Page 1

Warranty Registration and Inquiry

For product warranty registration, TOTO U.S.A. Inc. recommends online warranty registration. Please visit our web site

http://www.totousa.com.If you have questions regarding warranty policy or coverage, please contact TOTO U.S.A. Inc.,

Customer Service Department, 1155 Southern Road, Morrow, GA 30260 (888) 295-8134 or (678) 466-1300 when calling

from outside of U.S.A.

Installation and Owner’s Manual

Manual de Instrucciones y del Propietario

Manuel d’Installation et d’Utilisation

Manual de Instalação e do Proprietário

EcoPower® Automatic Faucets

Grifos Automáticos EcoPower®

Robinets Automatiques EcoPower®

Torneiras e Misturadores Eletrônicos Self Power

Page 2

2

TABLE OF CONTENTS

THANK YOU FOR CHOOSING TOTO!

The mission of TOTO is to provide the world with healthy, hygienic and more comfortable

lifestyles. We design every product with the balance of form and function as a guiding

principle. Congratulations on your choice.

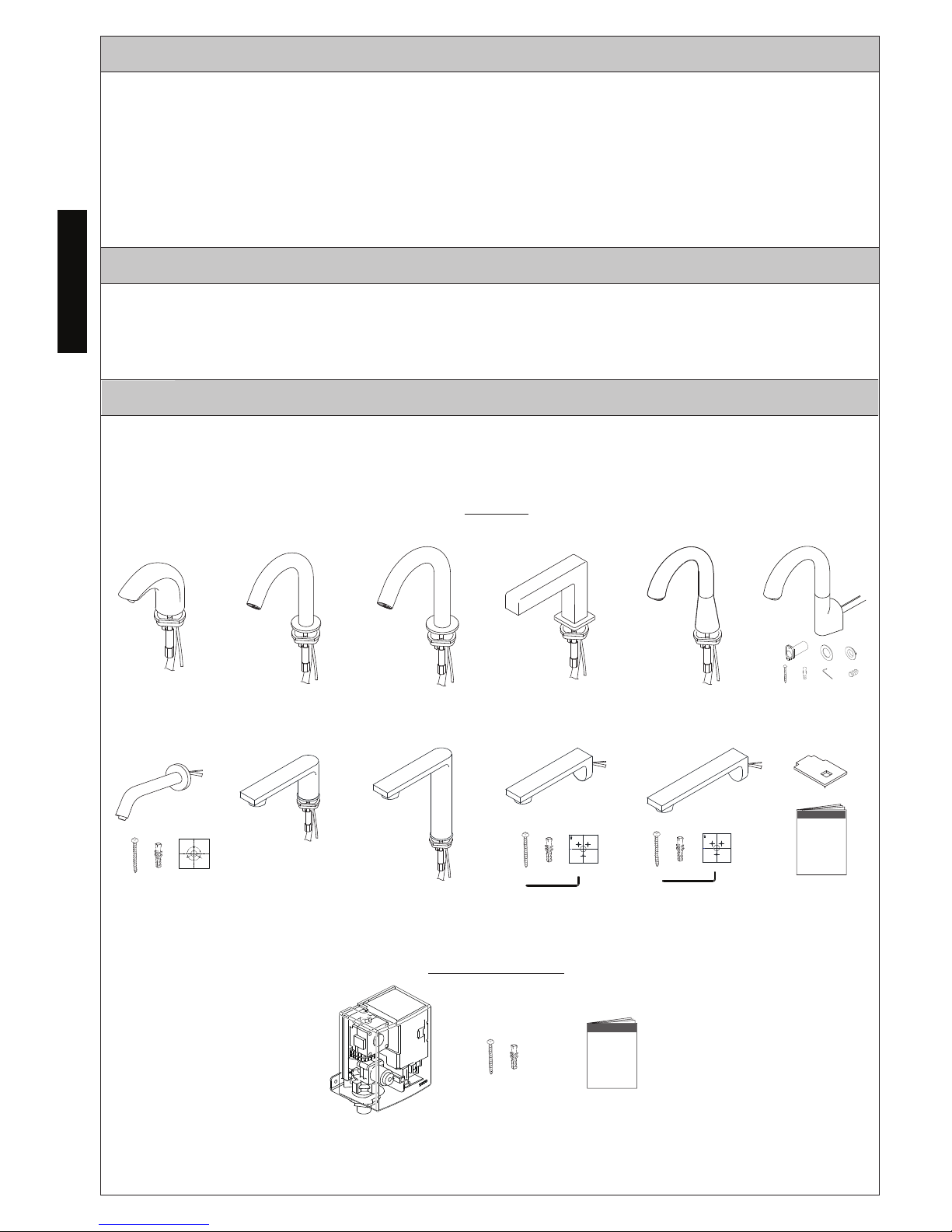

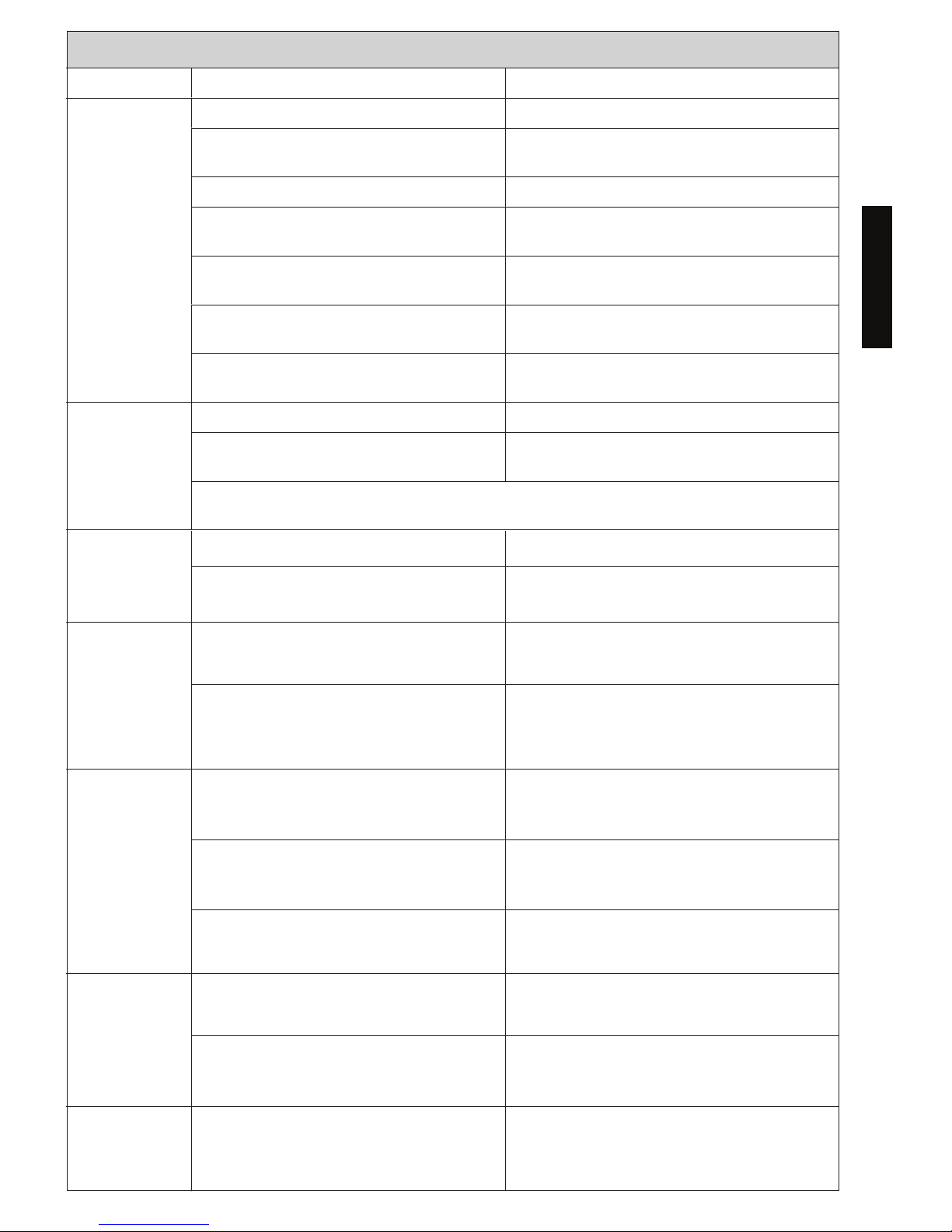

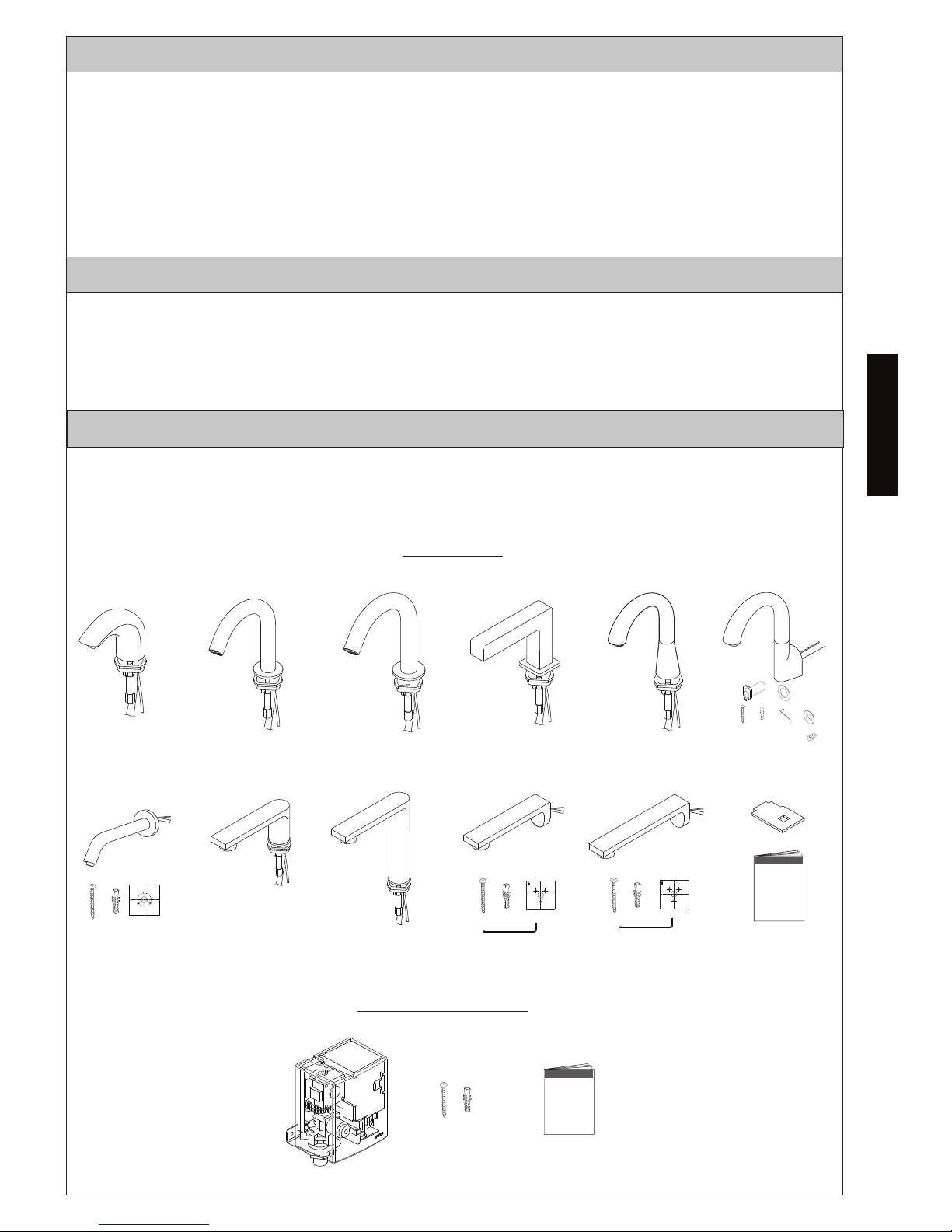

INCLUDED PARTS

Check to make sure you have all these parts from the package*:

(Appearance of some components may vary depending on the model)

SPOUT

CONTROLLER

STD

TELS10*

Gooseneck-Wall

Helix-Wall

TELS13*

Helix

TELS11* TELS16*

Helix-M

TELS12*

Axiom

TELS14*

Gooseneck

TELS15*

UP

UP

Libella Libella-M Libella Wall Libella-M Wall

TELS1C* TELS1D* TELS1A* TELS1B*

ENGLISH

Thanks for Choosing TOTO!

.................... 2

Included Parts .............................................. 2

Warnings .................................................... 3

Before Installation .....................................

3

Initializing the EcoPower Product .............

3

........................................

..............................

Care & Cleaning

Periodic Maintenance

7

Specifcations ...............................................

9

Troubleshooting .........................................

9

Warranty .....................................................10

Rough-In Dimensions ................................38

7

Installation Procedures .............................. 4

Page 3

3

ENGLISH

BEFORE INSTALLATION

Observe all local and plumbing codes.

Check the cold and/or hot water supply pressure.

The recommended working pressure range is 20 psi - 80 psi (138 kPa - 551 kPa).

If the supply pressure is higher than 80 psi (551 kPa), reduce to within recommended

range by using a pressure reducing valve (sold separatery).

Check the temperature of the water supply.

The recommended supply temperature range is 39°F - 104°F (4°C - 40°C)

Never use steam as a hot water supply.

Flush all water lines prior to installation.

Other precautions before you begin:

Pay special attention so that the sensor surface is not flawed or scratched during the

installation process.

Make sure that all pipework, stop valves, and connection lines are installed according

to local codes.

Do not place other devices that use an inverter or infrared sensor near the faucet,

as this may cause the faucet to malfunction.

Water pressures over 80 psi are not recommended for most plumbing fixtures. Check your

local plumbing code for details.

