Total Control Systems 700-20, 700-15, 700-25, 700 SERIES, 700-30 Engineering Manual

...

Toll: +1 (800) 348-4753

Tele: +1 (260) 484-0382

Fax: +1 (260) 484-9230

info@tcsmeters.com

www.tcsmeters.com

ENGINEERING MANUAL

700 SERIES ROTARY FLOW METER

© Total Control Systems 2007

Fort Wayne, Indiana U. S. A.

Page No.

Table of Contents

1

Quote and Purchase Specifications

2

Rotary Design

3

Meter Type Classification

4

Meter Selection Factors

Metrology

5

Accuracy

6

Material Compatibility

6

Flow Rate

6

Pressure

6

Temperature

7

Lubricity

7

Suspension and Suspended Solids

7

Foreign Materials

8

PH

8

Viscosity

8

Pressure Loss

9

Bearing Load

10

System Design

Plumbing Figuration

10

Slow Flooding of System

11

Protection From Debris

11

Calibration

11

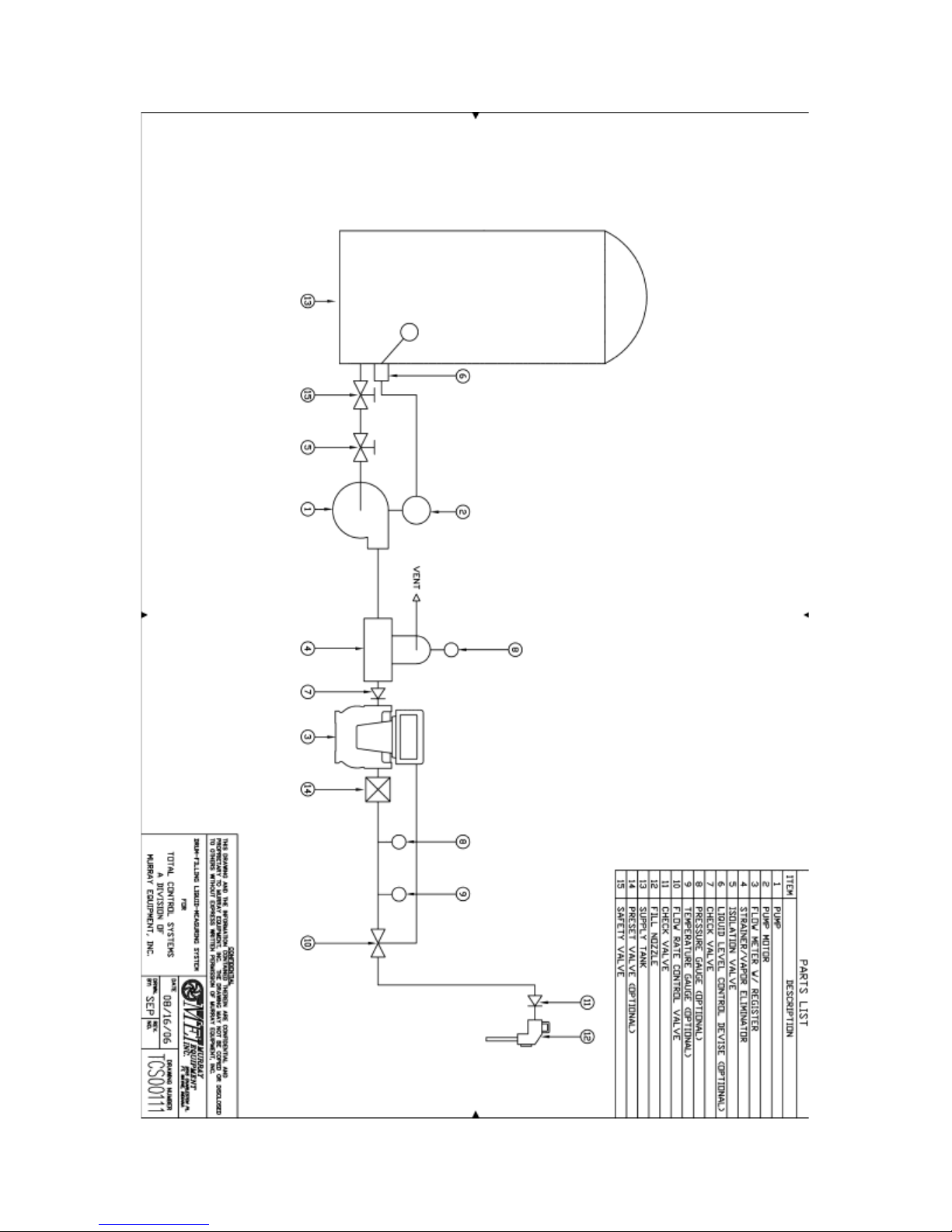

Drum Filling System

12

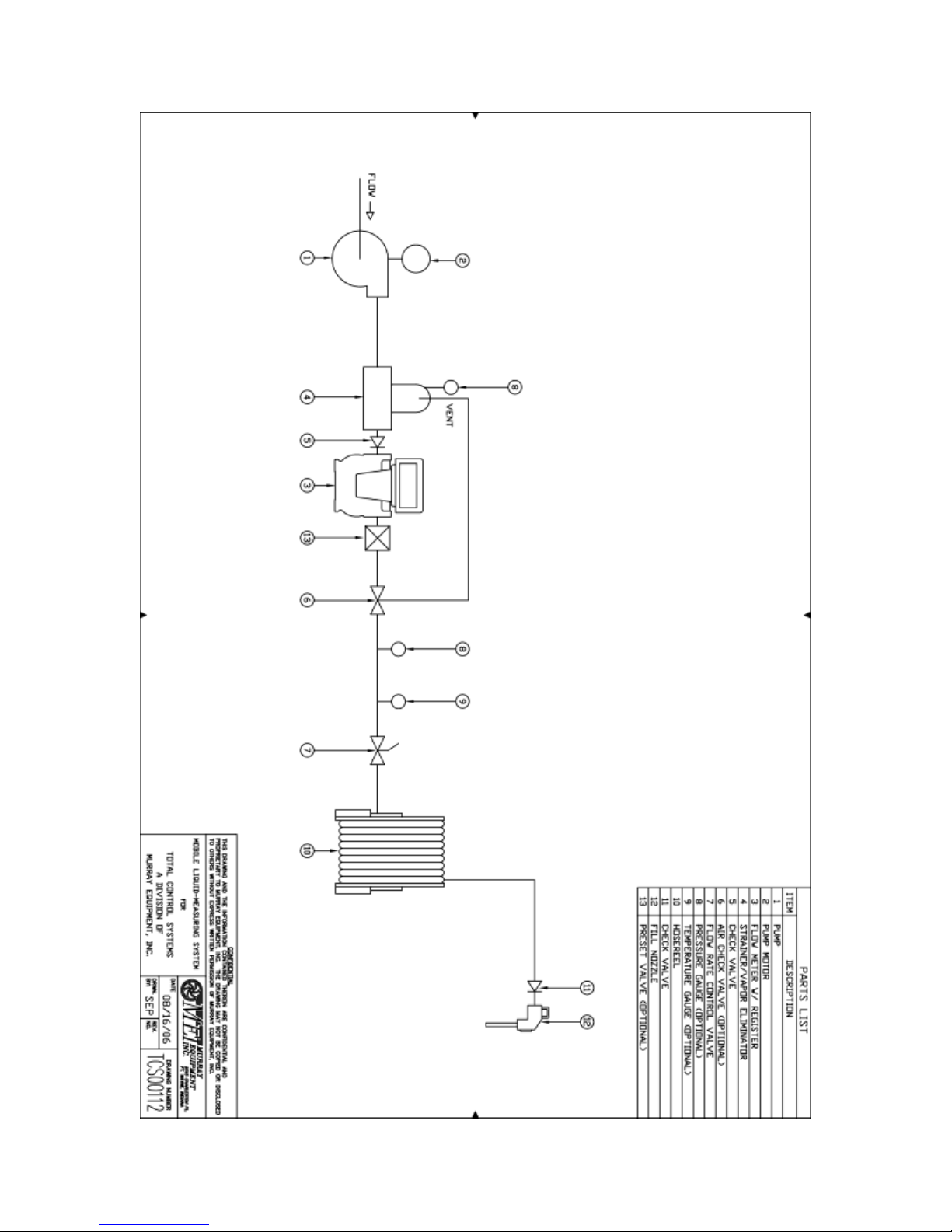

Mobile Fueling System

13

Hydraulic Shock

14

Thermal Expansion

14

Thermal Shock

14

Products that Dry/Congeal/Crystallize

14

LPG

14

Meter Calibration

16 - 18

Product Depletion (Split Compartment)

18 - 20

Calibration Procedure

21

Direction of Flow

22

700 Series Materials of Construction

23

Chemical Compatibility

23 - 35

Metric Conversion Guide

36

Registration Specifications

Gear Plate Information

37

Pulse Output

38

Approximate Weights

39

Glossary

40 - 42

Material Safety Data Sheet (MSDS) for Calibration Fluid

43 - 46

TABLE OF CONTENTS

- 1 -

QUOTE & PURCHASE SPECIFICATIONS

When issuing quote and purchase specifications and to assure you of receiving a Total Control

Systems meter with all of the many performance, installation, operating, and maintenance

advantages available only with a TCS meter. We suggest that 700 series meter-engineering

specifications include the following statements in addition to a TCS model number and

description.

“Meter shall be of a flow meter with a positive displacement design having rotary motion

without axial thrust or flow disruption. No eccentric, sliding, reciprocating or oscillating parts to

induce excess liquid shear or liquid compressibility within meter element. Meter shall have three

rotors that rotate in unison within the measuring chamber. Rotary parts to be horizontally

supported on both sides by solid support bearings and rotor journals of materials compatible with

product to be metered. Meter shall have stainless steel timing gears with no ball bearings, springs,

or cams. Rotary drive and meter adjustment output to all mechanical readout shall be capable of

infinite meter accuracy adjustment of 0.02% or better. Meter calibration adjustment device must

be externally accessible not requiring removal of any readout equipment for calibration or

replacement. Meter shall immediately respond to product low flow movement.”

NOTICE

Total Control Systems (TCS) shall not be liable for technical or editorial errors in this manual or

omissions from this manual. TCS makes no warranties, express or implied, including the

implied warranties of merchantability and fitness for a particular purpose with respect to this

manual and, in no event, shall TCS be liable for special or consequential damages including, but

not limited to, loss of production, loss of profits, etc.

The contents of this publication are presented for informational purposes only, and while every

effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, expressed or implied, regarding the products or services described herein or their use

or applicability. We reserve the right to modify or improve the designs or specifications of such

products at any time.

TCS does not assume responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use and maintenance of any TCS product remains solely with

the purchaser and end-user.

All rights reserved. No part of this work may be reproduced or copied in any form or by any

means – graphic, electronic or mechanical – without first receiving the written permission of

Total Control Systems, Fort Wayne, Indiana USA.

