Total Automotive Lifting Solutions Inc. TLSS14ALOFRR1 Installation, Operation & Service Parts Manual

1

14,000 lb.

FLUSHMOUNT SCISSOR LIFT

Part Number : D - SLSM - 14 FM

Total Automotive Lifting Solutions Inc.

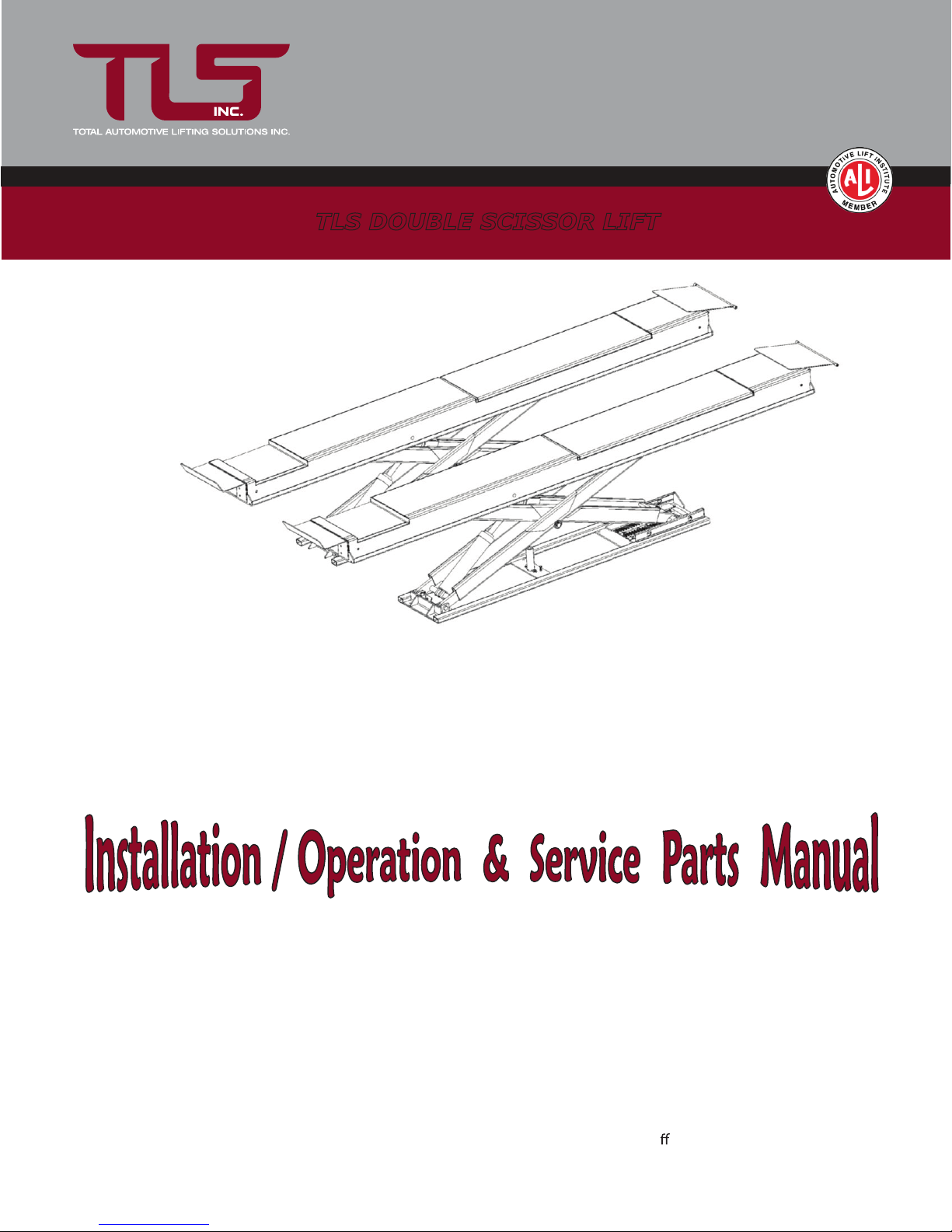

TLS DOUBLE SCISSOR LIFT

( 6350 kg )