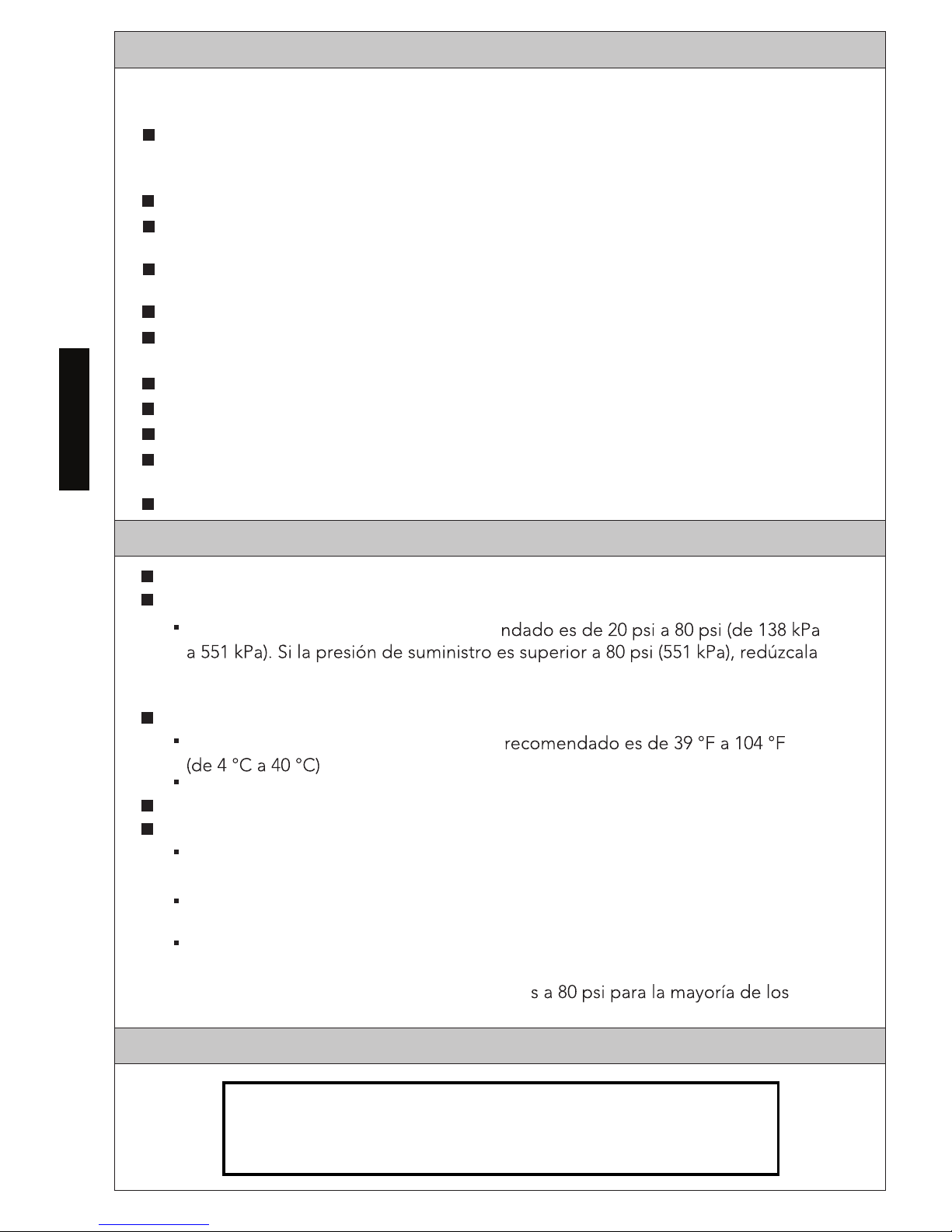

WARNINGS

Please read and adhere to the following notes. Failure to do so could result in personal

injury and/or property damage.

No person other than a service engineer should disassemble, repair or modify this faucet,

unless it is specifically described in this manual. Failure to do so may result in electric

shock or product malfunction.

Only set your faucet to the temperatures allowed in your local codes.

Do not use this faucet in a humid location where running water or condensation may

collect on the surface, especially in a sauna or steam room.

Do not strike or kick the faucet or controller box, as this may damage the unit or cause a leak.

Do not touch the hot surface of the stop valve of the controller, as it may be very hot.

Disconnect the backup battery connector when the faucet is not in use for a long period of time.

Always close the stop valve(s) before cleaning the strainer.

Periodically check the piping for leaks.

If the room temperature drops to freezing, wrap the pipes with insulation.

Make sure the power cord does not come in contact with the hot water supply pipe.

Avoid placing any objects within the detection range of the infrared sensor.

INITIALIZING THE ECOPOWER PRODUCT

Please note that it will take at least 5 minutes

after connecting the battery for the electronics to initialize.

This delay is a normal part of start up.

(Refer to Page 6 for more information)

Page 4

NOTE: Before installing the product, be sure to thoroughly flush the supply pipes of dirt and

debris. Shut off the water supply at the stop valves after flushing.

