Page 1

Installation and Owner’s Manual

Manual de Instrucciones y del Propietario

Manuel d’Installation et d’Utilisation

CST405F

CST405MF

CST406F

CST406MF

Warranty Registration and Inquiry

For product warranty registration, TOTO U.S.A. Inc. recommends online warranty registration. Please visit

our web site http://www.totousa.com. If you have questions regarding warranty policy or coverage, please contact TOTO U.S.A. Inc., Customer Service Department, 1155 Southern Road, Morrow, GA 30260

(888) 295-8134 or (678) 466-1300 when calling from outside of U.S.A.

Page 2

Page 3

TABLE OF CONTENTS

Thanks for Choosing TOTO

Before Installation

...............................................................................................................3

Common Tools Needed

Included Parts

Before Installation

..................................................................................................................... 3

...............................................................................................................4

Installation Procedure

Toilet Tank Fill Valve Instructions

Care and Cleaning

Warranty

.............................................................................................................................. 8

..............................................................................................................7

Rough-In Dimensions

Replacement Parts ............................................................................................................23

®

! ...........................................................................................3

....................................................................................................3

.....................................................................................................4-6

....................................................................................6-7

......................................................................................................23

THANKS FOR CHOOSING TOTO!

The mission of TOTO is to provide the world with healthy, hygienic and more

comfortable lifestyles. We design every product with the balance of form and function

as a guiding principle. Congratulations on your choice.

COMMON TOOLS NEEDED

• 10” adjustable wrench

• Hacksaw

• Carpenter’s Level

MATERIALS REQUIRED (not supplied):

• Bowl Wax Ring

• Water Supply Line

(typically 1/2” Compression

to 7/8” Ballcock)

• Tape Measure

• Pliers

• Flat Screwdriver

• Putty Knife

• Mounting (T) Bolts & Nuts (2pc)

• Toilet Seat

(TOTO SoftClose recommended)

ENGLISH

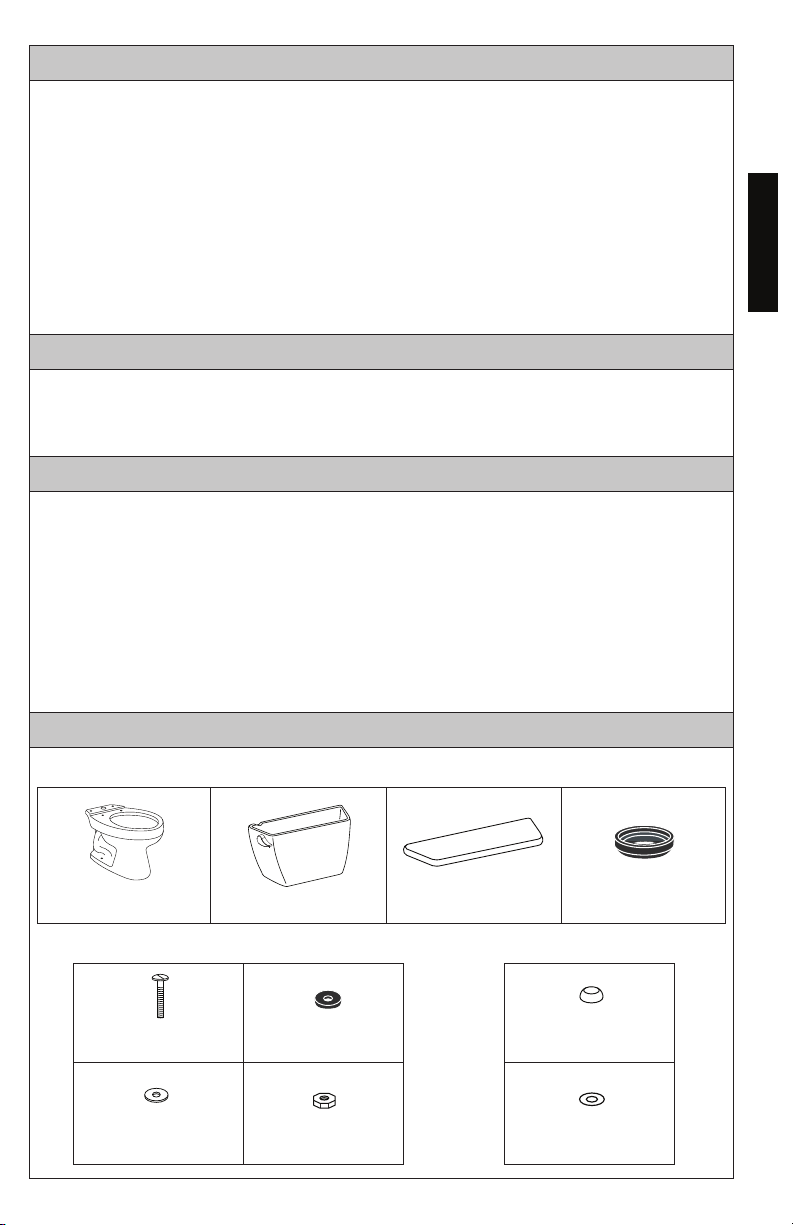

INCLUDED PARTS

Check to make sure you have all these parts from the package:

China Bowl

Tank to Bowl Hardware:

Bolts

(2 pieces)

Metal Washers

(4 pieces)

China Tank

Rubber Washers

(2 pieces)

Nuts

(4 pieces)

China Tank Lid Tank to Bowl Gasket

Flange Caps (for the Bowl):

3

Plastic Caps

(2 pieces)

Base Caps

(2 pieces)

Page 4

BEFORE INSTALLATION

Read these instructions thoroughly before beginning work.

Please leave these instructions for customers. These instructions contain mainte-

nance and warranty information.

If necessary, remove the existing toilet.

ENGLISH

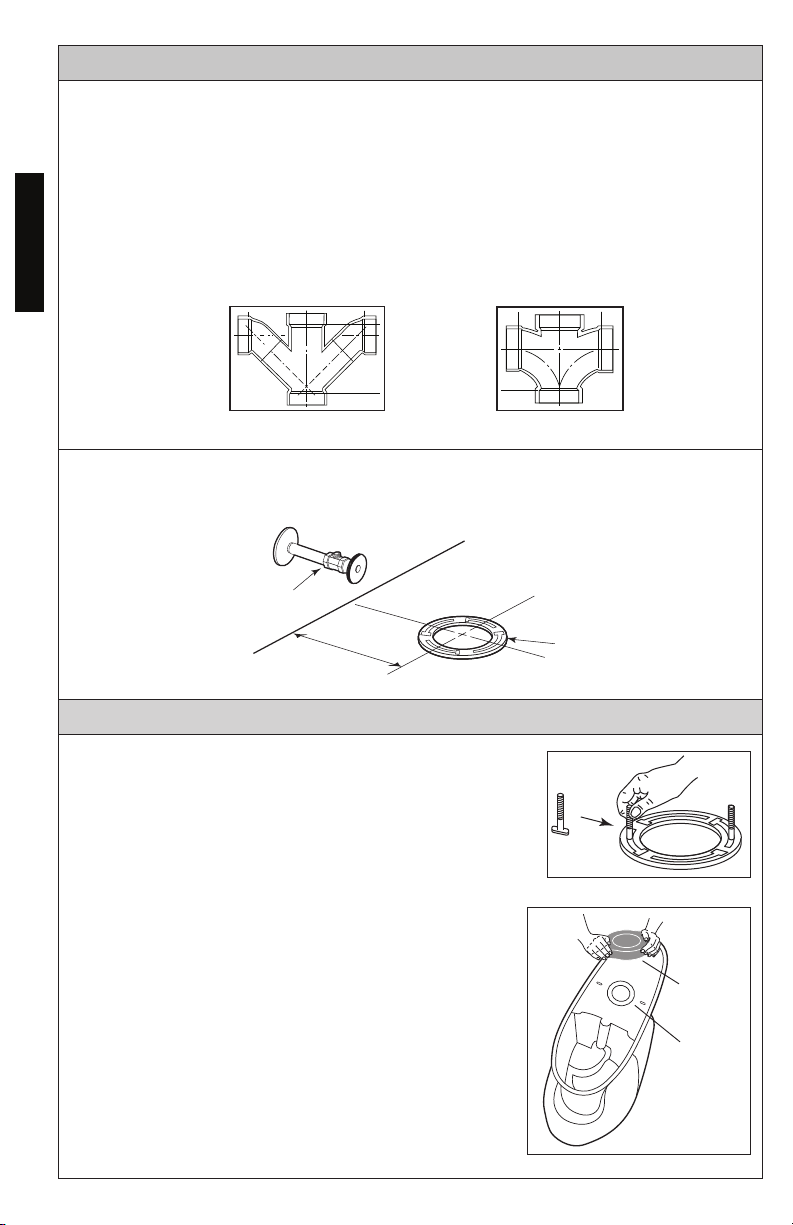

IMPORTANT!

Due to the powerful performance of our Cyclone, G-Max, E-Max and Power Gravity

flushing systems, they are not specified for back-to-back installations. The only

means of installing these toilets in a back-to-back situation is when the toilet drain

connections incorporate a WYE fitting. Please contact your builder or contractor prior

to this installation.

Double Combination WYE / 1/8 Bend

YES

Double Sanitary Tee / Sanitary Cross

NO

In order for your new TOTO® toilet to fit correctly, the distance between the finished

wall to the center of the closet flange must be at least 12 inches. This measurement is

called the Rough-In.

Finished Wall

Supply

Valve

"RI"

C/L

Closet

Flange

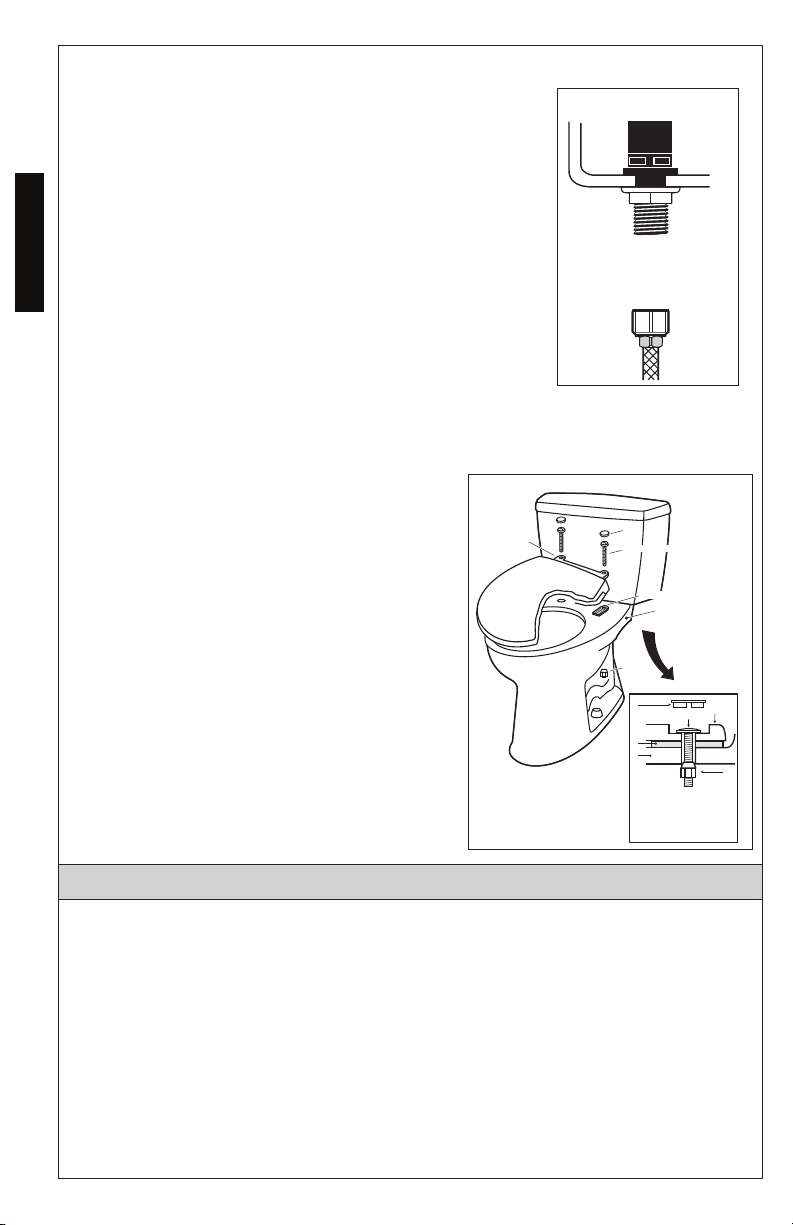

INSTALLATION PROCEDURE

1. Clean any debris out of the closet flange and

then install new mounting bolts (not supplied)

into the slots of the closet flange (see Ill. 1). The

head of the bolt should be inserted into the slot

with its threads facing upward.