- 2 -

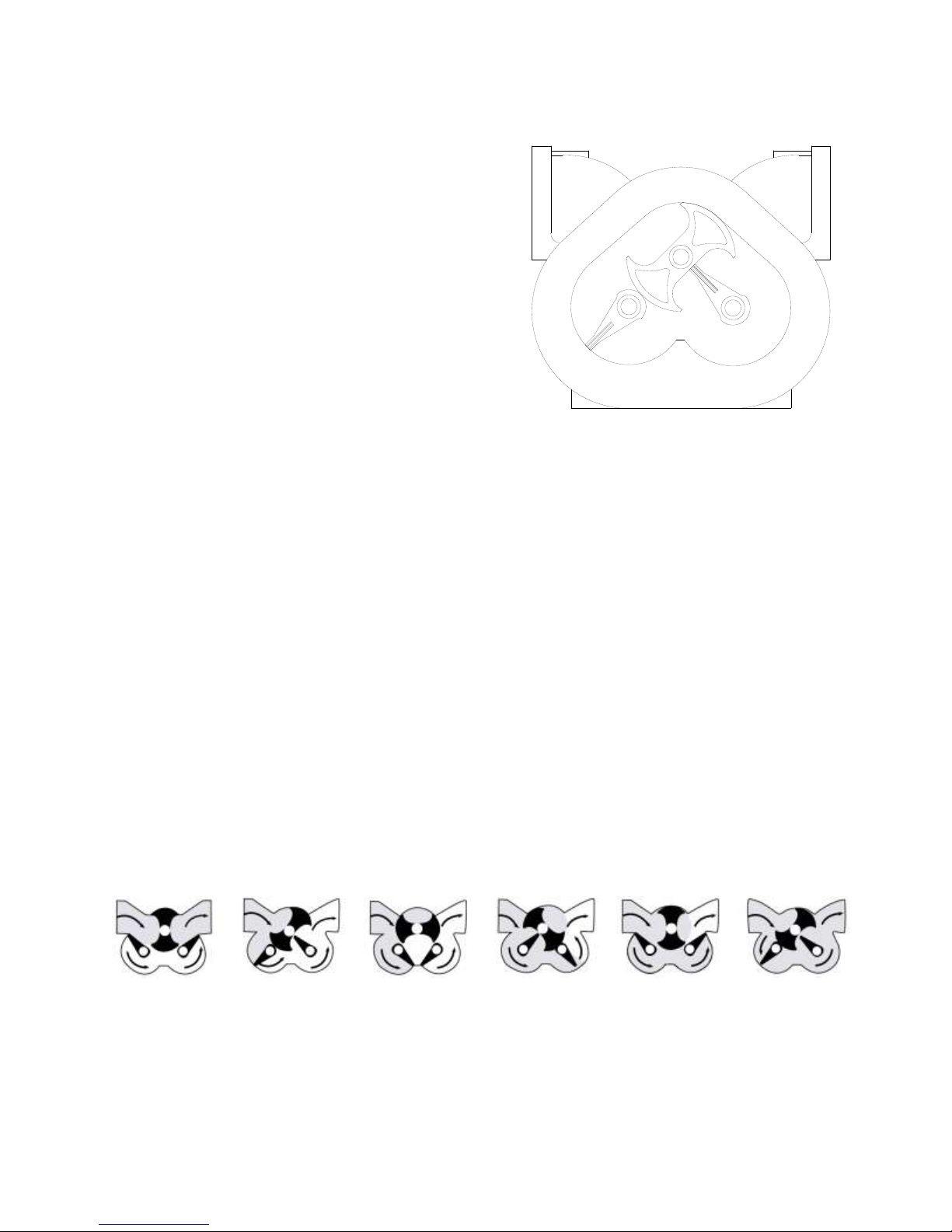

DESIGN

The TCS Model 700 series flow meter is a simple

and efficient design. The meter consists of a single

fluid chamber that contains a single blocking rotor

and two displacement rotors whose rotation is

synchronized with mating gears. As the fluid

enters the fluid chamber, the blocking rotor is

forced to rotate. The displacement rotors, also

rotating in conjunction with the blocking rotor help

direct the fluid flow through the chamber and to the

outlet. The linear flow of the fluid is thus

translated into rotary motion in the meter. The

output of the meter is picked up from the rotation

of the blocking rotor and transmitted to a register or

pulse transmitter.

The rotors in the meter are designed to operate at close tolerances to one another and the wall of

the fluid chamber. There are slight gaps between the rotors and the chamber wall. Because of

this, it is important that the meter be properly applied for the flow rate and operating pressure of

the system.

Because the fluid flowing through the meter is redirected only slightly from its natural flow,

there is very little pressure drop across the meter, unlike other meters that use multiple measuring

chambers.

The meter design uses high quality long life materials for the rotor bearings and journals. Since

there is no contact between the rotors and the fluid chamber wall, these critical components have

a long life expectancy.

Calibration of the meter involves adjusting the rotation of the output shaft relative to the rotation

of the internal rotors of the meter. This is accomplished by changing the settings on an adjuster

device. Calibration of the meter is discussed in detail in the section Meter Calibration.

700 METER FLOW ILLUSTRATION

