Page 1

D4267042B

DU Series

Thank you for purchasing our product.

Before using this CMOS camera, please read through this instruction manual

carefully in order to use this product correctly and safely.

After reading, keep this instruction manual handy so that you can refer to,

whenever you need it.

CMOS Camera

Instruction Manual

Model

B/W Camera : DU1207MG

Color Camera : DU1207MCG / DU1207MCF

Information contained in this document is subject to change without prior notice.

Standard name might be trade mark of each company.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

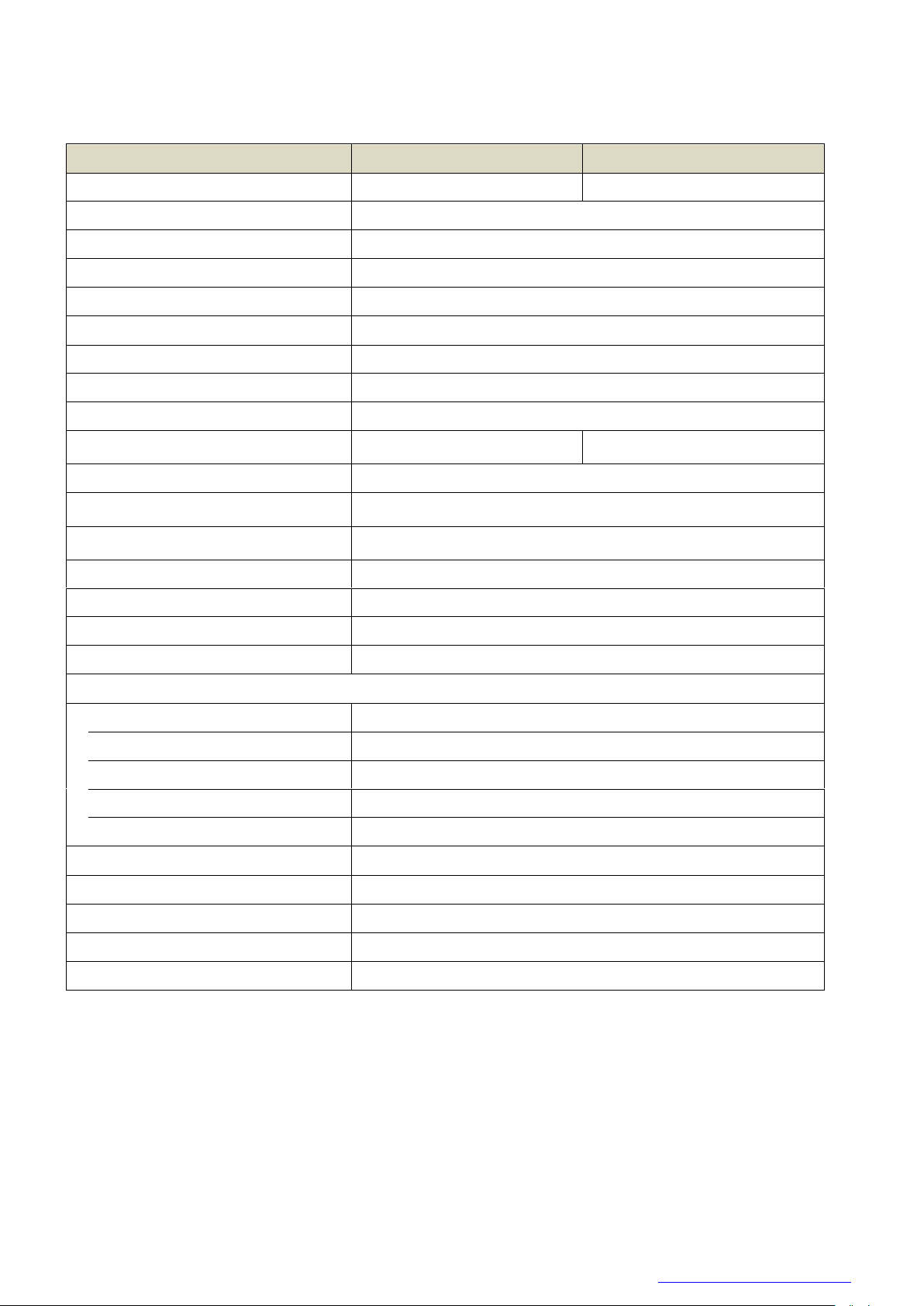

Page 2

D4267042B

Contents

Contents ................................................................................................................................................. 1

Safety Precautions ................................................................................................................................. 3

General Handing ............................................................................................................................ 4

CASES FOR INDEMNITY (LIMITED WARRANTY) ...................................................................... 6

RESTRICTION FOR USE .............................................................................................................. 7

Notes on using this product ............................................................................................................ 8

Installation ............................................................................................................................................ 12

Specifications ....................................................................................................................................... 13

Overview ....................................................................................................................................... 13

Features ........................................................................................................................................ 13

Configuration ................................................................................................................................ 15

Connection .................................................................................................................................... 16

Connector Pin Assignment ........................................................................................................... 17

Outline Drawing ............................................................................................................................ 18

General Specifications .................................................................................................................. 19

LED Status .................................................................................................................................... 22

I/O Specification ............................................................................................................................ 23

Timing Specification ...................................................................................................................... 27

Typical Spectral Response ........................................................................................................... 29

Operating Ambient Conditions ...................................................................................................... 31

Functions .............................................................................................................................................. 33

Bootstrap Registers ...................................................................................................................... 35

DeviceControl ............................................................................................................................... 37

ImageFormatControl ..................................................................................................................... 38

Scalable ........................................................................................................................................ 42

Binning .......................................................................................................................................... 47

Decimation .................................................................................................................................... 52

Reverse ........................................................................................................................................ 57

PixelFormat ................................................................................................................................... 60

BayerProcessingMode ................................................................................................................. 66

TestPattern .................................................................................................................................... 69

AcquisitionControl ......................................................................................................................... 73

ImageBuffer .................................................................................................................................. 79

TriggerControl ............................................................................................................................... 84

ExposureTime ............................................................................................................................... 94

DigitalIOControl ............................................................................................................................ 98

AntiGlitch / AntiChattering........................................................................................................... 108

TimerControl ............................................................................................................................... 112

Gain ............................................................................................................................................ 117

BlackLevel .................................................................................................................................. 120

Gamma ....................................................................................................................................... 122

Hue/Saturation ............................................................................................................................ 124

Sharpness ................................................................................................................................... 128

BalanceRatio .............................................................................................................................. 130

ColorCorrectionMatrix ................................................................................................................. 135

ALCControl ................................................................................................................................. 139

LUTControl ................................................................................................................................. 143

UserSetControl ........................................................................................................................... 146

EventControl ............................................................................................................................... 151

FrameSynchronization ................................................................................................................ 154

LEDIndicatorLuminance ............................................................................................................. 156

DPCControl ................................................................................................................................. 158

Chunk.......................................................................................................................................... 162

SequentialShutterControl ........................................................................................................... 168

Appendix ............................................................................................................................................ 173

1 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 3

D4267042B

UserSetSave and UserSetQuickSave difference ....................................................................... 173

MultiFrame and Bulk function difference .................................................................................... 175

Warranty rules .................................................................................................................................... 178

Repair ................................................................................................................................................. 179

2 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 4

D4267042B

Safety Signs

Description

WARNING

Indicates a potentially hazardous situation that may result in death or serious

injury (*1) in the event of improper handling.

CAUTION

Indicates a potentially hazardous situation that may result in light to moderate

injuries (*2) or only in property damage (*3)in the event of improper handling.

Safety Symbols

Description

PROHIBITED

This sign indicates PROHIBITION (Do not).

The content of prohibition is shown by a picture or words beside the symbol.

MANDATORY

This sign indicates MANDATORY ACTION (You are required to do).

The content of action is shown by a picture or words beside the symbol.

Safety Precautions

Before using this product, read these safety precautions carefully. Important information is shown in this

Instruction Manual to protect users from bodily injuries and property damages, and to enable them to use the

product safely and correctly.

Please be sure to thoroughly understand the meanings of the following signs and symbols before reading the

main text that follow, and observe the instructions given herein.

[Definition of Safety Signs]

Notes *1:“Serious injury” refers to cases of loss of eyesight, wounds, burns (high or low temperature),

electric shock, broken bones, poisoning, etc., which leave after-effects or which require

hospitalization or a long period of outpatient treatment of cure.

*2: "Light to moderate injuries" refers to injuries, burns, electric shock etc. that do not require

hospitalization or long-term treatment.

*3: "Property damage" refers to cases of extensive damage involving damage to buildings,

equipment, farm animals, pet animals and other belongings.

[Explanation of Safety Symbols]

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

3 / 179

Page 5

D4267042B

WARNING

Stop operation immediately when any abnormality or defect occurs.

If abnormal conditions are present, such as smoke, a burning smell, ingress of water or

foreign matter, or if the equipment is dropped or malfunctions, fire or electric shock may

result.

Be always sure to disconnect the power cable from the wall socket at once and contact

your dealer.

Unplug

Do not use the equipment in locations subject to water splashes.

Otherwise, fire or electric shock may result.

Do not get wet

Do not disassemble, repair, or modify the equipment.

Otherwise, fire or electric shock may result.

For internal repair, inspection, or cleaning, contact your sales representative.

Never pull apart

Do not place anything on the equipment.

If metallic objects, liquid, or other foreign matter enters the equipment, fire or electric

shock may result.

Avoid

Do not install the equipment in an unstable or inclined location or locations

subject to vibration or impact.

Otherwise, the equipment may topple over and cause personal injury.

Avoid

During an electrical storm, do not touch the power cable and the connection

cable.

Otherwise, an electric shock may result.

Do not touch

Instruction

Use the specified voltage.

Use of an unspecified voltage may result in fire or electric shock.

Do not be handled roughly, damaged, fabricated, bent forcefully, pulled, twisted,

bundled, placed under heavy objects or heated the power cable and the

connection cable.

Otherwise, fire or electric shock may result.

Avoid

General Handing

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

4 / 179

Page 6

D4267042B

CAUTION

Observe the following when installing the equipment:

·Do not cover the equipment with a cloth, etc.

·Do not place the equipment in a narrow location where heat is likely to accumulate.

Otherwise, heat will accumulate inside the equipment, possibly resulting in a fire.

Instruction

Do not place the equipment in locations subject to high moisture, oil fumes,

steam, or dust.

Otherwise, fire or electric shock may result.

Avoid

Do not install the equipment in locations exposed to direct sunlight or humidity.

Otherwise, the internal temperature of the equipment will rise, which may cause a fire.

Avoid

Use only specified the power cable and the connection cables.

Otherwise, fire or electric shock may result.

Instruction

Do not give strong impact against the equipment.

It may cause the trouble.

Avoid

When performing connection, turn off power.

When connecting the power cable and the connection cable, turn off the equipment

power.

Otherwise, fire or electric shock may result.

Instruction

Do not expose its camera head to any intensive light (such as direct sunlight).

Otherwise, its inner image pickup device might get damaged.

Avoid

Avoid short-circuiting signal output.

Otherwise, a malfunction may occur.

Avoid

Avoid giving a strong shock against the camera body.

It might cause a breakdown or damage. If your camera is used in a system where its

connector is subjected to strong repetitive shocks, its connector is possible to break

down. If you intend to use your camera in such a situation, if possible, bundle and fix a

cable in the place near the camera, and do not transmit a shock to the connector.

Avoid

Contact your sales representative to request periodic inspection and cleaning

(every approx five years).

Accumulation of dust inside the equipment may result in fire or electric shock.

For inspection and cleaning costs, contact your sales representative.

Instruction

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

5 / 179

Page 7

D4267042B

CASES FOR INDEMNITY (LIMITED WARRANTY)

We shall be exempted from taking responsibility and held harmless for damage or losses incurred by the user

in the following cases.

● In the case damage or losses are caused by natural disasters, such as an earthquake and thunder, fire, or

other acts of God, acts by a third party, deliberate or accidental misuse by the user, or use under extreme

operating conditions.