2. Carefully turn the toilet upside down onto some

padding. Firmly press a new bowl wax ring

(not supplied) onto the circular recess around

the toilet bowl’s horn (see Ill. 2). Turn the toilet

upright and gently lower into position over the

closet flange. With toilet properly aligned, press

firmly on both sides of toilet rim to set the bowl

wax ring.

C AUTION: Do not move the bowl after the bowl

wax ring is set. Thread nuts and tighten evenly until

bowl is snug to closet flange. Install the bolt caps.

Ill. 1

Ill. 2

Wax Ring

Horn

C AUTION: Do not over-tighten the nuts as damage to

the china bowl may result.

4

Page 5

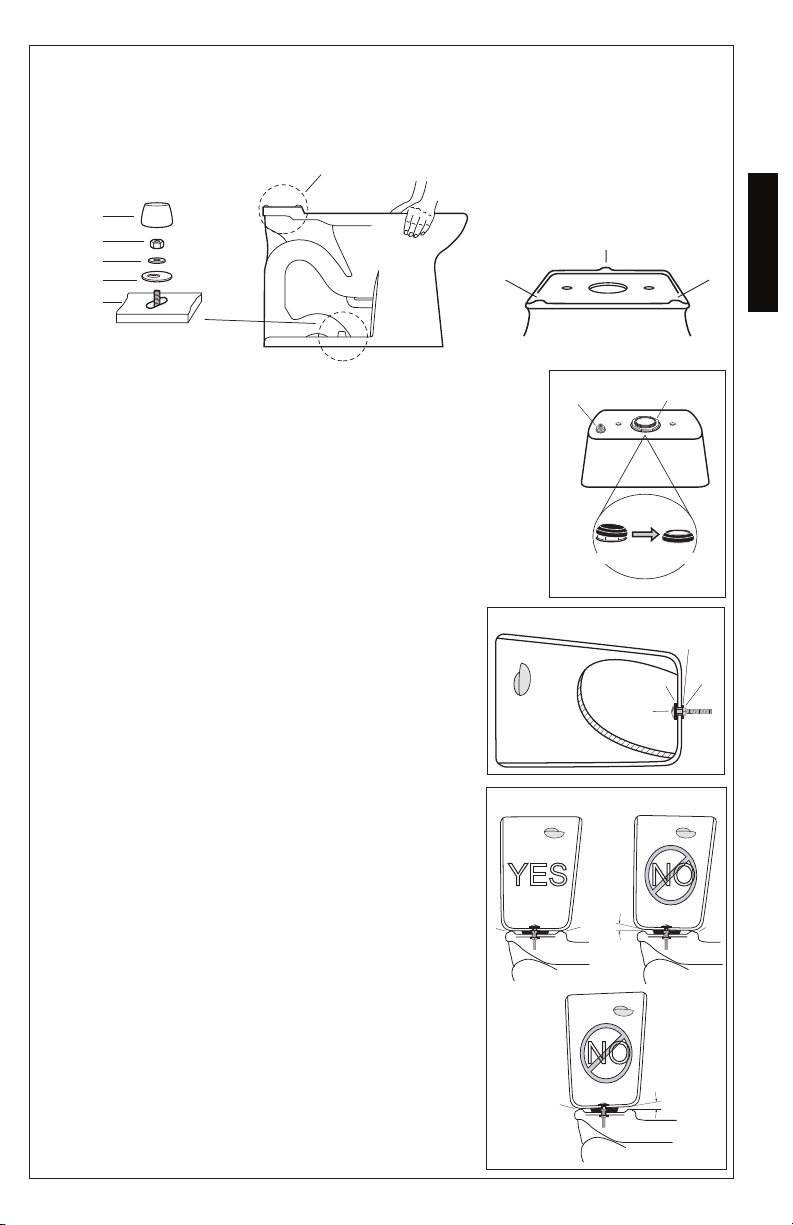

Installation Procedure (continued)

N OTE: The toilet bowl has three points of contact, which will actually contact the bottom of the

toilet tank when properly installed. The location of these points can be seen on the bowl at the

tank receiving area. The three points are front left (1), front right (2), and back center (3). Recall

these three points during the Toilet Tank installation.

Bolt Cap

Nut *

Washer *

Base Cap

Bowl Base

Three Points of Contact

2

1

3

ENGLISH

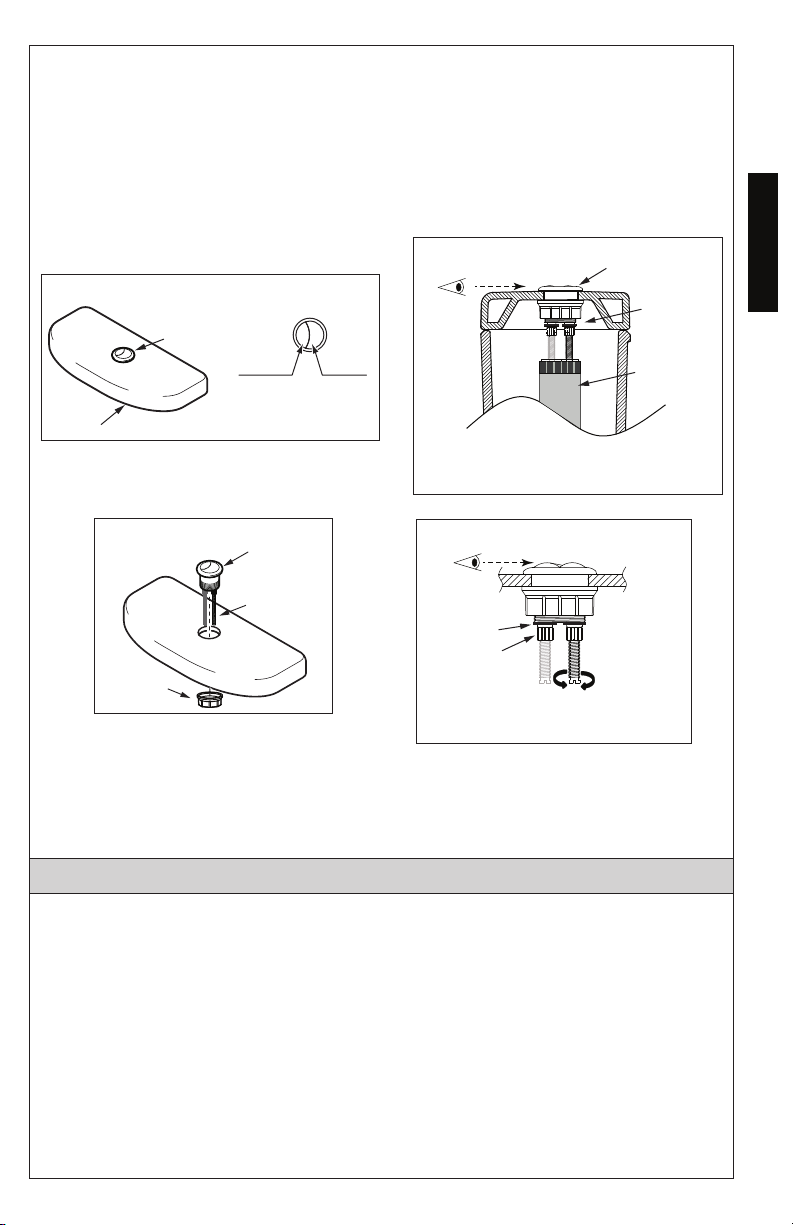

3. Place the tank upside down onto some

padding. Inspect the smaller fill valve nut

and larger flush valve nut for a secure

connection.

Try to tighten the nuts with your hands

see Ill. 3). If loose, tighten the nut hand

tight and an additional 1/4 turn for the

smaller fill valve nut and an additional 1/2

turn for the larger flush valve nut.

Place the tank-to-bowl gasket onto the

flush valve nut. While pressing down,

spread the gasket over the nut until the

gasket touches the bottom of the tank. A

slight gap between the tank bottom and

the gasket is allowable.

4. Lay the tank down on its back. Place a

rubber washer onto a brass bolt. Reach

inside the tank and position the bolt

through one of the holes in the bottom of

the tank (see Ill. 4).

On the outside of the tank, place a metal

washer and nut onto the bolt. Hold the

bolt centered in the hole and tighten

the nut finger tight. Turn the nut an

additional 1/2 turn with a wrench. Repeat

this process for the remaining hole in the

tank.

5. Pick up the tank and carefully guide the

brass bolts to align the tank with the

bowl. Attach a metal washer and nut to

each bolt. Tighten the nuts finger tight

and inspect that the tank is level (see Ill.

5). Once level, tighten the bolts equally

until the tank makes THREE POINTS OF

CONTACT with the bowl.

Ill. 4

Ill. 5

3

Ill. 3

Fill Valve Nut

Tank to Bowl Gasket

Rubber Washer

C

U

T

A

W

A

Y

V

I

E

1 & 2

3 GAP

NO

3

Metal Washer

Bolt

W

NOYES

1 & 2 GAP

Flush Valve

Nut

Nut

1 & 2

5

Page 6

Installation Procedure (continued)

6. Flush the water supply line for a few seconds to

remove any debris that may enter the new fill valve.

(For new home constructions and/or additions, flush

the water supply line for more than a minute to help

remove any residual PVC adhesives, solder flux, and/or

ENGLISH

pipe sealants that were used for the new plumbing.)

Connect the water supply line to the fill valve threads

as seen at the bottom of toilet tank (see Ill. 5). Tighten

this connection finger tight and then an additional 1/4

turn by hand. AVOID using a wrench to tighten the

connection as you may damage the plastic threads

and/or cause the fill valve to rotate inside the tank.

Water Supply Line Pressure should be 20 to 80 psi

Static.

N OTE: NO BALLCOCK / FILL VALVE

ADJUSTMENTS NEEDED. Water will automatically

stop at the proper level. Flush the toilet several times.

Check the flapper valve for proper operation. Make

sure that the chain is not tangled and the flapper arm

is in its proper position.

7. Install the toilet tank lid onto the toilet tank

top.

8. Install the toilet seat onto the toilet bowl

using the mounting hardware in the toilet

seat box (see Ill. 6). Place seat onto bowl

and rotate the hinge down. Position seat

stoppers under the seat hinge.

Insert bolt into seat hinge and through the

toilet bowl. Install plastic nut onto bolt from

underneath. Tighten the bolt securely. Install

the seat bolt caps.

N OTE: Tighten the seat bolt until the hinge

is secure. The seat and lid will have slight

side to side movement which is normal. This

freedom of movement allows the seat to

SoftClose® without binding.

Ill. 6

Seat Hinge

Ill. 5

7/8” BALLCOCK

THREAD

HAND TIGHTEN

1/4 TURN ONLY

Cap

Plastic Bolt

Plastic

Nut

Seat Stopper

Bowl

Mounting Hardware

1

2

4

5

1 - Cap

2 - Plastic Bolt

3 - Seat Hinge

4 - Seat Stopper

5 - Toilet Bowl

6 - Plastic Nut

3

6

ADJUSTING THE PUSH BUTTON RODS

CST405MF & CST406MF

After making sure the push buttons are installed correctly (see Ill. 8), place the

lid on the tank.

If the button(s) is too low (see Ill. 9):

1. Loosen the lock nut/s counterclockwise.

2. Turn the rod(s) counterclockwise to lengthen (each full turn is 1mm).

3. Place the lid on the tank to check the buttons.

If rod(s) is too long, water will keep running in the toilet.

1. Loosen the lock nut(s) counterclockwise.

2. Turn the rod(s) clockwise to shorten them.

6

Page 7

Installation Procedure (continued)

Adjust the rods as necessary by turning the rod 1 full turn (see Ill. 11); to lengthen,

turn the rod counterclockwise; to shorten, turn the rod clockwise.

When the adjustment is completed, tighten the lock nut to secure it (see Ill. 10).

