TOTALINE P707, P707-SHR1504, P707-SHR2004 Installation And Operation Instructions Manual

INSTALLATION

P707

AND OPERATION

INSTRUCTIONS

Part Numbers P707-SHR1504 and 2004

CONTENTS

SAFETY CONSIDERATIONS......................1

GENERAL ........................................1

INSTALLATION ................................ 2-10

Step 1 — Unit Location...........................2

Step 2 — Unit Mounting .......................... 2

Step 3 — Install Drain Line ....................... 3

Step 4 — Locate and Install Weather Hoods......3

Step 5 — Install Ducting To Weather Hood

Location ....................................... 3

Step 6 — Install Indoor Ductwork System ........4

• SUPPLY AIR DUCTING

• EXHAUST AIR DUCTING

• INSTALL DUCTING

• INSTALLATION EXAMPLES

Step 7 — Airflow Balancing ......................6

• AIRFLOW STATION METHOD

• PITOT TUBE BALANCING PROCEDURE

• BALANCING DAMPER ADJUSTMENT

Step 8 — Install Accessories ..................... 9

Step 9 — Electrical Connection to Furnace

(Air Systems Directly Connected to Furnace) .. 9

OPERATION...................................10,11

Winter ...........................................10

Spring...........................................10

Summer......................................... 10

Fall ..............................................10

Modes of Operation ............................. 10

• CONTINUOUS/VENTILATION MODE

• INTERMITTENT/STANDBY MODE

• DEFROST (FAN SHUTDOWN)

MAINTENANCE .................................11

Motor ........................................... 11

Chassis .........................................11

Condensation Panel............................. 11

Drain and Drain Line ............................ 11

Outside Hoods ..................................11

Filters ........................................... 11

Heat Recovery Core ............................. 11

TROUBLESHOOTING............................12

Heat Recovery

Ventilator

Before installation, always check to be sure main power to

systems are OFF. Electrical shock can cause personal

injury or death.

GENERAL

The P707-SHR1504 and P707-SHR2004 Heat Recovery

Ventilators (HRV) are used to exchange indoor stale air with

outside fresh air. The HRV unit is equipped with a special energy recovery core which transfers sensible heat with the fresh

incoming air. The cross-flow design core allows entering and

leaving airstreams to transfer heat energy without mixing.

The HRV is available in 2 sizes with airflow ranges of

150 cfm (SHR1504), and 200 cfm (SHR2004). The design of

this unit is horizontal. Special attention should be given to duct

application, balancing the HRV, and locating unit for easy

access and routine maintenance. See Table 1 and Fig. 1 for

performance data.

AIRFLOW (L/S)

SHR 2004

SHR 1504

120 160

AIRFLOW (CFM)

200 240

300

250

200

150

100

50

0

1.2

0.8

0.6

0.4

0.2

STATIC PRESSURE (IN. WG)

190 38 57 76 94 114

1

0

40080

Fig. 1 — Fan Performance

STATIC PRESSURE (PA)

SAFETY CONSIDERATIONS

Installing, starting up, and servicing ventilation equipment

can be hazardous due to system pressures, electrical components and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start up, and service this equipment.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment. Follow all safety codes.

Manufacturer reserves the right to

discontinue, or change at any time,

specifications or designs without notice

and without incurring obligations.

Table 1 — Performance Data

UNIT

SHR 1504 72% 69%

SHR 2004 71% 76%

REPLACEMENT CO MPON EN TS DIVI SIO N LITERATURE NUMBER P7 07- 5SI

© CARRIER CORPORATION 2004 4-04 REPLACES: New

PRINTED IN U.S.A. CATALOG NUMBER 570-332

APPARENT SENSIBLE

EFFECTIVENESS

AT 32 F (0° C)

APPARENT SENSIBLE

EFFECTIVENESS

AT –13 F (–24 C)

INSTALLATION

Step 1 — Unit Location —

The HRV must be located

in a heated space where it can be conveniently serviced.

Typically the HRV is located in the mechanical room or an area

close to the outside wall where the weather hoods will be

mounted. If a basement area is not convenient or does not

exist, a utility or laundry room may be used. See Fig. 2 for

dimensions.

Attic installations are not normally recommended due to the

complexity of work to install, freezing conditions in the attic,

and the difficulty of access for service and cleaning.

Connecting appliances to the HRV is not recommended

(such as a clothes dryer, range top, stovetop fan, or central

vacuum system). These appliances may cause lint, dust or

grease to collect in the HRV, damaging the unit.

