Toto ABA991X01FCP Installation Manual

NEOREST SE

AIR BATH

Installation Guide

Cautions and warnings……………2

Before installing the Neorest……..5

Included parts……………………...8

Required tools…………….………10

Specifications……………………..11

Dimension Drawings……………..13

Installation Procedure…………....15

Meaning of the indications……….15

Building a base for the bathtub….16

Installing the function module……20

Testing the operation……………..24

Finishing……………………………34

Installing the controller stand…….37

Cleaning the filter………………….41

Error Codes………………………..44

To installation contractors:

If possible, please explain the functions of the NEOREST and how to use them to the

customer. In new buildings or other places where there will be a significant time until

the customer uses the product, please shut off the power.

0GU5081, V.01

Cautions and Warnings

Before installing your NEOREST, be sure to read the following installation instructions. Install the product only as described in this guide. Follow all safety precautions and warnings.

!

WARNING

When this appears next to a

topic, this indicates that misoperation could result in death

or serious injury.

CAUTION

Symbol example

This symbol indicates something

that is prohibited.

WARNING

Do not install the tub with the rim surface as its sole support.

● Doing so could cause damage.

!

Prohibited

Do not stand on the bathtub while working.

● Doing so could cause one to slip and fall or could otherwise damage the product.

Only assemble the parts delivered or indicated. Do not change these parts

● In particular, do not change the dimensions.

Do not install the function module in a humid location such as a bathroom or a place

prone to flooding.

● Otherwise product problems or electric shock could result.

Install securely, in accordance with the Installation Guide.

● Improper installation can lead to electric shocks or fire. Additionally, it could cause water

leaks that damage or ruin household property.

Install the drainage pipes securely, in accordance with the procedure.

● Improper installation could lead to leaks that damage or ruin household property.

After unpacking, immediately dispose of unwanted packaging materials.

● There is a risk of injury from the wooden frame, nails, cardboard boxes, vinyl bags or sealing straps. Additionaly, ensure that children do not play with the packaging materials as this

could lead to suffocation or other accidents.

Required

All the operations related to the electrical system must be implemented by a certified

!

electrician.

● Improper operation could result in physical damage or material damage.

!

When this appears next to a topic,

this indicates that misoperation

may result in injury or physical

damage.

This symbol indicates something

!

that must be done.

2

All electrical equipment connected to the bathtub must be fitted with a ground fault

circuit interrupter (GFCI).

The bathtub must be connected to the drinking water supply.

The earth (ground) wire must be connected without fail.

Perform a potential equalization, and connect the plug to the bathtub frame.

● Improper ground connection could allow ground loops.

The voltage used must be the specified AC voltage.

● Use of different voltage could cause damage to the equipment, malfunction or fire.

WARNING

After the installation, test the ground fault circuit interrupter (GFCI) protecting this

appliance and periodically check it in accordance with the manufacturer’s instructions.

● An improperly functioning GFCI could lead to electric shock or fire.

!

Be sure that the equipment is installed in a stable place with sufficient load-bearing

strength, as set forth in the Installation Guide.

● Improper installation could cause the equipment to fall or topple over, causing injury.

When installing the function module using a metal lath or wire lath support, be certain

!

Required

not to connect the function module and support electrically.

● Doing so could lead to electric shock, overheating or fire.

When connecting the wiring, be certain that the power supply is not turned ON.

● Doing so could lead to electric shock.

The electronic components must be installed out of the reach of users in the bathroom. (However, this rule is not applied to ultralow voltage supply components at 12

V or less, such as remote controllers.)

Otherwise, an electric shock could result.

The function modules must not be installed in the bathroom.

The electronic components must be fixed so that they will not fall into the bathtub.

Otherwise, an electric shock could result.

The function modules must not be installed in the bathroom.

Ensure that you have an ergonomic working position during transport and assembly.

● Take care at every stage that your move is safe. Ensure that you have assistance to avoid

risk of accident or injury.

Observe the current local prevention of accidents and building regulations as well as

sanitary and environmental protection rules during installation.

CAUTION

Do not place anything heavy on the tub or anything in the tub for standing on.

● Doing so could cause damage.

!

Prohibited

Do not drop any heavy or hard objects in the bathtub.

● Injury may result from cracks in the bathtub or leaking water may contaminate or ruin

household property.

Keep sources of heat at a distance.

Do not smoke.

● Otherwise there is a risk of damage.

Do not install the bathtub outdoors or in a location where it will be constantly exposed

to sunlight (for example, in a sunroom).

● Otherwise there is a risk of frost damage or discoloration.

Do not bend the hoses or cables.

When transporting the bathtub, do not carry by the hoses or plumbing or strike it with

anything hard.

3

CAUTION

On opening the box, check that the bathtub and parts supplied are not damaged. Do

not use any parts that are damaged.

● Replace any damaged parts.

!

!

Required

tion module is anticipated, be sure to waterproof the floor.

● If there were to be a leak, it could damage the floor or floors below.

If installing the product in a location where damage from water leaking from the func-

Do not remove the protective sheet on the bathtub until installation is complete.

Ensure the bathtub can be used and maintained adequately.

● Consider water splashing from blocked shoulder warmers.

Check for leaks after installation is complete.

● Shut off the water supply if you discover any leaks and immediately repair them.

4

Before installing the NEOREST

The function module must not be installed in the bathroom.

In addition, the function module is not waterproof and should not be installed outdoors.

Be sure to install the function module indoors other than in the bathroom.

The function module requires a hot water supply temperature of at least 140°F (60°C). (No

more than 158°F (70°C))

If the supply temperature of the hot water is too low, it won’t be possible to fill the tub to the temperature

setting of the controller. The function module mixes the supply of hot and cold water and runs hot water

out of the fill-tub outlet, so the temperature of the water flowing out will be lower than the temperature of

the water being supplied to the function module.

The pressure of the hot and cold water supplied to the function module must be at least 29

psi (0.20 MPa) (when flowing). (No more than 108.75 psi (0.75 MPa))

The difference of water pressure between cold water and hot water should be such that the cold water is

kept higher and within 14.5 psi (0.10 MPa). If the pressure is low, the water won’t flow out like a waterfall. Additionally, it will take longer for the tub to fill with hot water.

Supply Equipment Specifications

Supply Pressure: 29 to 108.75 psi (0.20 to 0.75 MPa)

Supply Temperature: 140 to 158°F (60 to 70°C)

Hot Water usage:

Max. temperature 113°F (60°C)

Max. flow rate 9.2 gpm (35 L/min)

Max. capacity approx. 144 gallons (545 L)

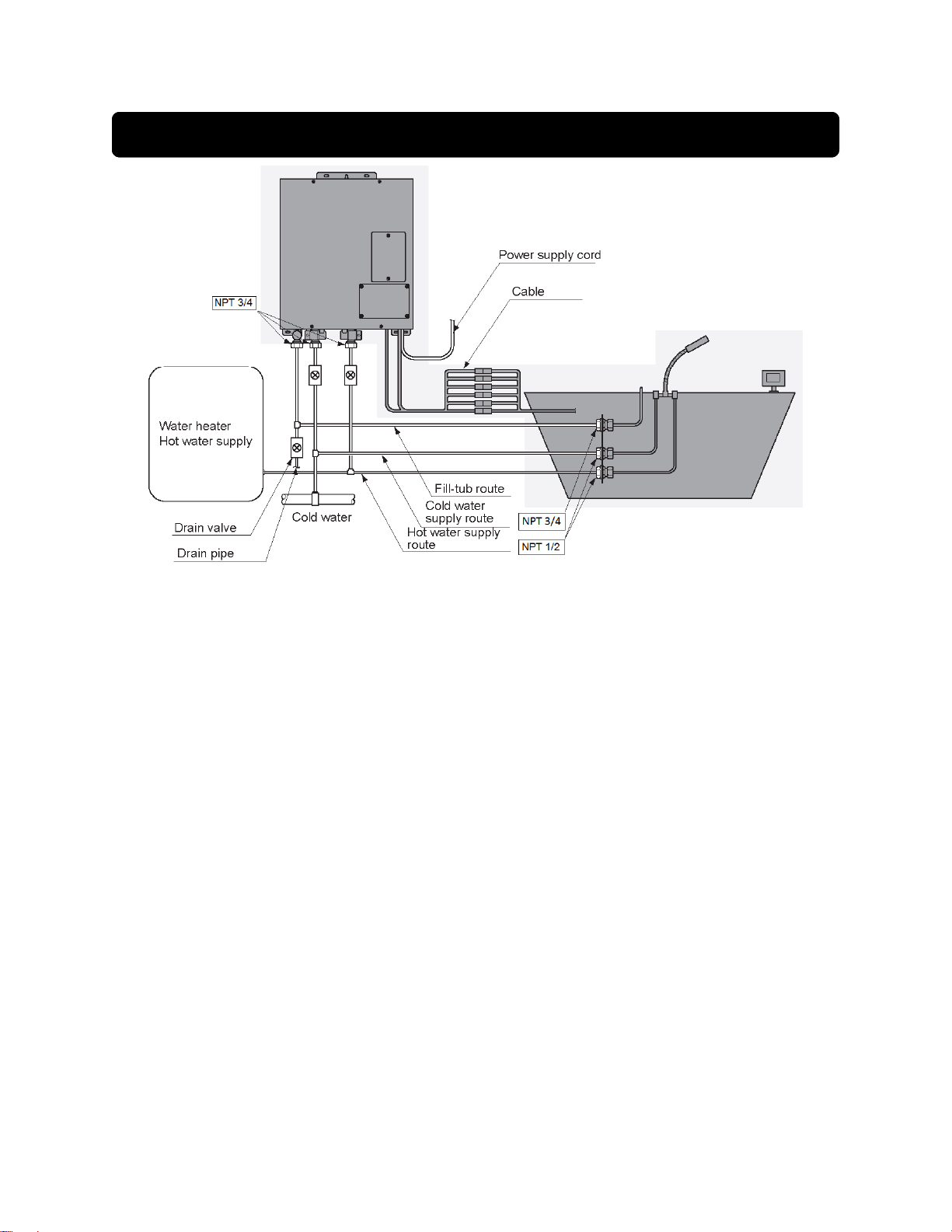

The diameter of the function module connector is NPT 3/4. Please do not make the diameter of the

plumbing smaller than the diameter of the connector to the function module. The use of equipment

below full capacity could lead to problems for the customer.

Use a sealant on the taper thread joint.

It is necessary to have space between the end of the drain hose and the drain. If not the water

could backflow.

Power supply connection The power inlet of the function module must be connected to the per-

manently installed power outlet (cable).

5

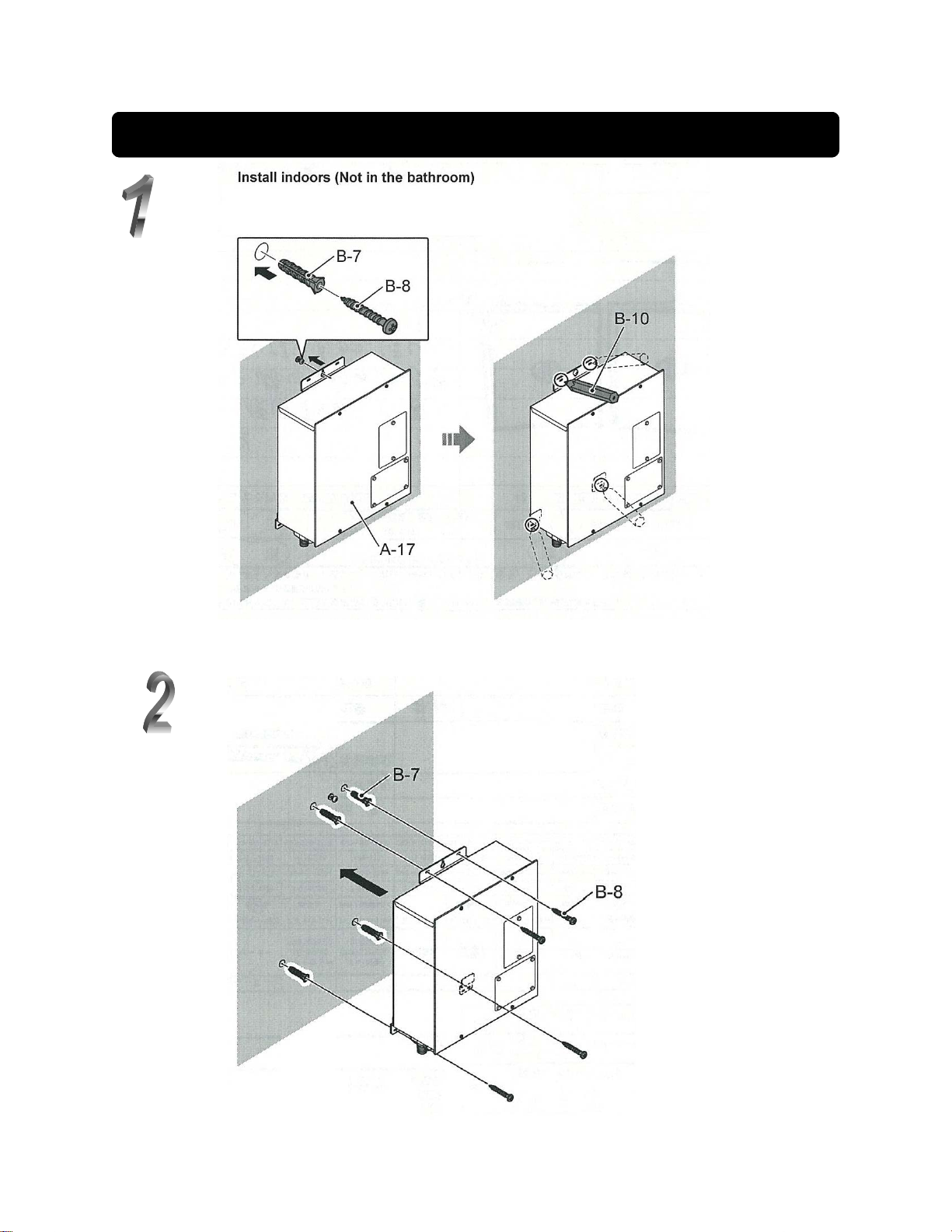

Function module installation locations

Install the function module indoors, in a room other than the bathroom.