READ the Manual Thoroughly Before Installing,

Operating, Servicing, or Maintaining the Lift

SAVE this MANUAL and ALL INSTRUCTIONS

2300 Speers Rd. Oakville, Ontario L6L 2X8

Phone: (905) 847-1198 Fax: (905) 891-1214

www.TLSLifts.com

Model TLSS14ALOFRR1

Issue 0 13 E ective : December 15 , 2010

Supersedes Issue 0 1 2 - April 15 , 200 9

2

Your new lift will provide years of dependable service if installed, operated and maintained

properly. Read and be prepared to follow all safety, installation,

operation, and maintenance instructions in this manual before

installing and operating the lift. In addition, read and follow all safety

and other information included on and with the lift be fore operating

the lift. Keep this manual in a secure place for future reference,

training and service part identification.

TABLE of CONTENTS

1. Unloading Procedure and Lift Package Contents page 3

2. Warranty and Safety page 4 - 6

3. General Requirements and Lift Specifications page 7 - 8

4. Pre Installation Procedures and Tools Required page 9 - 10

5. Installation Procedures page 10 - 12

6. Operating Instructions and Lift Maintenance page 13 - 14

7. Troubleshooting page 15

8. Lift Installation Diagrams and Parts Lists page 16 - 30

IMPORTANT : It is the shop owner's responsibility to provide a satisfactory installation

area for the lift. Lifts should only be installed in a "pit" with a minimum of 4 inches (102mm)

/ 3000 psi (20.7MPa) concrete that has been aged a minimum of 30 days. Please consult a

qualified individual if any doubt exists concerning proper installation and subsequent safe

operation of the lift. Do not install the lift on asphalt or outdoors. (see "pit" detail – page 8)

Prior to installation, it is the shop owner's responsibility to provide constant electrical power

in the correct voltage, phase, etc., and all wiring for electrical hook-up of the lift. The shop

owner must insure that the electrical installation conforms to local building and safety codes.

Where required, the shop owner will provide an electrical isolation switch located in close

proximity to the lift. This switch will have an emergency stop capability and isolate electrical

power from the lift for servicing requirements.

Hydraulic oil cannot be shipped with the lift and will be supplied by either the shop owner or

the installer. ISO 32 hydraulic oil (10W non detergent hydraulic oil) must be used to fill the

reservoir tank before operating the lift. Grout for lift leveling must also be purchased locally.

It is the shop owner's responsibility to train all operators in

lift operation and lift safety.

3

UNLOADING PROCEDURE and LIFT PACKAGE CONTENTS

For your information:

All lift components are packaged together in one module held together by steel bands

UNPACKING PROCEDURE:

When the lift arrives on site: - If possible have lift unloaded in the installation area

- Check for freight damage and report immediately to the

trucking company who delivered the lift

- Check for missing parts and report immediately to the factory

1 - 877 - 799 - LIFT (5438) or (905) 847 - 1198

Main Components include:

Runway Assembly - labeled #1

Runway Assembly - labeled #2

Approach Ramps – 2pc

Accessory and Hardware Box (see list below)

Optional Accessories: (included only if ordered)

Rolling Air/Hydraulic Jacks - 1 jack per box c/w coiled air line

Turnplates - 1 turnplate per box c/w retainer brackets

Accessory Box includes:

Operator Console (power unit) – 1 pc

Hydraulic Hose for Return Oil Line – 1 pc

Air Hose for Safety Locks and Optional Rolling Jacks – 2 pc

Approach Ramp Bracket and Pin – 2 pc

Front Wheel Stops – 2 pc

Hydraulic Line Covers - 4 pc

Wheel Chocks – 2pc

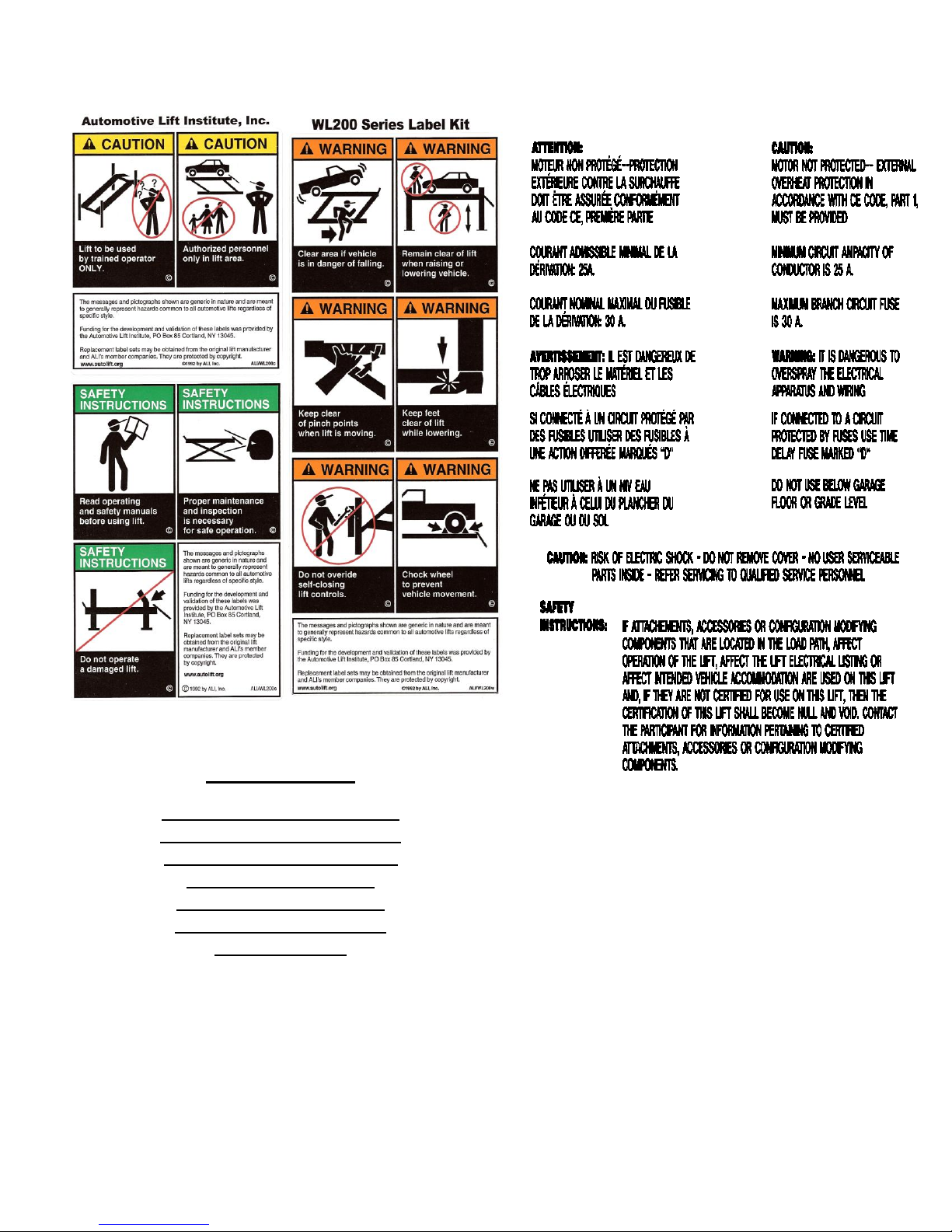

WL 200 Series Safety Information Label Kit

ALI - " Lifting It Right " Manual

ALI - " Vehicle Manufacturer's Lifting Point Guide" (CD)

Automotive Lift Safety Tips Hang Card

Automotive Lift, Operation, Inspection and Maintenance Manual

Owner’s Manual

Hardware Box includes: fittings, bolts, washers, nuts, anchor bolts, etc.

4

WARRANTY and SAFETY

Warranty: The scissor lift model identified in this manual has the following warranty

from date of purchase:

Structural Components - 5 years Accessory Items - 90 days

Hydraulic and Other Components - 1 year Labor - 1 year

The above items are warranted to be free of defects in material and workmanship to the

original owner of the lift as follows: During the first year (90 days for accessories), those parts

proven after inspection to be defective shall be repaired or replaced at the option of the

manufacturer. Structural components only are warranted for an extended four years and if

proven after inspection to be defective shall be repaired or replaced at the option of the

manufacturer. This warranty does not extend to defects caused by ordinary wear, misuse,

abuse, improper maintenance, shipping damage or where repairs have been attempted or

made by anyone other than the manufacturer or a manufacturer certified technician. This

warranty is exclusive and in lieu of all other warranties express or implied. In no event shall

the manufacturer be liable for special, incidental or consequential damages for any breach or

delay in performance of the warranty. The manufacturer reserves the right to change

specifications, designs or add improvements to its product line without incurring any obligation

to make such changes to products sold previously.