NOTE: Connecting any of these type of appliances to the

HRV will invalidate the warranty.

Locate the unit close to the outside wall on which the supply

and exhaust hoods will be mounted. There should be a nearby

power supply of 120 volts, 60 Hz available.

There should be access to a water drain for condensate

removal of the unit during defrost.

The unit should be located in a heated area (attic installation

is not recommended). The location should also minimize any

noise level that would be created by the unit in the living area.

Make sure there is adequate access for future maintenance.

Step 2 — Unit Mounting — The unit is typically hung

from the ceiling for mounting. See Fig. 2 for unit dimensions.

Perform the following to mount the HRV:

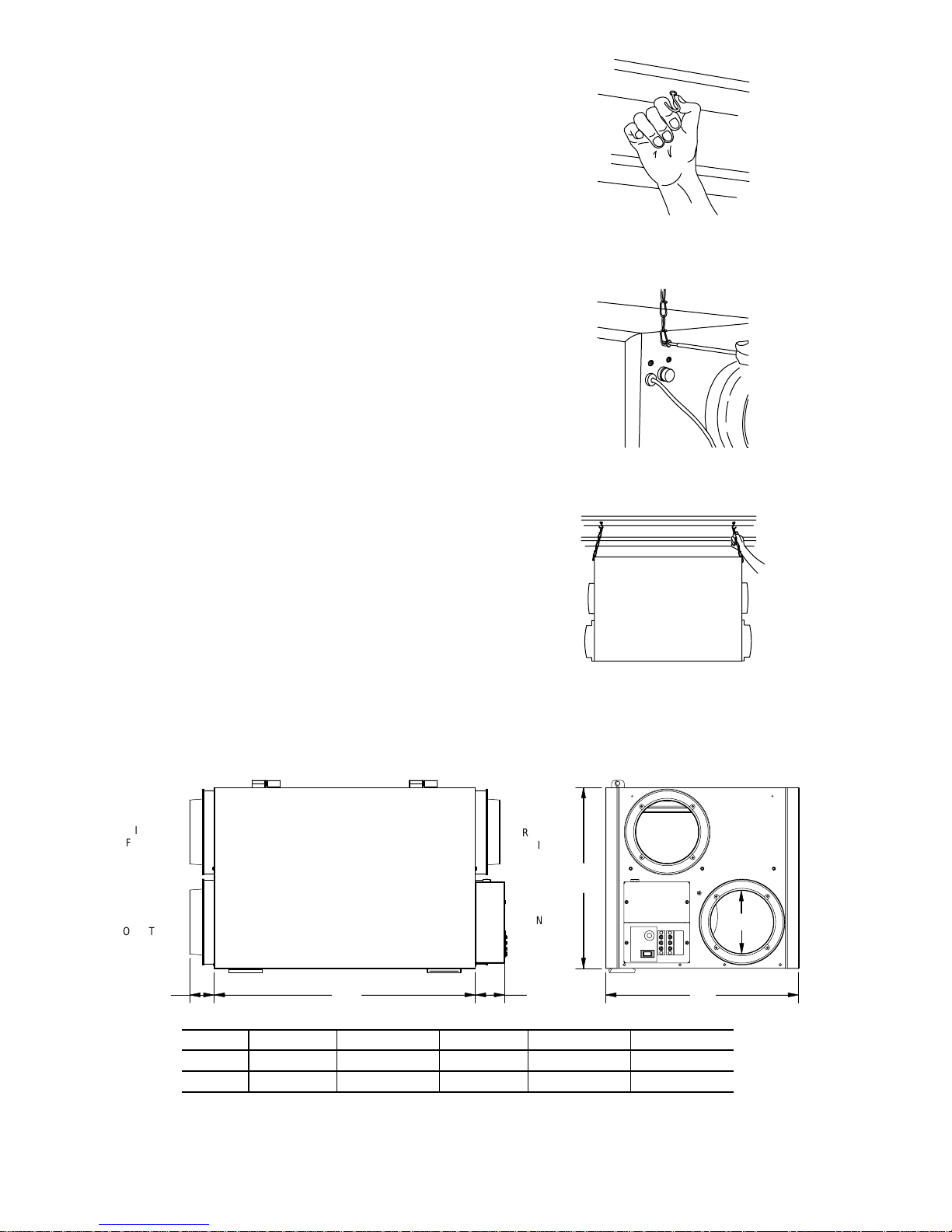

1. Place fastening hooks on the strapping board or the

floor joists. See Fig. 3.