Please leave a space of at least 24 inches (600 mm) in front of the equipment so that inspections or

repairs can be made. Also, please do not locate it on a second-story wall or other place without access.

Please take the following into consideration when deciding where to place the function module. The

length of the cables to the equipment (pumps and the like) that will be installed with the bathtub are

49 ft (15m).

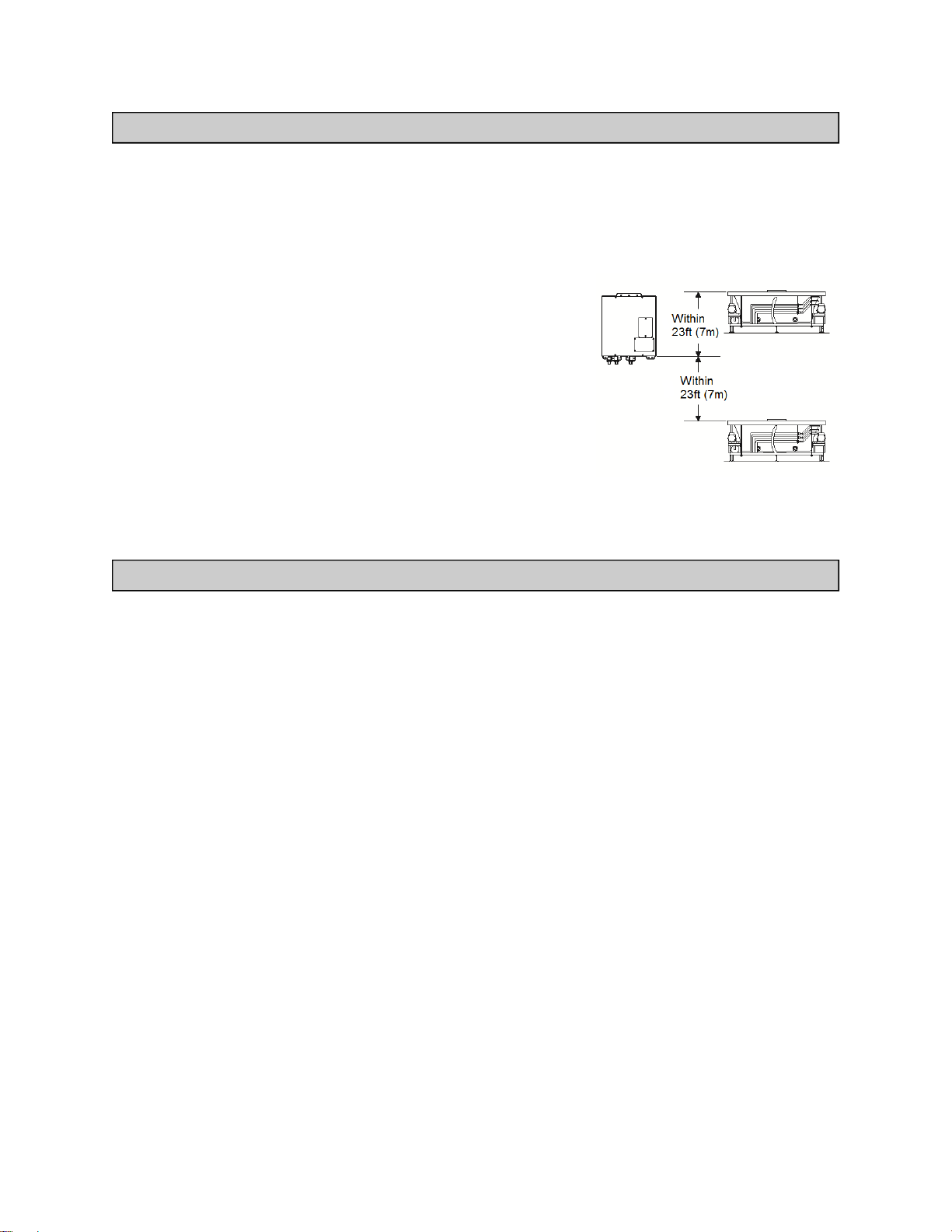

If the tub installation is downstairs the function module should be

within 23 ft (7 m) of the top of the tub.

If the tub installation is upstairs the function module should be

within 23 ft (7 m) of the top of the tub. In this case the supplied

water pressure should be 29 psi (0.20 MPa) above head pressure.

Be sure to install it on a vertical wall.

The plumbing that is connected to the equipment should be in-

stalled so that there will be no safety problems with respect to

earthquakes, other vibration or physical impact and caulking material should be used to seal the points where the hot and cold

water and the power lines pass through the walls.

Precautions when plumbing

If the plumbing materials are specified by the relevant local and national plumbing authorities, com-

ply with those specifications.

Be sure to flush filings, sand and debris from inside the pipes using water before connecting the

function module.

Use a union junction or similar means on the connection port and do not use excessive force.

The diameter of the pipe is not to be less than the diameter of the function module connector (NPT

3/4).

When the water pressure is high, either install a pressure-reducing valve or a device to prevent

“water hammer”. (Recommended water pressure: 29 to 108.75 psi (0.20 to 0.75 MPa) However,

limits set by local and national plumbing authorities should not be exceeded.)

Keep the number of unions as small as possible and do not use complicated plumbing. Additionally,

do not plumb in such a way that air can become trapped in the pipes.

Hot and cold water supply plumbing

Install an anti-backwash valve, a shut-off valve or a shut-off valve with an anti-backwash valve near

the hot and cold water supply ports.

In order for the customer to have a pleasant experience using this equipment, a hot and cold water

supply pressure of 29 to 108.75 psi (0.20 to 0.75 MPa) is required. If the water pressure is low, the

equipment will not function properly and could lead to trouble with the customer, so be prepared to

install a booster pump as a countermeasure.

Fill-tub plumbing

The pipes that are used with the fill-tub feature are to have a maximum length of 49 ft (15m) and 10

changes of direction.

Please incline the pipes so that it will be easier to remove water from the pipes when draining water

6

Shower Installation Conditions

1. Confirmation of water pressure

● Supply hot/cold water pressure:

Minimum required water pressure (when flowing): 11.6 psi (0.08 MPa)

Maximum water pressure (when not flowing): 108.75 psi (0.75 MPa)

● If the supply water pressure exceeds 108.75 psi (0.75 MPa) please reduce the pressure to

around 29 psi (0.20 MPa) using a commercially available pressure-reducing valve.

2. Confirmation of hot water supply temperature

● Please keep the hot water supply temperature no higher than 158°F (70°C).

● Please do not use steam in place of a hot water supply.

3. Plumbing

● Please do not connect the hot and cold water backward.

● Please install the hot water supply pipe at the shortest distance from the water heater to

reduce the resistance.

4. Local and national codes

●Adherence to all local and national codes is required and take precedence over requirements

listed in this manual.

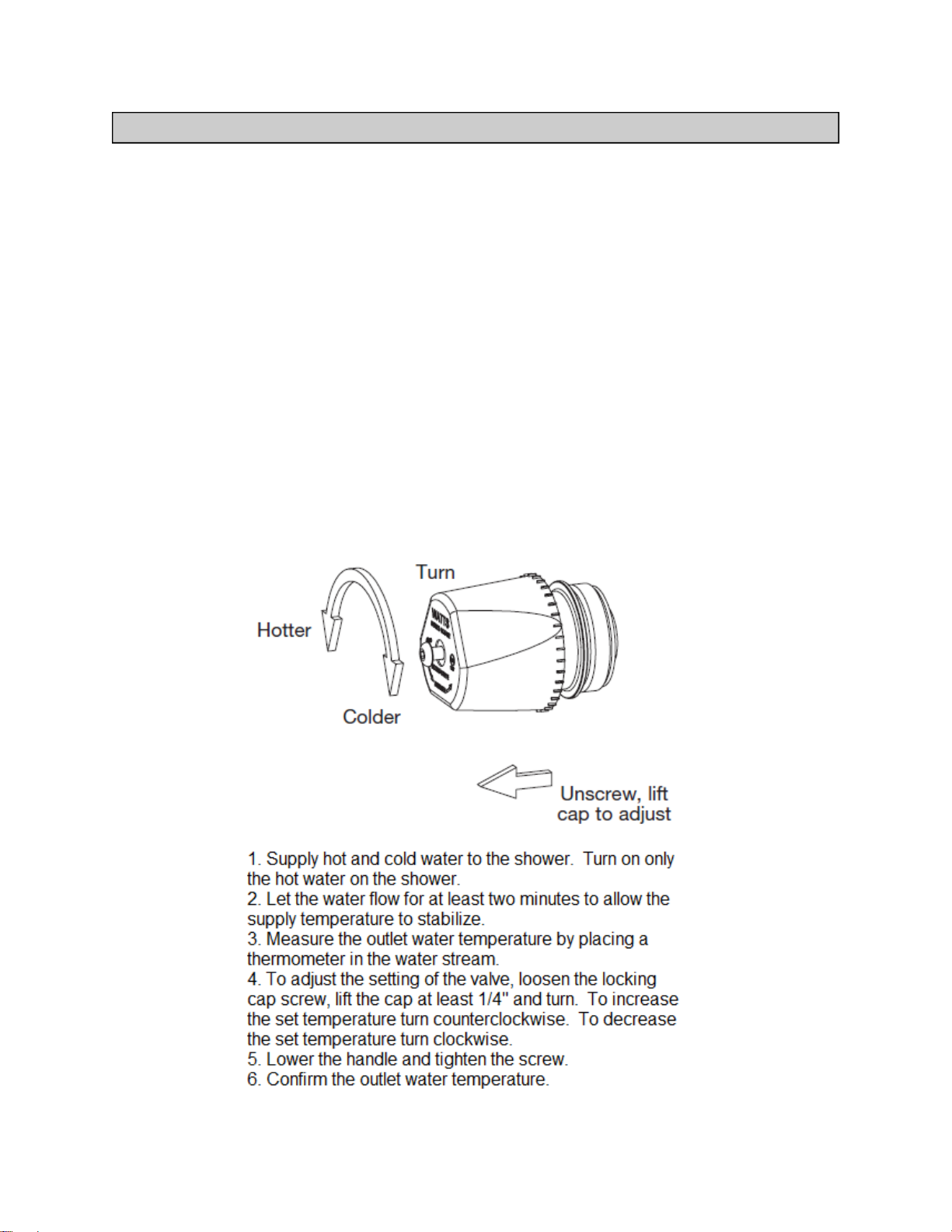

5. Tempering valve (supplied)

●The shower hot water output will be limited by the tempering valve. The tempering valve is

preset to 105°F (41°C)

●Check codes for compliance and adjust if needed. The tempering valve is located under the

shower near the tub frame. Below is the method of adjustment.

