Page 1

Ver.1.02

High Resolution CMOS camera

CSB1100F

Operation Manual

BEFORE USE – GENERAL SAFETY INSTRUCTIONS

This instruction manual contains important information for the operator (user) and/or people in the

vicinity to avoid personal injury, or property damage.

Prior to use, read this operation manual carefully to fully understand its instructions for correct use.

After reading, keep this manual near the equipment for future reference.

The meaning of each mark used in this instruction manual is given below.

[Definition of markings]

WARNING

This mark warns the user that improper use may cause death or

severe personal injury (*1) of the user or people in the vicinity.

CAUTION

This mark warns the user that improper use may cause personal

injuries (*2) or material damages (*3) against the user or people in

the vicinity.

*1: Severe personal injury means wounds, blin dness, physical injury, burns(low temperature・

high temperature), electric shocks, fracture, addictive and others for which have aftereffects

and hospitalization or long term care are required

.

*2: Personal injury means wounds, burns, electric shocks, and others for which hospitalization

or long term care are not required.

*3: Material damage means any consequential damage related to premise, possession,

domestic animals and pet.

[Definition of markings]

This mark indicates what the user SHOULD NOT DO. The details are given adjacent

the mark.

This mark indicates what the user MUST DO. The detail are given adjacent the mark.

●Handling Precautions

WARNING

Unplug

Immediately cease of the equipment i n the event of abnormality or

malfunction.

If abnormal conditions are present, such as smoke, a burning smell, ingress

of water or foreign matter, or if the equipment is dropped or malfunctions, fire

or electric shock may result.

If such abnormalities occur, disconnect the power pl ug from the outlet and

contact your sales representative.

Do not get wet

Do not use the equipment in locations subject to water splashes.

Otherwise, fire or electric shock may result.

Never pull

apart

Do not disassemble, repair, or modify the equipment.

Otherwise, fire or electric shock may result.

For internal repair, inspection, or cleaning, contact your sales representative.

Avoid

Do not place anything on the equipment.

If metallic objects, liquid, or other foreign matter enters the equipment, fire or

electric shock may result.

Avoid

Do not install the equipment i n an unstable or inclined location or l ocations

subject to vibration or impact.

Otherwise, the equipment may topple over and cause personal injury.

Do not touch

During an electrical stor m, do not touch the power cord or connection

cable.

Otherwise, an electric shock may result.

Instruction

Use the specified power supply.

Use of an unspecified power supply may result in fire or electric shock.

Avoid

Do not be handled roughly, damaged, fabricated, bent forcefully, pulled,

twisted, bundled, places under heavy objects or heated the power cord,

connection cable.

Otherwise, fire or electric shock may result.

CAUTION

Instruction

Observe the following when installing the equipment.

• Do not cover the equipment with a cloth, etc.

• Do not place the equipment in a narrow location where heat is likely to

accumulate. Otherwise, h eat will accumulate i nside the equipment, possibly

resulting in a fire.

Avoid

Do not place the equipment in locations subject to high moisture, oil fumes,

stream, or dust.

Otherwise, fire or electric shock may result.

Avoid

Do not install the equipment in locations exposed to direct sunlight or

humidity.

Otherwise, the internal temperature of the equipment will rise, which may

cause a fire.

Avoid

Use only specified DC power cables and connection cables.

Otherwise, fire or electric shock may result.

Avoid

When performing connection, turn off power.

When connecting the power cable or connection cable, turn off the

equipment power. Otherwise, fire or electric shock may result.

Avoid

Do not expose its camera head to any intensive light (such as direct

sunlight).

Otherwise, its inner image pickup devise might get damaged.

Avoid

Avoid short-circuiting signal output.

Otherwise, a malfunction may occur.

Avoid

Avoid giving a strong shock against the camera body.

If your camera is used in a system where its camera connector is subjected

to strong repetitive shocks, its camera connector is po ssible to break down.