IMPORTANT SAFETY INSTRUCTIONS

When using your garage equipment, basic safety precautions should always be followed,

including the following:

1. Read all instructions

2. Care must be taken as burns can result from touching hot parts

3. Do not operate equipment with a damaged cord or if equipment has been dropped or

damaged – until it has been examined by a qualified service person

4. Do not let a cord hang over the edge of the table, bench, or counter or come in contact

with hot manifolds or moving fan blades

5. Let equipment cool completely before putting away. Loop cord loosely around

equipment when storing

6. To reduce risk of fire, do not operate equipment in the vicinity of open containers of

flammable liquids (gasoline)

7. Adequate ventilation should be provided when working on operating internal

combustion engines

8. Keep hair, loose clothing, fingers, and all parts of body away from moving parts

9. To reduce the risk of electric shock, do not use on wet surfaces or expose to rain

10. Use only as directed in this manual. Use only manufacturer’s recommended

attachments

11. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only have impact resistant

lenses, they are not safety glasses

SAVE THESE INSTRUCTIONS

safety cont’d on page 5

5

Safety Continued

Basic common sense safety precautions should always be followed when installing, operating

and maintaining the lift as a risk of fire, electric shock, or injury may be present.

In addition:

1. Read and follow all safety instructions and decals included with the lift. Read and follow

all safety instructions in this manual. Read and follow the ALI "Lifting It Right" manual

(included with the lift). Always use the "Vehicle Lifting Points" reference guide when lifting a

vehicle (CD is included with the lift). Insure all materials stay up to date »» www.autolift.org/

2. Only trained and authorized personnel should position a vehicle and operate the lift. Do

not allow customers or bystanders to operate the liftd or be in the lift area.

3. Inspect the lift daily. Do not operate if potential problems have been identified or lift

malfunctions. Do not operate if lift has damaged or broken components. Never walk or

work under the lift unless all safety locks are completely engaged.

4. Never overload the lift. The rated capacity decal is located on the operator console. The

hydraulic system on this lift is not designed to be a load holding device. Mechanical safety

locks must be engaged before proceeding under the lift for vehicle servicing or lift

maintenance. Never override operating controls. This is unsafe and will void the warranty.

5. Before driving a vehicle onto the lift, insure that both slip plates and turn plates have all

lock mechanisms securely in position. Also insure that the lift and lift area is clear of all

debris and that all oil and grease has been cleaned from runway surfaces.

6. Before raising or lowering the lift, always totally secure the vehicle with wheel chocks.

7. When using a jack(s) to raise a vehicle, position jack lifting pads to contact vehicle

manufacturer's recommended lifting points (see CD included with the lift). Raise jack slowly

until all pads contact the vehicle. Confirm that the vehicle is stable on the jack(s) before

raising to desired working height.

8. Some pickup trucks may require optional truck adapters to clear running boards and other

installed accessories. Special care must be exercised with pick-up trucks to insure safe

lifting. Always use vehicle manufacturers lifting points and insure the contents of the

cargo box will not affect vehicle balance while on the jack(s).

9. Important: Removal or installation of heavier parts can change the vehicle's center of

gravity on the jack(s) resulting in a critical load shift. The vehicle may then be unstable.

Plan ahead for this possibility to insure continued safety and refer to the vehicle

manufacturer’s service manual for recommended procedures.

10. Always keep the lift area free of obstructions and debris. Grease and oil spills should be

cleaned up immediately.

11. Never raise a vehicle on the lift with passengers inside. Before lowering, check the lift

and lift area and remove all obstructions. Before removing vehicle from the lift or lift

area, confirm an unobstructed exit.

Safety continued on page 6 …….