7

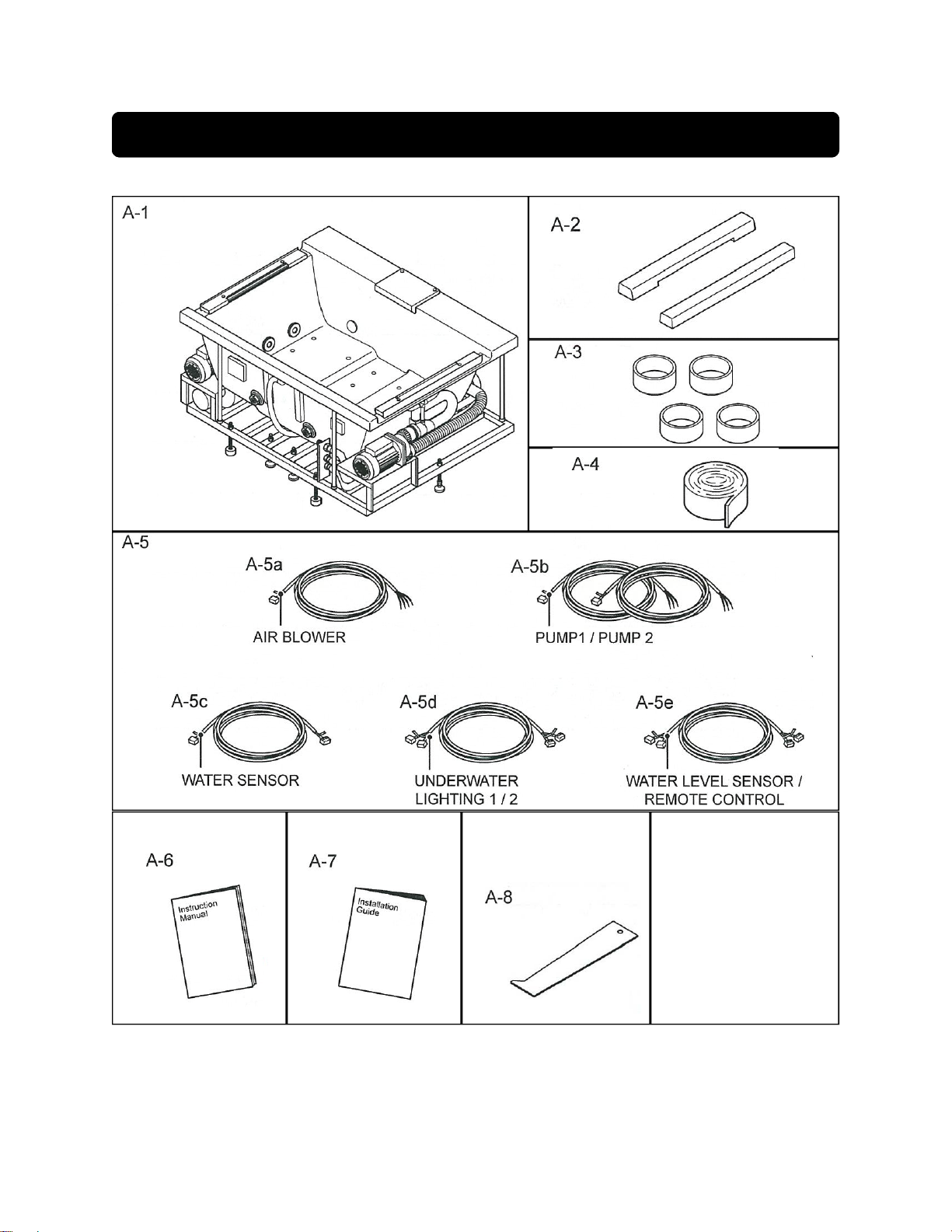

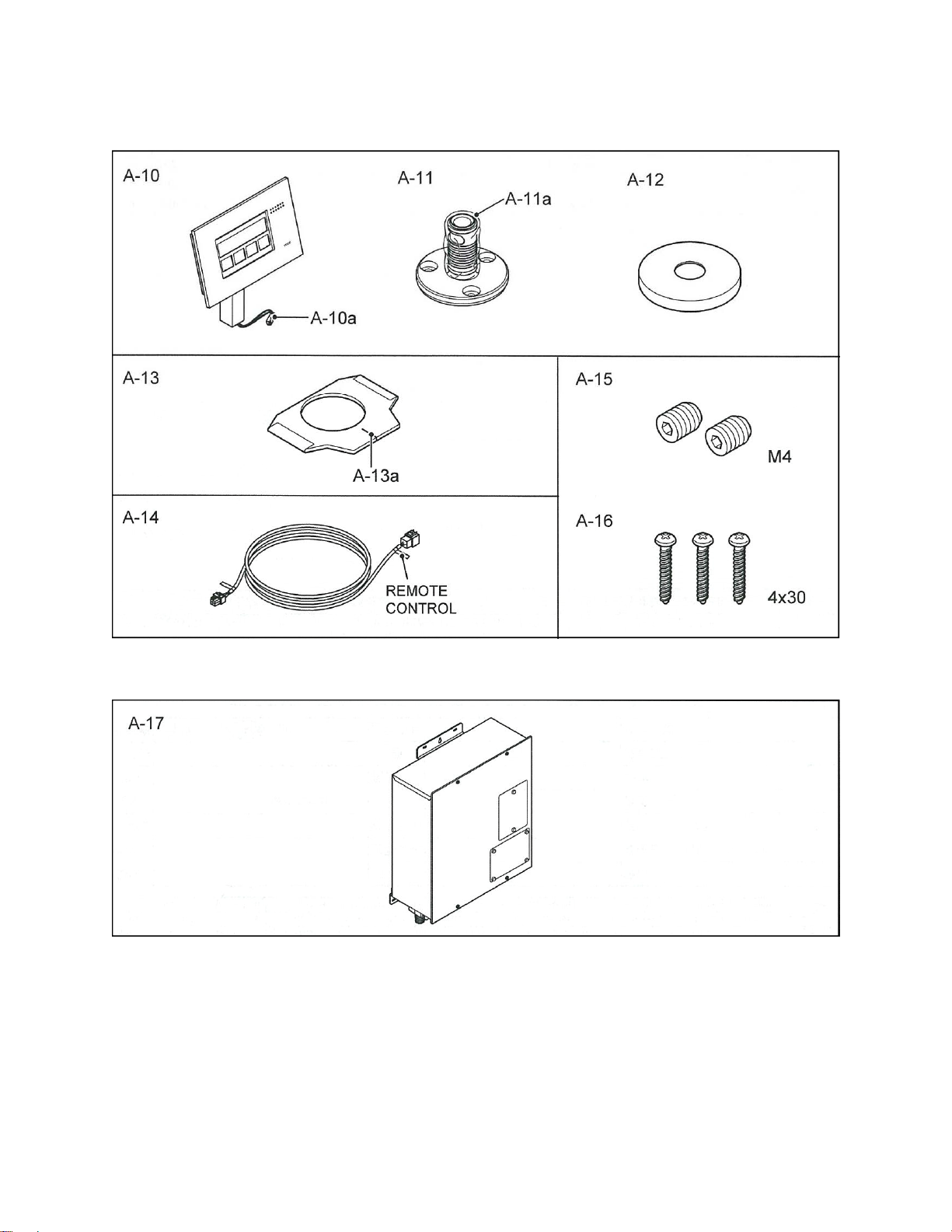

Included Parts

■ Bathtub

Bathtub

Assembly

Connecting

Harnesses

Pillows

Feet fixing

molds

Polyethylene

foam sheet

Instruction Manual

Items A-6 and A-8 should be passed on to the customer after installation is complete.

8

Installation Guide Cleaning spatula for

shoulder-warmer water

outlet

■ Controller stand

Controller

Stand

Assembly

Slip Ring

Assembly

Controller

Branch

Harness

Base Cover

Base Assembly

Set Screws

Base mounting screws

■ Function module

9

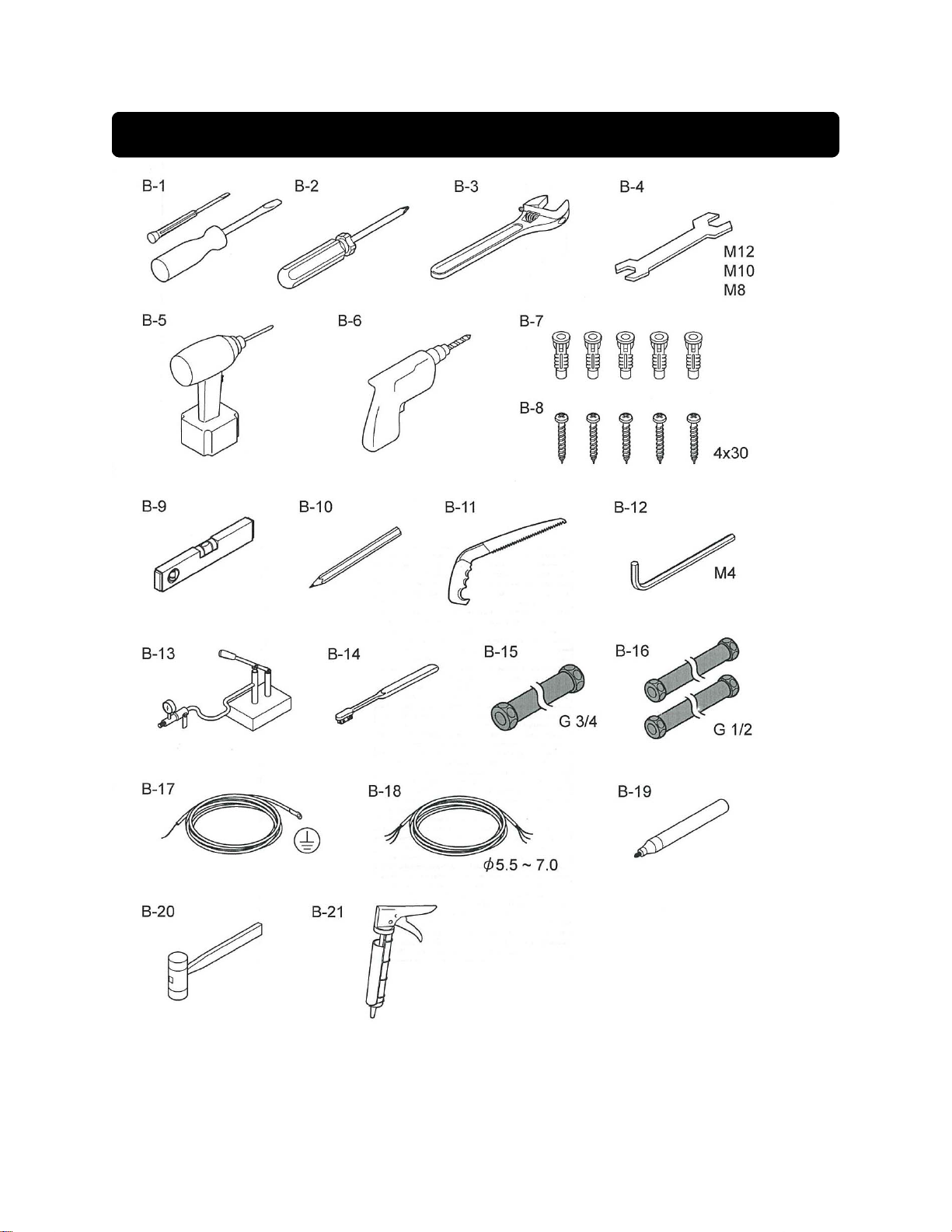

Required Tools

10

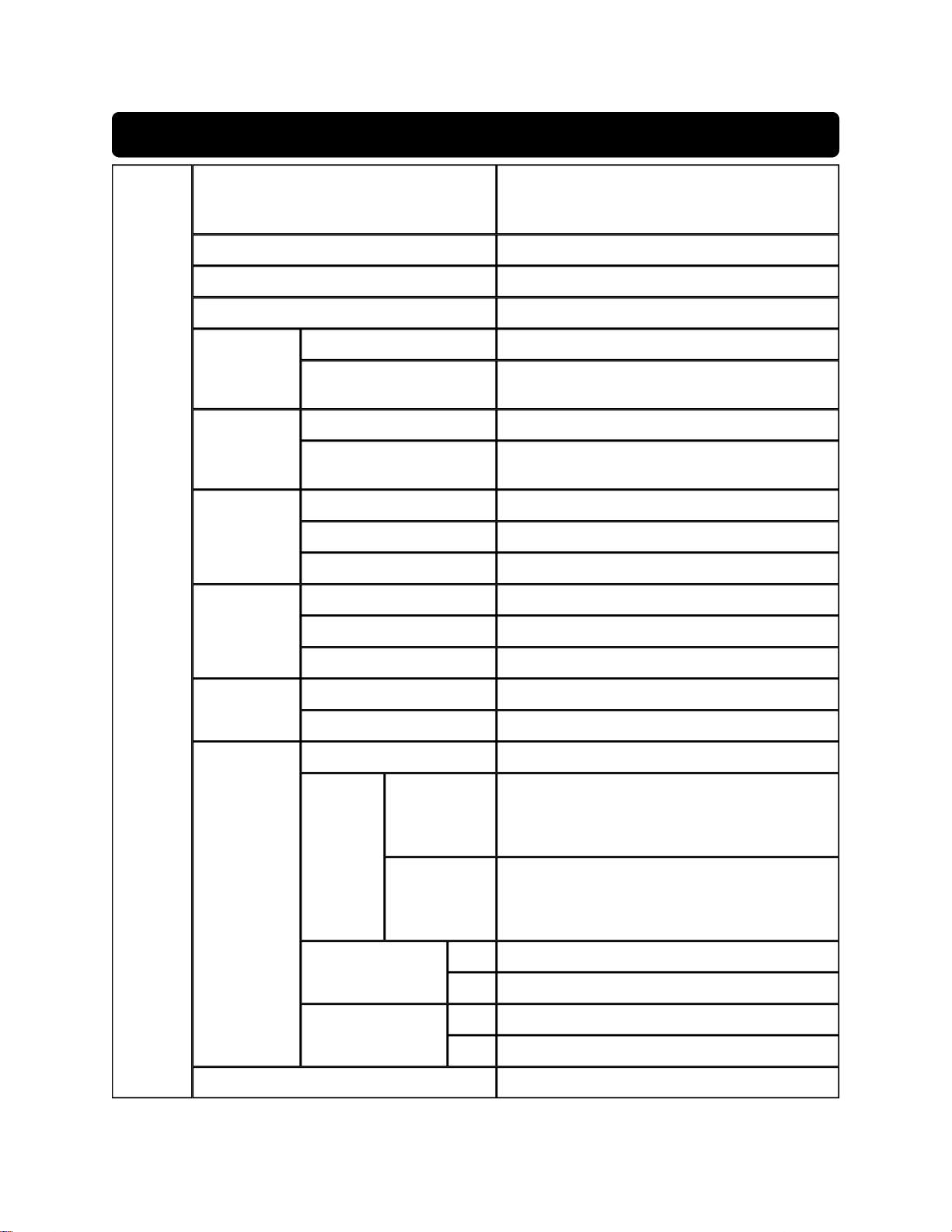

Specifications

Bathtub

Dimensions 70-7/8” x 55-1/8” x 30-1/8”

(1800mm x 1400mm x 765mm)

Includes the frame that supports the bathtub

Weight 397 pounds (180 kg)