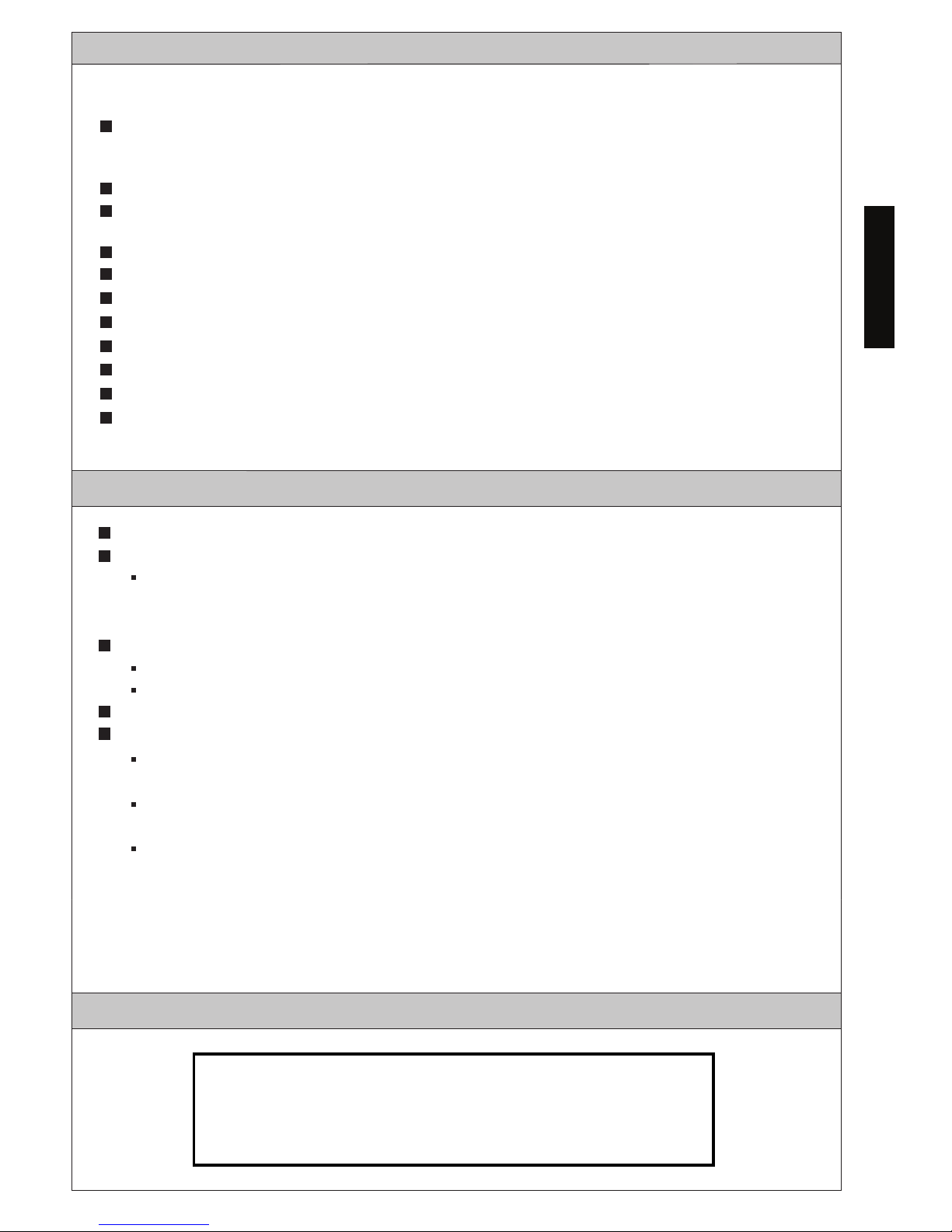

Install the Controller

4

ENGLISH

INSTALLATION PROCEDURE

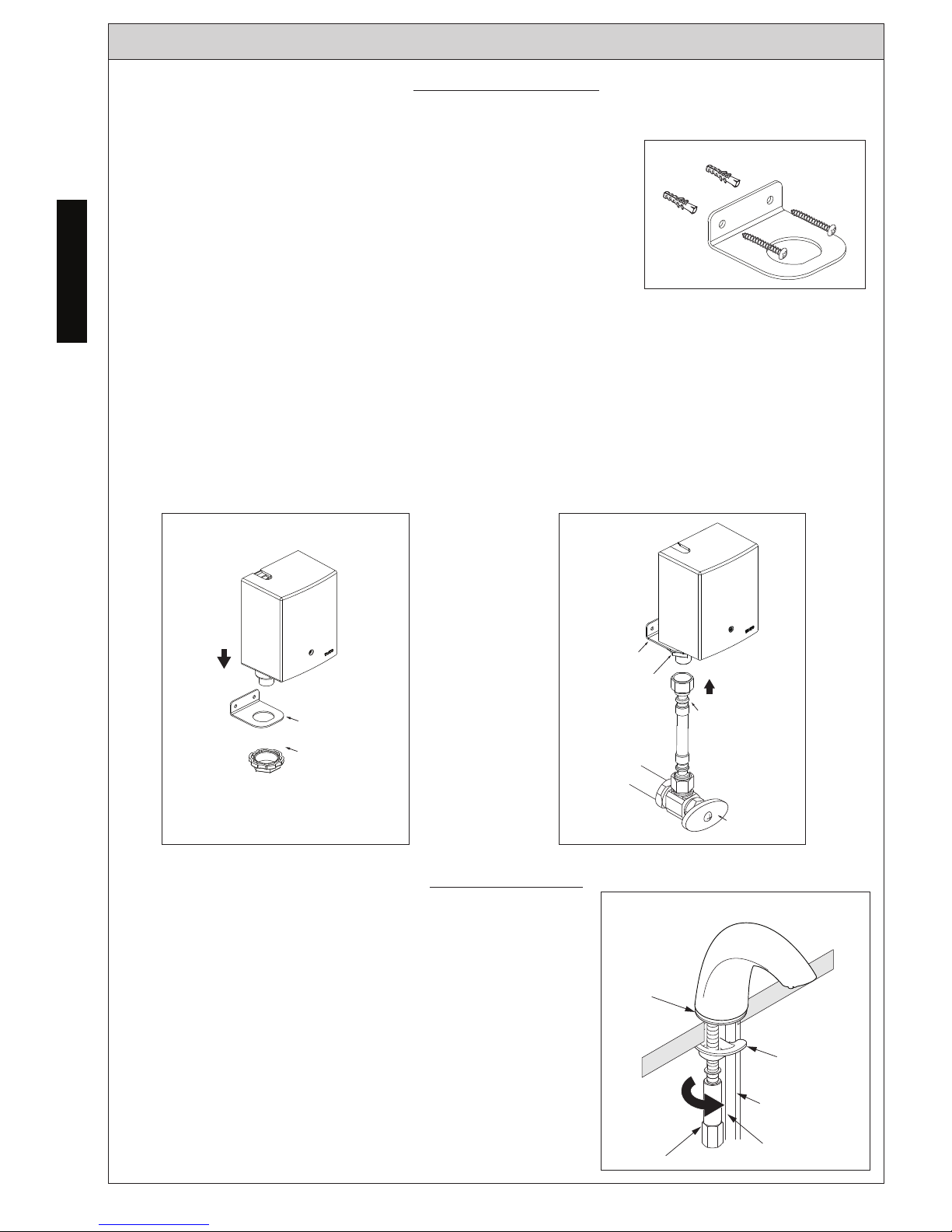

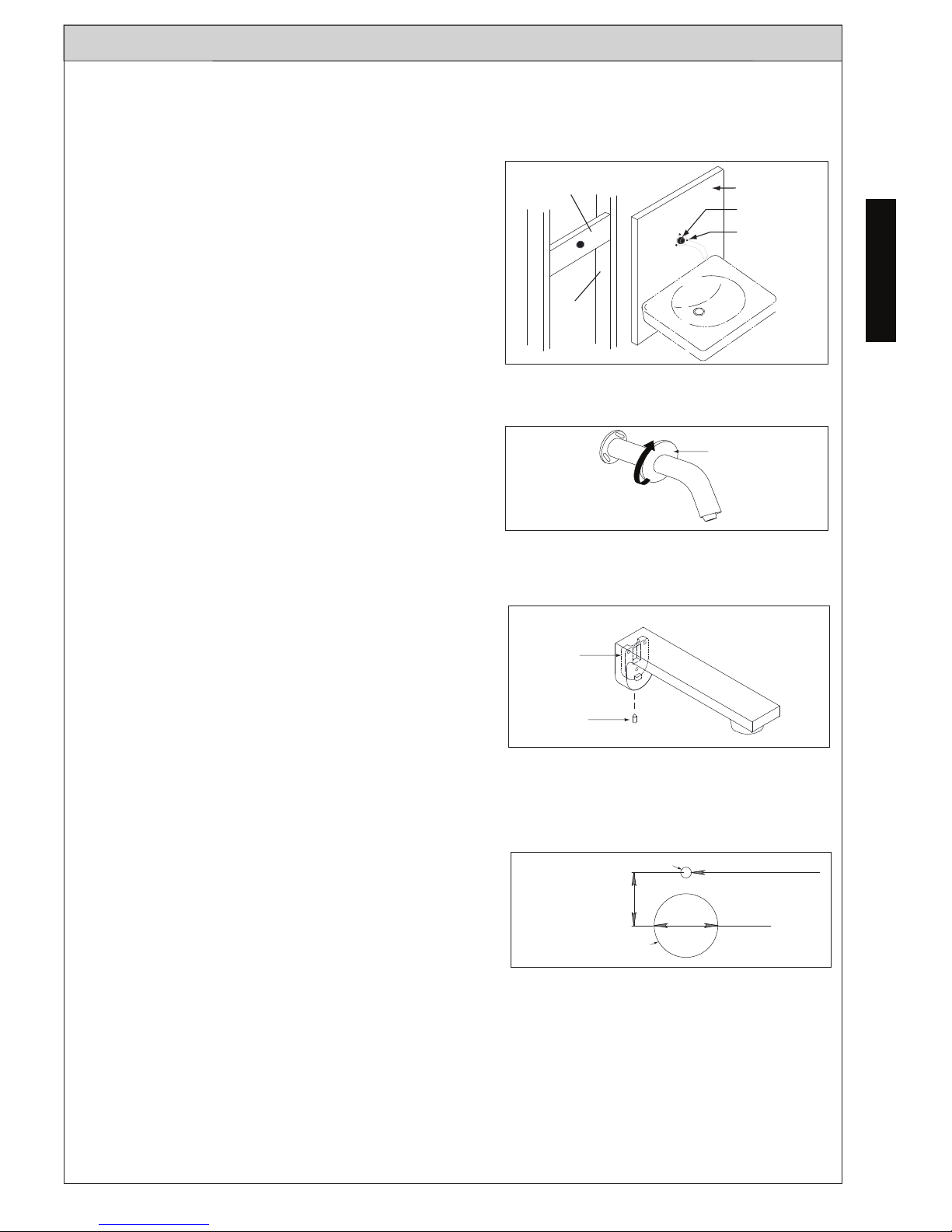

To Install Deck-Mounted Models (ill. 4):

Secure the spout to the countertop with the included

bracket and hexagonal nut. Make sure that the spout

is mounted with the tip directed towards the center

of the basin.

Install the Spout

SPOUT

ill. 4

NOTE:

If using a thermostatic valve (sold separately), please refer to its installation manual for

details.

ill. 2

ill. 3

Nut

Spout connecting

hose

Sensor cord

Gasket

Mounting Bracket

Mount Bracket

Nut

ill.1

Supply Hose

Mount Bracket

Nut

Stop valve

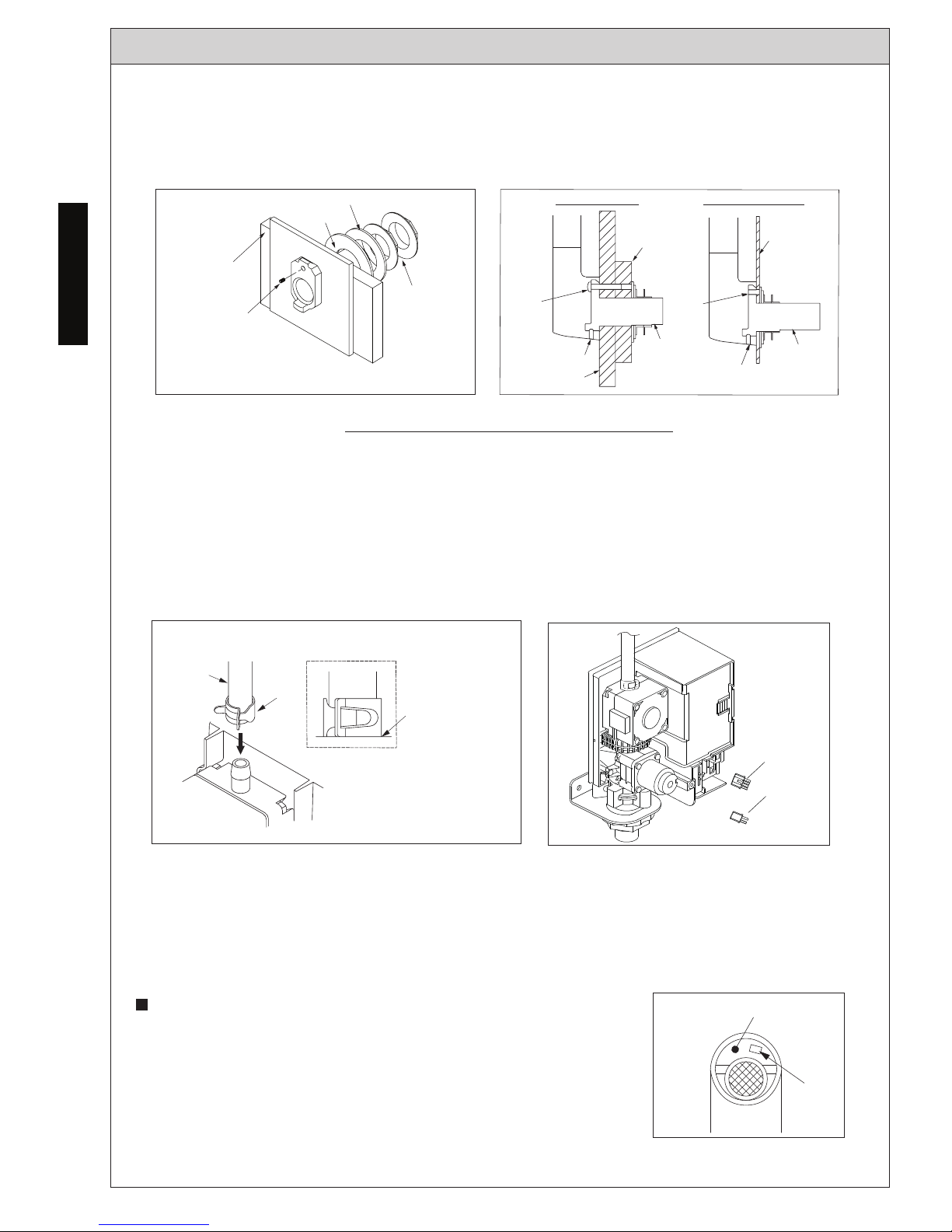

1. See the rough-in dimension page to determine the proper

location for the controller.

2. Remove the screws on the front of the controller cover and pull

to remove.

3. Mount the bracket on the wall. If necessary, use wall anchors

(see ill. 1).

4. From the top, place controller into the hole in the bracket.

From below the bracket, fasten the large nut to secure the controller (see ill. 2).

IMPORTANT!

Be sure to install controller in the correct orientation as shown. Otherwise, product will

not function properly.

5. Connect the water supply line to the inlet adapter (see ill. 3).

Page 5

To Install Helix and Libella Wall-Mounted Models (ill. 5):

NOTE: The addition of a 2 x 4” stringer behind the spout installation location is highly

recommended.

2 x 4

Stringer

2 x 4

Studs

Finished Wall

5/8” Hole for

spout

Holes for screws/

anchors

ill. 5

3. Feed the supply tube and sensor cord through

the 5/8" (16 mm) hole in center.

Place spout against wall and fasten securely with

the provided screws.

t until ekcarb eht ot noehctucse eht netsaF .4

hand-tight.

ill.6

Escutcheon

5

ENGLISH

INSTALLATION PROCEDURE

To Install Gooseneck Wall-Mounted Models (ill. 8, 9 & 10):

noitacol derised eht ta eloh )mm 92( ”8/1-1 a llirD .1

for the mounting bracket. Place the mounting

bracket

through a hole in the wall with the set

screw hole located at 12 o’clock. Mark the

location of the set screw hole on the wall and

remove the mounting bracket.

For sheet metal surface: Drill a 3/16” (5 mm) hole at the marked location.

For

a drywall/hollow wall surface: Drill a 1/4” (6.5 mm)

hole at the marked location, and install

the included wall anchors.

ill.7

Ø 1-1/8"

15/16"

Ø 3/16” (sheet metal surface)

Ø 1/4” (drywall/hollow wall)

ill. 8

Hole for set screw/machine

screw and wall

anchor

Hole for mounting bracket

To Install Helix Wall-Mounted Models (ill. 6):

3.

Place mounting bracket against wall and fasten

securely with the provided screws.

4. Pass the hose and sensor cord through the

mounting bracket, slide the spout base over the

mounting bracket and tighten the set screw to

secure the spout to the mounting bracket.

Mounting

Bracket

Set Screw

1. Place mounting template on wall at desired

location and mark all holes. Drill a 5/8" (16 mm)

diameter hole at the spout mounting location

(center) for the supply tube and sensor cord to

pass through.

2. For fastening to wood , drill three (3) pilot holes

7/64” (2.7 mm) in diameter at marked locations.

To Install Libella Wall-Mounted Models (ill. 7):

NOTE: Confirmation of wall strength is highly recommended before drilling.

For fastening to drywall or tile, drill three (3) holes

3/16” (5 mm) in diameter and insert anchors until

flush. Tap lightly with a hammer if needed.

NOTE: The addition of a 1 x 6” or plywood bracing behind the mounting location is highly

recommended for drywall/hollow wall installations. The overall maximum wall

thickness is 2” (50 mm).

NOTE: Drill bits (not supplied) for hard materials may be required.

Page 6

2. Install the mounting bracket using the rubber washer, brass washer, and both brass nuts

on back side of the installation surface. Install the included set screw (for sheet metal

installation) or 30 mm machine screw (for drywall installations).

3.

Pass the hose and sensor cord through the mounting bracket, slide the spout base over the

mounting bracket and tighten the set screw to

secure the spout to the mounting bracket.

Set Screw

(Sheet metal) or

Machine Screw

(Drywall/ Hollow

Wall)

Rubber Washer

Brass Washer

Nuts (2)

ill. 9

Plywood

(not required for sheet

metal installation)

M5x30

Machine

Screw

and

Wall

Anchor

ill. 10

Set Screw

Mounting

Bracket

M5 Set

Screw

1x6 or Plywood

Bracing

Set Screw

Sheetmetal InstallationDrywall Installation

Mounting

Bracket

Thin Wall

(Sheet

Metal

Surface)

Drywall

6

ENGLISH

INSTALLATION PROCEDURE

1.

If the spout connecting hose is too long, cut it to the appropriate length, making sure the

end is square.

2.

Push the spout connecting hose onto the outlet barb of the controller and secure it with

the hose clamp (see ill. 1). Make sure that the hose clamp is placed fully against the

controller.

NOTE: If you need to remove the hose, use

a flathead screwdriver to carefully pry

the hose from the barb.

3.

Connect the backup battery connector to the controller. It will take at least 5 minutes after

connecting the battery for the electronics to initalize. This is a normal part of startup.

Make sure there are no obstructions

between the sensor and the basin, then connect

the spout sensor connector to the

controller. (see ill. 2)

IMPORTANT!

The faucet will begin an automatic sensing range adjustment immediately after the

sensor connector is plugged into the controller. Do not place your hands or other

objects in front of the sensor.This process may take up to 20 seconds to complete.

If the sensor light continues to flash for more than 20

seconds, the spout direction will need to be readjusted

for proper operation. If adjustment is necessary, you

must do it within 10 minutes of the adjustment process

will end. To restart the process, unplug the sensor

connector for 10 seconds, then reconnect it (see ill. 3)

4. Double-check all connections, then reinstall the controller cover, securing it wit eht h

WARNING: Draw the sensor cord from the bottom of the controller while installing the

controller cover to ensure that the cord is not pinched.

Connect the Spout to the Controller

Hose

Clamp

Clamp fush

with

controller

ill. 1

Spout

Connecting

Hose

ill. 3

Sensor

Light

Sensor

ill. 2

Sensor

Connector

Battery

Connector

screws.