● In the case of indirect, additional, consequential damages (loss of business interests, suspension of

business activities) are incurred as result of malfunction or non-function of the equipment, we shall be

exempted from responsibility for such damages.

● In the case damage or losses are caused by failure to observe the information contained in the

instructions in this instruction manual and specifications.

● In the case damage or losses are caused by use contrary to the instructions in this instruction manual and

specifications.

● In the case damage or losses are caused by malfunction or other problems resulting from unintended use

of equipment or software etc. that are not specified.

● In the case damage or losses are caused by repair or modification conducted by the customer or any

unauthorized third party (such as an unauthorized service representative).

● Expenses we bear on this product shall be limited to the individual price of the product.

● The item that is not described in specifications of this product is out of the guarantee.

● The case of damages or losses which are caused by incorrect connection of the cable is out of the

guarantee.

6 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 8

D4267042B

RESTRICTION FOR USE

● Should the equipment be used in the following conditions or environments, give consideration to safety

measures and inform us of such usage:

1. Use of the equipment in the conditions or environment contrary to those specified, or use outdoors.

2. Use of the equipment in applications expected to cause potential hazard to people or property, which

require special safety measures to be adopted.

● This product can be used under diverse operating conditions. Determination of applicability of equipment or

devices concerned shall be determined after analysis or testing as necessary by the designer of such

equipment or devices, or personnel related to the specifications. Such designer or personnel shall assure

the performance and safety of the equipment or devices.

● This product is not designed or manufactured to be used for control of equipment directly concerned with

human life (*1) or equipment relating to maintenance of public services/functions involving factors of safety

(*2). Therefore, the product shall not be used for such applications.

(*1): Equipment directly concerned with human life refers to.

- Medical equipment such as life-support systems, equipment for operating theaters.

- Exhaust control equipment for exhaust gases such as toxic fumes or smoke.

- Equipment mandatory to be installed by various laws and regulations such as the Fire Act or Building

Standard Law

- Equipment related to the above

(*2): Equipment relating to maintenance of public services/functions involving factors of safety refers to.

- Traffic control systems for air transportation, railways, roads, or marine transportation

- Equipment for nuclear power generation

- Equipment related to the above

7 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 9

D4267042B

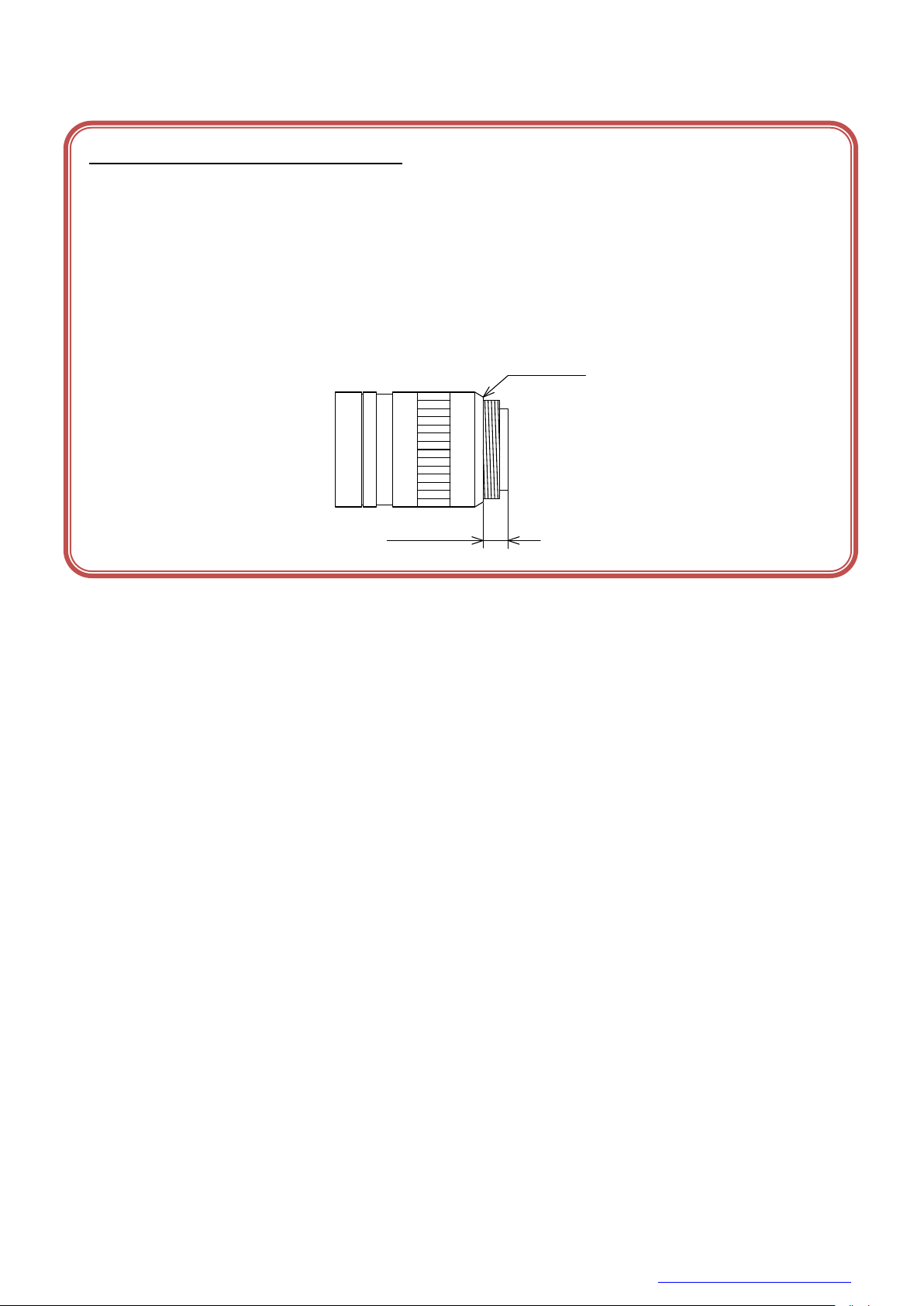

10mm or less

C-mount lens

Bottom of

the screw

8mm or less

Notes on using this product

● Handle carefully

Do not drop the equipment or allow it to be subject to strong impact or vibration, as such action may cause

malfunctions. Further, do not damage the connection cable, since this may cause wire breakage.

● Environmental operating conditions

Do not use the product in locations where the ambient temperature or humidity exceeds the specifications.

Otherwise, image quality may be degraded or internal components may be adversely affected. In particular,

do not use the product in areas exposed to direct sunlight. Moreover, during shooting under high

temperatures, vertical stripes or white spots (noise) may be produced, depending on the subject or camera

conditions (such as increased gain). However, such phenomena are not malfunctions.

● Check a combination with the lens

Depending on the lens and lighting you use, an image is reflected as a ghost in the imaging area. However,

this is not because of a fault of the camera.

In addition, depending on the lens you use, the performance of the camera may not be brought out fully due

to deterioration in resolution and brightness in the peripheral area, aberration and others.

Be sure to check a combination with the camera by using the lens and lightning you actually use.

When installing a lens in the camera, make sure carefully that it is not tilted.

In addition, use a mounting screw free from defects and dirt. Otherwise, the camera may be unable to be

removed.

Install a next lens; its dimension of protrusion from bottom of the screw is equal to or less than 8 mm. If a

lens does not stand to this condition, it might not be installed to this camera.

● Mounting to pedestal

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

When mounting this product to a pedestal, make sure carefully that lens doesn’t touch with the pedestal.

8 / 179

Page 10

D4267042B

● Do not expose the camera's image-pickup-plane to sunlight or other intense light directly

Its inner CMOS sensor might be damaged.

● Occurrence of moiré

If you shoot thin stripe patterns, moiré patterns (interference fringes) may appear. This is not a malfunction.

● Occurrence of noise on the screen

If an intense magnetic or electromagnetic field is generated near the camera or connection cable, noise may

be generated on the screen. If this occurs, move the camera or the cable.

● Handling of the protective cap

If the camera is not in use, attach the lens cap to the camera to protect the image pickup surface.

● If the equipment is not to be used for a long duration

Turn off power to the camera for safety.

● Maintenance

Turn off power to the equipment and wipe it with a dry cloth.

If it becomes severely contaminated, gently wipe the affected areas with a soft cloth dampened with diluted

neutral detergent. Never use alcohol, benzene, thinner, or other chemicals because such chemicals may

damage or discolor the paint and indications.

If the image pickup surface becomes dusty, contaminated, or scratched, consult your sales representative.

9 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 11

D4267042B

Following information is only for EU-member states:

The use of the symbol indicates that this product may not be treated as household waste. By

ensuring this product is disposed of correctly, you will help prevent potential negative

consequences for the environment and human health, which could otherwise be caused by

inappropriate waste handling of this product. For more detailed information about the take-back

and recycling of this product, please contact your supplier where you purchased the product.

“This symbol is applicable for EU member states only”

This equipment has been tested and found to comply with the limits for a class A digital device,

pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communication.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Defective pixels

A CMOS image sensor is composed of photo sensor pixels in a square grid array. Due to

the characteristics of CMOS image sensors, over- or under-driving of the pixels results in

temporary white or black areas (as if these are noises) appearing on the screen. This

phenomenon which is not a defect is exacerbated under higher temperatures and long

exposure time.

Image shading

The brightness of the upper part of the screen may be different from that of the lower part. Note

that this is a characteristic of a CMOS image sensor and is not a fault.

● Disposal

When disposing of the camera, it may be necessary to disassemble it into separate parts, in accordance with

the laws and regulations of your country and/or municipality concerning environmental contamination.

[Phenomena specific to CMOS sensor]

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

10 / 179

Page 12

D4267042B

环保使用期限标识,是根据电子信息产品污染控制管理办法以及,电子

信息产品污染控制标识要求(SJ/T11364-2014)、电子信息产品环保使用

期限通则,制定的适用于中国境内销售的电子信息产品的标识。

电子信息产品只要按照安全及使用说明内容,正常使用情况下,从生产

月期算起,在此期限内,产品中含有的有毒有害物质不致发生外泄或突

变,不致对环境造成严重污染或对其人身、财产造成严重损害。

产品正常使用后,要废弃在环保使用年限内或者刚到年限的产品时,请

根据国家标准采取适当的方法进行处置。

另外,此期限不同于质量/功能的保证期限。

The Mark and Information are applicable for People's Republic of

China only.

部件名称

有毒有害物质或元素

铅(Pb)

汞(Hg)

镉(Cd)

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

相机本体

× ○ ○ ○ ○

○

本表格依据SJ/T 11364的规定编制

○:表示该有毒有害物质在该部件所有均质材料中的含量均在电子信息产品中有毒有害物质的

限量要求标准规定的限量要求(GB/T26572)以下

×:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出电子信息产品中有毒有害

物质的限量要求标准规定的限量要求(GB/T26572)

This information is applicable for People's Republic of China only.

中华人民共和国

环保使用期限

ペーパーボード

纸板

Paper board

箱/箱子/Box

内部緩衝材料・袋

内部缓冲材料·袋

Internal buffer materials・Bag

10

<产品中有毒有害物质或元素的名称及含量>

リサイクルに関する情報(包装物)

有关再利用的信息(包装物)

Information on recycling of wrapping composition

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

11 / 179

Page 13

D4267042B

Installation

Before using this product, you shall install application software to display image and control registers of

camera, and IP configuration tool for network setting.

You can download the SDK for our USB camera products (TeliCamSDK) from the Service & Support section

of our website.

User registration is necessary to use downloading service. Please make a user registration, or contact your

sales representative.

● TOSHIBA TELI CORPORATION Top Page

http://www.toshiba-teli.co.jp/en/

● Service & Support

https://www.toshiba-teli.co.jp/cgi/ss/en/service.cgi

Please refer to the TeliCamSDK startup guide, about Operation environment, Installation, and Setup.