After Installation/Adjustment

Flush the toilet two to three times to confirm there is no water leakage and that the

push mechanism is working properly.

Ill. 8

Tank Lid

Push

Buttons

Left

Partial

Flush

Right

Full

Flush

Ill. 9

Tank

The rod(s) is too short, the buttons are lowered.

Push Button

Assembly

Lid

Flush Valve

ENGLISH

Ill. 10

Mounting

Nut

Push Button

Housing

Adjustable

Push Rods

Tank

Lid

Ill. 11

Clip

Lock Nut

Buttons are at the correct level.

Clockwise/

Counterclock-

wise

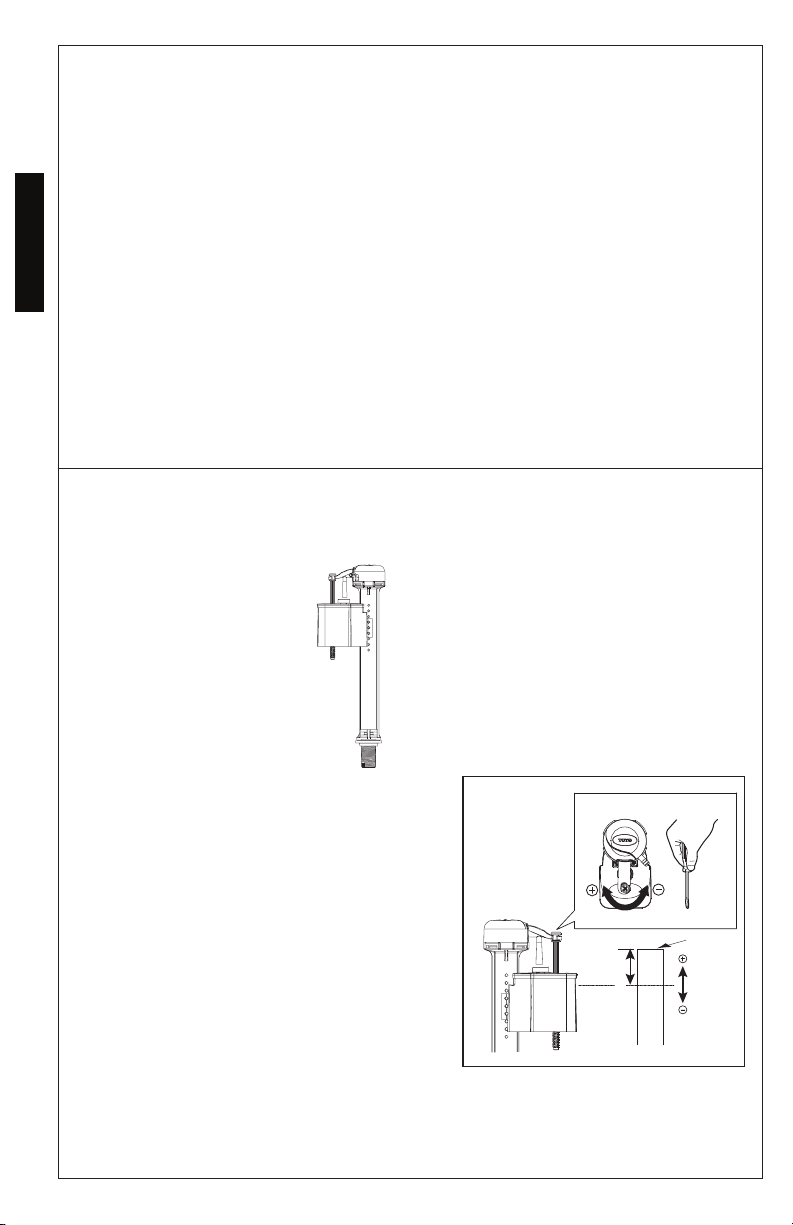

TOILET TANK FILL VALVE INSTRUCTIONS

CST405F & CST406F

Replacement Procedure

N OTE: The fill valve height has been preset at the factory and DOES NOT require

any height adjustments.

1. Shut off the water supply to the toilet.

2. Flush toilet and remove remaining water from tank with a sponge.

3. Remove the water supply connection at the fill valve.

7

Page 8

Replacement Procedure (continued)

WATER

LEVEL

4. Remove old fill valve and use damp sponge to clean hole in tank.

5. Place new fill valve inside tank hole.

6. Thread mounting nut onto fill valve shank and tighten the nut.

N OTE: Do not over-tighten. Be sure to install fill valve in a position that does not

ENGLISH

interfere with the trip lever operation.

7. Connect water supply to fill valve shank and hand-tighten only.

NO TE: Do not overtighten. These are plastic parts. Never use pipe dope on any

water supply connection.

8. Attach refill tube to fill valve nipple and clip other end of refill tube to the

overflow pipe.

9. Turn water supply ON and check for leaks outside the tank.

NO TE: As water fills the tank, water is also directed into the overflow tube via the

refill tube. This additional flow of water is critical to refilling your toilet’s bowl. Once

the water stops filling the tank, some residual drops of water may drip from the fill

valve.This is NORMAL as these drops will subside.

Water Level Adjustment

Refer to the water level (WL) setting

marked on the inner wall of the tank.

Allow the water to fill the tank. Turn the

adjustment screw clockwise in the (+)

direction to increase the water level height

(see Illustration 1). Turn the adjustment

screw counter-clockwise in the (-) direction

to decrease the water level height. Flush

the toilet to verify the correct water level.

Adjust as necessary.

Ill. 1

Top of

WL

8

Overflow

Tube

Page 9

TOILET TANK FILL VALVE INSTRUCTIONS

Gasket

Tank Wall

Mounting

Nut

Flanged

Supply Line

Coupling

Nut

Flat

Washer

Gasket

Tank Wall

Mounting

Nut

Cone

Seal

Flat Washer

Coupling

Nut

Copper Tube

Lock

Unlock

5

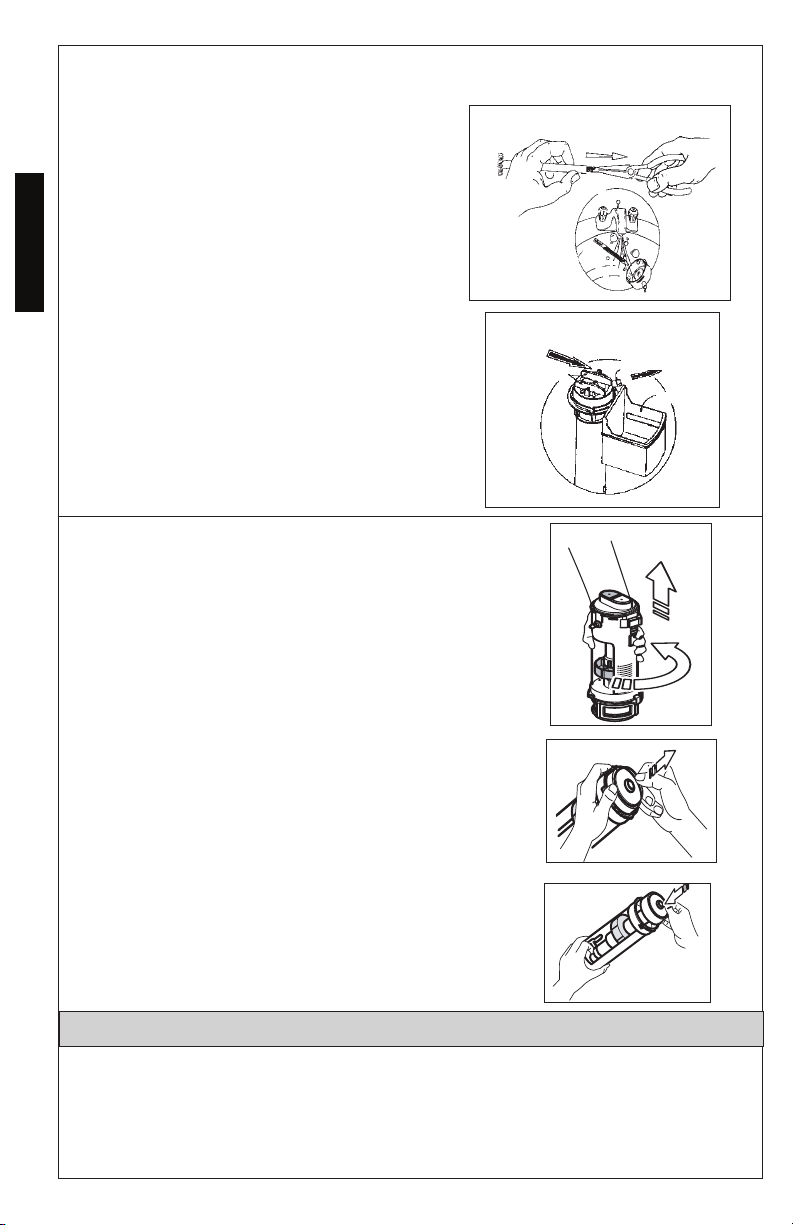

CST405MF & CST406MF

Replacement Procedure

1. Shut off the water supply. Flush the toilet and remove

any remaining water from the tank. Remove the old fill

valve.

2. Install new fill valve by sliding the threaded portion of

the shaft through the hole in the bottom of tank.

3. Thread mounting nut onto exposed shaft under the

tank/bowl and tighten nut.

WARNING! Do not over-tighten.

4. Connect the water supply (see Ill. 1 or Ill. 2). Pipe dope

is not recommended. Attach the refill tube to the

valve and clip the other end to the overflow pipe.

Water Level Adjustment

1. Remove the tamper proof key (see Ill. 3) and turn the

upper half of the valve counter-clockwise to unlock it

(see Ill. 4). Pull up the valve and set it to the desired

water level, then turn it clockwise until the valve snaps

into the locked position.

2. Turn on the water supply.

NOTE: The tamper proof key is optional and may be used

to prevent further adjustment.

Ill. 3 Ill. 4

Ill. 1

ENGLISH

Ill. 2

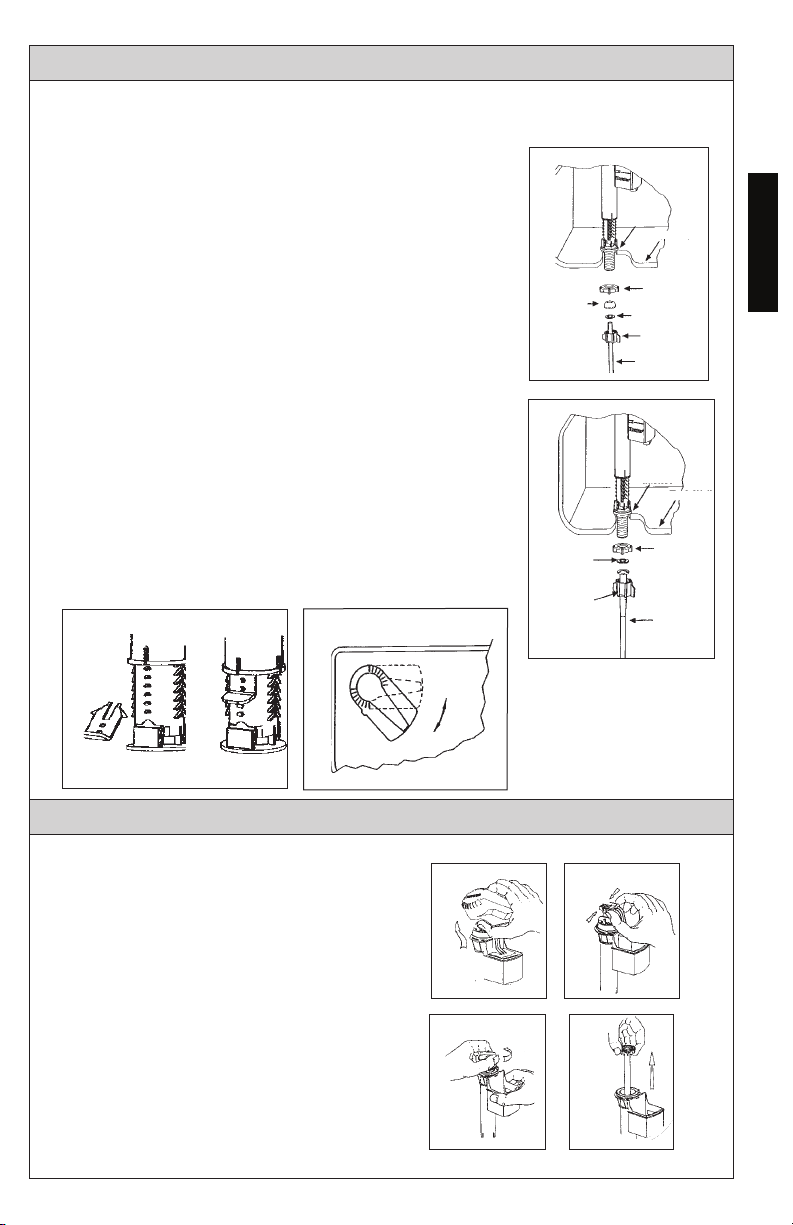

FILL VALVE/ FLUSH VALVE SERVICING INSTRUCTIONS

Fill Valve Servicing Instructions

1. Turn off the water supply, then flush

the toilet.