3

2. Attach a hanging chain (provided) to each no. 10

bolts (provided) on the top 4 corners of the unit and

tighten. See Fig. 4.

3. Hang the unit by slipping a link onto the hanging

hooks, making sure the unit is level. Unit condensate

will not drain properly unless unit is level. See Fig. 5.

/4-in.

Fig. 3 — Install Fastening Hooks

Fig. 4 — Install Hanging Chain

Fig. 5 — Unit Mounting

OUTDOOR

(FRESH AIR)

EXHAUST

(TO OUTSIDE)

INTAKE

AIR

A

UNITABCD E

SHR 1504

SHR 2004

1

/4″ (56 mm) 231/2″ (596 mm) 25/8″ (67 mm) 173/8″ (441 mm) 161/8″ (413 mm)

2

1

/4″ (56 mm) 277/8″ (707 mm) 25/8″ (67 mm) 173/8″ (441 mm) 201/2″ (520 mm)

2

EXHAUST

AIR FROM

FRESH AIR

BCD

INSIDE

TO INSIDE

E

6"

Fig. 2 — Unit Dimensions

2

Step 3 — Install Drain Line — Through normal op-

eration and during defrost mode, the HRV may produce some

condensation. This water should be directed to flow into a

nearby drain, or be removed by a condensate pump. The HRV

and all condensate lines must be installed in a space where the

temperature is maintained above the freezing point. A P-trap

should be made in the drain line. This will prevent odors from

being drawn back up into the unit.

To install the drain line, install the drain nipple provided.

See Fig. 6.

Install the drain hose onto the drain nipple. Loop the hose to

create a P-trap as shown in Fig. 7. Run the hose to a nearby

drain.

Step 4 — Locate and Install Weather Hoods —

The intake weather hood should be located upstream and at

least 4 to 6 ft away from the exhaust weather hood. The intake

weather hood should be at least 6 ft away from dryer vents and

furnace exhaust (on medium or high efficiency furnaces) and a

minimum of at least 6 ft from driveways, oil fill pipes, gas

meters, or garbage containers.

Locate the hoods at least 18 in. above the ground, or above

the depth of expected snow accumulation. The hoods should be

at least 3 ft from the corner of the building. Do not locate in a

garage, attic or crawl space.

A well designed and installed ducting system will allow the

HRV to operate at its maximum efficiency. Always keep duct

runs as short and straight as possible.