12 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 14

D4267042B

Specifications

Overview

DU1207M series is an integrated-(one-body)-type camera that adopts a global shutter CMOS sensor. These

are DU1207MG (12M type1.1). Suffix [C] are attached to the color models. For video output and camera

control, the USB 3.0 interface standard is adopted for high transfer rate, and it is easy to integrate into

industrial equipment.

Features

● High frame rate

Supporting high frame rate, DU1207MG 32fps (Mono8), DU1207MCG/MCF 31fps (Bayer8).

● Global shutter

As it employs a global electronic shutter similar to a CCD image sensor, clear images of even fast-moving

object are obtainable with less blur.

● USB*3.0 interface

Video output and camera control are performed via the USB 3.0 standard interface. Data transfer is up to

5Gbps (Maximum) that enables to output uncompressed video data at high frame rate.

● USB3 Vision*

This product is based on USB3 Vision Ver.1.0.

● GenICam* Ver 2.3

This product is based on GenICam Generic Interface for Cameras Ver 2.3.

● IIDC2* Digital Camera Control Specification Ver.1.1.0

This product is based on IIDC2 Digital Camera Control Specification Ver.1.1.0.

13 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 15

D4267042B

● e-CON* Connector adoption

The e-CON connector adoption enables to assemble the cable easily without using special tools.

● Random Trigger Shutter

The Random Trigger Shutter function provides images in any timing by input of an external trigger signal.

Trigger control from PC is available as well.

● Scalable

Selectable video output area. This mode achieves higher frame rate by reducing vertical output area. And

reduces occupied data rate of USB bus by reducing horizontal output area.

● Binning

Pixel data is combined by vertical and horizontal. It achieves high frame rate.

● Decimation

Camera reads all effective areas at high speed by skipping lines.

● Color processing

Color models have built in color processing.

There are RGB, BGR, YUV 4:2:2, YUV 4:1:1, Bayer and Mono output modes. In addition, it produced an

image with restrained false color by adaptive filter interpolating 7 x 7 pixels.

●Dust-proof Glass

Dust-proof Glass is built in default.

Suffix [G] is attached to the model name of built-in Glass.

● IR-cut filter

Build-in IR-cut filter models are optional for color models.

Suffix [F] is attached to the model name of built-in IR-cut filter model.

● EU RoHS & Chinese ROHS

* USB is a unified standard established by USB-IF(USB Implementers Forum).

* USB3 Vision is a unified standard established by AIA (Automated Imaging Association).

* GeniCam is a registered trademark of EMVA (European Machine Vision Association).

* IIDC2 is a unified standard established by JIIA (Japan Industrial Association).

* e-CON (Easy & Economy connector) is a sensor connector that is normalized by the manufacturer of the

sensor, FA equipment and connector.

14 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 16

D4267042B

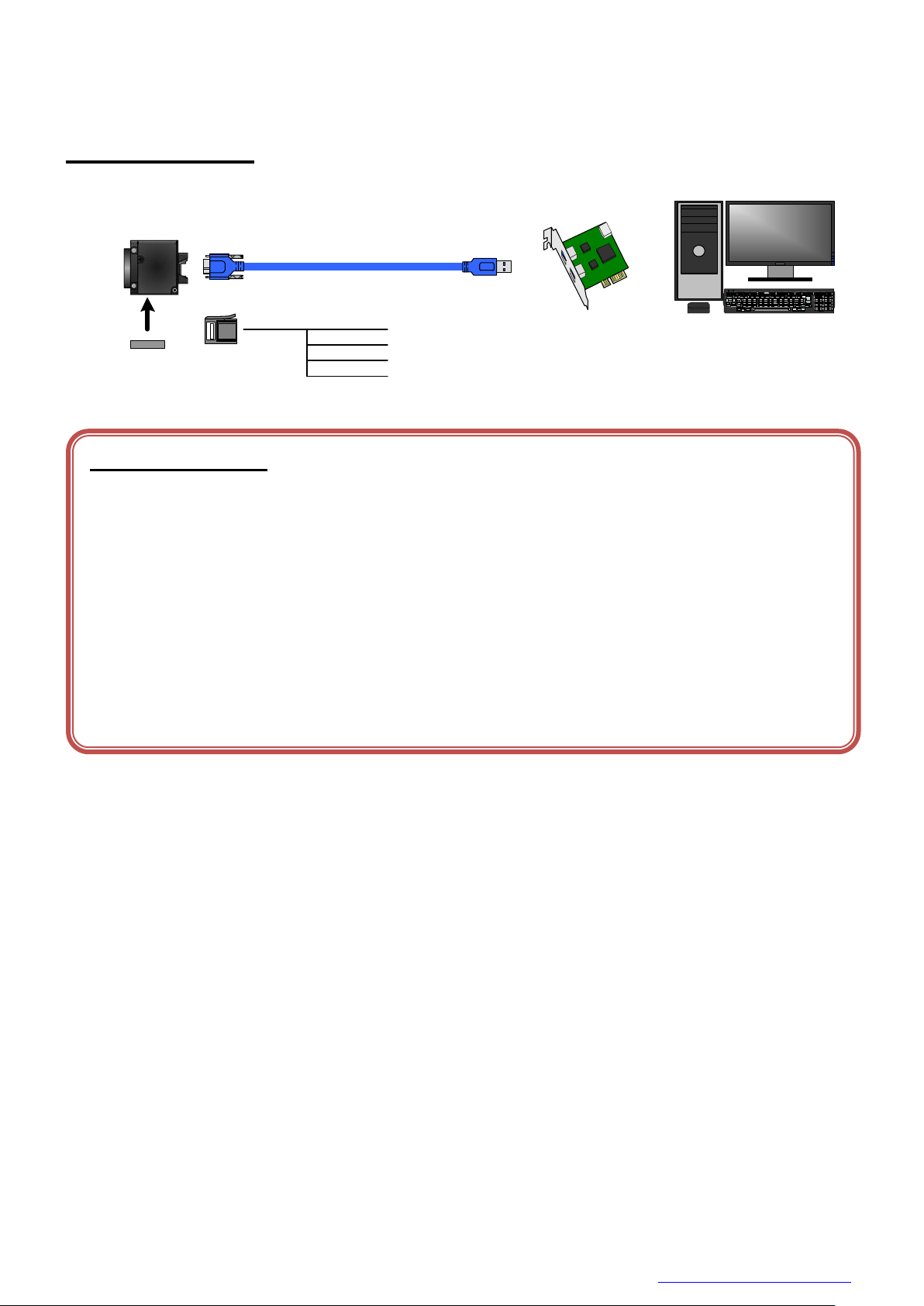

Configuration

The system configuration of this camera series is as follows;

This camera has no accessories, please prepare other equipment separately.

● Camera: This product.

● Camera mounting kit CPTC6M (*1): To fix a camera to a tripod; attach this to the bottom of the camera.

● USB3.0 Cable (*2): This cable is used to connect the camera to host PC. Please use

a USB3.0 cable of Standard A - Micro B. This product is able to

connect a USB cable equipped with screw lock mechanism.

Please use it as needed.

● USB3.0 Interface Card (*2): This is the interface card to connect to the camera. Usually this

card is installed to expansion slot of PC etc.

● e-CON Cable. (*2): This cable is used to input external trigger signal and output GPIO

signal.

We recommend using shielded cable, because there is likely to be

affected by the noise depending on the operating environment of

the camera.

*1: Optional part. Contact your sales representative for details of option units.

*2: Commercial items.

15 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 17

D4267042B

Camera

Host(PC etc.)

Camera mounting unit

CPTBU

Interface Card

Stream Packet →← Control Packet

USB3.0 Cable

(Mirco B) (Standard A)

1. Line2

2. Line1

3. GND

4. Line0

(e-CON)

e-CON Cable

Notes on Connection:

- Please confirm the power supply of the camera off when plugging in or pulling out the I/O Connector. It causes the

breakdown.

- If your camera is used in a system where its connectors are subjected to strong repetitive shocks, its connectors are

possible to break down. If you use your camera in such a situation, use an USB3.0 cable with a lock screw, and secure

the camera cable as close as possible to the camera body for avoid physical shock to the camera connector.

- About e-CON cable: In the case that electric-wire is long or thin, input and output voltage may not satisfy specifications

of the camera or your system by voltage drop. Please confirm wires’ specifications before use them.

- Los t packets may occur by an electrical characteristic of the transmission line of USB3.0. (USB3.0 Interface Card,

USB3.0 Cable, and USB3.0 HUB).

CPTC6M

Connection

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

16 / 179

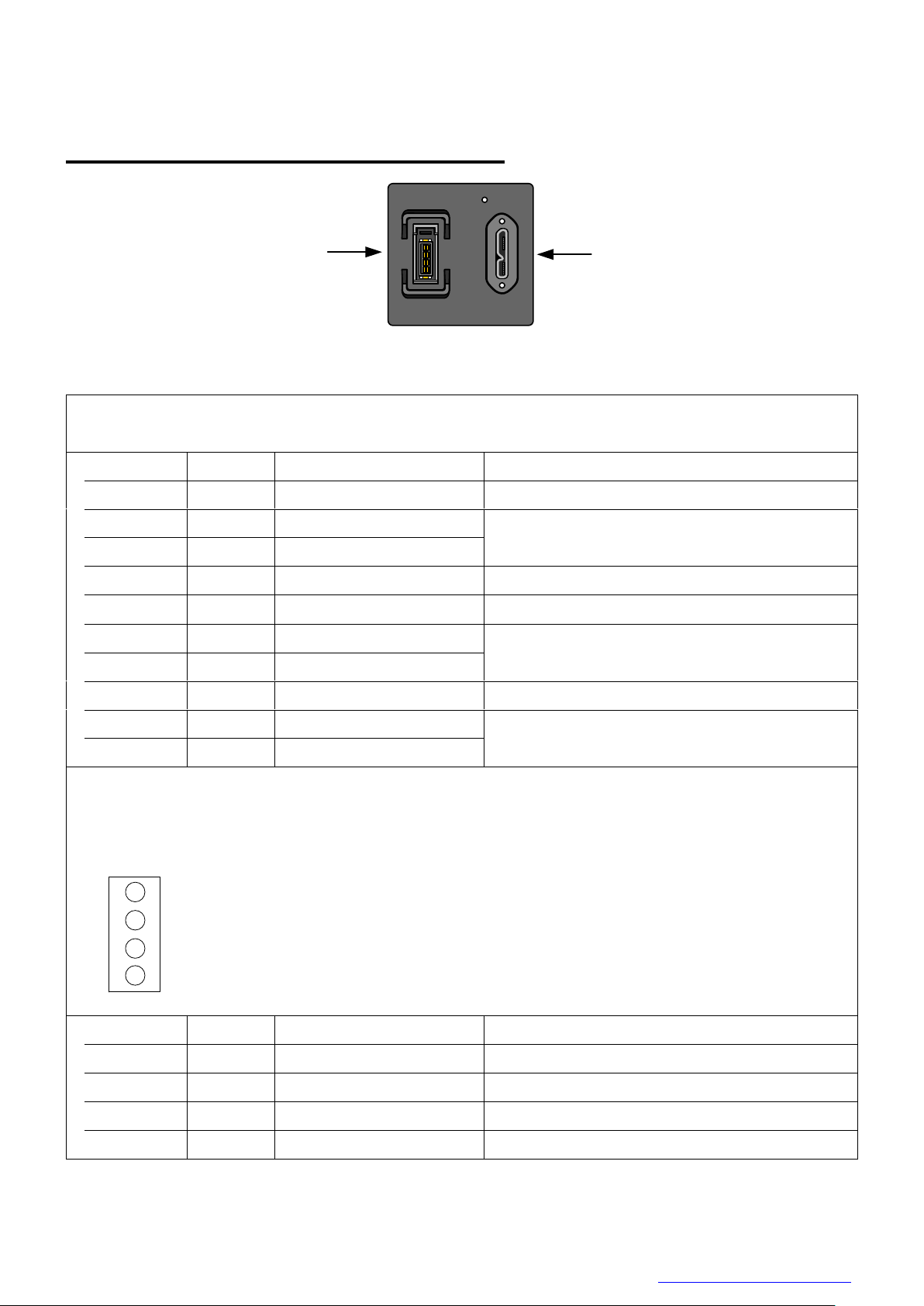

Page 18

D4267042B

①

②

1. USB3.0 Interface Connector

Connector model: WMUR-10F6L1PH5N (WIN WIN PRECISION INDUSTRIAL)

Pin No.