If you intend to use your camera in such a situation, if possible, bundle and

fix a camera cable in the place near the camera, and do not transmit a shock

to the camera connector.

Instruction

Contact your sales representative to request periodic inspection and

cleaning (every approx. five years).

Accumulation of dust inside the equipment may result in fire or electric

shock.

For inspection and cleaning costs, contact your sales representative.

CASE FOR INDEMNITY(LIMITED WARRANTY)

We shall be exempted from taking responsibility and held harmless for damage or losses incurred

by the user in the following cases.

In the case damage or losses are caused by fire, earthquake, or other acts of G od, acts by a

third party, deliberate or accidental misuse by the user, or use under extreme operating

conditions.

In the case of indirect, additional, consequential damages ( loss of business interests,

suspension of business activities) are incurred as result of malfunction or non-function of the

equipment, we shall be exempted from responsibility for such damages.

In the ca se damage or losses are caused by failure to observe the i nformation contained in the

instructions in this instruction manual and specifications.

In the case damage or losses are caused by use contrary to the instructions in thi s instruction

manual and specifications.

In the case damage or losses are caused by malfunction or other problems resulting from use

of equipment or software that is not specified.

In the case damage or losses are caused by repair or modification conducted by the customer

or any unauthorized third party(such as an unauthorized service representative).

Expenses we bear on this product shall be limited to the individual price of the product.

About the item which does not have a publication in the specifications and manual of this

product, it considers as the outside for a guarantee.

RESTRICTION FOR USE

Should the equipment be used in the following conditi ons or environments, give consideration

to safety measures and inform us of such usage:

1. Use of the equipment in the conditions or environment contrary to those specified, or use

outdoors.

2. Use of the equipment in applications expected to cause potential hazard to people or

property, which require special safety measures to be adopted.

This product can be used under diverse operating conditions. Determination of applicability of

equipment or devices concerned shall be determined after analysis or testing as necessary by

the de signer of such equipment or devices, or personal related to the specifications. Such

designer or personal shall assure the performance and safety of the equipment or devices.

This product is not designed or manufactured to be used for control of equipment directly

concerned with human life(*1) or equipment relating to maintenance of public

services/functions involving factors of safety(*2). Therefore, the product shall not be used for

such applications.

(*1): Equipment directly concerned with human life refers to:

• Medical equipment such as life-support systems, equipment for operating theaters.

• Exhaust control equipment for exhaust gases such as toxic fumes or smoke.

• Equipment mandatory to be installed b y various laws and regulations such as the Fire Act

or Building Standard Law.

• Equipment related to the above.

(*2): Equipment relating to maintenance of public services/functions involving factors of safety

refer to:

• Traffic control systems for air transportation, railways, roads, or marine transportation.

• Equipment for nuclear power generation.

• Equipment related to the above.

Usage Precautions

Handle carefully

Do not drop the equipment or allow it to be subject to strong impact or vibration, as such action

may cause malfunctions. Further, do not damage the connection cable, since this may cause

wire breakage.

Environmental operating conditions

Do not use the product i n l ocations where the ambient temperature or humidity exceeds

specifications. Otherwise, i mage quality may be degraded or internal components may be

adversely affected. In particular, do not use the product i n areas exposed to direct sunlight.

More over, during shooting under high temperatures, vertical stripes or white spots (noi se) may

be produced, depending on the subject or camera conditions ( such as increased gain).

However, such phenomena are not malfunctions.

Do not shoot under intense light

Avoid intense light such as spotlights on part of the screen because it may cause blooming or

smears. If intense light falls on the screen, vertical stripes may appear on the screen, but this is

not a malfunction.

Occurrence of moiré

If you shoot thin stripe patterns, moiré patterns (interference fringes) may appear. This is not

malfunction.

Occurrence of noise on the screen

If an intense magnetic or electromagnetic field is generated near the camera or co nnection

cable, noise may be generated on the screen. If this occurs, move the camera or the cable.