- 3 -

METER TYPES

SP STANDARD PETROLEUM

For metering refined petroleum products such as Leaded and Unleaded Gasoline, Fuel Oils,

Diesel, Bio-Diesel, Kerosene, Vegetable Oils, Motor Oils, Ethylene Glycol (Antifreeze), etc.

SPA STANDARD PETROLEUM (AVIATION)

For metering refined petroleum products such as Aviation Gasoline, Jet Fuels, Gasoline, Fuel

Oils, Diesel, Bio-Diesel, Kerosene, Motor Oils, etc.

SPD STANDARD PETROLEUM (DUCTILE IRON)

For metering alternative fuels such as Natural Gasoline, Ethanol, Methanol, Bio-Diesel, Aviation

Gasoline, Fuel Oils, Diesel, Motor Oils, etc.

LP LIQUEFIED PETROLEUM

For metering Liquefied Petroleum Gas (LPG).

IP INDUSTRIAL PRODUCTS

For metering Food Products, Industrial Products, General Solvents and many other liquids; such

as Liquid Sugars, Corn Syrup, Soy Bean Oil, Shortenings, Latex Products, Adhesives, etc.

IC INDUSTRIAL PRODUCTS WITH CARBON BEARINGS

For metering Industrial Chemicals, General Solvents, Water and other Non-lubricating Liquids,

such as Alcohol, Acetones, Ethanol, Naphtha, Xylene, MEK, Toluene, Deionized Water,

Demineralized Water, Potable Water, etc.

AF ALL FERROUS

For metering Pesticides, Nitrogen Solutions, Fertilizer, Chlorinated Solvents, Paints, Inks,

Alcohols, Adhesives, Motor Oils, Molasses, Corn Syrup, Liquid Sugars, etc.

SS STAINLESS STEEL

For metering the same liquids as the SP, SPA, SPD, IP, IC and AF flow meters, but includes

food processing and special handling fluids such as Nitric, Phosphorus and Glacial Acetic Acids,

Anti-Icing Fluids, Vinegar, Fruit Juices, etc.

- 4 -

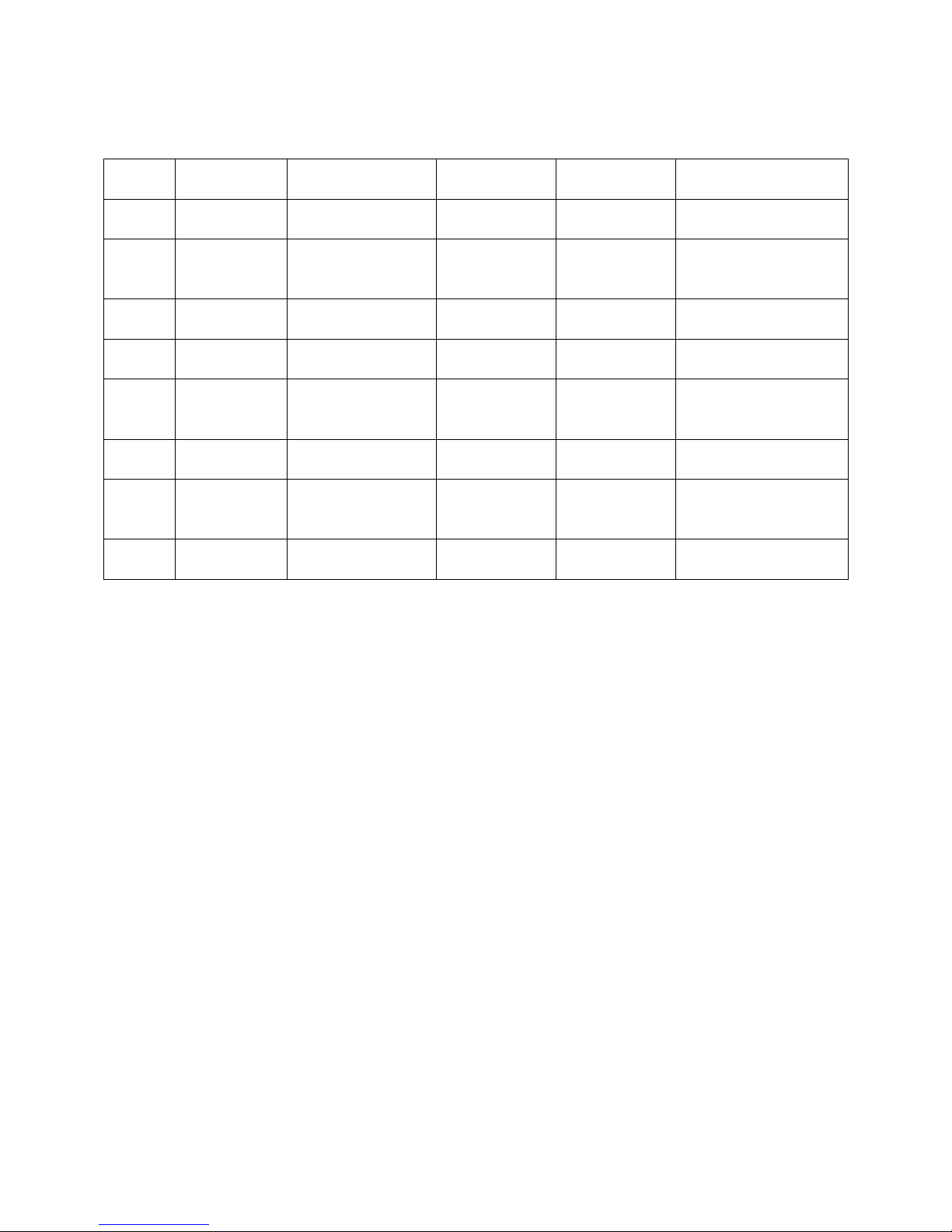

Meter

Type

Available

Flange

Connection*

Maximum

Capacity

Working

Pressure

Working

Temperature**

700-15

SP, SPA,

IP & IC

1½”NPT Flange;