2. Snap off the cover (see Ill. 1).

3. Gently press the float arms inward

and remove the float (see Ill. 2).

4. While holding the valve with one

hand, twist the cap 1/8 turn counterclockwise and remove it (see Ill. 3).

Ill. 1 Ill. 2

Ill. 3

9

Ill. 4

Page 10

RIBS IN LINE

WITH FLOAT

CHAMBER

RIBS

REFILL PORT

FLOAT

CHAMBER

Fill Valve Servicing Instructions (continued)

5. Lift out the center tube as shown

(see Ill. 4).

6. Remove the strainer from the center

ENGLISH

tube as shown (see Ill. 5). Clean the

strainer and cap by rinsing them off

under a faucet.

7. Carefully reassemble the valve in the

reverse order.

IMPORTANT

Note the position of the cap when it’s

properly assembled to the body. The

ribs on the cap are in line with the float

chamber and the refill port is aligned as

shown (see Ill. 6).

Flush Valve Servicing Instructions

1. Turn off water supply and flush the toilet.

2. Remove the tank lid and place it upside down on a

clean surface.

3. Note the orientation of the flush valve for

reassembly.

4. Turn the upper half of flush valve counter-clockwise

and pull it up to remove it (see Ill. 1).

5. Remove the clear rubber seal gasket and rinse

under running water to clean (see Ill. 2).

6. Place the gasket back on the flush valve (see Ill. 3).

7. Install the flush valve back on the base.

8. Rotate the flush valve so that the white button is on

the left and the blue button is on the right.

9. Carefully, install the tank lid back on the tank.

10. Flush the toilet several times using each push button to verify proper operation. Check for leakage.

Ill. 5

Ill. 6

Ill. 1

Ill. 2

Ill. 3

CARE AND CLEANING

WARNING!

DO NOT USE IN-TANK BOWLCLEANERS. The use of high concentration of chlorine

or chlorine-related products can seriously damage fittings in the tank. This damage

can cause leakage and property damage. TOTO

for any tank fitting failure or damage caused by the use of in-tank bowl cleaners.

10

®

shall not be responsible or liable

Page 11

WARRANTY

1. TOTO® warrants its vitreous china products (“Product”) to be free from defects in materials

and workmanship during normal use when properly installed and serviced, for a period of one

(1) year from date of purchase. This limited warranty is extended only to the ORIGINAL PURCHASER of the Product and is not transferable to any third party, including but not limited to

any subsequent purchaser or owner of the Product. This warranty applies only to TOTO Product

purchased and installed in North, Central and South America.

2. TOTO’s obligations under this warranty are limited to repair, replacement or other appropriate adjustment, at TOTO’s option, of the Product or parts found to be defective in normal

use, provided that such Product was properly installed, used and serviced in accordance with

instructions. TOTO reserves the right to make such inspections as may be necessary in order to

determine the cause of the defect. TOTO will not charge for labor or parts in connection with

warranty repairs or replacements. TOTO is not responsible for the cost of removal, return and/

or reinstallation of the Product.

3. This warranty does not apply to the following items:

a. Damage or loss sustained in a natural calamity such as fire, earthquake, flood, thunder,

b. Damage or loss resulting from any accident, unreasonable use, misuse, abuse, negli-

c. Damage or loss resulting from sediments or foreign matter contained in a water system.

d. Damage or loss resulting from improper installation or from installation of the Product in

e. Damage or loss resulting from electrical surges or lightning strikes or other acts which are

f. Damage or loss resulting from normal and customary wear and tear, such as gloss reduc-

g. Tank flushing mechanisms of plastic or rubber moving parts.

h. Toilet seats of plastic, wood or metal.

4. In order for this limited warranty to be valid, proof of purchase is required. TOTO encourages

5. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER RIGHTS

6. To obtain warranty repair service under this warranty, you must take the Product or deliver it

WARNING! TOTO shall not be responsible or liable for any failure of, or damage to, this Product caused by either chloramines in the treatment of public water supply or cleaners containing

chlorine (calcium hypochlorite). NOTE: The use of a high concentrate chlorine or chlorine related

products can seriously damage the fittings. This damage can cause leakage and serious property

damage.

THIS WRITTEN WARRANTY IS THE ONLY WARRANTY MADE BY TOTO. REPAIR, REPLACEMENT

OR OTHER APPROPRIATE ADJUSTMENT AS PROVIDED UNDER THIS WARRANTY SHALL BE

THE EXCLUSIVE REMEDY AVAILABLE TO THE ORIGINAL PURCHASER. TOTO SHALL NOT BE

RESPONSIBLE FOR LOSS OF THE PRODUCT OR FOR OTHER INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR EXPENSES INCURRED BY THE ORIGINAL PURCHASER, OR FOR

LABOR OR OTHER COSTS DUE TO INSTALLATION OR REMOVAL, OR COSTS OF REPAIRS BY

OTHERS, OR FOR ANY OTHER EXPENSE NOT SPECIFICALLY STATED ABOVE. IN NO EVENT

WILL TOTO’S RESPONSIBILITY EXCEED THE PURCHASE PRICE OF THE PRODUCT. EXCEPT TO

THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTIES, INCLUDING THAT

OF MERCHANTABILITY OR FITNESS FOR USE OR FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND EXCLUSION MAY NOT APPLY TO YOU.

electrical storm, etc.

gence, or improper care, cleaning, or maintenance of the Product.

a harsh and/or hazardous environment, or improper removal, repair or modification of the

Product. (NOTE: Product model codes allow a maximum of 80 PSI. Check local codes or

standards for requirements).

not the fault of TOTO or which the Product is not specified to tolerate.

tion, scratching or fading over time due to use, cleaning practices or water or atmospheric

conditions.

warranty registration upon purchase to create a record of Product ownership at http://www.

totousa.com. Product registration is completely voluntary and failure to register will not diminish your limited warranty rights.

WHICH VARY FROM STATE TO STATE, PROVINCE TO PROVINCE OR COUNTRY TO COUNTRY.

prepaid to a TOTO service facility together with proof of purchase (original sales receipt) and a

letter stating the problem, or contact a TOTO distributor or products service contractor, or write

directly to TOTO U.S.A., INC., 1155 Southern Road, Morrow, GA 30260 (678) 466-1300 or (888)

295-8134, if outside the U.S.A. If, because of the size of the Product or nature of the defect, the

Product cannot be returned to TOTO, receipt by TOTO of written notice of the defect together

with proof of purchase (original sales receipt) shall constitute delivery. In such case, TOTO may

choose to repair the Product at the purchaser’s location or pay to transport the Product to a

service facility.

ENGLISH

11

Page 12

Page 13

ÍNDICE

¡Gracias Por Elegir TOTO®! ............................................................................................. 10

Antes de la Instalación

Herramientas Necesarias Común

Incluía Partes

.....................................................................................................................10

Antes de la Instalación

Procedimiento de Instalación

.....................................................................................................10

...................................................................................10

.....................................................................................................11

.....................................................................................11-13

Instrucciones Para la Instalación de la Válvula de Llenado del Tanque

de la Cisterna

Cuidado y Limpieza

Garantía

Dimensiones Preliminares

Refacciones

..............................................................................................................13-14

.......................................................................................................... 14

............................................................................................................................. 15

................................................................................................ 23

....................................................................................................................... 23

¡GRACIAS POR ELEGIR TOTO!

La misión de TOTO es dar al mundo estilos de vida más saludables, higiénicos y

cómodos. Diseñamos cada producto guiándonos por el principio del equilibrio entre

forma y función. Felicitaciones por su elección.

HERRAMIENTAS QUE NECESITA

ESPAÑOL

• 10” adjustable wrench

• Hacksaw

• Carpenter’s Level

• Tape Measure

• Pliers

• Flat Screwdriver

• Putty Knife

MATERIALES NECESARIOS (no suministrados):

• Sello/Anillo de Cera

• Línea Abastecedora de Agua

(Generalmente compresión de

• Mounting (T) Bolts & Nuts (2pc)

• Silla del Inodoro

(Se recomienta silla TOTO SoftClose)

1/2” hasta flotador de 7/8”)

INCLUÍA PARTES

Asegúrese de que tiene todas las piezas del empaque:

Recipiente Porcelana

Tanque Porcelana

Herrajes pra el Tanque y Recipiente:

Pernos

(2 piezas)

Rondanas Goma

(2 piezas)

Tapa del Tanque

Porcelana

Empaquetadura

Tanque - Recipiente

Tapas de la Brida

(Para el Recipiente):

Tapas Plástica

(2 piezas)

Rondanas Metálicos

(4 piezas)

Tuercas

(4 piezas)

13

Base Plástica

(2 piezas)

Page 14

ANTES DE LA INSTALACIÓN

Lea estas instrucciones detenidamente antes de empezar a trabajar.

Deje estas instrucciones a los clientes. Estas instrucciones contienen información

acerca del mantenimiento y garantía..

Si es necesario, retire el inodoro existente.

¡IMPORTANTE!

Debido al poderoso desempeño de nuestros sistemas de descarga Cyclone, G-Max

y Power Gravity, no están especificados para instalaciones consecutivas. La única

manera de instalar estos inodoros en una forma consecutiva es cuando las conexiones

de drenaje del inodoro incorpora una instalación WYE. Póngase en contacto con su

constructor o contratista antes de esta instalación.

ESPAÑOL

Doble combinación WYE / doblado 1/8

SÍ

T doble sanitaria / cruz sanitaria

NO

Con el fin de que su nuevo inodoro TOTO quede bien instalado, la distancia entre la

pared terminada al centro de la brida de suelo debe ser de por lo menos 12 pulgadas.

Esta medida se llama Enfoscado.

Válvula de

suministro

Pared terminada

C/L

"RI"

PROCEDIMIENTO DE INSTALACIÓN

1. Limpie cualquier suciedad que haya de la brida de

suelo y después instale los nuevos pernos para montaje (no proporcionados) en las ranuras de la brida

de suelo (véase III.1). La cabeza del perno debe ser

insertada en la ranura con sus roscas hacia arriba.

2. Cuidadosamente voltee el inodoro hacia abajo en una

superficie suave. Firmemente oprima un nuevo anillo

de cera de la taza (no proporcionado) en el descanso

circular alrededor del conector de la taza del inodoro

(véase III.2). Voltee el inodoro hacia arriba y bájelo

cuidadosamente a su posición sobre la brida de suelo.

Con el inodoro alineado adecuadamente, oprima

firmemente en ambos lados de la orilla del inodoro

para fijar el anillo de cera de la taza.

PRECAUCIÓN: No mueva la taza después de haber fijado

el anillo de cera de la taza. Enrosque las tuercas y apriete

uniformemente hasta que la taza esté ajustado a la brinda

de suelo. Instale las tapas de los pernos.

PRECAUCIÓN: No apriete más de lo necesario las tuercas

ya que se puede dañar la taza de cerámica.

Ill. 1

Ill. 2

anillo de

cera

conector

Closet

Flange

14

Page 15

NOTA: La taza del inodoro tiene tres puntos de contacto, que de hecho estarán en contacto con

Procedimiento de instalación (continuación)

la parte inferior del tanque del inodoro cuando esté adecuadamente instalado. La ubicación

de estos puntos puede verse en la taza en el área de recepción del tanque. Los tres puntos son

frente izquierda (1), frente derecha (2) y parte posterior centro (3). Recuerde estos tres puntos

durante la Instalación del tanque del inodoro..