Handling of the protective cap

If the camera is not in use, attach the lens cap to the camera to protect the image pickup

surface.

If the equipment is not to be used for a long duration

Turn off power to the camera for safety.

Maintenance

Turn off power to the equipment and wipe it with a dry cloth.

If it becomes severely contaminated, gently wipe the affected areas with a soft cloth dampened

with diluted neutral detergent. Never use alcohol, benzene, thinner, or other chemicals because

such chemicals may damage or discolor the paint and indications.

If the image pickup surface becomes dusty, contaminated, or scratched, consult your sales

representative.

Disposal

When disposing of the camera, it may be necessary to disassemble it int o separate parts, in

accordance with the laws and regulations of your country and/or municipality concerning

environmental contamination.

CMOS sensor characteristics

• Defective pixels

A CMOS image sensor is composed of photo sensor pixels in a square grid array. Due to the

characteristics of CMOS image sensors, over- or under-driving of the pixels results in temporary

white or black areas (as if these are noises) appearing on the screen. This phenomenon, which is

not a defect is exacerbated under higher temperatures and long exposure times.

• Image shading

Under global shutter operation, the brightness of the upper part of the screen may differ from the

lower part. And, the brightness of the left part on the screen may differ from the right part.

However, this does not mean the CMOS image sensor is defective.

This phenomenon occurs under short exposure times and high illumination.

To counteract this phenomenon, reduce the illumination by se tting a longer exposure time, or

adjust the lens aperture.

It may be blurred by this phenomenon when fast-moving subject captured.

1. Product Description

Model CSB1100F is a high-resolution B/W CMOS camera achieving high-speed image processing

by a random access.

2. Features

(1) Ultra-high resolution

The CSB1100F features a high-pixel CMOS sensor (Total pixel count: 1.30 Mega pixels),

enabling high-density images (i.e., significantly reduced moiré and beat) to be obtained.

(2) Global shutter mode

This model features a Global shutter mode, which means that clear images of a fa st-moving

subject with little blurring are obtained.

(3) Random trigger shutter mode

This feature starts light-exposure in synchronization with external trigger signal, and enables

image capture at any given timing.

(4) W OI(Window Of Interest)

WOI is a feature enabling high-speed image processing.

By designating horizontal and vertical addresses, user-defined areas only are read out.

(5) High-dynamic range

This model features a high-dynamic range with multi slope integration mode, both high-and

low-intensity subjects can be captured at the same time despite the high difference in contrast.

3. Configuration

(1) Camera body ------------------------ 1

(2) Operation Manual ------------------- 1

4. Optional parts

(1) IEEE1394 cable (Recommended harness HSB-HCC-***)

(2) Camera mounting kit (Model name: CPT1100CL)

(3) TFL lens mount adapter (Model name: TCAR)

*NOTE: Application software is not supplied as a standard item.

5. Designation and Operation of each Part

(1) IEEE1394 Connector Digital data IN/OUT terminal

The VIDEO signal and the command are sent and received.

This connects to IEEE1394 interface board.

.

(2) Trigger connector

It is an input terminal of the trigger pulse.

6. Mounting the camera

There are various methods of fixing the camera. Choose from among the following options.

(1) Option 1: Using a camera tripod fixing kit.

Use an optional tripod fixing kit (1/4-20UNC) to fix the camera onto the tripod. Use attached

screws to affix tripod-mounting hardware to your camera. (See the figure below)

(2) Option 2: Using the mounting holes

If not using the tripod fixing kit, make sure that the M3 screws do not penetrate more th an 6 mm

into the camera body.

7. Connection

(1) IEEE1394

Connector (Camera side): 67430-001 (Manufactured by MOLEX)

Plug (Cable side): HSB-HCC-*** (Manufactured by DDK)

PIN No.