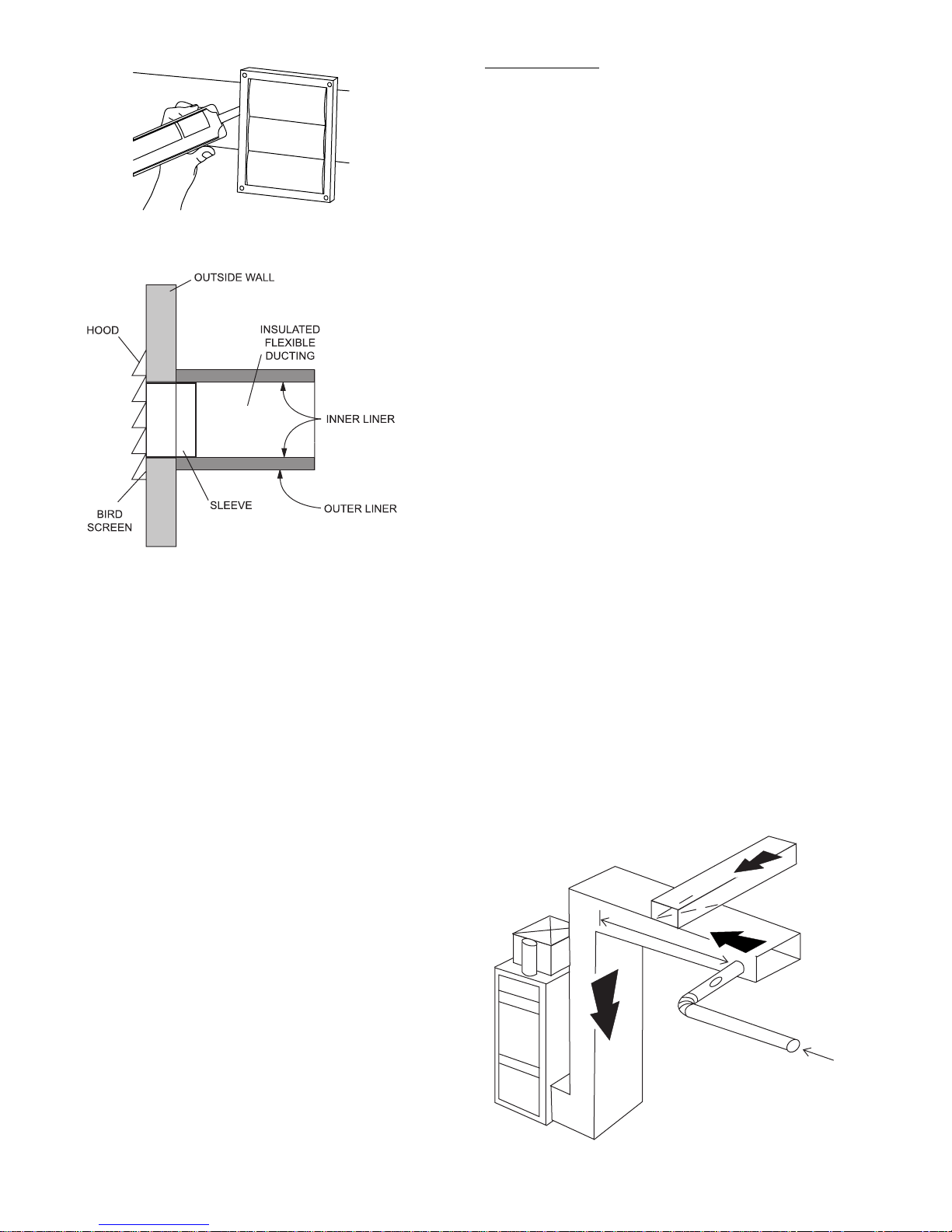

To install the intake and exhaust weather hoods, perform the

following:

1. Using the collar of the outside hood, outline the intake

and exhaust holes to be cut. The hole should be

slightly larger than the collar to allow for the thickness

of the insulated flexible duct. See Fig. 8.

2. Cut a holes using the outline from Step 1. See Fig. 8.

When cutting or drilling holes, be careful not to damage electrical wiring or other hidden objects in wall.

3. Pull the insulated flexible duct through the opening

until it is well extended and straight. Slide the duct

inner vinyl sleeve over the hood collar and secure. See

Fig. 9.

4. Pull the insulation over the duct and then the vapor

barrier over the sleeve and secure with duct tape. See

Fig. 9.

5. Push the hood into the opening. Attach the hood to the

outside wall with mounting screws. See Fig. 10.

6. Using a caulking gun, seal around the hoods to prevent

any leaks. See Fig. 11.

Step 5 — Install Ducting To Weather Hood

Location —

was secured to the intake and exhaust weather hoods in Step 4.

Run the other end of the flexible duct to the HRV installation

location. See Fig. 12.

Clamp the end of the duct to the appropriate port on the

HRV. See Fig. 2.

The insulation should remain full and not be crushed. The

outer liner, which acts as a vapor barrier must be completely

sealed to outer wall and the HRV using tape and/or caulking. A

good bead of high quality caulking (preferably acoustical sealant) will seal the inner flexible duct to both the HRV port and

the weather hood prior to clamping.

To minimize airflow restriction, the flexible insulated duct

that connects the two outside weather hoods to the HRV should

be stretched tightly and be as short as possible. Twisting or

folding the duct will severely restrict airflow.

The inner liner of the flexible insulated duct

Fig. 6 — Install Drain Nipple

Fig. 7 — Install P-Trap

Fig. 8 — Cut Holes for Weather Hoods

Fig. 9 — Install Duct and Sleeve

Fig. 10 — Install Hoods

3

Fig. 11 — Seal Hoods

Fig. 12 — Outdoor Ducting Installation

Step 6 — Install Indoor Ductwork System — To

maximize airflow in the ductwork system, all ducts should be

kept short and have as few bends or elbows as possible. Fortyfive degree elbows are preferred to 90 degree elbows. Use tees

instead of 90 degree elbows whenever possible.

All duct joints must be fastened with screws or duct sealant

and wrapped with a quality duct tape to prevent leakage.

Aluminum foil duct tape is recommended. Galvanized ducting

from the HRV to the living areas in the house is recommended

whenever possible, although flexible duct can be used in

moderation when necessary.

SUPPLY AIR DUCTING — In homes without a forced air

furnace, fresh air should be supplied to all high-usage rooms

including bedrooms and living areas. Air should be supplied

from high wall or ceiling locations. Grilles that diffuse the air

comfortably are recommended. To avoid possible noise transfer

through the ductwork system, a short length (approximately

12 in.) of nonmetallic flexible insulated duct should be connected between the HRV and the supply/exhaust ductwork system.