Page 7

7

ENGLISH

INSTALLATION PROCEDURE

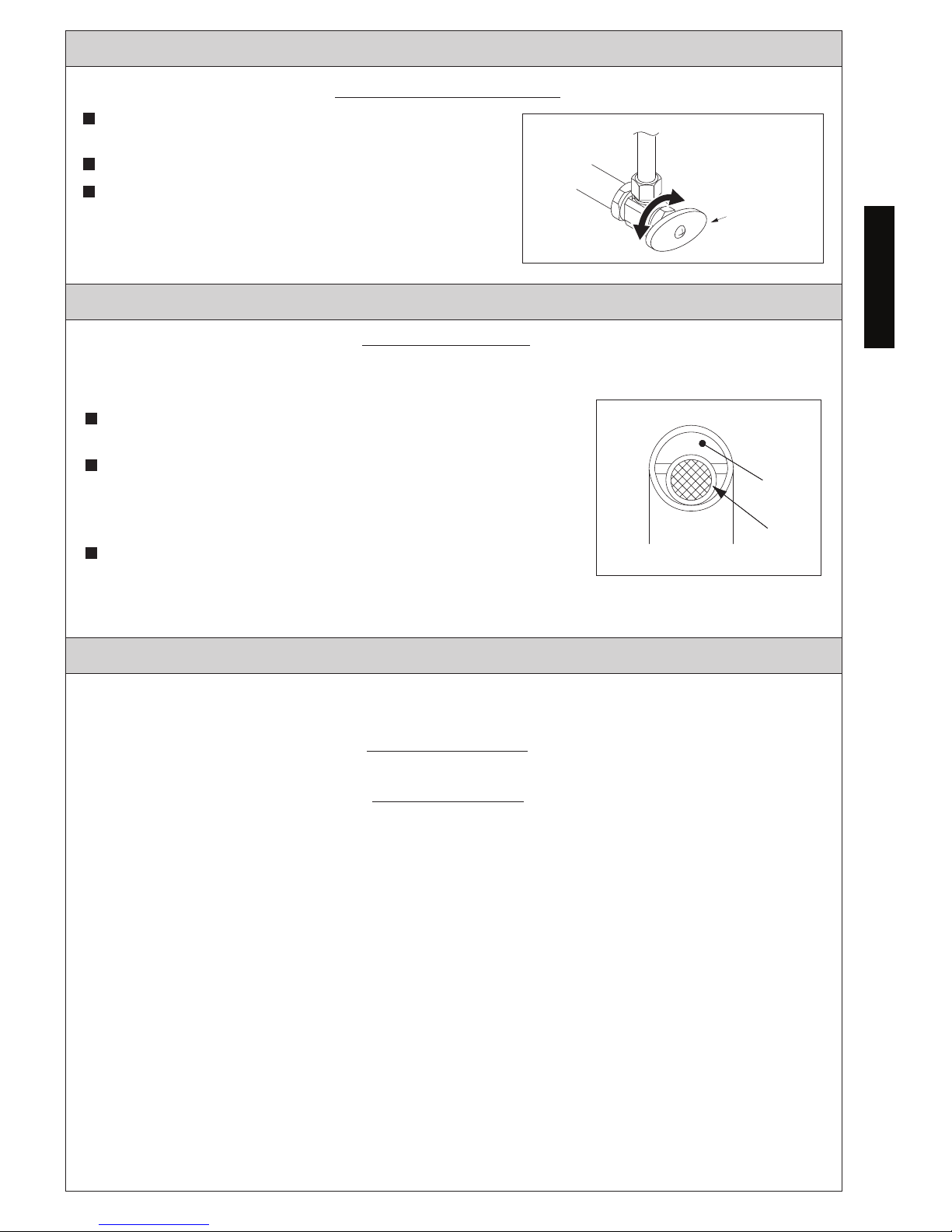

Testing After Installation

Open

Close

Stop Valve

ill. 1

dna sevlav pots eht ta ylppus retaw eht no nruT

inspect all the connections for any leaks (see ill. 1).

Place hand under the sensor to activate.

For 10 sec model: water will stop after 10 seconds

while your hand is under the sensor.

Water will stop when you remove your hand.

CARE & CLEANING

PERIODIC MAINTENANCE

gninaelc nehw Do not scratch the sensor IMPORTANT!

the spout (see ill. 2).

Avoid using any cleaning materials that may scratc eht h

spout surface.

Never use polishing powder, detergent that include s

coarse particles, thinners, benzene, acids, alkaline

detergents, or nylon scrub brushes, as they can damage

the surface of the spout.

To safely clean the surface, wipe it using a dampene tfos d

cloth with diluted dishwashing detergent and dry it with

another soft cloth. If this does not adequately clean the

surface, wipe the area with a neutral detergent and wet cloth.

ill. 2

Sensor Area

Outlet

Check your faucet at least once a month for the following potential problems and to do the

following maintenance procedures:

Inspect for Leakage

Check all water connections for signs of leakage.

Tighten the Spout

If the spout is loose, tighten the hexagonal nut underneath the spout for deck-mounted

models.

To tighten the Helix Wall-Mounted Spout:

1. Unscrew the escutcheon, tighten the three screws securing the mounting bracket to the

wall.

2. Reinstall escutcheon.

To tighten the Gooseneck Wall-Mounted Spout

1. Turn off the water supply at the stop valves.

2. Disconnect the spout connecting hose and sensor connector

from the controller.

3. Remove the spout from the mounting bracket by removing the set screw on the bottom

of the spout base.

4. Tighten the set screw on the back of the spout, then reinstall the spout on the mounting

bracket.

5. As required, ensure the set screw on the mounting bracket and mounting nuts behind

the sink/wall (refer to “Install the Spout” section) are tight.

For 20 sec model: water will stop after 20 seconds.

Spout and Sensor

Page 8

8

ENGLISH

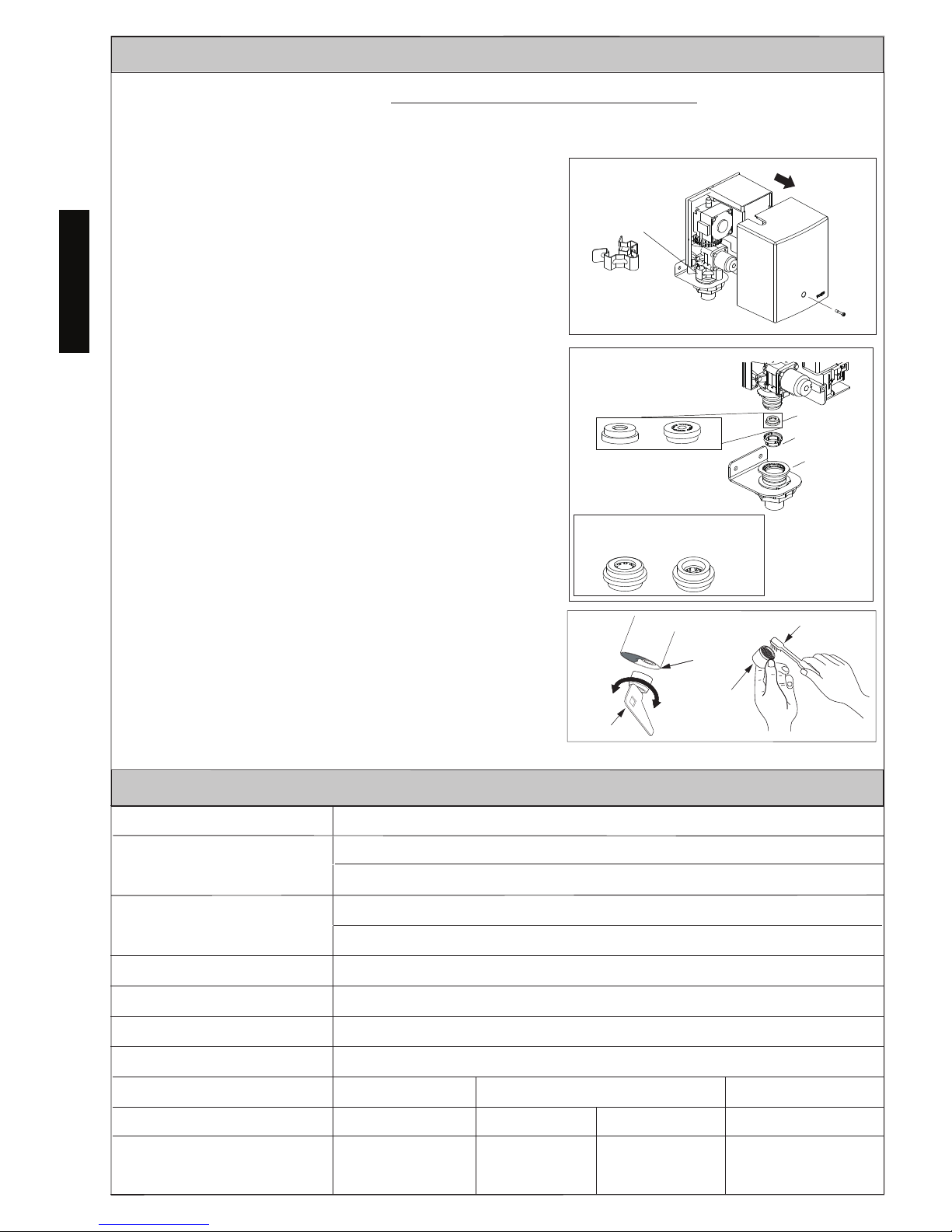

When the inlet screen is clogged, the flow rate will decrease. Decreased flow rate can

lead to insufficient power generation, which will deplete the backup battery prematurely.

Cleaning the screen (see ill. 1 & 2):

1. Turn the water off at the stop valves.

2. Remove controller cover and quick fastener.

3. Remove controller from hose adapter.

.hsurb a htiw ti naelc dna neercs evomeR .4

5. Reinstall the cleaned screen.

IMPORTANT!

If flow regulator (or flow regulator assembly

for TELC103-###E) falls out, reinstall it in the

correct orientation (O-ring side facing screen)

as shown. Otherwise, product will not

function properly.

6. Reinstall the controller into the hose adapter

until fully seated, and secure it with the

quick fastener.

7. Reinstall cover, securing it with the screws.

8. Open stop valves and check all connections.

Cleaning the nozzle (see ill. 3):

1. Remove the nozzle from the spout

with the supplied tool.

2. Clean the nozzle with a soft brush

to remove any dirt from the screen.

3. Re-install the nozzle in the spout.

Power supply

Hydropower Generation (self-powering power supply)

Sensor Detection Range

5-1/8”~ 7-7/8” (130 ~ 200mm)

Sensor is self-adjusting.

Water Supply Connection

Minimum : 15 psi (100 kPa) (Flowing)

Maximum : 80 psi (551 kPa)

Water Supply Pressure

G1/2 compatible with ½ NPSM

39 ~ 110°F (4 ~ 43.3°C)

Inlet Temperature range

Ambient Temperature

32 ~ 104°F (0 ~ 40°C)

Humidity

Max. 90% RH

0.09 gpc

(0.36 Lpc)

0.18 gpc

(0.67 Lpc)

0.19 gpc

(0.72 Lpc)

Flow Rate

Duration

10 seconds 20 seconds

SPECIFICATIONS

PERIODIC MAINTENANCE

Cleaning the Inlet Screen and Nozzle

Volume per cycle

1.0 gpm 0.5 gpm 0.35 gpm

10 seconds 20 seconds

0.11 gpc

(0.44 Lpc)

Open

Close

Spout

Nozzle

Key

ill. 3

Spout

Nozzle

Brush

ill. 1

Screen

Flow Regulator

Remove Quick Fastener

Hose Adapter

ill. 2

Flow regulator for TELC103-###E

models is assembled inside an adapter.

Install assembly with correct orientation.

Page 9

9

ENGLISH

Problem Cause Solution

Water won’t

begin run-

ning.

The surface of the sensor is dirty. Clean the surface of the sensor.

There is an obstruction in front of

the sensor.

Remove the obstruction.

The stop valve is turned off. Turn on the valve.

Backup battery connector is discon -

nected.

Connect the backup battery connector.

The power generator and sensor

connector is disconnected.

Securely attach the connector(s).

Water supply is suspended. Wait until the water supply is

restored.

The strainer or the regulating screen

is clogged.

Clean the strainer and the regulating

screen.

Water won’t

stop

running.

The surface of the sensor is dirty. Clean the surface of the sensor.

There is an obstruction in front of

the sensor.

Remove the obstruction.

If the water continues to run after attempting the above solutions, turn

off the stop valve.

Low flow

rate.

The stop valve is not fully opened. Open the stop valve fully.

The strainer or the regulating screen

is clogged.

Clean the strainer and the regulating

screen.

Water tem-

perature is

too high.

The temperature control handle is

set at “H”.

Set the temperature control

handle to the middle point.

The stop valve connected to the

cold-water supply is not fully

opened.

Open the cold-water stop valve fully.

Water tem-

perature is

too low.

The temperature control handle is

set at “C”.

Set the temperature control

handle to the middle point.

The stop valve connected to the hot

water supply is not fully opened.

Open the hot water stop valve fully.

The hot water supply temperature is

lower than 120°F.

Set the hot water supply temperature

to 120° F.

Water

tempera-

ture is not

controlled

properly.

One side of the stop valve is not

fully opened.

Open the stop valve fully.

The strainer or the regulating screen

is clogged.

Clean the strainer and the regulating

screen.

Short detec-

tion range.

The self-adjusting sensor may not

work properly when strained or

blocked by water droplets.

Clean the sensor surface.

TROUBLESHOOTING

Page 10

10

ENGLISH

WARRANTY

1. TOTO ® warrants its electronic flush valves, faucets and soap dispensers (“Product”) to be free from defects in

materials and workmanship during normal use when properly installed and serviced, for a period of three (3) years

from date of purchase. This limited warranty is extended only to the ORIGINAL PURCHASER of the Product and is

not transferable to any third party, including but not limited to any subsequent purchaser or owner of the Product.

This warranty applies only to TOTO Product purchased and installed in North, Central and South America.

2. TOTO’s obligations under this warranty are limited to repair, replacement or other appropriate adjustment, at

TOTO’s option, of the Product or parts found to be defective in normal use, provided that such Product was properly

sa snoitcepsni hcus ekam ot thgir eht sevreser OTOT .snoitcurtsni htiw ecnadrocca ni decivres dna desu ,dellatsni

ni strap ro robal rof egrahc ton lliw OTOT .tcefed eht fo esuac eht enimreted ot redro ni yrassecen eb yam

connection with warranty repairs or replacements. TOTO is not responsible for the cost of removal, return and/or

reinstallation of the Product.

4. In order for this limited warranty to be valid, proof of purchase is required. TOTO encourages warranty registration

upon purchase to create a record of Product ownership at http://www.se is required. TOTO encourages warranty

registration upon and failure to register will not diminish your limited warranty rights.

5. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE, PROVINCE TO PROVINCE OR COUNTRY TO COUNTRY.

6. To obtain warranty repair service under this warranty, you must take the Product or deliver it prepaid to a TOTO

service facility together with proof of purchase (original sales receipt) and a letter stating the problem, or contact

a TOTO distributor or products service contractor, or write directly to TOTO U.S.A., INC., 1155 Southern Road,

Morrow, GA 30260 (888) 295 8134 or (678) 466-1300, if outside the U.S.A. If, because of the size of the Product

or nature of the defect, the Product cannot be returned to TOTO, receipt by TOTO of written notice of the defect

esoohc yam OTOT ,esac hcus nI .yreviled etutitsnoc llahs )tpiecer selas lanigiro( esahcrup fo foorp htiw rehtegot

to repair the Product at the purchaser’s location or pay to transport the Product to a service facility.