Signal name I/O

1 POWER I

2 POWER(GND) I

3 TPB- I/O

4 TPB+ I/O

5 TPA- I/O

6 TPA+ I/O

(2) DATA IN/OUT

Connector (Camera side): 10226-2210VE (Manufactured by 3M)

Connector (Cable side): 10126-6000 (Manufactured by 3M)

PIN No.

Signal name I/O Notes

1 TRIG I

2 TRIG(GND) I

3 N.C. - Be sure use in open

4 S.G. I

8. Function

(1) Electronic shutter

The shutter-speed of CSB1100F is also manually adjustable. By manipulating t he internal register

setting value of CSB1100F, you can change the shutter-speed by user-defines setting value of 62.5

micro sec step.

*The longer a user sets the exposure time, the more defective pixels on the image is outstanding.

When you attach importance to image quality, it is recommendable to set the shutter speed at

30 msec or less.

(2) Random trigger shutter

Under the RTS mode, the camera can capture image at any user-defined timing with external

trigger signal. Under FIX mode, shutter speed can be set with the internal resister setting value.

Under pulse mode, shutter speed can be set with the trigger pulse width.

You can change the polarity of trigger pulse with the internal resister setting value.

(3) Multi slope function

By changing a slope position with internal resi ster setting value, you can set the sensitivity

matching to the subject luminance.

Refer to the interface specifications for the detail of the setting method separately.

(4) WOI (Window Of Interest)

Only user-defined area can be captured by designating of the horizontal and the vertical address.

Up to 16 areas can be set in 1 screen.

This function can increase a frame rate because the area other than designated is not captured.

The minimum area size is 50 dot(H) x 50 dot(V).

Horizontal address can set up only even number.

• The placement is available up to 16 windows in all active pixel area.

• The setting of readout address is available up to 8 types.

Thank you for purchasing our CSB1100F CMOS camera.

This operation manual includes some important information such as how to use this

equipment correctly and safely. Please read through this manual carefully. After reading, keep

this manual by the side of your equipment for your future reference.

Printed On Recycled Paper.

1

2

3

4

5

6

7

8

9

1011

12

13

14

15 16

5

1

2

3

4

6

7

8

Page 2

Ver.1.02

Practical operation example

9. Specification

[[[[Electronic Specification]]]]

(1) Image sensor CMOS image sensor

• Total pixel 1280(H) x 1024(V)

• Active pixel 1240 (H) x 1024(V)

• Pixel size 6.7(H) x 6.7(V) micro m

• Image area 8.30 8mm(H) x 6.854mm(V)

• Driving frequency 39.3216 MHz

(2) Scanning line 1024 lines

(3) Scanning system Progressive

(4) Frame rate 16 fps(Exposure time: 62.5 micro sec)

(5) Sync system Internal

(6) Aspect ratio 5 : 4

(7) Subject illumination 2600lx,F5.6(3100K)(Exposure time: Approx 16 msec)

(8) Video output time Approx. 62.2 msec

(9) Interface Conforms to IEEE Std. 1394a-2000

Transfer speed 400Mbps

(10) Video mode Format7/Special format (in WOI) Mono 8bit

(11) Protocol Conforms to 1394-based Digital Camera Specification ver.1.3

(12) Input signal TRIG (Shutter Trigger) 3.3V CMOS level

Grabbing timing Falling edge detection

Pulse width Minimum : 5 micro sec

Max : no limit

(13) Electronic shutter Shutter speed (preset inside the camera) selection via communication

command 1 through 4000 (approx. 62.5 micro sec through 1 sec)

(14) Shutter mode Global shutter

(15) Random Trigger RTS operation is available by external trigger input. Shutter speed

Shutter preset or shutter speed control by pulse width is available.

Mode 0 Shutter speed preset mode (preset inside camera)

Mode 1 Shutter speed can be controlled via shutter trigger pulse width.

The camera starts light-exposure at the falling edge timing and ends it at

the rising edge timing.

