TOTALINE P102-BB14A, P102-BB20 Installation, Operation And Maintenance Instructions

INSTALLATION,

OPERATION, AND

MAINTENANCE

INSTRUCTIONS

Part Numbers: P102-BB14A, P102-BB20

IMPORTANT: Read entire instructions before

installing the builder’s box media air cleaner.

IF YOU NEED HELP call toll free: 1-800-267-8305

CONTENTS

SAFETY CONSIDERATIONS

GENERAL

COMPONENTS

Cabinet

Filter

INSTALLATION

Location

Media Air Cleaner Installation

OPERATION

MAINTENANCE

Filter Replacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY CONSIDERATIONS

Read and follow manufacturer instructions carefully. Im-

proper installation may damage media air cleaner.

Recognize safety information. This is the safety al ert symbol . When the safety alert symbol is present on equipment

or in the instruction manual, be alert to the potential for personal injury.

Understand the sig nal words DANGER, WARNING, and

CAUTION. These words are used with the safety alert symbol.

DANGER identifies the most se rious hazards which will re sul t

in severe personal injury or death. WA RNING signifies a haz ard which could result in personal injury or death. CAUTION

is used to identify unsafe practices which would result in minor

personal injury or property damage.

Before beginning any installation or modification, be certain that the main line electrical disconnect switch is in the

OFF position. Electric shock could result. Tag disconnect

switch with suitabl e warn ing labe ls.

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should install, repair, or service air-conditioning equipment.

. . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . 2

Residential Duct Mount

Builder’s Box

Media Air Cleaner

Untrained personnel can perform the basic maintenance

functions of replacing filters. All other operations should be

performed by trained service personnel. When working on airconditioning equipment, observe precautions in the literature,

tags and labels attached to the unit, and other safety precautions

that may apply.

Follow all safety codes. Wear safety glasses and work

gloves.

GENERAL

The Builder’s Box Media Air Cleaner is designed to remove atmospheric and household dust, pollen, mold spores,

bacteria, fungi, insecticide dust, animal dander, coal dust,

mites, cooking smoke and grease, tobacco smoke, and other

particles down to 0.3 micron (1/84,000 in.)

Airborne pollutants are carried through the return air ducts

of the heating/cooling system to the media air cleaner. The particles are captured by the filter.

The media air cleaner can be easily upgraded to an electronic

air cleaner for additional air filtration. Additional clearance

above the media air cleaner is required for electronic air cleaner

upgrade.

Regular maintenance (replacement of filters) is required by

the home owner.

