Total Source SY8000 Operation Manual

Operating Instructions

User ManUal

Forklift Jack Operation Manual

Note: This manual contains important information about raising forklifts that you may not

know. Read this manual carefully and retain it for future reference.

Table of Contents

Safety Instructions .............................................................................................................................................................................1

Forward ..........................................................................................................................................................................................2

Specications .......................................................................................................................................................................................2

Signal Words .........................................................................................................................................................................................2

Component Identication ...............................................................................................................................................................3

Release Knob........................................................................................................................................................................................3

Using the Jack to Raise a Forklift ..................................................................................................................................................4

1. Inspect the jack for signs of wear or damage ..............................................................................................................4

2. Transport the Jack to the Work Area ...............................................................................................................................4

3. Select appropriate support strands and bring them to the immediate work area .......................................6

4. Prepare the surrounding area before using the jack ................................................................................................7

5. Identify a lift point, prepare the load for lifting and chock wheels .....................................................................7

6. Raise the forklift......................................................................................................................................................................9

7. Use appropriate support strands .....................................................................................................................................9

8. Lower the forklift ....................................................................................................................................................................10

Inspecting the Jack ............................................................................................................................................................................10

Pump Priming Instructions .............................................................................................................................................................11

Maintenance and Lubrication Instructions ...............................................................................................................................11

Troubleshooting .................................................................................................................................................................................12

Notes .......................................................................................................................................................................................................13

Parts List .................................................................................................................................................................................................14

Safety Instructions

! WARNING

Anyone who operates this jack must read and understand all the instructions and warning

provided with this jack before being allowed to use it. All operators must be careful, competent,

trained, and qualied in the safe operation of the jack. The owner (or other responsible individual) must

ensure that any operator observes the proper safety procedures for using this jack at all times. If the

operator does not read well or is not uent in English, the owner / manager must read and review the

instructions and warnings in the manual with the operator in the operator’s native language to be sure

that the operator will use the jack properly.

The owner / manager must keep this manual for future reference, and make sure the warning labels

on the jack are legible and intact at all times. Replacement labels and manuals are available from TVH. Call

customer service using the numbers shown on the back cover of this manual if you have any questions.

ALWAYS use appropriate support stands to support a forklift after it has been raised. This jack is a

lifting device only! NEVER perform any work on or around a forklift or allow any part of your body under

a raised load until the forklift is properly supported by support stands and the jack is removed from

the work area. If lifting the forklift from the front or rear, the wheels remaining on the ground must be

chocked.

Use this jack only to raise forklifts. This jack is not designed to raise loads other than forklifts. Using this

lift to raise loads other than forklifts can result in serious injury or death. NEVER use a forklift jack on a

forklift while the motor is running.

NEVER use this jack in conjunction with any other jack or lift. NEVER use this jack to raise one side (or

end) of a forklift unless the other side (or end) of the forklift is in contact with the ground.

NEVER overload this jack. The jack’s maximum capacity is 8,000 lbs. (3,630 kg). If you need to lift more

than this, use a jack that has a higher maximum capacity. NEVER use more than one jack to raise a forklift.

Protect hands, feet, and other body parts when using or transporting the jack. Keep hands, feet and

all other body parts out of the area of the scissors mechanism at all times during use or transport of the

jack. The scissors action of the lifting mechanism can cause serious injury to body parts.

NEVER modify the jack in any way. Modications may cause the jack to perform improperly, resulting in

injury or death. NEVER use the jack with aftermarket accessories, lift pads, or adapters, or with any other

pad or device added to the jack.

NEVER abuse or cause damange to the jack. Do not drop, throw, drive over, or otherwise abuse the

jack. NEVER subject the jack to abnormal shocks or loads. Your safety and that of others depends on the

proper operation of the jack.

1

Foreword

Thank you for your purchase. With TVH products, you take part in a long history of product engineering for

the transportation service industry. Our purpose is to provide you with quality equipment that makes your

job easier, and with exemplary service after the sale. Please call TVH’s customer service, at 1-800-255-4109 or

913-829-1000, with any comments or questions.