Capacity 151 gallons (570 L) to overflow line

Material Acrylic synthetic marble

Bathtub filling

Air Blower

Shoulder

Warmer

(cascade)

HydroHands

Outflow ports

Bathtub filling flow rate

Number of jets

Volume of air

Intake ports

Outflow ports

Flow rate

Intake ports

Outflow ports

One

Max. 9.2 gpm (35 Lpm) (controlled by function

module)

15 on the bottom of the bathtub

Max. 148 gpm (560 Lpm) (15 total, controlled by

function module)

Two

Two

Max. 10 gpm (38 Lpm) (2 Total)

Two

Four

Flow rate

Underwater

lighting

Shower

(Two knobs)

Bathtub filling connection dia. threads

Lighting modules

Colors

Uses Cleaning the bathtub

Water

pressure

perature

Connection diameter threads

Min. required

water pressure (when

flowing)

Max. water

pressure

(when not

flowing)

Hot Inlet water tem-

Cold

Hot

Cold

Max. 40 gpm (150 Lpm) (4 Total)

Two

Three pattern types, 10 individual colors

11.6 psi (0.08 MPa)

108.75 psi (0.75 MPa)

Controlled by tempering valve (supplied)

32 to 86°F (0 to 30°C) no freezing

NPT 1/2

NPT 1/2

NPT 3/4

11

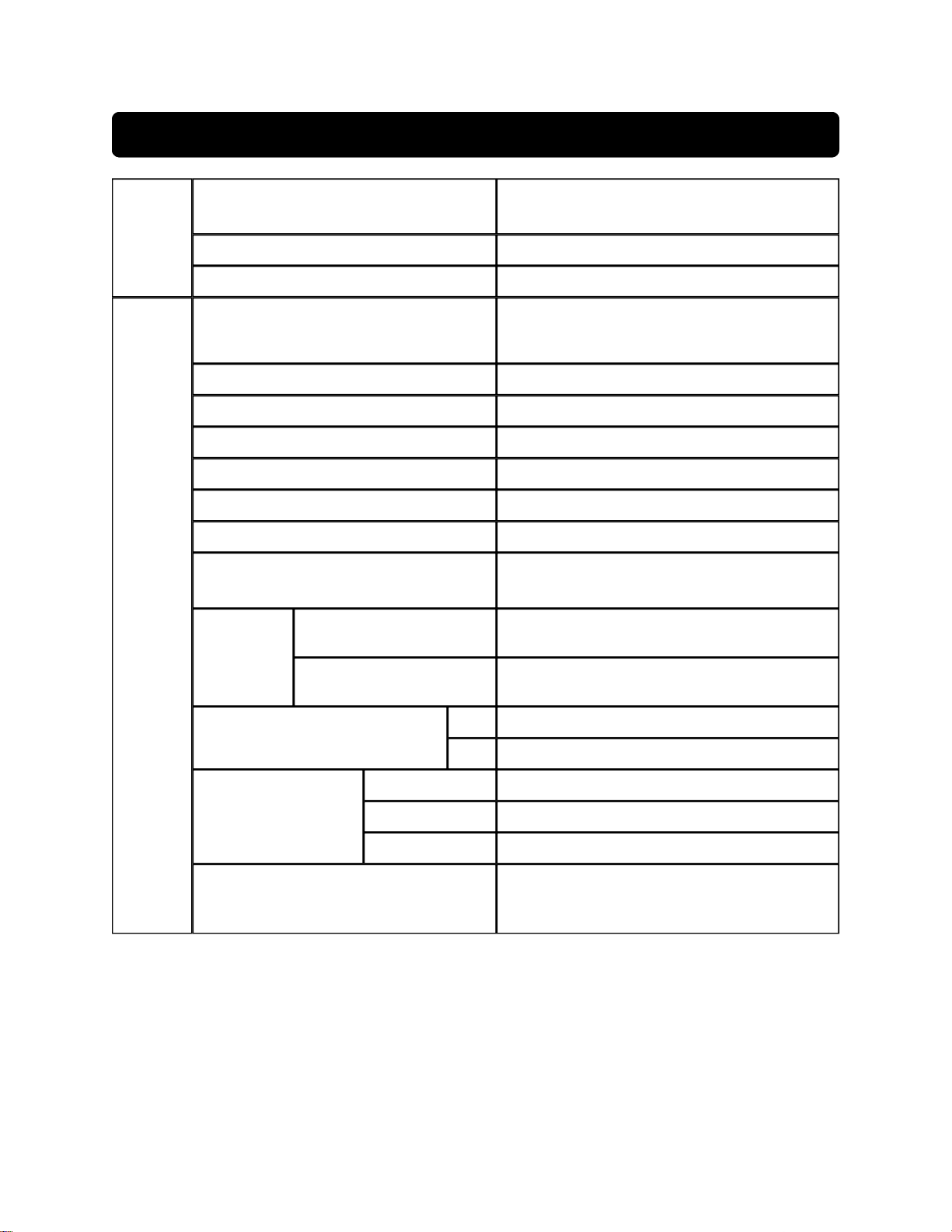

Specifications (continued)

Controller

Stand

Function

Module

Dimensions 9-11/16” x 4-7/16” x 10-1/16”

(246mm x 113mm x 255mm)

Weight 6 pounds (2.8 kg) including the controller

Adjustable arc 90°

Dimensions 16-5/8” x 7-1/16” x 18-3/4”

(422mm x 180mm x 476mm)

External height excludes the connection ports.

Weight 31 pounds (14 kg)

Rated voltage 120 VAC

Rated frequency 60 Hz

Rated current 14.3 A

Rated power consumption 1490 W

Standby power consumption 7.0 W

Installation location Indoors (location without condensation, damp-

ness or freezing: not the bathroom)

Water pressure

Min. required water pressure (when flowing)

Max. water pressure (when

not flowing)

29 psi (0.20 MPa)

108.75 psi (0.75 MPa)

12

Hot

Inlet water temperature

Cold

Hot Connection diameter

threads

Cold

Fill bathtub NPT 3/4

Safety device Continuous operation prevention device, over

140 to 158°F (60 to 70°C)

32 to 86°F (0 to 30°C) no freezing

NPT 3/4

NPT 3/4

current protection device, ground-fault circuit

interrupter (GFCI)

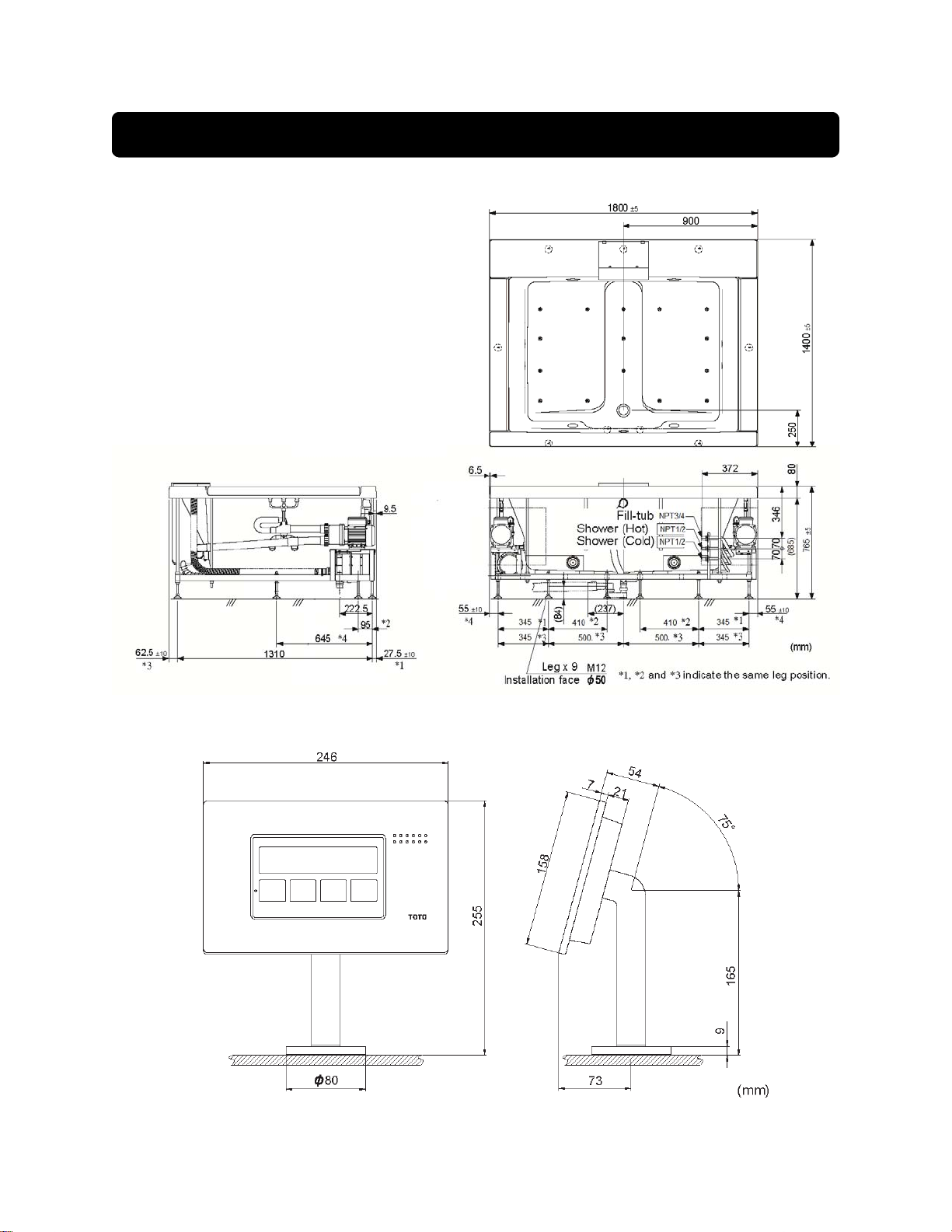

Dimension Drawings

■ Bathtub

■ Controller stand

13

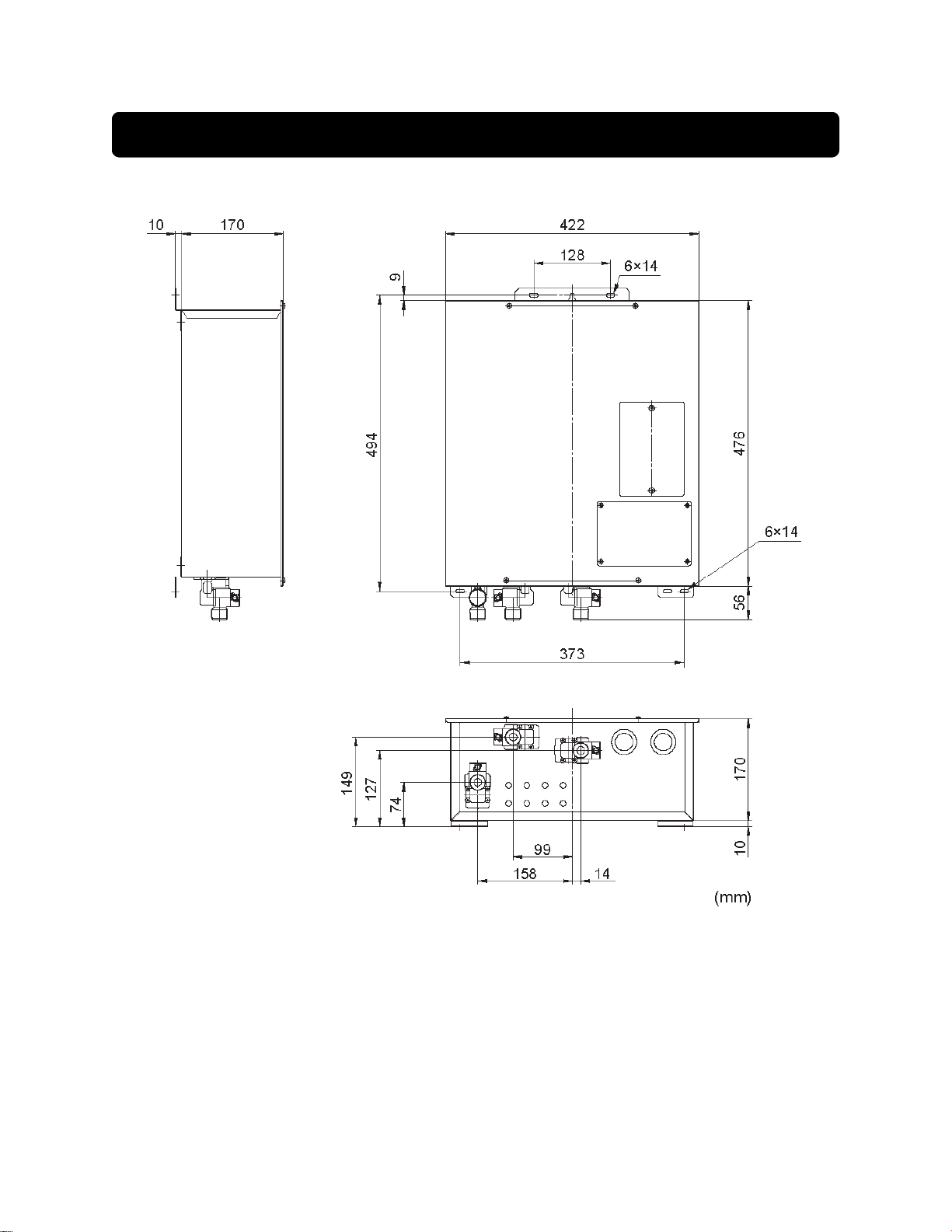

Dimension Drawings (continued)