Tapa del

perno

Tuerca *

Washer *

Tapa de la

base

Base dela

taza

Tres puntos de contacto

2

1

3

3. Coloque el tanque hacia abajo sobre alguna

superficie suave. Inspeccione que la tuerca

de la válvula de llenado más pequeña y la

tuerca de la válvula de descarga más grande

estén bien conectadas. Intente apretar las

tuercas con sus manos (véase III.3). Si están

flojas, apriételas con la mano y un 1/4 de giro

adicional a la tuerca de la válvula de llenado

más pequeña y 1/2 giro adicional para la

tuerca de válvula de descarga más grande.

Coloque la junta tanque a la taza sobre la

tuerca de la válvula de descarga. Mientras

oprime hacia abajo, expanda la junta sobre

la tuerca hasta que la junta toque la parte

inferior del tanque. Se permite un pequeño

espacio entre la parte inferior del tanque y la

junta.

4. Recueste el tanque en su parte posterior.

Coloque una arandela de hule en el perno

de latón. Meta dentro del tanque y coloque

el perno a través de uno de los orificios

en la parte inferior del tanque (véase III.4).

En la parte exterior del tanque coloque una

arandela de metal y enróquela en el perno.

Sostenga el perno centrado en el orificio y

apriete la tuerca con los dedos. Gire la tuerca

1/2 giro adicional con una llave. Repita este

proceso para el orificio restante en el tanque.

5. Levante el tanque y guíe cuidadosamente los

pernos de latón para alinear el tanque con la

taza. Fije una arandela de metal y tuerca en

cada perno. Apriete las tuercas con los dedos

e inspeccione que el tanque esté nivelado

(véase III.5). Una vez nivelado, apriete los

pernos de la misma forma hasta que el tanque

haga los TRES PUNTOS DE CONTACTO con

la taza.

Ill. 4

Ill. 5

3

Ill. 3

Tuerca de la válvula de llenado

Junta del tanque a

Arandela de hule

Perno

C

U

T

A

W

A

Y

V

I

E

W

1 & 2

3 GAP

NO

3

Tuerca de la

válvula de

descarga

la taza

Arandela de metal

Tuerca

NOYES

1 & 2 GAP

ESPAÑOL

1 & 2

15

Page 16

6. Descargue la línea de suministro de agua por algunos

Procedimiento de instalación (continuación)

segundos para retirar cualquier desecho que pudiera entrar

a la nueva válvula de llenado. (Para las construcciones nuevas

en el hogar y/o adiciones, descargue la línea de suministro

de agua por más de un minuto para ayudar a retirar

cualquier resto de adhesivos de PVC, flujo de la soldadura

y/o selladores de las tuberías que se utilizaron para la nueva

instalación de plomería.) Conecte la línea del suministro de

agua para llenar las roscas de la válvula de llenado como se

ve en la parte inferior del tanque del inodoro (véase III.5).

Apriete esta conexión con los dedos y después 1/4 de giro

adicional con la mano. EVITE el uso de una llave para apretar

la conexión ya que puede dañar las roscas de plástico y/o

ESPAÑOL

causar que la válvula de llenado rote dentro del tanque. La

presión de la línea de suministro de agua debe ser de 20 a 80

psi estático.

NOTA: NO SE NECESITA HACER NINGÚN AJUSTE AL

FLOTADOR/VÁLVULA DE LLENADO. El agua se detendrá

automáticamente en el nivel adecuado. Descargue el inodoro

varias veces. Revise que la válvula de sapo tenga una operación

adecuada. Asegúrese que la cadena no esté enredada y que

el brazo del sapo esté en la posición adecuada

7. Instale la tapa del tanque del inodoro en la parte

superior del tanque del inodoro.

8. Instale el asiento del inodoro en la taza del

inodoro utilizando las piezas para montaje en la

caja del asiento del inodoro (véase III.6). Coloque

el asiento en la taza y gire la bisagra hacia abajo.

Coloque los frenos del asiento debajo de la bisagra

del asiento.

Inserte un perno en la bisagra del asiento y a través

de la taza del inodoro. Instale la tuerca de plástico

en el perno de abajo. Apriete el perno de forma

segura. Instale las tapas de los pernos del asiento.

NOTA: Apriete el perno del asiento hasta que

la bisagra esté segura. El asiento y tapa tendrán

un ligero movimiento hacia los lados, el cual es

normal. Esta libertad de movimiento permite que el

asiento se cierre suavemente sin doblarsebinding.

Ill. 6

Bisagra de

la Silla

Ill. 5

rosca del flotador

7/8” BALLCOCK

d 7/8" apriete con

THREAD

la mano 1/4 de giro

HAND TIGHTEN

únicamente

1/4 TURN ONLY

Tapa

Perno Plastico

Piezas de Restriccion

Recipiente

Tuerca

Platica

Herrajes de Montaje

1

2

4

5

1 - Tapa

2 - Perno Plasticot

3 - Bisagra de la Silla

4 - Piezas de Restriccion

5 - Recipiente

6 - Tuerca Plastia

3

6

AJUSTANDO LAS VARILLAS DE LOS BOTONES PARA DESCARGAR*

CST405MF & CST406MF

Después de asegurarse que los botones para descargar están instalados

correctamente (véase III.7), coloque la tapa en el tanque.

Si el(los) botón(es) está(n) muy bajo(s) (véase III.9):

1. Afloje la(s) tuerca(s) de aseguramiento en sentido contrario de las manecillas del reloj.

2. Gire la(s) varilla(s) en sentido contrario de las manecillas del reloj para alargar

(cada giro completo es 1mm).

3. Coloque la tapa en el tanque para verificar los botones.

Si la(s) varilla(s) están demasiado largas, el agua seguirá corriendo en el inodoro.

1. Afloje la(s) tuerca(s) de aseguramiento en sentido contrario de las manecillas del reloj.

2. Gire la(s) varilla(s) en sentido contrario de las manecillas del reloj para acortarlas.

16

Page 17

Procedimiento de instalación (continuación)

Ajuste las varillas según sea necesario girando la varilla 1 giro completo (véase

III.10); para alargarlas, gire la varilla en sentido contrario de las manecillas del reloj;

para acortarlas, gire la varilla en el sentido de las manecillas del reloj.

Después de la instalación/ajuste

Descargue el inodoro de dos a tres veces para confirmar que no haya fugas y que

el mecanismo para descargar esté funcionando adecuadamente.

Ill. 8

Tapas del tanque

Botones para

descargar

Izquierdo

descarga

parcial

Dere-

cho

descarga

completa

Ill. 9

Tank

The rod(s) is too short, the buttons are lowered.

Cubierta de

los botones

para descar-

gar

Lid

Válvula de

descarga

ESPAÑOL

Ill. 10

Mounting

Nut

Push Button

Housing

Adjustable

Push Rods

Tank

Lid

Ill. 11

Sentido de las

Clip

Tuerca de

asegura-

miento

Los botones están en el nivel correcto

manecillas del

reloj/sentido

contrario a las

manecillas del

reloj

INSTRUCCIONES DE LA VÁLVULA DE LLENADO DEL TANQUE DEL INODORO

CST405F & CST406F

Procedimiento de sustitución

NOTA: La altura de la válvula de llenado fue preconfigurada en fábrica y NO requiere

de ningún ajuste.

1. Pague el suministro de agua.

2. Descargue el inodoro y retire el agua restante del tanque con una esponja.

3. Retire la conexión del suministro de agua a la válvula de llenado.

17

Page 18

Procedimiento de reemplazo (continuación)

WATER

LEVEL

4. Retire la válvula de llenado anterior y utilice una esponja húmeda para limpiar el

orificio en el tanque.

5. Coloque la nueva válvula de llenado dentro del orificio del tanque.

6. Enrosque la tuerca para montaje en el mango de la válvula de llenado y apriete la

tuerca.

NOTA: NO apriete más de lo necesario. Asegúrese de instalar la válvula de

llenado en una posición que no interfiera con la operación de la palanca de

disparo.

7. Conecte el suministro de agua al mango de la válvula de llenado y apriete

superficialmente únicamente.

NOTA: No apriete más de lo necesario. Estas son partes de plástico. Nunca utilice

lubricantes para tuberías en ninguna conexión del suministro de agua.

8. Fije el tubo de rellenado a la niple de la válvula de llenado y engrape el otro

ESPAÑOL

extremo del tubo de rellenado al tubo de desagüe.

9. ENCIENDA el suministro de agua y revise si hay fugas fuera del tanque.

NOTA: Mientras el agua llena el tanque, el agua también se dirige al tubo de desagüe

a través del tubo de rellenado. Este flujo adicional de agua es crítico para rellenar la

taza de su inodoro. Una vez que el agua deje de llenar el tanque, algunas residuales

de agua pueden gotear de la válvula de llenado. Esto es NORMAL ya que estas gotas

pararán.

Ajuste del nivel de agua

Consulte la configuración del nivel de

agua (WL) marcada en la pared interior del

tanque. Deje que el agua llene el tanque.

Gire el tornillo de ajuste en el sentido de las

manecillas del reloj en la dirección (+) para

aumentar la altura del nivel de agua (véase

Ilustración 1). Gire el tornillo de ajuste en el

sentido contrario de las manecillas del reloj

en la dirección (-) para disminuir la altura del

nivel de agua. Descargue el inodoro para

verificar el nivel correcto de agua. Ajuste

según sea necesario.

18

Ill. 1

Parte

WL

superior

del tubo

de desagüe

Page 19

INSTRUCCIONES DE LA VÁLVULA DE LLENADO DEL TANQUE DEL INODORO

Gasket

Tank Wall

Mounting

Nut

Flanged

Supply Line

Coupling

Nut

Flat

Washer

Gasket

Tank Wall

Mounting

Nut

Cone

Seal

Flat Washer

Coupling

Nut

Copper Tube

Lock

Unlock

5

CST405MF & CST406MF

Procedimiento de reemplazo

1. Apague el suministro de agua. Descargue el inodoro

y retire cualquier agua restante del tanque. Retire la

válvula de llenado anterior.

2. Instale la nueva válvula de llenado deslizando la parte

enroscada del eje a través del orificio en la parte

inferior del tanque.

3. Enrosque la tuerca para montaje hacia el eje expuesto

debajo del tanque/taza y apriete la tuerca.

¡ADVERTENCIA! No apriete más de lo necesario.

4. Conecte el suministro de agua (véase III.1 ó III.2). No

se recomiendan lubricantes para tuberías. Fije el tubo

de rellenado a la válvula y engrape el otro extremo a

la tubería de desagüe.

Ajuste del nivel de agua

1. Retire la llave inviolable (véase III.3) y gire la mitad superior de la válvula en sentido contrario a las manecillas del reloj para abrirla (véase III.4). Jale hacia arriba

la válvula y fíjela en el nivel de agua deseado, después

gírela en sentido de las manecillas del reloj hasta que

la válvula se cierre en la posición asegurada.

2. Encienda el suministro de agua.

NOTA: La llave inviolable es opcional y puede utilizarse

para prevenir un ajuste posterior.

Ill. 3

Ill. 4

Ill. 1

Ill. 2

ESPAÑOL

INSTRUCCIONES DE MANTENIMIENTO DE LA VÁLVULA DE LLENADO

Instrucciones de mantenimiento de

la válvula de llenado

1. Apague el suministro de agua,

después descargue el inodoro.

2. Desprenda la cubierta (véase III.1).

3. Oprima cuidadosamente los brazos

del flotador hacia adentro y retire el

flotador (véase III.2).

4. Mientras sostiene la válvula con una

mano, gire la tapa 1/8 de giro en

sentido contrario a las manecillas del

reloj y retírela (véase III.3).

Ill. 1 Ill. 2

Ill. 3

19

Ill. 4

Page 20

RIBS IN LINE

WITH FLOAT

CHAMBER

RIBS

REFILL PORT

FLOAT

CHAMBER

Instrucciones de mantenimiento de la válvula de llenado (continuación)

Ill. 5

5. Levante hacia afuera el tubo central

como se muestra (véase III.4).

6. Retire la coladera del tubo central

como se muestra (véase III.5). Limpie

la coladera y la tapa enjuagándolas

debajo del chorro de agua.

7. Cuidadosamente vuelva a montar la

válvula en orden inverso.