2” optional

60 GPM

(227 LPM)

150 PSI

(10.5 BAR)

-40°F to 160°F

(-40°C to 71°C)

700-20

SP, SPA,

SPD, IP, IC,

AF & SS

2” NPT Flange;

1½”optional

100 GPM

(380 LPM)

150 PSI

(10.5 BAR)

-40°F to 160°F

(-40°C to 71°C)

700-20

LP

2” NPT Flange;

1½”optional

100 GPM

(380 LPM)

350 PSI

(24.1 BAR)

-30°F to 140°F

(-30°C to 60°C)

700-25

SPA, SPD

2” NPT Flange

150 GPM

(567 LPM)

150 PSI

(10.5 BAR)

-40°F to 160°F

(-40°C to 71°C)

700-30

SP, SPA,

SPD, IP, IC

& AF

3” NPT Flange

2”optional

200 GPM

(760 LPM)

150 PSI

(10.5 BAR)

-40°F to 160°F

(-40°C to 71°C)

700-35

SPA, SPD

3” NPT Flange

300 GPM

(1135 LPM)

150 PSI

(10.5 BAR)

-40°F to 160°F

(-40°C to 71°C)

700-40

SP, SPA,

SPD, IP, IC

& AF

4” NPT Flange;

3” optional

500 GPM

(1893 LPM)

150 PSI

(10.5 BAR)

-40°F to 160°F

(-40°C to 71°C)

700-45

SPA, SPD

4” NPT Flange

600 GPM

(2271 LPM)

150 PSI

(10.5 BAR)

-40°F to 160°F

(-40°C to 71°C)

METER OPERATING SPECIFICATIONS

* Flanged NPT is Standard; BSPT, Slip Weld, ANSI and others are available upon request.

** Higher working temperatures can be achieved at reduced pressures (consult factory for more information)

METER SELECTION FACTORS

WEIGHTS&MEASURES

Before any meter can be specified, knowledge of each application is required. If the liquid is to

be sold through a metered delivery, domestic or international certification from a governing body

may be required. Total Control Systems strictly adheres to all domestic and international

metrology conformance regulations for the custody transfer of fluids. For questions regarding

weights and measures approvals or other issues, please consult factory.

- 5 -

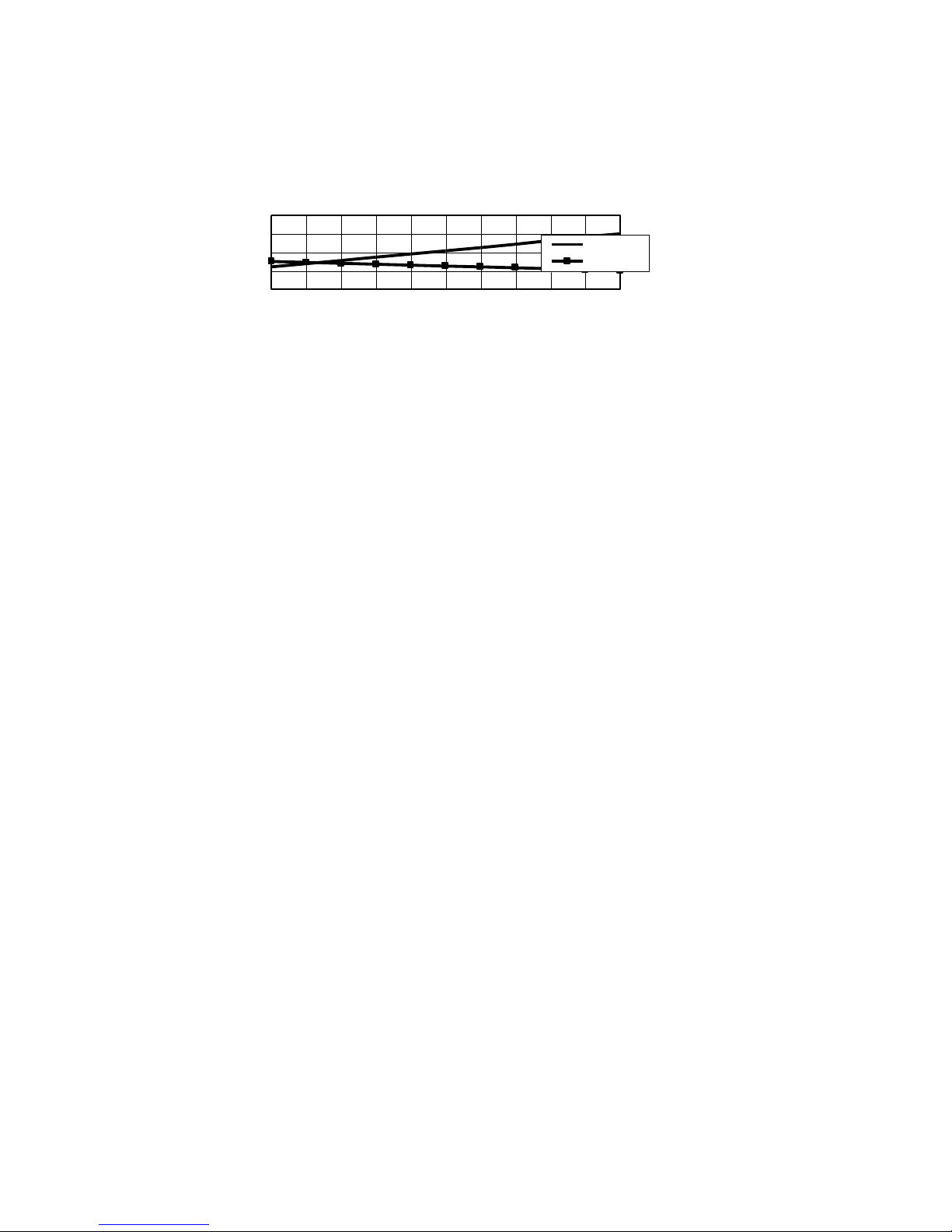

TYPICAL ACCURACY CURVE

-0.4

-0.2

0

0.2

0.4

0 10 20 30 40 50 60 70 80 90 100

PERCENT OF FLOW RATE

% DEVIATION

Gasoline

Fuel Oil

The 700-meter’s accuracy (percent of error over or under the zero – error level) remains within

design parameters (+/- 0.15%) over its minimum rated flow range to its maximum rated flow

range for custody transfer meter requirements. This percentage meets or exceeds the Wholesale

and Vehicle accuracy requirements for accurate custody transfer of product, as specified in the

National Institute of Standards and Technology (NIST) Handbook 44.