■ Function module

14

Installation Procedure

Building a base for the bathtub - seating the bathtub ► See page 16

Installing the function module ► See page 20

Testing the operation ► See page 24

●Error Codes ► See page 44

Finishing ► See page 34

Installing the controller stand ► See page 37

Cleaning the filter in the water drain plug ► See page 41

Meaning of the indications

15

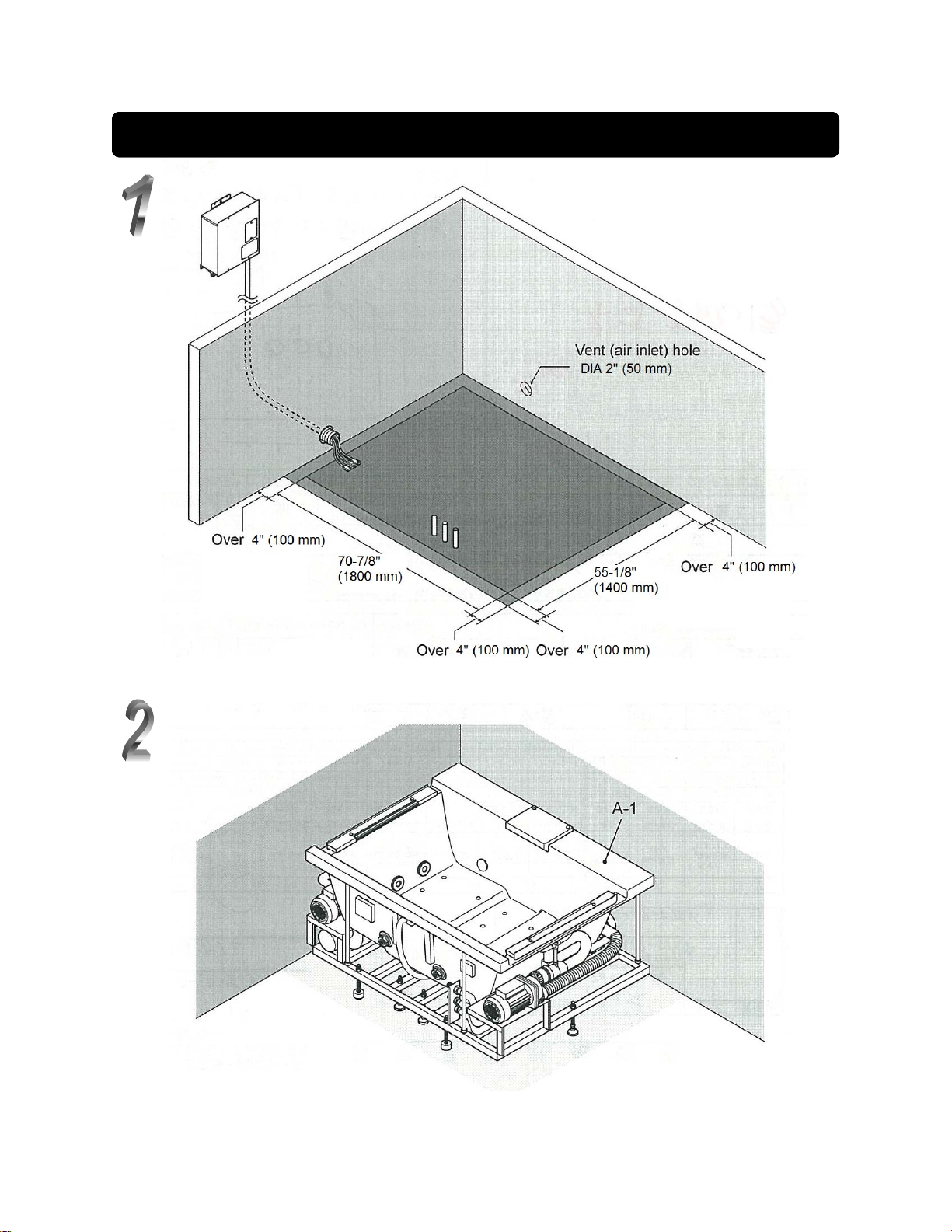

Building a base for the bathtub - seating the bathtub

16

Building a base for the bathtub - seating the bathtub

17

Building a base for the bathtub - seating the bathtub

18

Building a base for the bathtub - seating the bathtub

19

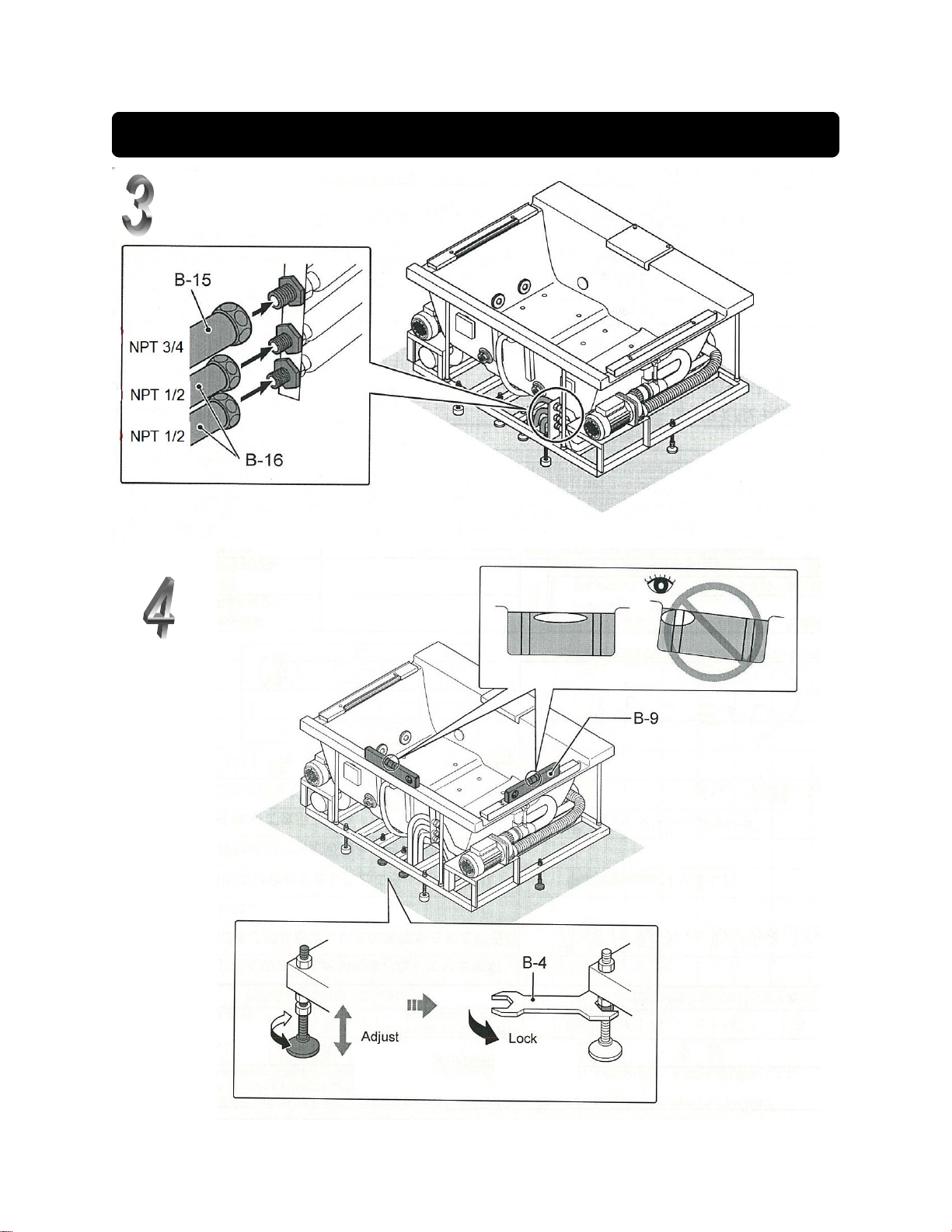

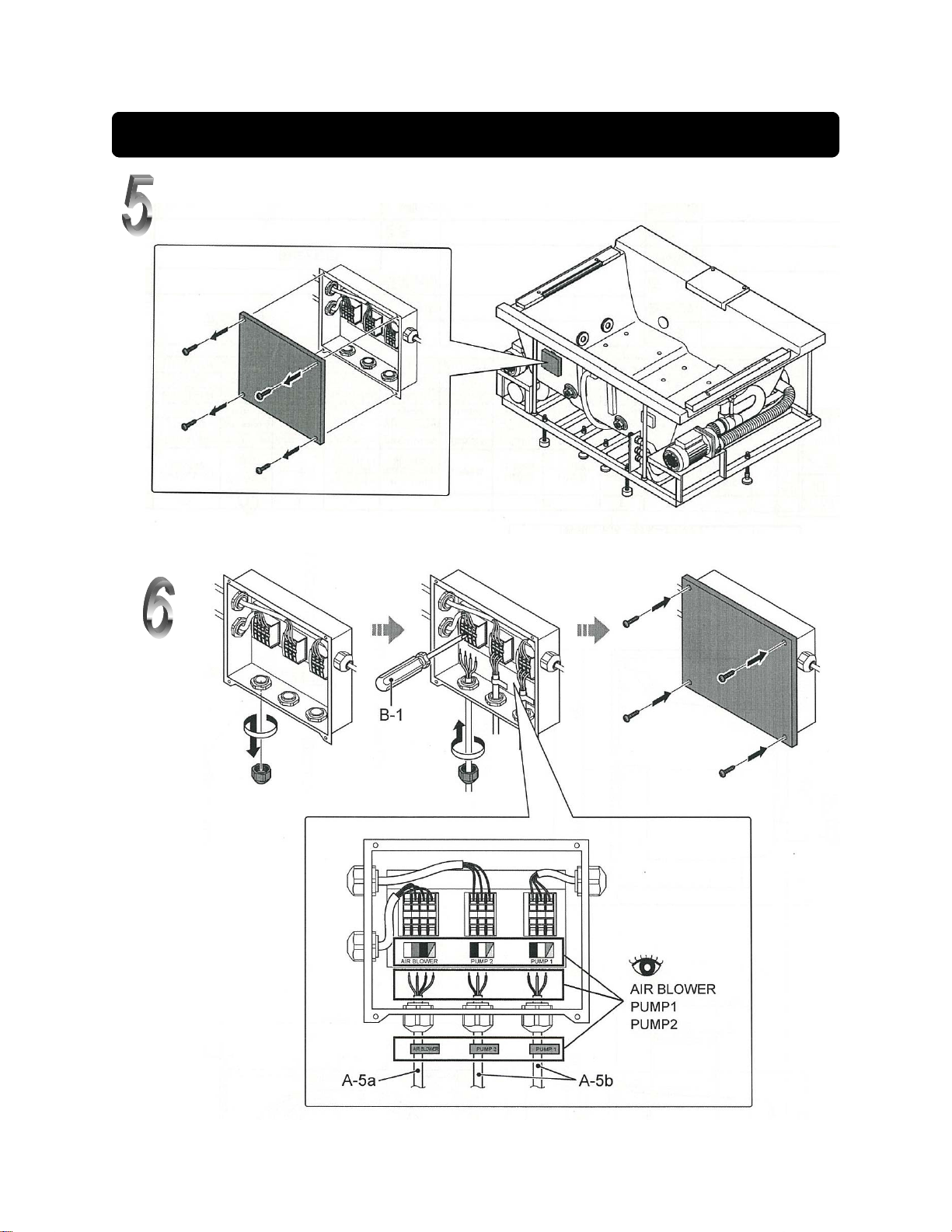

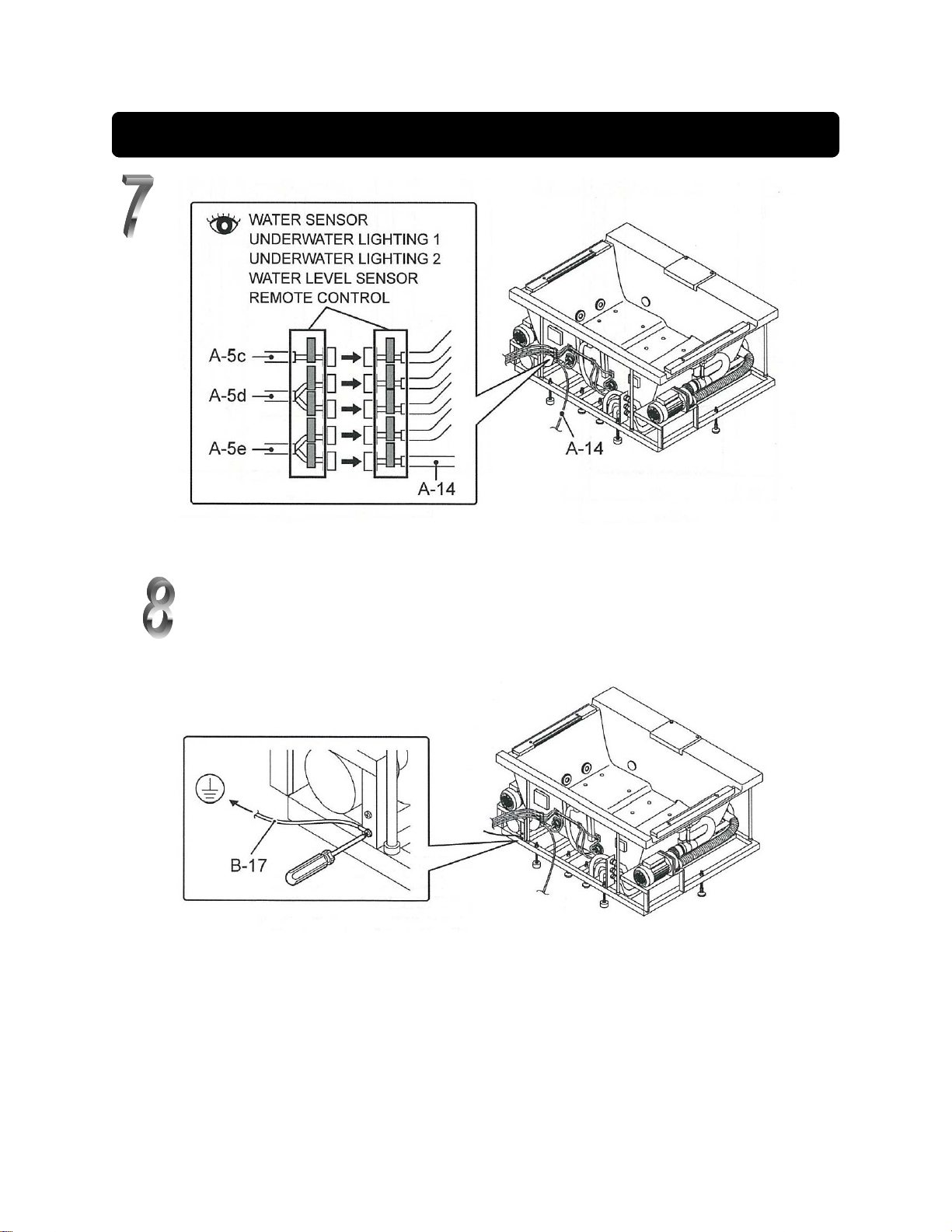

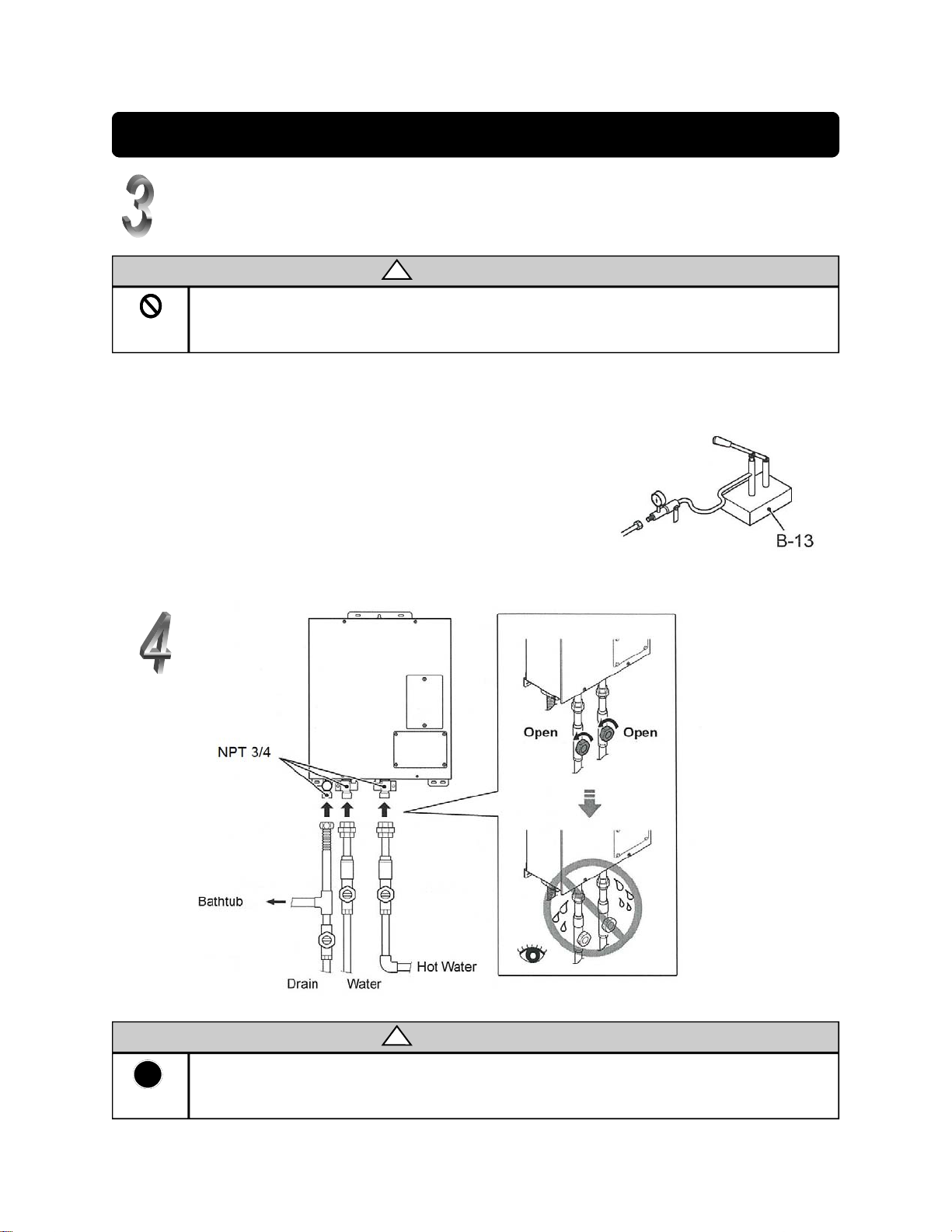

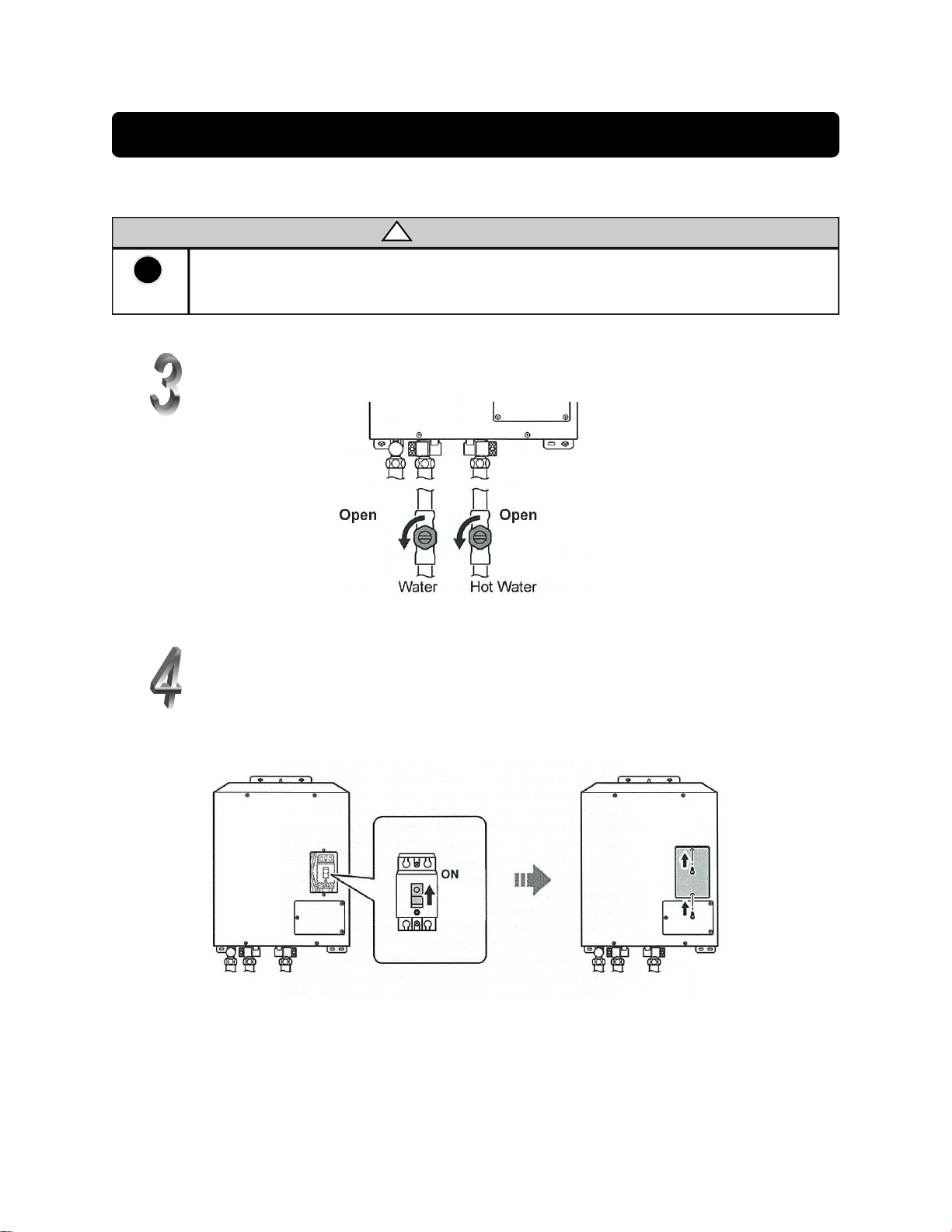

Installing the function module

20

Installing the function module

■ Inspect for leaks in the fill-tub plumbing

CAUTION

Do not apply additional pressure to the equipment.

● Inspection pressure and time: 43.5 psi (0.30 MPa) for five minutes or longer.

Prohibited

1. Install a valve on one end of the fill-tub plumbing. (Valve open.)

2. Install a booster pump on the other end to feed water into the fill-tub plumbing.

3. Once the air has been removed from the fill-tub plumbing and it has

been filled with water, close the installed valve.

4. Inspect for leaks.

● Use a pressure meter that suits the pressure being checked

when inspecting the pressure.

● Be sure that there are no leaks or pressure drops across the

gauge.

5. If pressure leaks are discovered, run the test again after fixing the

leaky areas.

!

CAUTION

!

Required

21

Fit the hot/cold water pipes with anti-backwash valves and shut-off valves.

!