I/O

Signal

Function

1 -

VBUS

Power

2 I/O

D-

USB2.0 differential pair

3 I/O

D+

4 -

NC

Not connected

5 -

GND

Ground for power return

6 O

SSTX-

SuperSpeed transmitter differential pair

7 O

SSTX+

8 -

GND_DRAIN

Ground for SuperSpeed signal return

9 I

SSRX-

SuperSpeed receiver differential pair

10 I SSRX+

2. I/O Connector

Connector (Camera side) 37204-62B3-004PL (Sumitomo 3M) or equivalent

Matching connector (Cable side) Connectors which conformed to e-CON

e.g. 37104 series (Sumitomo 3M), RITS 4P series (Tyco)

* Matching connector is not an accessory of this product.

Pin assignment

↑TOP

*Above figure is connector view from insert side.

Pin No.

I/O

Signal

Function

1 I/O

Line2

GPIO Input / Output

2 O

Line1

GPIO Output

3 -

GND

Ground

4 I

Line0

GPIO Input

1

2

3

4

Connector Pin Assignment

Rear View

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

17 / 179

Page 19

D4267042B

Outline Drawing

18 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 20

D4267042B

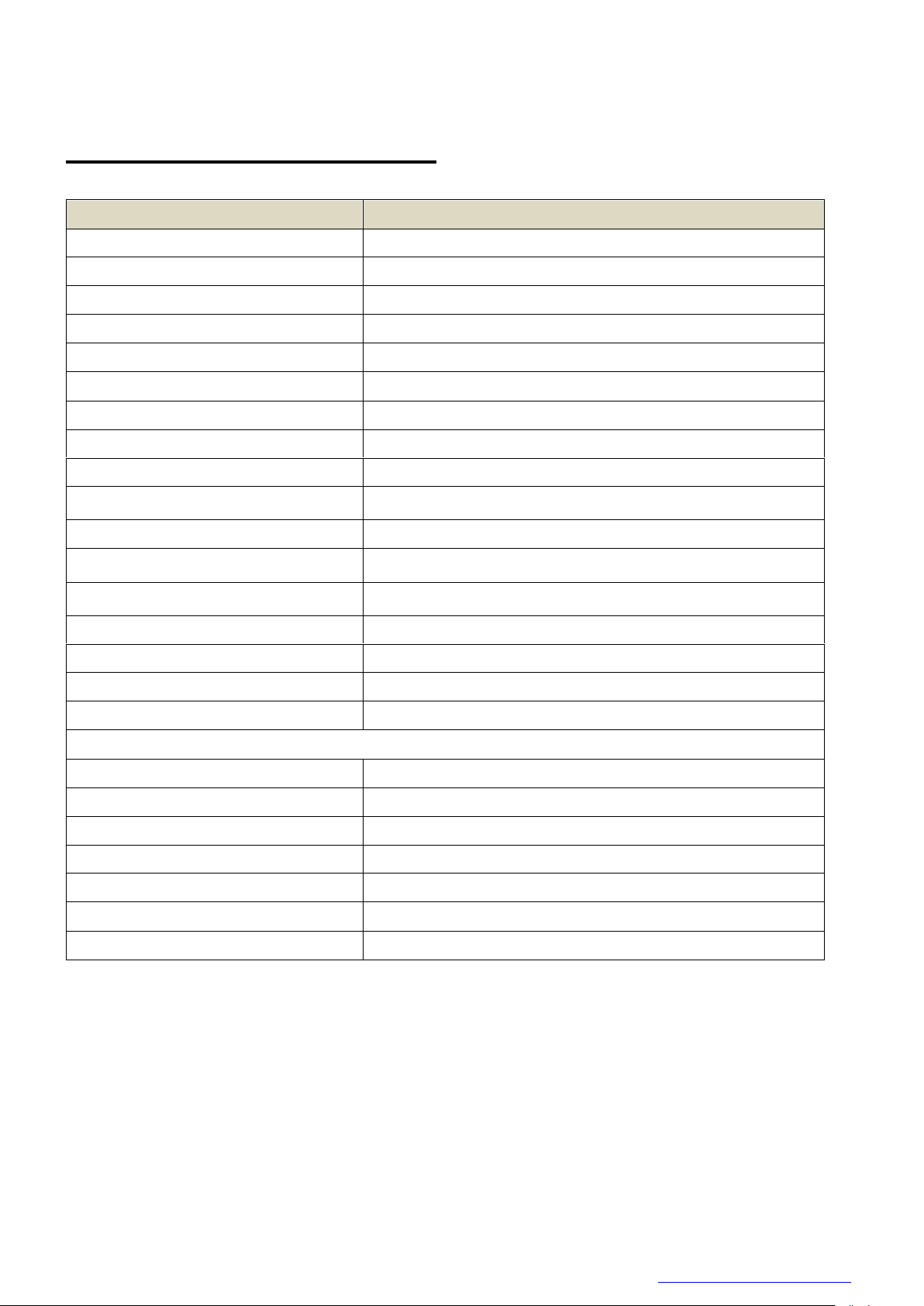

Model Name

DU1207MG

Optical part

Optical glass

Imager

CMOS image sensor

Number of Video out pixels (H) × (V)

4096 x 3000

Optical Size

type1.1

Scanning area (H) × (V)[mm]

14.19 x 10.34

Pixel size (H) × (V)[μm]

3.45 ×3.45

Scan method

Progressive

Electronic shutter method

Global shutter

Aspect ratio

4 : 3

Sensitivity

860lx, F5.6, 1/32s

Minimum illuminance

2lx (F1.4, Gain +24dB, Video Level 50%)

Power supply

DC +5V5% (from USB connector)

Power consumption (*1)

4.0W (maximum)

Interface

USB 3.0 (Only SuperSpeed is supported)

Transmission speed

5Gbps (maximum)

Protocol

USB3 Vision

Image format

Mono8, Mono10, Mono12

Maximum Frame rate (*2)

Mono8

32 fps

Mono10, Mono12

16 fps

Dimensions

40 mm(W) x 40 mm (H) x 35 mm (D) (Not including protrusion)

Mass

90g

Lens mount

C-mount

Flange back

17.526mm

Camera body grounding: insulation status

Conductive between circuit GND and camera body

General Specifications

● B/W model

*1, *2 at the all pixel readout

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

19 / 179

Page 21

D4267042B

Model Name

DU1207MCG

DU1207MCF

Optical Part

Optical glass

IR cut filter

Imager

CMOS image sensor

Number of Video out pixels (H) × (V)

4096 x 3000

Optical Size

Type 1.1

Scanning area (H) × (V)[mm]

14.19 x 10.34

Pixel size (H) × (V)[μm]

3.45 ×3.45

Scan method

Progressive

Electronic shutter method

Global shutter

Aspect ratio

4 : 3

Sensitivity

1150lx, F5.6, 1/31s

1425lx, F5.6, 1/31s

Minimum illuminance

3lx (F1.4, Gain +24dB, Video Level 50%)

Power supply

DC +5V5% (from USB connector)

Power consumption (*1)

4.5W (maximum)

Interface

USB 3.0 (Only SuperSpeed is supported)

Transmission speed

5Gbps (maximum)

Protocol

USB3 Vision

Image format

RGB, BGR, YUV422, YUV411, Bayer8, Bayer10, Bayer12, Mono8

Maximum Frame rate (*2)

Bayer8, Mono8

31 fps

YUV411

21 fps

YUV422

16 fps

Bayer10, Bayer12

16 fps

RGB, BGR

10 fps

Dimensions

40 mm(W) x 40 mm (H) x 35 mm (D) (Not including protrusion)

Mass

90g

Lens mount

C-mount

Flange back

17.526mm

Camera body grounding: insulation status

Conductive between circuit GND and camera body

● Color model

*1, *2 at the all pixel readout

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

20 / 179

Page 22

D4267042B

Notes on combination of C-mount lens:

- Depending on the lens you use, the performance of the camera may not be brought out fully due to the deterioration in

resolution and brightness in the peripheral area, occurrence of a ghost, aberration and others. When you check the

combination between the lens and camera, be sure to use the lens you actually use.

- In addition, use a mounting screw free from defects and dirt. Otherwise, the camera may be unable to be removed.

- As for the C-mount lens used combining this camera, the projection distance from bottom of the screw should use

8mm or less.

10mm or less

C-mount lens

Bottom of

the screw

8mm or less

21 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 23

D4267042B

Camera state

Lamp indication

No power

Off

Link detection in progress

Fast flash green (ON:20ms, OFF:60ms)

Connection Error

Flash alternate red / green

SuperSpeed connected, but no data being transferred

Flash green (ON: 200ms, OFF: 800ms)

SuperSpeed connected, waiting for trigger

Flash orange (ON: 200ms, OFF: 800ms)

Data being transferred

Fast flash green (ON:60ms, OFF:20ms)

Error during data transfer

Solid Red (Time period: 500ms)

Stand-by

Super slow flash orange (ON:200ms, OFF: 2800ms)

LED Status

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

22 / 179

Page 24

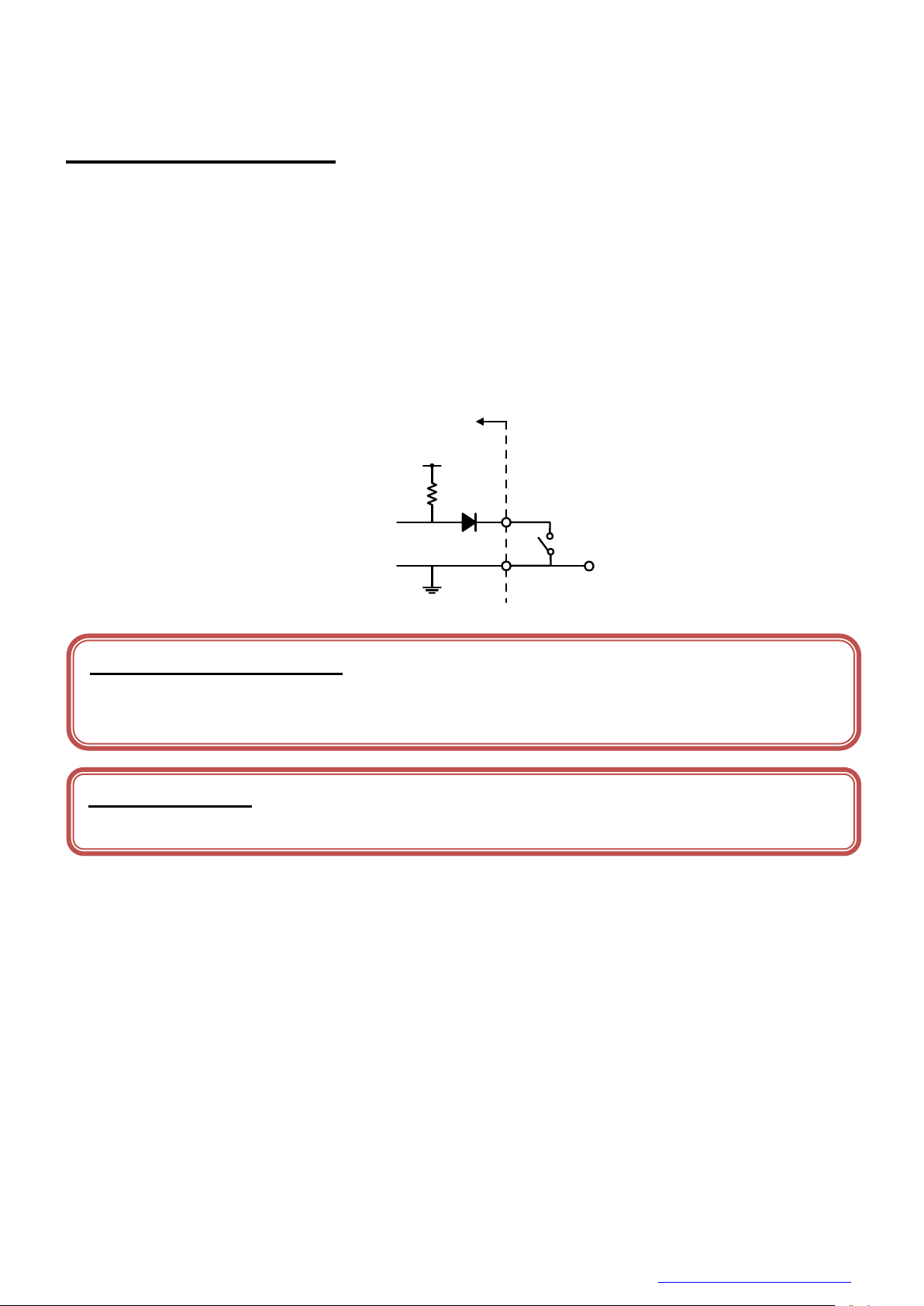

D4267042B

Inside

DC3.3V

0V

10kΩ

Notes of external trigger signal:

Depending on cable length, cable kinds and input current of trigger input line, Random Trigger Shutter operation may not

satisfy timing specification or camera may not receive EXT_TRIG signal. Please confirm it before use.