PRODUCT CHARACTERISTICS

A) Material Compatibility

The product intended to be measured must review Total Control Systems CHEMICAL

COMPATIBILITY on page 23 to 35 to find the suitable materials and meter type. Materials

incompatible with product will potentially reduce accuracy, operation life, contaminate liquid

and may be harmful to others.

B). Flow Rate

The minimum and maximum system rate of flow must be determined for the selection of

flow meter. The flow rate of the system is dependent upon the product viscosity; the desired

meter configuration, the systems pump capabilities, and the plumbing configuration.

C) Pressure

The maximum working pressure allowed should be reviewed under flow meter type and

pressure rating. All meters meet the European Pressure Equipment Directive (PED) No.

97/23/EC. Failure to adhere to the maximum allowable pressure may potentially cause a seal

leak or casting rupture.

-6 -

Meter Type

SP/SPA/SPD/IP/IC/AF/SS

LP

150F/150PSI

150F/350PSI

200F/100PSI

200F/275PSI

250F/75PSI

250F/250PSI

300F/50PSI

300F/150PSI

D) Temperature

The operating temperature has a great effect on the meter seals and its relationship to the

maximum pressure allowed with the flow meter castings. It will be necessary to reduce the

maximum rated working pressure as the operating temperature increases. Any metering

system operating over 160F (71C) will require extra clearance rotors to compensate for

material expansion. Any metering system operating over 180F (82 C) will require at least a

one (1) foot registration extension to protect the registration devices. Increase in temperature

may increase the corrosion rate of some products.

1) O-ring / Packing Seal Temperature Rating

UL Buna -20F to 140F -30C to 60C

UL Viton -104F to 221F -75C to 105C

Viton -31F to 400F -35C to 204C

Simriz -40F to 450F -10C to 230C

Teflon -20F to 500F -30C to 260C

The Acetyl Face Gear and Bushings, in the register support assembly;

maximum temperature is 180F (82C)

2) Pressure rating at elevated temperatures.

E) Lubricity

The lubricity or non-lubricity of the product will determine the bearing sleeve material

suitable for use. Products with no lubrication will require the use of Carbon Graphite or

Ceramic bearing sleeves. Products with lubrication will reduce friction between two metal

surfaces and help dissipate heat.

F) Suspensions & Suspended Solids

Products with a low percentage of soft suspensions or suspended solids will require clearance

rotors and/or Ceramic bearing sleeves to protect the meter from its abrasive effects. High

percentages (5%) of suspensions or suspended solids, or any hard solids, such as sand, are

not recommended for the 700 series meter. Due to the very tight machining tolerances any

solid, larger than the thickness of a piece of paper, has the potential of stopping the flow

through the meter and can cause damage to the meter.

- 7 -

pH SCALE

NEUTRAL

0 1 2 3 4 5 6 8 9

10

11

12

13

14

◄——— ACID REACTION ———

——— ALKALINE REACTION ——►

7

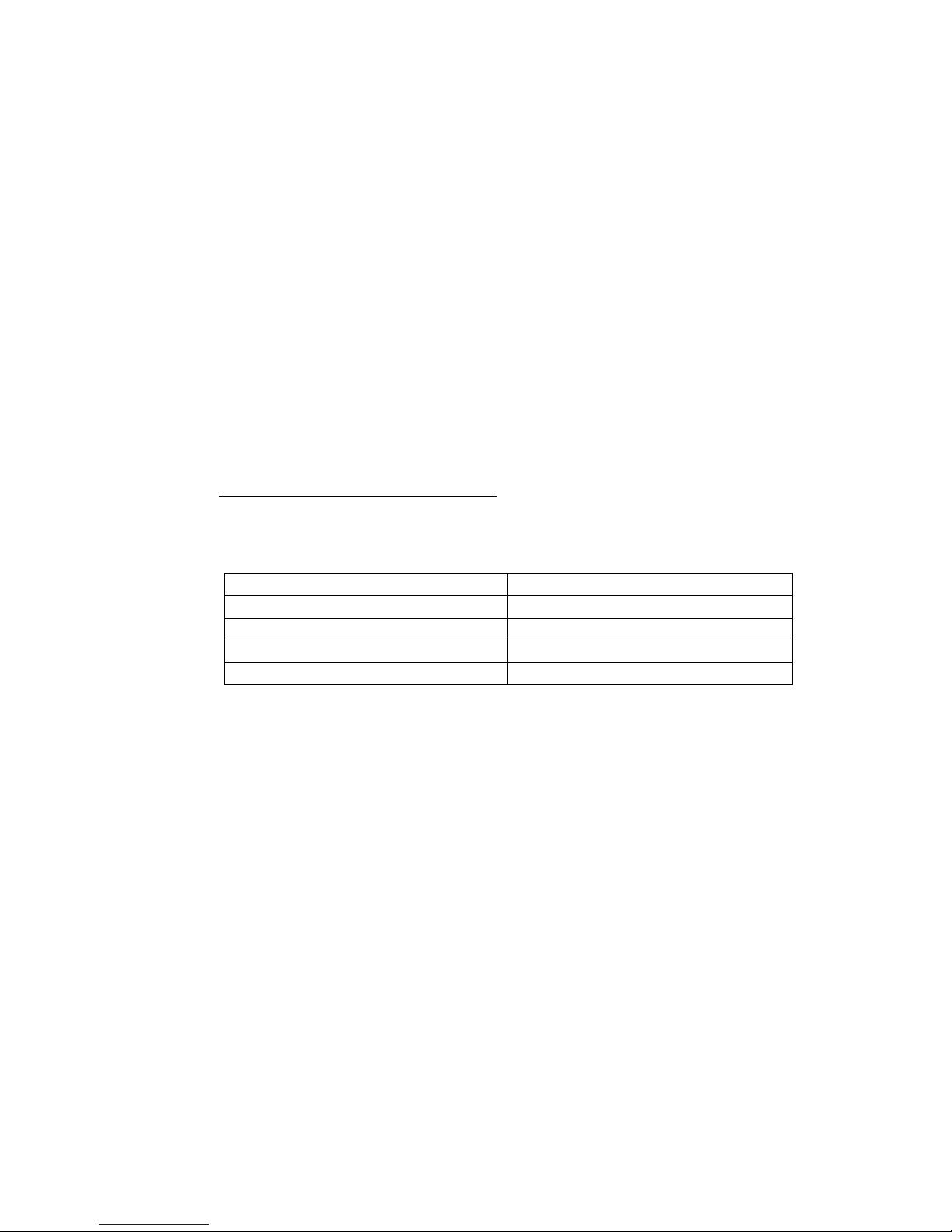

1) Thixotropic Liquids (Plastic and Peudoplastic)

Viscosity decreases as shear rate increases. Typical liquids include

Gels, Latex paints, lotions, Shortening, Mayonnaise, Printers Ink, Hand

cleaner and Yeast.

2) Newtonian Liquids – Viscosity remains unchanged with shear.