Specications

Capacity ......................................................................................................8,000 lbs./3,630 kg.

Maximum Lift Height .............................................................................16”

Reach (raised position) ..........................................................................7”

(Distance from reservoir to lift pad)

Width ...........................................................................................................8”

Starting Pad Height (lift arm notch) .................................................2 ¼”

Starting Pad Height (serrated lift pad) .............................................2 ½”

Weight .........................................................................................................68 lbs.

Signal Words

Signal words call attention to a safety message or messages, or a property damage message or messages,

and designates a degree or level of hazard seriousness. The signal words are “DANGER”, “ WARNING”,

“CAUTION”, and “NOTICE”.

• DANGER: Indicates a hazardous situation, which, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations.

• WARNING: Indicates a hazardous situation, which, if not avoided, could result in death or

serious injury.

• CAUTION: Indicates a hazardous situation, which, if not avoided, could result in minor or

moderate injury. It may be used to alert against unsafe practices.

• NOTICE: Indicates a property damage message.

2

SPECIFICATIONS

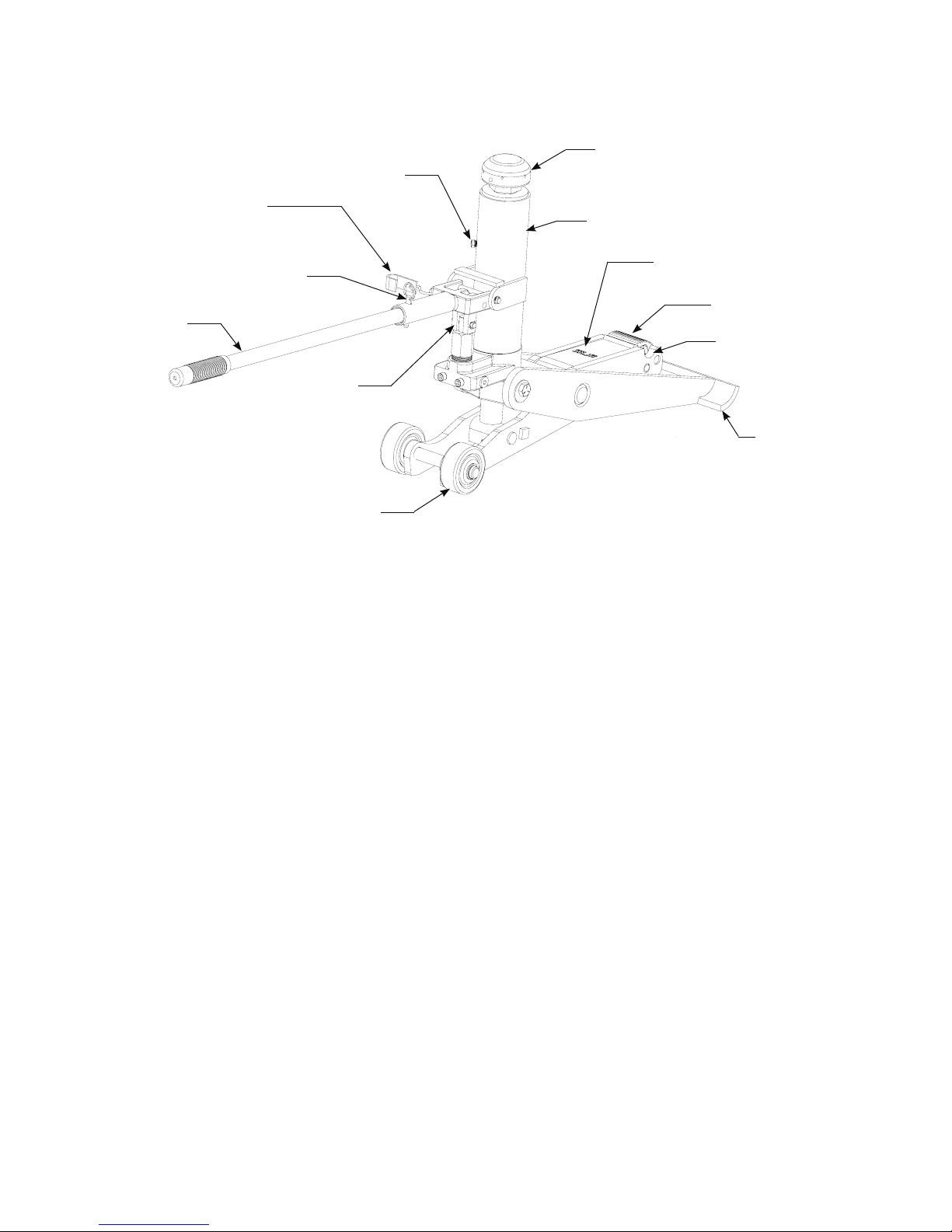

COMPONENT IDENTIFICATION

J-Clip

(slips around pump plunger shaft to lock

handle in UP position so jack can be dollied)

Quick Release-Locking Pin

Pump Handle

Pump Plunger

Shaft

Component Identication

Release Knob, Spring Loaded

Fill Plug

(Twist counter-clockwise and hold to

Reservoir

lower jack)

Lift Arm

Serrated Lift Pad

Lift Arm Notch

Front Foot Pad

Wheel

Release Knob

The release knob has a “Hold-to-Run™” feature that utilizes a heavy-duty return spring to automatically close

the release valve when the operator “lets go” of the release knob. With this feature, the operator should

never have to physically close the valve by turning the release knob in a clockwise direction.

A mechanical stop prevents turning the release knob more than 1/2 turn counterclockwise. WARNING!