The main supply and return lines to and from the HRV must

be 6 in. minimum. Branch lines to the individual rooms may

be as small as 4 in., but 5 in. lines are preferred. If floor

installation is the only option available, then special care

should be taken in locating grilles. Installation areas, such as

under baseboard heaters, will help to temper the air. In homes

with a forced air furnace, it may be advisable to connect the

HRV to the furnace ductwork (direct connection).

Building Codes and Combustion Appliance Installation

Codes do not allow location of return air grilles or any opening

such as a breathing tee in an enclosed room with spillage

susceptible combustion appliances.

The fresh air inlet from the HRV must be a minimum

distance of 3 ft from the furnace return drop to ensure proper

air mixing and temperature at the furnace core.

Direct Connection

— A direct connection requires that the

furnace fan run continuously. See Fig. 13. The fan may be

inter-linked electrically (low voltage) with the HRV accessory

control contacts for intermittent demand.

To hard duct the supply air directly into the cold air return of

the furnace, remember to check the airflow balance of the HRV

with the furnace fan both on and off to determine that it does

not imbalance the HRV more than 10%. Make sure that the

minimum distance from the supply air of the HRV to the

furnace is followed. Refer to the local and National Building

and Heating Codes for any variations in these notes.

EXHAUST AIR DUCTING — The stale air exhaust system

is used to draw air from the points in the house where the worst

air quality problems occur. It is recommended that return air

ducts be installed in the bathroom, kitchen, and laundry room.

Additional return air ducts from strategic locations (i.e., greenhouse, atrium, swimming pool, sauna, etc.) may be installed.

The furnace return duct may be also used.

In this method, the exhaust air is not ducted back from

bathrooms, kitchens, etc. to the HRV with dedicated lines.

This method has become popular and provides good

ventilation when installed in accordance with the instructions.

The furnace blower must be running when the HRV is operating for this method to be effective.

INSTALL DUCTING — To install indoor ductwork, perform

the following:

1. Begin with the duct collar on the HRV marked Exhaust

Air In. Slide a short piece (12-in.) of flexible duct over

the duct collar. Using duct tape, tape the flexible duct

to the collar.

2. Run the flexible ducting to the main rigid duct trunk

line, which connects to the remainder of the ducts

going to and from rooms in the house. Repeat the steps

for the Supply Air Out on the side of the HRV.

3. Working from a closet, attic or inside joist wall, run the

length of ducting required for the proper grille location

and cut a hole in the wall.

4. Fasten the mounting collar (field-supplied) to the ducting and fasten the collar to the wall or ceiling with

screws.

5. The field supplied grille may be adjustable. It is recommended that the grilles be completely opened at

first and then adjusted later as needed.

6. Push the grille into the mounting collar or directly into

installed elbow.

FROM HRV

Fig. 13 — Direct Duct Connection

4

INSTALLATION EXAMPLES — It is the responsibility of

the installer to ensure all ductwork is sized and installed as

designed to ensure the system will perform as intended. All air

movement devices have a performance curve. The amount of

air (cfm) that an HRV will deliver is directly related to the total

external static pressure (E.S.P.) of the system. Static pressure is

a measure of resistance imposed on the blower by length of

duct work/number of fittings used in ductwork, duct heater etc.

BEDROOMS

Fully Dedicated System (New Construction)

—Staleairis

drawn from key areas of home (bathroom, kitchen, laundry).

Fresh air is supplied to main living areas. The HRV must be

balanced. See Fig. 14.

Partially Dedicated System

— Stale air drawn from key areas

of home (bathroom, kitchen, laundry) Fresh air supplied to

main living areas via the forced air system. HRV must be balanced. See Fig. 15 and 16.

EXHAUST

BATHROOM

CENTRAL CONTROL

(OPTIONAL)

FRESH AIR TO

LIVING ROOM

FRESH AIR

BEDROOMS

1800 MM

EXHAUST AIR

460 MM

Fig. 14 — Fully Dedicated System

MIXED SUPPLY /

VENTILATION

AIR

HRV

EXHAUST

CENTRAL CONTROL

(OPTIONAL)

BATHROOM

RETURN AIR

THERMOSTAT

SUPPLY

EXHAUST

FURNACE

FRESH AIR

TWO SPEED

FURNACE

EXHAUST AIR

1800 MM

HRV

460 MM

Fig. 15 — Partially Dedicated System

5

HRV CONNECTION

Loading...

Loading...