Notes of input level:

Line0 and Line2 have different input level. Please use input level within the voltage described in this specification.

I/O Specification

● Signal Specification

- Line0 (GPIO Input, I/O connector : 4 pin)

Input Circuit : LVTTL

Level : Low 0 ~ 0.5V, High 2.0 ~ 24.0V

Polarity : High active / Low active (initial factory setting: Low active)

Pulse Width : Minimum 50μs

Input circuit diagram

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

23 / 179

Page 25

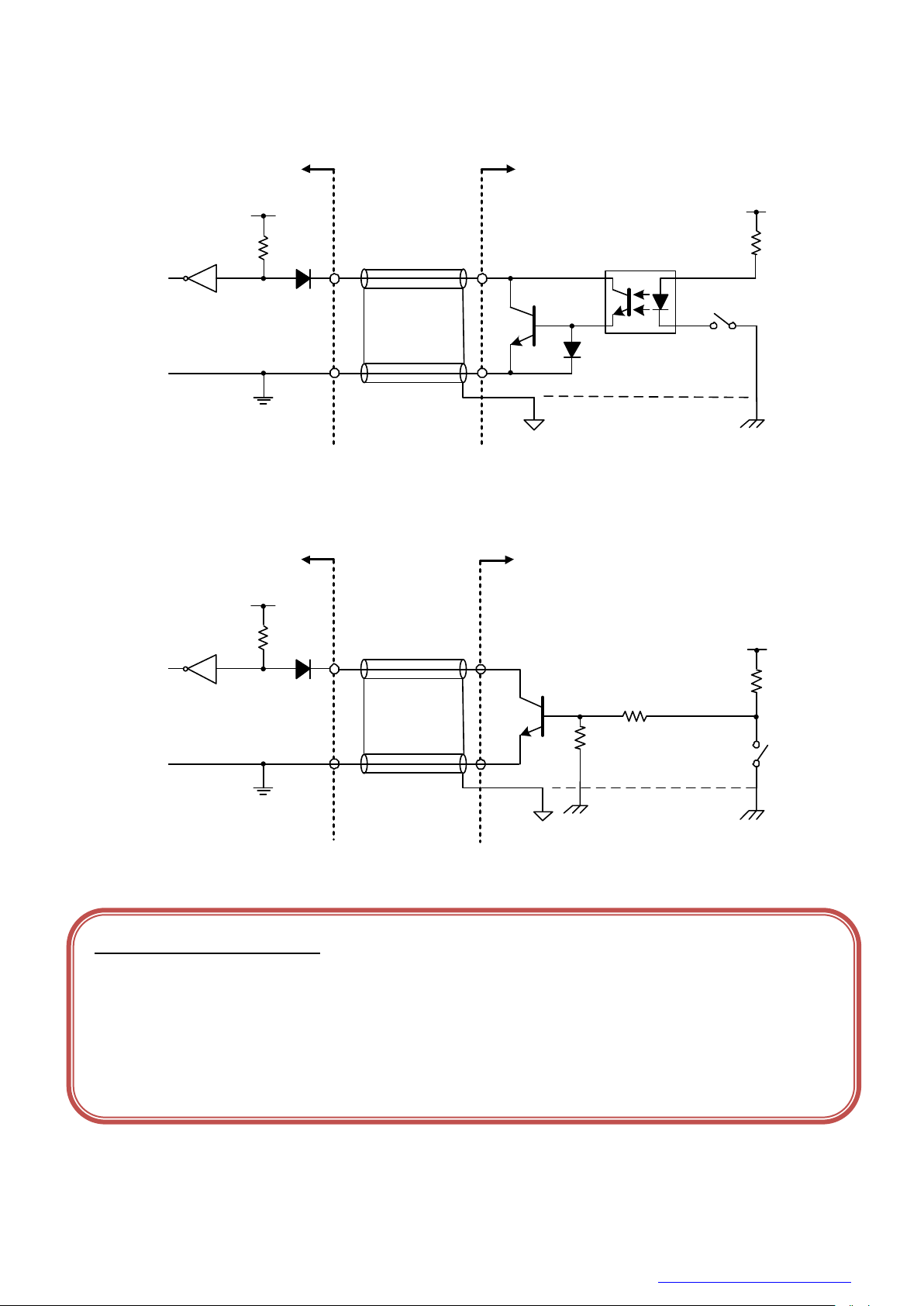

D4267042B

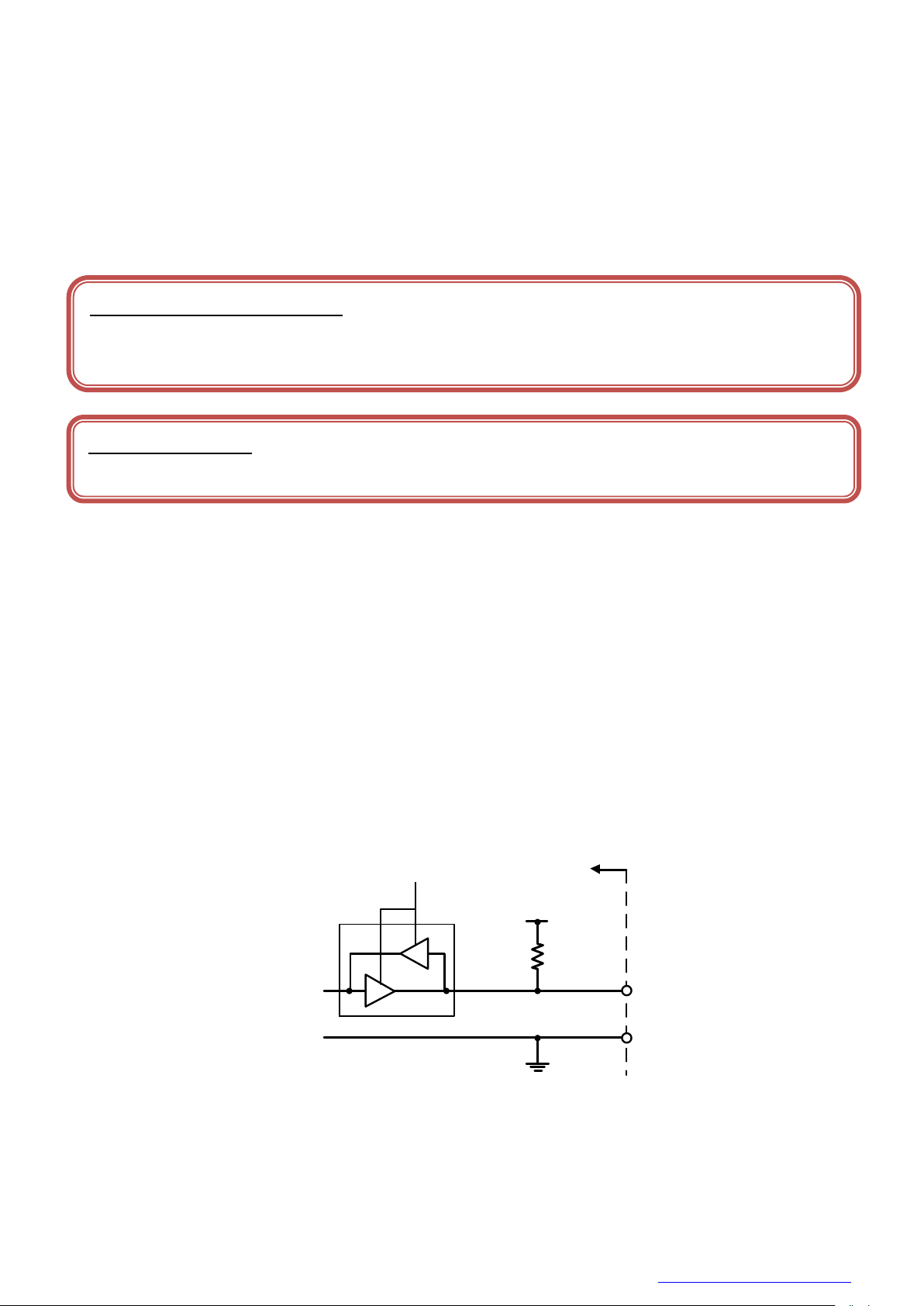

● External trigger input recommended circuit

CAMERA Inside

DC3.3V

10kΩ

4

3

Photocoupler

Camera

GND

Your

GND

Your system

Your

Secondary GND

Your

GND

Your system

Your

FRAME GND

DC3.3V

10kΩ

4

3

Camera

GND

CAMERA Inside

Notes of trigger input cable:

- The recognition of the trigger signal depends on the length, characteristic or driving current of the cable. Therefore

please confirm your system about those conditions.

- Pin 3 is conducted with camera frame.

Using shield cable, terminal processing of the shield is referred as above.

- Please confirm the EMC adaptability in whole of your system.

- Isolated I/F

- Non-Isolated I/F

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

24 / 179

Page 26

D4267042B

- Line2 (GPIO Input / Output, initial factory setting: Input, I/O connector : 1 pin)

Inside

DC5.0V

10kΩ

1

3

IOLineModeAll

Notes of external trigger signal:

Depending on cable length, cable kinds and input current of trigger input line, Random Trigger Shutter operation may not

satisfy timing specification or camera may not receive EXT_TRIG signal. Please confirm it before use.

Notes of input level:

Line0 and Line2 have different input level. Please use input level within the voltage described in this specification.