IMPORTANTE

Ill. 6

Note la posición de la tapa cuando está

adecuadamente montada en el cuerpo.

ESPAÑOL

Los ribetes en la tapa están alineados

con la cámara del flotador y el puerto de

rellenado está alineado como se muestra

(véase III.6).

Instrucciones de mantenimiento de la válvula de descarga

1. Apague el suministro de agua y descargue el inodoro.

2. Retire la tapa del tanque y colóquelo hacia abajo en una

superficie limpia.

3. Note la orientación de la válvula de descarga para poder

volver a montarla.

4. Gire la mitad superior de la válvula de descarga en sentido

contrario a las manecillas del reloj y jálela hacia arriba para

retirarla (véase III.1).

5. Retire la junta del sello de hule transparente y enjuague

debajo del chorro de agua para limpiarla (véase III.2).

6. Coloque la junta de nuevo en la válvula de descarga (véase III.3).

7. Instale la válvula de descarga de nuevo en la base.

8. Rote la válvula de descarga de tal forma que el botón

blanco quede a la izquierda y el botón derecho a la

derecha.

9. Cuidadosamente, instale la tapa del tanque nuevamente

en el tanque.

10. Descargue el inodoro varias veces utilizando cada botón

para descargar para verificar su operación adecuada.

Revise si hay fugas.

Ill. 1

Ill. 2

Ill. 3

CUIDADO Y LIMPIEZA

¡ADVERTENCIA!

NO UTILICE LIMPIADORES DE TAZA PARA DENTRO DEL TANQUE. El uso de una

concentración alta de cloro o productos relacionados con el cloro puede dañar

gravemente los accesorios en el tanque. Este daño puede causar fugas y daños a la

propiedad. TOTO no se hace responsable de ninguna falla o daño en los accesorios

del tanque por el uso de limpiadores de taza para dentro del tanque.

20

Page 21

GARANTÍA

1. TOTO® garantiza que su vitreos china producto no presenta defectos en sus materiales ni de fabricación durante su uso normal cuando es instalado y mantenido adecuadamente, por un periodo

de uno (1) año(s) a partir de la fecha de compra. Esta garantía limitada es válida solamente para el

COMPRADOR ORIGINAL del Producto y no es transferible a una tercera persona, incluyendo, pero

sin limitarse a, cualquier comprador o propietario subsecuente del Producto. Esta garantía aplica

solamente al Producto TOTO comprado e instalado en América del Norte, Central, Latina y del Sur.

2. Las obligaciones de TOTO bajo esta garantía se limitan a la reparación, cambio o cualquier otro

ajuste, a petición de TOTO, del Producto o partes que resulten defectuosas en su uso normal,

siempre que dicho Producto haya sido instalado, utilizado y mantenido de acuerdo con las instrucciones. TOTO se reserve el derecho de hacer tantas inspecciones como sean necesarias para

determinar la causa del defecto. TOTO no cobrará por la mano de obra o partes relacionadas con

las reparaciones o cambios garantizados. TOTO no es responsable por el costo de la remoción,

devolución y/o reinstalación del Producto.

3. Esta garantía no aplica en los siguientes casos:

a) Daño o pérdida ocurrida en un desastre natural, tal como: incendio, sismo, inundación, re-

b) Daño o pérdida resultado de cualquier accidente, uso inaceptable, mal uso, abuso, negli-

c) Daño o pérdida causada por los sedimentos o material extraña contenida en un sistema de

d) Daño o pérdida causada por una mala instalación o por la instalación del Producto en un

e) Daño o pérdida causada por sobrecargas eléctricas o rayos u otros actos que no sea respon-

f) Daño o pérdida causada por el uso normal y personalizado, tal como reducción del brillo,

4. Para que esta garantía limitada sea válida, prueba de compra es necesaria. TOTO anima el registro

5. ESTA GARANTÍA LE DA DERECHOS LEGALES ESPECÍFICOS. USTED PODRÍATENER OTROS

6. Para obtener el servicio de reparación de esta garantía, debe llevar el Producto o enviarlo prep-

ESTA GARANTÍA ESCRITA ES LA ÚNICA GARANTÍA HECHA POR TOTO. LA REPARACIÓN, CAMBIO U OTRO AJUSTE ADECUADO, TAL COMO APARECE EN ESTA GARANTÍA, SERÁ EL ÚNICO

REMEDIO DISPONIBLE PARA EL COMPRADOR ORIGINAL. TOTO NO SERÁ RESPONSABLE POR

LA PÉRDIDA DEL PRODUCTO O POR CUALQUIER OTRO DAÑO ACCIDENTAL, ESPECIAL O CONSECUENTE O POR DAÑOS INCURRIDOS POR EL COMPRADOR ORIGINAL, O POR LA MANO DE

OBRA U OTROS COSTOS RELACIONADOS CON LA INSTALACIÓN O REMOCIÓN, O COSTOS

DE REPARACIONES HECHAS POR OTROS, O POR CUALQUIER OTRO GASTO NO INDICADO DE

MANERA ESPECÍFICA EN LOS PÁRRAFOS ANTERIORES. EN NINGÚN CASO LA RESPONSABILIDAD DE TOTO EXCEDERÁ EL PRECIO DE COMPRA DEL PRODUCTO. EXCEPTO EN LA MEDIDA

EN QUE QUEDE PROHIBIDO POR LA LEYAPLICABLE, TODA GARANTÍA IMPLÍCITA, INCLUYENDO

AQUELLAS DE COMERCIABILIDAD O IDONEIDAD DE USO PARA EL USO O PARA UN PROPÓSITO

PARTICULAR, ESTÁ EXPRESAMENTE PROHIBIDA. ALGUNOS ESTADOS NO PERMITEN LAS LIMITACIONES ACERCA DE LA DURACIÓN DE UNA GARANTÍATÁCITA, O LA EXCLUSIÓN O LIMITACIÓN

DE DAÑOS INCIDENTALES O CONSECUENTES, POR LO QUE LA LIMITACIÓN E INCLUSIÓN ANTERIORES PUEDEN NO APLICAR A USTED.

AVISO TOTO no será responsable de fallas o daños ocasionados en este producto de plomería o

componente del producto causados por cloraminas en el tratamiento del suministro de agua público

o en los limpiadores en el recipiente del tanque que contengan cloro (hipoclorito de calcio). Nota:

el uso de cloro en alta concentración o productos derivados del cloro puede dañar seriamente los

accesorios. Este daño puede ocasionar fugas y daños graves en la propiedad. Para obtener más información, llámenos al (888) 295-8134.

lámpago, tormenta eléctrica, etc.

gencia o cuidado, limpieza o mantenimiento inadecuado del Producto.

agua.

ambiente duro y/o peligroso, o una remoción, reparación o modificación inadecuada del

Producto.

sabilidad de TOTO o que el Producto no esté especificado para tolerar.

rayado o pérdida de color en el tiempo debido al uso, prácticas de limpieza o condiciones

del agua o atmosféricas.

de la garantía sobre compra para cree un archivo de la propiedad del producto en http://www.

totousa.com. El registro del producto es totalmente voluntario y la falta a registrar no disminuirá

sus derechas de garantía limitada.

DERECHOS QUE PUEDEN VARIAR DEPENDIENDO DEL ESTADO O PROVINCIA EN EL QUE SE

ENCUENTRE.

agado a un modulo de servicios TOTO junto con la prueba de compra (recibo de compra original)

y una carta en la que plantee el problema, o póngase en contacto con un distribuidor TOTO o el

contratista de servicio de los productos, o escriba directamente a TOTO U.S.A., INC., 1155 Southern Road, Morrow, GA 30260 (678) 466-1300 o 888) 295-8134, si fuera de los E.E.U.U. Si, debido

al tamaño del producto o naturaleza del defecto, el Producto no puede ser devuelto a TOTO, la

recepción en TOTO del aviso escrito del defecto junto con la prueba de compra (recibo de compra

original) constituirá el envío. En tal caso, TOTO podrá escoger entre reparar el Producto en el domicilio del comprador o pagar el transporte del Producto a un módulo de servicio.

21

ESPAÑOL

Page 22

Page 23

TABLE DES MATIÈRES

Merci d’Avoir Choisi TOTO®! ..........................................................................................17

Outils Communs Nécessaires ..........................................................................................17

Pièces Incluses

..................................................................................................................17

Avant de Commencer ......................................................................................................18

Procédure d’Installation ..............................................................................................18-20

Instructions du Robinet de Remplissage du Réservoir

Entretien et Nettoyage

....................................................................................................21

.............................................20-21

Garantie .............................................................................................................................22

Dimensions Brutes ............................................................................................................23

Pièces de Rechange .........................................................................................................23

MERCI D’AVOIR CHOISI TOTO!

La mission de TOTO est d’offrir au monde entier un style de vie sain, hygiénique et

plus confortable. comme principe de base, nous concevons chaque produit avec un

équilibre entre la forme et la fonction. félicitations pour votre choix.

OUTILS NÉCESSAIRES

• Clé à Molette de 10 po.

• Scie à Métaux

• Niveau à Bulle d’Air

• Mètre à Ruban

• Pince

• Tournevis

• Couteau à Mastiquer

MATERIEL REQUIS (pas fournis):

• Anneau de Cire de la Cuvette

• Conduites d`Eau

(En général, une compression de

• Boulons de Montage et Ecrous (2pc)

• Siège des Toilettes

(TOTO SoftClose recommandé)

1/2” et un robinet à flotteur de 7/8”)

PIÈCES INCLUSES

Assurez-vous que vous avez toutes ces parties de l’emballage:

Cuvette en Porcelaine

Quincaillerie Réservoir-Cuvette:

Boulons

(2 pièces)

Réservoir en Porcelaine

Rondelles

Caoutchouc

(2 pièces)

Couvercle du Réser-

voir en Porcelaine

FRANÇAIS

Joint Réservoir-

Cuvette

Capot de Brides

(pour la cuvette):

Bouchons Plastique

(2 pièces)

Rondelles Métallique

(4 pièces)

Ecrous

(4 pièces)

Support Plastique

(2 pièces)

23

Page 24

AVANT L’INSTALLATION

Lisez ces instructions en détail avant de commencer les travaux.

Veuillez laisser ces instructions pour les clients. Ces instructions contiennent des

information de maintenance et de garantie.

Si nécessaire, retirez les toilettes existantes.

IMPORTANT!

En raison de la puissante performance de nos cyclone, le G-Max, E-Max et la gravité

d’alimentation des chasses d’eau, elles ne sont pas destinées à des installations

consécutives. Le seul moyen d’installer ces toilettes de manière consécutive est

quand les connexions de vidange des toilettes incorporent un raccord WYE. S’il vous

plaît contacter votre constructeur ou entrepreneur avant cette installation.

Combinaison double WYE / 1 / 8 courbure

OUI

Sanitaires double en T / sanitaires croisées

NON

Pour que votre nouvelle toilette TOTO s’adapte correctement, la distance entre le

mur fini et le centre de la bride du sol doit être d’au moins 12 pouces. Cette mesure

est appelée mesure brute.

FRANÇAIS

Valve

d’alimentation

Mur fini

"RI"

PROCÉDURE D’INSTALLATION

1. Nettoyez tous les débris de la bride du sol et ensuite

installez les nouveaux boulons de fixation (non fournis) dans les fentes de la bride de sol (voir III.1). La

tête du boulon doit être insérée dans la fente avec

ses rainures dirigées vers le haut.

2. Tournez soigneusement la toilette à l’envers sur du

rembourrage. Pressez fermement un nouvel anneau

de bol en cire (non fourni) sur le renfoncement

circulaire autour de la corne des cuvettes de la

toilette (voir III.2). Tournez la toilette verticalement

et abaissez la doucement en place sur la bride de

sol. Avec la toilette correctement alignée, appuyez

fermement sur les deux côtés du rebord de la

toilette pour régler l’anneau de cire du bol.

ATTENTION: Ne pas déplacer le bol après que l’anneau

de cire du bol soit fixé. Enfilez les écrous et serrez uniformément jusqu’à ce que le bol soit serré à la bride de sol.

Installez les bouchons du boulon

ATTENTION: Ne pas trop serrer les écrous considérant

que la cuvette en porcelaine peut etre endommagée.