THIS WRITTEN WARRANTY IS THE ONLY WARRANTY MADE BY TOTO. REPAIR, REPLACEMENT OR OTHER APPROPRIATE

ADJUSTMENT AS PROVIDED UNDER THIS WARRANTY SHALL BE THE EXCLUSIVE REMEDY AVAILABLE TO THE ORIGINAL

PURCHASER. TOTO SHALL NOT BE RESPONSIBLE FOR LOSS OF THE PRODUCT OR FOR OTHER INCIDENTAL, SPECIAL

OR CONSEQUENTIAL DAMAGES OR EXPENSES INCURRED BY THE ORIGINAL PURCHASER, OR FOR LABOR OR OTHER

COSTS DUE TO INSTALLATION OR REMOVAL, OR COSTS OF REPAIRS BY OTHERS, OR FOR ANY OTHER EXPENSE NOT

SPECIFICALLY STATED ABOVE. IN NO EVENT WILL TOTO’S RESPONSIBILITY EXCEED THE PURCHASE PRICE OF THE

PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTIES, INCLUDING THAT

OF MERCHANTABILITY OR FITNESS FOR USE OR FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, OR THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND EXCLUSION MAY NOT

APPLY TO YOU.

3. This warranty does not apply to the following items:

a. Damage or loss sustained in a natural calamity such as fire, earthquake, flood, thunder, electrical storm, etc.

b. Damage or loss resulting from any accident, unreasonable use, misuse, abuse, negligence, or improper

care, cleaning, or maintenance of the Product.

c. Damage or loss resulting from sediments or foreign matter contained in a liquid soap system.

ro/dna hsrah a ni tcudorP eht fo noitallatsni morf ro noitallatsni reporpmi morf gnitluser ssol ro egamaD .d

hazardous environment, or improper removal, repair or modification of the Product.

e. Damage or loss resulting from electrical surges or lightning strikes or other acts which are not the fault of

TOTO or which the Product is not specified to tolerate.

f. Damage or loss resulting from normal and customary wear and tear, such as gloss reduction, scratching or

fading over time due to use, cleaning practices or water or atmospheric conditions, including but not limited

to, the use of bleach, alkali, acid cleaners, dry (powder) cleaners or any other abrasive cleaners or the use

of metal or nylon scrubbers.

Page 11

11

L O Ñ A P S E

ÍNDICE

GRACIAS POR ELEGIR TOTO!

INCLUÍA PARTE

La misión de TOTO es dar al mundo estilos de vida más saludables, higiénicos y cómodos.

Diseñamos cada producto guiándonos por el principio del equilibrio entre forma y función.

Felicitaciones por su elección.

Asegúrese que todas estas partes estén incluidas en su empacado*:

(La apariencia de algunos componentes puede variar dependiendo del modelo)

CONTROLADOR

SURTIDOR

STD

TELS10*

Gooseneck-Wall

Helix-Wall

TELS13*

Helix

TELS11* TELS16*

Helix-M

TELS12*

Axiom

TELS14*

Gooseneck

TELS15*

UP

UP

Libella Wall Libella-M Wall

TELS1C* TELS1D* TELS1A* TELS1B*

Libella Libella-M

¡Gracias Por Elegir TOTO! ..................

11

Incluía Parte............................................ 11

Precaución............................................... 12

Antes de la Instalación........................... 12

12

Cuidado y Limpieza....................................... 16

Mantenimiento Periódico......................... ..... 16

Especificacione...............................................17

Resolución de Problemas.............................. 18

Garantía .......................................................... 19

Bosquejo......................................................... 38

Procedimiento de Instalación............... 13

Inicializando el Producto EcoPower......

Page 12

12

PRECAUCIÓN

ANTES DE LA INSTALACIÓN

Siga todos los códigos locales de plomería y construcción.

Verifique la presión de suministro de agua fría y/o caliente.

El rango de presión de trabajo recome

hasta alcanzar el rango recomendado usando una válvula de reducción de la

presión (se vende por separado).

Verifique la temperatura del suministro de agua.

El rango de temperatura de suministro

Nunca utilice vapor como un suministro de agua caliente.

Descargue todas las líneas de agua antes de su instalación.

Otras precauciones antes de comenzar:

Ponga especial atención para que la superficie del sensor no se dañe o raye

durante el proceso de instalación.

Asegúrese que toda la tubería, válvulas de paso y líneas de conexión

estén instaladas de acuerdo con los códigos locales.

No coloque otros dispositivos que utilicen un inversor o sensor infrarrojo cerca

del grifo, ya que puede causar un malfuncionamiento del grifo.

No se recomiendan presiones de agua superiore

accesorios de fontanería. Consulte su código de fontanería local para obtener detalles.

Lea las siguientes notas y sígalas siempre. De lo contrario, podría resultar herido y/o

causar daños materiales.

Ninguna persona que no sea un ingeniero de servicios debe desensamblar, reparar

o modificar este grifo, a menos que se describa específicamente en este manual.

No hacer lo anterior puede resultar en un malfuncionamiento del producto.

Fije las temperaturas del grifo únicamente a las permitidas en sus códigos locales.

No utilice este grifo en una ubicación húmeda donde se pueda acumular agua

corriente o condensación en la superficie, especialmente en un sauna o vapor.

No golpee o patee el grifo o la caja del controlador, ya que puede dañar la unidad

o causar fugas.

Desconecte el conector de la batería de respaldo cuando el grifo no esté en uso por

un largo periodo de tiempo.

Siempre cierre la(s) válvula(s) de paso al limpiar el filtro.

Revise periódicamente la tubería para verificar que no haya fugas.

Si la temperatura ambiente cae drásticamente, envuelva la tubería con aislante.

Asegúrese de que el cable de energía no entre en contacto con la tubería de

suministro de agua caliente.

Evite colocar cualquier objeto dentro del rango de detección del sensor infrarrojo.

INICIALIZANDO EL PRODUCTO ECOPOWER

No toque la superficie caliente de la llave de paso, ya que puede estar muy caliente.

ESPAÑOL

Tenga en cuenta que tardará al menos 5 minutos

después de conectar la batería para que la electrónica se inialice.

(Consulte la página 6 para ver las ilustraciones.)

Page 13

13

PROCEDIMIENTO DE INSTALACIÓN

NOTA: Antes de instalar el producto, asegúrese de descargar perfectamente las tuberías de

suministro de suciedad y desechos. Cierre el suministro de agua en las llaves de

paso después de descargarlas.

Para Instalar Modelos Montados en el Mostrador

(vea la ilust. 4):

Asegure el surtidor a la parte superior del mostrador

con el soporte incluido y la tuerca hexagonal.

Asegúrese de que el surtidor sea montado con la

punta apuntando hacia el centro del lavabo.

Instale el Controlador

Instale el Surtidor

SURTIDOR

ill. 4

1. Vea la página de dimensiones en borrador para determinar

la ubicación adecuada para el controlador.

2. Retire los tornillos en la parte de enfrente de la cubierta del

controlador y jale para retirarla.

3. Monte el soporte sobre la pared. De ser necesario, use anclajes

de pared (vea la ilust. 1).

4. Desde la parte superior, coloque el controlador en el orificio, en el soporte. Desde la

parte inferior del soporte, ajuste la tuerca grande para fijar el controlador (vea la ilust. 2).

IMPORTANTE!

Asegúrese de instalar el controlador en la orientación correcta, como se muestra.

De lo contrario, el producto no funcionará correctamente.

5. Conecte la línea de suministro de agua al adaptador de entrada (vea la ilust. 3).

NOTA: Si usa una válvula termostática (se vende por separado), consulte su manual de

instalación para obtener detalles.

ill. 2

ill. 3

La tuerca

Manguera flexible

del surtidor

Cable del sensor

Empaque

Retenedor

del surtidor

El soporte

La tuerca

Llave de paso

Las mangueras

de suministro.

El soporte

La tuerca

ill.1

ESPAÑOL

Page 14

14

ESPAÑOL

PROCEDIMIENTO DE INSTALACIÓN

2. Para ajustar a una superficie de madera,

perfore tres (3) orificios piloto con un

diámetro de 7/64 in (2,7 mm) en las ubicaciones marcadas.

Para ajustar a una pared laminada o azulejo, perfore tres (3) orificios con un diámetro de

3/16 in (5 mm) e inserte los anclajes hasta que estén a ras. Dé golpes suaves con un

martillo si es necesario.

3. Alimente el tubo de suministro y el cable

e

salida contra la pared y ajústelo firmem

-ente con los tornillos proporcionados.

Para Instalar los Modelos Montados en Pared Cuello de Ganso (ill. 8, 9& 10):

NOTA: La adición de un contrachapado de recubrimiento de 1 x 6” detrás de la ubicación

de montaje es altamente recomendable para las instalaciones en pared laminada/

pared

hueca. El grosor de pared máximo total es de 2” (50 mm).

1.

Perfore un orificio de 1-1/8” (29 mm) en

la ubicación deseada para el soporte de

montaje. Ponga el soporte de montaje a

través de un orificio en la pared con el

orificio del tornillo de fijación ubicado a

las 12 en punto. Marque la ubicación del

orificio del tornillo de fijación en la pared y retire el soporte de montaje.

Para una superficie de hoja de metal: Perfor

e un orificio de 3/16” (5 mm) en la ubicación marcada.

NOTA: Se pueden necesitar brocas de taladro (no proporcionadas) para materiales duros.

Para una superficie de pared laminada/pared hueca: Perfore un orificio de 1/4”(6.5 mm) en

la ubicación marcada e instale los taquetes incluidos.

NOTA: Es altamente recomendable la confirmación de la resistencia de la pared antes de perforar.

STEP 8

2 x 4

Marco de

2 x 4

Montantes

Pared Terminada

Orificio de 3/4” de

Diámetro para Taquetes

Orificio de 3/16” de

Diámetro para Taquetes

ill. 5

ill.6

Escudete

Ø 1-1/8"

15/16"

Ø 3/16” (Superficie de la hoja metálica)

Ø 1/4” (superficie de pared laminada/

pared hueca)

ill. 8

Orificio para el tornillo de fijación/

tornillo de máquina

y anclaije de pared

Orificio para el surtidor al

soporte de montaje

Para Instalar Modelos Montados en la Pared de Helix y Libella (ill. 5)

NOTA: La adición de un marco de 2 x 6” detrás de la ubicación de la instalación del

surtidor es altamente recomendable.

1. Coloque la plantilla de montaje sobre

lapared en la ubicación deseada y marque

todos los orificios. Perfore un orificio con

un diámetro de 5/8 in (16 mm) en la

ubicación del montaje del tubo de salida

(centro) para que pasen el tubo de suministro

y el cable del sensor.

ill.7

Retenedor

del surtidor

Tornillo de Fijación

4. Ajuste manualmente el escudete al soporte.

3. Coloque el soporte de montaje contra la

pared y fíjelo firmemente con los tornillos

que se incluyen.

4. Pase la cuerda del sensor y la manguera a

través del soporte de montaje, deslice la

base de la boquilla de escape sobre el

soporte de montaje y apriete el tornillo de

fijación para fijar la boquilla de escape en

el soporte de montaje.

Para Instalar Modelos Montados en la Pared de Libella (ill. 7)

Para Instalar Modelos Montados en la Pared de Helix (ill. 6)

Page 15

15

Ñ A P S E

PROCEDIMIENTO DE INSTALACIÓN

1. Si la manguera que conecta el surtidor es demasiado larga, córtela a la longitud

adecuada, asegurándose que el extremo esté cuadrado.

2. Empuje la manguera que conecta el surtidor en la lengüeta de salida del controla

-dor y asegúrela con la abrazadera de la manguera (ver iII.1). Asegúrese que la

abrazadera de la manguera esté perfectamente colocada contra el controlador.

3. Conecte el conector de la batería de respaldo al controlador. Se tardará al menos

obstrucciones entre el sensor y el lavabo, después conecte el conector del sensor

del surtidor al controlador (ver iII. 2).

IMPORTANTE!

de que el conector del sensor esté enchufado al controlador

No coloque las manos ni

otros objetos frente al sensor.Completar este proceso puede llevar hasta 20 segundos.

,sodnuges 02 ed sám rop odnaedaprap eugis rosnes led zul al iS

se deberá reajustar la dirección del surtidor para una operación

adecuada. Si el ajuste es necesario, debe hacerlo dentro de los

siguientes 10 minutos o el proceso de ajuste terminará. Para

reiniciar el proceso, eso, desconecte el conector del sensor 10

segundos y vuélvalo a conectar (ver iII. 3).

4. Vuelva a revisar todas las conexiones, después reinstale la

cubierta del controlador, asegurándola con los tornillos.

ADVERTENCIA: Lleve el cable del sensor a la parte inferior del controlador mientras instala

la cubierta del controlador para asegurarse que el cable no quede atrapado.

Conecte el Surtidor al Controlador

2. Instale el soporte de montaje utilizando una arandela de hule, arandela de latón y

ambas tuercas de latón en la parte posterior de la superficie de instalación. Instale

el tornillo de fijación incluido (para la instalación en hoja metálica) ó tornillo de

máquina de 30 mm (para instalaciones en pared laminada).

3. Pase la manguera y el cable del sensor a través del soporte de montaje, deslice la

base del surtidor sobre el soporte de montaje y apriete el tornillo de fijación para

asegurar el surtidor al soporte de montaje.