- Input signal specification

Level : Low 0 ~ 0.5V, High 4.0 ~ 5.0V

Polarity : High active / Low active (initial factory setting: Low active)

Pulse Width : Minimum 50μs

- Output signal specification

Output Circuit : 5V CMOS

Maximum Current : +/-32mA

Polarity : High active / Low active (initial factory setting: Low active)

Signal Source : TIMER0 ACTIVE

USER OUTPUT

EXPOSURE ACTIVE

FRAME ACTIVE

FRAME TRANSFER

FRAME TRIGGER WAIT

Input / Output circuit diagram

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

25 / 179

Page 27

D4267042B

- Line1 (GPIO Output, I/O connector : 2 pin)

Output Circuit : 5V CMOS

Maximum Current : +/-32mA

Polarity : High active / Low active (initial factory setting: Low active)

Signal Source : TIMER0 ACTIVE

USER OUTPUT

EXPOSURE ACTIVE

FRAME ACTIVE

FRAME TRANSFER

FRAME TRIGGER WAIT

26 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

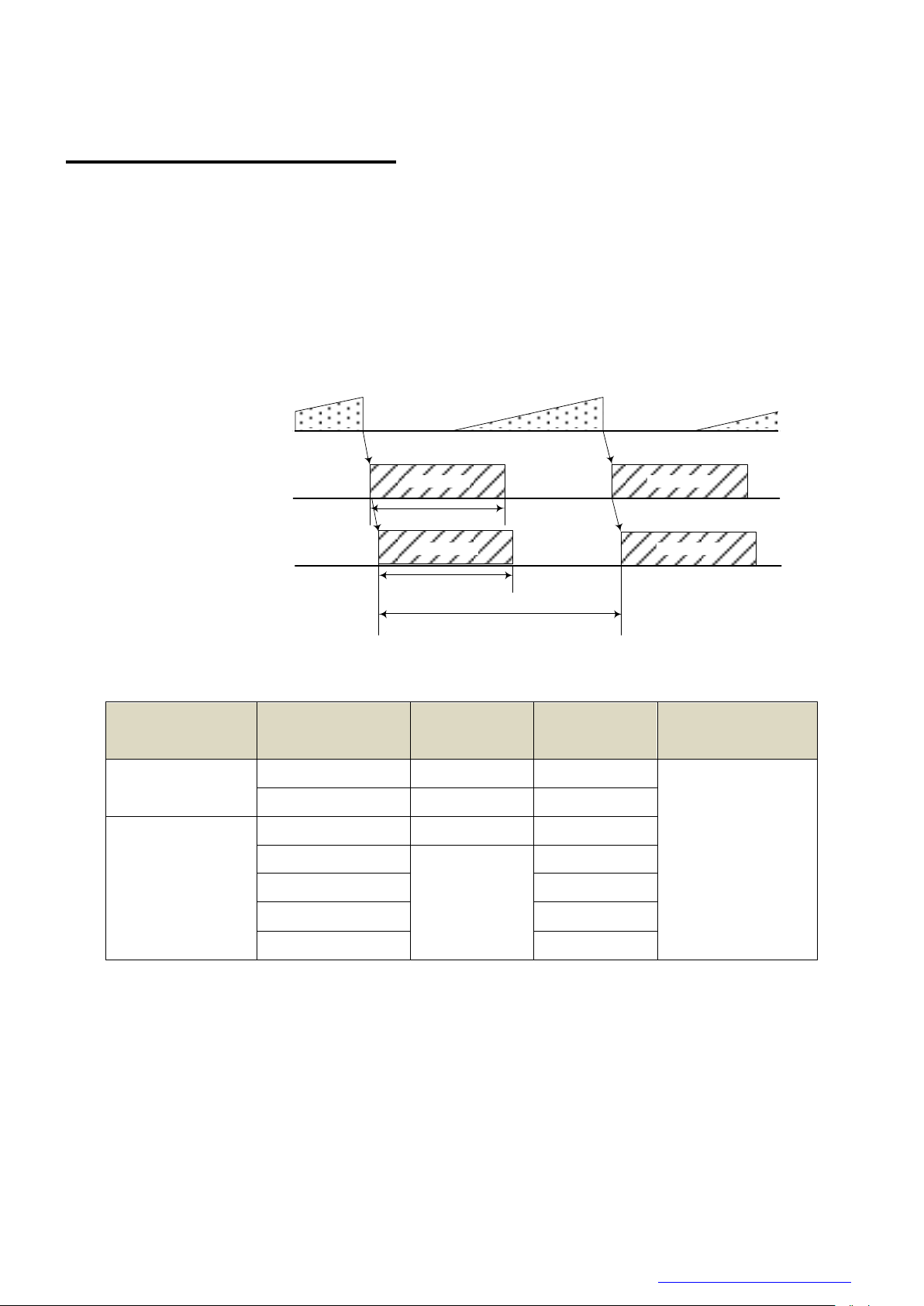

Page 28

D4267042B

T1

Sensor Output

Exposure

Image Image

T3

T2

Image Image

USB Streaming

Model Name

format

T1

[ms]

T2

[ms]

T3

[s]

DU1207MG

Mono8

15.8

30.85

1/(Frame Rate setting)

Mono10, Mono12

22.0

61.83

DU1207MCG/CF

Bayer8, Mono8

15.8

30.85

YUV 4:1:1

22.0

46.28

YUV 4:2:2

61.83

Bayer10, Bayer12

61.83

RGB, BGR

92.57

Timing Specification

Image data outputs are transferred with USB bulk transfer. Timing numerical value below is described by

absolute prerequisite that camera can use transmission band without restriction of other device. When there

is other device on the same bus, the value described below is not guaranteed.

● In Manual Shutter mode

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

27 / 179

Page 29

D4267042B

Image

USB Streaming

Exposure

TRIG_IN

T4

T2

Image

USB Streaming

Exposure

TRIG_IN

T4

T2

T5

Model Name

format

T4

[μs]

T5

[μs]

DU1207MG

Mono8

16.1

30.4

Mono10, Mono12

22.3

36.6

DU1207MCG/CF

Bayer8, Mono8

16.1

30.4

YUV 4:1:1

22.3

36.6

YUV 4:2:2

Bayer10, Bayer12

RGB, BGR

Notes of random trigger shutter mode:

- In the period when FRAME_TRIGGER_WAIT (GPIO signal) is inactive, user must not input external trigger signal to

this camera.

- When the interval of the input trigger signal is extremely short, or when the trigger signal is noisy, there is a possibility

of causing the malfunction. In this case, please input a proper trigger signal.

● In Random Trigger Shutter mode

Edge mode / Bulk mode (at all pixels readout)

Level mode (at all pixels readout)

* The value of T2 is the same as the value of normal shutter mode.

* T4 and T5 are typical value.

* In case that the Trigger mode is Level mode, exposure time is 14.26μs longer than trigger signal width due

to the CMOS sensor specifications.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

28 / 179

Page 30

D4267042B

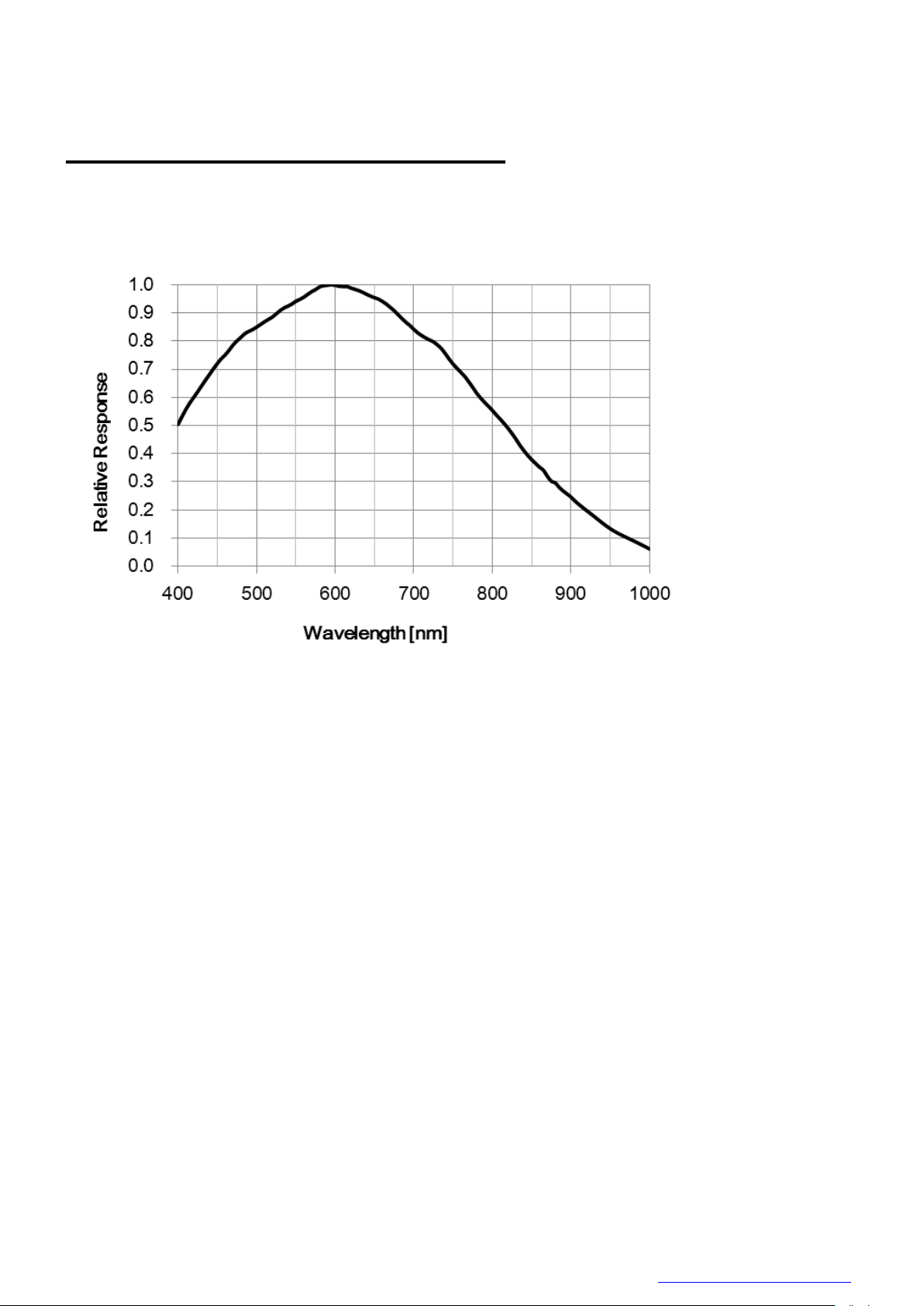

Typical Spectral Response

* The lens characteristics and light source characteristics is not reflected in table.

● DU1207MG

29 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 31

D4267042B

●DU1207MCG

R

G

B

R

G

B

●DU1207MCF

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

30 / 179

Page 32

D4267042B

Notes on Heat Radiation:

The temperature of camera housing must be kept less than 65 °C.

Please provide sufficient heat radiation depending on your installation.

Operating Ambient Conditions

● Ambient conditions

- Performance Assurance

Temperature: 0°C ~ 40°C, Camera housing temperature: less than 55 °C

Humidity: 10% ~ 90% (no condensation)

- Operating Assurance

Temperature: -5°C to +45°C, Camera housing temperature: less than 65 °C

Humidity: 10% to 90% (no condensation)

- Storage Assurance

Temperature: -20°C to +60°C

Humidity: 90% or less (no condensation)

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

31 / 179

Page 33

D4267042B

Notes on Conformity of the EMC:

The adaptability of the safety standard of this camera is assured in the condition of combination with the following parts:

- USB Cable USB3-KR1-A-MBS-030 (OKI Electric Cable Co., Ltd.)

- e-CON Cable 3.0m, Shield cable (Fabricated parts)

Parts:

- e-CON connector XN2A-1470 (OMRON Corporation)

- Shielded wire UL1533 (AWG28) (Hitachi cable, Ltd.)

Connection:

e-CON

1

2

3

4

BNC

GPIO(Line2)

GPIO(Line1)

GND

TRIG IN(Line0)

GPIO(Line2)

GPIO(Line1)

TRIG IN(Line0)

BNC

Please confirm the EMC adaptability when it combines with parts other than them.

● EMC Conditions

- EMI (Electro-Magnetic Interference): EN61000-6-3

FCC Part 15 Subpart B Class A

- EMS (Electro-Magnetic Susceptibility): EN61000-6-2

32 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 34

D4267042B

Category

Function

USB3 Vision

Bootstrap Registers

USB3 Vision standard registers

DeviceControl

DeviceControl

Device information

ImageFormatControl

ImageFormatSelector

Image format selection

Scalable

Scalable control

Binning

Binning control

Decimation

Decimation control

Reverse

Image flip

PixelFormat

Pixel format selection

BayerProcessingMode

BayerProcessingMode control

TestPattern

Test pattern control

AcquisitionControl

AcquisitionControl

Image stream start / stop

ImageBuffer

Image buffer control

TriggerControl

Trigger control

ExposureControl

Exposure time control

DigitalIOControl

DigitalIOControl

GPIO signal control

CounterAndTimerControl

TimerControl

Timer0Active signal control

AnalogControl

Gain

Gain control

BlackLevel

Black level control

Gamma

Gamma correction

Hue

Hue control

Saturation

Saturation control

BalanceRatio

Color gain (R, B)

BalanceWhiteAuto

Execute auto white balance once

ColorCorrectionMatrix

Color matrix correction

ALCControl

ALCControl

ALC control

LUTControl

LUTControl

LUT control

UserSetControl

UserSetControl

Load / Save user setting

EventControl

EventControl

Event packet control

VenderUniqueControl

FrameSynchronization

Frame synchronization control

LEDIndicatorLuminance

LED luminance control

AntiGlitch

AntiGlitch control

AntiChattering

AntiChattering control

DPCControl

DPCControl

Defect pixel correction control

SequentialShutterControl

SequentialShutterControl

Sequential shutter control

ChunkDataControl

Chunk

ChunkDataControl

Functions

This section introduces standard functions. DU1207M series provides following functions.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

33 / 179

Page 35

D4267042B

Features supported by each model are as follows.