Ill. 1

Ill. 2

C/L

Anneau de

Corne

Bride du

sol

cire

24

Page 25

REMARQUE: La cuvette des toilettes a trois points de contact, qui seront effectivement en

Procédure d’Installation (suite)

contact avec le fond du réservoir de la toilette lorsqu’elle est correctement installée. La localisation de ces points peut être vue sur le bol vers le réservoir. Les trois points sont avant gauche (1),

avant droit (2), et centre arrière (3). Rappelons ces trois points lors de l’installation du réservoir de

toilette.

Bouchon du

boulon

Ecrou *

Rondelle *

Bouchon de

la base

Base du bol

3. Placez le réservoir à l’envers sur du rembourrage.

Inspectez l’écrou de la petite valve de

remplissage et l’écrou de la grande valve de

chasse pour une connexion sécurisée. Essayez

de serrer les écrous avec vos mains (voir III.3). Si

relâché, serrer l’écrou fermement à la main et

un tour supplémentaire de 1/4 pour l’écrou de

la valve de remplissage plus petite et un tour

supplémentaire de 1/2 pour l’écrou de la valve de

chasse plus grande. Placez le joint du réservoir

à la cuvette sur l’écrou de la valve de chasse.

Tout en appuyant vers le bas, enfilez le joint sur

l’écrou jusqu’à ce que le joint touche le fond du

réservoir. Un écart léger entre le fond du réservoir

et le joint est permis.

4. Couchez le réservoir sur le dos. Placez une

rondelle en caoutchouc sur un boulon en laiton.

Allez à l’intérieur du réservoir et positionnez le

boulon à travers un des trous dans le fond de la

cuve (voir III.4). À l’extérieur de la cuve, placez

une rondelle en métal et l’écrou sur le boulon.

Tenez le boulon au centre du trou et serrez

fermement le doigt de l’écrou. Tournez l’écrou de

1/2 tour supplémentaire avec une clé. Répétez ce

processus pour le trou restant dans le réservoir.

5. Ramassez le réservoir et guidez soigneusement

les boulons en laiton pour aligner le réservoir

avec le bol. Attachez une rondelle en métal et

l’écrou sur chaque boulon. Serrez fermement

le doigt des écrous et vérifiez que le réservoir

est à niveau (voir III.5). Une fois à niveau, serrez

les boulons de manière égale jusqu’a ce que le

réservoir ait trois points de contact avec le bol.

Trois points de contact

1

Ill. 4

Ill. 5

3

2

Ill. 3

Ecrou de la valve

de remplissage

Joint du réservoir à la

cuvette

Rondelle en métal

Rondelle en

caoutchouc

Boulon

C

U

T

A

W

A

Y

V

I

E

W

1 & 2

3 GAP

NO

Écrou de

valve de

chasse

NOYES

Ecrou

3

FRANÇAIS

1 & 2

25

3

1 & 2 GAP

Page 26

Procédure d’installation (suite)

6. Rincez la ligne d’alimentation d’eau pendant quelques

secondes pour enlever tous les débris qui pourraient

entrer dans la nouvelle valve de remplissage. (Pour les

constructions de maisons neuves et / ou des ajouts,

rincer la ligne d’alimentation en eau pendant plus d’une

minute pour aider à éliminer toute colles PVC résiduelles,

flux de soudure, et / ou les scellants de tuyaux qui ont

été utilisés pour la nouvelle plomberie.) Connectez la

ligne d’alimentation d’eau aux rainures de la valve de

remplissage comme on le voit au fond du réservoir de

la toilette (voir III.5). Serrez cette connexion fermement

et ensuite d’un tour supplémentaire de 1/4 à la main.

ÉVITEZ d’utiliser une clé pour serrer la connexion de peur

d’endommager les rainures en plastique et / ou la rotation

de la valve de remplissage à l’intérieur du réservoir. La

Pression de la ligne d’approvisionnement en eau devrait

être de 20 à 80 psi statique.

NOTE: PAS D’AJUSTEMENT NECESSAIRE POUR LE

FLOTTEUR / VALVE DE REMPLISSAGE. L’eau s’arrêtera

automatiquement au niveau approprié. Tirez la chasse d’eau

plusieurs fois. Vérifiez que le clapet de la valve fonctionne

FRANÇAIS

correctement. Assurez-vous que la chaîne n’est pas emmêlé

et que le bras du clapet est dans la position correcte.

7. Installez le couvercle du réservoir de la toilette sur

le dessus du réservoir de la toilette.

8. Installez le siège de toilette sur la cuvette des

toilettes en utilisant le matériel de montage dans

la boîte du siège de la toilette (voir III.6). Placez

le siège sur le bol et faites pivoter la charnière

vers le bas. Positionnez les arrêts du siège sous

la charnière du siège. Insérez le boulon dans la

charnière du siège et à travers la cuvette des

toilettes. Installez l’écrou en plastique sur la vis par

le dessous. Serrez le boulon de manière sécure.

Installez les couvercles de boulon du siège.

REMARQUE: Serrez le boulon du siège jusqu’à

ce que la charnière soit sécurisée. Le siège et le

couvercle auront un léger mouvement d’un côté à

l’autre qui est normal. Cette liberté de mouvement

permet au siège de fermer en douceur sans liaison.

Ill. 6

Seat Hinge

Ill. 5

Serrez à la main sur

7/8” BALLCOCK

le filetage du robinet

THREAD

à flotteur de 7/8 " de

HAND TIGHTEN

1/4 TURN ONLY

1/4 de tour seulement

Cap

Plastic Bolt

Seat Stopper

Bowl

Plastic

Nut

Mounting Hardware

1

2

4

5

1 - Cap

2 - Plastic Bolt

3 - Seat Hinge

4 - Seat Stopper

5 - Toilet Bowl

6 - Plastic Nut

3

6

RÉGLAGE DES TIGES POUSSOIR

CST405MF & CST406MF

Après s’être assuré que les boutons poussoir sont correctement installés (voir III.7),

placez le couvercle sur le réservoir.

Si le bouton (s) est trop bas (voir III.9):

1. Desserrez l’écrou (s) de verrouillage dans le sens opposé des aiguilles d’une montre.

2. Tournez la tige (s) dans le sens opposé des aiguilles d’une montre pour allonger

(chaque tour complet est de 1mm).

3. Placez le couvercle sur le réservoir pour contrôler les boutons.

Si la tige (s) est trop longue, l’eau continuera à couler dans la toilette.

1. Desserrez l’écrou (s) dans le sens opposé aux aiguilles d’une montre.

2. Tournez la tige (s) dans le sens opposé des aiguilles d’une montre pour raccourcir.

26

Page 27

Procédure d’installation (suite)

Ajustez les tiges si nécessaire en tournant la tige d’1 tour complet (voir III.10); Pour

allonger, tournez la tige dans le sens opposé des aiguilles d’une montre; Pour

raccourcir,tournez la tige dans le sens des aiguilles d’une montre.

Après l’installation / Réglage

Tirez la chasse d’eau deux à trois fois pour confirmer l’absence de fuites d’eau et

que le mécanisme de poussée fonctionne correctement.

Ill. 8

Boutonspoussoirs

Couvercle du réservoir

Gauche

chasse

partielle

Droite

chasse

complète

Ill. 9

Tank

The rod(s) is too short, the buttons are lowered.

Push Button

Assembly

Lid

Flush Valve

Ill. 10

Mounting

Nut

Logements des

boutons-poussoir

Tiges

réglables

Couvercle du

réservoir

Ill. 11

Attache

Ecrou de

verrouillage

Les boutons sont au niveau correct

Dans le sens

des aiguilles

d’une montre/

Dans le sens

opposé aux

aiguilles d’une

montre

INSTRUCTIONS POUR LA VALVE DE REMPLISSAGE DU RÉSERVOIR DE LA TOILETTE

CST405F & CST406F

Procédure de remplacement

REMARQUE: La hauteur de la valve de remplissage a été préréglée en usine et ne

nécessite aucun réglage de la hauteur.

1. Coupez l’alimentation en eau de la toilette.

2. Tirez la chasse d’eau et enlevez l’eau restante dans le réservoir avec une éponge.

3. Retirez le raccord d’alimentation d’eau au niveau de la valve de remplissage.

FRANÇAIS

27

Page 28

Procédure de remplacement (suite)

WATER

LEVEL

4. Retirez l’ancienne valve de remplissage et utilisez une éponge humide pour

nettoyer le trou dans le réservoir.

5. Placez la nouvelle valve de remplissage à l’intérieur du trou du réservoir.

6. Enfilez l’écrou de montage sur la queue de la valve de remplissage et serrez

l’écrou.

REMARQUE: Ne serrez pas trop fort. Veuillez installer la valve de remplissage

dans une position qui n’interfère pas avec le fonctionnement du levier de

déclenchement.

7. Connectez l’alimentation d’eau à la queue de la valve de remplissage et serrez

vers le haut seulement.

REMARQUE: Ne pas trop serrer. Ce sont des pièces en plastique. Ne jamais

utiliser de la pâte à joint sur toute connexion d’alimentation en eau.

8. Fixez le tube de remplissage au mamelon de la valve de remplissage et attachez

l’autre extrémité du tube de remplissage au tuyau de débordement.

9. Allumez l’alimentation d’eau et vérifiez l’absence de fuites à l’extérieur du

réservoir.

NOTE: Pendant que l’eau remplit le réservoir, l’eau est également dirigée vers le

tube de débordement via le tube de remplissage. Ce flux d’eau supplémentaire

FRANÇAIS

est crucial pour le remplissage de votre bol de toilette. Une fois que l’eau cesse de

remplir le réservoir, quelques gouttes d’eau résiduelles peuvent s’écouler de la valve

de remplissage. Ceci est normal car ces gouttes diminueront.

Réglage du niveau d’eau

Reportez-vous au niveau de l’eau (WL) la

mise marquée sur la paroi intérieure de la

cuve. Laissez l’eau pour remplir le réservoir.

Tournez la vis de réglage dans le sens

des aiguilles d’une montre dans le sens

(+) pour augmenter la hauteur du niveau

d’eau (voir illustration 1). Tournez la vis de

réglage dans le sens opposé aux aiguilles

d’une montre dans le sens ( -) pour

diminuer la hauteur du niveau d’eau. Tirez

la chasse d’eau pour vérifier que le niveau

d’eau est correct. Ajustez si nécessaire.

28

Ill. 1

Top of

WL

Overflow

Tube

Page 29

INSTRUCTIONS POUR LA VALVE DE REMPLISSAGE DE LA TOILETTE

Gasket

Tank Wall

Mounting

Nut

Flanged

Supply Line

Coupling

Nut

Flat

Washer

Gasket

Tank Wall

Mounting

Nut

Cone

Seal

Flat Washer

Coupling

Nut

Copper Tube

Lock

Unlock

5

CST405MF & CST406MF

Procédure de remplacement

1. Coupez l’alimentation en eau. Tirez la chasse d’eau et

enlevez toute l’eau restante dans le réservoir. Retirez la

vieille valve de remplissage.

2. Installez une nouvelle valve de remplissage en faisant

glisser la partie filetée de l’arbre dans le trou au fond du

réservoir.

3. Enfilez l’écrou de montage sur l’arbre exposé sous le

réservoir / cuvette et serrez l’écrou.

ATTENTION! -Ne pas trop serrer!

4. Connectez l’alimentation en eau (voir III.1 ou III.2). La

pâte à joint n’est pas recommandée. Fixez le tube de

remplissage à la valve et attachez l’autre extrémité à la

canalisation de débordement.

L’ajustement du niveau d’eau

1. Retirez la clé inviolable (voir III.3) et tournez la moitié

supérieure de la valve dans le sens opposé aux aiguilles

d’une montre pour la déverrouiller (voir III.4). Tirez la

valve vers le haut et réglez la au niveau d’eau désiré, puis

tournez dans le sens des aiguilles d’une montre jusqu’à

ce que la valve s’enclenche en position verrouillée.

2. Allumez l’alimentation en eau.

REMARQUE: La clé inviolable est facultative et peut être utilisée pour empêcher tout ajustement supplémentaire.

Ill. 3

Ill. 4

Ill. 1

Ill. 2

FRANÇAIS

VALVE DE REMPLISSAGE/INSTRUCTIONS D’ENTRETIEN DE LA VALVE DE CHASSE

Instructions d’entretien de la valve

de remplissage

Ill. 1 Ill. 2

1. Coupez l’alimentation en eau, puis

rincer la toilette.