COMPONENTS

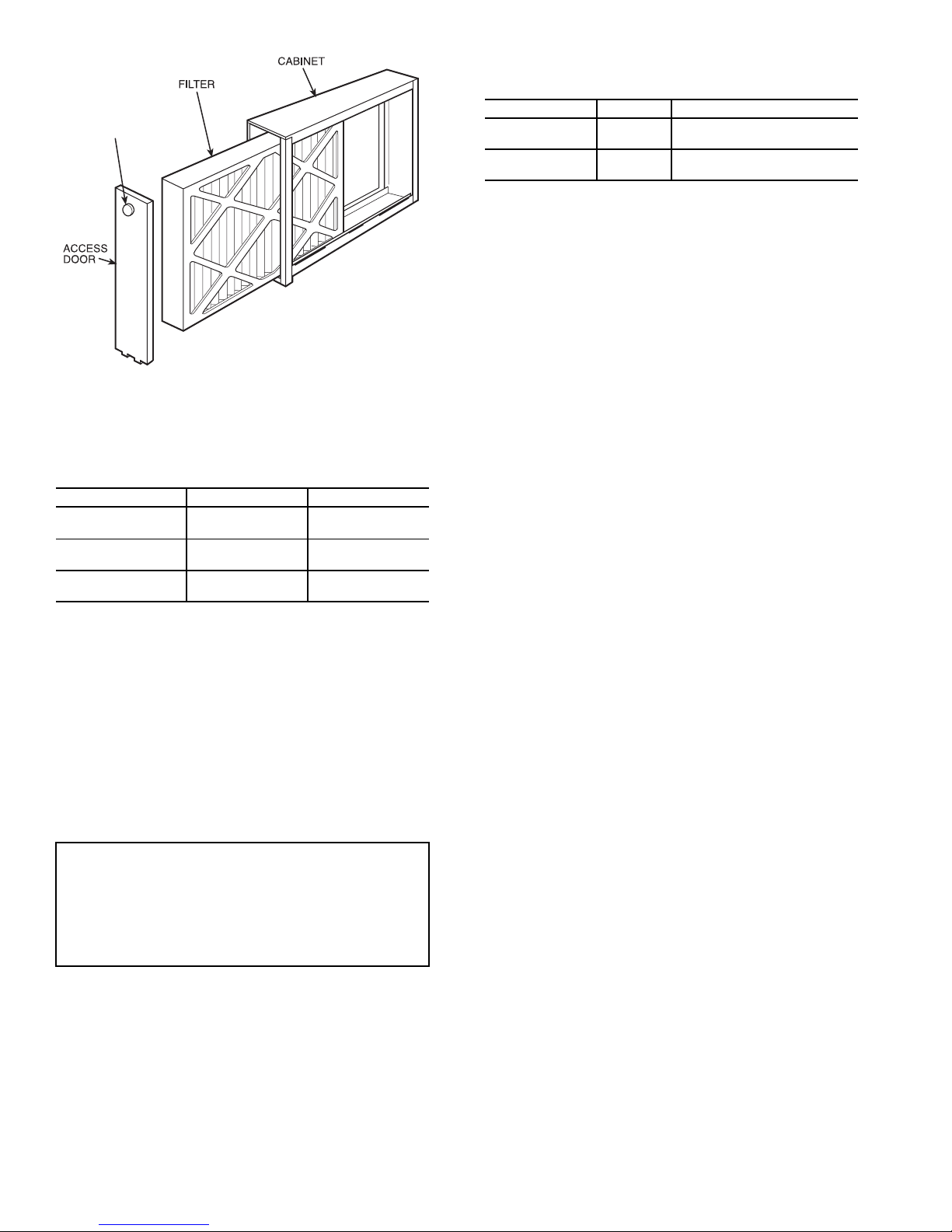

See Fig. 1 for a description of the media air cleaner. See

T able 1 for media air cleaner specifications.

Cabinet —

nized steel. Holes are provided in the cabinet for easy mounting

in the ductwork or air-handling equipment. See Fig. 2 for cabinet dimensions.

Filter —

will not shred or absorb moisture. The unique design of the filter includes a structured density gradient with a polarized

charge for higher initial and sustained efficiency. The filter media is supported by an open steel mesh and enclosed by a high

strength, beverage board. The filters have an Underwriters’

Laboratories Class 2 rating.

The efficiency of the filter is based on ASHRAE (American

Society of Heating, Refrigeration and Air Conditioning Engineers) Standard 52.2P. The maximum veloci ty is 500 ft/min.

An arrow indicates direction of airflow.

The cabinet is constructed of heavy gage galva-

The filter is constructed of polyolefin fibers that

Manufacturer reserves the right to

discontinue, or change at any time,

specifications or designs without notice

and without incurring obligations.

REPLACEMENT COMPONENTS DIVISION

© CARRIER CORPORATION 3/01 LITERATURE NUMBER AC-1SI

PRINTED IN U.S.A. CATALOG NUMBER 570-617

Table 2 — Media Air Cleaner Pressure Drop

(in. wg)

PLASTIC

KNOB

Fig. 1 — Media Air Cleaner

Table 1 — Specifications

PART NUMBER P102-BB14A P102-BB20

House Size Area

Airflow

Duct Size

< 3000 ft

< 278.70 m

up to 1400 CFM

up to 2379 m

16 x 25 in.