Function

DU1207MG

DU1207MCG

DU1207MCF

Bootstrap Registers

○ ○ ○

DeviceControl

○ ○ ○

ImageFormatSelector

○ ○ ○

Scalable

○ ○ ○

Binning

○ ○ ○

Decimation

○ ○ ○

Reverse

○ ○ ○

PixelFormat

○ ○ ○

TestPattern

○ ○ ○

BayerProcessingMode

- ○ ○

AcquisitionControl

○ ○ ○

ImageBuffer

○ ○ ○

TriggerControl

○ ○ ○

ExposureControl

○ ○ ○

DigitalIOControl

○ ○ ○

TimerControl

○ ○ ○

Gain

○ ○ ○

BlackLevel

○ ○ ○

Gamma

○ ○ ○

Hue

- ○ ○

Saturation

- ○ ○

BalanceRatio

- ○ ○

BalanceWhiteAuto

- ○ ○

ColorCorrectionMatrix

- ○ ○

ALCControl

○ ○ ○

LUTControl

○ ○ ○

UserSetControl

○ ○ ○

EventControl

○ ○ ○

FrameSynchronization

○ ○ ○

LEDIndicatorLuminance

○ ○ ○

AntiGlitch

○ ○ ○

AntiChattering

○ ○ ○

DPCControl

○ ○ ○

SequentialShutterControl

○ ○ ○

Chunk

○ ○ ○

Details of each feature are described in following pages.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

34 / 179

Page 36

D4267042B

USB3 Vision ABRM

Register

Address

GenICam

Interface

Length

Byte / [bit]

Access

Description

ManufactureName

0x00004

String

64

R

Manufacturer name

ModelName

0x00044

String

64

R

Device model name

FamilyName

0x00084

String

64

R

Device family name

DeviceVersion

0x000C4

String

64

R

Device version

ManufacturerInfo

0x00104

String

64

R

Additional manufacturer specific information

SerialNumber

0x00144

String

64

R

Serial number of the device

UserDefinedName

0x00184

String

64

R/W

User defined name of the device.

SBRM Address

0x001D8

Integer 8 R

Start Address of the SBRM

Bootstrap Registers

This camera is based on USB3 Vision.

Please refer to USB3 Vision specification for details about Bootstrap Registers defined in USB3 Vision.

AIA (Automated Imaging Association) USB3 Vision Homepage.

http://www.visiononline.org/vision-standards-details.cfm?type=11

Followings are commonly used registers.

- UserDefinedName

UserDefinedName is used for assigning unique ID to the camera.

You can store an arbitrary string into non-volatile memory.

- StreamEnable

When StreamEnable bit is set. Camera starts to send image streaming.

TeliU3vSDK / TeliCamSDK require some setups on your application in opening and closing the stream

channel. Please refer to the library manual for details.

- EventEnable

When EventEnable bit is set. Camera is enabled to send event packets.

TeliU3vSDK / TeliCamSDK require some setups on your application in opening and closing the event

channel. Please refer to the library manual for details.

● Registers

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

35 / 179

Page 37

D4267042B

USB3 Vision SBRM

Register

Address

GenICam

Interface

Length

Byte / [bit]

Access

Description

SIRMAddress

0x10020

Integer 8 R

Start Address of the SIRM

EIRMAddress

0x1002C

Integer 8 R

Start Address of the EIRM

IIDC2Address

0x10038

Integer 8 R

Start Address of the IIDC2

CurrentSpeed

0x10040

Integer

[3..0]

R

[0]: Low-Speed connection (not supported)

[1]: Full-Speed connection (not supported)

[2]: High-Speed connection

[3]: Super-Speed connection

USB3 Vision SIRM

Register

Address

GenICam

Interface

Length

Byte / [bit]

Access

Description

StreamEnable

0x20004

Integer

[0]

R/W

0: Disable data transfer of the streaming

1: Enable data transfer of the streaming

SIRequiredPayloadSize

0x20008

Integer 8 R

Minimum required payload size with current settings

SIRequiredLeaderSize

0x20010

Integer 4 R

Minimum required leader size

SIRequiredTrailerSize

0x20014

Integer 4 R

Minimum required trailer size

SIMaximumLeaderSize

0x20018

Integer 4 R

Maximum leader size

SIPayloadTransferSize

0x2001C

Integer 4 R

Expected Size of a single Payload Transfer

SIPayloadTransferCount

0x20020

Integer 4 R

Expected Number of Payload Transfers

SIPayloadFinalTransfer1Size

0x20024

Integer 4 R

Size of first final Payload transfer

SIPayloadFinalTransfer2Size

0x20028

Integer 4 R

Size of second final Payload transfer

SIMaximumTrailerSize

0x2002C

Integer 4 R

Maximum trailer size

USB3 Vision EIRM

Register

Address

GenICam

Interface

Length

Byte / [bit]

Access

Description

EventEnable

0x30000

Integer

[0]

R/W

0: Disable data transfer of the event

1: Enable data transfer of the event

● Note

DU series doesn’t support image transfer in High-Speed connection.

CurrentSpeed register could be used for showing the warning message on your application when

camera is connected to USB2.0 port.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

36 / 179

Page 38

D4267042B

Register

Address

GenICam

Interface

Length

Byte / [bit]

Access

Description

DeviceReset

0x20003C

Command

[0]

W

[1] Resets the device.

DeviceVendorName

0x200070

String

16

R

Same as ManufactureName in Bootstrap Registers

DeviceModelName

0x200090

String

16

R

Same as ModelName in Bootstrap Registers

DeviceManufactureInfo

0x2000B0

String

16

R

Same as ManufacturerInfo in Bootstrap Registers

DeviceVersion

0x2000D0

String

16

R

Same as DeviceVersion in Bootstrap Registers

DeviceID

0x200110

String

16

R

Same as SerialNumber in Bootstrap Registers

DeviceControl

Registers of this category provide various information of the camera.

● Registers

● Note

- DeviceReset

Camera executes the USB Bus reset operation by DeviceReset command.

- Plug-and-play happens, camera handles used in the application become invalid.

- The application is required to close and re-open the camera.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

37 / 179

Page 39

D4267042B

Format2

Format1

Format0

ImageSize

Width

Height

OffsetX

OffsetY

BinningHorizontal

BinningVertical

DecimationHorizontal

DecimationVertical

ReverseX

ReverseY

PixelFormat

PixelEndian

ImageSize

Width

Height

OffsetX

OffsetY

BinningHorizontal

BinningVertical

DecimationHorizontal

DecimationVertical

ReverseX

ReverseY

PixelFormat

PixelEndian

ImageSize

Width

Height

OffsetX

OffsetY

BinningHorizontal

BinningVertical

DecimationHorizontal

DecimationVertical

ReverseX

ReverseY

PixelFormat

PixelEndian

ImageFormatControl

Registers of this category are related to image format control.

Camera has three different banks of image format. You can select image format by ImageFormatSelector.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

38 / 179

Page 40

D4267042B

● GenICam Node

Name

Interface

Length

Byte / [bit]

Access

Description

ImageFormatSelector

IEnumeration

4

R/W

Selects an image format.

Register

Field

Address

Length

Byte / [bit]

Access

Description

ImageFormatSelector

Implemented

0x202020

[31]

R

Returns the state whether the function is implemented.

ListOfElements

0x20202C

16

R

[0] : Format0

[1] : Format1

[2] : Format2

Value

0x20203C

4

R/W

Selects an image format.

ImageFormat 0 - 2

Width

Height

OffsetX

OffsetY

BinningHorizontal

BinningVertical

DecimationHorizontal

DecimationVertical

ReverseX

ReverseY

PixelFormat

PixelEndian

● IIDC2 Register

List of registers to be applied by ImageFormatSelector

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

39 / 179

Page 41

D4267042B

API name

Description

GetCamImageFormatSelector

Get current ImageFormatSelector value

SetCamImageFormatSelector

Set new ImageFormatSelector value

Integer

String

0(*)

Format0

1

Format1

2

Format2

// GenICam node handle

CAM_NODE_HANDLE hSelector = NULL;

// Retrieve GenICam node.

Nd_GetNode(s_hCam, "ImageFormatSelector", &hSelector);

// ImageFormat = Format2

Nd_SetEnumStrValue(s_hCam, hSelector, "Format2");

● Control with TeliCamSDK

Camera feature API

Control ImageFormat using dedicated API.

Please refer to [Controlling camera feature functions] in [TeliCamAPI Library manual] for more detail.

GenICam function API

Control ImageFormat using GenICam API.

ImageFormat

Select an image format by ‘ImageFormatSelector’.

Integer value and string value of Enumeration are as follows.

* initial factory setting

Please refer to [INode functions], [IEnumeration node functions] in [TeliCamAPI Library manual] for

more detail.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

40 / 179

Page 42

D4267042B

API name

Description

Cam_ReadReg

Read register value

Cam_WriteReg

Write register value

// ImageFormat = Format2

uint32_t uiSelector;

uiSelector = 2;

Cam_WriteReg(s_hCam, 0x20203C, 1, &uiSelector);

Register access API

Control Gain by accessing IIDC2 registers directly.

ImageFormat

Write to ‘Value’ field of ‘ImageFormatSelector’ register.

Please refer to [Camera functions] in [TeliCamAPI Library manual] for more detail.

● Note

Changing ‘ImageFormatSelector’ register value is invalid during image stream data output.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

41 / 179

Page 43

D4267042B

⇒

( X , Y )=( 4 * i , 2 * j )

A + 4 * m

B + 2 * n

Scalable

Scalable function reads out the region of interest (ROI) of the sensor.

If height size is set small, it is possible to increase the frame rate.

Only single rectangle is selectable. Concave or convex shape is not selectable.

- Window size: {A + 4 × m (H)} × {B + 2 × n (V)}

A, B = minimum unit size

m, n = integer

The window size is equal or less than maximum image size.

- Start address: {4 x i (H)} x {2 x j (V)}

i, j = integer

The window size is equal or less than maximum image size.

Scalable

42 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 44

D4267042B

Name

Interface

Length

Byte / [bit]

Access

Description

Width

IInteger

4

R/W

Sets width (in pixels) of the image data.

Height

IInteger

4

R/W

Sets Height (in pixels) of the image data.

OffsetX

IInteger

4

R/W

Sets horizontal offset (in pixels) from the origin to the region of interest.

OffsetY

IInteger

4

R/W

Sets vertical offset (in pixels) from the origin to the region of interest.

Register

Field

Address

Length

Byte / [bit]

Access

Description

ImageSize

Implemented

0x202060

[31]

R

Returns the state whether the function is implemented.

OffsetXMin

0x20206C

4

R

Returns the minimum starting position of the horizontal direction

OffsetXInc

0x202070

4

R

Returns the unit starting position of the horizontal direction

WidthMin

0x202074

4

R

Returns the minimum size of width

WidthInc

0x202078

4

R

Returns the unit size of width

SensorWidth

0x20207C

4

R

Returns effective width of the sensor in pixels

OffsetYMin

0x202080

4

R

Returns the minimum starting position of the vertical direction

OffsetYInc

0x202084

4

R

Returns the unit starting position of the vertical direction

HeightMin

0x202088

4

R

Returns the minimum size of height

HeightInc

0x20208C

4

R

Returns the unit size of height.