(16) Power supply DC+8V through DC+30V (IEEE1394 cable power supply)

(17) Power condition Approx. 1.5W (at +30V)

Approx. 1.4W (at +12V)

Approx. 1.4W (at +8V)

[[[[Mechanical Specification]]]]

(1) External dimension 44(W)×29(H)×52(D) mm(Without projection)

(2) Weight Approx. 120 g

(3) Lens mount C-mount

(4) Flange back 17.526 mm

(5) Chassis grounding Between Connector shell and FG Continuity provided

/insulation Between FG and SG Continuity not provided

[[[[Use environmental conditions]]]]

(1) Ambient condition

Temperature:

Performance guaranteed From 0 through 40 degrees Celsius

Operation guaranteed From –5 through 45 degrees Celsius

Preservation From –20 through 60 degrees Celsius

Humidity:

Performance guaranteed From 20 through 80 % (No condensing)

Operation guaranteed From 20 through 80 % (No condensing)

Preservation From 20 through 95 % (No condensing)

[[[[Interface specification]]]]

Please contact our sales person about interface specification.

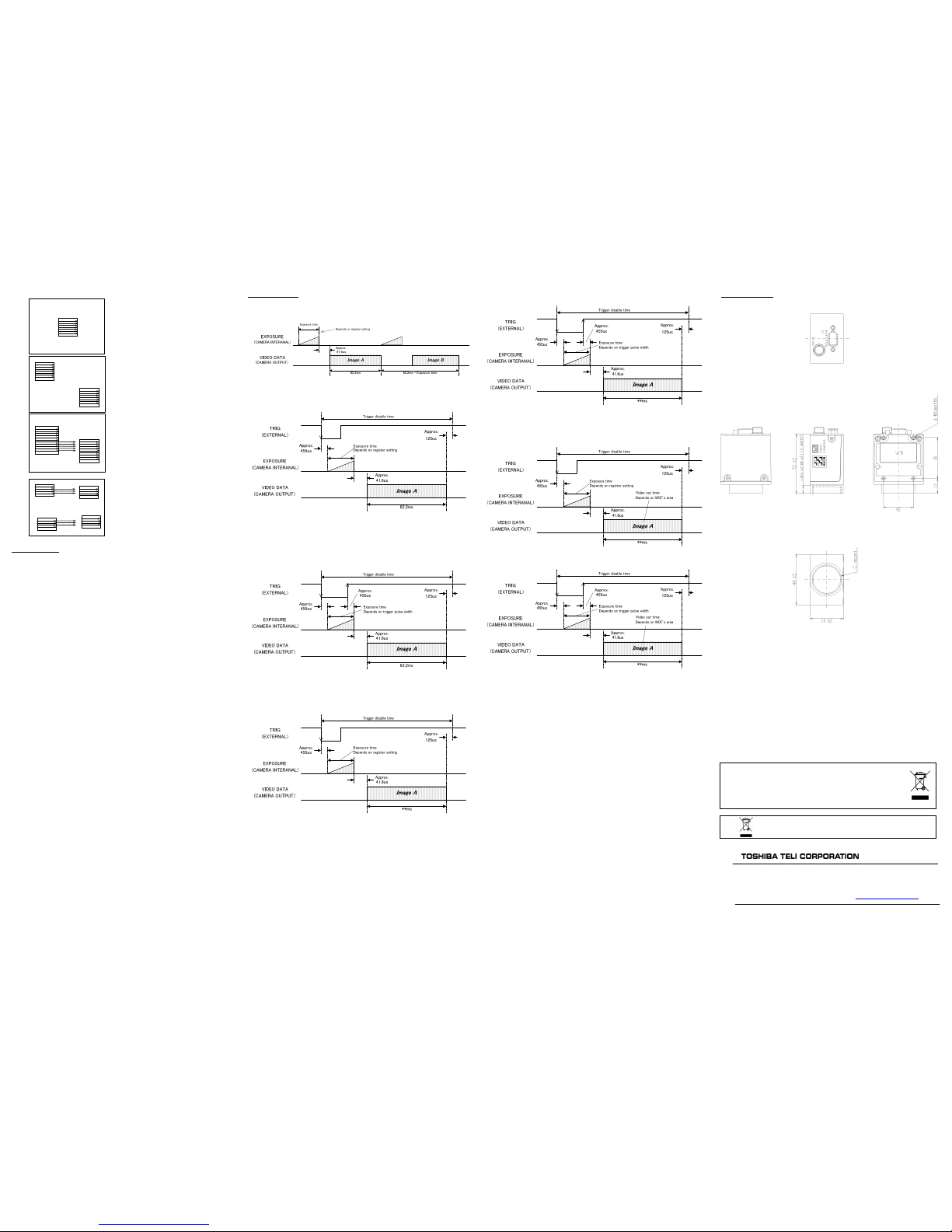

10. Timing Chart

(1) Normal shutter mode (Format 7 mode 0)

(2) Random Trigger Shutter mode (Fix mode, Format 7 mode 0)

Shutter speed depends on the internal resister setting value.

After trigger IN, next trigger signal is not acceptable until the readout is completed.

(3) Random Trigger Shutter (Pulse width control, Format 7 mode 0)

Shutter speed depends on the trigger pulse width.

After trigger IN, next trigger signal is acceptable until the readout is completed.

(4) Scalable (Fix mode, Format 7 mode 1)

(5) Scalable (Pulse width control, Format 7 mode 1)

(6) WOI mode (Fix mode, Format X)

(7) WOI mode (Pulse width control, Format X)

11. External View

Following information is only for EU-member states:

The use of the symbol indicates that this product may not be treated as household

waste. By ensuring this product is disposed of correctly, you will help prevent

potential negative consequences for the environment and human health, which