405 x 635 mm

2

2

3

/hr

> 3000 ft

> 278.70 m

up to 2000 CFM

up to 3398 m3/hr

20 x 25 in.

510 x 635 mm

2

2

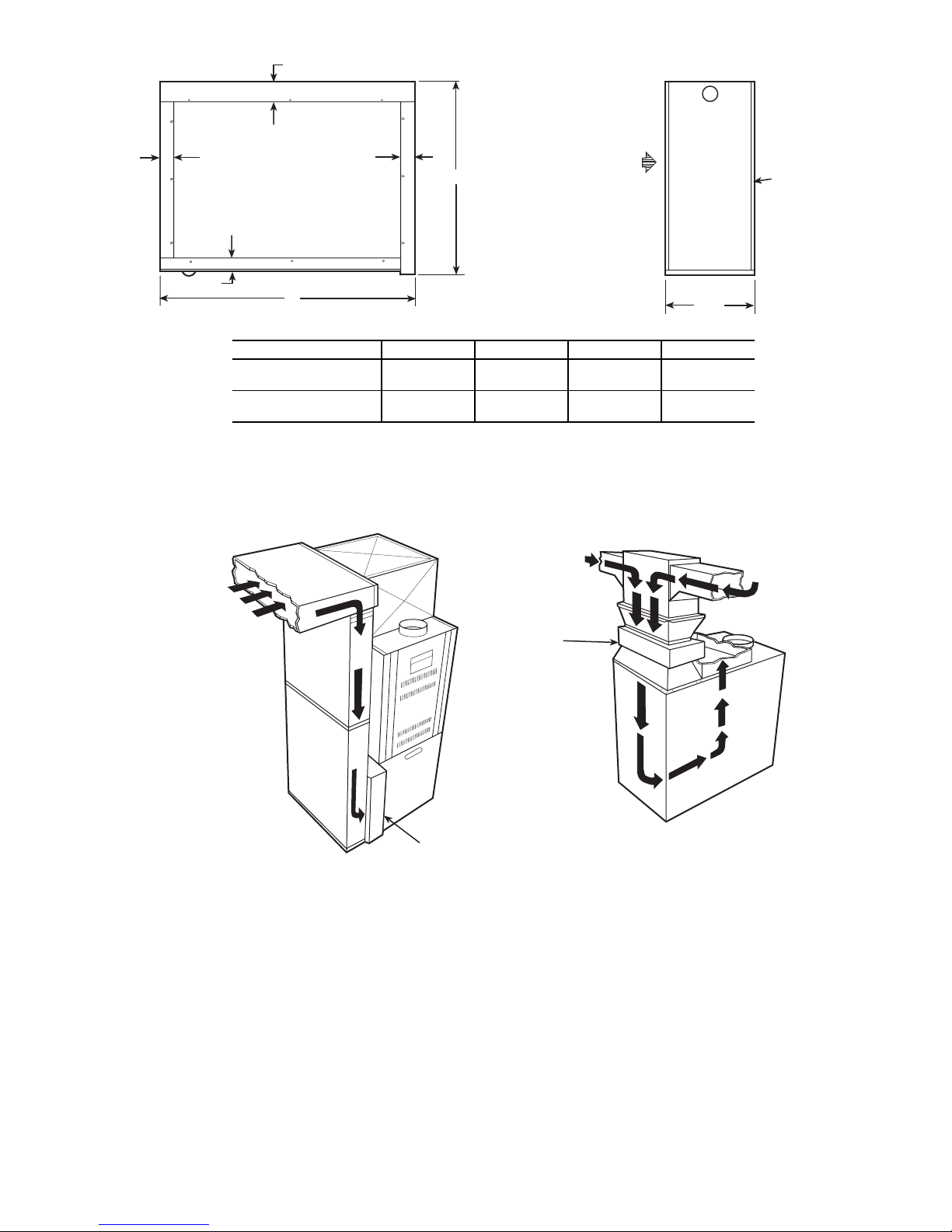

INSTALLATION

Location —

return air duct, as close to the blower compartment as possible.