3) Dilatants Liquids – Viscosity increases as shear rate increases. Most

liquids in this category are unsuitable with PD flow meters; these

include Clay, Slurries and some confectionary bases.

Material pH

Aluminum 5 – 8

Ductile Iron 5.5 – 11

Ni-Resist 5.5 – 14

Stainless Steel 0 – 14

G) Foreign Materials

Products that are to be measured may have foreign materials present. The inlet side of any

positive displacement meter should be equipped with a strainer. Matching the strainer size or

one size larger, with an appropriate size screen will protect the meter and accessories from

damage in the system. A minimum of 40-mesh screen is recommended for petroleum service.

H) pH

The metal resistance to the effects of high or low

PH is difficult to calculate because of the varying

concentrations and corrosiveness of properties.

This is a generalized rating for pH resistance.

I) Viscosity

Viscosity is the property of a fluid that is a measure of its resistance to flow. Among the

earliest to express this quantitatively was Sir Isaac Newton. He reasoned that the viscosity of

a liquid was proportional to its shear stress (or resistance to shear). Liquids that behave in

this manner are referred to as “Newtonian” liquids and are typically by petroleum fluids,

water and similar chemicals.

Other types of fluids are grouped into a general category called “Non-Newtonian” which

includes dilatants, plastic, pseudoplastic and thixotropic. Liquids in this group are

characterized by viscosity that changes with the rate of shear as compared to the NonNewtonian fluids where viscosity is basically constant with shear and flow rate. As a

consequence, Newtonian fluids are much easier to predict with regard to their performance

through a flow meter than are the Non-Newtonian liquids.

Many of the more viscous liquids pumped through the 700 series rotary flow meter are

plastic and pseudoplastic and as such are reduced in effective viscosity after being presheared by the pump. The diagram below shows how viscosity varies as a function of shear

rate on various types of liquids.

- 8 -

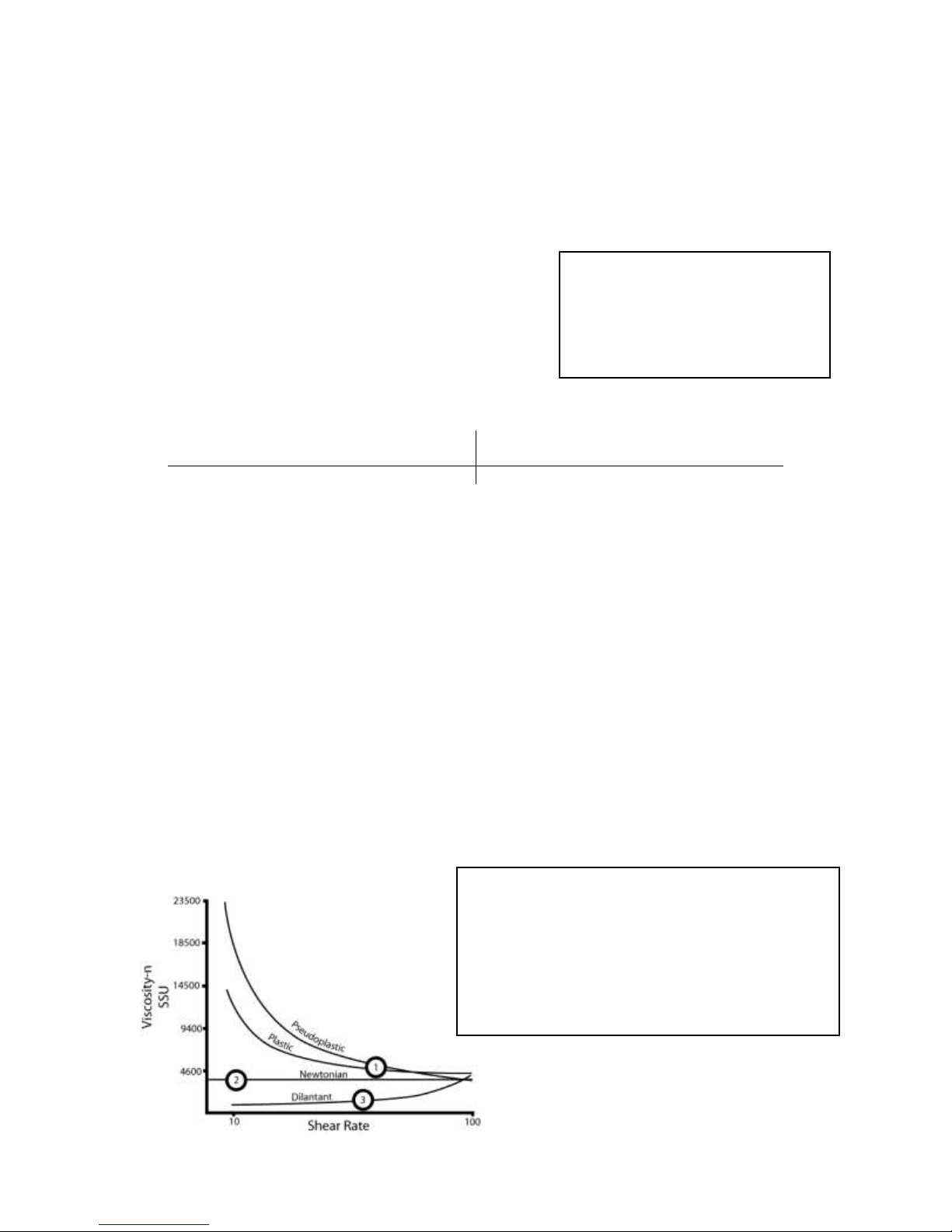

PRESSURE DROP CURVE

32 SSU SOLVENT

0

0.5

1

1.5

2

2.5

3

0 10 20 30 40 50 60 70 80 90 100

PERCENT OF FLOW RATE

P.S.I.