Tornillo de Fijación

(Hoja Metálica) or Tornillo

de Máquina (pared

laminada/pared hueca)

Arandela de

goma

Arandela de Latón

La tuerca (2)

ill. 9

Contrachapado

(no se requiere para la

instalación en hoja

metálica)

M5x30

Tornillo de

Máquina y

Taquetes

ill. 10

Tornillo de Fijación

Retenedor

del surtidor

M5 Tornillo

de Fijación

1x6 o Contrachapado

de Recubrimiento

Tornillo de

Fijación

Instalación en Hoja MetálicaInstalación en Pared Laminada

Retenedor

del surtidor

Pared Delgada

(Superficie de la

Hoja Metálica)

Pared Laminada

Abrazadera

de la manguera

Abrazadera a

ras con

controlador

ill. 1

Manguera

flexible

del surtidor

ill. 2

Conector

del Sensor

ill. 3

Luz del

Sensor

Sensor

El grifo comenzará un ajuste de rango de detección automático inmediatamente después

Conector de

la batería

NOTA:

Si necesita quitar la manguera, utilice

un destornillador de cabeza plana para

sacar cuidadosamente la manguera

de la lengüeta.

5 minutos después de conectar la batería para que la electrónica se inicialice.

Esta es una parte normal de la puesta en marcha. Asegúrese que no haya

ESPAÑOL

Page 16

16

PROCEDIMIENTO DE INSTALACIÓN

Prueba después de la instalación

Abrir

Cerrar

Llave de paso

ill. 1

Encienda el suministro de agua en las llaves de

paso e inspeccione todas as conexiones

para verificar que no haya fugas (ver iII. 1).

Coloque la mano debajo del sensor para activar.

Para el modelo de 10 seg.: el agua se detendrá

después de 10 segundos mientras la mano está

debajo del sensor. El agua sedetendrá cuando retire la mano.

Para el modelo de 20 seg.: el agua se detendrá después de 20 segundos.

CUIDADO Y LIMPIEZA

MANTENIMIENTO PERIÓDICO

Surtidor y Sensor

IMPORTANTE!

No raye el sensor al limpiar el surtidor (ver iII. 2).

Evite utilizar cualquier material de limpieza que pueda

rayar la superficie del surtidor.

Nunca utilice polvo para pulir, detergente que incluya

partículas corrosivas, thinners, benceno, ácidos,

detergentes alcalinos ni estropajos de nylon, ya que

pueden dañar la superficie del surtidor.

Para limpiar la superficie con seguridad, límpiela con un trapo remojado en detergente

para trastes diluido y séquelo con otro trapo. Si esto no limpia adecuadamente la

superficie, límpiela conun detergente neutro y un trapo mojado.

ill. 2

Sensor

Boquilla del surtidor

Revise su grifo al menos una vez al mes para los siguientes problemas potenciales y para

realizar los siguientes procedimientos de mantenimiento:

Inspeccione para ver si hay Fugas

Revise todas las conexiones de agua para ver si hay signos de fugas.

Apriete el Surtidor

Si el surtidor está flojo, apriete la tuerca hexagonal debajo del surtidor para los modelos

montados en el mostrador.

Para apretar el Surtidor Montado en la Pared de Helix:

1. Desatornille el escudete, apriete los tres ornillos que aseguran el soporte de montaje

a la pared y los tres tornillos que aseguran el surtidor al soporte de montaje.

.eteducse le elatsnieR .2

Para apretar el Surtidor Montado en la Pared Cuello de Ganso:

1. Cierre el suministro de agua en las llaves de paso.

2. Desconecte la manguera flexible del surtidor y conector del sensor.

3. Retire el surtidor del soporte de montaje qu itando el tornillo de fijación en la parte

inferior de la base del surtidor.

4. Apriete el tornillo de fijación en la parte posterior del surtidor, después reinstale el

surtidor en el soporte de montaje.

5 Según se requiera, asegure el tornillo de fijación en el soporte de montaje y las tuercas

de fijación detrás del lavabo/pared (consulte la sección “Instale el surtidor”) están

apretadas.

LOÑAPSE

Page 17

17

ESPAÑOL

Limpiando el Filtro de Entrada y la Boquilla

Cuando el filtro de entrada esté tapado, la velocidad de flujo disminuirá. Una disminución

en la velocidad del flujo puede llevar a una generación de energía insuficiente, que la

batería de respaldo rápidamente.

Para limpiar el filtro (ver iII. 1):

1. Cierre el agua en las válvulas de suspensión.

2. Retire la tapa y luego retire el sujetador rápido.

3. Retire el controlador.

4. Retire el filtro y límpielo con un cepillo.

IMPORTANTE!

Si regulador del flujo (o montaje de regulador del

flujo para TELC103-###E) se cae, vuelva a instalarlo

en la orientación correcta como se muestra (anillo

en O hacia filtro).

De lo contrario el producto

6. Vuelva a instalar el controlador en el adaptador

hasta que esté completamente asentado, y

asegúrelo con el fijador rápido.

7. Vuelva a instalar la cubierta, asegurándola

con los tornillos.

8. Abra la tapa angular y verifique todas las

conexiones.

Para limpiar la boquilla (ver iII. 2):

1. Retire la boquilla del surtidor con la

herramienta proporcionada.

2. Limpie la boquilla con un cepillo suave

para retirar toda la suciedad de la pantalla.

3.

Reinstale la boquilla en el surtidor.

ESPECIFICACIONES

Abrir

Cerrar

Boquilla

del Surtidor

Llave

Boquilla

del Surtidor

Cepillo

Filtro

Regulador

del flujo

Suministro de energía

Generación de Hidroenergía

Rango de detección

del sensor

5-1/8’”~ 7-7/8” (130~200mm)

El sensor tiene ajuste automático.

Presión del suministro

Mínima requerida: 15 psi (100 kPa) (fluyendo)

Máxima: 80 psi (551 kPa)

Conexión del suministro

G1/2

39 ~ 110°F (4 ~ 43.3°C)

Temperaturas de entrada

Temperaturas ambiente

32 ~ 104°F (0 ~ 40°C)

Humedad

Max. 90% RH

Velocidad del flujo

Duración

MANTENIMIENTO PERIÓDICO

0.09 gpc

(0.36 Lpc)

0.18 gpc

(0.67 Lpc)

0.19 gpc

(0.72 Lpc)

10 segundos 20 segundos

1.0 gpm 0.5 gpm 0.35 gpm

10 segundos 20 segundos

0.11 gpc

(0.44 Lpc)

Volumen por ciclo

ill. 3

ill. 1

Retire fijador rápido

Adaptador de

tubo

ill. 2

Reguladores de flujo para el modelo TELC103-###E

se montan dentro de un adaptador.

Instale el conjunto con la orientación correcta.

5. Vuelva a instalar el filtro limpio.

funcionará mal.

Page 18

18

ESPAÑOL

Problema Causa Solución

La superficie del sensor está sucia. Limpie la superficie del sensor.

Hay una obstrucción enfrente del

sensor.

Retire la obstrucción.

La válvula de suspensión está

apagada.

Abra la válvula.

El conector de la batería de respaldo

está desconectada.

Conecte el conector de la batería de

respaldo.

El generador de energía y el conector

del sensor están desconectados.

Fije perfectamente el (los)

conector(es).

El suministro de agua está

suspendido.

Espere a que el suministro de agua

se restablezca.

El filtro o la pantalla reguladora está

tapado.

Limpie el filtro y la pantalla reguladora.

El agua

no sigue

corriendo.

La superficie del sensor está sucia. Limpie la superficie del sensor.

Hay una obstrucción enfrente del

sensor.

Retire la obstrucción.

Si el agua continúa corriendo después de intentar las soluciones

anteriores, cierre la válvula de suspensión.

Velocidad del

flujo baja.

La válvula de suspensión no está

completamente abierta.

Abra la válvula de suspensión

completamente.

El filtro o la pantalla reguladora está

tapado.

Limpie el filtro y la pantalla

reguladora.

La tempera-

tura del agua

es demasia do

alta.

La manija del control de temperatura

está fija en “H”.

Fije la manija del control de

temperatura en el punto medio.

La válvula de suspensión conectada

al suministro de agua fría no está

completamente abierta.

Abra la válvula de suspensión de agua

fría completamente.

La tempera-

atura del agua

es demasiado

baja.

La manija del control de temperatura

está fija en “C”.

Fije la manija del control de

temperatura en el punto medio.

La válvula de suspensión conectada a

l suministro de agua caliente no está

completamente abierta.

Abra la válvula de suspensión de

agua caliente completamente.

La temperatura del suministro de

agua caliente es menor a 120F.

Fije la temperatura del suministro de

agua caliente en 120F.

La tempera-

atura del agua

no está contr-

olada adecua-

damente.

Un lado de la válvula de suspensión

no está completamente abierto.

Abra la válvula de suspensión

completamente.

El filtro o la pantalla reguladora

está tapado.

Limpie el filtro y la pantalla

reguladora.

Rango de det-

ección corto.

El sensor de ajuste automático puede

no funcionar adecuadamente cuando

está tapado o bloqueado por gotitas

de agua.

Limpie la superficie del sensor.

RESOLUCIÓN DE PROBLEMAS

El agua no

empieza a

correr.

Page 19

19

ESPAÑOL

Garantía

1. TOTO ®garantiza que sus válvulas de descarga electrónica, grifos y dispensadores de jabón (“Producto”) están

libres de defectos en los materiales y mano de obra durante el uso normal cuando se instala y se mantiene de

manera adecuada, por un período de tres (3) años a partir de la fecha de adquisición. Esta garantía limitada se

extiende solamente al COMPRADOR ORIGINAL del Producto y no es transferible a terceros, incluyendo pero no

taxativamente cualquier comprador o propietario subsecuente del Producto. Esta garantía se aplica solamente al

producto TOTO adquirido e instalado en América del Norte, Central y Sur.

2. Las obligaciones de TOTO conforme a esta garantía se limitan a la reparación, reemplazo u otro ajuste apropiado,

a discreción de TOTO, del Producto o las piezas que resulten defectuosas en su uso normal, siempre que dicho

Producto fuera instalado, utilizado y mantenido adecuadamente en consonancia a las instrucciones. TOTO se

reserva el derecho de realizar tantas inspecciones como sean necesarias para determinar la causa del defecto.

TOTO no cobrará por la mano de obra o piezas con respecto a las reparaciones o reemplazos de la garantía.

TOTO no es responsable del costo de la retirada, devolución o reinstalación del Producto.

4. Para que esta garantía limitada sea válida, se requiere el comprobante de compra. Se requiere que TOTO exija el

registro de garantía en la compra para crear un registro de propiedad del Producto en http://www.se. TOTO exige

el registro de la garantía y si no se registra no se reducirán sus derechos de garantía limitada.

5. ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS. PUEDE TENER OTROS DERECHOS

QUE VARÍAN ENTRE ESTADOS, PROVINCIAS O PAÍSES.

6. A fin de obtener el servicio de reparación de la garantía en virtud de esta garantía, deberá llevar el producto o

entregarlo prepago a un servicio técnico de TOTO junto con el comprobante de compra (recibo de venta original) y

una carta que indique el problema, o póngase en contacto con un distribuidor o contratista de servicio de productos

de TOTO o bien escriba directamente a TOTO U.S.A., INC., 1155 Southern Road, Morrow, GA 30260 (888) 295

8134 o (678) 466-1300, si no se encuentra en los Estados Unidos. Si, debido al tamaño del Producto o a la

naturaleza del defecto, el Producto no se puede devolver a TOTO, el recibo de TOTO del aviso por escrito del

defecto junto con el comprobante de compra (recibo de venta original) constituirá la entrega. En tal caso, TOTO

puede optar por reparar el Producto en el lugar del comprador o pagar para transportar el Producto a un servicio

técnico.

ESTA GARANTÍA POR ESCRITO ES LA ÚNICA GARANTÍA REALIZADA POR TOTO. LA REPARACIÓN, REEMPLAZO U OTRO

AJUSTE ADECUADO, TAL COMO APARECE EN ESTA GARANTÍA SERÁ EL ÚNICO RECURSO DISPONIBLE PARA EL

COMPRADOR ORIGINAL. TOTO NO SERÁ RESPONSABLE DE LA PÉRDIDA DEL PRODUCTO O DE OTROS DAÑOS

INCIDENTALES, ESPECIALES O CONSECUENCIALES O GASTOS INCURRIDOS POR EL COMPRADOR ORIGINAL, O DE LA

MANO DE OBRA U OTROS COSTOS RELACIONADOS CON LA INSTALACIÓN O RETIRADA, O COSTOS DE REPARACIONES

REALIZADOS POR OTROS O DE NINGÚN OTRO GASTO QUE NO SE HUBIERA ESPECIFICADO ANTERIORMENTE. EN

NINGÚN CASO LA RESPONSABILIDAD DE TOTO EXCEDERÁ EL PRECIO DE COMPRA DEL PRODUCTO. SALVO

DISPOSICIÓN LEGAL CONTRARIA, TODA GARANTÍA IMPLÍCITA, QUE INCLUYE LA DE COMERCIABILIDAD O IDONEIDAD

PARA USO O PARA UN PROPÓSITO PARTICULAR, ESTÁ EXPRESAMENTE PROHIBIDA. ALGUNOS ESTADOS NO

PERMITEN LIMITACIONES SOBRE LA DURACIÓN DE UNA GARANTÍA IMPLÍCITA, O LA EXCLUSIÓN O LIMITACIÓN DE

DAÑOS INCIDENTALES O CONSECUENTES, POR ESO LA LIMITACIÓN Y EXCLUSIÓN ANTERIORES PUEDEN NO

APLICARSE EN ESTE CASO.

3. Esta garantía no se aplica a los siguientes puntos:

a. Daños o pérdidas resultantes de una calamidad natural como incendio, terremoto, inundación, truenos,

tormenta eléctrica, etc.

b. Daños o pérdidas resultantes de cualquier accidente, uso irrazonable, uso indebido, abuso, negligencia, o

cuidado inadecuado, limpieza o mantenimiento del Producto.

c. Daños o pérdidas resultantes de los sedimentos o cuerpos extraños en un sistema de jabón líquido.

d.