This location provides the most even airfl ow across the filter

and allows the media air cleaner to keep the system motor and

blower clean. See Fig. 3. When choosing location, there must

be adequate room to remove filters.

NOTE: Be sure to notify home owner not to install any device

within 3 ft from the side of the media air cleaner after installation is complete. Regular servicing of the medi a air cleaner is

required. A 3 ft clearance is required to remove filters for

maintenance or replacement.

IMPORTANT: The media air cleaner will cause

more of a restriction of your heating or cooling system than a regular furnace filter due to its increased

efficiency. As the filter collects contaminants, the

pressure drop increases. The media air cleaner is not

recommended in systems where pressure drop is

critical. See Table 2 for pressure drop information.

The media air cleaner must be installed in the

PART NUMBER CFM PRESSURE DROP (in. wg)

P102-BB14A

P102-BB20

700

1400

1000

2000

0.077

0.26

0.079

0.26

INSTALLATION LOCATION WITH HUMIDIFIER — If

a separate humidifier is purchased, it should be installed in the

furnace warm air duct. However, a humidifier may be installed

in the return air duct without causing problems to the media air

cleaner. Care must be taken to ensure that the humidifier does

not leak, as this may cause damage to the media air cleaner and

mineral deposits on the filter.

An atomizing-type humidifier should only be installed

downstream of the media air cleaner. If the atomizing-type humidifier is installed upstream, high humidity, salts, and minerals may damage the filter and cause service problems.

If the atomizing-type humidifier must be installed upstream,

the atomizing-type humidifier must be installed as far from the

media air cleaner as possible.

INSTALLATION LOCATION WITH AIR CONDITIO NER — Whenever possible, the media air cleaner should

be installed upstream of the cooling coil. This location will

clean the air before it reaches the evaporator coil.

Media Air Cleaner Installation —

Perform the fol-

lowing to install the media air cleaner.

1. Remove the existing furnace filter. Thoroughly clean

the blower compartment and ductwork where the

media air cleaner is to be installed.

2. Remove access door by uns crewing plas tic kno b. Slide

the filter out of the cabinet.

3. Place cabinet in ductwork. Holes are provided to

attach cabinet to ductwork or equipment. If the adjoining ductwork is flanged, install the screws so that the

screw heads are inside the cabinet. This will help prevent damage to filters during removal for cleaning.

When the air duct does not fit the media air cleaner

opening, a gradual transition is recommended to

reduce air turbulence through the media air cleaner and

to increase its efficiency. There should not be more

than 20 degrees of expansion used on each side of

the transition fitting. Do not reduce ductwork to a

smaller media air cleaner or it will increase the velocity of airflow.

4. If the media air cleaner is installed adjacent to an

elbow or angel fitting, turning vanes are recommended

to improve air distribution across the filter.

5. After media air cleaner has been secured, seal seams

airtight with duct tape or caulking to prevent dust from

entering the system.

6. Replace filter. Make sure arrow on filter is pointing

towards the fan. Replace the access door.

2

D

C

C

RETURN AIR

C

A

B

AIR FLOW

LEFT TO RIGHT

OR

RIGHT TO LEFT

7 1/2"

UNIT ABCD

P102-BB14A

P102-BB20

1

17

(435)

22

(560)

/

16

26

(660)

26

(660)

1

(25)

1

1

(30)

/

4

1

2

(55)

23/

(60)

/

8

8

Fig. 2 — Dimensions

RETURN AIR

RETURN AIR

ACCESS DOOR

RETURN AIR

MEDIA AIR

CLEANER

NOTE: Provide a 3 ft (.914 m) clearance for filter removal.

Fig. 3 — Media Air Cleaner Installation Location

MEDIA

AIR

CLEANER

3

Loading...

Loading...