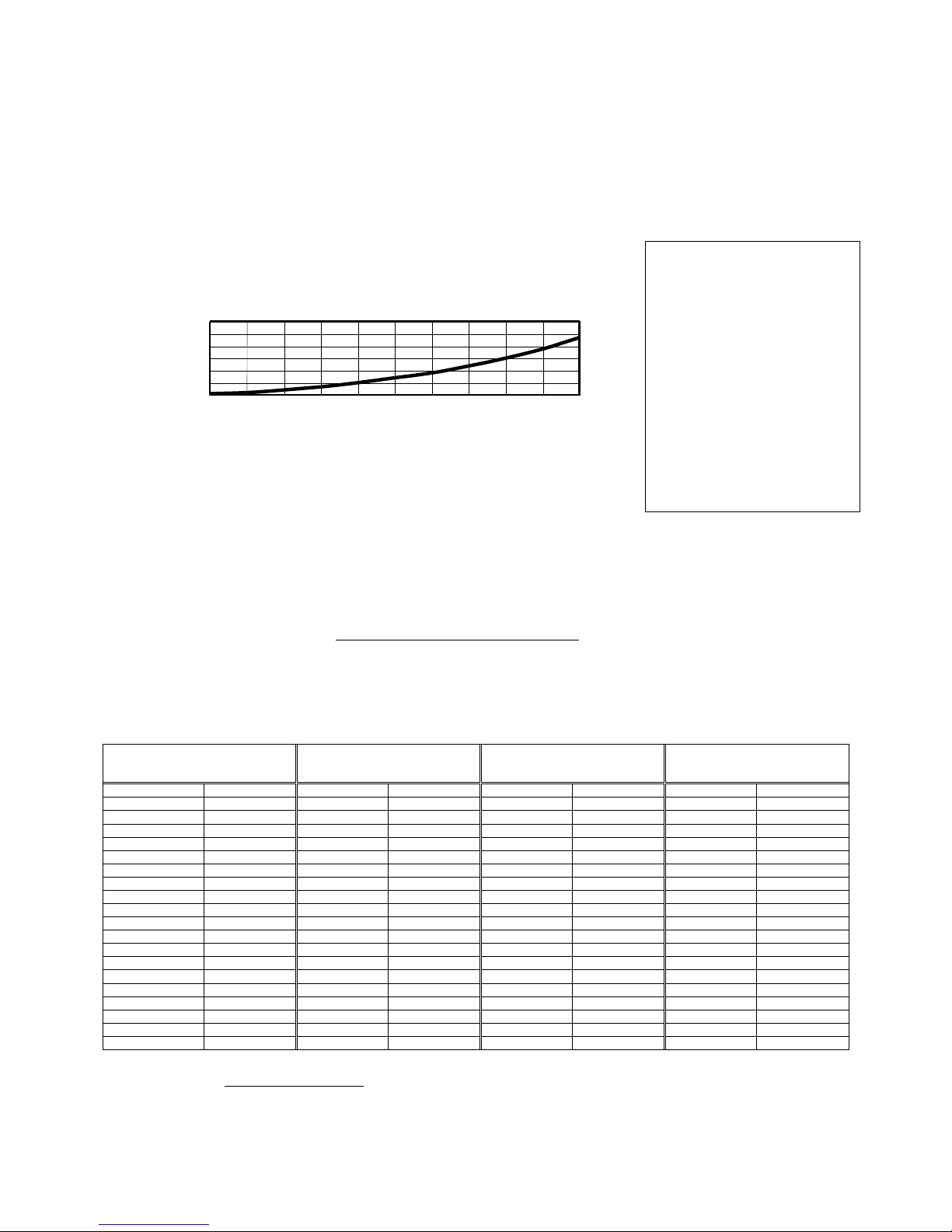

SSU SSU SSU SSU

CPS

Saybolt

CPS

Saybolt

CPS

Saybolt

CPS

Saybolt

Centipoise

Universal

Centipoise

Universal

Centipoise

Universal

Centipoise

Universal 1 31

200

1,000

900

4,300

7,000

32,500 2 34

220

1,100

1,000

4,600

8,000

37,000

4

38

240

1,200

1,200

5,620

8,500

39,500

7

47

260

1,280

1,300

6,100

9,000

41,080

10

60

280

1,380

1,400

6,480

9,500

43,000

15

80

300

1,475

1,500

7,000

10,000

46,500

20

100

320

1,530

1,700

8,000

15,000

69,400

25

130

340

1,630

1,800

8,500

20,000

92,500

30

160

360

1,730

1,900

9,000

30,000

138,500

40

210

380

1,850

2,000

9,400

40,000

185,000

50

260

400

1,950

2,200

10,300

50,000

231,000

60

320

420

2,050

2,400

11,200

60,000

277,500

70

370

440

2,160

2,500

11,600

70,000

323,500

80

430

460

2,270

3,000

14,500

80,000

370,000

90

480

480

2,380

3,500

16,500

90,000

415,500

100

530

500

2,480

4,000

18,500

100,000

462,000

120

580

550

2,660

5,000

23,500

125,000

578,000

140

690

600

2,900

5,500

26,000

150,000

694,000

160

790

700

3,380

6,000

28,000

175,000

810,000

180

900

800

3,880

6,500

30,000

200,000

925,000

Centistokes

=

Centipoise

Centipoise

=

Centistokes x Specific Gravity

Specific Gravity

CONVERSION FACTOR

SSU

Multiplier

30 = 1.0

100 = 1.5

500 = 2.5

1000 = 3.2

2000 = 4.0

3000 = 4.7

4000 = 5.0

5000 = 5.5

7500 = 6.5

10000 = 7.0

25000 = 10.0

50000 = 13.5

J) Pressure Loss

The pressure drop is the difference between of the inlet and outlet pressure of the flow meter

while operating. When measuring a liquid, the pressure drop will increase as the flow rate

increases. When the metering system has accessories such as an air eliminator or valve,

these items will be approximately the same pressure drop through equivalent size meter.

EXAMPLE:

A 700-20SP flow meter, air eliminator, strainer and preset valve. Operating at 80 GPM on a

2000 SSU lubricating oil.

Flow Meter: 1.5 PSI x 4.0 = 6 PSI Pressure Loss

Air Eliminator/Strainer: 1.5 PSI x 4.0 = 6 PSI Pressure Loss

Preset Valve: 1.5 PSI x 4.0 = 6 PSI Pressure Loss

Total Pressure Loss is 18 PSI

VISCOSITY CONVERSION

(Specific Gravity = 1)