Daños o pérdidas resultantes de una instalación incorrecta o de la instalación del Producto en un ambiente

áspero o peligroso, o retirada, reparación o modificación inadecuada del Producto.

e. Daños o pérdidas resultantes de sobrecargas eléctricas o rayos u otros actos que no sean responsabilidad

de TOTO o que el Producto no es especificado para tolerar.

f.

Daños o pérdidas resultantes del desgaste normal y habitual, como pérdida de brillo, rayado o desvanecimiento

con el tiempo debido al uso, prácticas de limpieza, condiciones atmosféricas o agua, incluyendo

pero no taxativamente, el uso de lejía, alcalinos, limpiadores ácidos, limpiadores secos (polvo) o

limpiadores abrasivos o el uso de depuradores de metal o nylon.

Page 20

20

SIAÇNARF

TABLE DES MATIÈRES

MERCI D’AVOIR CHOISI TOTO!

PIÈCES INCLUSES

La mission de TOTO est d’offrir au mond e entier un style de vie sain, hygiénique et

plus confortable. Comme principe de base, nous concevons chaque produit avec un

équilibre entre la forme et la fonction. Félicitations pour votre choix.

Vérifiez que toutes les pièces sont inclues dans votre paquet:*:

(l’apparence de certains éléments pourrait varier en fonction du modèle)

Merci d’avoir choisi TOTO!................... 20

Pièces incluses........................................ 20

Prudence................................................. 21

12............................rrecnemmoc ed tnavA

Initialisation du produit EcoPower........ 22

Entretien et nettoyage................................. 25

Maintenance périodique.............................. 25

Caractéristiques..... ..... .. .......... ........... 62

Dépannage................................................... 27

Garantie....................................................... 28

83 ........................................eturb eiretteniboR

Procédure d’installation......................... 22

BEC

CONTRÔLEUR

STD

TELS10*

Gooseneck-Wall

Helix-Wall

TELS13*

Helix

TELS11* TELS16*

Helix-M

TELS12*

Axiom

TELS14*

Gooseneck

TELS15*

UP

UP

Libella Libella-M Libella Wall Libella-M Wall

TELS1C* TELS1D* TELS1A* TELS1B*

Page 21

21

PRUDENCE

AVANT DE COMMENCER

Respecter tous les codes locaux de plomberie et de construction.

Vérifiez la pression de la source d’eau froide et/ou chaude.

La plage de pression recommandée e

réduire la pression à la plage recommandée au moyen d’une valve de

réduction de pression (vendue séparément).

Vérifiez la température de l’alimentation en eau.

La plage de température d’alimenta

N’utilisez jamais la vapeur comme source d’eau chaude.

Rincez toutes les conduites d’eau avant l’installation.

Autres précautions à prendre avant de commencer:

Portez une attention particulière afin que la surface du capteur ne soit pas

défectueuse ou rayée pendant le processus d’installation.

Assurez vous que toute la tuyauterie, les valves d’arrêt, et les lignes de

connexion sont installées en accordance avec les codes locaux.

Ne placez pas d’autres appareils qui utilisent un onduleur ou un capteur

infrarouge près du robinet, car ceci pourraitcauser le dysfonctionnement du robinet.

Il n’est pas recommandé d’avoir une press

plupart des

appareils de plomberie. Vérifiez votre code de plomberie local pour plus de détails.

Veuillez lire et respecter les consignes suivantes. Le non-respect de ces recommandations

pourrait entraîner des blessures et/ou des dommages matériels.

Personne d’autre qu’un ingénieur de service ne devrait démonter, réparer ou

modifier ce robinet, à moins que ce ne soit décrit spécifiquement dans ce manuel.

Le non-respect de ces recommandations pourrait causer le dysfon ctionnement du produit.

Réglez votre robinet seulement aux températures autorisées dans vos codes locaux.

N’utilisez pas ce robinet dans des endroits humides où l’eau courante ou de la condensation

pourrait s’accumuler à la surface, particulièrement dans un sauna ou un hammam.

Ne pas frapper ou botter le robinet ou la boîte du contrôleur, car ceci pourrait

endommager l’unité ou provoquer une fuite.

Ne pas toucher la surface chaudes de la vanne d’arrêt de contrôleur, que la surface peut

être très chaude.

Débranchez le connecteur de la batterie de secours lorsque le robinet n’est pas

utilisé pendant une longue période de temps.

Assurez vous de toujours fermer la valve d’arrêt avant de nettoyer l’épurateur.

Vérifiez régulièrement les tuyaux pour détecter les fuites.

Si la température de la pièce dminue au point de congélation, enveloppez les tuyaux

avec un isolant.

Assurez vous que le cordon d’alimentation n’entre pas en contact avec le tuyau

d’alimentation d’eau chaude.

Évitez de placer tout objet dans la zone de détection du capteur infrarouge.

INITIALISATION DU PRODUIT ECOPOWER

Comprenez qu'il faudra au moins 5 minutes après la connexion de la batterie

pour que l’électronique s’intensifie. Ce délai est normal lors du démarrage.

(Reportez-vous à la page 6 pour des illustrations.)

S I A Ç N A R F

NARF SI

A

Ç

Page 22

22

SIAÇNARF

PROCÉDURE D’INSTALLATION

sûr de rincer soigneusement les xuayut

d’alimentation pour éliminer toute saleté et tous débris. Fermez la source

d’ eau aux valves d’arrêt après le rinçage.

Pour installer les modèles montés sur pont (iII. 4):

Serrer le bec sur le comptoir avec le support inclus

et l’écrou hexagonal. Assurez-vous que le bec est

monté avec la pointe dirigée vers le centre du

bassin.

Installez le Contrôleur

Installez le Bec Verseur

BEC

ill. 4

1. Voir le sommaire de la page des dimensions pour déterminer

l’emplacement approprié pour le contrôleur.

2. Enlevez les vis à l’avant de la couverture du contrôleur et tirez

pour enlever.

3. Montez le support sur le mur. Si nécessaire, utilisez des

chevilles (voir l’ill. 1).

4. Par le dessus, placez le contrôleur dans l’orifice du support. Serrez le grand écrou situé

situé sous le support pour fixer le contrôleur (voir l’ill. 2).

IMPORTANT!

Assurez-vous d’installer le contrôleur dans le bon sens, comme indiqué. Sinon, le

produit ne fonctionnera pas correctement.

5. Connectez la conduite d’alimentation en eau à l’adaptateur d’entrée (voir l’ill. 3).

consulter son manuel d’installation pour plus de détails.

ill.1

ill. 2

ill. 3

Écrou

Tuyau de raccord du bec

Câble du capteur

Joint

Rondelle

Support

Écrou

Valves d’arrêt

Tuyaux

d’alimentation.

Support

Écrou

REMARQUE: Avant d’installer le produit, soyez

REMARQUE: Si vous utilisez une vanne thermostatique (vendue séparément), veuillez

Page 23

23

SIAÇNARF

PROCÉDURE D’INSTALLATION

2. Pour une installation sur du bois, percez

s marqués.

Pour une installation dans une cloison

sèche ou dans des carreaux, percez trois

et insérez les chevilles à ras. Enfoncez-les

légèrement à l’aide d’un marteau au besoin.

3. Faites passer le tube d’alimentation et le

cordon du capteur à travers le trou central de

e mur et

fixez-le solidement avec les vis fournies.

4. Fixez la rosace sur le support en la serrant à

la main.

Pour installer les modèles muraux à col de cygne (ill.8,9,10):

NOTE: L’ajout d’un 1 x 6 “ou de contreplaqué contreventement derrière l’emplacement

de montage est fortement recommandé pour les cloisons sèches / installations

dans les murs creux. L’épaisseur totale maximale du mur est 2” (50 mm).

1.

Percez un trou de 1-1/8” (29 mm) à l’

emplacement désiré pour monter le support.

Mettez le support de montage à travers le

trou avec le trou de vis de réglage située à la

position 12 heures.

Marquez l’emplacement du trou de la vis de

réglage sur le mur et enlevez le support de

montage.

Pour la tôle: Percez un trou 3/16” (5 mm) à l’endroit marqué.

NOTE: Les forets (non fourni) pour les matériaux durs peuvent être nécessaires.

Pour une cloison sèche / la surface du mur

creux: Percez un trou de 1 / 4 “(6,5 mm) à l’endroit marqué,et installez les chevilles inclus.

NOTE: Il est fortement recommandé de confirmer la solidité du mur avant de percer.

STEP 8

2 x 4

Encadrement

2 x 4

Goujons

Mur fini

Ancres à trous de

diamètre de 3/4”

Ancres à trous de

diamètre de 3/16”

ill. 5

ill.6

Écusson

Ø 1-1/8"

15/16"

Ø 3/16” (surface de la tôle)

Ø 1/4” (cloisons sèches/mur creux)

ill. 8

Trou pour vis de réglage/vis

de machine et

ancrage mural

Trou pour support de montage

Pour installer les modèles muraux à Helix et Libella (iII. 5)

NOTE: L’ajout d’une charpente 2 x 6 “f derrière l’ emplacement du bec est fortement

recommandé.

1. Placez le gabarit de montage sur le mur à

l’endroit désiré et marquez l’emplacement de

tous les trous. Percez un trou de 5/8 po (16 mm)

de diamètre à l’ emplacement de montage du

bec (centre) pour faire passer le tube

d’alimentation et le cordon du capteur à travers.

3. Placez le support de montage contre le mur

et fixez-le solidement avec les vis fournies.

Pour installer les modèles muraux à Libella (iII. 7)

Pour installer les modèles muraux à Helix (iII. 6)

4. Insérez le tuyau et le cordon du capteur dans

le support de montage, glissez la base du

robinet sur le support de montage et serrez

la vis sans tête pour fixer le robinet au support

de montage.

ill.7

Rondelle

Vis de réglage

Page 24

24

PROCÉDURE D’INSTALLATION

1. Si le tuyau de connexion du bec est trop long, coupez le à la longueur appropriée, et

assurez vous que la pointe est carrée.

2. Poussez le tuyau de connexion du bec sur la bordure de la sortie du contrôleur et le fixer

tse uayut ud egarres ed reilloc el euq suov-zerussA )1.lli riov( egarres ed reilloc el ceva

placé complètement contre le contrôleur.

3. Connectez le connecteur de la batterie de secours au contrôleur. Il faudra au moins 5

Assurez-vous qu’ il n’ya pas d’obstacle entre le capteur et le bassin, puis connectez le

connecteur du capteur du bec au contrôleur (voir iII.2).

IMPORTANT!

Le robinet commencera un ajustement automatique de la plage de détection immédiatement

immédiatement après avoir branché le connecteur du capteur au contrôleur. Ne mettez pas

les mains ni aucun objet devant le capteur. Ce processus peut prendre jusqu’ à 20 secondes.

Si la lumière du capteur continue à clignoter pendant plu ed s

20 secondes, la direction du bec devra être ajustée pour une

opération correcte. Si l’ajustement est nécessaire, vous devez le

faire dans les 10 minutes ou le processus d’ ajustement se termine.

Pour recommencer le processus, débranchez le

connecteur

du capteur pendant 10 secondes, et rebranchez le

(voir iII.3)

.

4. Vérifiez toutes les connexions puis réinstallez la couverture

du contrôleur en la fixant avec des vis.

AVERTISSEMENT: Tirez le cordon du capteur à partir du bas du contrôleur au moment de

l’installation de la couverture du contrôl eur afin de s’assurer que le cordon

n’ est pas compressé.

Connectez le Bec au Contrôleur

Collier de

serrage

Collier de

serrage doit

être alignée

avec le contrôleur

ill. 1

Tuyau de

raccord

du bec

ill. 2

Connecteur

du capteur

ill. 3

Lumière du capteur

Capteur

2. Installez le support de montage en utilisant la rondelle en caoutchouc, la rondelle en

laiton, et les deux écrous en laiton sur le côté arrière de la surface d’ installation.

Installez l’ensemble de vis inclues (pour la tôle) ou la vis de machine (pour l’installation

des cloisons sèches).

3. Passez le tuyau et le cordon du capteur à travers le support de montage, faites glisser

la base du bec au dessus du support de montage et serrez la vis de réglage pour fixer

le bec au support de montage.

Vis de réglage

(Tôle) ou vis de

machine (Cloisons

sèches / murs creux)

Rondelle

caoutchouc

Rondelle laiton

Écrou (2)

ill. 9

Contreplaqué

(non requis pour l’

installation de la tôle)

M5x30

Vis de

machine

et ancrage

mural

ill. 10

Vis de réglage

Rondelle

M5 Rondelle

1x6 ou Contreplaqués

de contreventement

Vis de réglage

Installation de la tôleInstallation de cloisons sèches

Rondelle

Paroi fine

(Surface de

la tôle)

Cloisons sèches

Connecteur

de la batterie

REMARQUE : Si vous devez retirer

le tuyau, utilisez un tournevis pour

enlever le tuyau de la barbe.

minutes après la connexion de la batterie pour l'électronique pour l'initérer.

SIAÇNARF

Page 25

25

PROCÉDURE D’INSTALLATION

Essai de l’installation

Ouvrir

Fermer

Valve d’arrêt

ill. 1

Ouvrez la source d’eau aux valves d’arrêt et inspectez

toutes les connexions pour détecter toute fuite (voir iII.1).

Placez la main sous le capteur pour l’ activer.

de couler après 10

secondes alors que votre main est sous le capteur. L’eau

s’arrête de couler dès que vous retirez votre main.

de couler après 20

ENTRETIEN ET NETTOYAGE

MAINTENANCE PERIODIQUE

Bec et Capteur

IMPORTANT!

Ne pas rayer le capteur lors du nettoyage du bec (voir iII.2).

Évitez d’utiliser tout matériel de nettoyage qui pourraient

rayer la surface du bec.

Ne jamais utiliser de poudre de polissage, détergent qui

comprend de grosses particules, de diluants, benzène,

acides, alcalins ou de brosse à récureren nylon, comme

ceux ci pourrait endommager la surface du bec.