SensorHeight

0x202090

4

R

Returns effective Height of the sensor in pixels

OffsetX

0x202094

4

RW

Sets horizontal offset (in pixels) from the origin to the region of interest

Width

0x202098

4

RW

Sets width (in pixels) of the image data.

OffsetY

0x20209C

4

RW

Sets vertical offset (in pixels) from the origin to the region of interest

Height

0x2020A0

4

RW

Sets Height (in pixels) of the image data.

● GenICam Node

● IIDC2 Register

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

43 / 179

Page 45

D4267042B

API name

Description

GetCamSensorWidth

Get effective width of the sensor in pixels

GetCamSensorHeight

Get effective height of the sensor in pixels

GetCamRoi

Get ROI (Region of Interest) of the camera

SetCamRoi

Set ROI (Region of Interest) to the camera

GetCamWidthMinMax

Get minimum and maximum value

GetCamWidth

Get width of image

SetCamWidth

Set width of image

GetCamHeightMinMax

Get minimum and maximum value

GetCamHeight

Get height of image

SetCamHeight

Set height of image

GetCamOffsetXMinMax

Get minimum and maximum value

GetCamOffsetX

Get horizontal offset of image

SetCamOffsetX

Set horizontal offset of image

GetCamOffsetYMinMax

Get minimum and maximum value

GetCamOffsetY

Get vertical offset of image

SetCamOffsetY

Set vertical offset of image

● Control with TeliCamSDK

Camera feature API

Control Scalable using dedicated API.

Please refer to [Controlling camera feature functions] in [TeliCamAPI Library manual] for more detail.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

44 / 179

Page 46

D4267042B

// GenICam node handle

CAM_NODE_HANDLE hWidth = NULL;

CAM_NODE_HANDLE hHeight = NULL;

CAM_NODE_HANDLE hOffsetX = NULL;

CAM_NODE_HANDLE hOffsetY = NULL;

// ROI = {OffsetX, Width, OffsetY, Height};

uint64_t ROI[] = {612,1224, 512,1024};

// Retrieve GenICam node.

Nd_GetNode(s_hCam, “Width”, &hWidth);

Nd_GetNode(s_hCam, “Height”, &hHeight);

Nd_GetNode(s_hCam, “OffsetX”, &hOffsetX);

Nd_GetNode(s_hCam, “OffsetY”, &hOffsetY);

// Set ROI

Nd_SetIntValue(s_hCam, hWidth, ROI[1]);

Nd_SetIntValue(s_hCam, hOffsetX, ROI[0]);

Nd_SetIntValue(s_hCam, hHeight, ROI[3]);

Nd_SetIntValue(s_hCam, hOffsetY, ROI[2]);

API name

Description

Cam_ReadReg

Read register value

Cam_WriteReg

Write register value

// ROI = {OffsetX, Width, OffsetY, Height};

uint32_t ROI[] = {612,1224, 512,1024};

// Set ROI (in one by one)

Cam_WriteReg(s_hCam, 0x202094, 1, &ROI[0]);

Cam_WriteReg(s_hCam, 0x202098, 1, &ROI[1]);

Cam_WriteReg(s_hCam, 0x20209C, 1, &ROI[2]);

Cam_WriteReg(s_hCam, 0x2020A0, 1, &ROI[3]);

// Set ROI (in block)

Cam_WriteReg(s_hCam, 0x202094, 4, &ROI[0]);

GenICam function API

Control Scalable using GenICam API.

Scalable

If you’re going to reduce width size, set Width, first. Then set OffsetX.

If you’re going to increase width size, set OffsetX, first. Then set Width.

If you’re going to reduce height size, set Height, first. Then set OffsetY.

If you’re going to increase height size, set OffsetY, first. Then set Height.

Please refer to [INode functions] and [IInteger node functions] in [TeliCamAPI Library manual] for more

detail.

Register access API

Control Scalable by accessing IIDC2 registers directly.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Scalable

Write to ‘Value’ field of ‘OffsetX’, ’Width’, ‘OffsetY’, ‘Height’ register.

45 / 179

Page 47

D4267042B

In IIDC2 registers access,

Model

DU1207MG/MCG/MCF

Width/OffsetX unit size

4

Height/OffsetY unit size

2

Minimum unit size

64 x 64

Maximum unit size(*)

4096 x 3000

you can set OffsetX, Width, OffsetY, Height in any order. (in one by one access)

you can also set OffsetX, Width, OffsetY, Height with single access. (in block access)

Please refer to [Camera functions] in [TeliCamAPI Library manual] for more detail.

Minimum/Maximum Value

● Note

* initial factory setting

Changing “Width”, “Height”, “OffsetX”, “OffsetY” register value is invalid during image stream data output.

46 / 179

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

Page 48

D4267042B

2048

2448

1224

All pixel readout

Binning

1024

4096

3000

2048

1500

Binning operation (e.g. Binning 2x2)

Binning

In the binning mode, a pixel is added with the neighboring pixel(s).

This increases the sensitivity of the image. It’s alike scalable, the frame rate can be faster and USB bandwidth

occupation decrease.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

47 / 179

Page 49

D4267042B

● Framerate in each output format (fps)

Mono8

H

Mono10

/Mono12

H

1 2 4 1 2 4 V 1

32

62

62

V 1

16

32

42 2 64

121

121 2

32

64

83 4 121

121

121 4

64

83

83

Bayer8

/Mono

H

Bayer10

/Bayer12

H

1 2 4 1 2 4 V 1

31

31

31

V 1

16

28

28 2 31

31

31 2

28

28

28 4 31

31

31 4

28

28

28

YUV411

H

YUV422

H

1 2 4 1 2 4 V 1

21

28

28

V 1

16

28

28 2 28

28

28 2

28

28

28 4 28

28

28 4

28

28

28

RGB

/BGR

H

1 2 4 V 1

10

21

28 2 21

28

28 4 28

28

28

Binning

DU1207MG

DU1207MCG

/ DU1207MCF

Vertical

Horizontal

Analog stage

Digital stage

Analog stage

Digital stage

1 2 - ✓ - ✓ 1 4 - ✓ - ✓ 2 1 ✓ - - ✓ 2 2 ✓ - - ✓ 2 4 ✓ ✓ - ✓ 4 1 ✓ ✓ -

✓

4 2 ✓ ✓ - ✓ 4 4 ✓ ✓ -

✓

- DU1207MG

- DU1207MCG/CF

Combination of Binning operation

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

48 / 179

Page 50

D4267042B

Name

Interface

Length

Byte / [bit]

Access

Description

BinningHorizontal

IInteger

4

R/W

Sets the Binning Horizontal.

BinningVertical

IInteger

4

R/W

Sets the Binning Vertical.

Register

Field

Address

Length

Byte / [bit]

Access

Description

BinningHorizontal

Implemented

0x202120

[31]

R

Returns the state whether the function is implemented.

Min

0x202134

4

R

Returns the minimum value of BinningHorizontal Value register.

Max

0x202138

4

R

Returns the maximum value of BinningHorizontal Value register.

Value

0x20213C

4

R/W

Sets the Binning Horizontal.

BinningVertical

Implemented

0x202140

[31]

R

Returns the state whether the function is implemented.

Min

0x202154

4

R

Returns the minimum value of BinningVertical Value register.

Max

0x202158

4

R

Returns the maximum value of BinningVertical Value register.

Value

0x20215C

4

R/W

Sets the Binning Vertical.

● GenICam Node

● IIDC2 Register

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

49 / 179

Page 51

D4267042B

API name

Description

GetCamBinningHorizontalMinMax

Get minimum and maximum value

GetCamBinningHorizontal

Get current BinningHorizontal value

SetCamBinningHorizontal

Set new BinningHorizontal value

GetCamBinningVerticalMinMax

Get minimum and maximum value

GetCamBinningVertical

Get current BinningVertical value

SetCamBinningVertical

Set new BinningVertical value

// GenICam node handle

CAM_NODE_HANDLE hBinning = NULL;

// Binning = 2x2

uint64_t Binning = 2;

// Retrieve GenICam node.

Nd_GetNode(s_hCam, “BinningHorizontal”, &hBinning);

// Nd_GetNode(s_hCam, “BinningVertical”, &hBinning); // either will do

// Set Binning

Nd_SetIntValue(s_hCam, hBinning, Binning);

● Control with TeliCamSDK

Camera feature API

Control Binning using dedicated API.

Please refer to [Controlling camera feature functions] in [TeliCamAPI Library manual] for more detail.

GenICam function API

Control Binning using GenICam API.

Binning

Please refer to [INode functions], [IInteger node functions] in [TeliCamAPI Library manual] for more

detail.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

50 / 179

Page 52

D4267042B

API name

Description

Cam_ReadReg

Read register value

Cam_WriteReg

Write register value

// Binning = 2x2

uint32_t Binning = 2;

// Set Binning

Cam_WriteReg(s_hCam, 0x20213C, 1, &Binning);

// Cam_WriteReg(s_hCam, 0x20215C, 1, &Binning); // either will do

Register access API

Control Binning by accessing IIDC2 registers directly.

Binning

Write to ‘Value’ field of ‘BinningHorizontal’ register to control BinningHorizontal.

Or write to ‘Value’ field of ‘BinningVertical’ register to control BinningVertical.

Please refer to [Camera functions] in [TeliCamAPI Library manual] for more detail.

● Note

Binning is disabled when the camera is running in Decimation mode.

Scalable is enabled when the camera is running in Binning mode.

Changing “BinningHorizontal”, “BinningVertical” register value is invalid during image stream data output.

Binning Horizontal / Vertical = 3 is not available.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

51 / 179

Page 53

D4267042B

2048

2448

All pixel readout

Decimation

1024

1224

4096

3000

2048

1500

4096

3000

2048

1500

Decimation operation (e.g. Decimation 2x2)

Decimation

Decimation feature reads out all effective areas at high speed by skipping pixels and lines.

Decimation feature can make frame rate faster, and decrease interface bandwidth occupation.

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

52 / 179

Page 54

D4267042B

● FrameRate in each output format (fps)

Mono8

H

Mono10

/Mono12

H

1 2 4 1 2 4 V 1

32

62

62

V 1

16

32

42 2 62

121

121 2

32

64

83 4 62

121

121 4

42

83

83

Bayer8

/Mono

H

Bayer10

/Bayer12

H

1 2 4 1 2 4 V 1

31

31

31

V 1

16

28

28 2 31

121

121 2

28

64

83 4 31

121

121 4

28

83

83

YUV411

H

YUV422

H

1 2 4 1 2 4 V 1

21

28

28

V 1

16

28

28 2 28

83

83 2

28

64

83 4 28

83

83 4

28

83

83

RGB

/BGR

H

1 2 4 V 1

10

21

28 2 21

43

83 4 28

83

83

Binning

DU1207MG

DU1207MCG

/ DU1207MCF

Vertical

Horizontal

Analog stage

Digital stage

Analog stage

Digital stage

1 2 - ✓ - ✓ 1 4 - ✓ - ✓ 2 1 - ✓ - ✓ 2 2 ✓ - ✓ - 2 4 ✓ ✓ ✓ ✓ 4 1 - ✓ -

✓

4 2 ✓ ✓ ✓ ✓ 4 4 ✓ ✓ ✓

✓

- DU1207MG

- DU1207MCG/CF

Combination of Decimation operation

Copyright © 2017 TOSHIBA TELI CORPORATION, All rights reserved. http://www.toshiba-teli.co.jp/en/

53 / 179

Page 55

D4267042B

Name

Interface

Length

Byte / [bit]

Access

Description

DecimationHorizontal

IInteger

4

R/W

Sets the Decimation Horizontal.

DecimationVertical

IInteger

4

R/W

Sets the Decimation Vertical.

Register

Field

Address

Length

Byte / [bit]

Access

Description

DecimationHorizontal

Implemented

0x202160

[31]

R

Returns the state whether the function is implemented.

Min

0x202174

4

R

Returns the minimum value of DecimationHorizontal Value register.

Max

0x202178

4

R