6

Safety Instruction and Information Decal Kit (included with the lift)

Review all safety

information daily

with all lift

operators

LIFT SAFETY and LIFT MAINTENANCE

MUST BE PART OF YOUR DAILY ROUTINE

IMPORTANT :

Insure Safety Instruction

Decals and Hang Card are

affixed to the lift console

or operator pendant

immediately following

installation and before

the lift is used

ELECTRICAL SAFETY DECAL

7

25"

(639 mm)

48"

(1219 mm)

Console

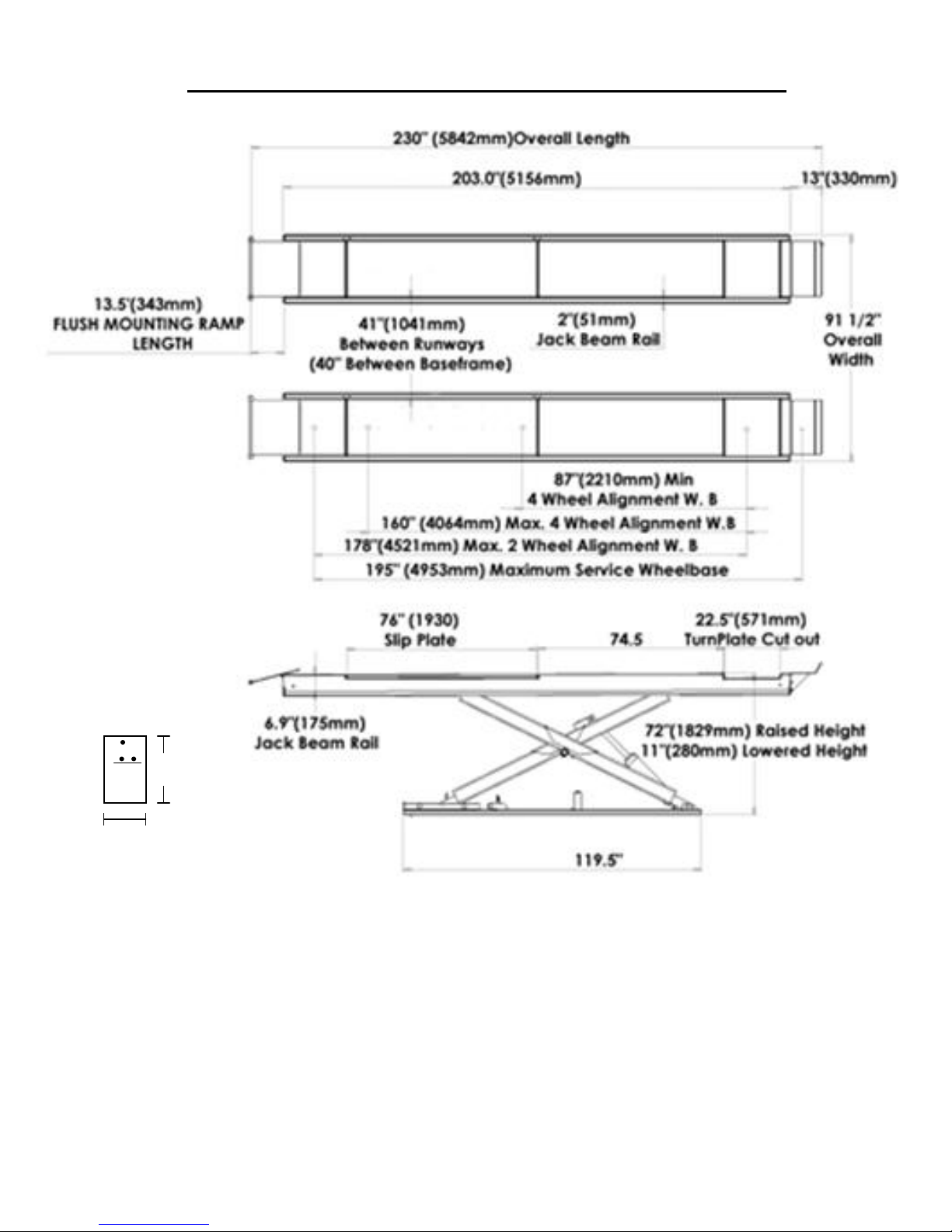

GENERAL REQUIREMENTS and LIFT SPECIFICATIONS

Ongoing design modifications and quality improvements may change specifications listed in this manual without notice

Lift should only be installed in "pit" with a minimum of 4 inches (102mm) / 3000 psi

(20.7MPa) concrete that has been aged a minimum of 30 days (see details next page)

A constant supply of 230 volt – 1 phase – 60 Hz – 30 amp electrical power and a

constant supply of 125 psi dry compressed air is required for this lift.