2. Enlever le couvercle (voir III.1).

3. Appuyez doucement sur le bras du

flotteur vers l’intérieur et retirez le

flotteur (voir III.2).

4. Pendant que vous tenez la valve avec

une main, tournez le bouchon d’1/8

de tour dans le sens opposé aux

aiguilles d’une montre et retirez le

(voir III.3).

29

Ill. 3

Ill. 4

Page 30

RIBS IN LINE

WITH FLOAT

CHAMBER

RIBS

REFILL PORT

FLOAT

CHAMBER

Instructions de service de la valve de remplissage (suite)

5. Soulevez le tube central, comme indi-

qué (voir III.4).

6. Retirez le tamis du tube central,

comme indiqué (voir III.5). Nettoyez le

filtre et le bouchon en les rinçant sous

un robinet.

7. Soigneusement remonter la valve

dans l’ordre inverse.

IMPORTANT

Notez la position du bouchon quand il

est correctement assemblé au corps. Les

côtes sur le bouchon sont en ligne avec la

cavité du flotteur et le port de recharge est

aligné comme indiqué (voir III.6).

Instructions d’entretien de la valve de chasse

1. Coupez l’alimentation d’eau et rincez les toilettes.

FRANÇAIS

2. Retirez le couvercle du réservoir et placez le à l’envers

sur une surface propre.

3. Notez l’orientation de la valve de chasse pour le

remontage.

4. Tournez la moitié supérieure de valve de chasse dans

le sens opposé aux aiguilles d’une montre et tirez vers

le haut pour le retirer (voir III.1).

5. Retirez le joint d’étanchéité clair en caoutchouc et

rincez le sous l’eau courante pour nettoyer (voir III.2).

6. Remettez le joint sur la valve de chasse (voir III.3).

7. Installez la valve de vidange à nouveau sur la base.

8. Tournez la valve de vidange de sorte que le bouton

blanc soit sur la gauche et le bouton bleu soit sur la

droite.

9. Installez soigneusement le couvercle du réservoir sur

le réservoir.

10. Tirez la chasse d’eau plusieurs fois en utilisant chaque

bouton-poussoir afin de vérifier leur bon fonctionnement. Vérifiez qu’il n’y ait pas de fuites.

Ill. 5

Ill. 6

Ill. 1

Ill. 2

Ill. 3

ENTRETIEN ET NETTOYAGE

ATTENTION!

NE PAS UTILISER LES NETTOYANTS DE CUVETTE DANS LE RÉSERVOIR.

L’utilisation de concentrations élevées de chlore ou de produits à base de chlore

peuvent endommager sérieusement la robinetterie dans le réservoir. Ces dommages peuvent entraîner des fuites et des dégâts matériels. TOTO ne peut être tenu

responsable ou assujetti pour toute défaillance du réservoir ou tout dommage causé

par l’utilisation de nettoyants de cuvette dans le réservoir.

30

Page 31

GARANTIE

1. TOTO® garantit sa vitreous china produits contre tout défaut de matériau et de fabrication pendant l’utilisation normale, lorsqu`elle est correctement installée et maintenue pour une période

de une (1) ans à dater de l`achat. La présente garantie limitée ne peut être prolongée que pour

le seul ACHETEUR D`ORIGINE de l`appareil et n`est pas transférable à un tiers, y compris mais

pas limité à tout acheteur ou propriétaire subséquent du produit. Cette garantie n’est applicable

qu’aux produits achetés et installés en Amérique du Nord, Centrale, Latine, et du Sud.

2. Les obligations de TOTO selon les termes de cette garantie sont limitées à la réparation, remplacement ou autre ajustement en conséquent, au choix de TOTO, des produits ou des pièces

défectueuses en service normal, pourvu qu’un tel produit ait été installé, utilisé et entretenu

conformément aux instructions. TOTO se réserve le droit d`effectuer ce genre de vérifications en

cas de nécessité afin de déterminer la cause du défaut. TOTO ne facturera pas les interventions

ou les pièces relatives à la réparation et au remplacement sous garantie. TOTO n`est pas responsable du coût de désinstallation, de renvoi et/ou de réinstallation de l`appareil.

3. La garantie ne s`applique pas dans les cas suivants:

a) Dommage ou perte suite à une cause naturelle telle que incendie, tremblement de terre,

b) Dommage ou perte causés par tout accident, utilisation non adaptée, un abus, une négli-

c) Dommage ou perte causé par des sédiments ou tout autre corps étranger contenus dans

d) Dommage ou perte suite à une mauvaise installation ou à l`installation de l`appareil dans

e) Dommage ou perte suite à des surtensions, foudres ou tous autres actes qui ne sont pas

f) Dommage ou perte résultant d`une usure normale et habituelle, telle que la diminution

4. Pour que la garantie limitée soit valable, la preuve d’achat est exigée. TOTO vous encourage

5. CETTE GARANTIE DONNE DES DROITS SPÉCIFIQUES. IL EST POSSIBLE QUE L’ACHETEUR AIT

6. Pour obtenir une réparation selon les termes de cette garantie, l’acheteur doit livrer à un centre

CETTE GARANTIE ÉCRITE EST LA SEULE GARANTIE FAITE PAR TOTO. LA RÉPARATION, LE

REMPLACEMENT OU TOUT AUTRE AJUSTEMENT APPROPRIÉ SELON LES TERMES DE CETTE

GARANTIE EST LE SEUL RECOURS DE L’ACHETEUR INITIAL. TOTO N’EST PAS RESPONSABLE

DE LA PERTE DU PRODUIT OU DE TOUT AUTRE DOMMAGE INDIRECT, SPÉCIAL OU SECONDAIRE OU DES DÉPENSES ENCOURUES PAR L’ACHETEUR INITIAL NI DE LA MAIN-D’OEUVRE

OU AUTRES FRAIS ASSOCIÉS À L’INSTALLATION OU LA MANIPULATION, OU LES FRAIS DE

RÉPARATION PAR DES TIERS, NI POUR TOUS AUTRES FRAIS PAS SPÉCIFIQUEMENT MENTIONNÉS. EN AUCUN CAS, LA RESPONSABILITÉ DE TOTO NE PEUT DÉPASSER LE PRIX D’ACHAT

DU PRODUIT. SAUF QUAND INTERDITE PAR UNE LOI APPLICABLE, TOUTE GARANTIE SOUSENTENDUE, Y COMPRIS CELLE DE VENDABILITÉ OU D’APPLICATION POUR UN USAGE PARTICULIER, EST EXPRESSÉMENT REJETÉ. CERTAINES PAYS NE PERMETTENT PAS LA LIMITATION

DE LA LONGUEUR D’UNE GARANTIE SOUS-ENTENDUE, OU L’EXCLUSION OU LA LIMITATION

DES DOMMAGES INDIRECTS OU SECONDAIRES, IL EST DONC POSSIBLE QUE CETTE LIMITATION ET EXCLUSION NE S’APPLIQUE PAS À VOTRE CAS.

ATTENTION ! TOTO décline toute responsabilité quant aux panes ou aux dommages causés sur

ce produit de plomberie ou composant du produit par la chloramine contenue dans le traitement

de l’alimentation en eau publique ou dans les produits d’entretien pour réservoirs des toilettes

contenant du chlore (hypochlorite de calcium). Remarque : l’utilisation d’une forte concentration

de chlore ou de produits à base de chlore risque d’endommager sérieusement la tuyauterie. Ces

dommages peuvent provoquer des fuites et des dégâts des eaux. Pour plus d’informations, contactez-nous au (888) 295-8134.

inondation, tonnerre, orage etc.

gence ou un mauvais traitement, nettoyage ou entretien de l`appareil.

un réseau d`alimentation en eau.

un environnement rude et/ou dangereux ou une mauvaise désinstallation, réparation ou

m.

la responsabilité de TOTO, ou actes stipulés non supportables par le produit.

du lustre, grattage ou décoloration avec le temps, habitude de nettoyage, l`eau, ou des

conditions atmosphériques.

à enregistrer votre produit après l’achat pour créer un record du propriété, cela peut être fait

au site http://www.totousa.com. L’enregistrement du produit est complètement volontaire et à

défaut de l’enregistrement ne va pas limiter votre droit au garantie limitée.

D’AUTRES DROITS QUI VARIENT DUN ÉTAT A UN AUTRE OU D’UNE PROVINCE À L’AUTRE.

de réparation de TOTO port payé avec preuve d’achat (reçu de caisse original), et une lettre

expliquant le problème, ou contacter un distributeur de TOTO ou un entrepreneur de réparation

du produit ou écrire directement à TOTO U.S.A., INC., Southern Road, Morrow, Géorgie 30260,

(678) 466-1300 ou appelé (888) 295-8134, si en dehors de L’Etat Unis. Si, à cause de la taille du

produit ou de la nature du défaut, il n’est pas possible de renvoyer le produit à TOTO, la réception par TOTO d’un avis écrit du défaut avec preuve d’achat (reçu de caisse original) constitue

livraison. Dans un tel cas, TOTO peut choisir de réparer le produit chez l’acheteur ou de payer le

transport du produit à un centre de réparation.

FRANÇAIS

31

Page 32

ROUGH-IN DIMENSIONS / DIMENSIONES PRELIMINARES /

SPECIFICATIONS

• Water Use 1.6 GPF (6.0 LPF)

• Flush System Gravity

• Min. Water Pressure 8 psi (fl owing)

• Water Surface 5-1/2" x 7-1/4"

• Trap Diameter 1-7/8"

• Rough-in 12"

• Trap Seal 2"

• Warranty One Year Limited Warranty

• Material Vitreous china

• Shipping Weight C406F - 53lbs

ST406 - 35lbs

• Shipping Dimensions C406F - 28" x 16" x 17"

ST406 - 20-1/2" x 9" x 17-1/2"

CST406F

Rowan™ Close Coupled Toilet, 1.6GPF

Double Sanitary Tee / Sanitary CrossDouble Combination Wye / 1/8 Bend

ONSEY

INSTALLATION NOTES

Back-to-Back Toilet Installations:

TOTO recommends the use of a nationally listed,

double sanitary tee-wye only, in vertical waste stacks,

in accordance with the stipulations noted in the

majority of nationally recognized plumbing codes.

m

3/8" (289mm)

DIMENSIONS BRUTES

7" (177mm)

A

5-1/2"

(140mm)

14-1/8"

(359m

28-1/4" (717mm)

WATER LEVEL

3/4"

(20mm)

B

6-11/16"

(171mm)

5-11/16"

(145mm)

12" (305mm)

11-

Model

Modelo

Model

CST405F 26 ¼” 16-1/8” 31-11/16”

CST405MF 26 ¼” 16-1/8” 31-11/16”

CST406F 28 ¼” 16-1/8” 31-11/16”

CST406MF 28 ¼” 16-1/8” 31-11/16”

* Recommended Dimensions

* Dimensiones Recomendadas

* Dimensions Recommandées

18-1/2" (470mm)

SUPPLY

AS REQ'D

C

29-1/2"

(750mm)

*8" (203mm)

*5-7/8"

(149mm)

9-1/16" (230mm)

14-9/16"

(370mm)

A B C

REPLACEMENT PARTS / REFACCIONES /

PIÈCES DE RECHANGE

Model

Modelo

Model

Válvula de

Llenado

Robinet de

Remplissage

ST406 TSU30A THU364 THU068#XX

ST405M TSU09A.7 THU362 THU363#CP

Fill Valve

Flush Valve Assembly

with Flapper

Válvula de Descarga

Asamblea con Trampa

Soupape de Chasse

Assemblée Tambour

32

Trip Lever/ Push Button

Palanca de Descarga/

Botón pulsador

Levier de Déclenchement/

Bouton-poussoir

Page 33

TOTO® U.S.A., Inc. 1155 Southern Road,

Morrow, Georgia 30260

Tel: 888-295-8134 Fax: 800-699-4889

www.totousa.com

0GU073

Rev Date: 08/11

Warranty Registration and Inquiry

For product warranty registration, TOTO U.S.A. Inc. recommends online warranty registration. Please visit

our web site http://www.totousa.com. If you have questions regarding warranty policy or coverage, please contact TOTO U.S.A. Inc., Customer Service Department, 1155 Southern Road, Morrow, GA 30260

(888) 295-8134 or (678) 466-1300 when calling from outside of U.S.A.

Loading...

Loading...