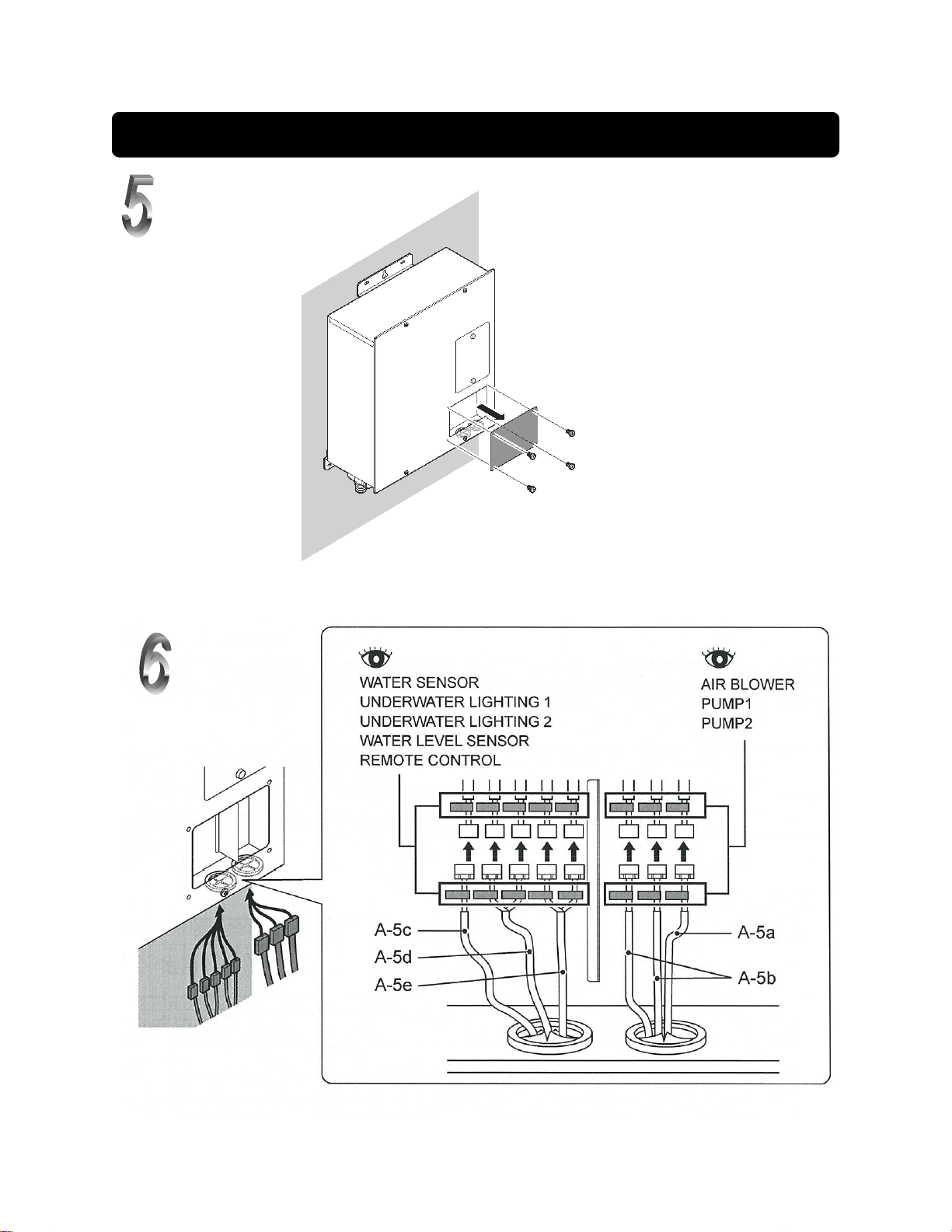

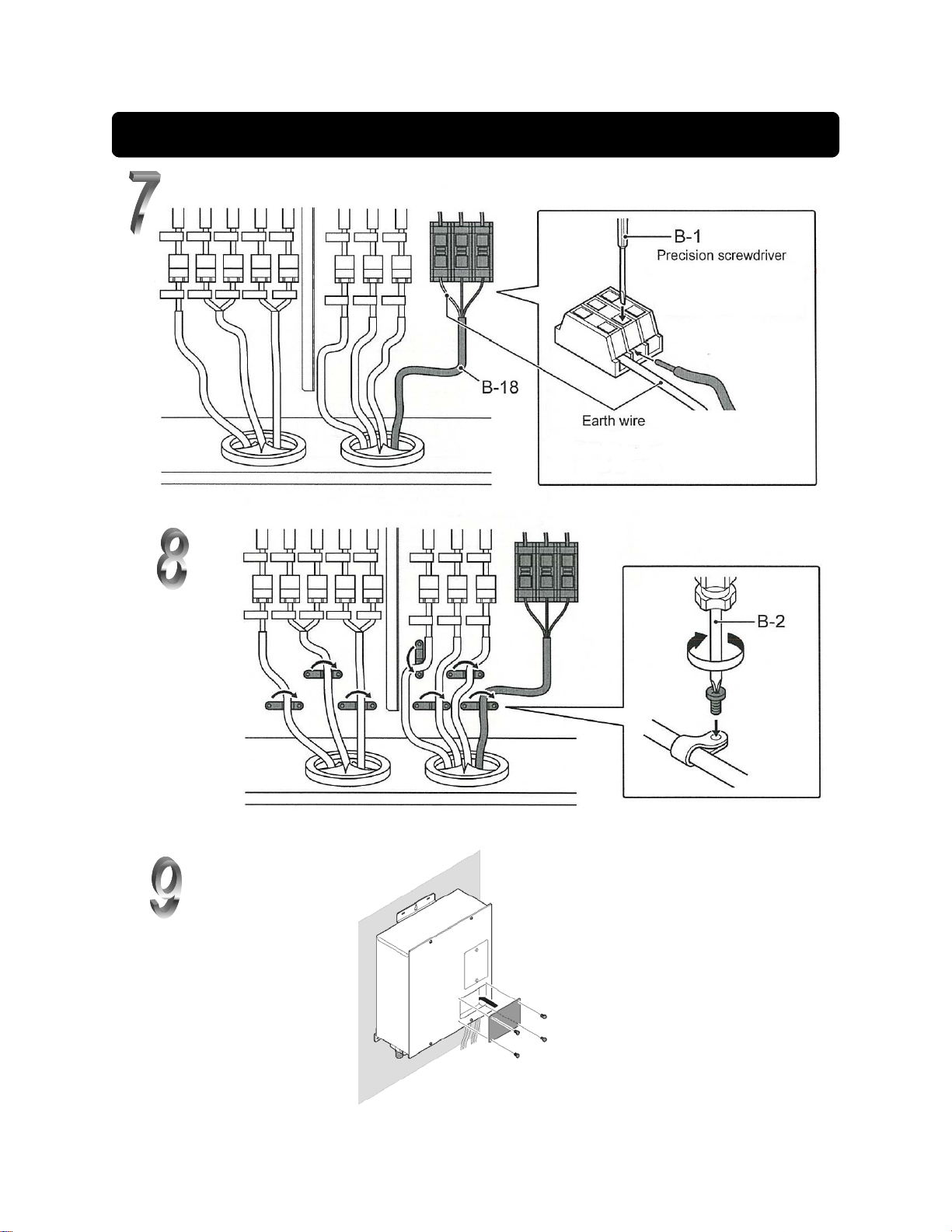

Installing the function module

22

Installing the function module

23

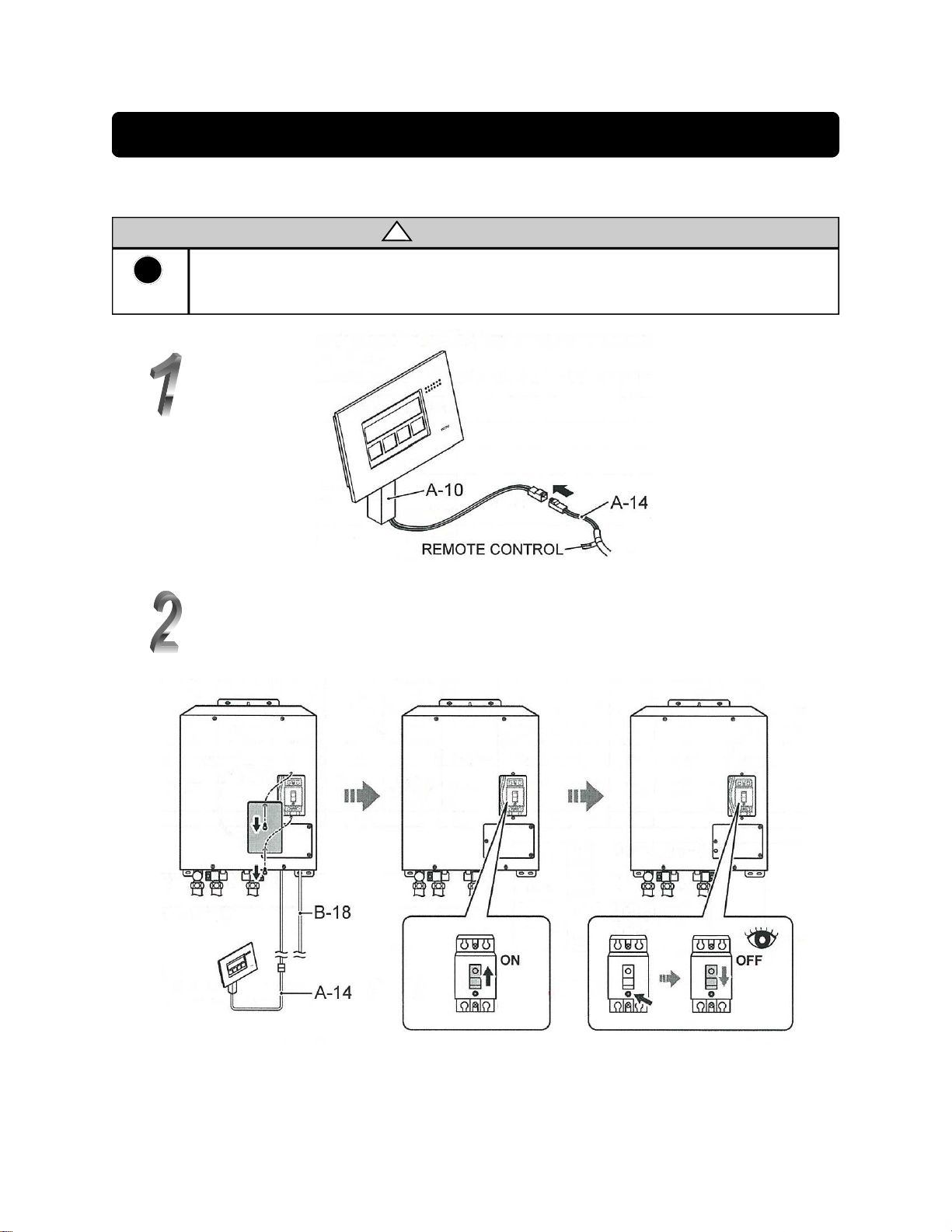

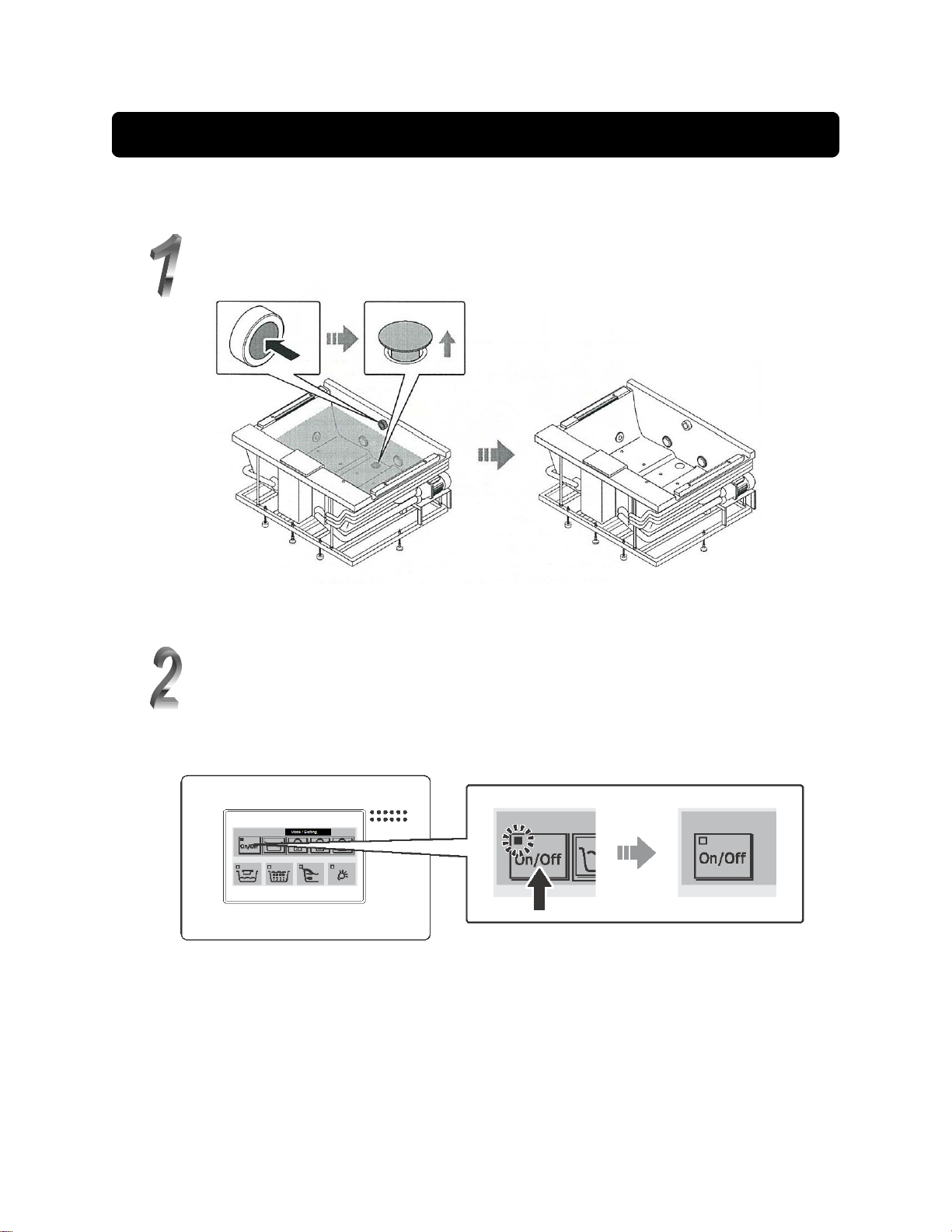

Testing the operation

■ Preparation for testing

CAUTION

!

Required

Operate with the bathtub empty of water.

!

24

Testing the operation

■ Preparation for testing (continued)

CAUTION

!

Required

Operate with the bathtub empty of water.

!