14,000 lb. (6,350 kg) Capacity - 7,000 lbs. (3,175 kg) each Runway

8

In-Ground Pit Detail for Flushmount Installation

Rear Mount Console

Front Mount Console

9

TOOLS REQUIRED and PRE INSTALLATION PROCEDURES

Tools Required:

25ft. Measuring Tape

Chalk Line and Chalk

Side Cutters (tin snips)

Floor Jacks – 2 (or engine crane)

Crow Bar

Metric and SAE Wrenches and Ratchet Sets

Metric and SAE Allen Key Sets

Hammer

Screwdrivers

4 ft. Level (and laser level)

Rotary Hammer Drill

¼ inch and ¾ inch diameter Masonry Drill Bits

Grout – 1 pail purchased locally (see last page of this manual for reference information)

Trowel, Float and Mixing Pail for hydraulic grout

Pre Installation Procedures

Before proceeding with installation, read the installation manual and insure all instructions

are fully understood and all component parts are accounted for.

IMPORTANT: DO NOT CUT THE SHIPPING STRAPS HOLDING EACH RUNWAY

ASSEMBLY TOGETHER UNTIL INSTRUCTED TO DO SO (step 3 – page 10).

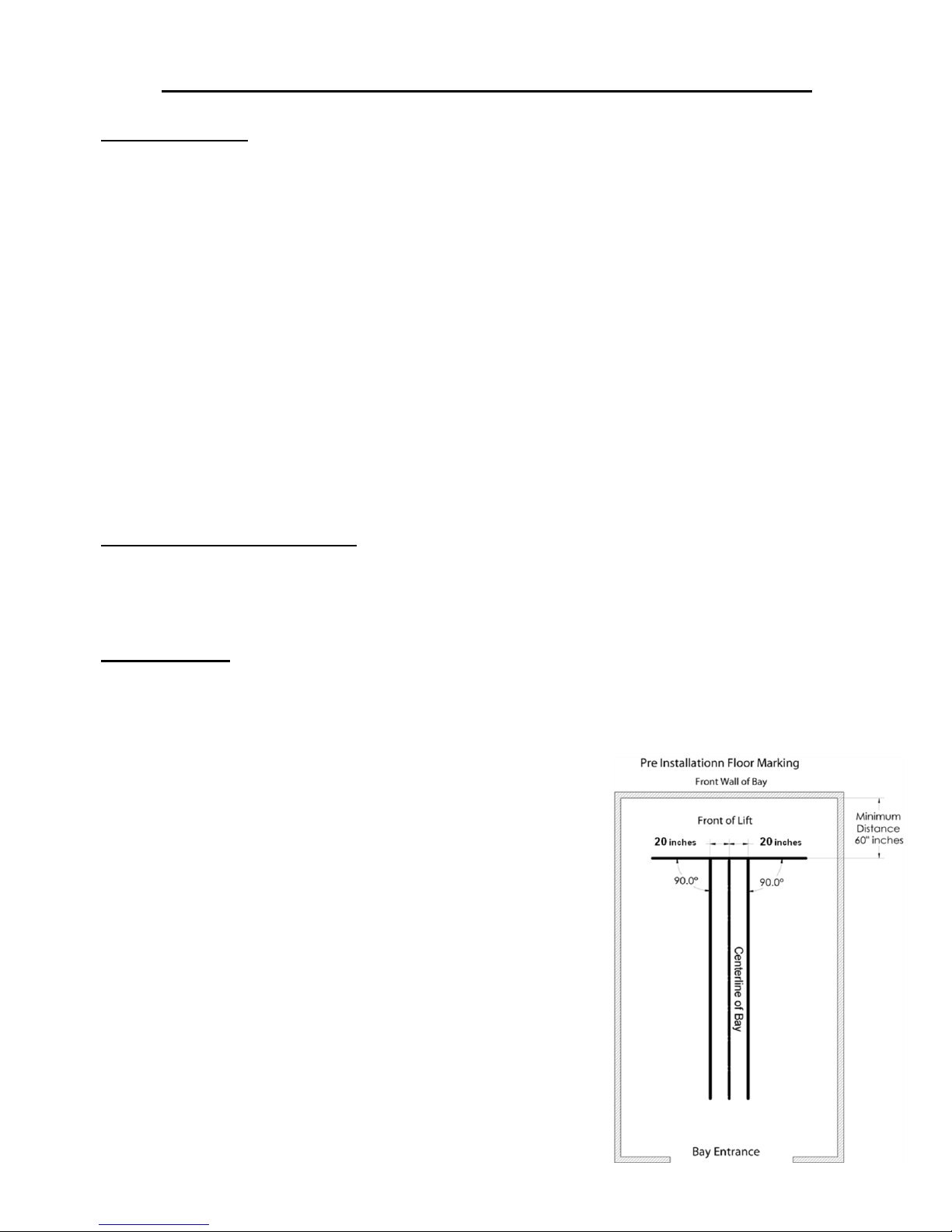

1. Identify pit center line near the front and mark the floor.

Also mark the center of pit at the rear. Connect these

two points with a chalk line. Locate the position for the

front of the lift and draw a second chalk line at 90° to

the centerline (this will be used to position the fronts of both

runway assemblies - refer to lift dimensions on pages 7 & 8).

2. At the front, measure 20 inches out from either side

of the centerline and mark the floor. Near where the

rear of the lift will be, measure 20 inches out from

either side of the centerline and mark the floor. Using

these marks draw two parallel chalk lines the length of

the lift (these will be used to position the inside edge of each

base frame).

Pre Installation Instructions continued on page 10

10

3. Carefully remove accessory box, (rolling air/hydraulic jack(s), and

turnplate boxes if applicable) from on top of runway assemblies.

Identify top runway assembly (see diagram to the right > >).

Move it to its proper position on the chalk lines you have marked.

Use extreme care not to damage preinstalled hydraulic, air and

electrical lines stored under the rear of each runway assembly.

Remove approach ramps from lower runway assembly and set

off to one side. Position second runway assembly on the chalk

lines you have marked. Confirm that turnplate pockets are at

the front of the bay and that all base frame edges are a minimum

6 inches from any floor seam. All anchor bolts must also be a