Never remove this mechanical stop. NEVER force the release knob more than 1/2 turn counterclockwise as doing

this may damage the release knob’s return spring.

If the valve ever behaves as if it is not completely closing (e.g., the jack won’t raise or won’t hold a load), the

operator may gently turn the release knob in a clockwise direction until resistance is felt. The jack should

then raise when the lift arm is pumped. If it doe not, please call customer service at one of the numbers

shown on the back cover of this manual for assistance.

3

Using the Jack to Raise a Forklift

This section discusses the appropriate and safe methods for using the SY8000 Walking Beam Forklift Jack to

raise and lower a forklift.

! WARNING

Using the jack to raise a forklift requires several steps that must be followed

each and every time the jack is used:

1. Inspect the jack for signs of wear or damage.

2. Transport the jack to the work area.

3. Select appropriate support stands and bring them to the immediate

work area.

4. Prepare the surround area before using the jack.

5. Identify a lift point, prepare the load for lifting, and chock the wheels

that remain on the ground.

6. Raise the forklift.

7. Use appropriate support stands.

8. Lower the forklift.

Each of these steps is discussed in detail in the following sections. Failure to

follow all of these instructions can lead to serious injury or death.

1. Inspect the Jack for Signs of Wear or Damage

Before each use, you should inspect the jack for any visible signs of wear or damage. See the

“Inspecting the Jack” section for details about how to inspect the jack. WARNING! If you see any signs

of wear or damage, or if there is any indication that the jack is not performing normally, immediately take

it out of service and call customer service at 800-255-4109 or 913-829-1000. NEVER use a jack that appears

damaged in any way.

2. Transport the Jack to the Work Area

Transport the jack to the work area by either (a) wheeling it or (b) lifting and carrying it. The jack should

always be wheeled to the work area if possible - only lift and carry the jack if it cannot be wheeled

safely. Wheel the jack only across smooth surfaces. If the surface is rough or uneven, lift and carry the

jack instead of wheeling it. WARNING! Jolting caused by the wheels catching on uneven surfaces can

cause physical strain and personal injury.

4

Loading...

Loading...