25

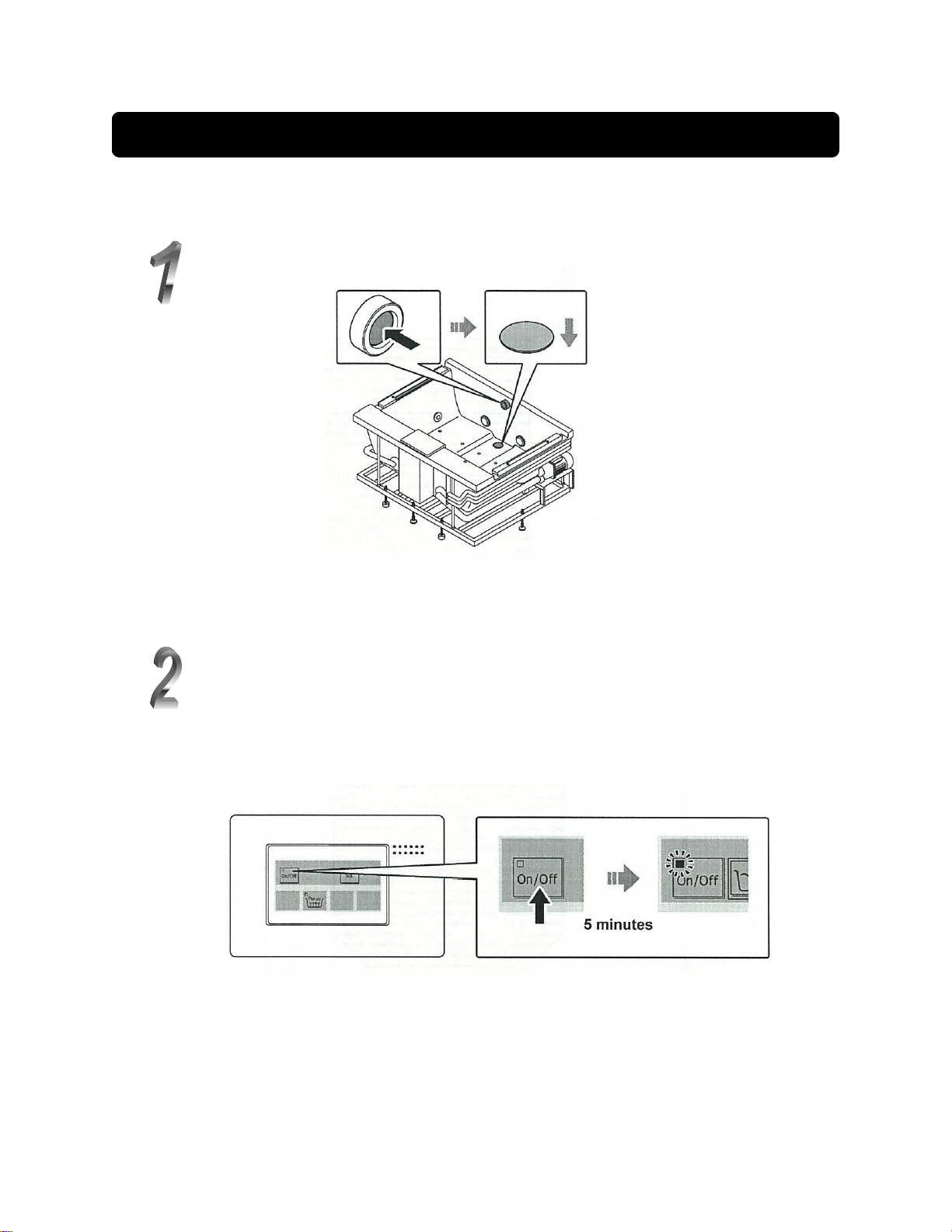

Testing the operation

■ Bathtub data reset

26

Testing the operation

■ Fill-tub operation

27

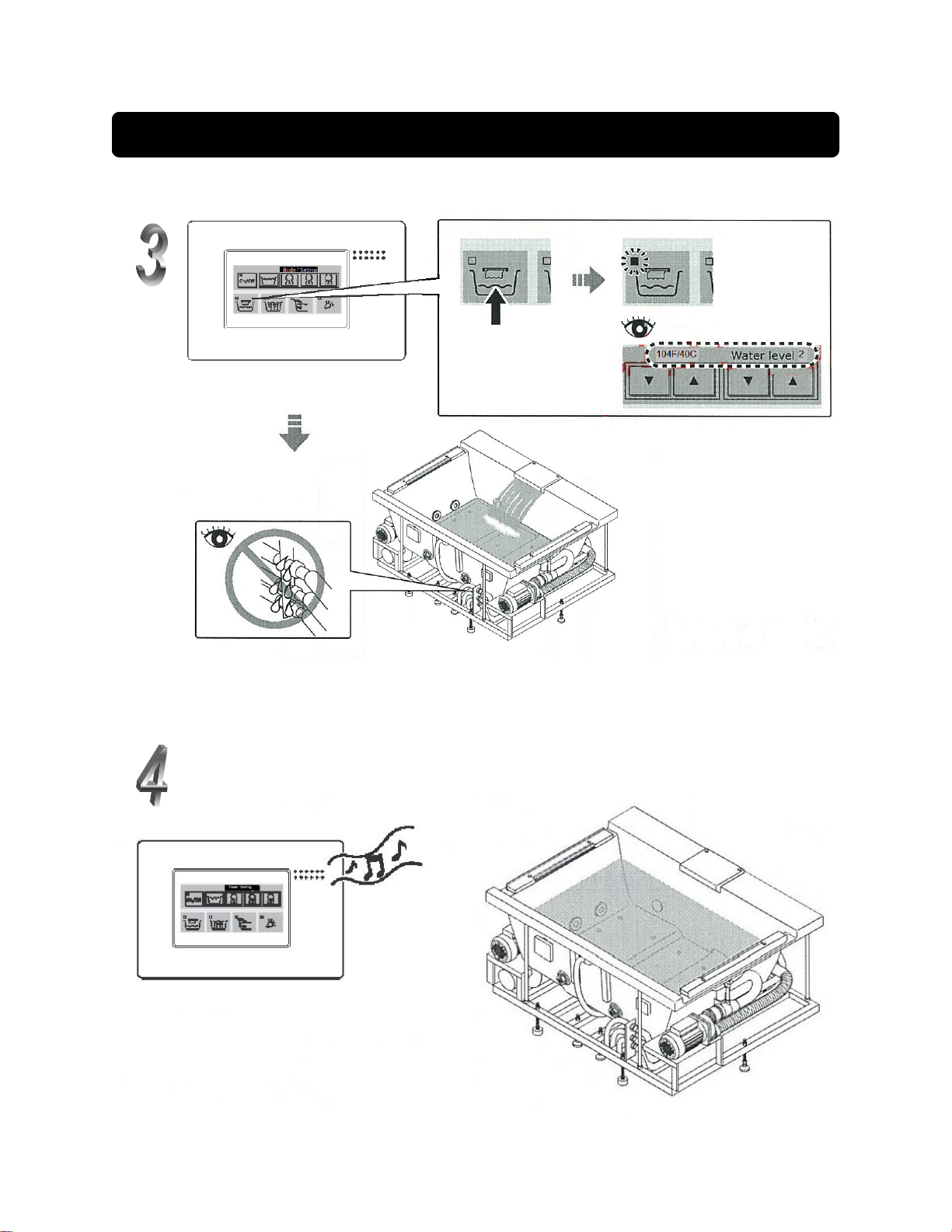

Testing the operation

■ Fill-tub operation (continued)

28

Testing the operation

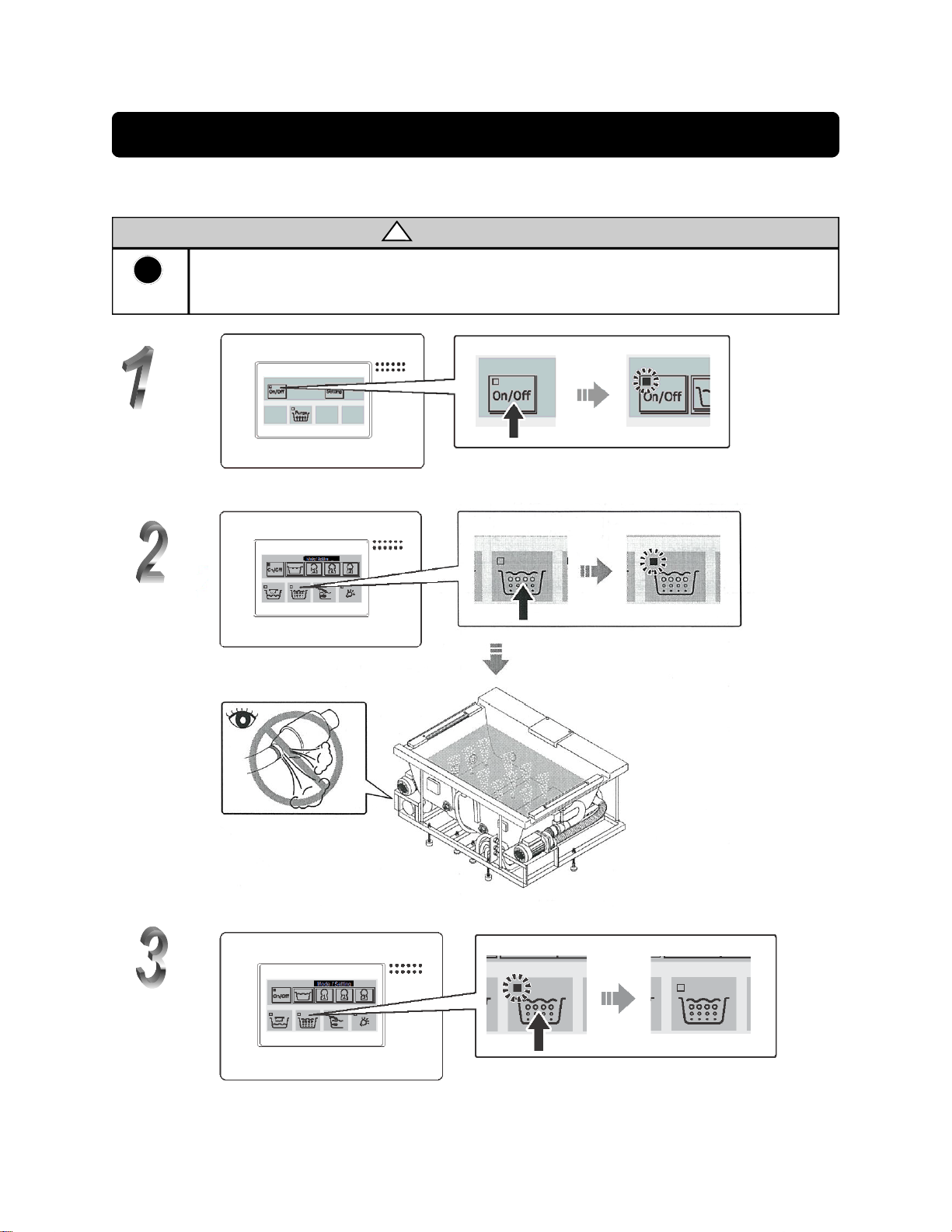

■ Air blower (10 minutes)

CAUTION

!

Required

Make sure that there is hot water in the tub after running the fill-tub feature.

!

29

Testing the operation

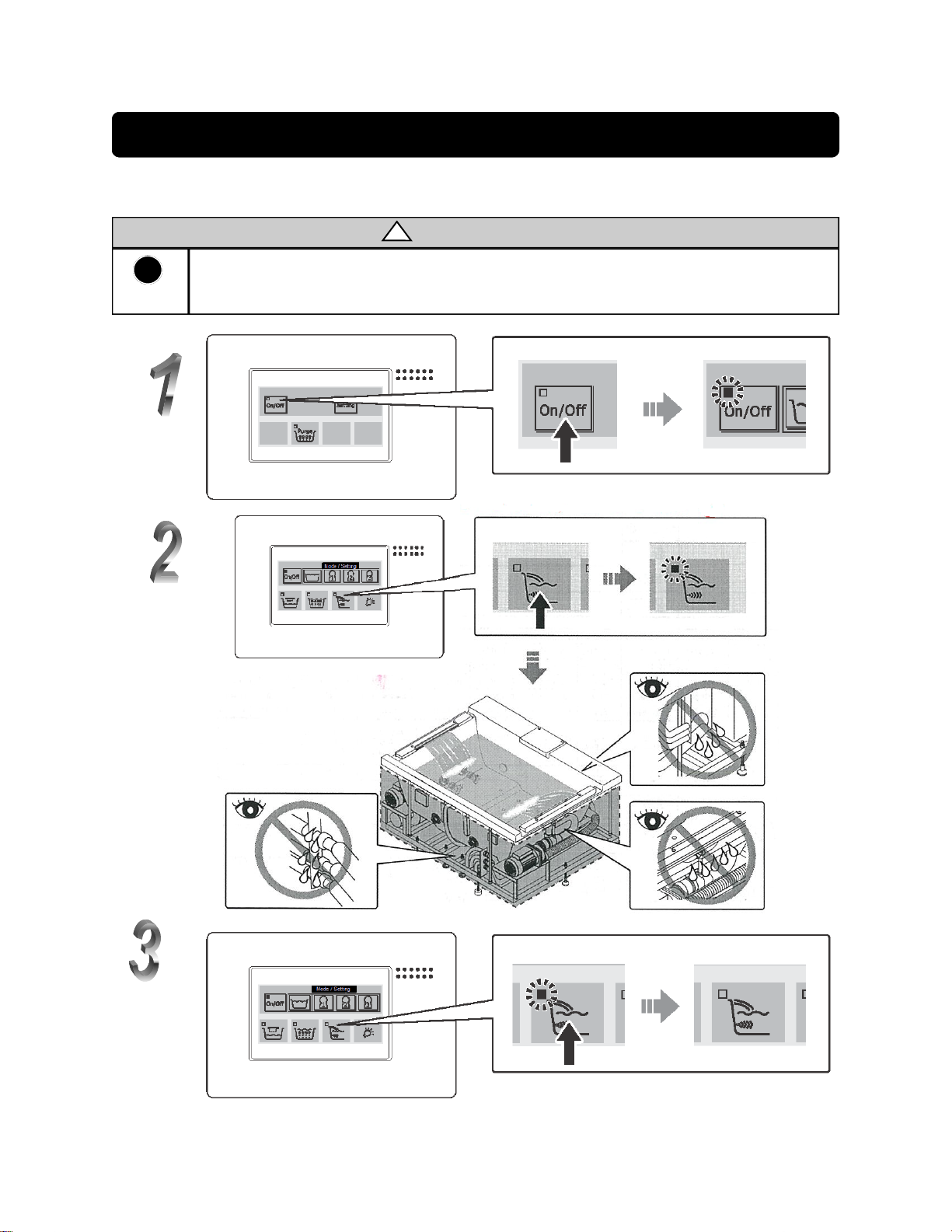

■ Hydro Hands Shoulder-warmer (10 minutes)

CAUTION

!

Required

Make sure that there is hot water in the tub after running the fill-tub feature.

!

30

Loading...

Loading...