled correct ly,

please explain to your customer how to use it and tell them

to observe the following instructions.

1. Do not put any object in fron t of the sensor window

wh ich c oul d obs tru ct th e se nso r, ca usin g it to

malfunction.

2. For troubleshooting, consult the Owner's Manual.

If you lack t he ne cessary skills requ ired o r hav e

diffi culty follow ing t he d irection s fo r ins tallati on,

ma inte nan ce, re pai rs, tr oubl esh ooti ng or

adjustments, of the product, do not proceed without

he lp from a qu alif ied pe rso n t o a ssi st you in

performing any of these functions.

1. Adjustment of the discharge quantity

(1) Remove the sensor top cover.

(2) Adjust the discharge quantity by rotating the screw

on the piston valve.

2. Adjustment of the flow rate

Adjust the flow rate by turning the screw of the control

stop.

Turn the screw to the right to decrease the flow rate and

turn it to the left to increase.

3. Adjustment of the detection range

The detection range of the i nfrared sensor does not

need to be adjusted because it has been factory-preset.

Printed in September, 2007

8

Friction Washer

Vacuum Breaker

Tube Nut

Spud Nut

Slip Gasket

Rubber Gasket

Escutcheon

To increase To decrease

Control stop

Note

Control stop

Snap ring

O-ring

Supplied

Allen wrench

Loading...

Loading...