could otherwise be caused by inappropriate waste handling of this product.

For more detailed information about the take-back and recycling of this product,

please contact your supplier where you purchased the product.

”This symbol is applicable for EU member states only”

Head Office:

Head Office:Head Office:

Head Office: 7-1, 4 chome, Asahigaoka, Hino-shi, Tokyo, 191-0065, Japan

(Overseas Sales Department)

Phone: +81-42-589-8771 Fax: +81-42-589-8774

URL: http://www.toshiba-teli.co.jp

A-block

(1)

(2)

(4)

(6)

(X1,Y1)

(X2,Y2)

B-block

(3)

(5)

(7)

(8)

(X3,Y3)

(X4,Y4)

C-block

(10)

(12)

(14)

(16)

(X5,Y5)

(X6,Y6)

D-block

(9)

(11)

(13)

(15)

(X7,Y7)

(X8,Y8)

In the case of four readout areas

The designated areas are read out in order of

address from start (X1, Y1) to the end (X8, Y8).

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(X1,Y1)

(X2,Y2)

In the case of only one readout area

A readout area can be designated by t he start

address (X1, Y1) and the end address (X2, Y2).

The camera can read out the user-defined area

through this function.

The each address is designated by the start

address and lengths (pixel numbers) of “X” and

“Y” directions.

A-block

B-block

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(X1,Y1)

(X2,Y2)

(X3,Y3)

(X4,Y4)

In the case of more than two readout areas

The area designated by the start address (X1, Y1)

and the end address (X2, Y2) is read out fi rst

(A-block in the left figure).

After reading out of A-block, the next area

designated by (X3, Y3) and (X4, Y4) is read ou t

(B-block in the left figure)

A-block

B-block

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(9)

(11)

(13)

(15)

(8)

(10)

(12)

(14)

(16)

(17)

(18)

(19)

(20)

(X1,Y1)

(X2,Y2)

(X3,Y3)

(X4,Y4)

In the case of more than two readout areas and

including the same readout lines with each other

The designated areas are read out in order of

address from the start (X1, Y1) to the end (X4,

Y4).

Loading...

Loading...