- 9 -

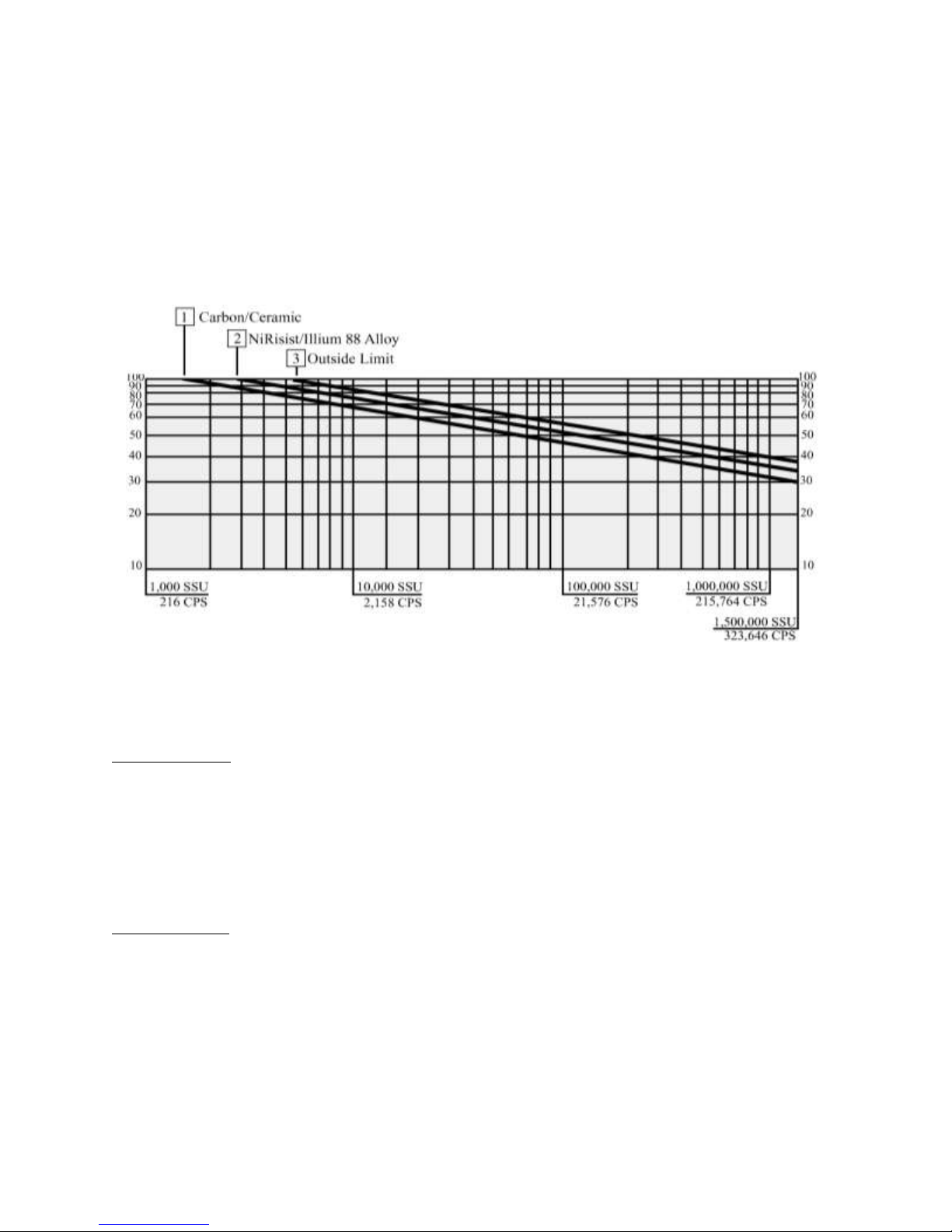

K) Bearing Load

The product viscosity will have a direct relationship on the flow rate of the system. The

following chart is a flow meter selection guide based on the relationship of viscosity and

flow rate. The bearing material is illustrated according to maximum bearing load allowable.

In the following flow chart, please choose the system flow rate and the product viscosity.

Then select the proper bearing sleeve material to identify the flow limitations of the flow

meter. If the system flow rate and viscosity do not meet your requirements, choose the next

size of flow meter or reduce the flow rate.

SYSTEM DESIGN

Meter Selection

The flow meter must be carefully chosen from the Meter Selection factors in the Engineering

Manual. The meter must be selected based on the operating system and product characteristics.

System variables include flow rate, temperature and pressure. The product characteristics

include the material compatibility, lubricity, viscosity, suspensions, pH, and whether the product

can congeal, crystallize or leave a dry film. Failure to select the correct flow meter may result in

system failure or serious injury.

Air Elimination

In any system that the tank may be completely drained or multiple products manifold into one

metering system, the possibility of air being present increases. The solution is an air or vapor

eliminator located before the flow meter to vent the air or vapor from the system before it can be

measured. Air or vapor elimination is required for all weights and measures regulatory

approvals in custody transfer applications.

- 10 -

Control Valves

Safety and isolation valves should be used throughout the metering system. In any pumping

system where there is one (1) pump and multiple flow meters, a digital or hydro-mechanical

Rate-of-Flow control valve must be used at each flow meter to prevent over speeding of the flow

meters.

Best Plumbing Configuration

1). Flow meter must have secure mounting to a riser stand or the foundation.

2). The inlet and outlet piping must be securely supported, in a manner of not to allow pipe

stress on flow meter.

3). System should be designed to keep the flow meter full of liquid at all times.

4). System piping should have the same full pipe diameter or larger as the flow meter,

throughout the metering system to allow for minimal pressure loss.

5). The pipe should be laid out as straight as possible to reduce pressure loss from flow

restriction.

6). The meter and piping must be installed in such as way as to avoid accidental draining of the

meter. Meter inlet and outlet should be lower than the associated system plumbing (sump

position).

7). It is not necessary for the air eliminator to be installed bolted directly to the meter. It can be

installed upstream from the meter. For effective operation of the air eliminator, it should be

mounted between the meter and any valves, tees or any other potential places where air may

enter the system.

8). The metering system should include a means for calibration.

Protection From Debris

On new installations, care must be taken to protect the meter from damage during start-up. It is

recommended to put a strainer before the meter. Damage may result from the passage through

the meter of dirt, sand, welding slag or spatter, thread cuttings, rust, etc. The insertion of a spool

(a flanged length of pipe equal in length to the meter and accessories attached to the meter) in

place of the meter until the system is flushed, temporarily bypassing the plumbing around the

meter, will also protect the meter from debris. Once the system has run “clean” for a period of

time the meter may be reinstalled or protective devices removed.

Thermal Expansion

As with most liquids, they will expand and contract with temperature. In any system where there

is a chance for liquid to be captured between closed valves without relief, thermal expansion will

likely occur and create dangerously high pressures within the system. Care should be taken in

designing the system in which thermal shock may occur by implementing Pressure Relief Valves

or Thermal Expansion Joints in the system design.

When product is trapped within the system, the pressure will increase by 126 PSI (8.69 BAR) for

every one (1) temperature degree increase.

- 11 -

Thermal Shock

The system operating temperature will expand or contract the metals within the flow meter. For systems

that have sudden or immediate temperature increases of 68 F (20 C) degrees or more, will require

clearance rotors. Clearance rotors will be necessary to eliminate the effect of immediate

expansion of the rotors vs. meter body, caused by thermal shock.

Hydraulic Shock (Water Hammer)

Hydraulic shock is a rise in pressure, which happens when an operating system has immediate

change in direction of flow such as a fast valve closure at a high operating flow rate. Hydraulic

shock can damage any item in the way of the product flow such as internal parts of the meter,

valves, and pump. System design and improper operating procedures will elevate this problem.

The use of 2-stage preset control valves or surge suppressing bladders or risers will help reduce

or eliminate this problem.

To compute the shock pressure when a valve is closed quickly (recommended to be less than 6

PSI):

Shock Pressure (PSI) = 63 x Velocity (FPS)

In order to eliminate hydraulic shock, you need to slow down the valve closure rate. The time

required to close the valve so that the line pressure will not exceed the normal pressure at no

flow is:

Time (seconds) = 0.027 x L x V

N – F

V = Velocity in Feet/Seconds

L = Length of pipe before the valve in feet

N = Line pressure at no flow

F = Line pressure at full flow

Products that Dry/Congeal/Crystallize

There are many liquids that crystallize, harden and/or solidify on contact with air or with an

increase in temperature. A proper system design and a good understanding of the product being

measured will help to avoid the possibility of air entering into the system and the product being

affected.

Calibration

The meter shall be tested and calibrated with the product it is intended to measure when installed.

Total Control Systems shall not be responsible for loss of product or any damages resulting from

the end user’s failure to test this meter to insure proper calibration. Every 700 series meter is

tested and calibrated at the factory to prove it is calibratable in your system. It is the owner’s

responsibility to report this device to the local Weights and Measures officials for their

inspection before the meter is put to use. Refer to the Material Safety Data Sheet of the

calibration fluid used in testing on pages 43 to 46 for more information.

- 12 -

- 13 -

- 14 -

Loading...

Loading...