minimum of 6 inches away from any floor seam. Do not install if

floor has cracks or deterioration that could affect lift stability or

safety. The shop owner is responsible for confirming there are

no obstructions in the installation area like floor drains, under floor

piping or electrical conduit that could be damaged or would

prevent safe lift installation and secure lift anchoring. Check

ceiling for beams or heating ducts and walls for protruding

structures, etc.. Insure that the lift can be safely installed in the

position you have marked on the bay floor. Remove all packaging

material from installation area.

INSTALLATION PROCEDURE

See the Installation and Parts Reference section of this manual for diagrams and parts lists

that will assist you during the installation process (pages 16 – 30). Use these diagrams and

parts lists together with the following written instructions. Insure the lift installation complies

with ANSI/ALI/ALIS, Safety Requirements for Installation and Service of Automotive Lifts.

1. Remove hydraulic, air and electrical lines from under the rear of each runway assembly.

Use extreme care not to damage any of these preinstalled items. Place on top of runway.

2. Unbolt steel shipping supports and remove from installation area.

3. Confirm that the front of both runways and inside base frame edges are on the chalk lines

you have marked. Also confirm that the runway assemblies are parallel to one another

(inside base frame distance front and rear must be equal - diagonal base frame distances front to

rear must also be equal). After confirming that the two runway assemblies are exactly

where they need to be, remove the shipping straps.

4. Unpack operator console and move to desired location (reference diagram #1).

5. Carefully uncoil hydraulic, air and electrical lines and route them to the operator console

insuring there are no kinks.

6. Connect hydraulic, air and electrical lines as follows: (reference diagrams #3 to #8)

(i) Connect hydraulic line from passenger side of lift to console manifold marked

“passenger side”. Connect hydraulic line from driver side of lift to console manifold

marked “driver side”.

(ii) Connect passenger side return oil line (5/32” black tubing) to “T” fitting from accessory box.

Connect driver side return oil line (5/32” black tubing) to “T” fitting. Connect “T” fitting to

oil reservoir cap in console using 5/32” black tubing from accessory box.

Installation Procedure continued on page 11

Loading...

Loading...