Pour nettoyer la surface en toute sécurité, essuyez la

avec une chiffon doux et humide, imbibé de savon vaisselle dilué et séchez avec

un autre chiffon doux. Si cela ne nettoie pas convenablement la surface, essuyez

la surface avec un détergent neutre et un chiffon humide.

ill. 2

Capteur

Bec verseur

Inspectez votre robinet au moins une fois par mois pour détecter les problèmes potentiels

suivants et pour conduire les procédures de maintenance suivantes:

Inspectez pour détecter toute fuite

Vérifiez toutes les connexions d’eau pour détecter tout signe de fuite.

Serrez le bec

Au cas où le bec est desserré, serrez l’écrou hexagonal sous le bec pour les modèles

montés sur pont.

Serrez les spirales murales du bec:

1. Dévissez l’écusson, serrez les trois vis qui maintiennent le support de montage au mur

et les trois vis qui maintiennent le bec au support de montage.

2. Réinstallez l’écusson.

Pour serrer le bec mural à col de cygne:

1. Fermez la source d’eau au dessus des valves.

2. Débranchez le tuyau de connexion du bec et connecteur du capteur, du contrôleur.

3. Enlevez le bec du support de montage en élevant la vis de réglage au bas de la base

du bec.

4. Serrer la vis de réglage à l’arrière du bec, puis réinstallez le bec sur le support de

montage.

5. Comme requis, assurez-vous que la vis de fixation sur le support de montage et les

écrous de montage derrière l’évier/mur (Voir la section “Installer le bec”) sont bien

serrés.

secondes.

SIAÇNARF

Page 26

26

FRANÇAIS

Nettoyez le Tamis d’Entrée et le Bec Verseur

Lorsque le tamis de l’entrée est bouché, le débit va diminuer. Une réduction du débit peut

conduire à une production d‘électricité insuffisante,

qui va appauvrir la batterie de secours rapidement.

Pour nettoyer le tamis (voir iII. 1):

1. Fermez l’eau et arrêtez les valves.

2. Retirez le couvercle puis débranchez l’ attache

rapide.

3. Déposez le contrôleur.

4. Déposez la crépine et nettoyez-la avec une

brosse.

5. Réinstallez la crépine nettoyée.

IMPORTANT!

Veillez à installer le régulateur de débit (ou

ensemble régulateur de débit pour TELC103-###E)

dans le bon sens, comme indiqué (joint torique

orienté vers filtre). Sinon, le produit ne

fonctionnera pas correctement.

6. Réinstaller le contrôleur dans l'adaptateur

jusqu’à celui-ci est bien en place, et le fixer

avec l'attache rapide.

7. Remettre le couvercle et le fixer avec les vis.

8. Ouvrez la vanne d'arrêt et vérifier toutes

les connexions.

Pour nettoyer la buse (voir iII. 2):

1.

Enlevez la buse du bec avec les outils fournis.

2. Nettoyez la buse avec un brosse douce

pour enlever toute saleté de l’écran.

3. Réinstallez la buse dans le bec.

CARACTÉRISTIQUES

Ouvrir

Fermer

Bec

verseur

Clé

Bec

verseur

Brosse

Régulateur

Source d’énergie

Production Hydroélectrique

Détection du capteur

5-1/8’”~ 7-7/8” (130 ~ 200mm)

Le capteur est auto-réglable.

Pression d'alimentation

Minimum requise: 15 psi (100 kPa) (coulant)

Maximum: 80 psi (551 kPa)

Connexion d'alimentation

G1/2

39 ~ 110°F (4 ~ 43.3°C)

Température d'alimentation

Température ambiante

32 ~ 104°F (0 ~ 40°C)

Humidité

Max. 90% RH

Débit

Durée

MAINTENANCE PERIODIQUE

0.09 gpc

(0.36 Lpc)

0.18 gpc

(0.67 Lpc)

0.19 gpc

(0.72 Lpc)

10 secondes 20 secondes

1.0 gpm

0.5 gpm 0.35 gpm

10 seconde 20 secondes

0.11 gpc

(0.44 Lpc)

Volume par cycle

ill. 3

ill. 1

Filtre

Retirez attache rapide

Adaptateur

de tuyaux

ill. 2

Les régulateurs de débit pour le modèle TELC103-###E

sont assemblés à l'intérieur d'un adaptateur.

Installer l'assemblage avec l'orientation correcte.

Page 27

27

FRANÇAIS

Problème Cause Solution

La surface du capteur est sale. Nettoyez la surface du capteur.

Il y a un obstacle devant le capteur. Enlevez l’obstacle.

La valve d’arrêt est fermée. Allumez la valve.

La batterie de secours est

débranchée.

Branchez les connecteurs de la

batterie de secours.

Le générateur d’énergie et le connecteur du capteur sont débranchés.

Fixez solidement le(s) connecteurs.

La source d’eau est suspendue. Attendez jusqu’à ce que la source

d’eau soit restaurée.

Le tamis ou l’écran de réglage est

bouché.

Nettoyez le tamis et l’écran régulateur.

L’eau ne

coule pas co-

ntinuellement.

La surface du capteur est sale. Nettoyez la surface du capteur.

Il y a un obstacle devant le capteur. Enlevez l’obstacle.

Si l’eau continue à couler après avoir tenté toutes les solutions au

dessus, fermez les valves d’arrêt.

Débit faible.

La valve d’arrêt n’est pas

complètement ouverte.

Ouvrez la valve d’arrêt complètement.

Le tamis ou l’écran de réglage est

bouché.

Nettoyez le tamis et l’écran régulateur.

La tempéra-

ture de l’eau

est trop

élevée.

La poignée de contrôle de la

température est fixée à “H” .

Fixez la poignée de contrôle de la

température au point du milieu.

La valve d’arrêt connectée à la

source d’eau froide n’est pas

complètement ouverte.

Ouvrez la valve d’arrêt d’eau

froide complètement.

La températ-

ure de l’eau

est trop basse.

La poignée de contrôle de la

température est fixée à “C” .

Fixez la poignée de contrôle de la

température au point du milieu.

La valve d’arrêt connectée à la

source d’eau chaude n’est pas

complètement ouverte.

Ouvrez la valve d’arrêt d’eau

chaude complètement.

La température de la source d’ eau

chaude est plus basse que 120°F.

Fixez la température de la source

d’eau chaude à 120°F.

La tempéra-

ture de l’eau

n’est pas

contrôlée

correctement.

Un côté de la valve d’arrêt n’est pas

complètement ouvert.

Ouvrez la valve d’arrêt complètement.

Le tamis ou l’écran de réglage est

bouché.

Nettoyez le tamis et l’écran régulateur.

Fourchette de

détection

courte.

Le capteur d’autoréglage peut ne

pas fonctionner correctement

lorsque tendu ou bloqué par des

gouttelettes d’eau.

Nettoyez la surface du capteur.

DÉPANNAGE

L’ eau ne

commence

pas à couler.

Page 28

28

FRANÇAIS

GARANTIE

1. TOTO

®

garantit que ses robinets de chasse électroniques, robinets et distributeurs de savon (« produit ») sont

exempts de défauts de matériaux et de fabrication pendant l’utilisation normale lorsqu’il sont correctement installés

et entretenus, pour une durée de trois (3) ans à partir de la date d’achat. Cette garantie limitée est seulement offerte

à l’ACHETEUR ORIGINAL du produit et n’est pas transférable à un tiers, y compris mais non de façon limitative tout

acheteur ou propriétaire ultérieur du produit. Cette garantie s’applique uniquement aux produits de TOTO achetés et

installés en Amérique du Nord, Centrale et du Sud.

2. Les obligations de TOTO en vertu de cette garantie sont limitées à la réparation, au remplacement ou à l’ajustement

approprié, à la discrétion de TOTO, du produit ou des pièces défectueuses pendant l’utilisation normale, à condition

qu’un tel produit soit correctement installé, utilisé et entretenu selon les instructions. TOTO se réserve le droit

d’effectuer toute inspection jugée nécessaire dans le but de déterminer la cause du défaut. TOTO ne facturera pas

la main-d’oeuvre ou les pièces relatives à des réparations ou remplacements sous garantie. TOTO n’est pas

responsable du coût du retrait, du retour et/ou de la réinstallation du produit.

4. Pour que cette garantie limitée soit valide, une preuve d’achat est requise. TOTO vous encourage à enregistrer la

garantie à l’achat pour créer une déclaration de propriété du produit sur http://www.se. TOTO vous encourage à

enregistrer la garantie à l’achat, mais le fait de ne pas l’enregistrer ne diminuera en rien vos droits de garantie limitée.

5. CETTE GARANTIE VOUS DONNE DES DROITS LÉGAUX SPÉCIFIQUES. VOUS POURRIEZ AVOIR D’AUTRES

DROITS VARIANT D’UN ÉTAT À L’AUTRE, D’UNE PROVINCE À L’AUTRE OU D’UN PAYS À L’AUTRE.

6. Pour obtenir une réparation sous garantie, vous devez emmener le produit ou le faire livrer en port payé à un centre

de service TOTO avec une preuve d’achat (reçu d’achat original) et une lettre expliquant le problème, ou contacter

un distributeur de TOTO ou un prestataire de service pour les produits, ou écrire directement à TOTO U.S.A., INC.,

1155 Southern Road, Morrow, GA 30260 (888) 295 8134 ou (678) 466-1300, si vous vous trouvez hors des

États-Unis. S’il est impossible de retourner le produit à TOTO en raison de sa taille ou de la nature du défaut, la

réception par TOTO d’un avis écrit du défaut accompagné de la preuve d’achat (reçu d’achat original) constitue la

livraison. En pareil cas, TOTO pourrait choisir de réparer le produit sur le lieu où se trouve l’acheteur ou de payer

le transport du produit vers un centre de service.

CETTE GARANTIE ÉCRITE CONSTITUE LA SEULE GARANTIE OFFERTE PAR TOTO. TOUTE RÉPARATION, TOUT

REMPLACEMENT OU TOUT AUTRE AJUSTEMENT NÉCESSAIRE COUVERT PAR CETTE GARANTIE SERA LA SOLUTION

EXCLUSIVE À LA DISPOSITION DE L’ACHETEUR ORIGINAL. TOTO N’EST PAS RESPONSABLE DE LA PERTE DU PRODUIT

OU D’AUTRES DÉPENSES OU DOMMAGES ACCIDENTELS, PARTICULIERS OU CONSÉCUTIFS OCCASIONNÉS PAR

L’ACHETEUR ORIGINAL, OU DE LA MAIN-D’OEUVRE OU DES AUTRES FRAIS DUS À L’INSTALLATION OU AU RETRAIT, OU

DES FRAIS DE RÉPARATION PAR DES TIERS, OU DE TOUTE AUTRE DÉPENSE QUI N’EST PAS EXPRESSÉMENT

MENTIONNÉE CI-DESSUS. EN AUCUNE CIRCONSTANCE LA RESPONSABILITÉ DE TOTO NE SERA SUPÉRIEURE AU PRIX

D’ACHAT DU PRODUIT. SAUF DANS LA MESURE OÙ CELA EST INTERDIT PAR LA LOI EN VIGUEUR, TOUTE GARANTIE

IMPLICITE, Y COMPRIS CELLE DE VALEUR MARCHANDE OU D’ADAPTATION À UN USAGE OU UN EMPLOI PARTICULIER,

EST EXPRESSÉMENT EXCLUE. CERTAINS ÉTATS N’AUTORISENT PAS DE LIMITATIONS SUR LA DURÉE DE LA GARANTIE

IMPLICITE OU L’EXCLUSION OU LA LIMITATION DES DOMMAGES INDIRECTS OU CONSÉCUTIFS; IL EST DONC POSSIBLE

QUE LA LIMITATION ET L’EXCLUSION SUSMENTIONNÉES NE S’APPLIQUENT PAS À VOUS.

3. Cette garantie ne s’applique pas aux éléments suivants :

a. Dommage ou perte résultant d’une catastrophe naturelle comme un incendie, un tremblement de terre, une

inondation, la foudre, un orage électrique, etc.

b. Dommage ou perte résultant de tout accident, de toute utilisation non raisonnable, incorrecte, abusive ou

négligente, ou de soins, de nettoyage ou d’entretien inappropriés du produit.

c. Dommage ou perte résultant des sédiments ou des corps étrangers présents dans un système de savon

liquide.

d.

Dommage ou perte résultant de l’installation inappropriée ou de l’installation du produit dans un environnement

rude et/ou dangereux, ou le retrait, la réparation ou la modification inapproprié(e) du produit.

e. Dommage ou perte résultant de surtensions électriques, de la foudre ou d’autres actes qui ne constituent

pas la faute de TOTO ou que le produit n’est pas conçu pour tolérer.

f.

Dommage ou perte résultant de l’usure normale et habituelle, comme la réduction de la brillance, les rayures ou

la décoloration au fil du temps dues à l’usure, les pratiques de nettoyage ou l’eau ou les conditions atmosphériques,

y compris mais non de façon limitative, l’utilisation de javellisant, d’alcalis, de nettoyants acides, de

nettoyants secs (en poudre) ou de tout autre nettoyant abrasif, ou l’utilisation de brosses en nylon ou en métal.

Page 29

29

PORTUGUÊS

ÍNDICE

OBRIGADO POR ESCOLHER TOTO!

PEÇAS INCLUÍDAS

A missão da TOTO é proporcionar ao mundo um estilo de vida saudável, higiênico e

mais confortável. Como princípio norteador, projetamos cada produto com equilíbrio

entre forma e função. Parabéns pela sua escolha.

Confira para certificar-se que todas estas peças constam da embalagem*:

(Aspecto de alguns componentes podem variar dependendo do modelo)

BICA

STD

TELS10*

Gooseneck-Wall

Helix-Wall

TELS13*

Helix

TELS11* TELS16*

Helix-M

TELS12*

Axiom

TELS14*

Gooseneck